Patents

Literature

328 results about "Aluminium-lithium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

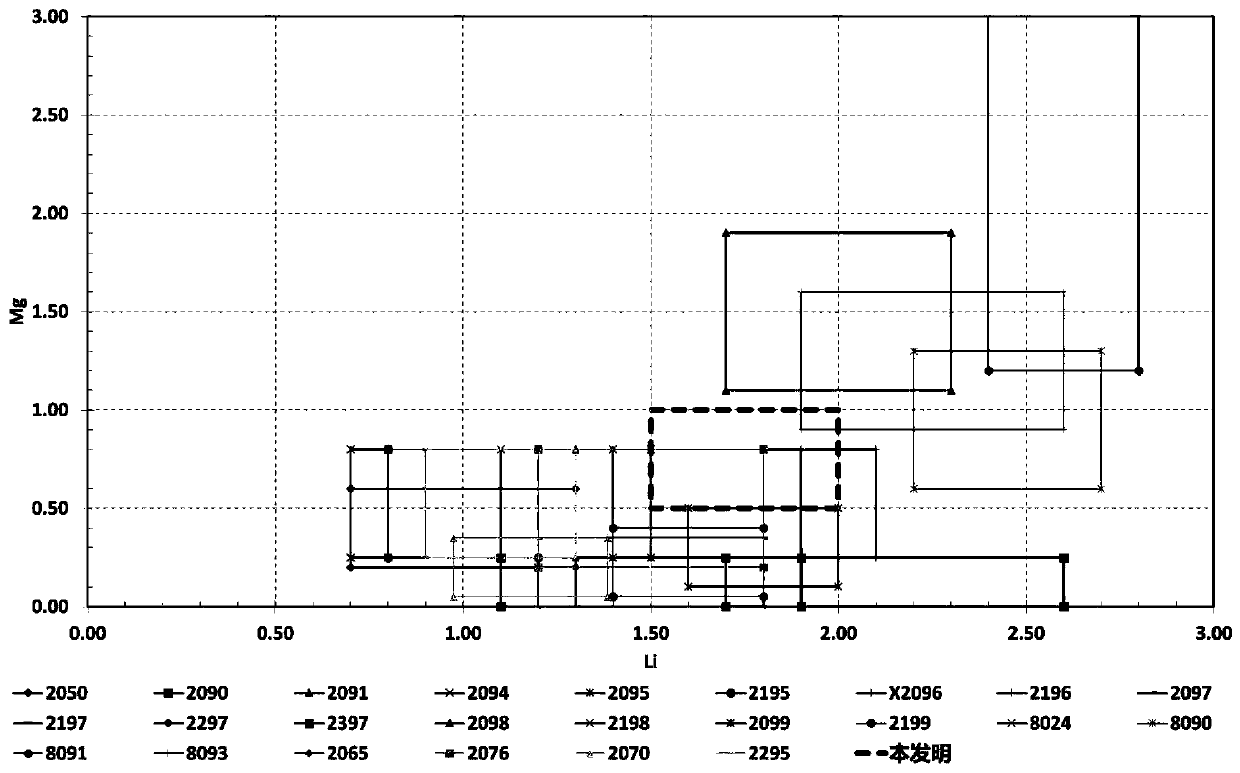

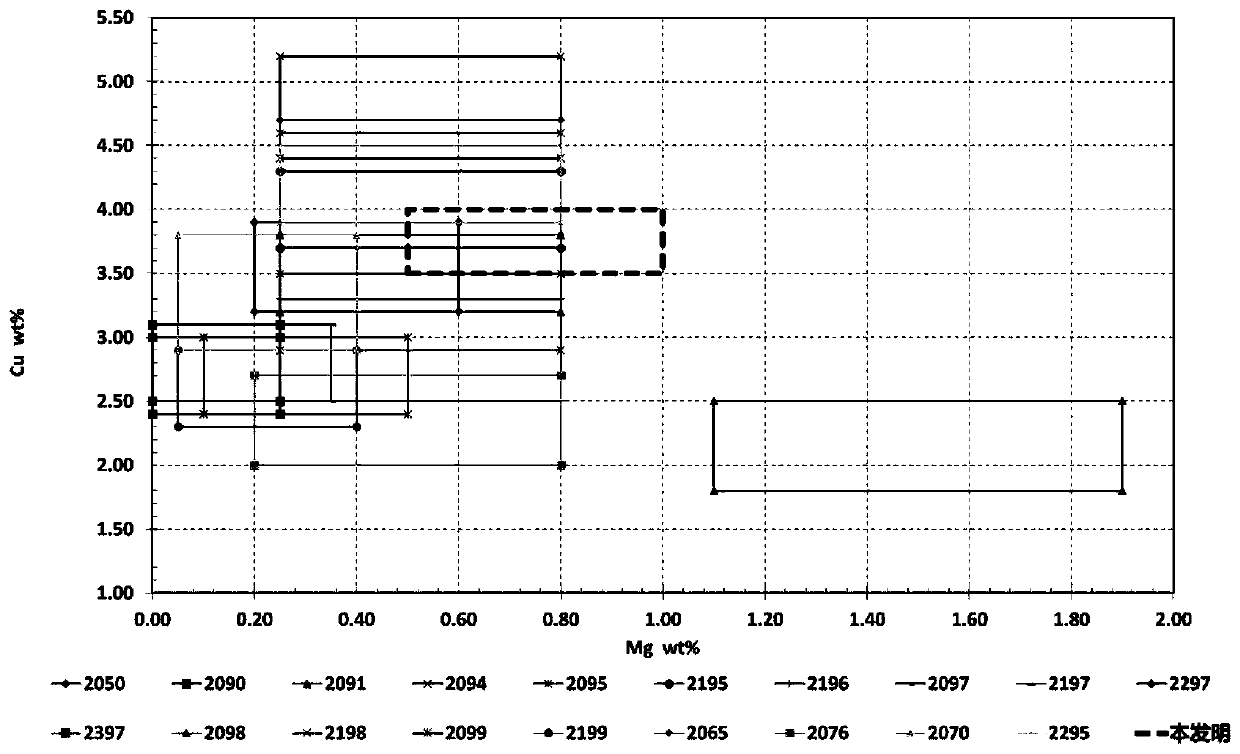

Aluminium–lithium alloys (Al–Li) are a set of alloys of aluminium and lithium, often also including copper and zirconium. Since lithium is the least dense elemental metal, these alloys are significantly less dense than aluminium. Commercial Al–Li alloys contain up to 2.45% by mass of lithium.

Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

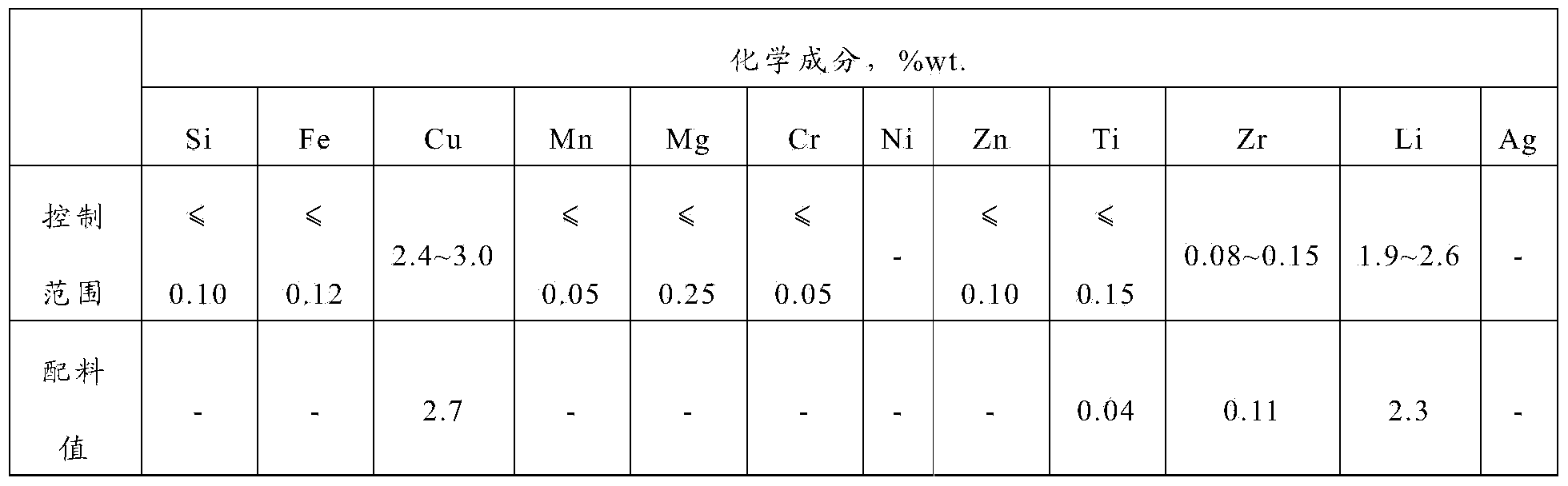

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

High-toughness aluminum lithium alloy and preparation method thereof

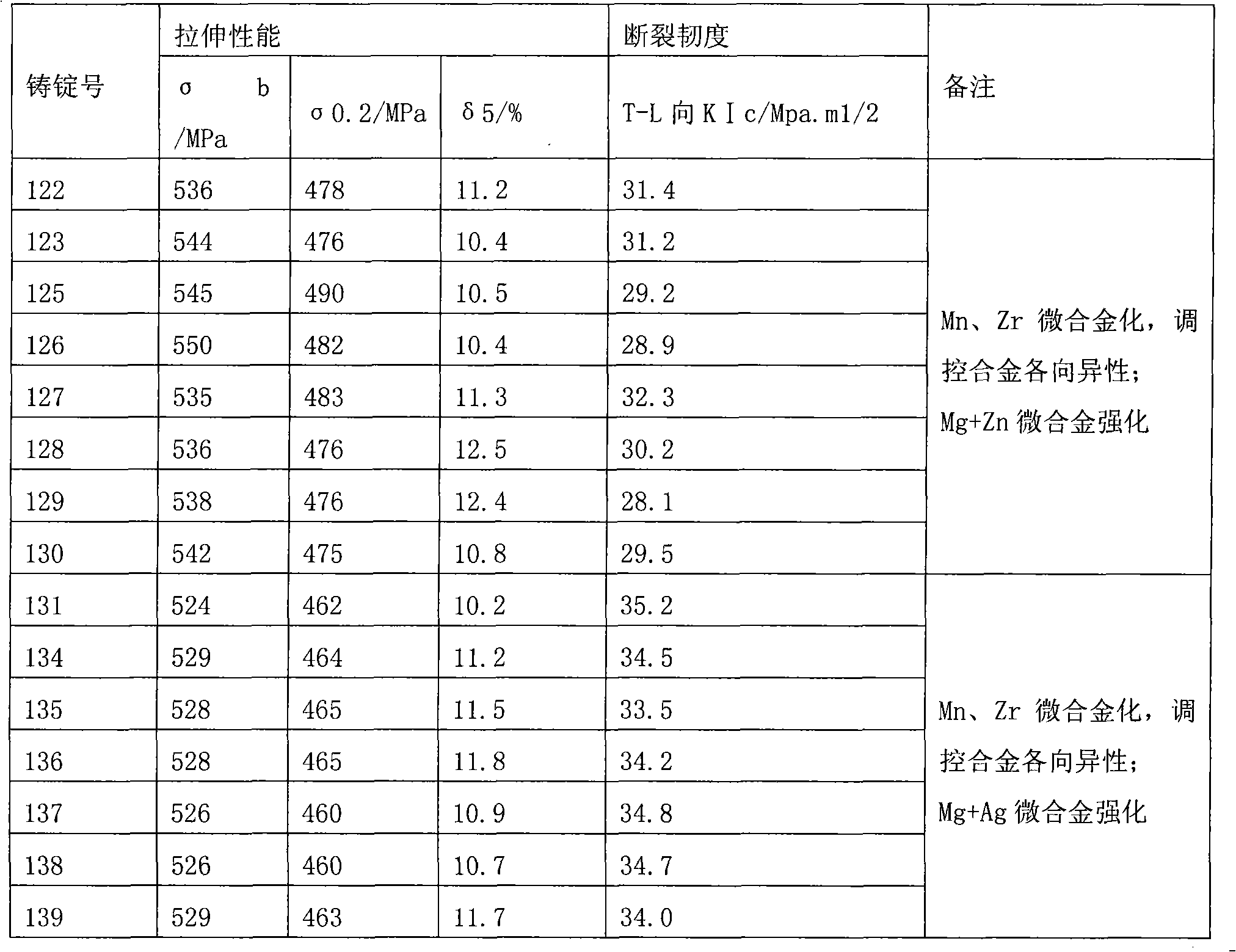

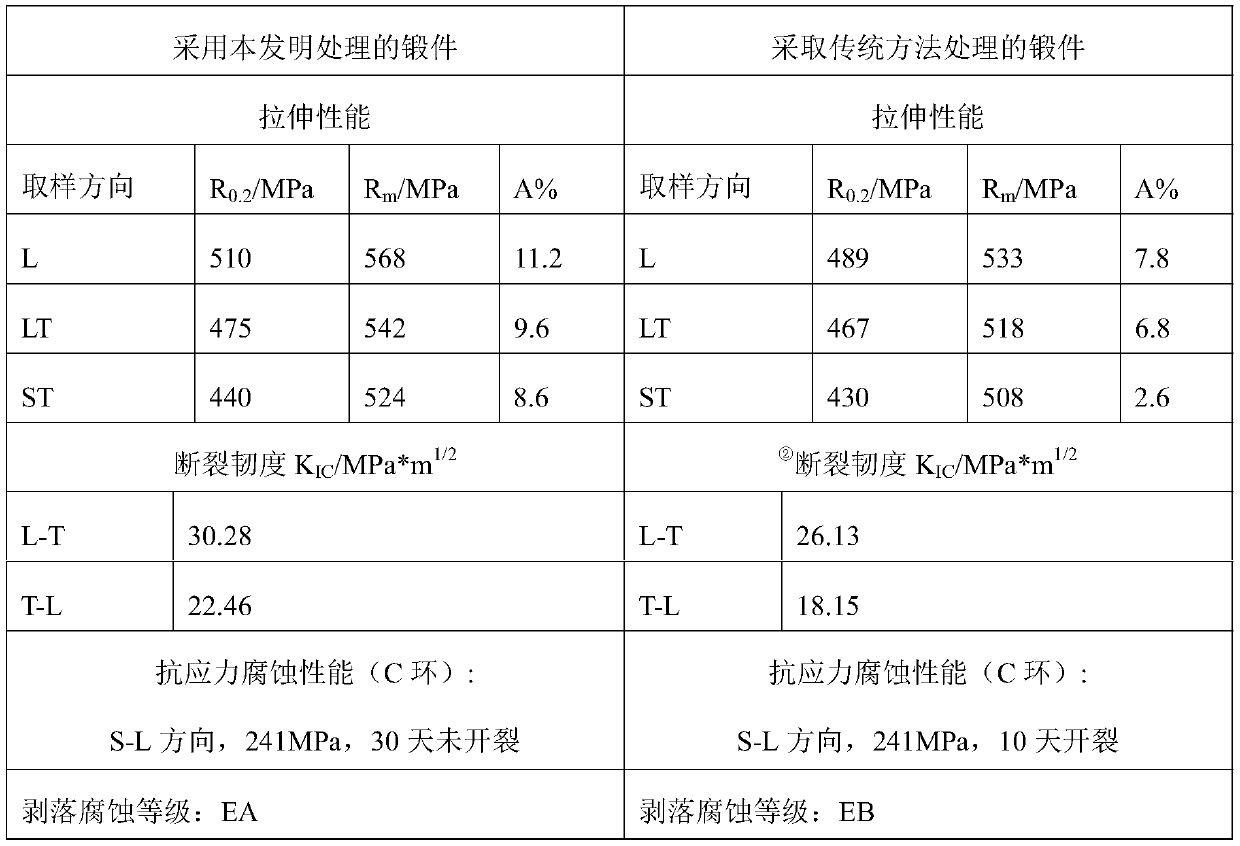

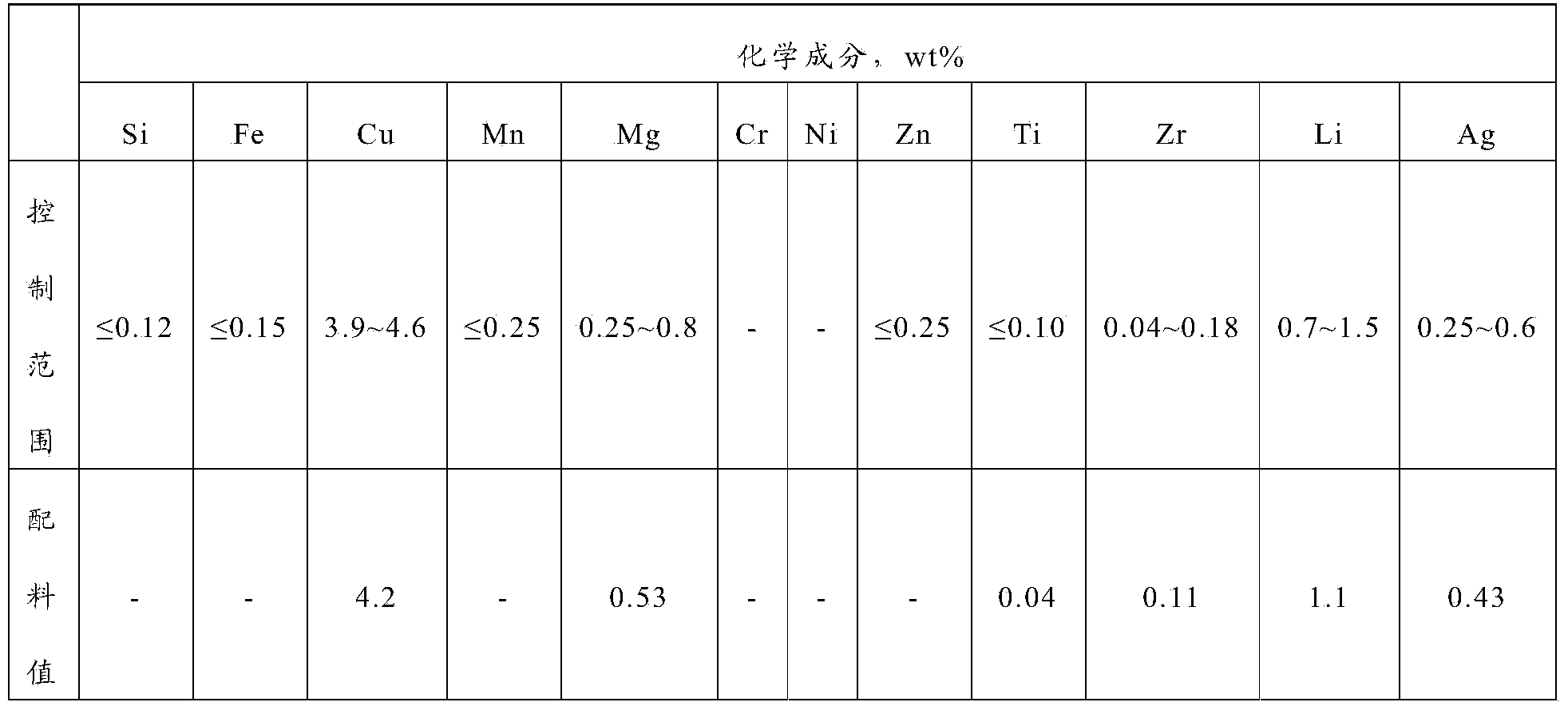

The invention discloses a high-toughness aluminum lithium alloy and a preparation method thereof. The alloy comprises the following chemical components in percentage by weight: 3.2 to 4.2 percent of Cu, 0.7 to 1.8 percent of Li, 0.20 to 0.60 percent of Mn, 0.20 to 0.60 percent of Zn, 0.06 to 0.20 percent of Zr, 0.20 to 0.80 percent of Mg, 0.2 to 0.7 percent of Ag, less than or equal to 0.10 percent of Si, less than or equal to 0.10 percent of Fe, less than or equal to 0.12 percent of Ti, less than or equal to 0.15 percent of other impurities (single impurity is less than or equal to 0.05 percent) and the balance of Al. One or five of alloy elements Mn, Zn, Mg, Ag and Zr can be selectively added. Proportioning is performed according to the alloy components, the raw materials are melted, then furnace refining and standing are performed, and alloy ingots with required specifications are cast. The alloy ingots are preferably homogenized and then molded by any process of hot extruding, hot rolling and the like, and the alloy ingots thermally treated by the preferable process can be used for processing parts. The high-toughness aluminum lithium alloy material has uniform microscopic structure and stable performance, and is suitable for manufacturing thick plates and extruded materials. The ultimate tensile strength can reach over 510MPa, and meanwhile, the elongation rate is more than 8 percent and the KIc can reach over 30MPam1 / 2. The material product can be used for structural elements of the fields of aerospace, nuclear industry, traffic and transportation, sports goods, weapons and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

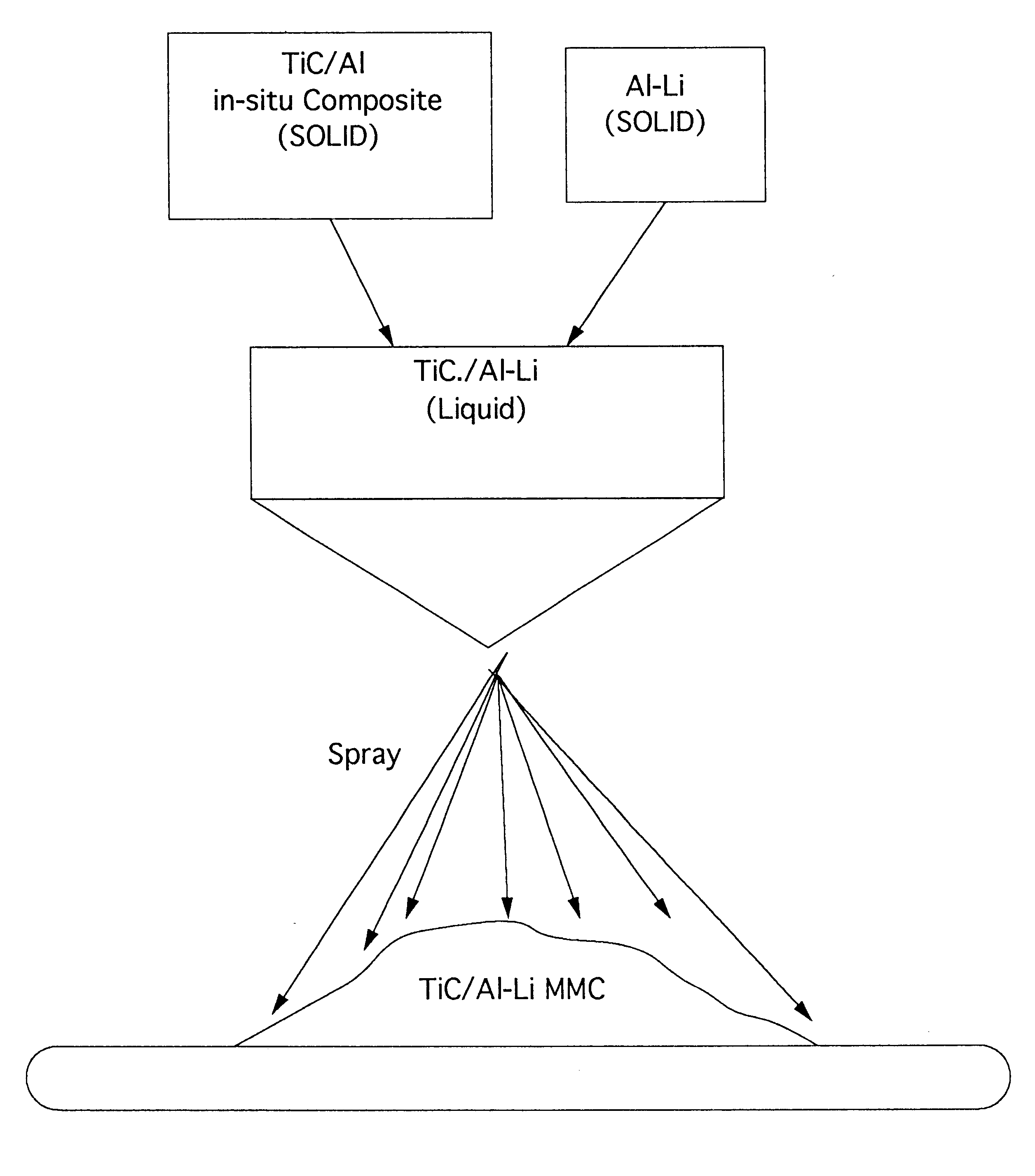

Aluminum-lithium alloy

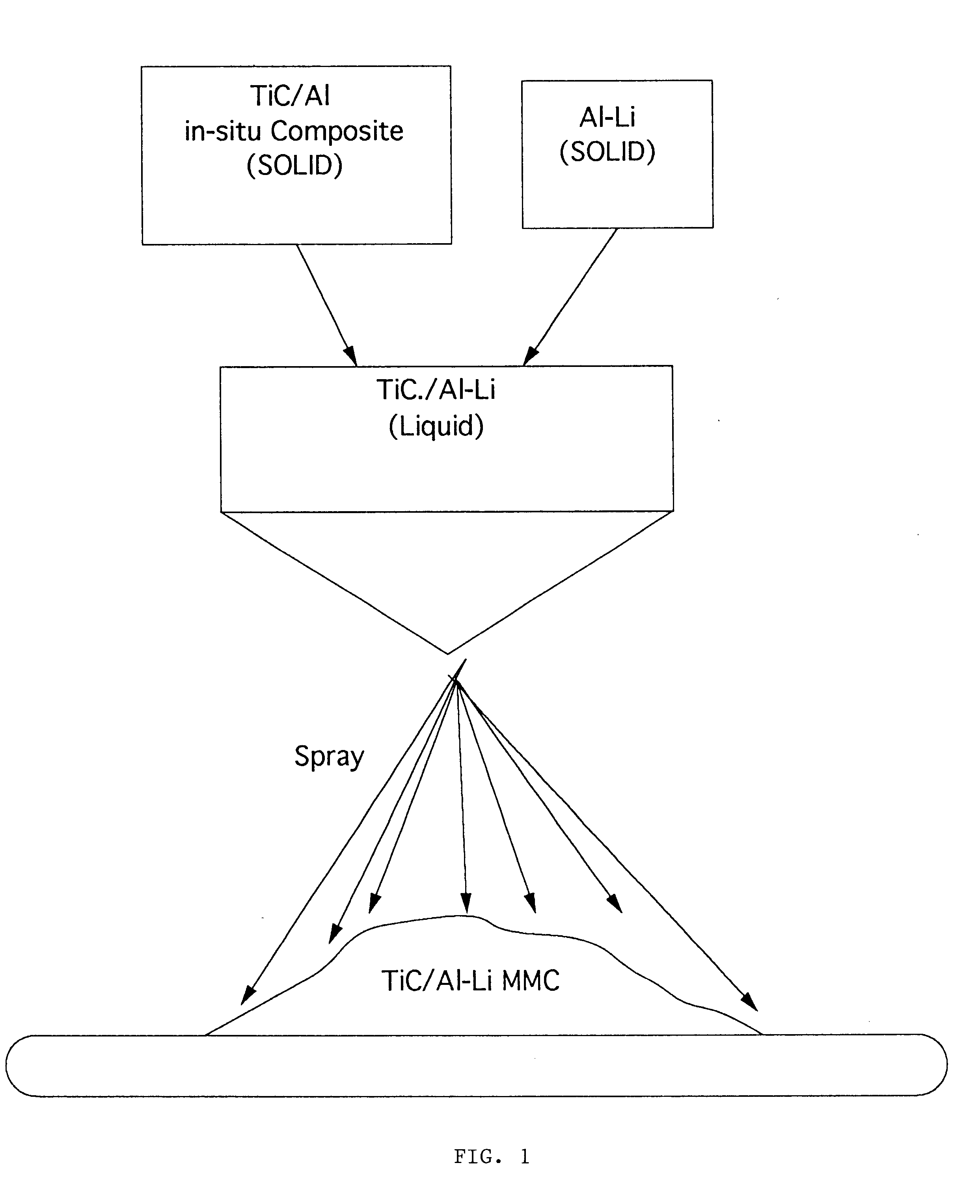

A method for mixing an in-situ aluminum matrix composite with an aluminum-litium alloy via the spray deposition process to obtain an Al-Li composite.

