Heat-resistant and solvent-resistant PC/PET modified resin

A modified resin and solvent-resistant technology, which is applied in the field of polyurethane composition manufacturing to achieve the effects of low production cost, good tensile properties, and excellent heat and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

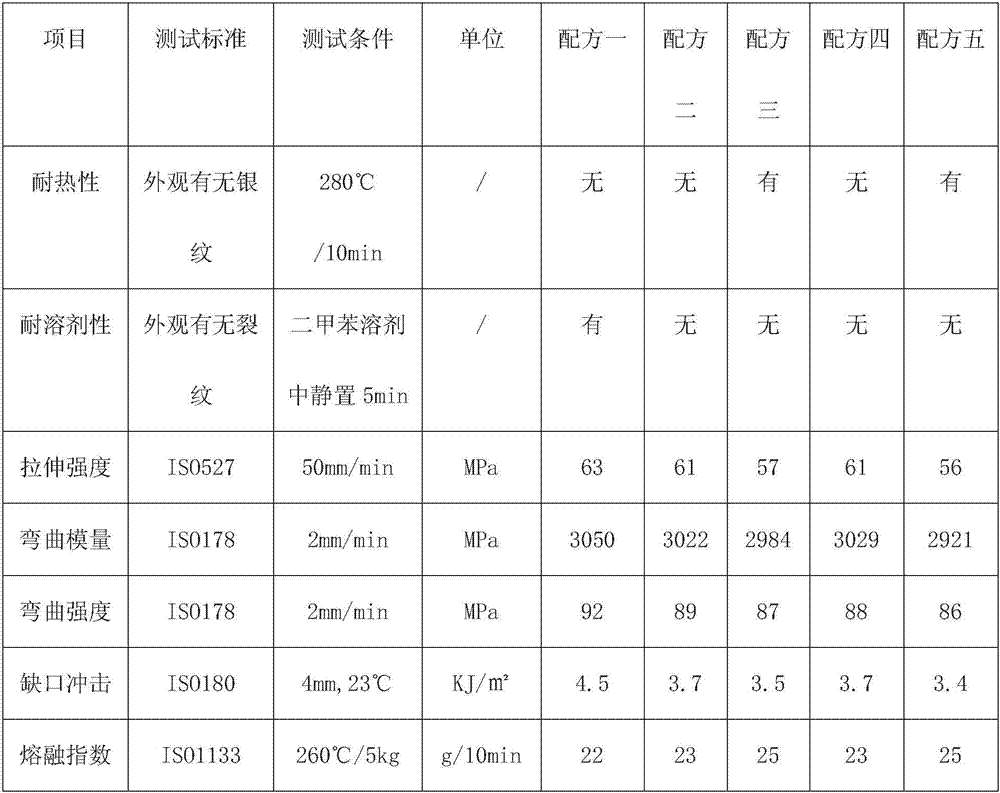

Examples

specific Embodiment approach

[0023] Step 1, by weight, add 50-80 parts of PC, 10-40 parts of PET, 3-10 parts of minerals, 1-3 parts of compatibilizer, and 0.2-1 part of antioxidant into the extruder to form homogeneous mixture;

[0024] Step 2: Adjust the temperature of the extruder to 240-270°C, transform the mixture obtained in Step 1 into a molten state, knead and extrude the mixture, and perform granulation to obtain the heat-resistant and solvent-resistant PC / PET modified resin .

Embodiment approach 1

[0026] Add PC, PET, minerals, compatibilizers, and antioxidants to the mixer to disperse evenly, then add the mixture to the extruder, adjust the temperature of the extruder to 240-270°C, and convert the mixture into a molten state. The mixture is kneaded and extruded, and granulated to obtain a heat-resistant and solvent-resistant PC / PET modified resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com