Patents

Literature

88 results about "Exfoliation corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

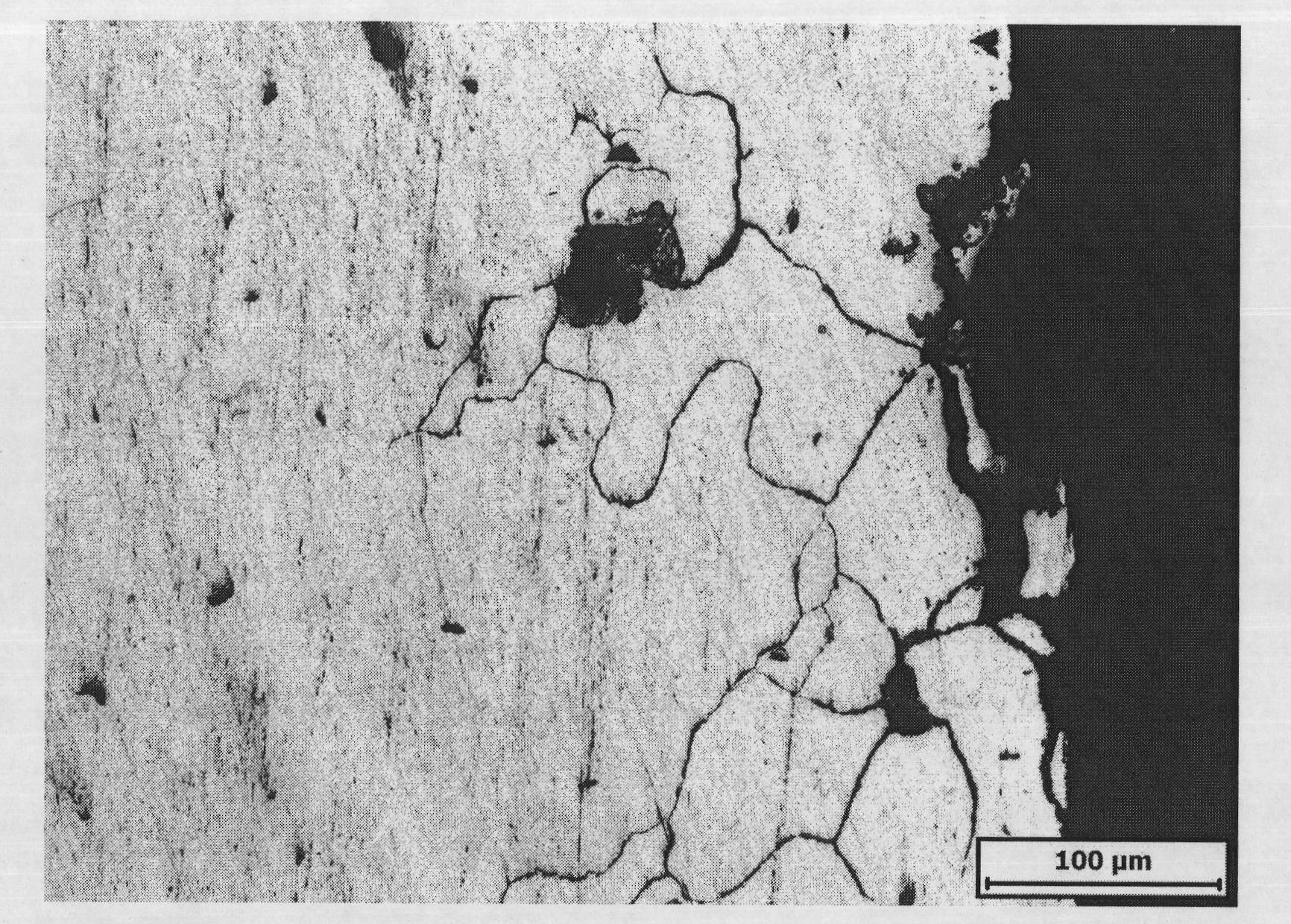

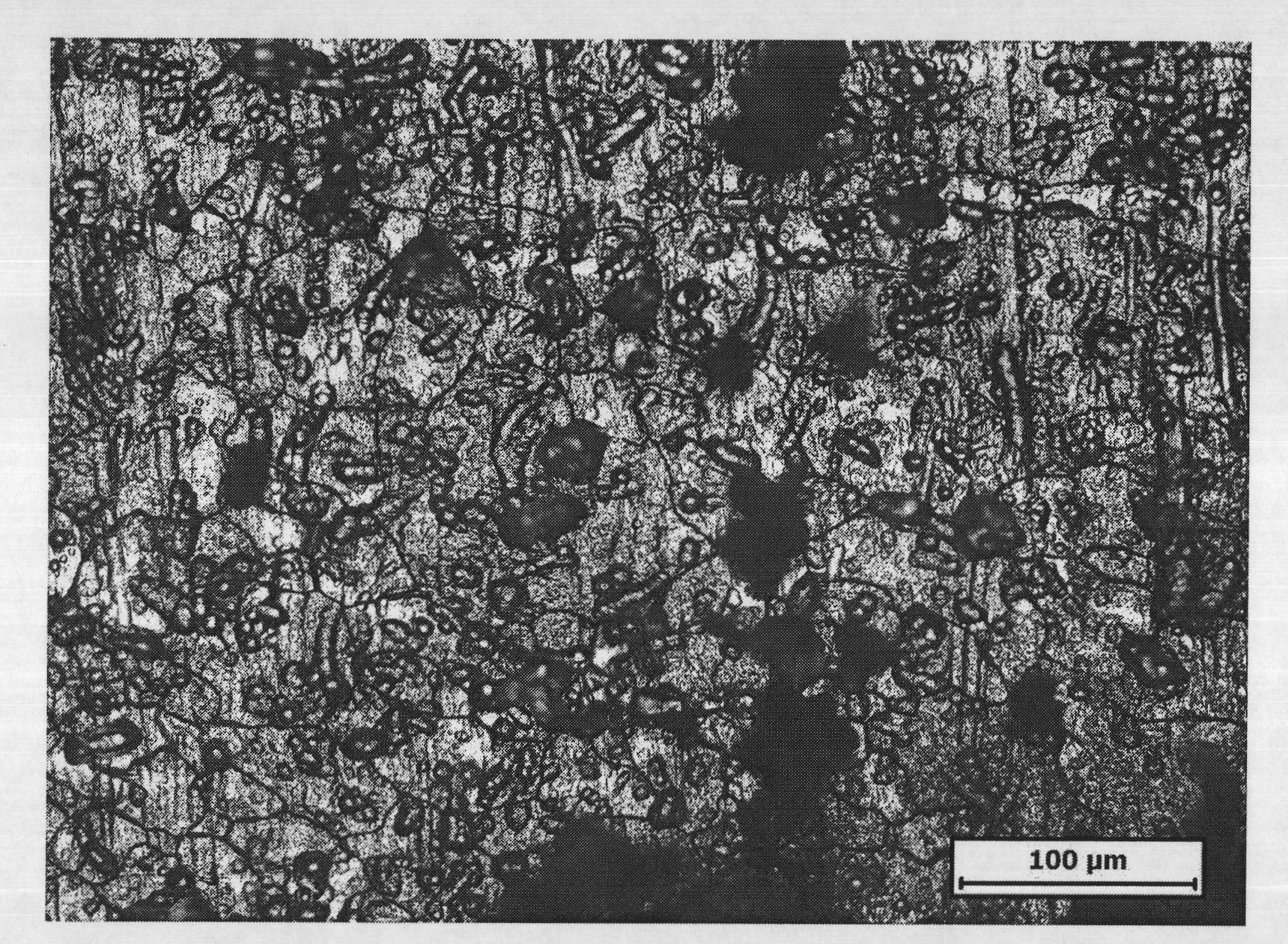

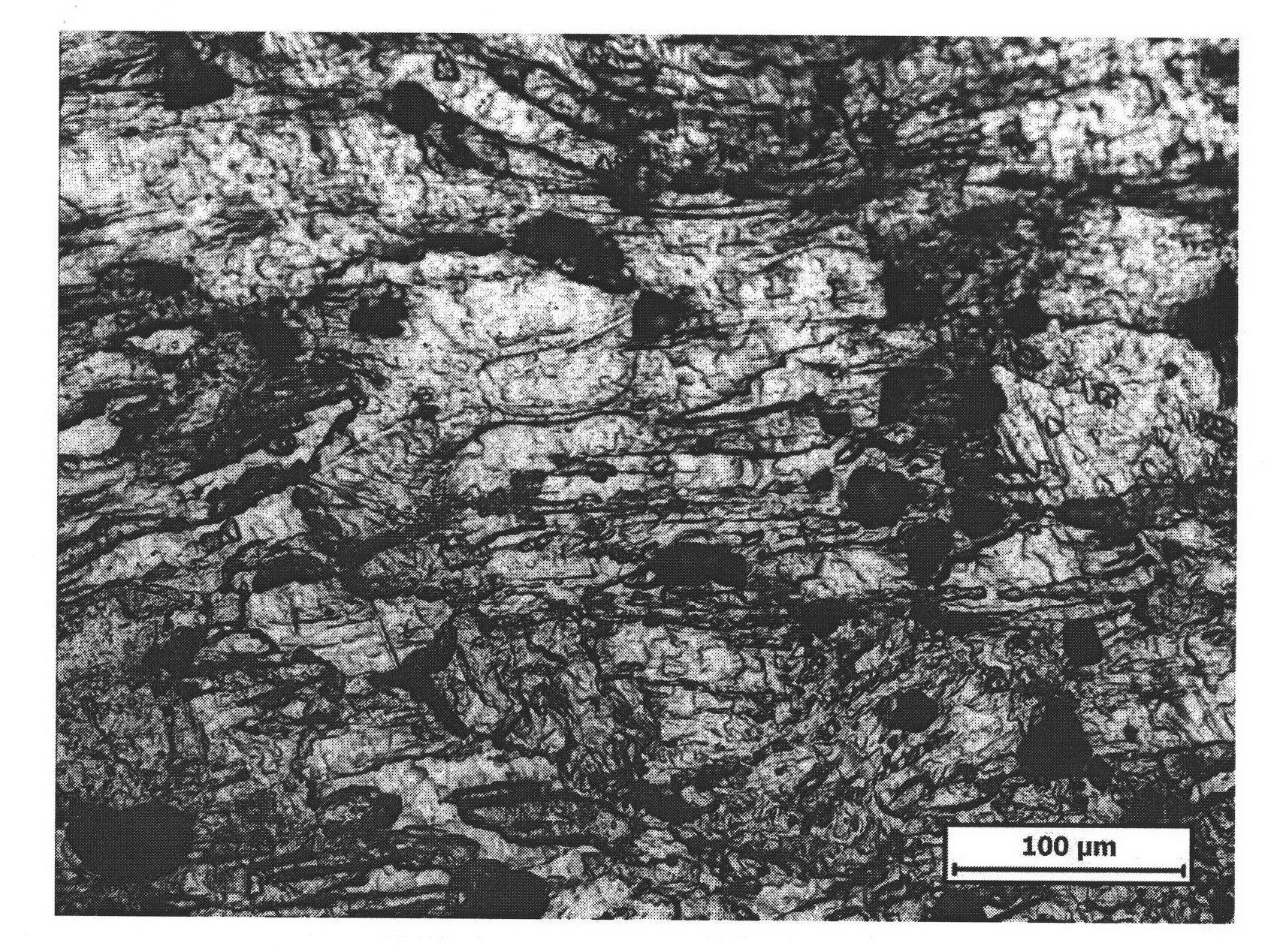

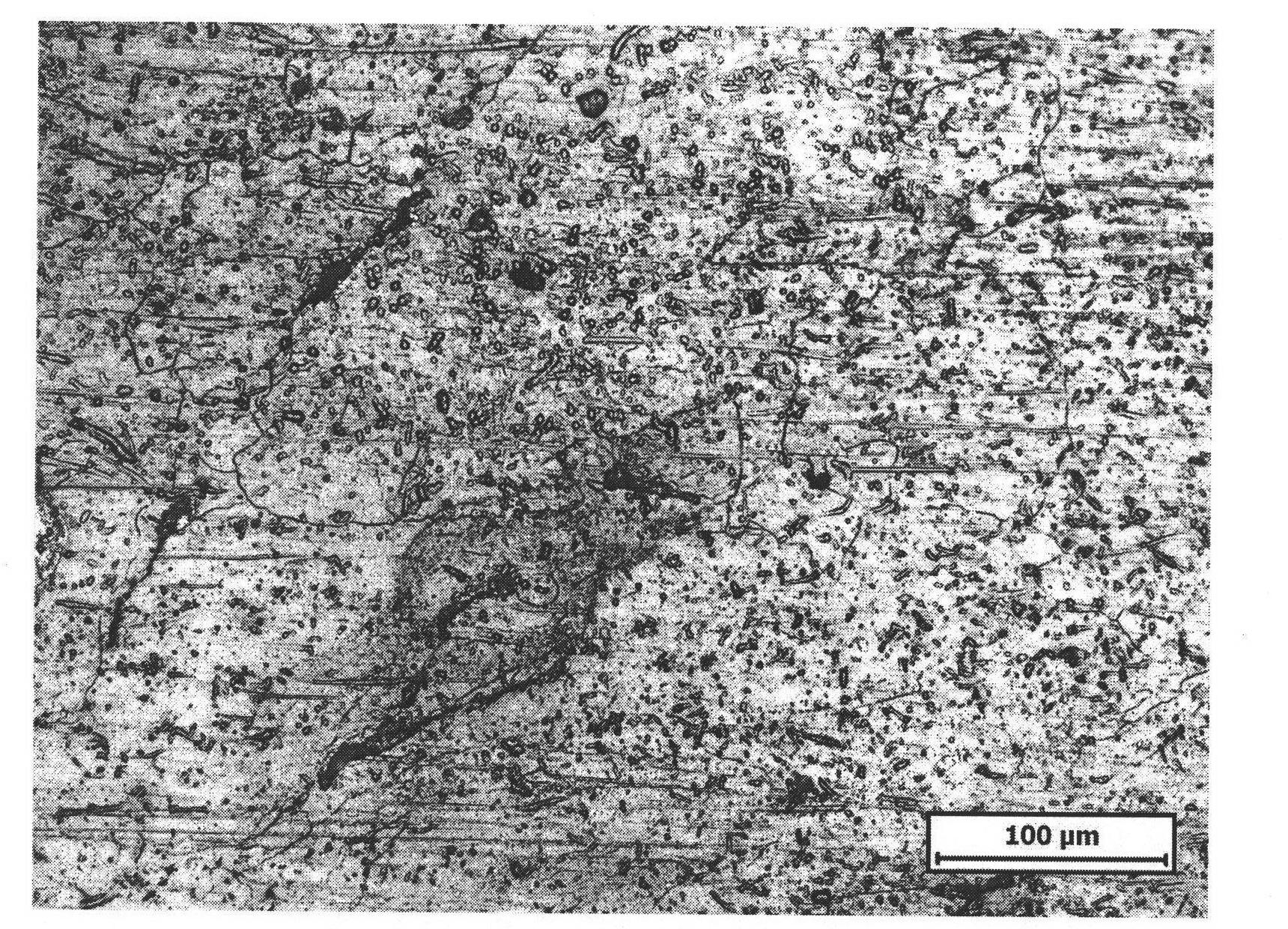

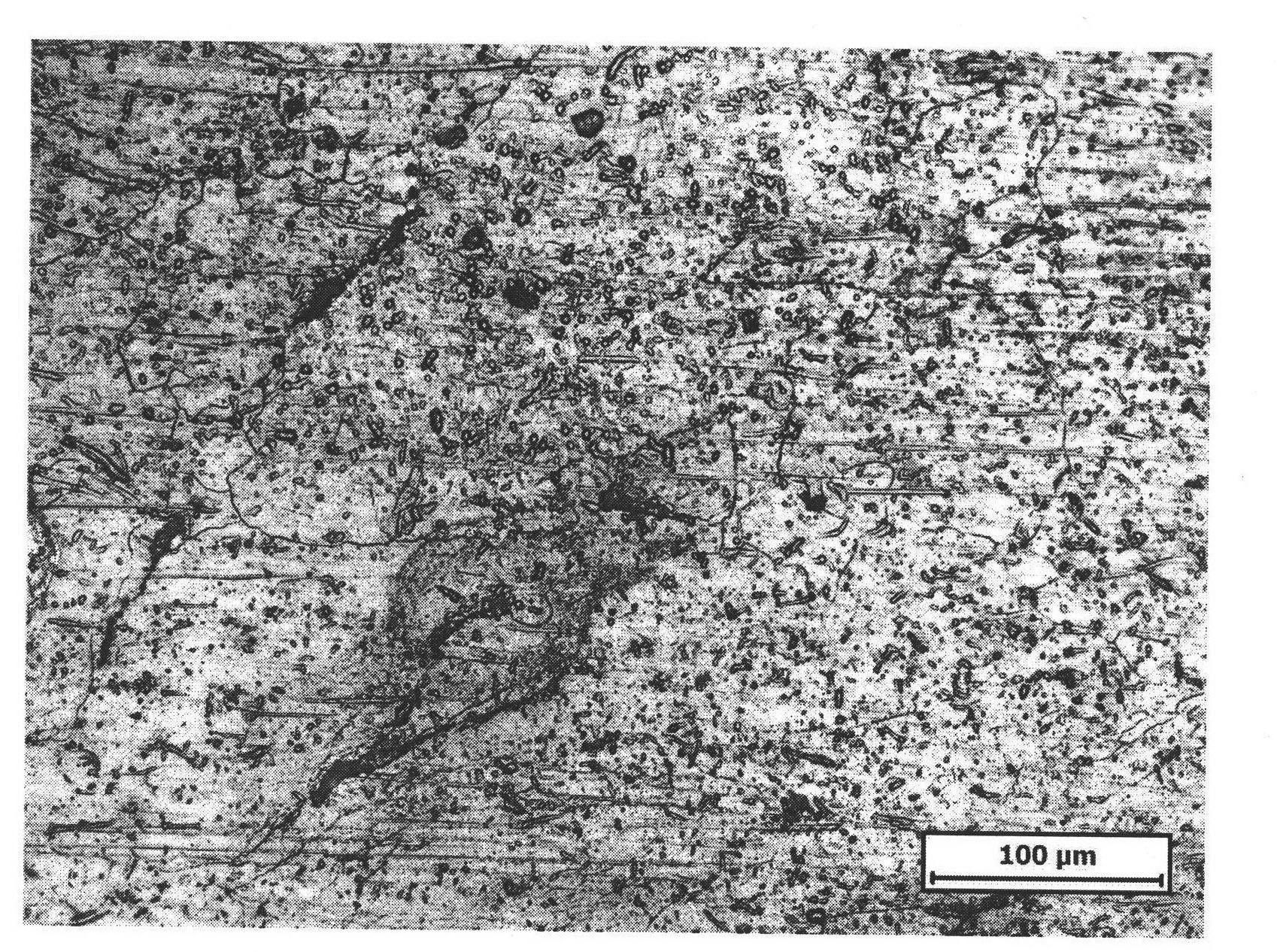

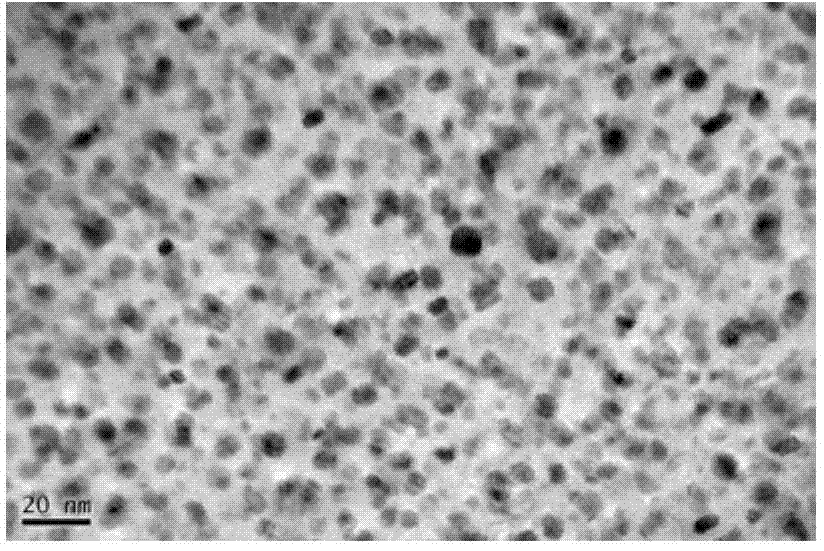

Exfoliation corrosion (metallurgy) In metallurgy, exfoliation corrosion (also called lamellar corrosion) is a severe type of intergranular corrosion that raises surface grains from metal by forming corrosion products at grain boundaries under the surface.

