High-strength damage-resistant aluminum-lithium alloy and preparation method and application thereof

An aluminum-lithium alloy and damage-resistant technology, applied in the field of high-strength damage-resistant aluminum-lithium alloy and its preparation, can solve the problems of low yield strength, low density, high density, etc., and achieve high room temperature strength, low density, low fatigue crack The effect of the expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

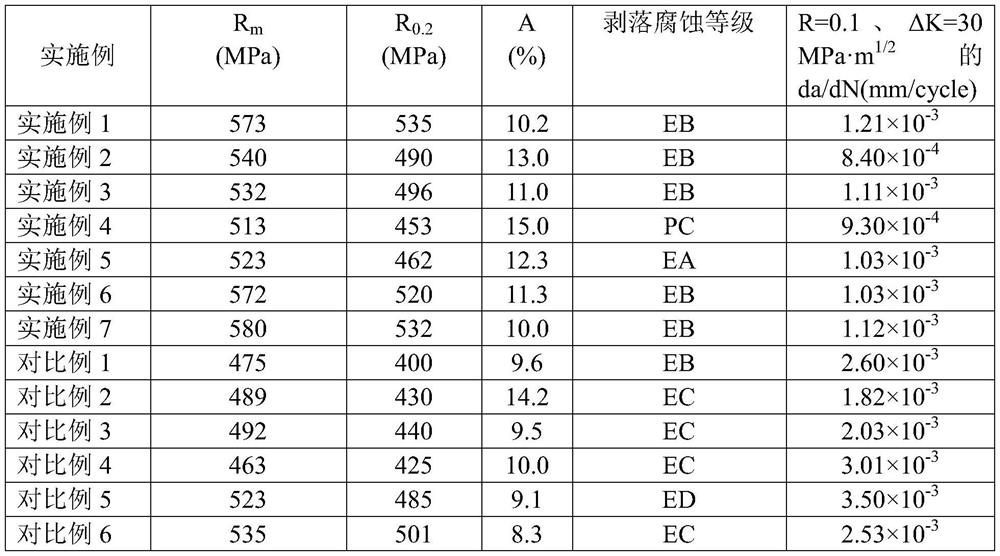

Examples

preparation example Construction

[0040] In some embodiments, the method for preparing a high-strength and damage-resistant aluminum-lithium alloy sheet includes the following steps: melting and casting into an ingot according to the designed ratio of aluminum-lithium alloy elements, and then annealing the ingot, hot rolling, Intermediate annealing, cold rolling into plates, and then solution quenching, pre-deformation, and aging treatment to obtain the final thin plates.

[0041] Preferably, the cast aluminum-lithium alloy ingot is subjected to three-stage annealing treatment, and the annealing process is (300-400)°C×(2-8)h+(400-460)°C×(2-10)h+(480-500 )°C×(20~30)h. More preferably, the annealing process is (350-380)°C×(3-5)h+(430-450)°C×(4-6)h+(490-500)°C×(20-24)h. The purpose of three-stage annealing with increasing temperature in sequence is to gradually dissolve non-equilibrium solidified phases with different melting points in the ingot during the heating process, thereby reducing the occurrence of over...

Embodiment 1

[0049] The composition and weight percentage of the alloy are 3.5% Cu-1.2% Li-0.5% Mg-0.3% Ag-0.1% Zn-0.1% Zr-0.3% Mn, the total amount of Cu and Li is 4.7%, the mass of Cu and Li Ratio 2.9, impurity Fe 0.08%, Si 0.08%, balance Al. Raw materials are added in the form of pure aluminum, pure lithium, pure magnesium, pure silver, pure zinc, Al-10Mn, Al-4Zr alloy, Al-50Cu alloy, etc. Alloy melting is melted and casted in a vacuum melting furnace. The ingot was annealed in three stages at 300°C×8h+450°C×4h+480°C×30h. The surface of the annealed ingot is machined to the slab. The slab is kept at 430°C for 4 hours, after hot rolling (the deformation does not exceed 30%), it is placed in a furnace at 430°C for 1 hour, and hot rolling is continued. After multiple passes of hot rolling, it becomes a 6mm plate. ℃ annealing for 5h, and then cold rolled into a 2mm thin plate. The thin plate is solidified at 530°C for 2h, water quenched to room temperature, pre-deformed by 3%, and then ...

Embodiment 2

[0051] The composition and weight percentage of the alloy are 3.9% Cu-1.1% Li-0.76% Mg-0.3% Ag-0.34% Zn-0.1% Zr-0.27% Mn, the total amount of Cu and Li is 5.0%, the mass of Cu and Li Ratio 3.5, impurity Fe 0.05%, Si 0.05%, balance Al. Raw materials are added in the form of pure aluminum, pure lithium, pure magnesium, pure silver, pure zinc, Al-10Mn, Al-4Zr alloy, Al-50Cu alloy, etc. Alloy melting is melted and casted in a vacuum melting furnace. The ingot was annealed three-stage at 350°C×5h+430°C×6h+500°C×24h. The surface of the annealed ingot is machined to the slab. The slab is kept at 450°C for 5 hours, after hot rolling (the deformation does not exceed 30%), it is placed in a furnace at 450°C for 1 hour, and hot rolling is continued until it is rolled into a 6mm plate after multiple passes of hot rolling. The hot-rolled sheet was annealed at 400°C for 3h, and then cold-rolled into a 2mm thin sheet. The thin plate was solidified at 510°C for 3h, water quenched to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com