Owner:ARMY UNITED STATES OF AMERICA AS REPRENSENTED BY THE SEC OF

New Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

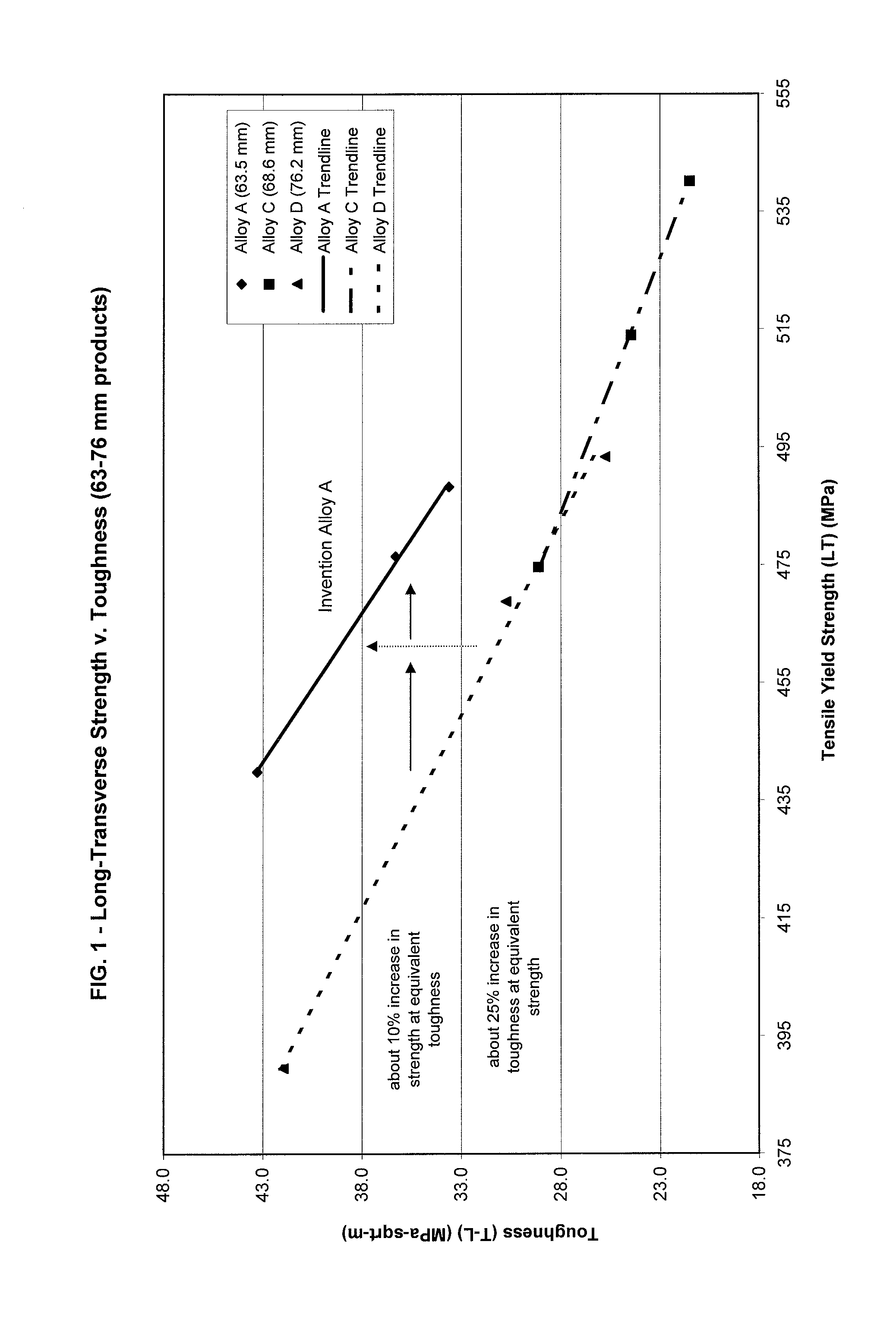

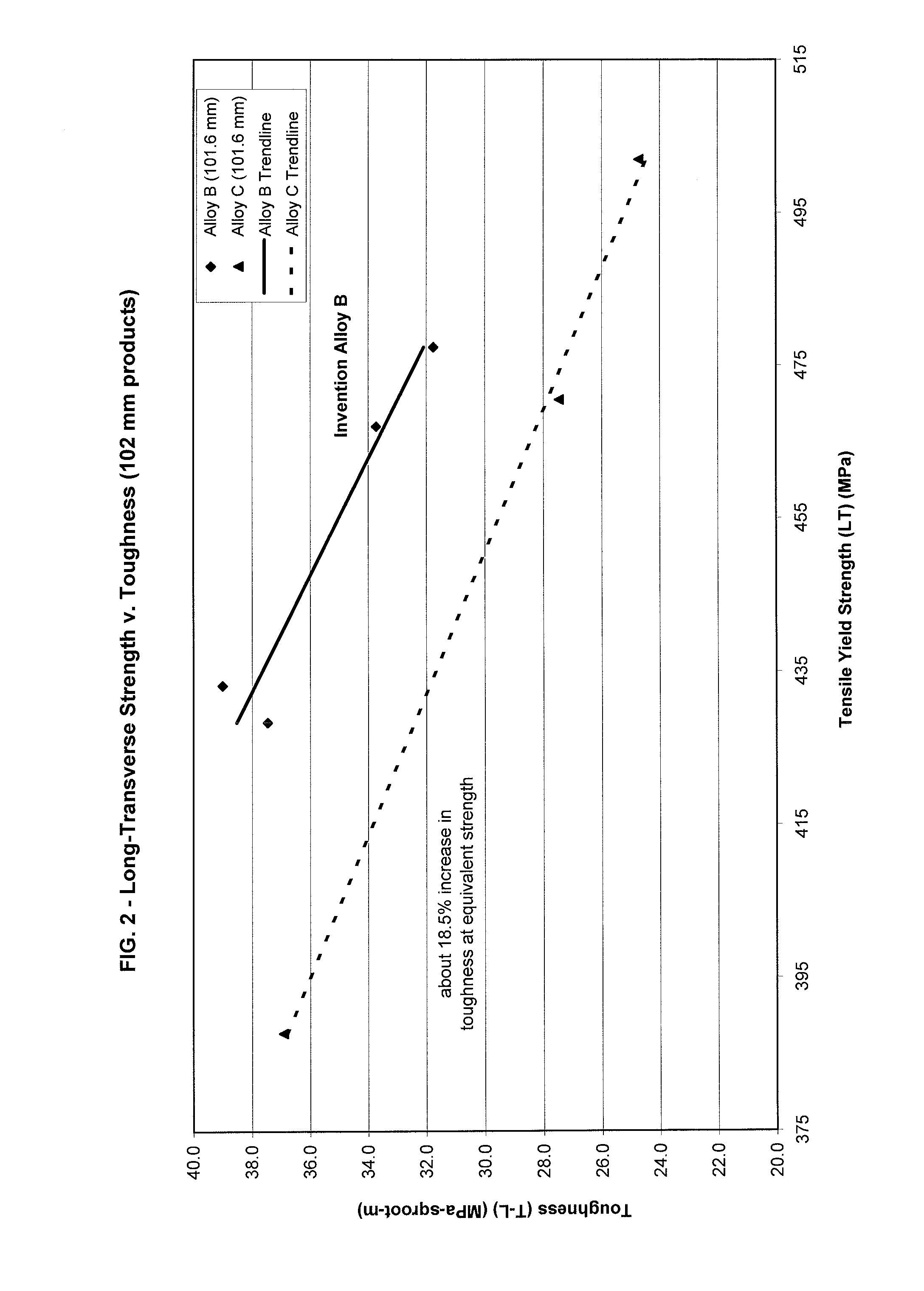

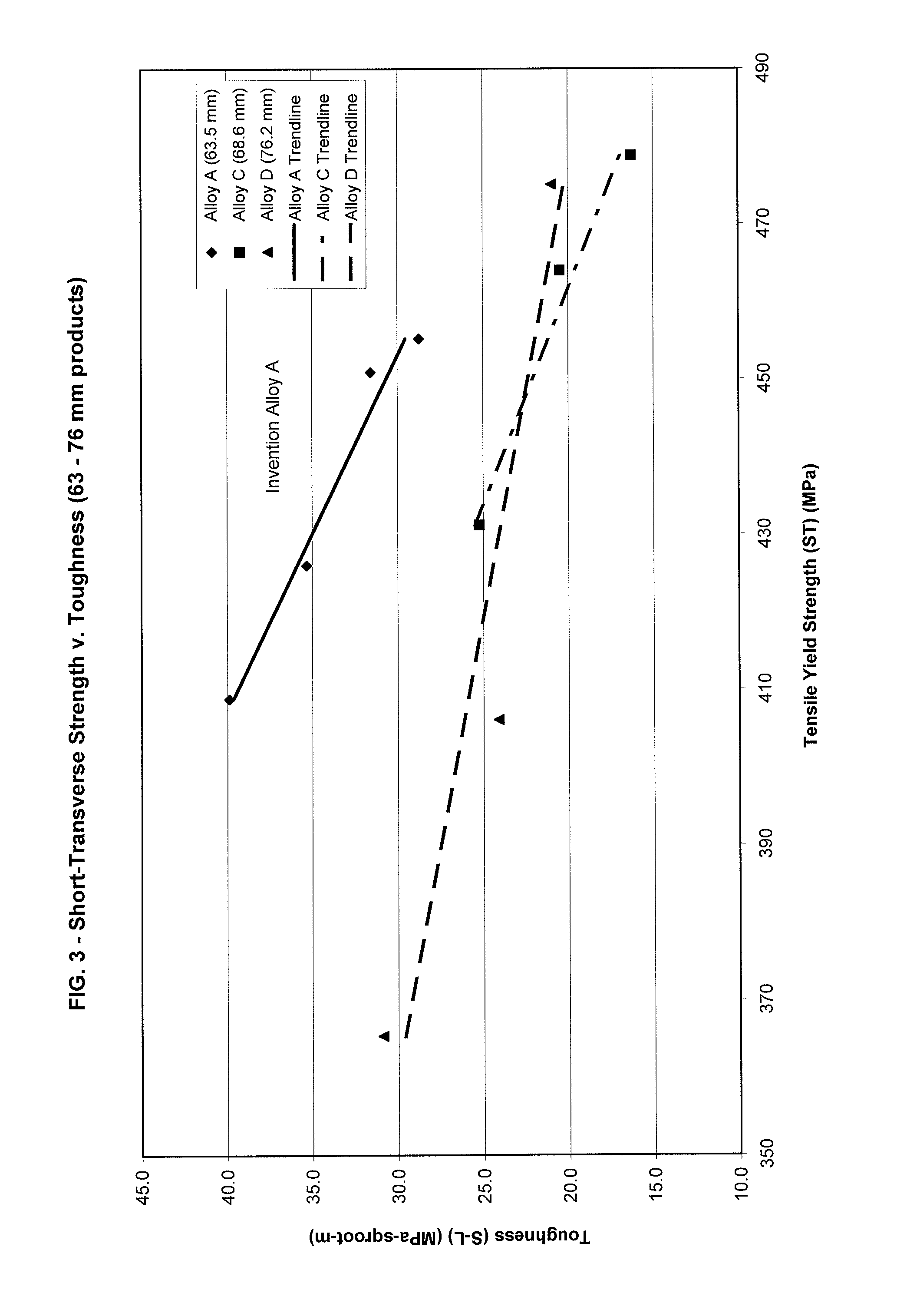

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

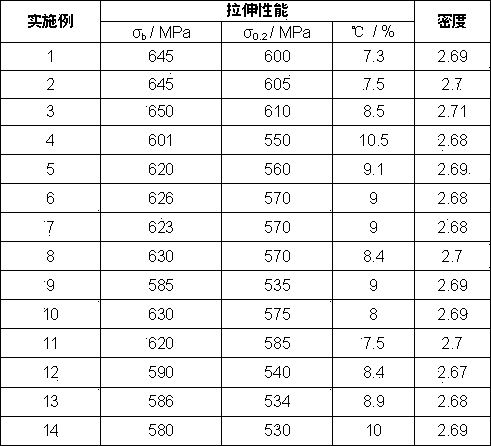

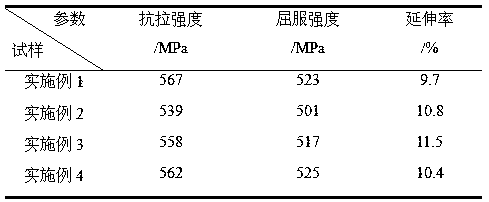

Ultrahigh strength aluminum lithium alloy and preparation method thereof

The invention discloses ultrahigh strength aluminum lithium alloy and a preparation method thereof. The ultrahigh strength aluminum lithium alloy comprises the following microelements by mass percent: 3.5 to 4.5 percent of Cu, 1.0 to 1.6 percent of Li, 0.30 to 0.70 percent of Mg, 0.2 to 0.70 percent of Ag, 0.30 to 0.80 percent of Zn, 0.20 to 0.50 percent of Mn, 0.06 to 0.16 percent of Zr, less than 0.10 percent of impurity Si, less than 0.10 percent of Fe, less than 0.05 percent of other single impurity, and the balance of Al, wherein the total amount of other impurities is less than 0.15 percent. The method comprises the steps of compounding microelements of Mg, Ag and Zn, microalloying and strengthening the microelements, performing batching according to alloy constituents, melting the raw materials, performing refining and standing on the raw material in a furnace, and casting the raw material into alloy ingots satisfying required specifications. Plates manufactured through the alloy have the advantages that the tensile strength can reach more than 580MPa, the elongation percentage is higher than 7 percent at the same time, and the plates can be applied to structural elements in fields of aerospace, nuclear industry, transportation, weapons and the like.

Owner:CENT SOUTH UNIV +1

Low-density and high-rigidity cast aluminum-lithium alloy and method for preparing same

The invention discloses low-density and high-rigidity aluminum-lithium alloy and a method for preparing the same. The low-density and high-rigidity cast aluminum-lithium alloy comprises, by weight, 3-3.5% of Li, 1-2% of Cu, 0.5-2% of Mg, 0.4-0.8% of Ag, 0.14-0.2% of Zr, 0.3-0.8% of Mn, lower than 0.25% of impurity elements Si, Fe, Na and K and the balance Al. The low-density and high-rigidity cast aluminum-lithium alloy and the method have the advantages that alloy elements (the Li, the Cu, the Mg, the Ag, the Zr and the Mn) are added by the aid of the method, solid solution and aging treatment is carried out by the aid of the method, and accordingly the low-density and high-rigidity cast aluminum-lithium alloy with excellent mechanical properties can be obtained and is high in elastic modulus and low in density as compared with the traditional cast aluminum alloy; the low-density and high-rigidity cast aluminum-lithium alloy is high in Li element yield and low in cost.