Aluminium-magnesium alloy plate or extrusion

A high strength Al-Mg alloy in plate or extrusion form having significantly improved strength in both soft and work-hardened tempers as compared with AA5083 is provided. The materials have ductility, pitting, stress and exfoliation corrosion resistances equivalent to those of the AA5083. The materials have improved long term stress and exfoliation corrosion resistances at temperatures above 80° C. The composition is 5-6% Mg, >0.6-1.2% Mn, 0.4-1.5% Zn, 0.05-0.25% Zr, up to 0.3% Cr, up to 0.2% Ti, up to 0.5% each Fe and Si, up to 0.4% each Cu and Ag, remainder Al and inevitable impurities. Manufacture of plate of this alloy is by homogenizing an ingot, hot rolling the ingot into plate in the range 400-530° C., cold rolling the plate with or without inter-annealing, final and optionally inter-annealing of the cold rolled material at temperatures in the range 200-550° C.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

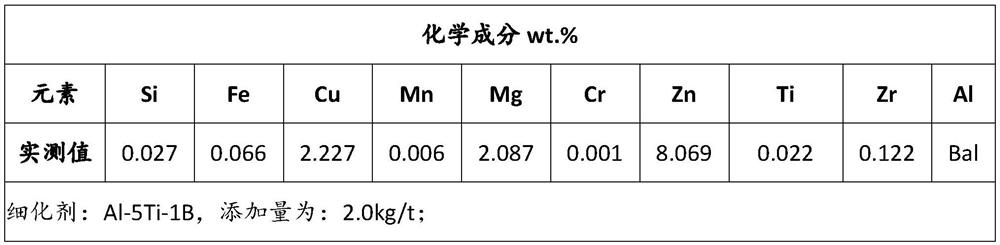

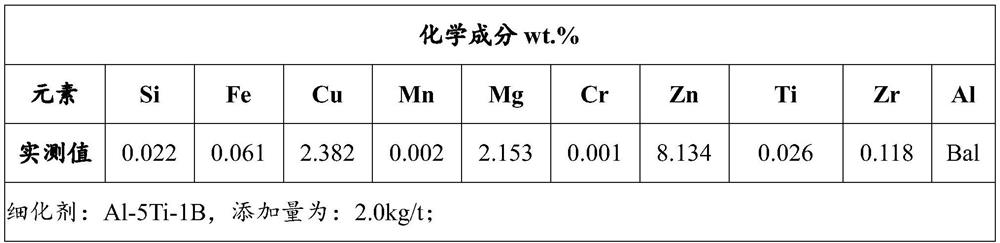

High-strength, light, corrosion-resistant and weldable Al-Zn-Mg alloy and preparation method

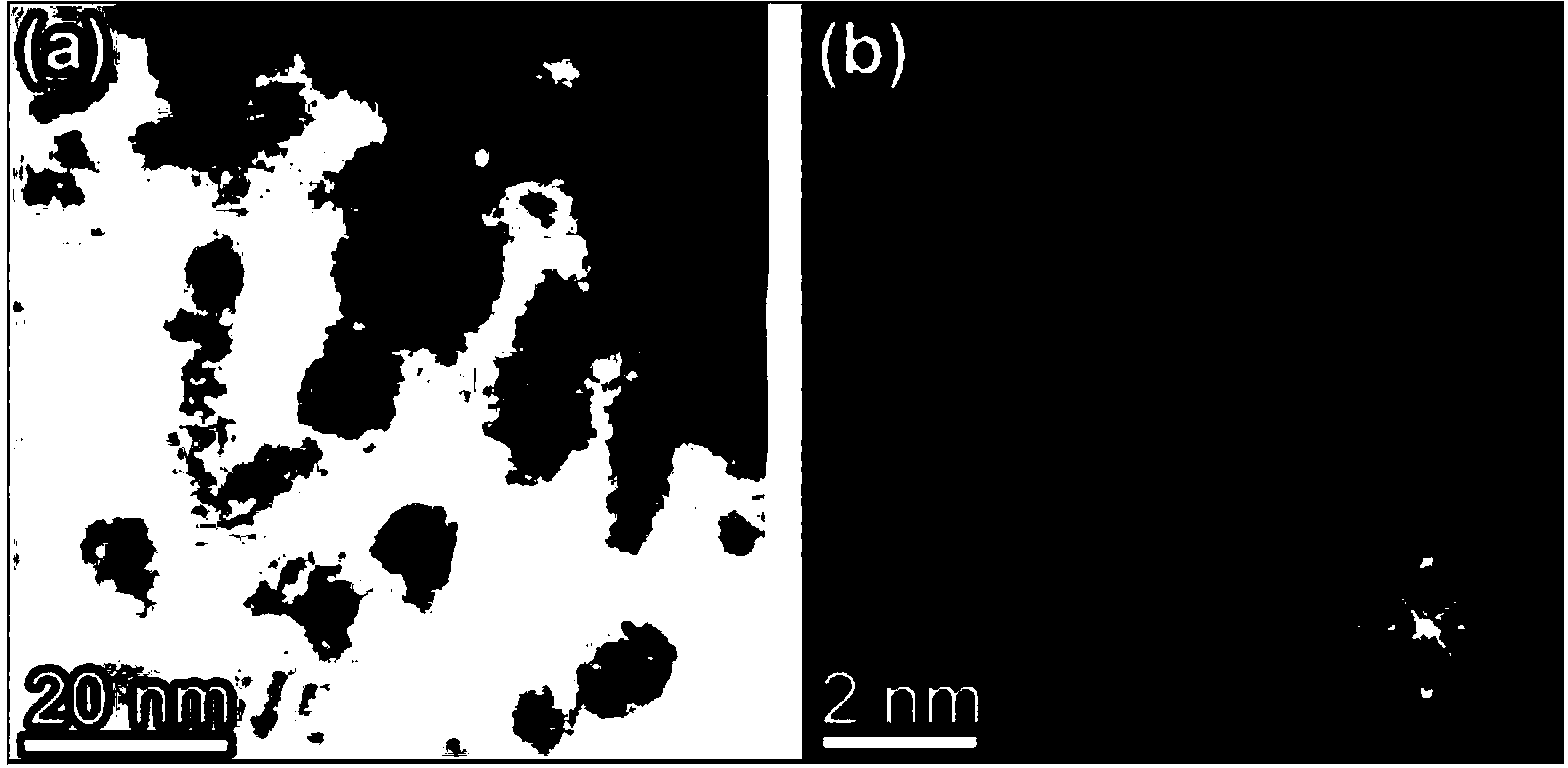

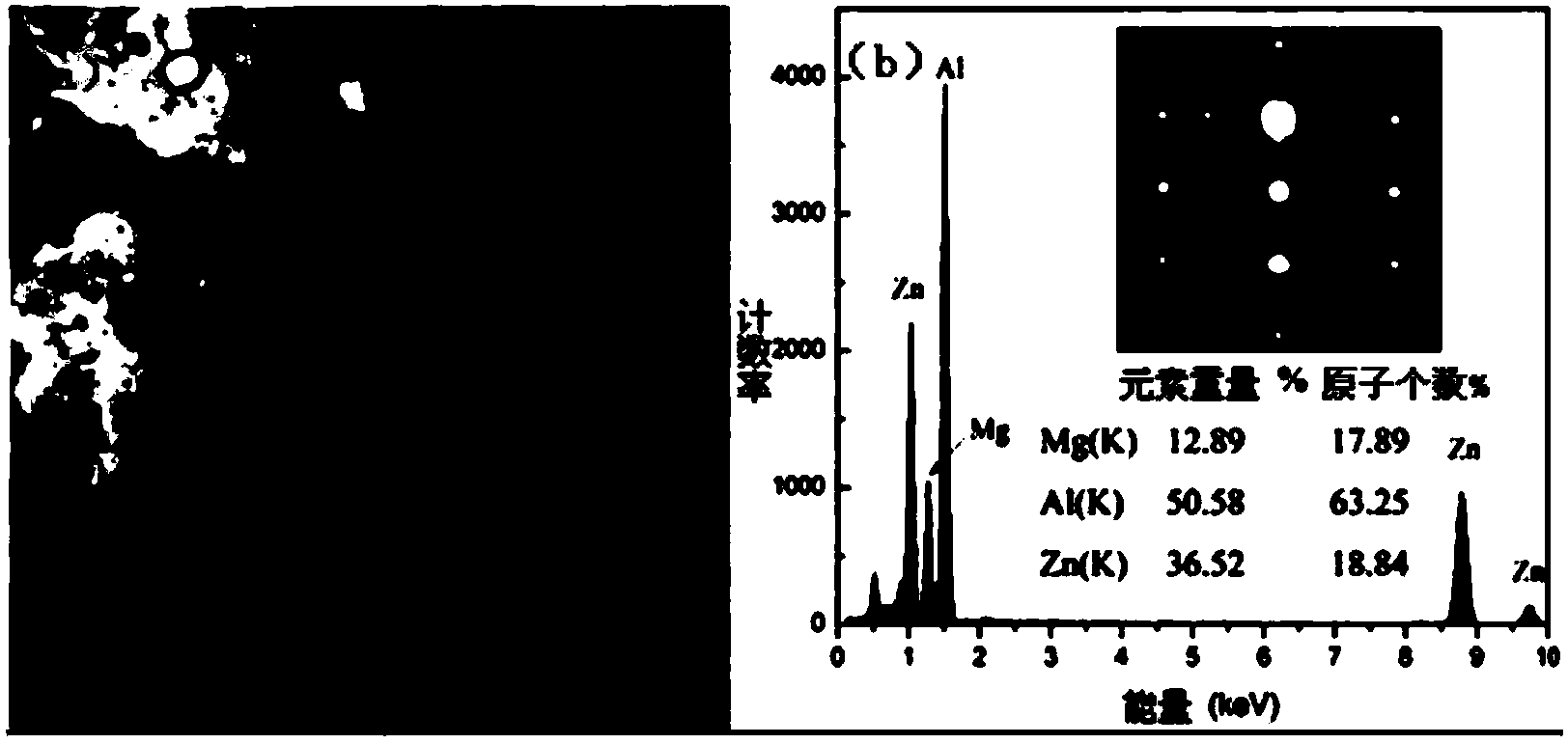

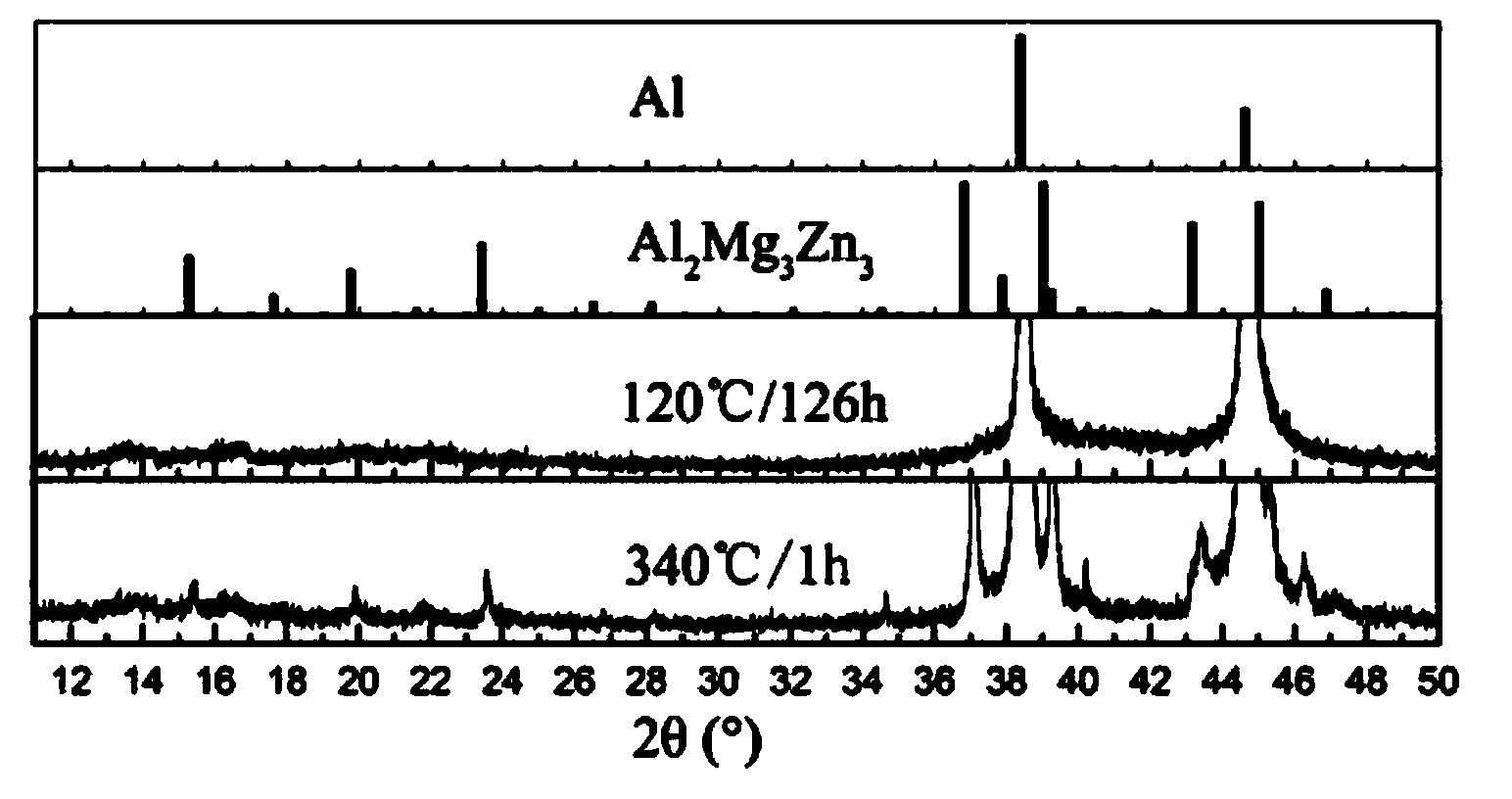

The invention relates to a high-strength, light, corrosion-resistant and weldable Al-Zn-Mg alloy and a preparation method, and belongs to the technical field of Al-Zn-Mg high-strength aluminum alloy preparation. The Al-Zn-Mg alloy is prepared, by mass ratio, from 6.8-9.2% Zn, 2.0-3.4% Mg, 0.08-0.30% Zr, and the balance of Al and unavoidable impurity elements, wherein the Mg : Zn is 0.28-0.42, the total quantity of the impurity elements is smaller than or equal to 0.3%, and in the impurity elements, the content of Cu is smaller than or equal to 0.1% of the total quantity of the alloy. The main precipitated strengthening phase of the Al-Zn-Mg alloy is a T precursor phase, the chemical formula of the T precursor phase is Al2+x+yMg3-xZn3-y, wherein x is larger than zero and smaller than three, and y is larger than zero and smaller than three. The hardness of the Al-Zn-Mg alloy is 205-214 HV after the Al-Zn-Mg alloy is processed by T6 aging, and the strength of the Al-Zn-Mg alloy is equivalent to that of a 7055 commercial alloy, while the density of the Al-Zn-Mg alloy is lower than that of the 7055 commercial alloy. The Al-Zn-Mg alloy has the advantages of being light, high-strength, weldable, strong in intergranular-corrosion-resistance and exfoliation corrosion resistance, and suitable for many kinds of high-strength weldable products such as high-speed trains and airplane structural components.

Owner:HUNAN UNIV

Aluminum alloy 7085 microalloyed with strontium and preparation method thereof

The invention discloses an aluminum alloy 7085 microalloyed with strontium, which is formed by microalloying aluminum alloy 7085 with a small amount of strontium. The alloy mainly comprises Al, Zn, Mg, Cu, Zr and Sr, wherein the mass percent of Zn is 7.0-7.95%, the mass percent of Mg is 1.41-1.80%, the mass percent of Cu is 1.50-1.59%, the mass percent of Zr is 0.138-0.148%, the mass percent of Sr is 0.0228-0.0237%, and the balance is Al and a small amount of impurity elements. The preparation process flow of the alloy is as follows: melting pure Al, sequentially adding Al-Cu intermediate alloy, Al-Sr intermediate alloy, Al-Zr intermediate alloy, pure Zn and pure Mg, melting, adding hexachloroethane for refining, standing and maintaining the temperature for 5-10 minutes, and then casting into ingots; and carrying out post treatments of annealing, stamping and soilid solution ageing on the alloy ingots formed by casting. The invention has the advantages of high rigidity, good exfoliation corrosion resistance and wide application range.

Owner:JIANGSU UNIV

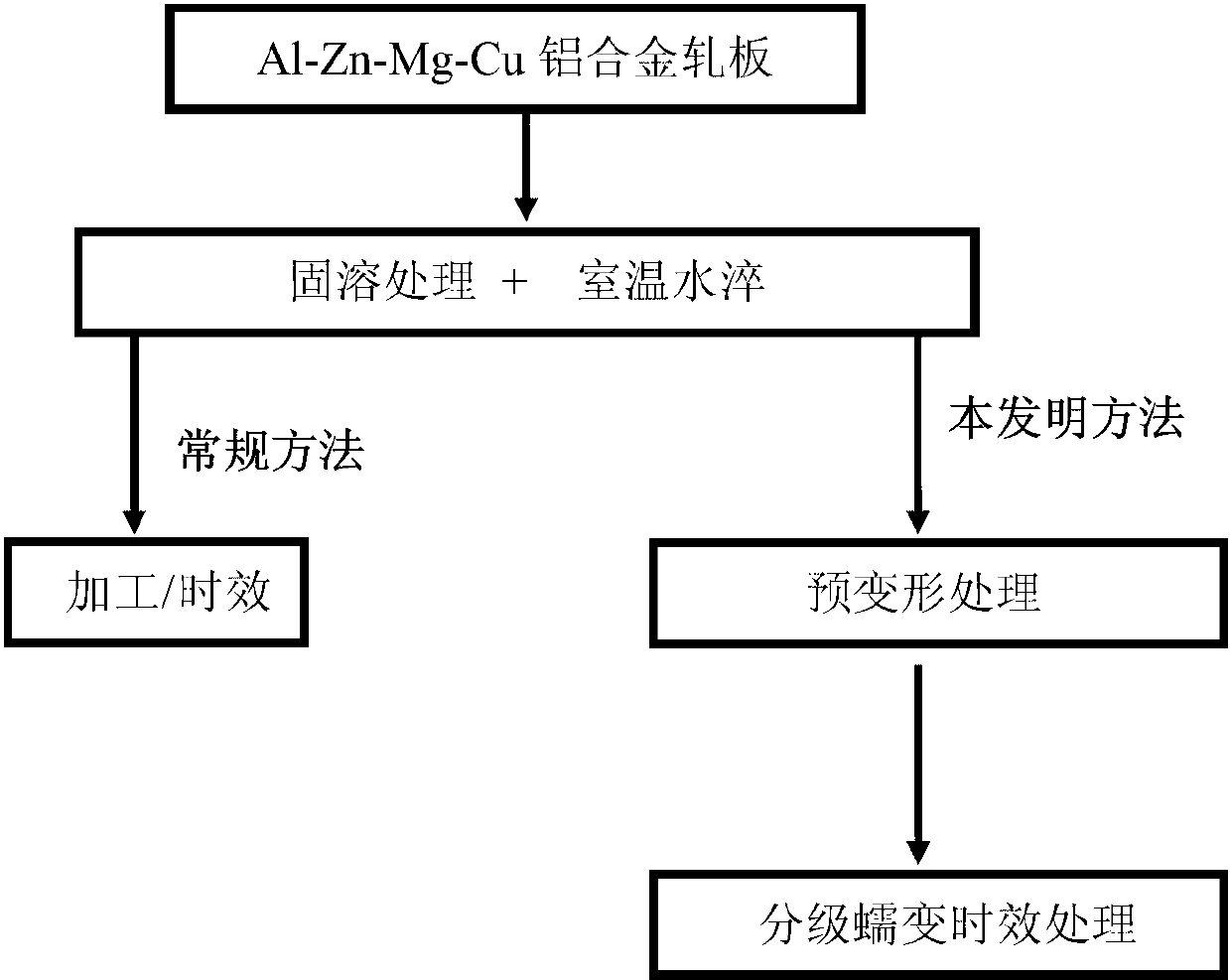

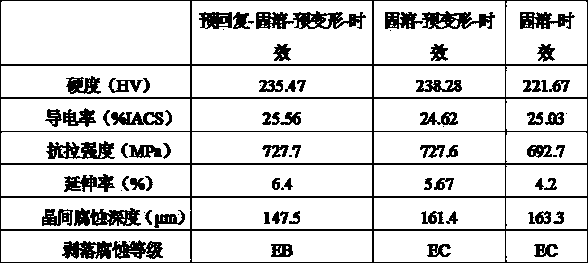

Method for multilevel creep age forming of Al-Zn-Mg-Cu series aluminium alloy plate

ActiveCN102978544AImprove mechanical propertiesImprove corrosion resistanceCreep stressThermal insulation

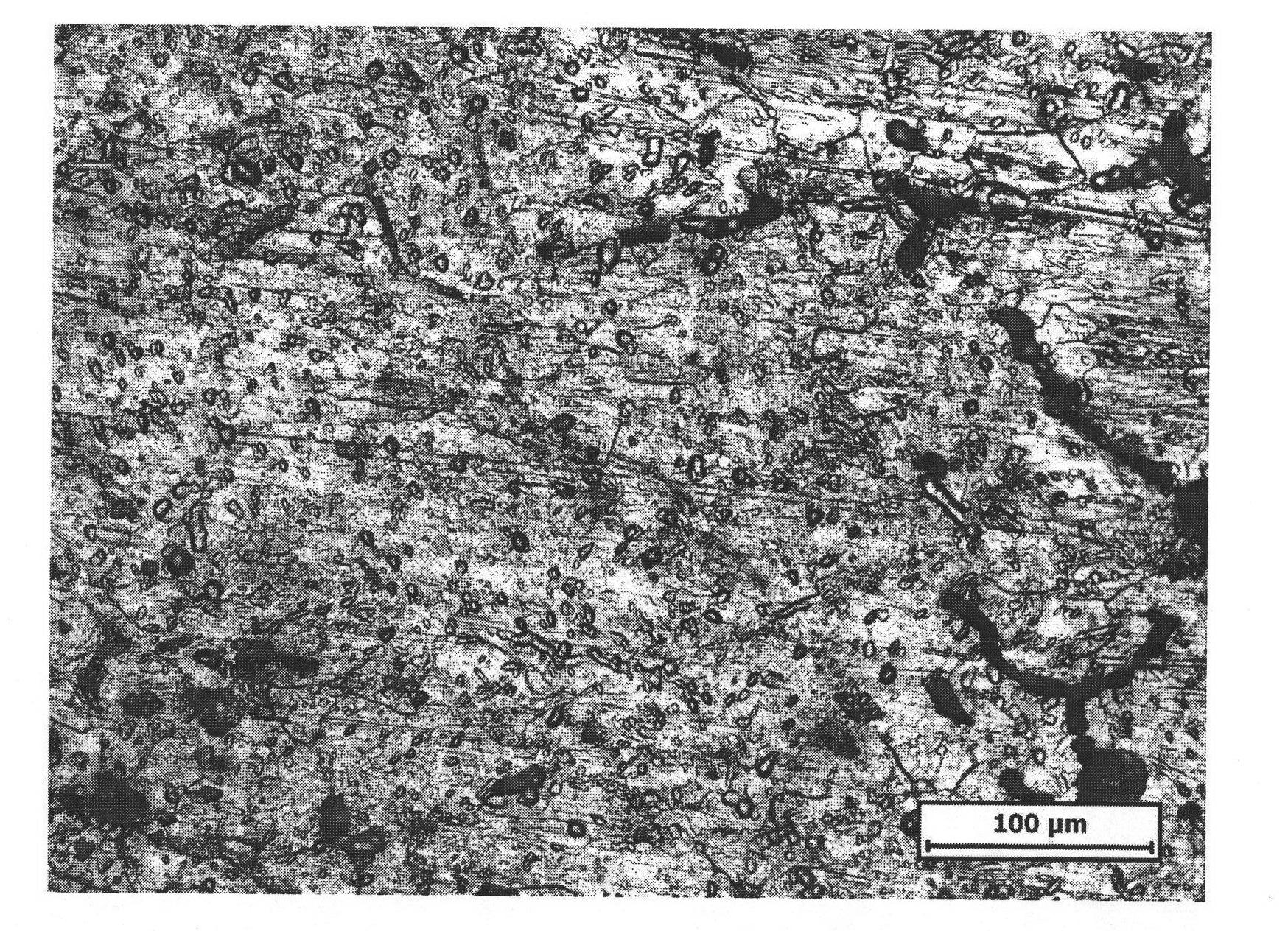

The invention relates to a method for multilevel creep age forming of an Al-Zn-Mg-Cu series aluminium alloy plate. The method is characterized in that a reasonable solid solution-quenching-pretreating-multilevel creep aging system is adopted, is suitable for plates with the thickness of 2 millimeters-30millimeters and comprises the following steps that solid solution is carried out at 470-485 DEG C for 30 minutes-120 minutes, quenching is then carried out, the quenched plate is subjected to 0-10% predeformation treatment and creep aging at 120 DEG C and is thermally insulated for 24 hours, the creep return temperature is between 150 and 170 DEG C, return thermal insulation is carried out for 20-240 minutes, and another creep aging is thermally insulated at 120 DEG C for 24 hours, wherein the creep stress is between 100 and 150 mega pascals, and the forming bending radius is between 800 millimeters and 5000 millimeters. The method is utilized to treat Al-Zn-Mg-Cu series aluminium alloy, so that the alloy creep aging strengthening phase can be effectively regulated, the mechanical property of the alloy plate and the alloy creep formability are improved, the residual stress of the alloy plate is reduced, and the alloy exfoliation corrosion resistance is improved.

Owner:CENT SOUTH UNIV

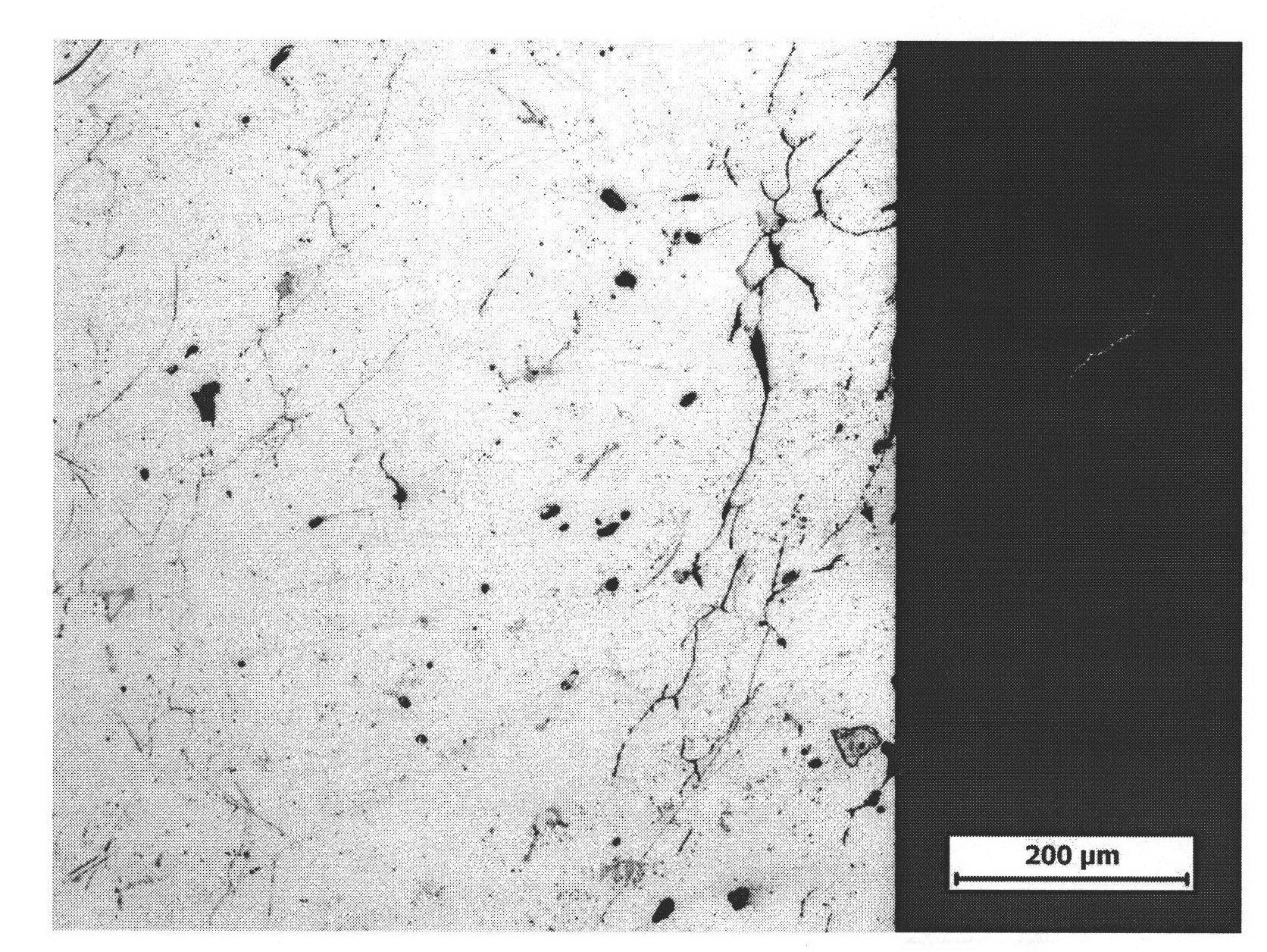

Anti-exfoliation corrosion high-strength aluminum-zinc-magnesium-copper alloy and heat treatment process

ActiveCN103614597AAvoid the disadvantage of serious strength dropHigh strengthHeat treatingExfoliation corrosion

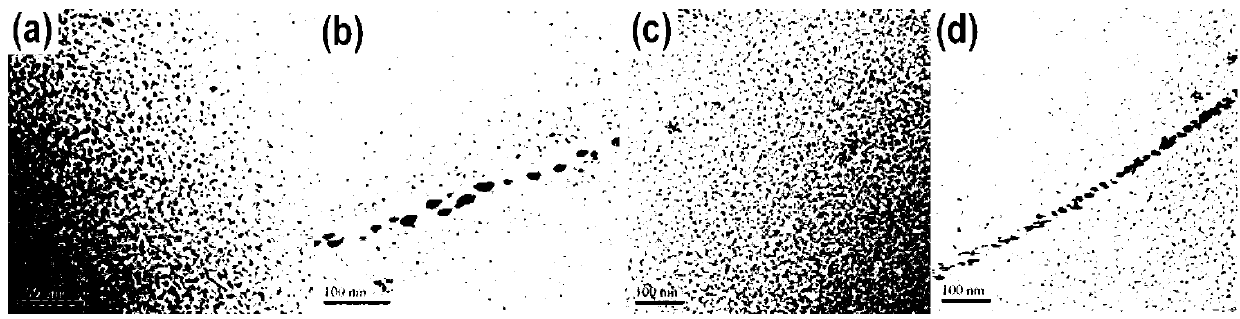

The invention discloses an anti-exfoliation corrosion high-strength aluminum-zinc-magnesium-copper alloy and a heat treatment process. The heat treatment process comprises the steps of controlling the Zn content and Zn / Mg weight ratio in the alloy; performing solution treatment and water quenching on the alloy, and performing pre-deformation; then performing first-level low-temperature aging at 122-132 DEG C and second-level aging at 163-180 DEG C. The alloy has relatively high strength and toughness, the self-corrosion current of the alloy in a corrosive medium is reduced, and the corrosion resistance of the alloy is improved. In the alloy disclosed by the invention, the ratio of the components is reasonable, the process is simple, the production period is short, and the operation is convenient; the total aging time is shortened to 10-15 hours from the traditional two-level aging time 25-30 hours, and the production efficiency is high; the alloy has the performance characteristics of high strength, good toughness and exfoliation corrosion resistance, and is suitable for the industrial application of the fields of aerospace and the like.