Owner:SHANGHAI JIAO TONG UNIV

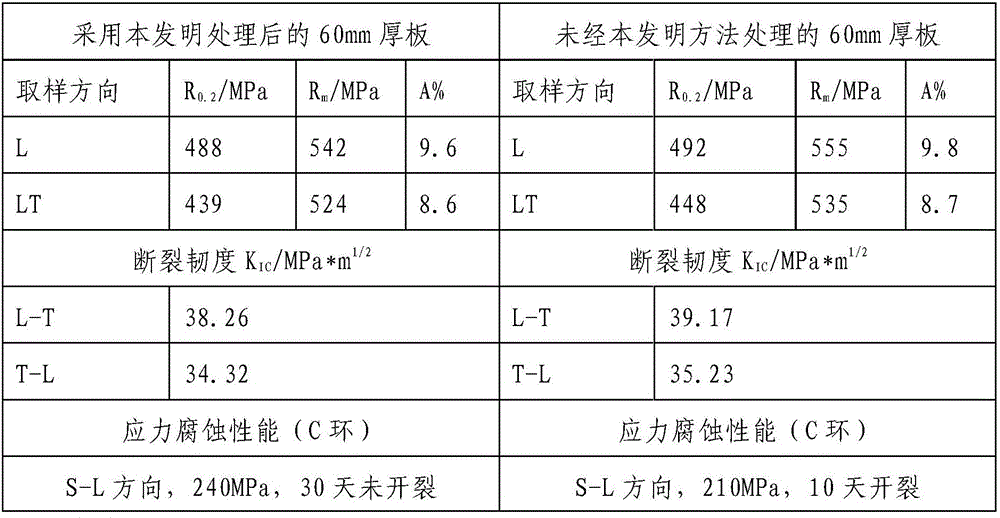

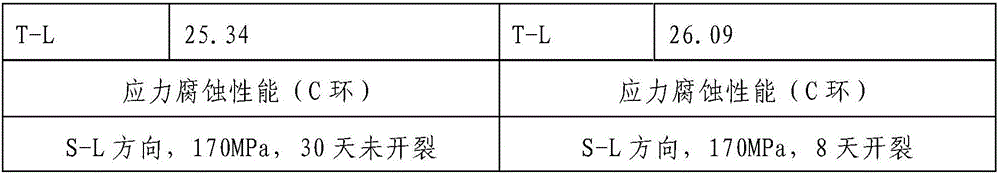

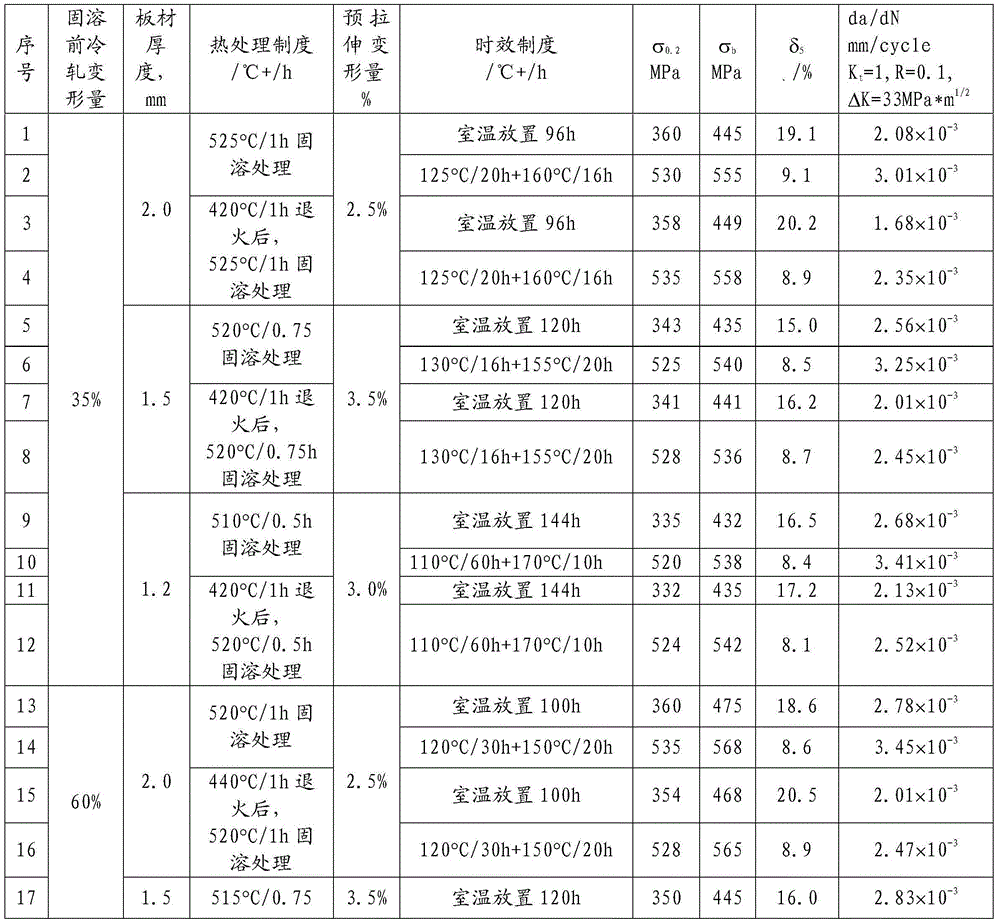

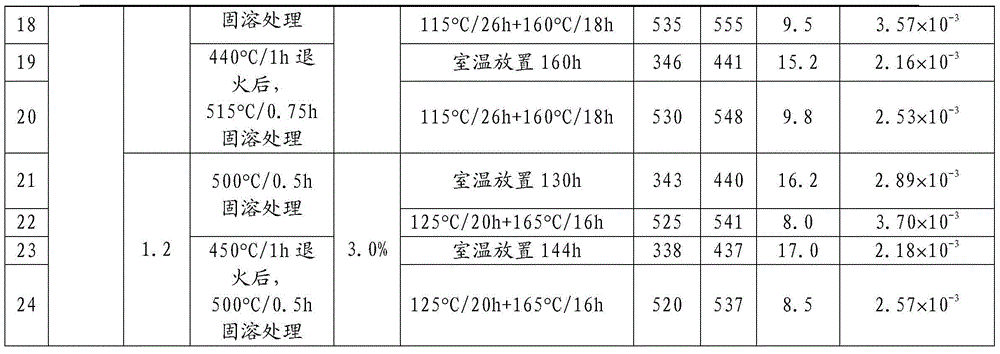

Method for improving stress corrosion resisting performance of aluminum lithium alloy

ActiveCN106591650AImprove stress corrosion resistanceIncreased process windowSolution treatmentLithium

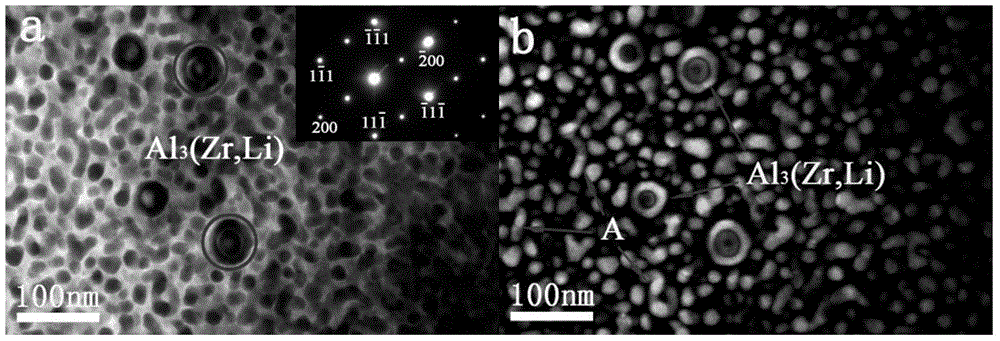

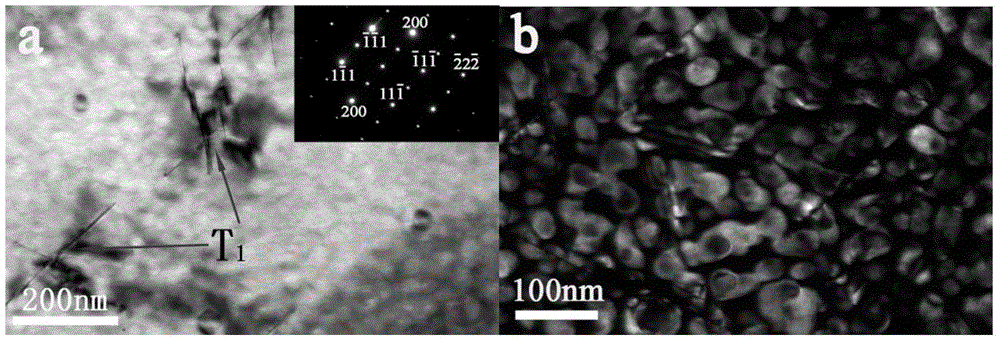

The invention belongs to the aluminum lithium alloy heat treatment technology, in particular to a heat treatment technology capable of improving the stress corrosion resisting performance of an aluminum lithium alloy. Applicable alloy components of the technology comprise main alloying elements including, by weight percent, 0.5%-5.0% of Cu, 0.4%-2.5% of Li, 0.1%-4.0 % of Mg and 0.1%-4.0% of Zn, comprise microalloying elements including any one to four of, by weight percent, 0.04%-0.02% of Zr, 0.05%-0.60% of Sc, 0.20%-0.80% of Mn and 0.1%-0.9% of Ag and comprise, by weight percent, smaller than or equal to 0.10% of Si, smaller than or equal to 0.10% of Fe, smaller than or equal to 0.10% of Ti, smaller than or equal to 0.05% of each of other impurities and the balance Al, wherein the total amount of other impurities is smaller than or equal to 0.15%. After a deformed product is subjected to annealing treatment, cold deformation of a certain deformation amount is conducted, then solution hardening is conducted, regulation and control over the recrystallization degree and the grain boundary precipitates can be achieved through the manner, and other mechanical properties of the alloy are kept unchangeable while the stress corrosion resisting performance of the alloy is improved. The alloy preparing steps include annealing treatment, cold deformation treatment, solution treatment and ageing treatment. The technology is suitable for high-performance Al-Cu-Li-X series aluminum lithium alloy thick plates and forge pieces used in the fields of aviation, spaceflight and weapons.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

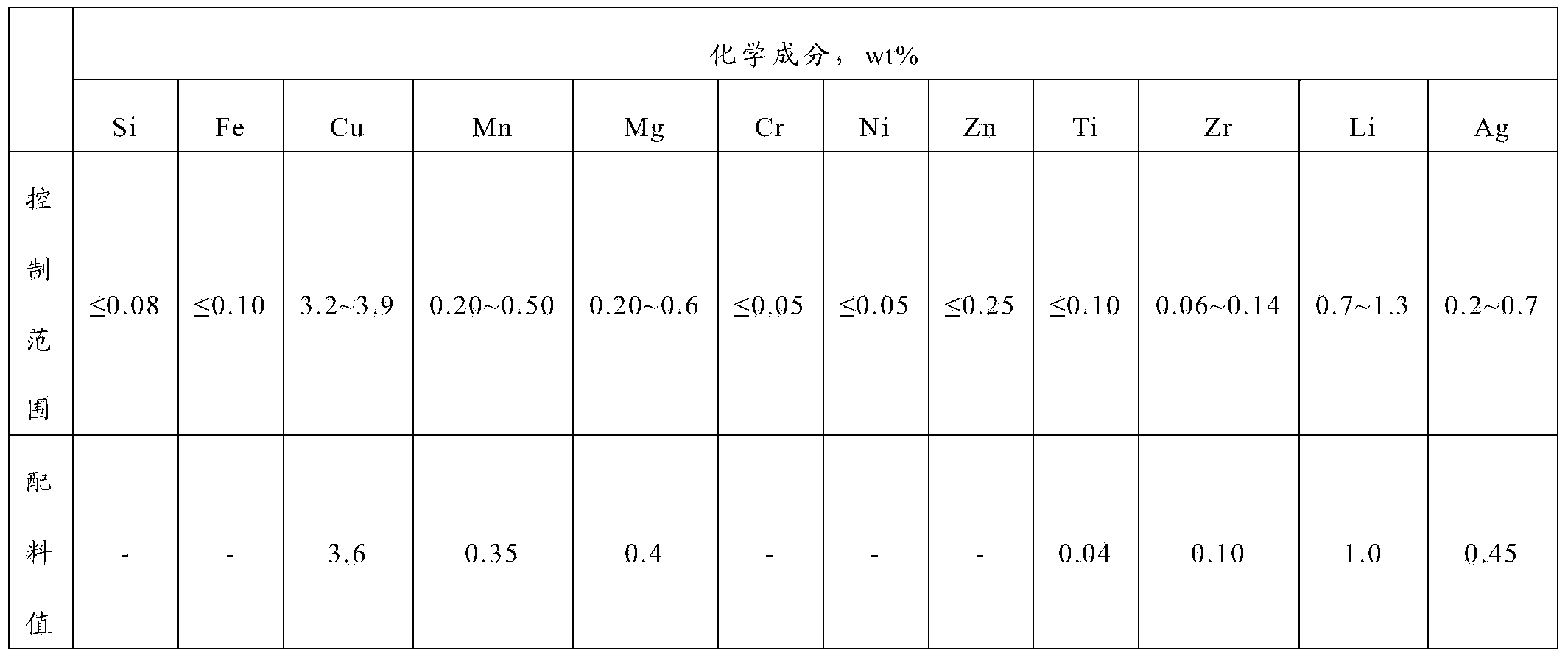

Heat treatment method for improving damage resistance of aluminum lithium alloy thin plate

The invention relates to a heat treatment method for improving damage resistance of an Al-Cu-Li-X series aluminum lithium alloy thin plate. The alloy thin plate comprises: by weight, 2.0-5.0% of Cu; 0.8-2.5% of Li; any one to five of 0.20-0.60% of Mn, 0.20-0.80% of Zn, 0.04-0.20% of Zr, 0.20-0.80% of Mg and 0.1-0.7% of Ag; 0.10% or less of Si; 0.10% or less of Fe; 0.12% or less of Ti; 0.15% or less of other impurities with the respective content of 0.05% or less; and the balance of Al. The method comprises the following steps: carrying out cold finish rolling on the alloy thin plate to form a thin plate with a final thickness, carrying out short-time annealing treatment at a certain temperature, carrying out solid solution quenching, and carrying out subsequent aging treatment to reach a required state. The method can regulate the microstructure and performances of the plate to make the damage resistance of the plate be greatly improved without changing other performances.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Aluminum alloy structure material and preparation thereof

ActiveCN104651684AScientific and reasonable formula designAvoid blindnessIngotAluminium-lithium alloy

The invention discloses an aluminum alloy structure material. The aluminum alloy structure material is Al-Mg-Si-Mn-Ti alloy and comprises the following elements based on a magnesium charging material as a benchmark in percentage by mass: 10.5-17.4% of Mg, 0.01-0.05% of Be, 1.0-5.0% of Si, 0.3-0.8% of Mn, 0.15-0.25% of Ti and the balance of Al and other unavoidable impurities. In the preparation process, the method comprises the following steps: putting the weighed charging material into a medium frequency smelting furnace for melting the alloy, degassing and purifying, pouring and carrying out spray depositing to obtain a round ingot blank; and performing extrusion processing, product processing and thermal processing to obtain the product. The aluminum alloy structure material is scientific and reasonable in compound design, simple in preparation process and short in technological process by adopting a spray deposition technology to prepare the low-density high-strength aluminum alloy metallurgy microstructure; the produced aluminum alloy has a mechanical property of the high-strength aluminum alloy and a low density of the aluminum lithium alloy and can be used for manufacturing the ground vehicles and space vehicle structure products.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Ultrahigh-strength aluminum-lithium alloy and preparation method thereof

The invention relates to an ultrahigh-strength aluminum-lithium alloy and a preparation method thereof. The alloy comprises the following components of, by mass, 4.3%-5.2% of Cu, 0.8%-1.2% of Li, 0.3%-0.7% of Mg, 0.1%-0.5% of Ag, 0.81%-1.5% of Zn, 0.1%-0.2% of Mn, 0.1%-0.2% of Zr, 0.09%-0.3% of Sc and the balance Al, wherein the mass percentage ratio of Cu / Li is 4.3 to 6.5. The preparation methodcomprises the following steps that the components are weighed according to the designed aluminum alloy component ratio, atmospheric smelting or vacuum smelting is adopted to cast a molded cast ingot,and then multi-stage homogenization treatment, hot extrusion deformation, step-by-step heating and solid solution, cold rolling deformation and aging treatment are carried out. According to the ultrahigh-strength aluminum-lithium alloy and the preparation method thereof, a product which has the performances more superior than that of an existing aluminum-lithium alloy is prepared, and the producthas the characteristics of being high in yield strength, high in hardness, high in elasticity modulus, capable of being strengthened through heat treatment and the like.