Owner:CENT SOUTH UNIV

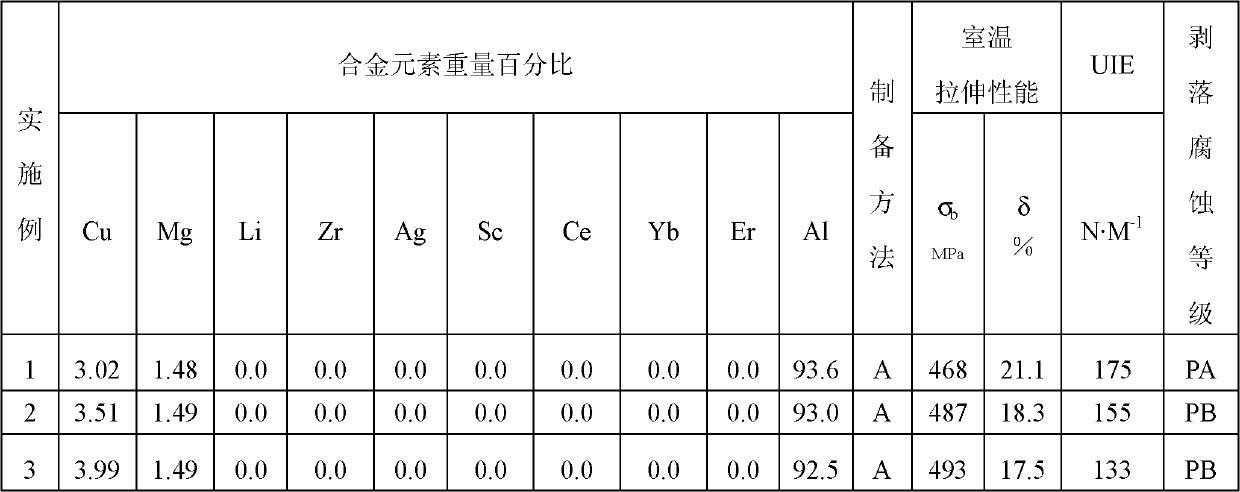

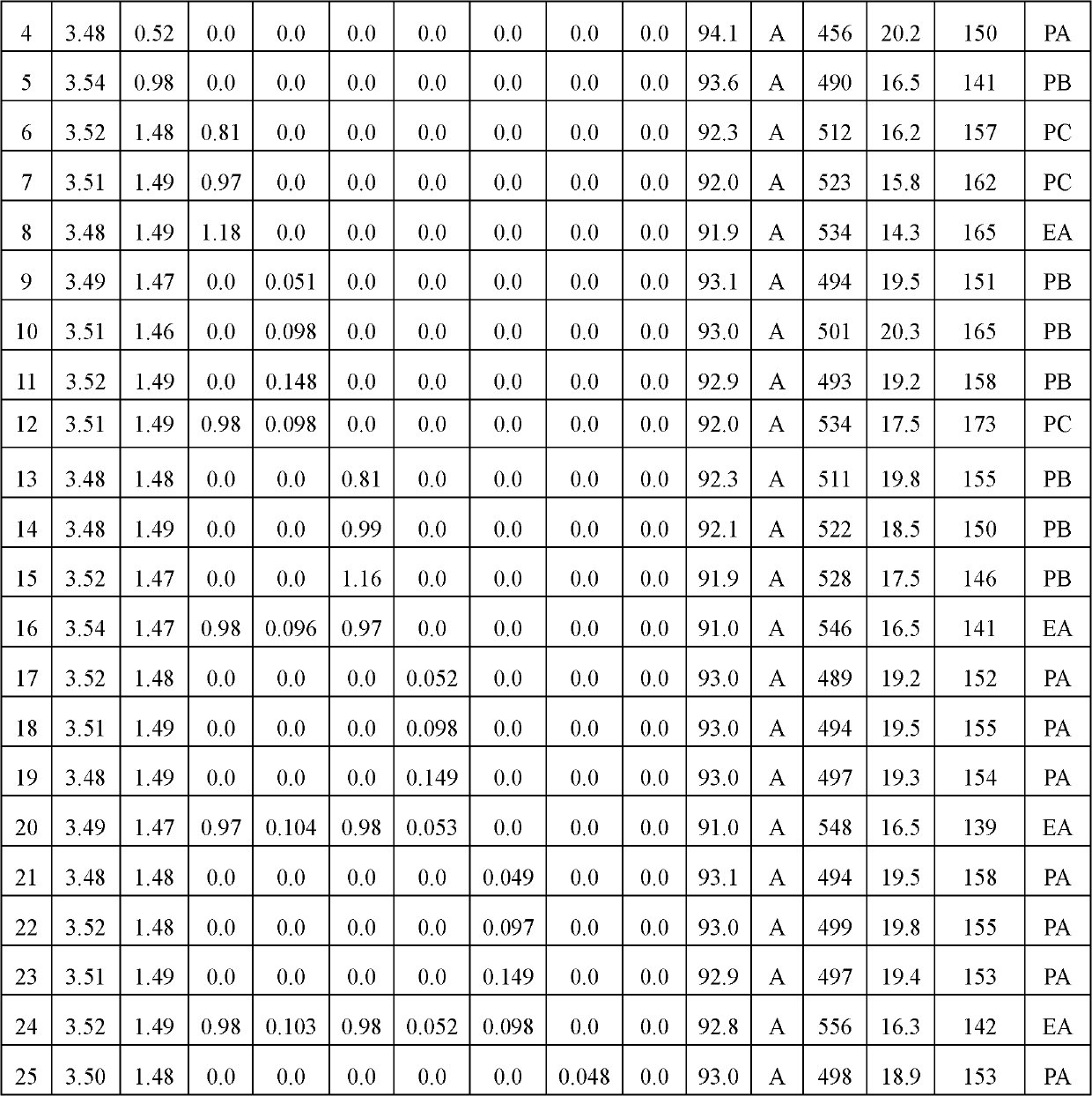

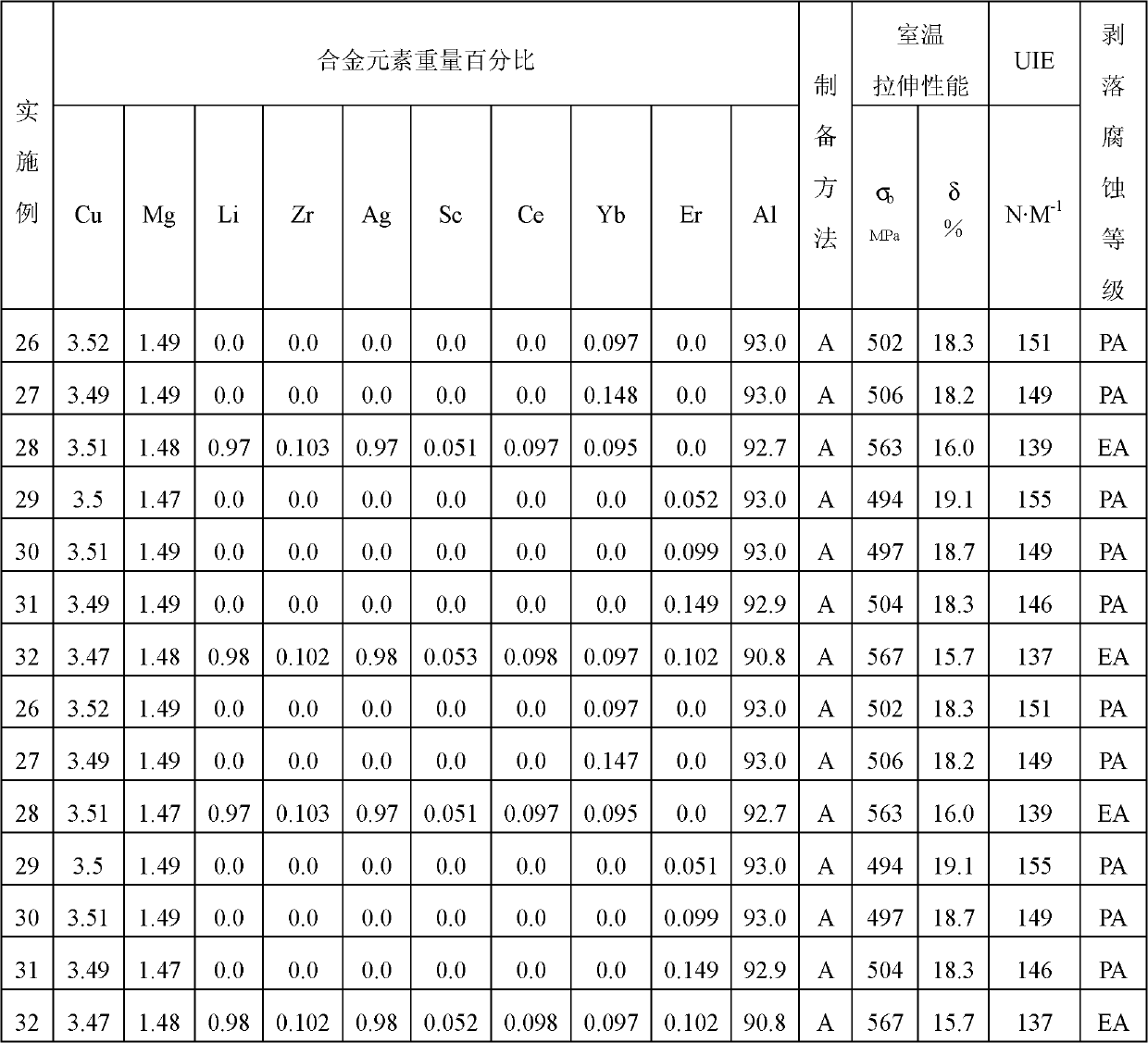

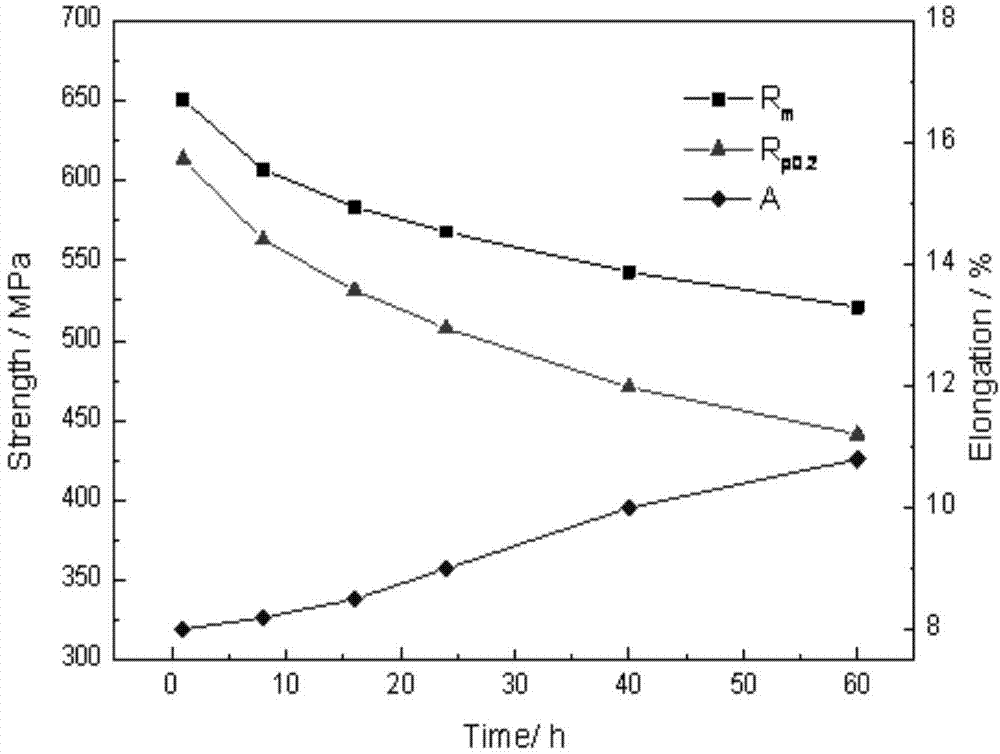

High-strength high-toughness corrosion-resistant Al-Cu-Mg aluminum alloy

The invention relates to a high-strength high-toughness corrosion-resistant Al-Cu-Mg serial aluminum alloy. The key point is to regulate the mass ratio of the elements in the Al-Cu-Mg alloy. The high-strength high-toughness corrosion-resistant Al-Cu-Mg aluminum alloy comprises the following components in percentage by weight: 3.0-4.0% of copper, 0.5-1.5% of magnesium, less than 0.2% of zinc, less than 0.06% of titanium, less than 0.2% of silicon, less than 0.25% of iron, less than 1.2% of manganese and the balance of aluminum. The novel aluminum alloy provided by the invention has the advantages of higher strength, better plasticity, favorable exfoliation corrosion resistance and favorable fracture toughness. The strength of the material (component) prepared from the alloy after peak aging is greater than 480Mpa, the elongation percentage of the material at room temperature is not lower than 10%, the Vickers hardness number is not lower than 140HV, the exfoliation corrosion resistance is within the EB range, and the comprehensive properties are apparently higher than those of the reported Al-Cu-Mg serial aluminum alloy.

Owner:CENT SOUTH UNIV

Compound 6013-type aluminum alloy microalloyed by zirconium and strontium and preparation method thereof

The invention discloses a 6013-type aluminum alloy microalloyed by zirconium and strontium, which mainly comprises Al, 1.22% to 1.52% of Mg, 0.90% to 1.15% of Si, 0.804% to 1.04% of Cu, 0.451% to 0.661% of Mn, 0.0311% to 0.135% of Zn, 0.0915% to 0.135% of Zr and 0.0157% to 0.0391% of Sr. The preparation method of the alloy comprises the steps of: melting pure Al; sequentially adding Al-Cu intermediate alloy, Al-Si intermediate alloy, Al-Mn intermediate alloy, Al-Zr intermediate alloy, Al-Sr intermediate alloy, pure Zn and pure Mn; melting and adding hexachloroethane for refining; standing and keeping the temperature for 5 to 10 minutes; removing residues; casting into ingots; and treating the cast ingots. The hardness of the alloy reaches 156.0 to 159.1 HV; the performance of resisting intergranular corrosion is in fourth level; and the performance of resisting exfoliation corrosion is not less than PB level. The alloy can be widely applied to the fields of modern aerospace, weaponry and the like, and has wide application prospect.

Owner:NANTONG JIANGZHONG PHOTOELECTRIC

Heat treatment method capable of improving anti-fatigue performance of aluminum alloy

ActiveCN103045976AEliminate entangled dislocation configurationsStress reliefRoom temperatureCorrosion fatigue

The invention relates to a heat treatment method capable of improving the anti-fatigue performance of Al-Cu-Mg alloy. The method comprises the following steps: performing intermediate annealing on a cold-rolled plate at the temperature of between 300 and 440 DEG C for 20 to 120 minutes; performing solution hardening treatment at the temperature of between 475 and 505 DEG C for 10 to 120 minutes; and naturally ageing at room temperature for at least 100 hours. The Al-Cu-Mg alloy comprises the following components: Cu, Mg, Mn, Ti and Al. The process method is simple and reasonable. By the intermediate annealing heat treatment process, the Gauss texture score of the alloy is increased, and orientation of most of crystal faces {111} of crystal grains of the cold-rolled Al-Cu-Mg alloy is positioned or close to the direction of the maximum external shearing stress, so that reciprocating sliding dislocated under the action of alternating stress is promoted, the closed effect of fatigue crack is improved, the spreading rate of the fatigue crack is reduced, and the alloy has excellent stress corrosion resistance and anti-stripping corrosion fatigue performance and is suitable for industrialized application.

Owner:CENT SOUTH UNIV

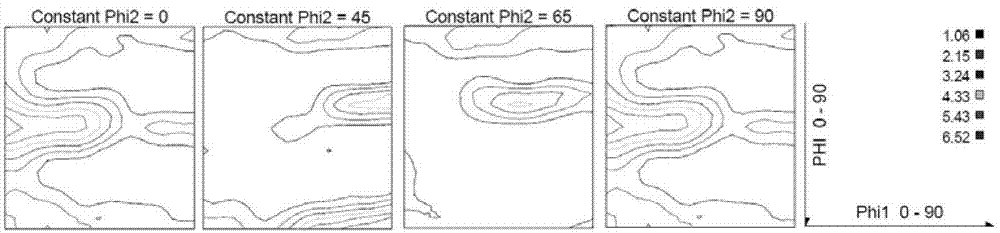

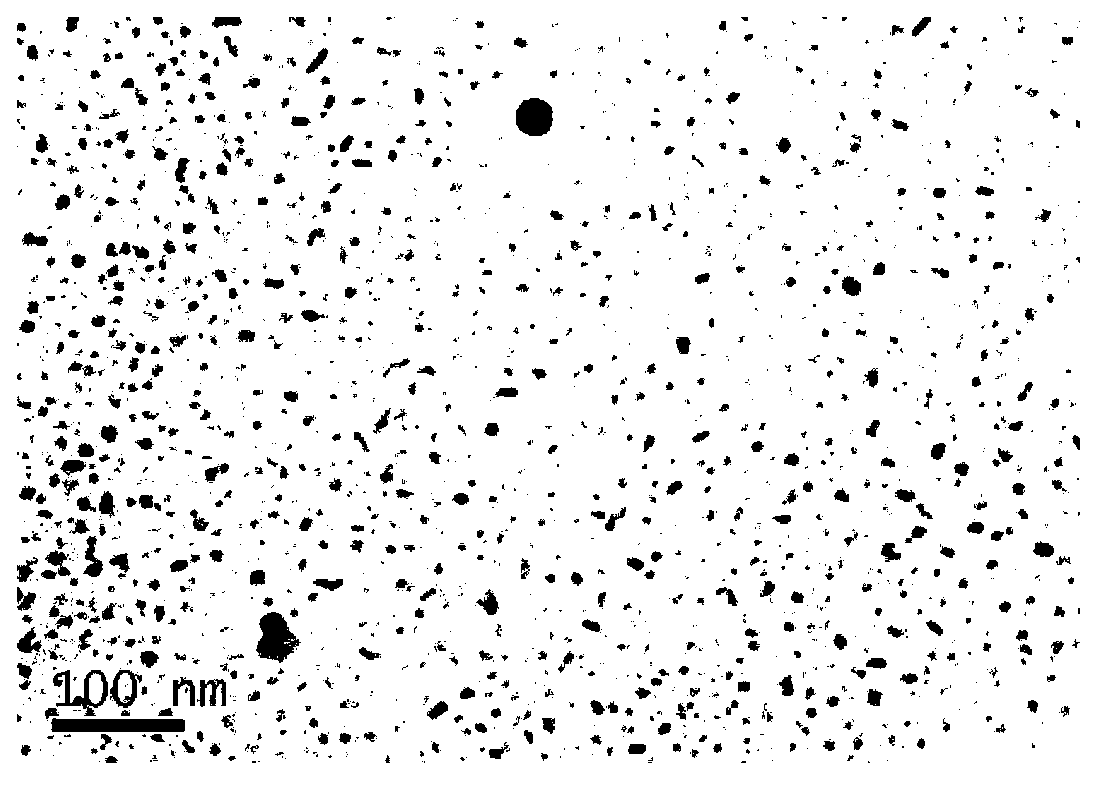

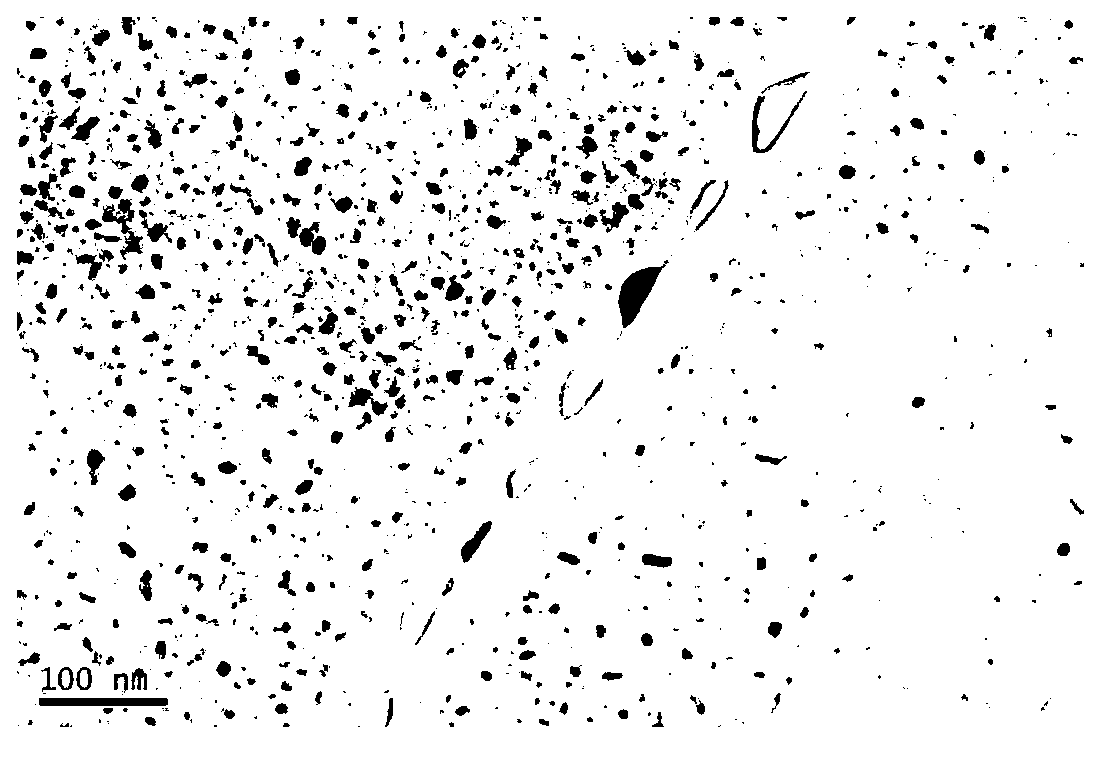

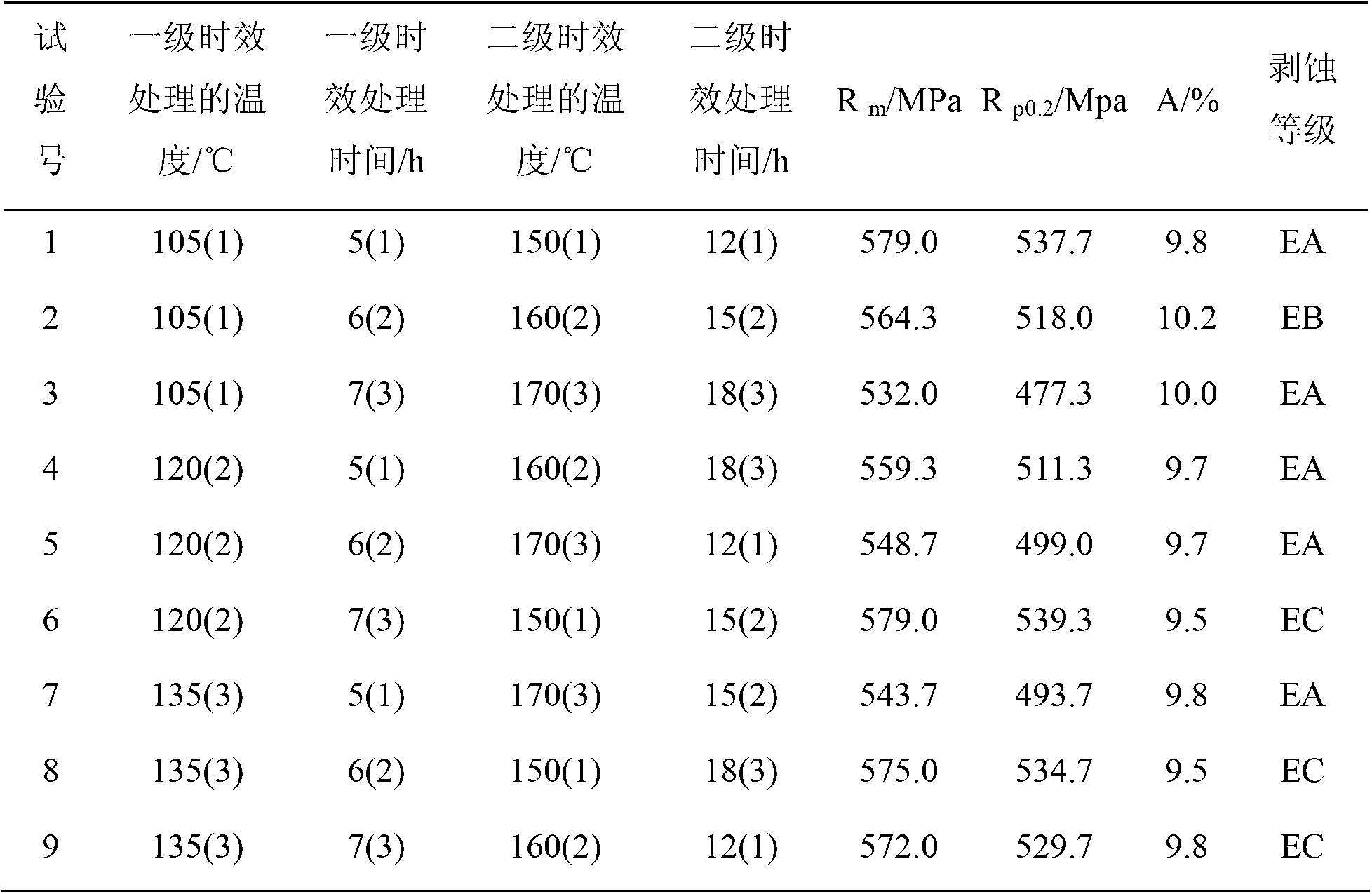

Two-stage aging process of Al-Zn-Mg-Cu-Zr-Er alloy

The invention relates to a two-stage aging process of an Al-Zn-Mg-Cu-Zr-Er alloy and belongs to the technical field of non-ferrous metal. The two-stage aging process comprises the steps of: carrying out solution treatment on an Al-5.6Zn-2.6Mg-1.5Cu-0.2Zr-0.2Er alloy at 470 DEG C for 2 hours, and then quenching in water; and carrying out two-stage aging heat treatment, wherein first-stage aging heat treatment is carried out at 105-135 DEG C for 5-7 hours, and second-stage aging heat treatment is carried out at 150-170 DEG C for 12-18 hours. The obtained alloy has high hardness and toughness and good exfoliation corrosion performance.

Owner:BEIJING UNIV OF TECH

Thermal treatment method for simultaneously improving strength and fatigue resistance property of aluminum alloy

The invention relates to a thermal treatment method for simultaneously improving the strength and fatigue resistance property of aluminum alloy. The method comprises the following steps of: heating aluminum / zinc / magnesium / copper alloy subjected to solution treatment for 2 hours at the temperature of 460-495 DEG C to 70-120 DEG C, and carrying out heat preservation for 24-96 hours; then carrying out heat preservation for 2-120 minutes at the temperature of 150-170 DEG C, and cooling to room temperature; and subsequently, carrying out heat preservation for 24-96 hours at the temperature of 70-120 DEG C, and then discharging and performing air cooling, wherein the aluminum / zinc / magnesium / copper alloy comprises the following components: Zn, Mg, Cu, Mn, Zr and Al. The thermal treatment provided by the invention is simple and reasonable in technology; through three-stage aging thermal treatment technology, the grain boundary of the aluminum / zinc / magnesium / copper alloy is in an overaging state, and the structure in the grain mainly consists of eta ' phase and a G.P. zone; and the overaging structure of the grain boundary is good in corrosion resistance, and the G.P. zone particles in the grain are beneficial to reciprocating slippage and crack closing dislocated under the alternating stress action, so that the fatigue resistance property is improved, and the alloy is good in stress corrosion resistance property and exfoliation corrosion resistance property and is suitable for industrial application.

Owner:CENT SOUTH UNIV

High-strength corrosion-resistant AL-Mg alloy

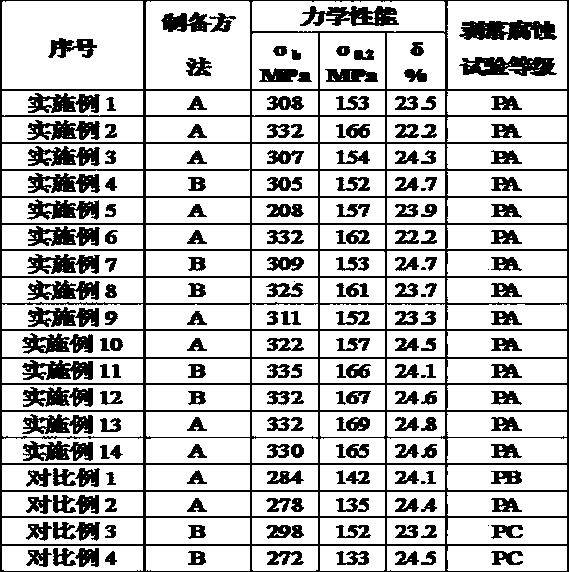

The invention discloses a high-strength corrosion-resistant AL-Mg alloy. The high-strength corrosion-resistant AL-Mg alloy comprises the following chemical components in percentage by weight: less than or equal to 0.3% of Fe, less than or equal to 0.25% of Si, less than or equal to 0.1% of Cu, 0.4-1.2% of Mn, 4.5-6.0% of Mg, 0.25-0.55% of Zn, 0.10-0.3% of Cr, less than or equal to 0.15% of Zr, less than or equal to 0.15% of Ti, and the balance of Al. The high-strength corrosion-resistant AL-Mg alloy solves the problems that the strength and the corrosion resistance of the conventional aluminum alloy 5083 in the manufacturing of a traffic tool are not good, the tensile strength of the obtained alloy sigma b is more than or equal to 320Mpa, the yield strength sigma 0.2 is more than or equal to 160 Mpa, the ductility delta is more than or equal to 23%, and the grade of an exfoliation corrosion test reaches PA level.

Owner:CENT SOUTH UNIV

Aluminium-magnesium alloy plate or extrusion

A high strength Al-Mg alloy in plate or extrusion form having significantly improved strength in both soft and work-hardened tempers as compared with AA5083 is provided. The materials have ductility, pitting, stress and exfoliation corrosion resistances equivalent to those of the AA5083. The materials have improved long term stress and exfoliation corrosion resistances at temperatures above 80° C. The composition is 5-6% Mg, >0.6-1.2% Mn, 0.4-1.5% Zn, 0.05-0.25% Zr, up to 0.3% Cr, up to 0.2% Ti, up to 0.5% each Fe and Si, up to 0.4% each Cu and Ag, remainder Al and inevitable impurities. Manufacture of plate of this alloy is by homogenizing an ingot, hot rolling the ingot into plate in the range 400-530° C., cold rolling the plate with or without inter-annealing, final and optionally inter-annealing of the cold rolled material at temperatures in the range 200-550° C.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

Corrosion-resistant structural aluminum alloy and preparation method thereof

ActiveCN107447150AImprove corrosion resistanceRadius of capacitive reactance arc increasedImpurityCorrosion resistant

The invention discloses a corrosion-resistant structural aluminum alloy and a preparation method thereof. The corrosion-resistant structural aluminum alloy comprises the following components, by mass percentage, 4-9% of Zn, 1.5-2.8% of Mg, 1-2.8% of Cu, 0.2-0.35% of Mn, 0-0.3% of Cr, 0.1-0.4% of Zr, 0.1-0.5% of Yb 0.1-0.5% of Er, 0.1-0.4% of Sn, 0.1-0.35% of Ge and the balance Al and inevitable impurities. The aluminum alloy has the advantages that the recrystallization fraction is low, the number of small-angle grain boundaries is large, and the expansion of corrosion cracks can be effectively resisted; the crystal boundary precipitation phase is large in size and discontinuous in distribution so that the expansion of the corrosion cracks can be further effectively hindered, and therefore the exfoliation corrosion resistance of the aluminum alloy can be obviously improved, and the evaluation grade can reach the P grade; and meanwhile, the hardness of the aluminum alloy is greater than or equal to 143HV, the yield strength Rp0.2 is greater than or equal to 387MPa, the tensile strength Rm is greater than or equal to 410MPa, and the elongation rate A is greater than or equal to 14.5%.

Owner:福建祥鑫股份有限公司

Novel Al-Mg-Si alloy material high in strength and resistant to seawater corrosion and preparation method thereof

InactiveCN106480343AHigh strengthReduces electrochemical kinetics of corrosionUltimate tensile strengthSeawater

The invention discloses a novel Al-Mg-Si alloy material high in strength and resistant to seawater corrosion and a preparation method thereof. By adoption of the alloy material, mutual contradiction between the corrosion resistance and the strength in the ship material designing process is effectively overcome. The alloy material comprises, by mass, 1.8-3.6 wt% of Mg, 1.6-3.3 wt% of Si, 0.45-0.65 wt% of Mn, 0.25-0.35 wt% of Cr, 0.15-0.3 wt% of Zr, 0.2-0.3 wt% of Ti, 0.2-0.5 wt% of Ag, no more than 0.03 wt% of each impurity, no more than 0.1 wt% of all impurities, and the balance Al. According to the novel Al-Mg-Si alloy material high in strength and resistant to seawater corrosion and the preparation method thereof, the multi-component composite micro-alloyed element design is adopted, and the smelting and casting technique, the rolling control method and the solution and aging heat treatment technique are optimized, so that the Al-Mg-Si alloy material which is accurate in component, reasonable in structure regulation and control, and excellent in comprehensive performance is prepared. The tensile strength of the obtained material is not smaller than 375 MPa, the ductility is not smaller than 12.0%, the intercrystalline corrosion resistance is the first level (according to GB / T 7998-2005), the maximum corrosion depth is 0.03 [mu]m, and the exfoliation corrosion resistance is the N level (according to GB / T 22639-2008).

Owner:CENT SOUTH UNIV

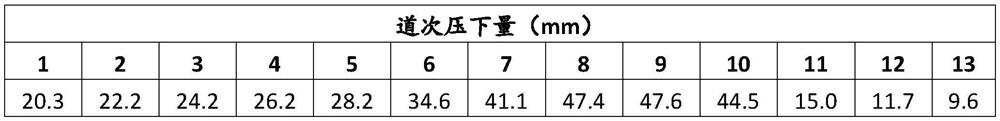

Preparation method of high-strength, high-toughness and corrosion-resistant 7055 aluminum alloy medium-thickness plate

The invention relates to a preparation method of a high-strength, high-toughness and corrosion-resistant 7055 aluminum alloy medium-thickness plate, and belongs to the field of aluminum alloy machining. The preparation method comprises the steps of material proportioning, smelting, casting, homogenizing, sawing and milling, preheating, hot rolling, solid solution quenching, pre-stretching and aging. According to the preparation method of the high-strength, high-toughness and corrosion-resistant 7055 aluminum alloy medium-thickness plate, parameters of various process steps are optimized, the Zn / Mg ratio and the Cu / Mg ratio are reasonably controlled, and a foundation is laid for obtaining a finished product with good performance; a two-stage homogenization system of 465 DEG C / (10-15) h + 475 DEG C / (20-25) h is adopted, an eutectic structure is eliminated on the premise of avoiding overburning of an aluminum alloy cast ingot, and a primary phase generated in the casting process is regulated and controlled; crystalline grains are completely crushed and refined by adopting a rolling mode with a large machining rate and a large rolling reduction in a middle pass; the initial rolling temperature and the final rolling temperature are accurately controlled, so that the recrystallization degree and the grain size of the plate are controlled, and then the strength, the fracture toughness and the exfoliation corrosion resistance of the plate are improved; and a three-stage aging system (100-110) DEG C / 24h + (175-185) DEG C / (30-120) min + 121 DEG C / 24h is adopted, so that the comprehensive performance of a finished product is improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Method for preparing III-V chemical compound electronic device

InactiveCN103258913AMeet thermal requirementsIntegrity guaranteedFinal product manufacturePhotovoltaic energy generationChemical compoundExfoliation corrosion

The invention discloses a method for preparing an III-V chemical compound electronic device. The method includes the steps that (1), a lining is provided; (2) a sacrificial layer is formed on the lining; (3) an active layer is formed on the sacrificial layer; (4) a backing layer is formed on the active layer. The backing layer comprises a metal layer adhered to the active layer and a heat-conductive backing layer pasted on the metal layer. When the thickness of the backing layer is insufficient so that the electronic device can not be supported independently, a first temporary transfer layer and a second temporary transfer layer can be utilized for transfer, and a heat-conductive supporting layer can be conveniently pasted on the heat-conductive backing layer to supply sufficient supporting force for the heat-conductive backing layer. When the thickness of the backing layer is sufficient, the electronic device can be supported independently and the backing layer is not exfoliation corrosion liquid resistant, a temporary protecting layer is pasted on the heat-conductive backing layer. After the sacrificial layer is removed through exfoliation corrosion liquid, a metal electrode is pasted on the active layer, and the temporary protecting layer is removed finally. By means of the method, the completeness of the electronic device is guaranteed, and meanwhile the electronic device of high heat dissipation performance is manufactured.

Owner:苏州强明光电有限公司

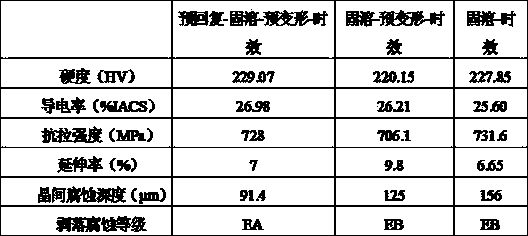

Method for enhancing anti-corrosion property of 700 MPa strength level high-alloying 7000 series aluminum alloy

The invention relates to a method for enhancing the anti-corrosion property of a 700 MPa strength level high-alloying 7000 series aluminum alloy. The method is characterized by comprising the following steps: previous recovery (250 DEG C*24h+300 DEG C*6h+350 DEG C*6h+400 DEG C*6h), solution treatment (450 DEG C*2h+460 DEG C*2h+470 DEG C*2h water quenching at room temperature after heat preservation), pre-deformation (2% plastic deformation) and aging (121 DEG C*24h). The method disclosed by the invention outstandingly enhances the intergranular corrosion resistant property and exfoliation corrosion resistant property of an alloy under the condition without lowering the strength of the alloy.