Owner:CENT SOUTH UNIV

High-strength high-toughness aluminum lithium alloy and preparation method thereof

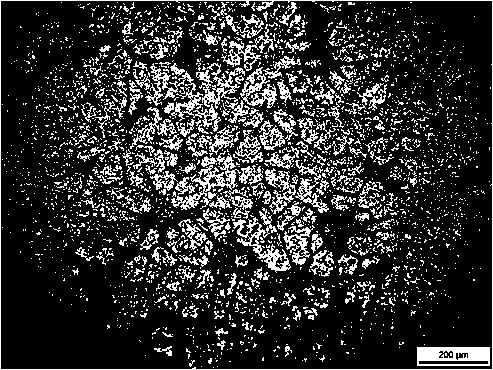

The invention discloses a high-strength high-toughness aluminum lithium alloy. The high-strength high-toughness aluminum lithium alloy is composed of the following ingredients of, in percentage by mass, 1.6-2.3% of lithium, 2.9-3.8% of copper, 0.15-0.60% of magnesium, 0.18-0.35% of cobalt, 0.05-0.25% of strontium, 0.09-0.18% of yttrium, 0.06-0.12% of zirconium and the balance aluminum, wherein themass ratio of copper to lithium (Cu / Li) is controlled to be 1.3-2.0. The invention further discloses a preparation method for the high-strength high-toughness aluminum lithium alloy, and the preparation method for the high-strength high-toughness aluminum lithium alloy comprises the following steps of material confecting, smelting, casting, homogenizing, hot rolling, annealing, cold rolling, solid dissolving and aging. According to the high-strength high-toughness aluminum lithium alloy and the preparation method for the high-strength high-toughness aluminum lithium alloy, by means of composite microalloying and vacuum solvent-free casting, high-quality casting ingots are obtained, and by means of subsequent large deformation and the solid dissolving and aging process, the aluminum lithium alloy with good match of strength and plasticity toughness is obtained.

Owner:郑州轻研合金科技有限公司

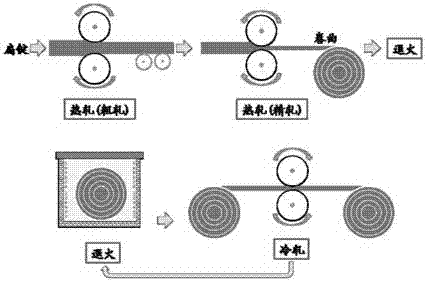

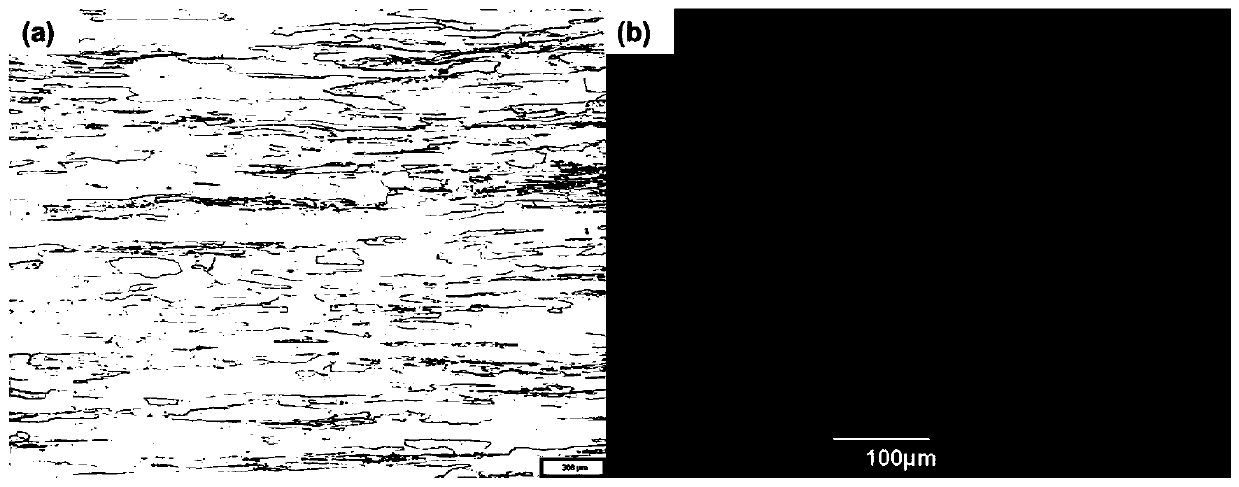

Preparation method of Al-Cu-Li-X series aluminum lithium alloy sheet

The invention discloses a preparation method of an Al-Cu-Li-X series aluminum lithium alloy sheet. The sheet prepared by the method is 0.8mm-8.0mm in thickness. The method comprises the following steps: cogging and hot-rolling homogenized slab ingots to a specified thickness and coiling; carrying out annealing treatment, uncoiling and carrying out band-type cold-rolling; carrying out intermediate annealing according to deformation during cold-rolling, thus obtaining the sheets with uniform thicknesses. The sheets can be in different states after being subjected to solution treatment, prestretching and aging treatment, so as to meet different usage requirements. Compared with the prior art, the aluminum lithium alloy sheet with high surface quality, uniform sheet size and smooth sheet shape is prepared by the method through band-type cold-rolling. The sheets can be in different states by different heat-treating processes, so as to meet usage requirements under different application conditions.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Aluminum-lithium alloys, and methods for producing the same

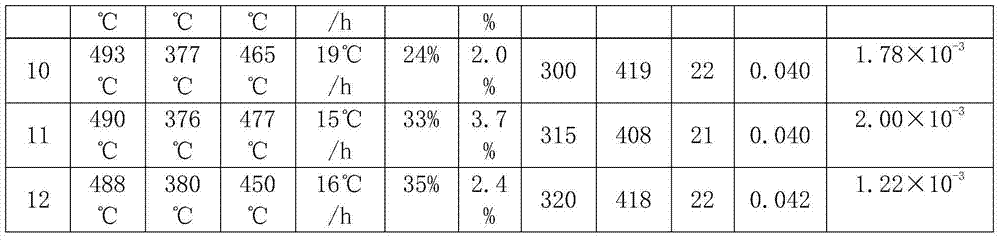

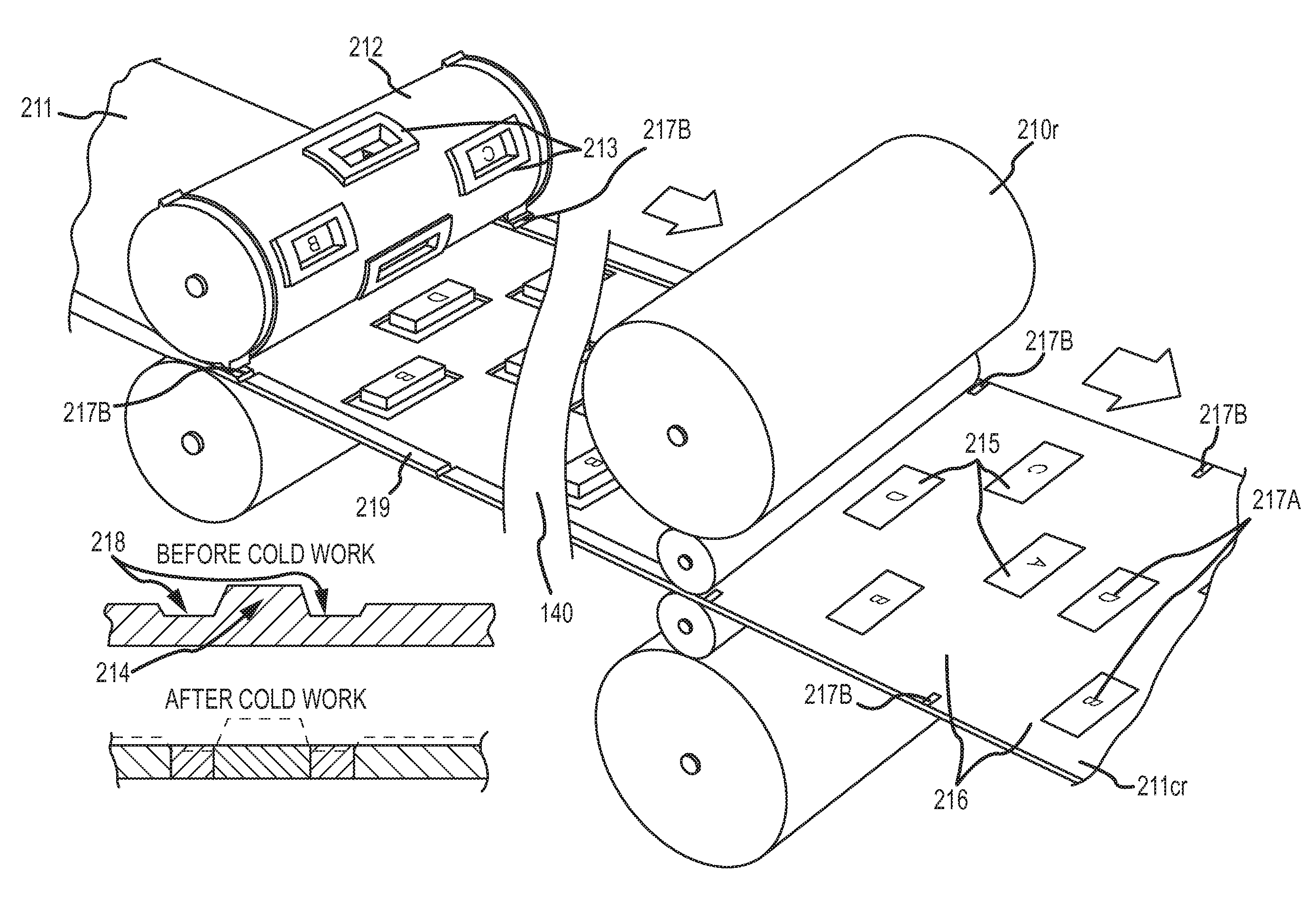

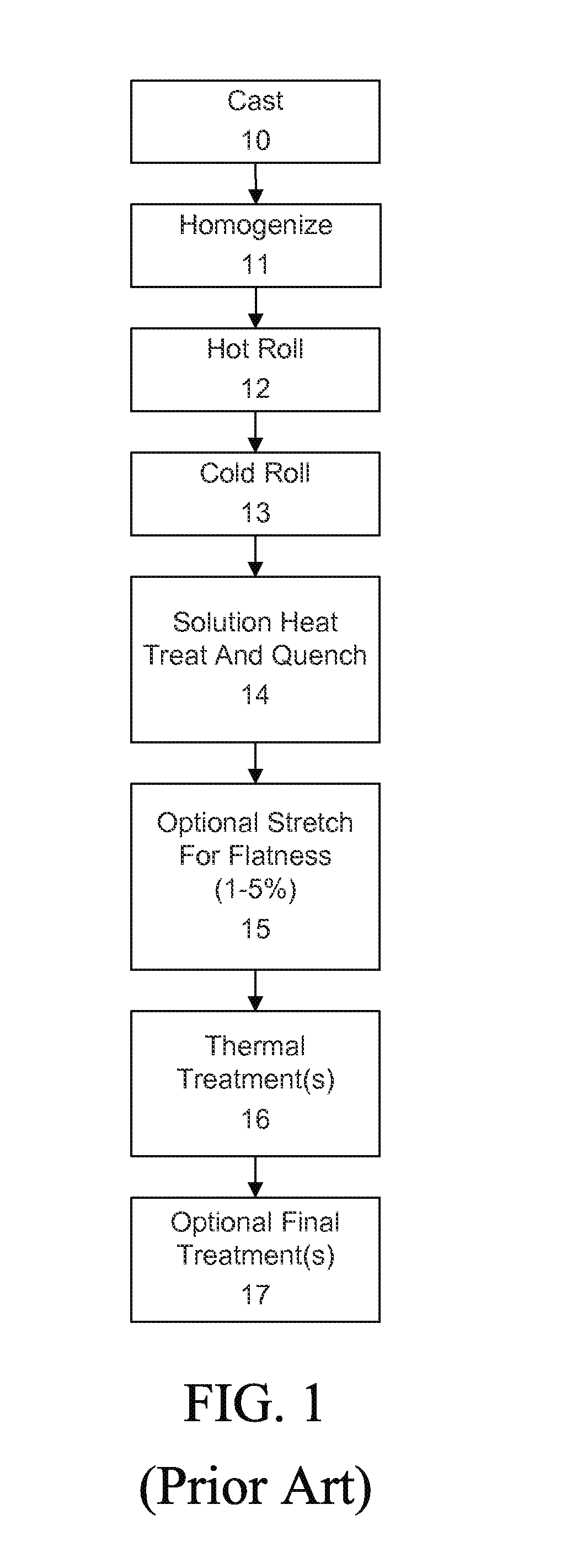

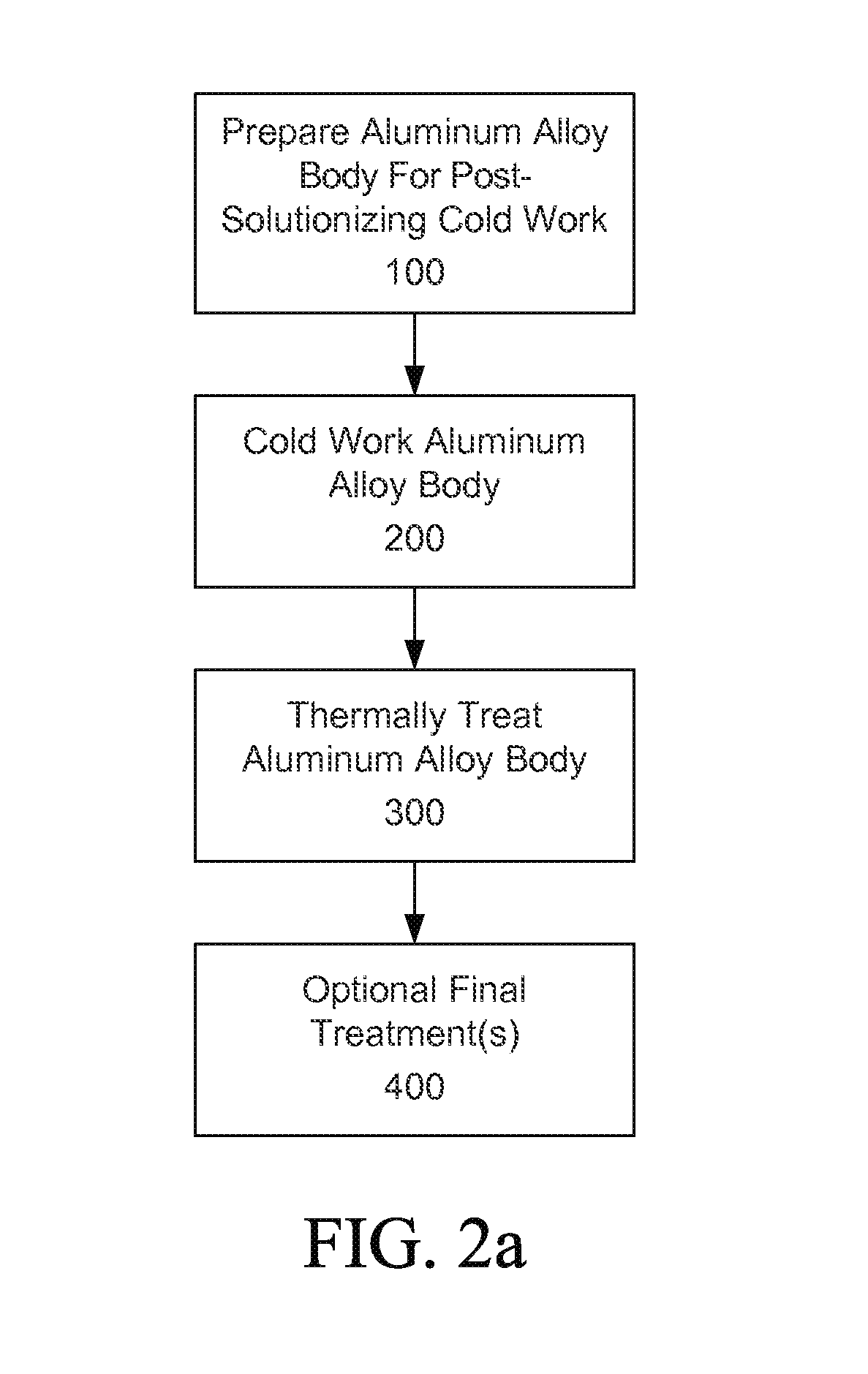

InactiveUS20140367000A1Minimize changesAvoid unevennessShaping toolsLithiumUltimate tensile strength

New Al—Li alloy bodies and methods of producing the same are disclosed. The new Al—Li alloy bodies may be produced by preparing the aluminum alloy body for post-solutionizing cold work, cold working by at least 25%, and then thermally treating. The new Al—Li alloy bodies may realize improved strength and other properties.