Owner:靖江新源电力器械有限公司

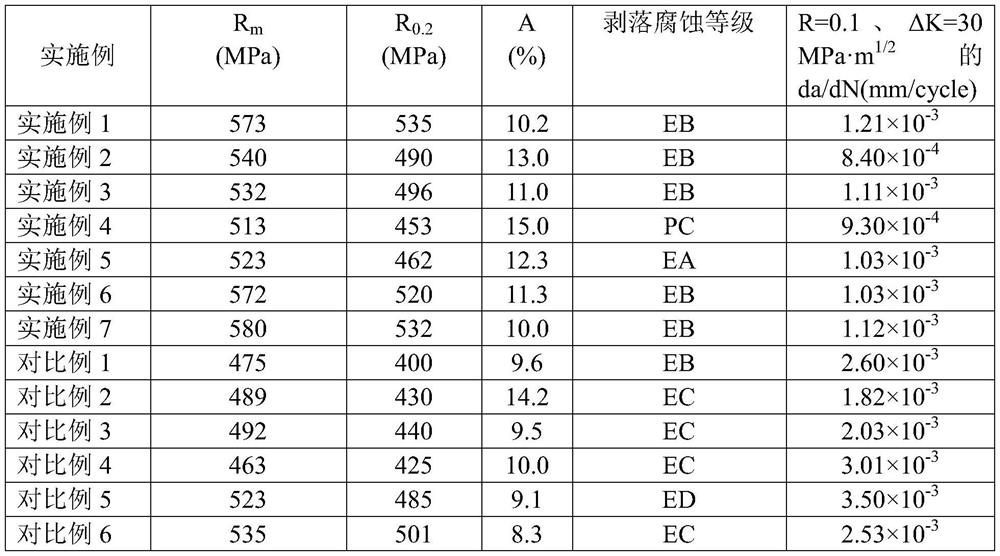

High-strength damage-resistant aluminum-lithium alloy and preparation method and application thereof

The invention discloses a high-strength damage-resistant aluminum lithium alloy and a preparation method and application thereof. The preparation method comprises the following steps of obtaining raw materials comprising the following elements in percentage, by mass, 0.7-1.2% of Li, 3.5-4.0% of Cu, 0.1-0.5% of Zn, 0.5-1.0% of Mg, 0.2-0.5% of Ag, 0.1-0.3% of Mn, 0.1-0.2% of Zr, less than or equal to 0.08% of Fe, less than or equal to 0.08% of Si and the balance of Al, the total amount of Cu and Li is 4.0-5.5%, and the mass ratio of Cu to Li is 2.9-5.0; and the high-strength damage-resistant aluminum-lithium alloy is obtained by smelting and casting raw materials into a cast ingot, annealing, hot rolling, intermediate annealing and cold rolling the cast ingot into a plate, and then carrying out solid solution quenching, pre-deformation and aging treatment to obtain the high-strength damage-resistant aluminum-lithium alloy. The prepared aluminum-lithium alloy and the thin plate thereof have the comprehensive mechanical properties of low density, high room temperature strength, low fatigue crack propagation rate, exfoliation corrosion resistance and the like.

Owner:CENT SOUTH UNIV

Alloy aluminum rod containing rare earth elements and preparation process thereof

ActiveCN110218917AImprove antioxidant capacityImprove ductilityRare-earth elementExfoliation corrosion

The invention discloses an alloy aluminum rod containing rare earth elements and a preparation process thereof, and belongs to the field of preparation of aluminum alloy materials. The alloy aluminumrod comprises the following components of, in percentage by weight, 1.5%-3.3% of Mg, 0.7%-1.1% of Si, 1.0%-1.7% of Cu, 0.04%-0.1% of Fe, 0.35%-0.7% of Mn, 0.2%-0.6% of Ni, 0.07 %-0.12% of Ti, 0.15%-0.3% of Y, 0.07%-0.1% of Er, 0.05%-0.11% of Gd, 0.07%-0.24% of La, not more than 0.5% of impurity elements of other metals and nonmetals, and the balance Al. The alloy aluminum rod is prepared through the steps of melting, alloying, refining, ingot casting, homogenization treatment, extrusion molding and the like. By adding the rare earth elements, the dendritic crystal web cell structure can be refined, iron with needle-like structure in aluminum liquid can be transformed into particles, so that the corrosion resistance and mechanical properties of the aluminum rod are improved and the surfaceroughness of aluminum alloy parts prepared by the aluminum rod are reduced. The alloy aluminum rod prepared by the method has high strength, high plasticity, excellent corrosion resistance, no tendency of exfoliation corrosion, stress corrosion and intergranular corrosion, good processing and welding performance, is suitable for manufacturing automobile parts, and has excellent industrial application value.

Owner:广西平果铝合金精密铸件有限公司

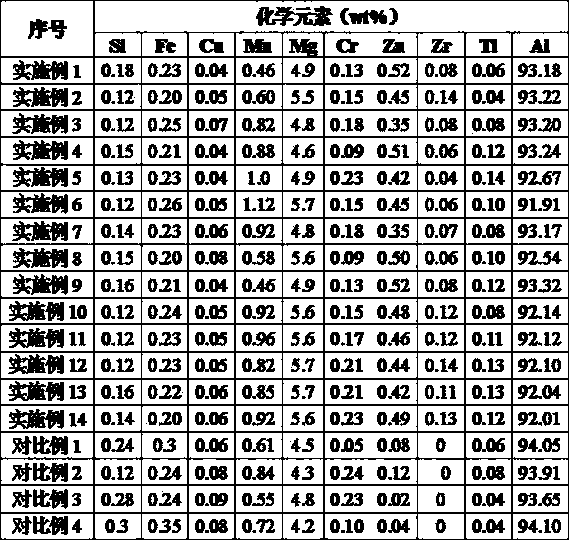

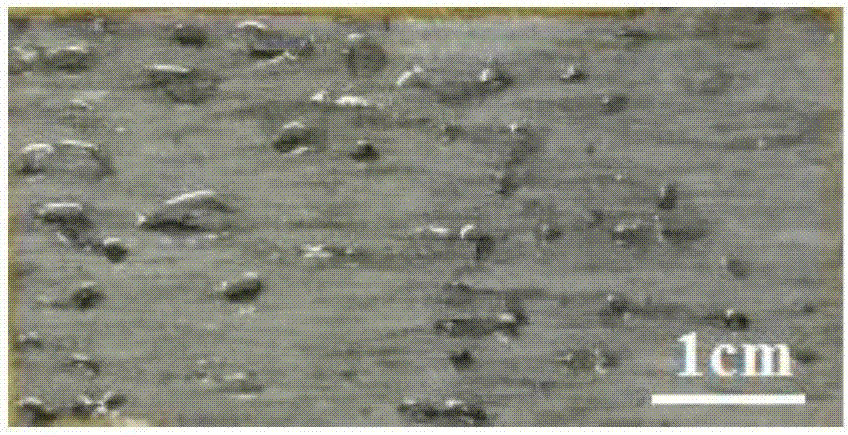

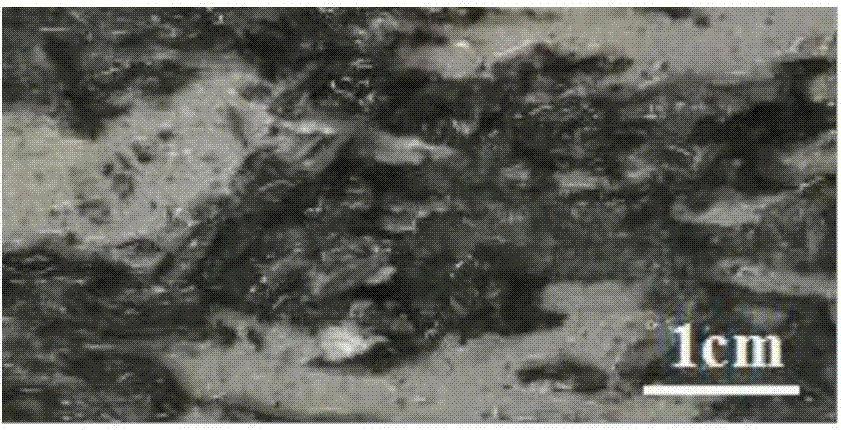

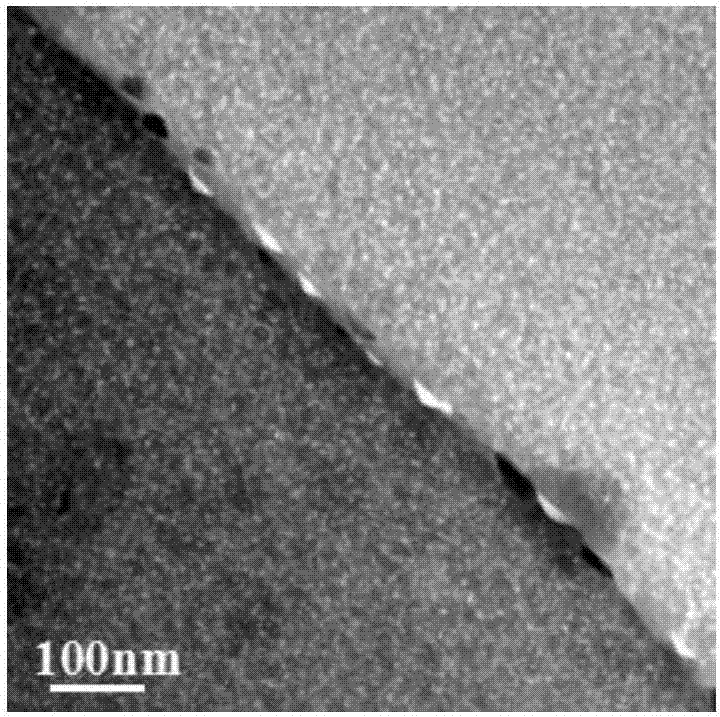

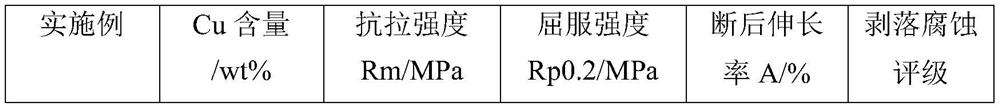

Cu-containing high-strength corrosion-resistant Al-Mg-Si alloy and preparation method thereof

The invention discloses a Cu-containing high-strength corrosion-resistant Al-Mg-Si alloy and a preparation method thereof, and belongs to the technical field of non-ferrous metal alloys. The alloy comprises the following chemical element components: 0.8 wt%-1.2 wt% of Mg; si, 1.2 wt% to 1.6 wt%; 0.05 wt% to 0.6 wt% of Cu; mn, 0.2 wt% to 0.6 wt%; 0.01 wt% to 0.2 wt% of Er; the aluminum alloy comprises, by weight, 0.01%-0.2% of Zr and the balance Al. A casting method is adopted to obtain a cast ingot, the cast ingot is subjected to two-stage homogenization heat treatment, and the first stage is kept at 300 + / -10 DEG C for 10 h; at the second stage, heat preservation is conducted for 12 h at the temperature of 535 + / -20 DEG C, hot rolling is conducted, and the deformation And then solid solution aging treatment is carried out, and the aged alloy is subjected to a tensile test and an exfoliation corrosion test. The obtained alloy has high strength and excellent corrosion resistance.

Owner:BEIJING UNIV OF TECH

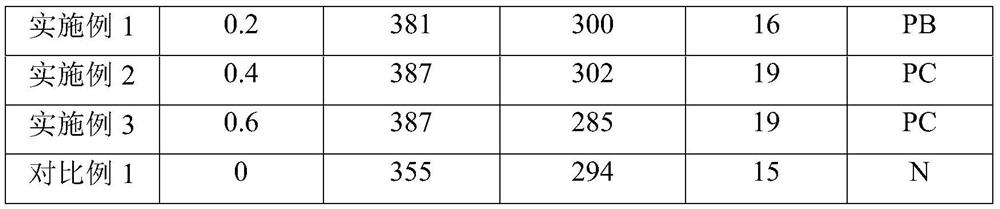

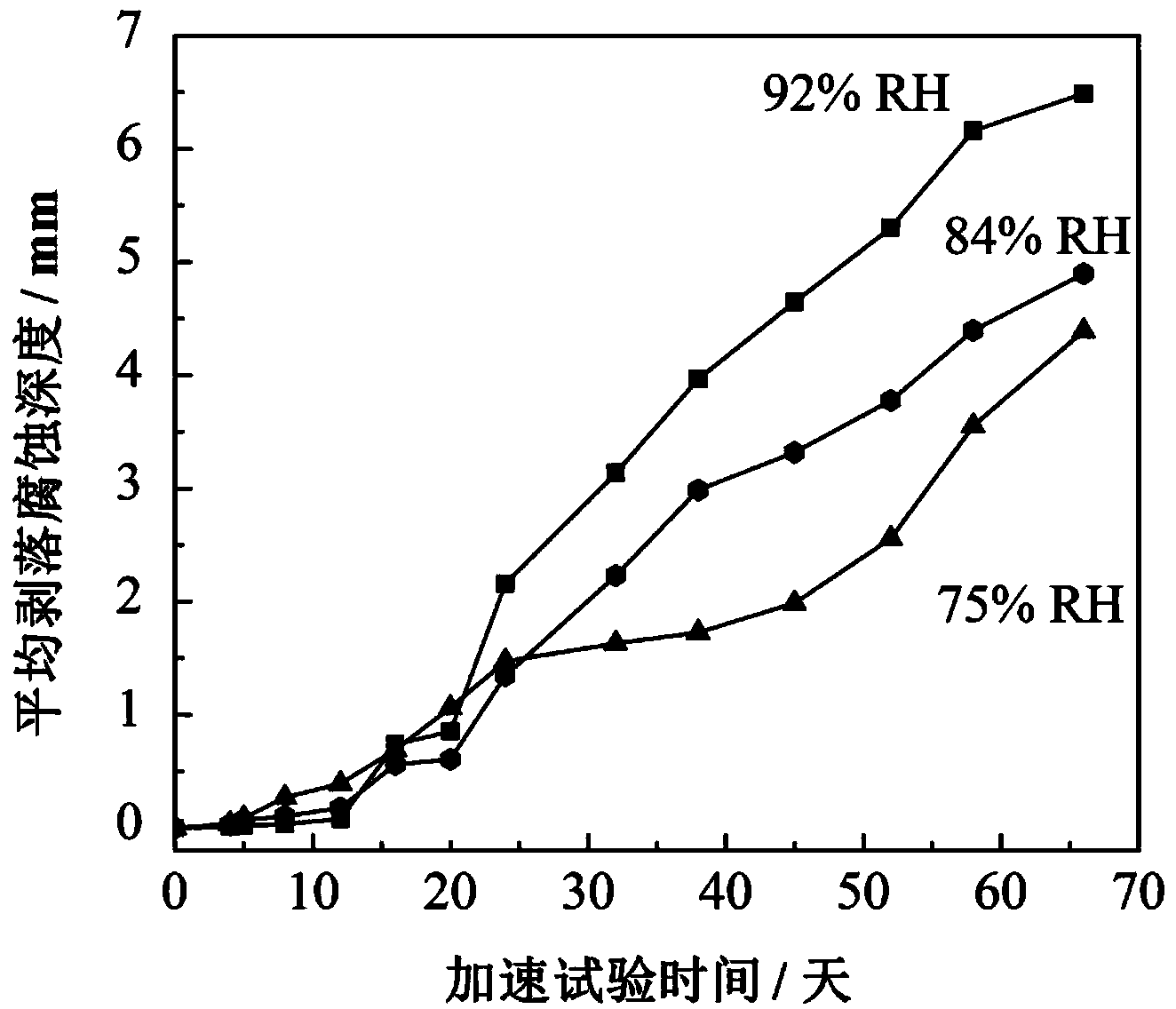

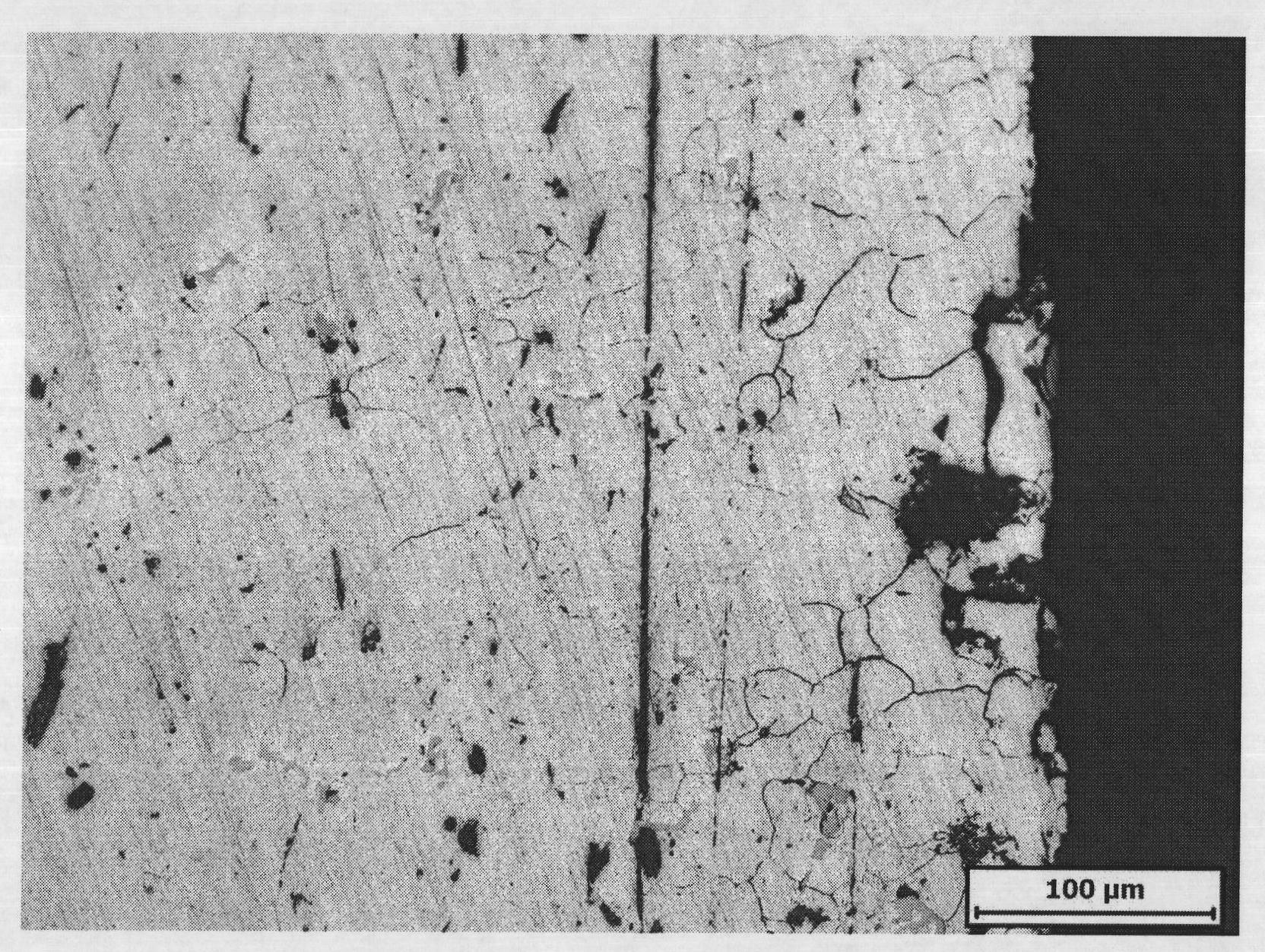

Denudation rapid testing method for simulating high-strength aluminum alloy in ocean atmospheric environment

InactiveCN103900947AGuaranteed simulation effectGuaranteed reproducibilityWeather/light/corrosion resistanceElectricityTest sample

The invention discloses a denudation rapid testing method for simulating a high-strength aluminum alloy in an ocean atmospheric environment and belongs to the technical field of simulation of exfoliation corrosion of the high-strength aluminum alloy. The denudation rapid testing method comprises the following steps: pre-treating a test sample; putting the pre-treated test sample into an electrolyte solution to carry out constant-current pre-polarization; after the polarization, carrying out ultrasonic cleaning; putting the test sample subjected to the ultrasonic cleaning into an immersion solution and immersing for a period of time; then putting the test sample into the environment with relative humidity and temperature and carrying out an analysis on the exfoliation corrosion depth; selecting constant-current polarization time, the content of NaCl in the immersion solution, the constant temperature and the relative humidity to simulate an exfoliation corrosion process of the high-strength aluminum alloy in the ocean atmospheric environment, and researching exfoliation corrosion laws and mechanisms of the high-strength aluminum alloy under the effects of different ocean atmospheric environment factors. The method disclosed by the invention can be used for researching exfoliation corrosion behaviors and laws of the high-strength aluminum alloy under the effects of the different ocean atmospheric environment factors.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

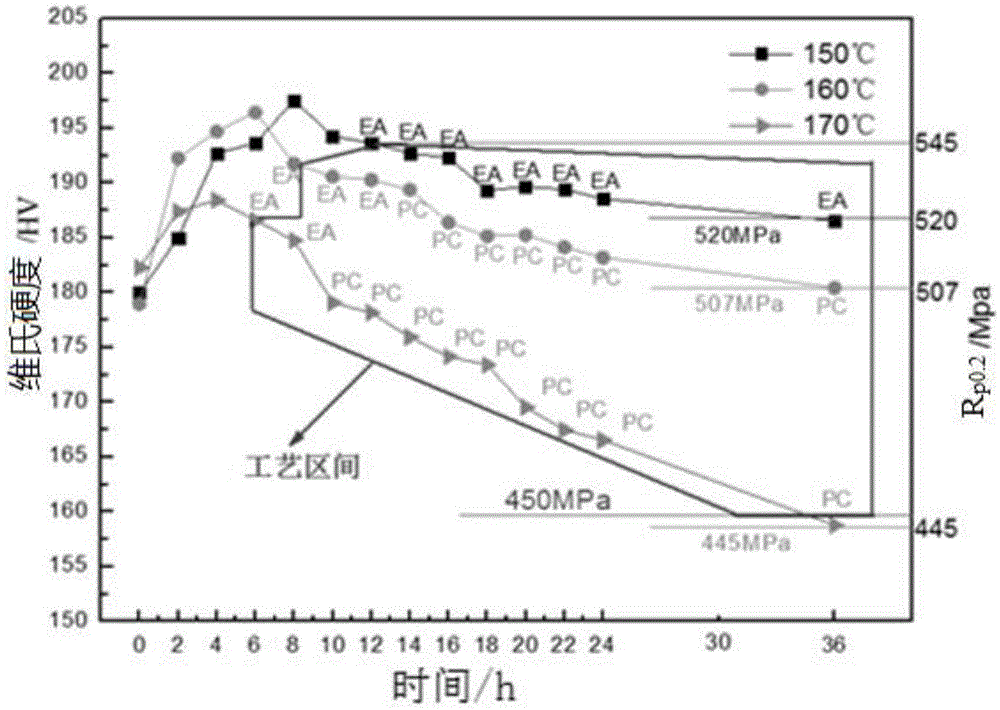

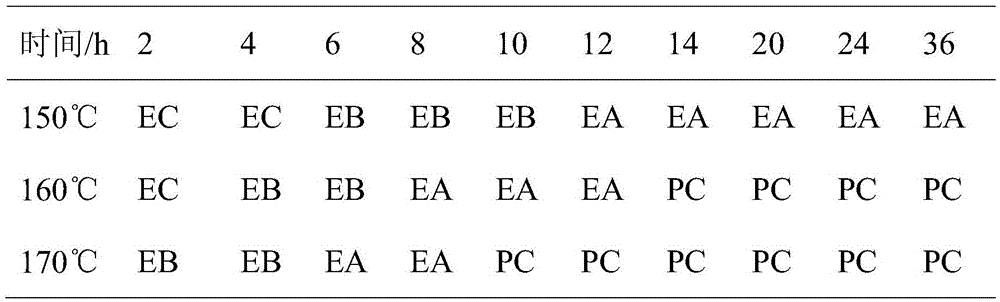

Two-stage aging process of Al-5.6Zn-2.1Mg-1.2Cu-0.1Zr-0.1Er alloy

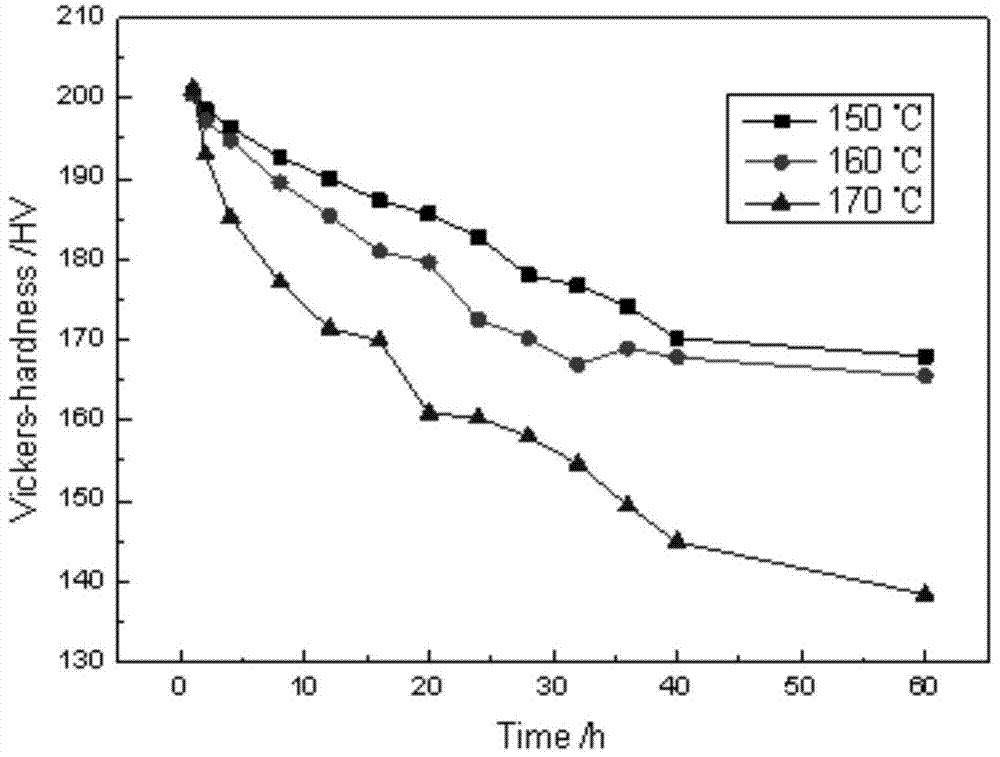

The invention discloses a two-stage aging process of an Al-5.6Zn-2.1Mg-1.2Cu-0.1Zr-0.1Er alloy and belongs to the technical field of nonferrous metals. The two-stage aging process comprises the following specific process steps of firstly, performing solution treatment on the alloy, improving the temperature from room temperature to 475DEG C at the speed of 2DEG C / min, insulating for 2h and performing water cooling and quenching at the room temperature; secondly, performing low-speed temperature-rise two-stage aging heat treatment: for the first-stage aging, improving the temperature from the room temperature to 120DEG C at the speed of 1DEG C / min and insulating for 5h; for the second-stage aging, improving the temperature from 120DEG C to the second-stage aging temperature at the speed of 1DEG C / min; and for a second-stage aging system, insulating at 150DEG C for 12-36h, insulating at 160DEG C for 8-36h or insulating at 170DEG C for 6-34h. According to the two-stage aging process disclosed by the invention, the yield strength of about 450-545MPa can be obtained, a Vickers hardness value is about 160-193HV; and comprehensive performance of an alloy of which the exfoliation corrosion resistance is EV grade or above is improved.

Owner:BEIJING UNIV OF TECH

Zirconium-micro-alloyed 6013 type aluminium alloy and preparation method thereof

The invention discloses a zirconium-micro-alloyed 6013 type aluminium alloy mainly comprising aluminium (Al), magnesium (Mg), silicon (Si), copper (Cu), manganese (Mn), zinc (Zn), ferrum (Fe) and zirconium (Zr). The preparation method of the alloy comprises the following steps of: firstly, sequentially adding Al-Cu intermediate alloy, Al-Si intermediate alloy, Al-Mn intermediate alloy, Al-Zr intermediate alloy, pure Zn and pure Mg after melting pure Al, adding hexachloroethane for refining after melting the mixture, and then deslagging and casting into ingots after standing and preserving heat for 5-10 min; and secondly, carrying out back annealing, forging and pressing and the aftertreatment of solid solution aging treatment on the alloy cast into the ingots. The hardness of the alloy can achieve 149.5-152.0 HV, the intercrystalline corrosion resistance of the alloy is not lower than the fourth level through determining according to the national standard GB / T 7998-2005 (method for determining the intercrystalline corrosion of the aluminium alloy), the exfoliation corrosion resistance of the alloy is in the PB level through determining according to the national standard GB / T 22639-2008 (an exfoliation corrosion test method of an aluminium alloy processing product), and the aluminium alloy can be widely applied to the fields of modern aerospace, weaponry and the like and has wide application prospect.

Owner:JIANGSU UNIV

High-hardness corrosion resistant 7000 series aluminum alloy and production method thereof

The invention relates to high-hardness corrosion resistant 7000 series aluminum alloy and a production method thereof. The high hardness corrosion resistant 7000 series aluminum alloy is characterized by mainly comprising Al, Zn, Mg, Cu, Zr, Sr and Sc, wherein the mass percentage of Zn is 7.95-8.34%, Mg is 1.80-1.89%, Cu is 1.59-1.83%, Zr is 0.148-0.151%, Sr is 0.0237-0.599%, Sc is 0.015-0.103%, and the balance is aluminum and a trace amount of impurity elements. The production method of the aluminum alloy comprises the following steps of melting pure Al, sequentially adding Al-Cu master alloy, Al-Sr master alloy, Al-Zr master alloy, Al-Sc master alloy, pure Zn and pure Mg, adding hexachloroethane for refining after melting of the above metal, standing and preserving heat for 5-10 minutes and then casting ingots; and then annealing, forging and carrying out post treatment of solution and aging treatment. The hardness of the alloy can reach up to 210.1-212.2HV, the surfaces thereof only have slight pitting corrosion and stay in PA level by performing corrosion according to the national standard GB / T 22639-2008 (Test method of exfoliation corrosion for wrought aluminium and aluminium alloys).

Owner:JIANGSU UNIV

Two-stage aging technology of exfoliation corrosion resistant erbium-containing Al-Zn-Mg-Cu alloy

ActiveCN103898423AExcellent resistance to exfoliation corrosionHigh strengthSolution treatmentWater cooling

A two-stage aging technology of exfoliation corrosion resistant erbium-containing Al-Zn-Mg-Cu alloy belongs to the technical field of non-ferrous metals. The invention aims at providing the two-stage aging technology suitable for an erbium-containing Al-Zn-Mg-Cu alloy extrusion sheet material so as to solve the problem of poor exfoliation corrosion resistance. The two-stage aging technology comprises the following steps: carrying out solution treatment on the alloy at the temperature of 470 DEG C for 2 hours, carrying out water cooling and quenching; then carrying out aging thermal treatment at the temperature of 120 DEG C for 4 hours and at the temperature of 150-170 DEG C for 1-60 hours, and preferably selecting 120DEG C / 4h and 160 DEG C / (8-16) / h as a two-stage aging system. The two-stage aging technology can be used for ensuring that the alloy has relatively high strength and good exfoliation corrosion resistance.

Owner:BEIJING UNIV OF TECH

Casting process of aluminum alloy ingots for ships and warships

The invention discloses a casting process of aluminum alloy ingots for ships and warships. The process comprises the following steps that A, alloys are smelted to obtain aluminum alloy melts; B, the aluminum alloy melts are subjected to counter gravity casting, and the aluminum alloy ingots are obtained; and C, the obtained aluminum alloy ingots are sequentially subjected to homogenization, solidsolution treatment and aging treatment, and the aluminum alloy ingots for the ships and warships are obtained. The process can obtain the aluminum alloys with the excellent comprehensive properties like tensile strength, yield strength, ductility and exfoliating corrosion resistance, solves the problems that when existing aluminum alloys are applied on ships, the aluminum alloys are poor in corrosion resistance and low in intensity, and accordingly prolonging the service life of the ships in complex and atrocious environments of the ocean.

Owner:CENT SOUTH UNIV

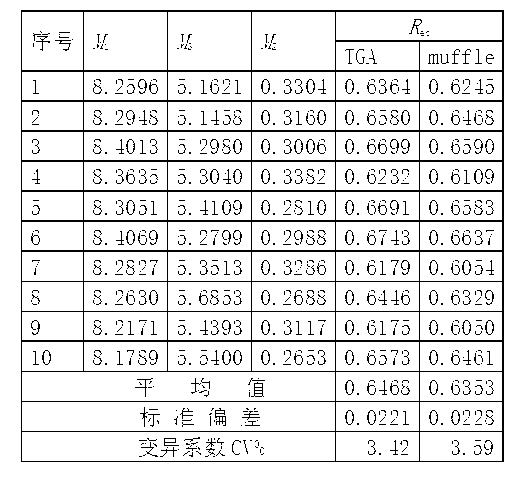

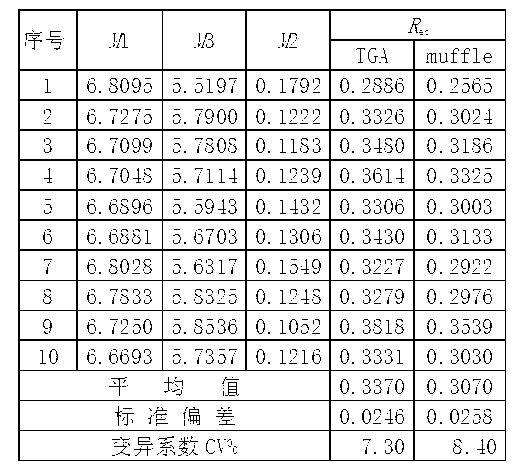

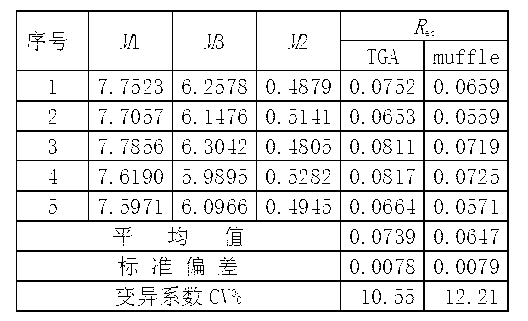

Determination method for ablation residue ratio of heat-insulating material

InactiveCN103207128AMeet the testing requirementsThe experimental method is simpleWeighing by removing componentThermal insulationEngineering

The invention relates to a detection method for thermal insulation performance of a rubber heat-insulating material used in the fields of guided missiles and spaceflight, i.e., a determination method for an ablation residue ratio of the heat-insulating material. The determination method comprises the following four steps: making and pretreatment of a to-be-tested member and marking of initial mass; determination and marking of a carbon residue ratio of a film; formation of a to-be-tested ablation member and marking of mass after ablation; and determination of an ablation residue ratio. Through the four steps, determination of the ablation residue ratio of the rubber heat-insulating material is realized; the method can reliably evaluate a residue amount consumed in scouring and exfoliation corrosion by high-temperature high-speed gas flow during the ablation process of the ablation member, greatly guarantees validity, safety and reliability of the heat-insulating material and has the advantages of easiness, accurate detection data, high control stability and good test repeatability.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