Owner:ARCONIC INC

2xxx series aluminum lithium alloys

Thick wrought 2xxx aluminum lithium alloy products are disclosed. The wrought aluminum alloy products have a thickness of at least 12.7 mm and contain from 3.00 to 3.80 wt. % Cu, from 0.05 to 0.35 wt. % Mg, from 0.975 to 1.385 wt. % Li, wherein −0.3*Mg−0.15Cu+1.65≦Li≦−0.3*Mg−0.15Cu+1.85, from 0.05 to 0.50 wt. % of at least one grain structure control element, wherein the grain structure control element is selected from the group consisting of Zr, Sc, Cr, V, Hf, other rare earth elements, and combinations thereof, up to 1.0 wt. % Zn, up to 1.0 wt. % Mn, up to 0.12 wt. % Si, up to 0.15 wt. % Fe, up to 0.15 wt. % Ti, up to 0.10 wt. % of any other element, with the total of these other elements not exceeding 0.35 wt. %, the balance being aluminum.

Owner:ARCONIC TECH LLC

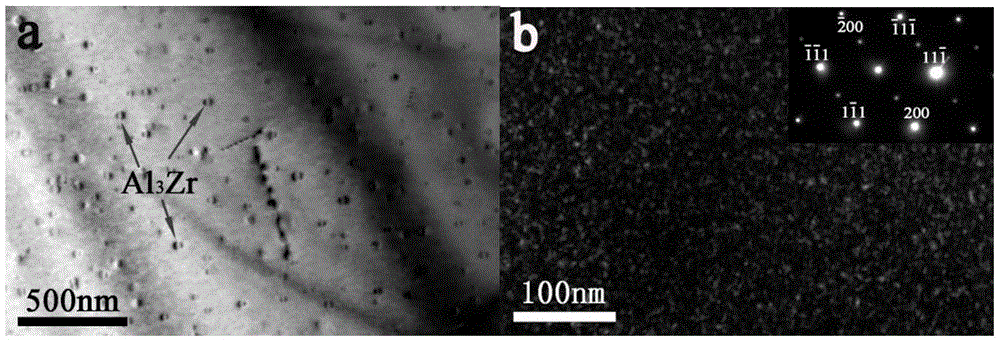

A scandium-containing cast aluminum-lithium alloy and a preparation method thereof

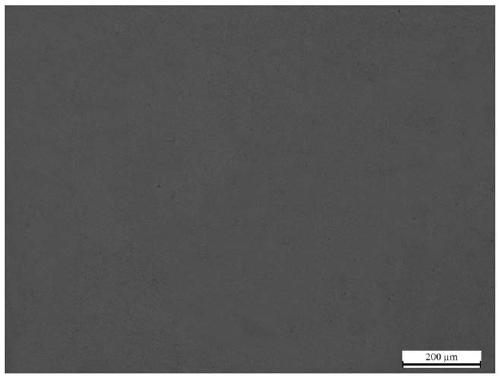

A novel scandium-containing cast aluminum-lithium alloy is disclosed. The alloy includes, by weight, 1.6-1.99% of Li, 0.9-1.9% of Cu, 0.2-0.7% of Mg, 0.1-0.25% of Zr, 0.05-0.35% of Sc, and impurity elements which are Fe, Si, Na, K and P, with the balance being Al, with the Fe content being less than 0.15% and the total content of the impurity elements being less than 0.25%. During preparation, Al-Cu and Al-Zr master alloys, pure aluminum, pure Mg and pure Li are smelted to obtain an aluminum alloy; then three stages of solid solution heat treatment are performed including solid solution heat treatment at 440-460 DEG C for 32 h, solid solution heat treatment at 510-520 DEG C for 24-32 h and solid solution heat treatment at 530-540 DEG C for 1-6 h; and after water quenching, artificial ageing treatment at 150-190 DEG C is performed for 16-48 h to obtain the novel scandium-containing cast aluminum-lithium alloy. The obtained novel scandium-containing cast aluminum-lithium alloy has a uniform microscopic structure, stable performance, density lower than density of traditional aluminum alloys, higher elastic modulus and rigidity, and other mechanical properties, and is low in cost. Theultimate tensile strength of the novel scandium-containing cast aluminum-lithium alloy can be 450-490 MPa and the specific elongation is 4.5-7.0%.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing aluminum lithium alloy superplastic plate

ActiveCN103882351ASolve the cracking problemRaise the annealing temperatureAluminium-lithium alloySuperplasticity

The invention discloses a method for preparing an aluminum lithium alloy superplastic plate. The process route of the method comprises the following steps: carrying out solid solution on a raw material, namely a 2A97 aluminum lithium alloy plate blank with certain initial thickness at 460-540 DEG C for 0.5-4 hours, carrying out water quenching, and then carrying out heat preservation at 400 DEG C for 8-48 hours; then rolling an alloy to 1.0-4.0 mm. Compared with the traditional thermomechanical treatment method, the method disclosed by the invention can be used for effectively solving the problem of easiness for cracking of a large-sized plate during rolling by increasing the intermediate annealing temperature, enhancing the deformation stored energy of the alloy and solving the problem of low superplastic elongation percentage of a plate by changing the traditional warm rolling process into a cold rolling process by retaining 20%-30% of deformation amount and can be used for firstly preparing the 2A97 aluminum lithium alloy large-sized superplastic plate with good superplastic property.

Owner:CENT SOUTH UNIV

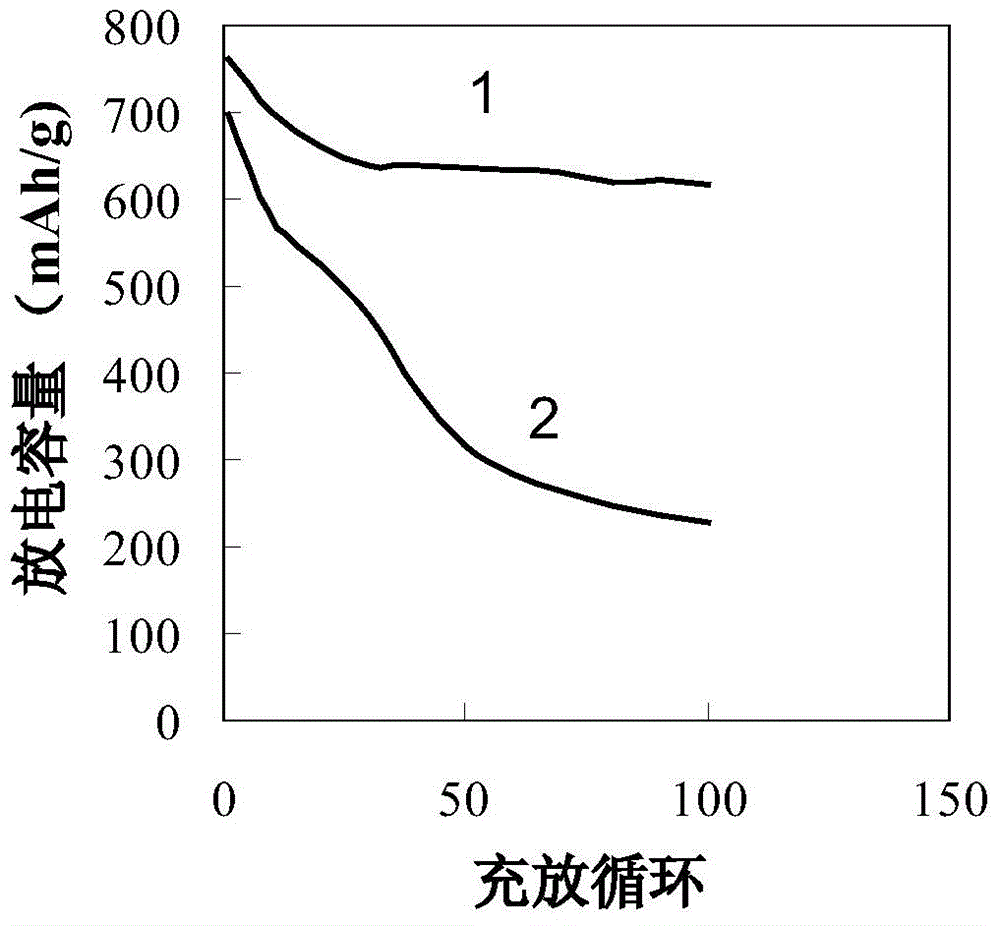

Lithium metaaluminate coated aluminum lithium alloy composite material and preparation method of lithium sulphur battery

InactiveCN104157825AStable structureReduce contact resistanceElectrode manufacturing processesLi-accumulatorsAlloy compositeLithium aluminate

The invention relates to the technical field of lithium ion batteries and provides a lithium metaaluminate coated aluminum lithium alloy composite material and a preparation method of a lithium sulphur battery. A preparation method of the lithium metaaluminate coated aluminum lithium alloy composite material comprises the following steps: mixing spherical aluminum powder and lithium resource compound powder, and heating to obtain lithium metaaluminate coated aluminum lithium alloy composite material powder; the lithium sulphur battery comprises a diaphragm, a positive electrode, a negative electrode and electrolyte; and the negative electrode material of the negative electrode comprises the lithium metaaluminate coated aluminum lithium alloy composite material. The prepared lithium metaaluminate coated aluminum lithium alloy composite material has a stable charging and discharging voltage platform, so that organic electrolyte can be safely applied to the battery; the composite material has good electrode reaction reversibility and good chemical stability and thermal stability, lithium dendrites can be avoided in the lithium sulphur battery, and short circuit can be effectively prevented, so that the reliability and the safety of the lithium sulphur battery can be effectively improved.