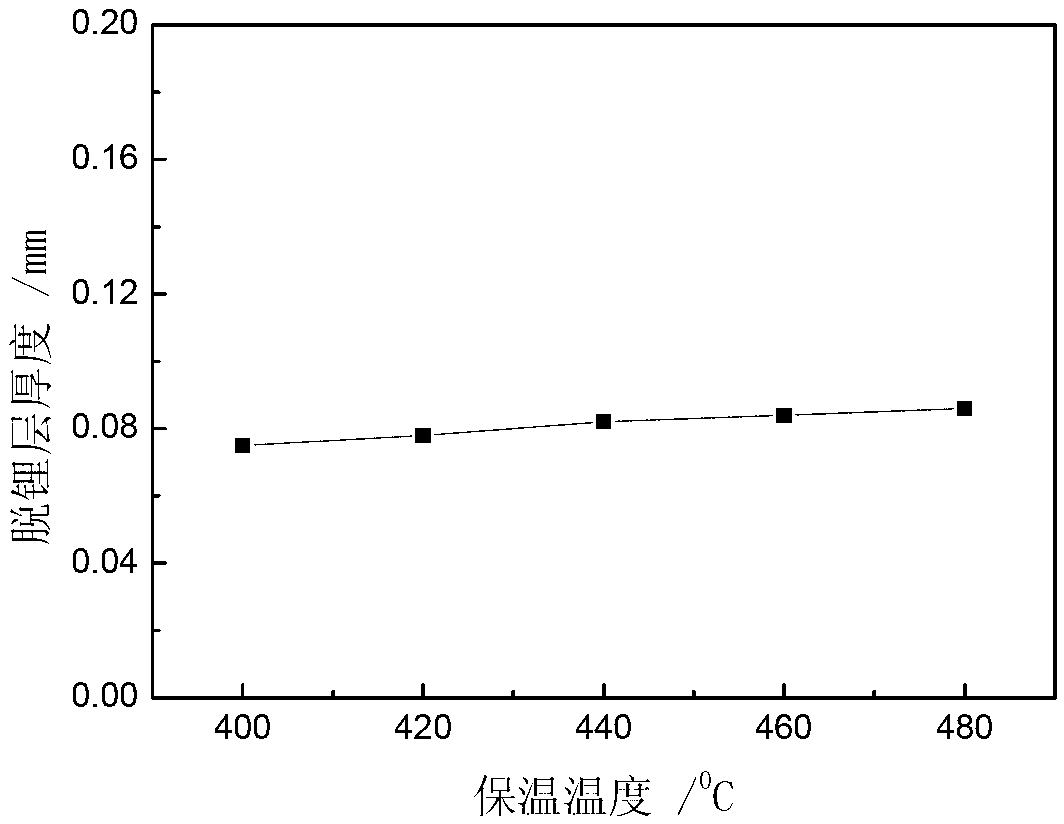

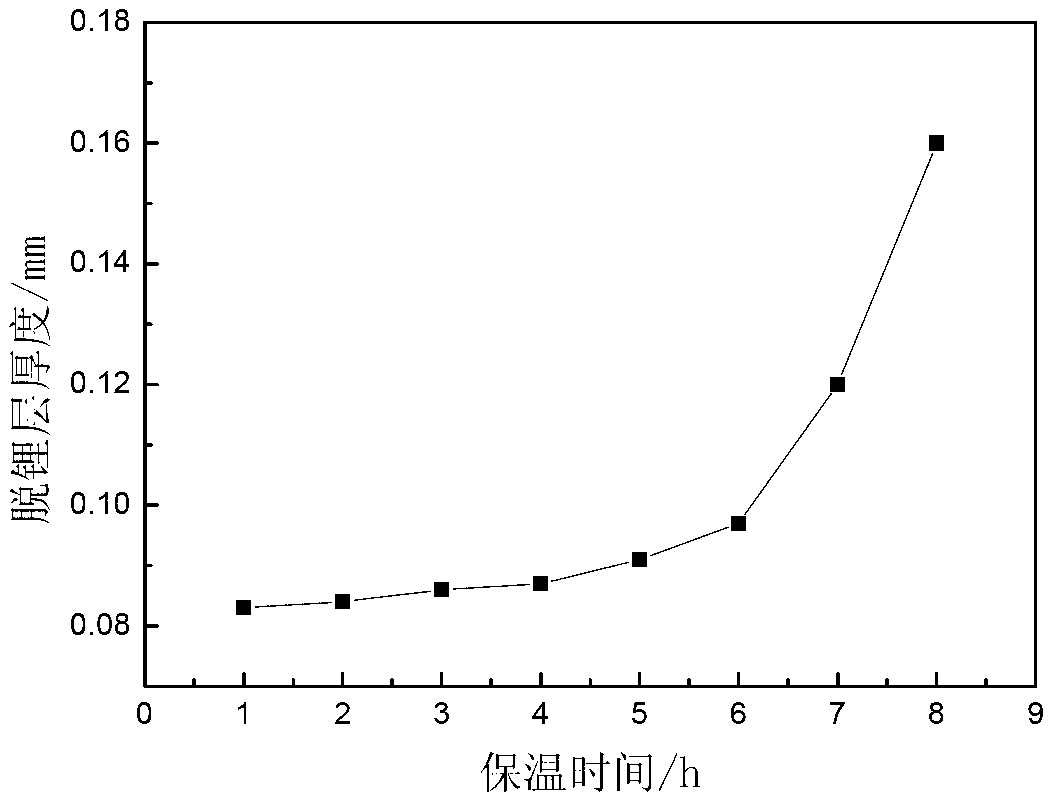

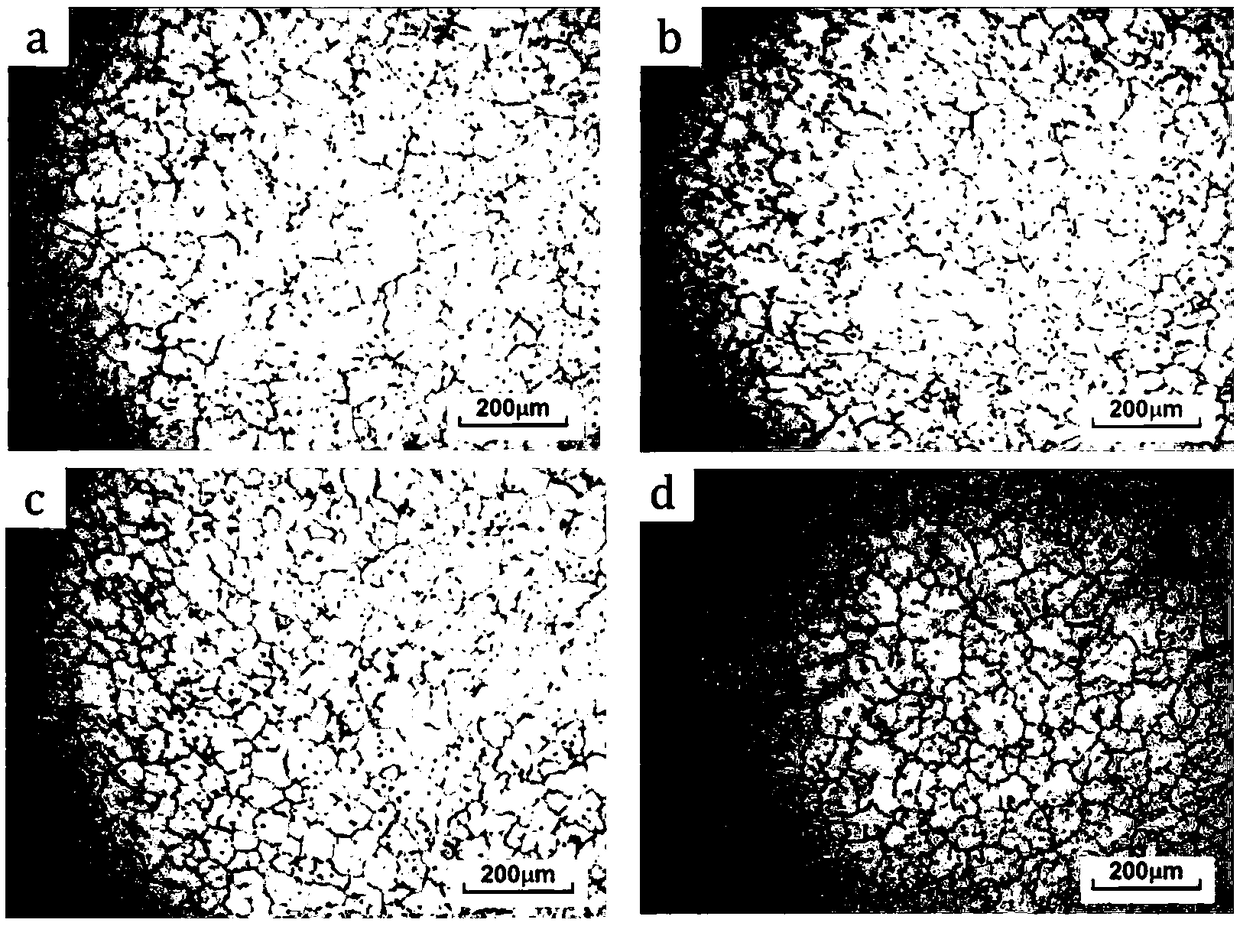

Preparation method of surface deintercalation layer of Al-Cu-Li-X aluminium-lithium alloy

ActiveCN103173700AImprove corrosion resistanceEliminate intergranular corrosionSolution treatmentLithium

The invention discloses a preparation method of a surface deintercalation layer of an Al-Cu-Li-X aluminium-lithium alloy. According to the method, by using a principle that lithium elements on the near-surface layer of the aluminium-lithium alloy are diffused to the surface of the alloy to carry out oxidization in the process of high-temperature heating, and a uniform deintercalation layer is formed on the near-surface layer of the alloy through controlling the heating temperature and the heat preservation time, so that the intergranular corrosion and the occurrence of exfoliation corrosion are effectively inhibited on the premise of not affecting the mechanical properties; and the method is also a necessary process of surface aluminium-clad rolling for aluminium alloys. The method comprises the steps of low-temperature long-period heat-preservation deintercalation treatment; and high-temperature solution treatment. An applicable aluminium-lithium alloy disclosed by the invention comprises the following components by weight percent: 2.0-5.0% of Cu, 0.8-2.5% of Li, 0.20-0.60% of Mn, 0.20-0.80% of Zn, 0.04-0.20% of Zr, 0.20-0.80% of Mg, 0.1-0.7% of Ag, less than or equal to 0.10% of Si, less than or equal to 0.10% of Fe, less than or equal to 0.12% of Ti, less than or equal to 0.05% of other single impurities, less than or equal to 0.15% of total impurities, and the balance of Al. According to the method, the corrosion resistance of Al-Cu-Li-X series alloys can be significantly improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Alloy steel material for engine piston

The invention discloses an alloy steel material for an engine piston. The elements are: carbon: 0.5-0.8%, silicon: 1.3-1.8%, manganese: 1.2-1.5%, magnesium: 0.001-0.03%, nickel: 0.05‑0.07, vanadium: 0.02‑0.05%, neodymium: 0.07‑0.11%, aluminum: 0.003‑0.05%, barium 0.001‑0.02%, zirconium: 0.4‑0.5%, sulfur ≤0.015%, phosphorus ≤0.015%, balance Iron and unavoidable impurities; the steel of the invention has excellent stress corrosion resistance and spalling corrosion fatigue resistance, reduces fatigue crack growth rate, and makes the steel suitable for industrial application of auto parts.

Owner:ANHUI HEKUANG MACHINERY

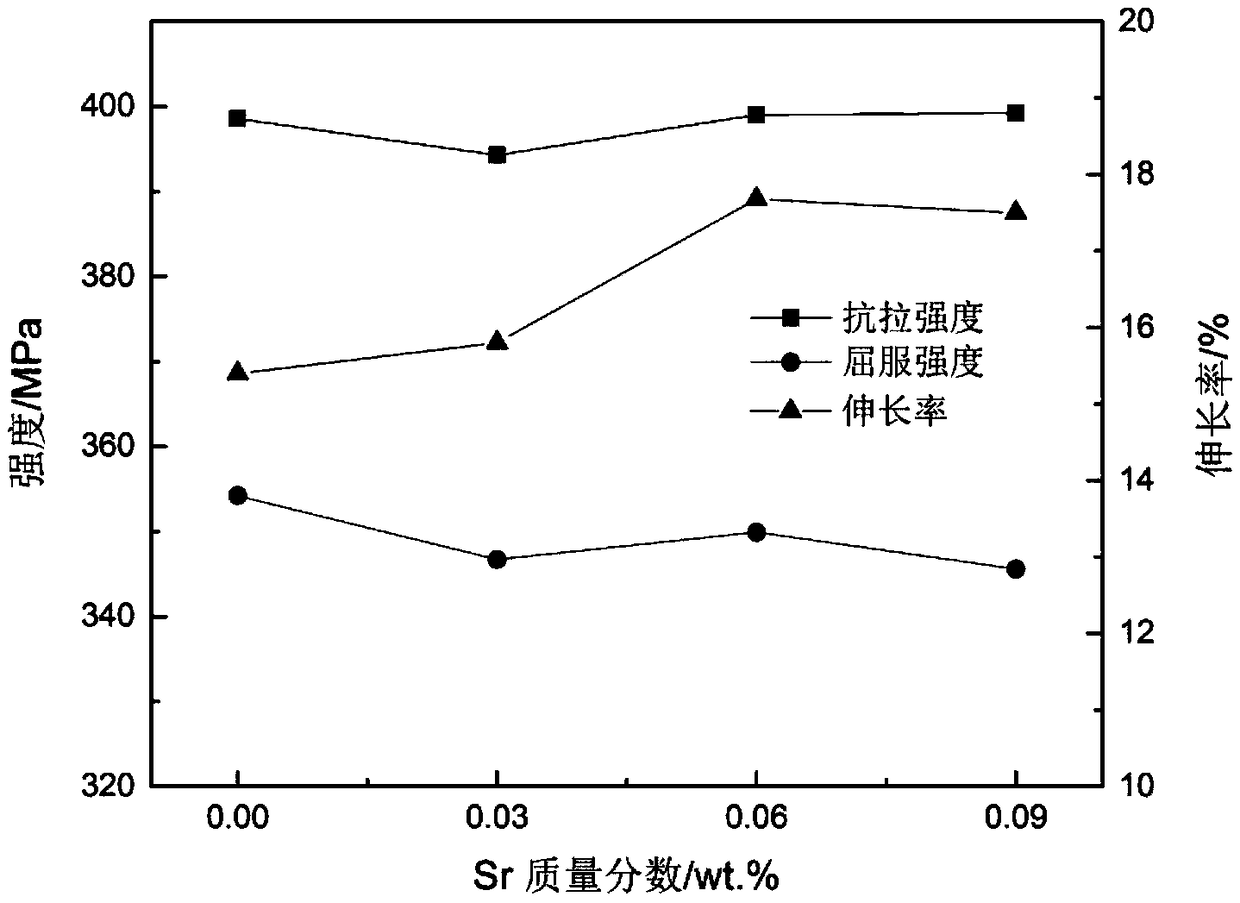

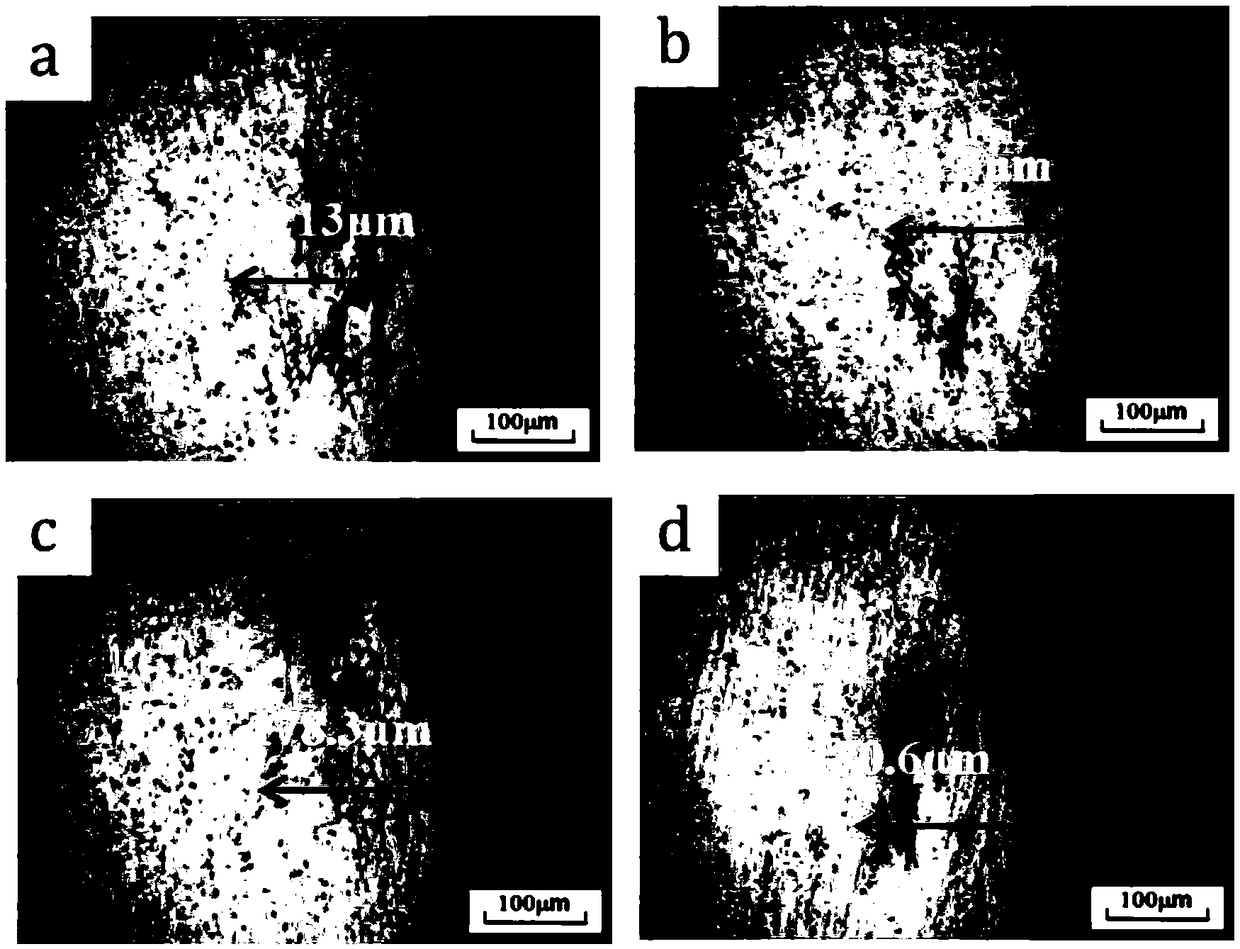

Al-Mg-Si-Cu-Mn-Sr alloy with excellent corrosion resistance and preparation method thereof

InactiveCN108913956AImprove corrosion resistanceImprove mechanical propertiesAlkaline earth metalSmelting process

The invention discloses an Al-Mg-Si-Cu-Mn-Sr alloy with excellent corrosion resistance. The alloy contains alkaline-earth metal Sr with the mass percentage of 0.06-0.09%. The element Sr is added in the Al-Mg-Si-Cu-Mn-Sr alloy; the contents of the other alloy elements are reasonably designed; a reasonable smelting process and a quick solidification technology are adopted; and repeated rolling and proper heat treatment are performed to prepare an Al-Mg-Si-Cu-Mn-Sr alloy material with uniform microscopic structures and fine grains; the obtained alloy material is better in mechanical performance and corrosion resistance; the tensile omega b is not less than 395 Mpa; the ductility delta is not less than 17%; the exfoliation corrosion resisting grade is PC grade; the maximum intergranular corrosion depth is not more than 180 microns; and the alloy is simple in process, low in cost and excellent in comprehensive performance.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com