Owner:ZHEJIANG UNIV

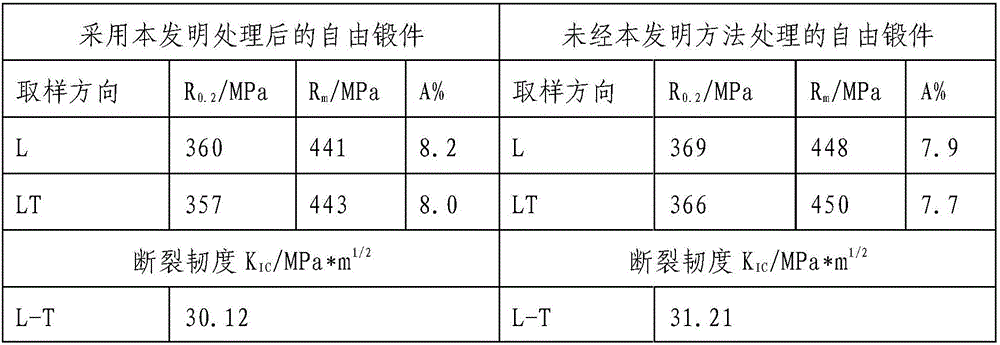

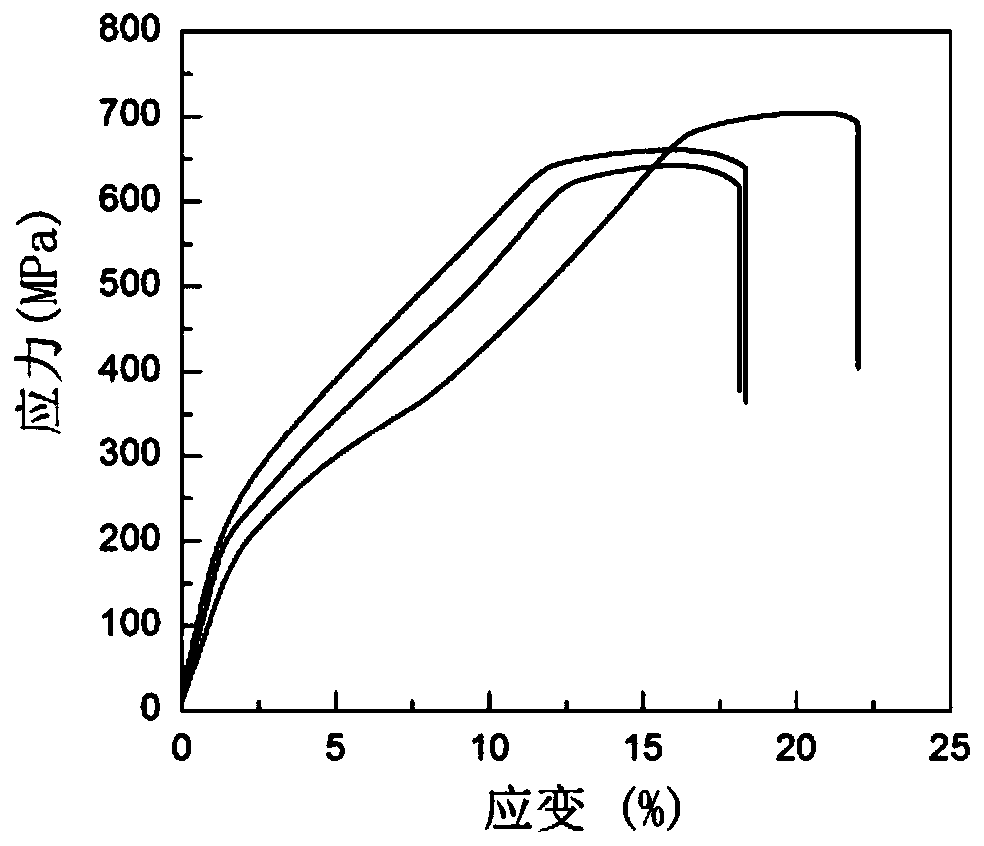

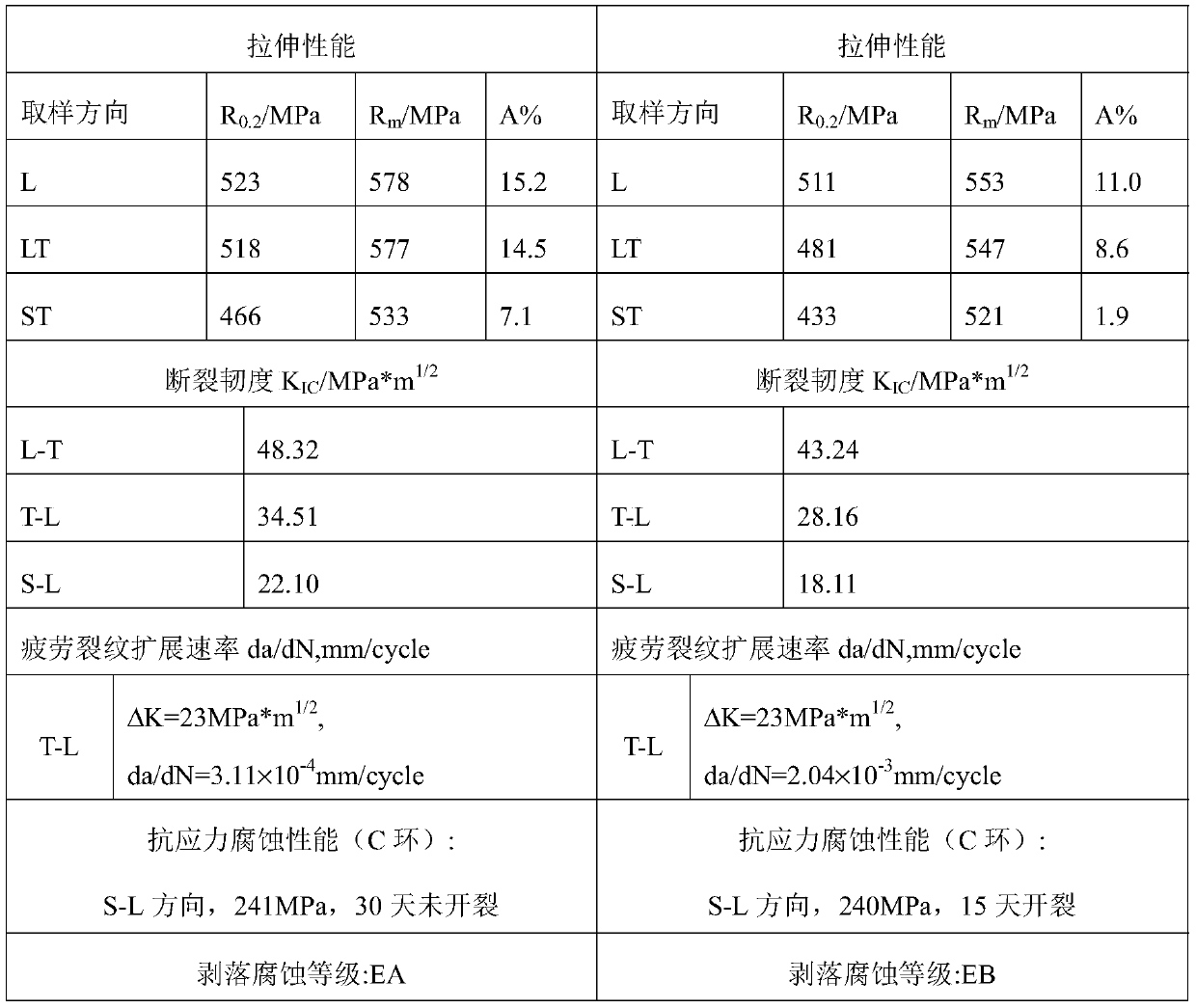

Preparation process for improving comprehensive performance of aluminum-lithium alloy product

The invention relates to the technical field of aluminum alloy thermal deformation and heat treatment, and in particular relates to a preparation process for improving the comprehensive performance ofan aluminum-lithium alloy product. The preparation process comprises the following steps that after a hot rolled plate / a hot forging completed forge piece is subjected to solution and quenching treatment, heat preservation is carried out for a period of time at a certain temperature, rolling treatment of certain deformation is carried out, and then secondary solution and quenching temperature, cold deformation and artificial aging treatment are carried out; after the solution and quenching temperature is carried out, medium-temperature heating and heat preservation are carried out; and a certain deformation energy storage is introduced in subsequent medium-temperature rolling deformation rolling, so that the plate is re-crystallized to a certain degree in the secondary solution and quenching temperature, the horizontal grain boundary among grains in the hot rolled plate is eliminated, a part of " nested " morphology is formed, improvement is achieved from two aspects of grain boundarymorphology and interface " purity ", and the comprehensive performance of an alloy is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

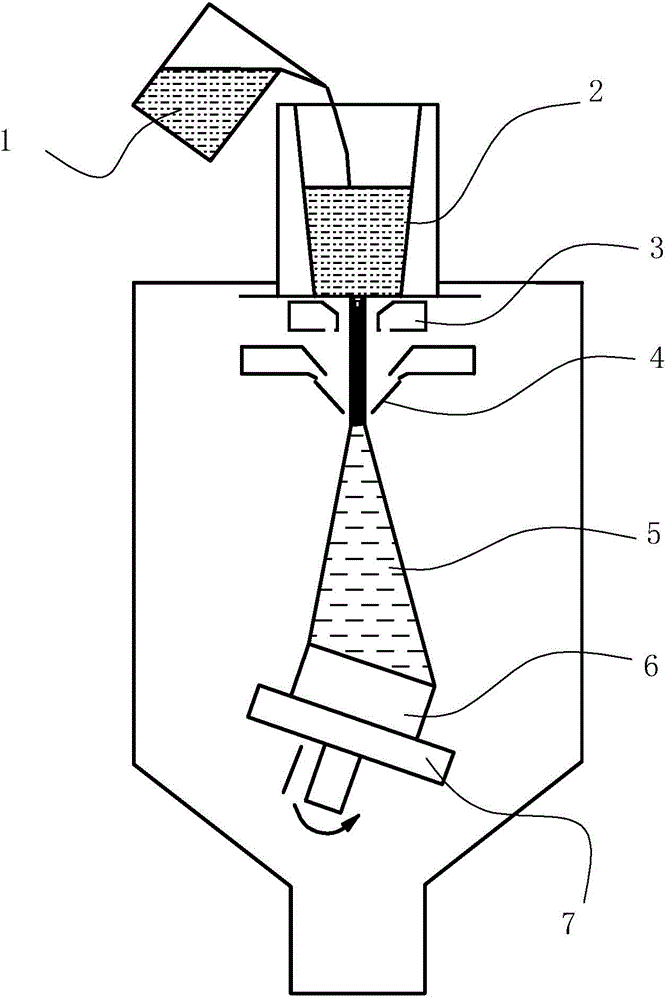

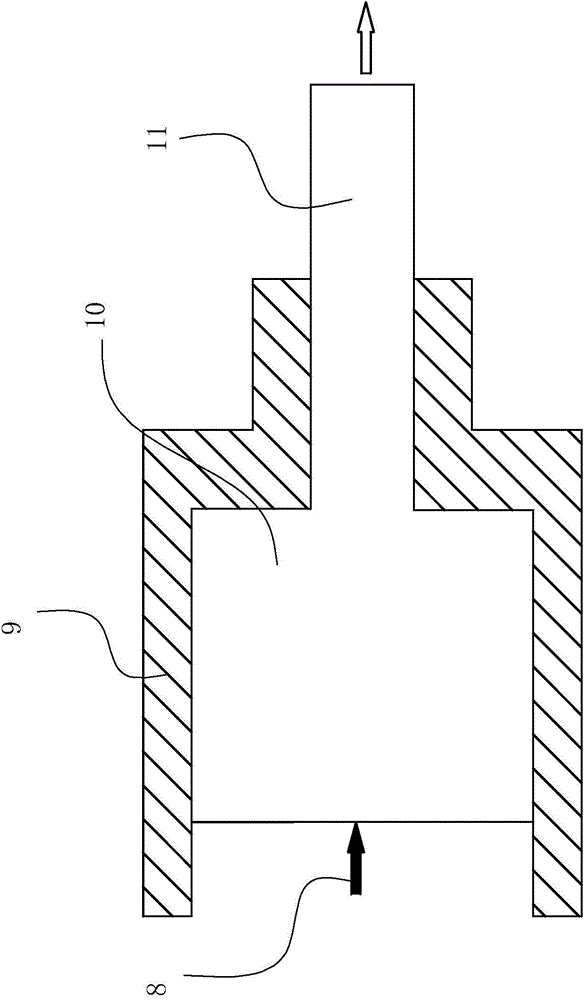

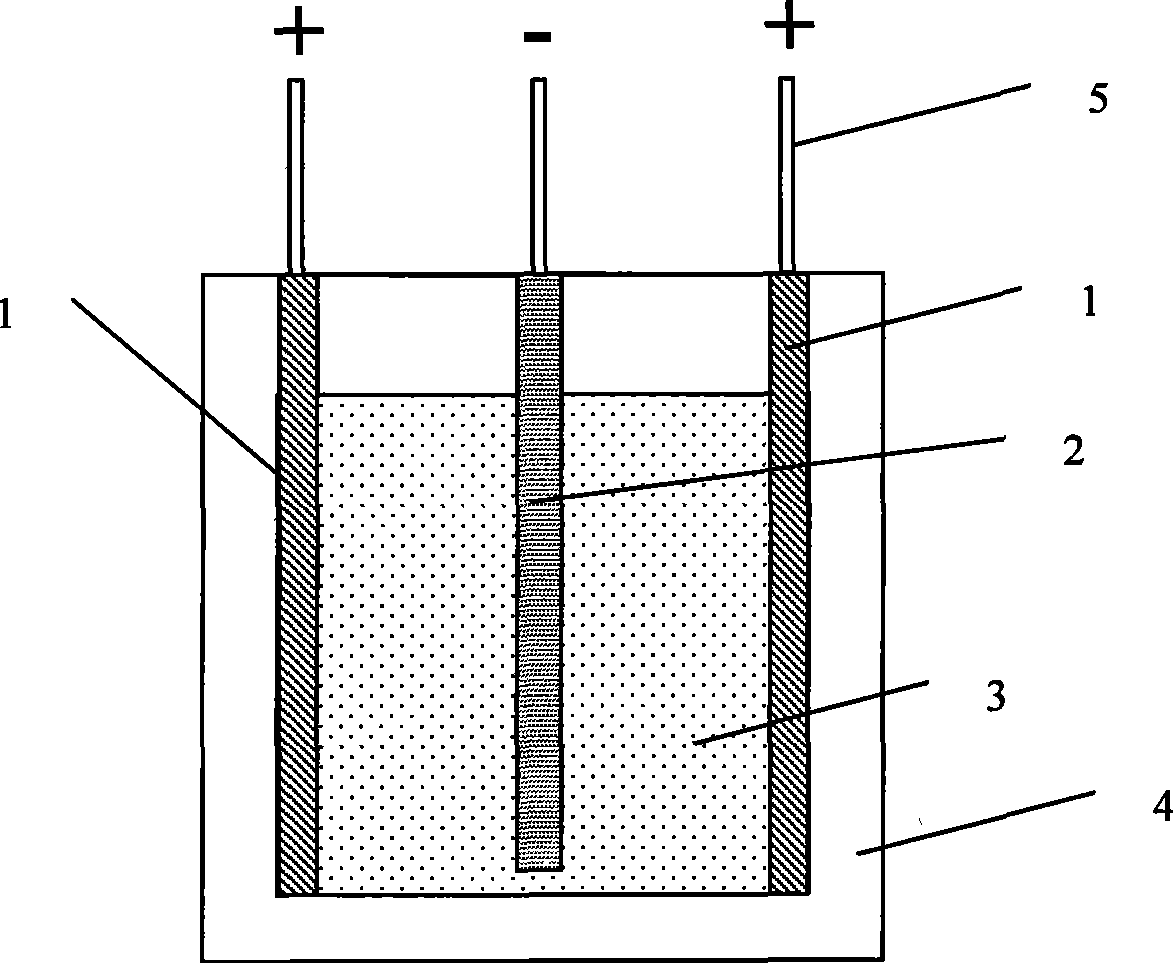

Method for producing aluminium-lithium alloy with high lithium content by low-temperature molten salt electrolysis

The invention provides a method for producing an aluminium-lithium alloy with high lithium content by low-temperature molten salt electrolysis. In an electrolytic furnace, aluminium is taken as a cathode, a cathode sleeve is sheathed thereon, graphite is taken as an anode, an electrolyte system is formed from LiCl and KCl, wherein, the weight ratio of LiCl: KCl is equal to 45: 55, the electrolysistemperature is 380-450 DEG C, the self-consumption cathode method is adopted for carrying out electrolysis, the current density of the cathode is 1-3.0A / cm<2>, the current density of the anode is 0.5A / cm<2>, the cell voltage is 4.1-5.6V, LiCl is supplemented during the electrolysis process for leading the mixing ratio of LiCl: KCl of the electrolyte to be in the vicinity of an eutectic point, theliquid aluminium-lithium alloy with high lithium content is deposited in the vicinity of the cathode in a molten salt electrolytic cell by 1-4 hours of electrolysis, and the solid aluminium-lithium alloy is prepared by solidification. The method can obtain the liquid aluminium-lithium alloy with evenly distributed alloy components at low temperature. The method can avoid the defects of burning loss of lithium during the doping process and the like, simultaneously save energy consumption of doping, mixing and melting process, avoid cracking of the cathode and uneven components, and avoid the defects of burning loss of the lithium caused by higher temperature and volatilization loss of LiCl.

Owner:HARBIN ENG UNIV

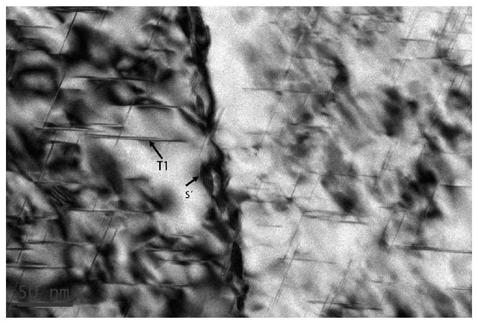

Extrusion deformation aluminum-lithium alloy with high Zn content and high strength and toughness, and preparation method thereof

The invention relates to an extrusion deformation aluminum-lithium alloy with high Zn content and high strength and toughness, and a preparation method thereof. The alloy comprises, by weight, 4.1%-5.5% of Zn, 2%-4.5% of Cu, 2%-3% of Mg, 1%-2% of Li, 0.1%-0.5% of Zr, less than 0.25% of impurity elements in total, and the balance Al. Through melting and casing as well as extrusion deformation, theextrusion deformation aluminum-lithium alloy with high Zn content is prepared. Through deformation and aging treatment, not only lots of Tl(Al2CuLi) but also S' (Al2CuMg) phases and eta' (MgZn2) phases are precipitated from the alloy with high Zn content, and the strength and toughness of the alloy are improved effectively. The aluminum-lithium alloy prepared with the preparation method provided by the invention not only has excellent mechanical properties, but also is low in alloy cost, and has broad application prospects in the fields, such as aerospace, high-speed railways and robots.

Owner:SHANGHAI JIAO TONG UNIV +1

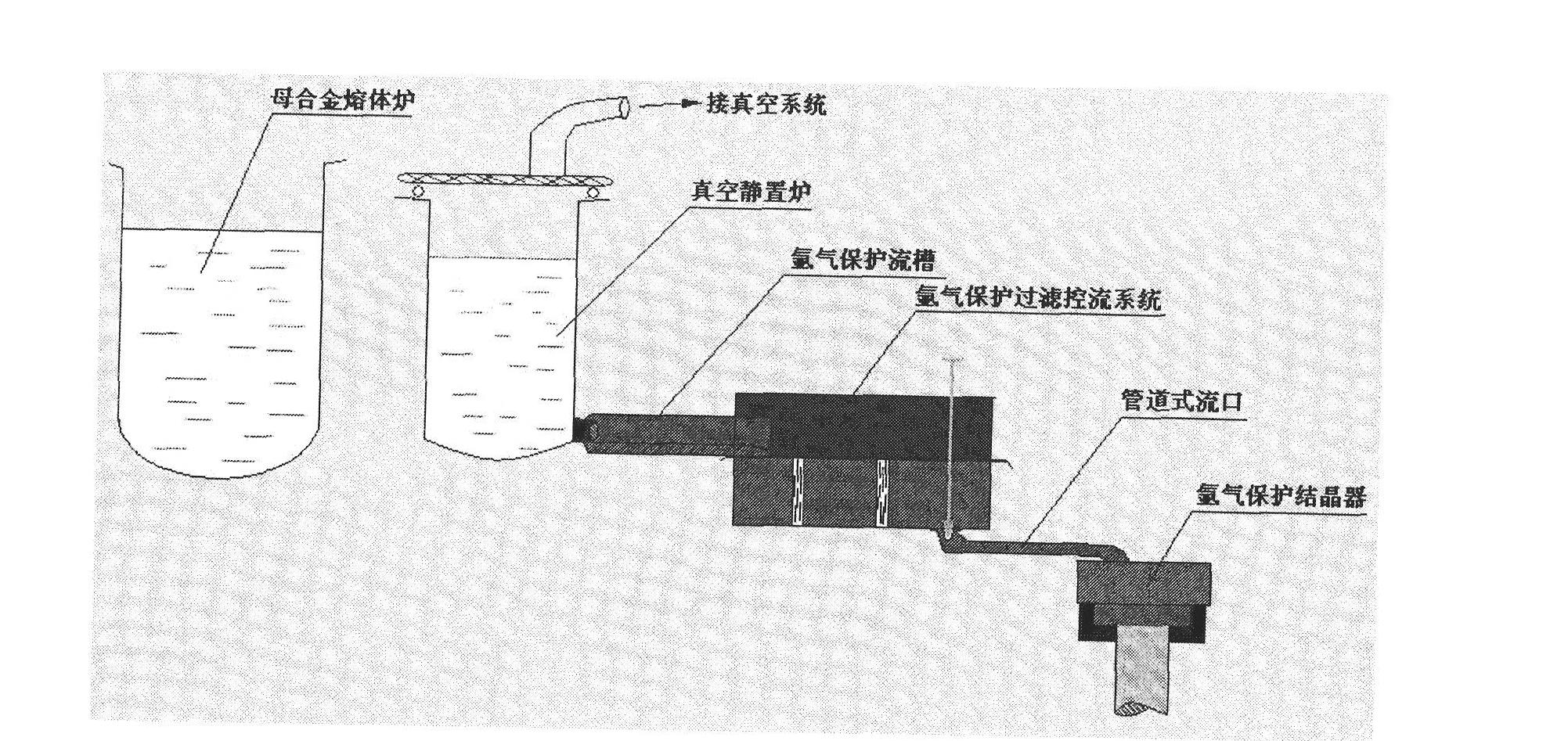

Preparation method of aluminum lithium alloy ingot

The invention provides a preparation method of an aluminum lithium alloy ingot. The preparation method comprises the following steps: (a) melting raw materials for smelting; (b) refining the raw material after being melted to obtain a melt; (c) transferring the melt to a holding furnace for sampling before smelting, and then carrying out vacuum refining; (d) casting the melt after being refined, wherein the speed of casting is 25-35 mm / min, the water pressure of casting is 0.02-0.08 MPa, and the temperature of casting is 710-750 DEG C; (e) annealing an obtained aluminum lithium alloy ingot to obtain the aluminum lithium alloy ingot. The dimensions of the aluminum lithium alloy ingot prepared by the invention can reach (400-500) mm * (1200-1500) mm. Experimental results show that the breaking tenacity of the large-specification aluminum lithium alloy ingot prepared by the invention when the thickness is 100 mm is 32-35 MPa * m<1 / 2>.

Owner:SOUTHWEST ALUMINUM GRP

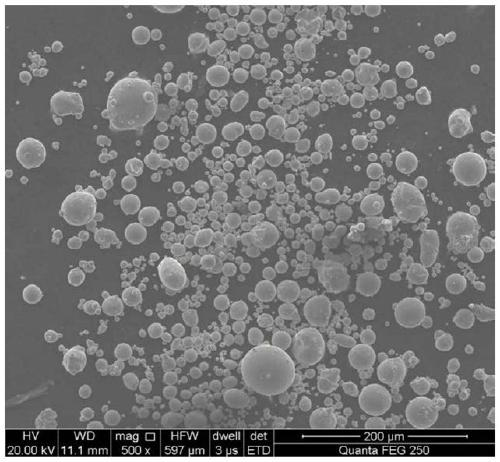

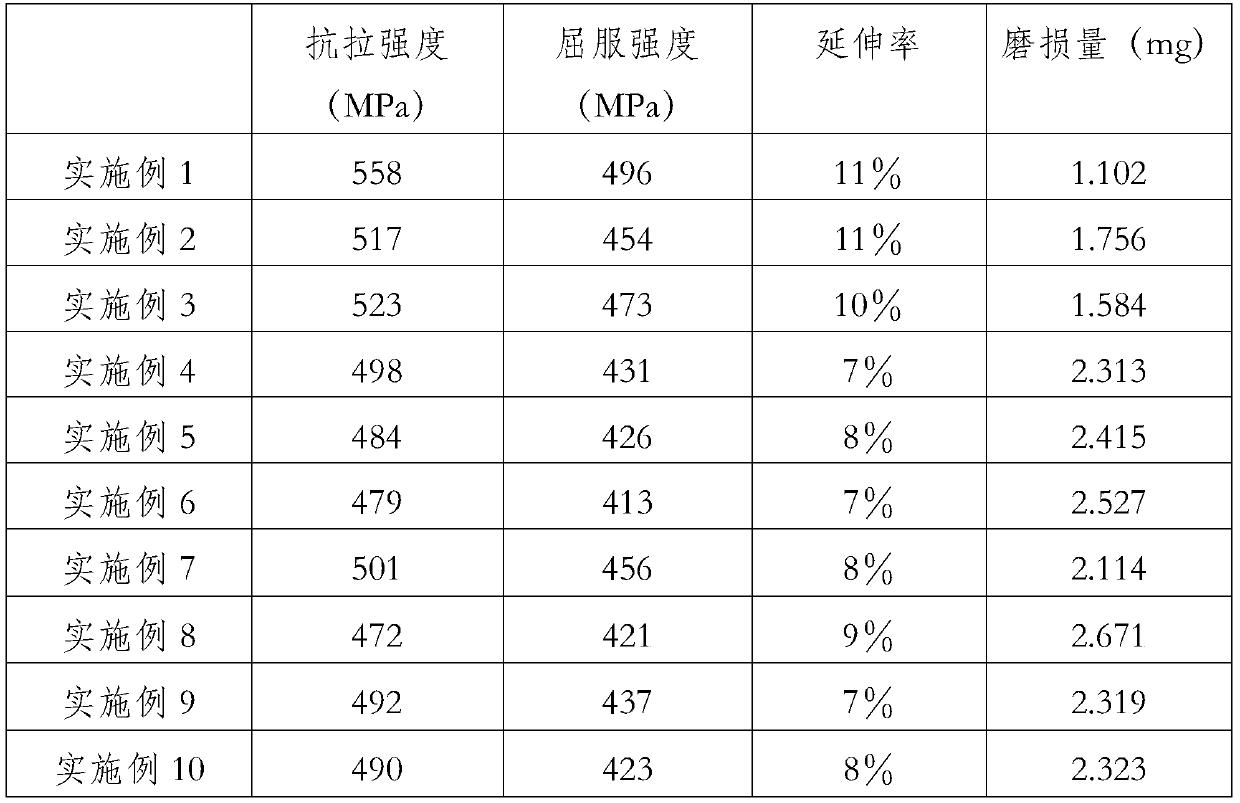

3D printing aluminum lithium alloy, preparing method of 3D printing aluminum lithium alloy and part printing method of 3D printing aluminum lithium alloy

ActiveCN110144502AImprove microstructureSimple structureAdditive manufacturing apparatusLithiumAlloy

The invention discloses a 3D printing aluminum lithium alloy, a preparing method of the 3D printing aluminum lithium alloy and a part printing method of the 3D printing aluminum lithium alloy. The 3Dprinting aluminum lithium alloy comprises, by mass percent, 0.5 to 2.0% of Li, 2.5 to 5.0% of Cu, 0.3 to 1.2% of Mg, 0.2 to 0.8% of Ag, 0.06 to 0.1% of Cr, 0.1 to 0.5% of Zr, 0.08 to 0.14% of Y, 0.02to 0.08% of Er, 0.1 to 0.5% of Sc, 0.02 to 0.08% of Ru, 0.1 to 1.5% of Ti and the balance Al. The obtained alloy sample is smooth in surface, free of obvious cracks, and high in compactness, the tensile strength is 558 MPa, the yield strength is 496 MPa, and the ductility is 11%.

Owner:CENT SOUTH UNIV +1

Low-cost and high-toughness aluminum lithium alloy

The invention relates to a high-strength and low-cost deformed aluminum lithium alloy product containing no silver. The aluminum lithium alloy can be formed through casting or injection to extrude rods or profiles; and the rods or the profiles are applied to aerospace parts. The alloy comprises the following components: 3.5-4.0 weight% of Cu, 1.5-2.0 weight% of Li, 0.5-1.0 weight% of Mg, 0.5-1.0 weight% of Zn, Mn not more than 0.5 weight%, and 0.1-1.0 weight% of such elements as Ti, Zr, Cr, V and Ce. The contents of impurities are controlled as follows: the content of silicon not more than 0.15%, the content of iron not more than 0.15 weight%, and the content of other elements not more than 0.15 weight%. The alloy product has such advantages as low anisotropism and low processing sensitivity, and can be used for forming high-quality aluminum lithium alloy parts.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for aluminum lithium alloy preparation by fused salt electrolysis process

The invention relates to a method for preparing Al-Li alloy by a molten salt electrolysis method, which is characterized in that mixed carbonate or mixed nitrate containing lithium salt is used as an electrolyte; the mixed salt is arranged in an electrobath, the material of the cathode of which is aluminum, heated to an electrolysis temperature, then electrolyzed; the current density during electrolysis is 0.05 to 0.3A / cm2; after the electrolysis is accomplished, the cathode mixed with the metal Li is taken out; then a new cathode aluminum plate or stick is arranged to be continuously electrolyzed to obtain Al-Li alloy, the Li content of which is between 1 and 15wt percent. In the invention, the molten salt electrolyte and materials of an achloride system is adopted; no chlorine generates during the electrolysis process; the electrolysis temperature does not exceed 600 DEG C; the electrolysis temperature is low; the energy consumption is low; the method for preparing an Al-Li alloy is easily operated and managed.

Owner:NORTHEASTERN UNIV

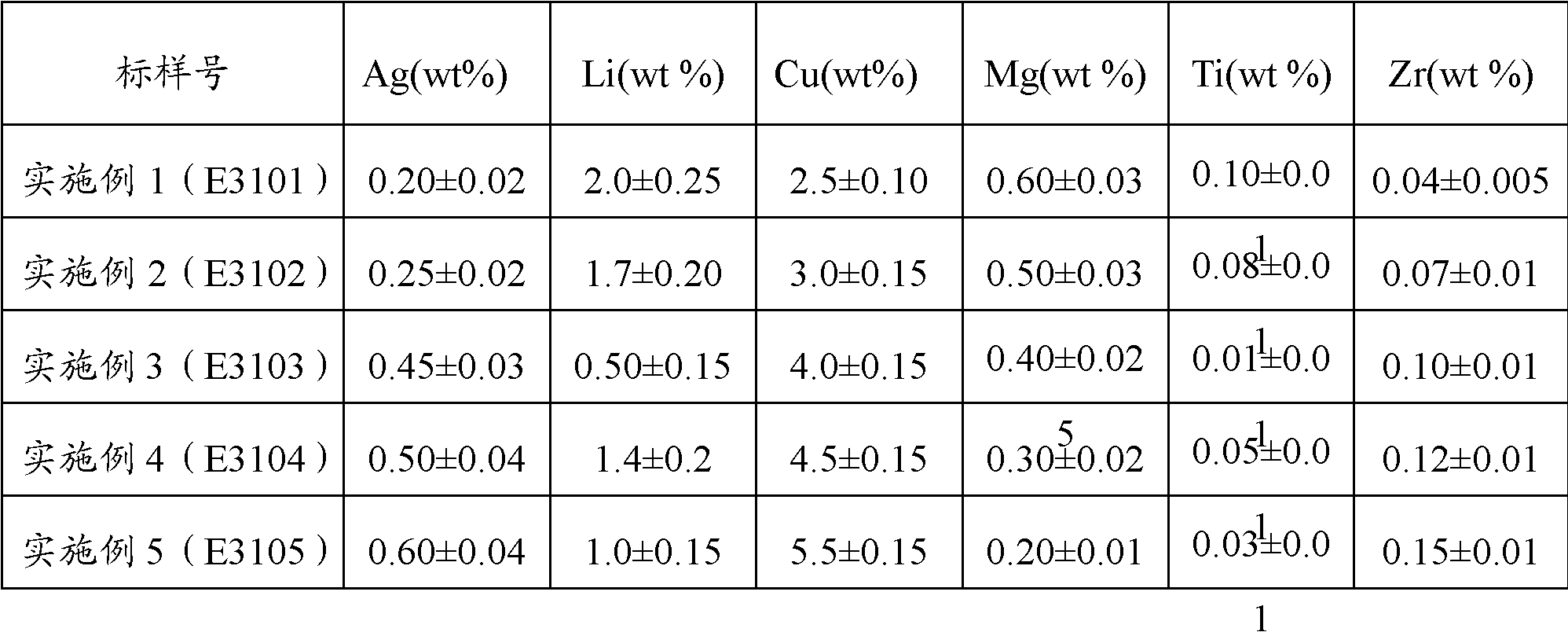

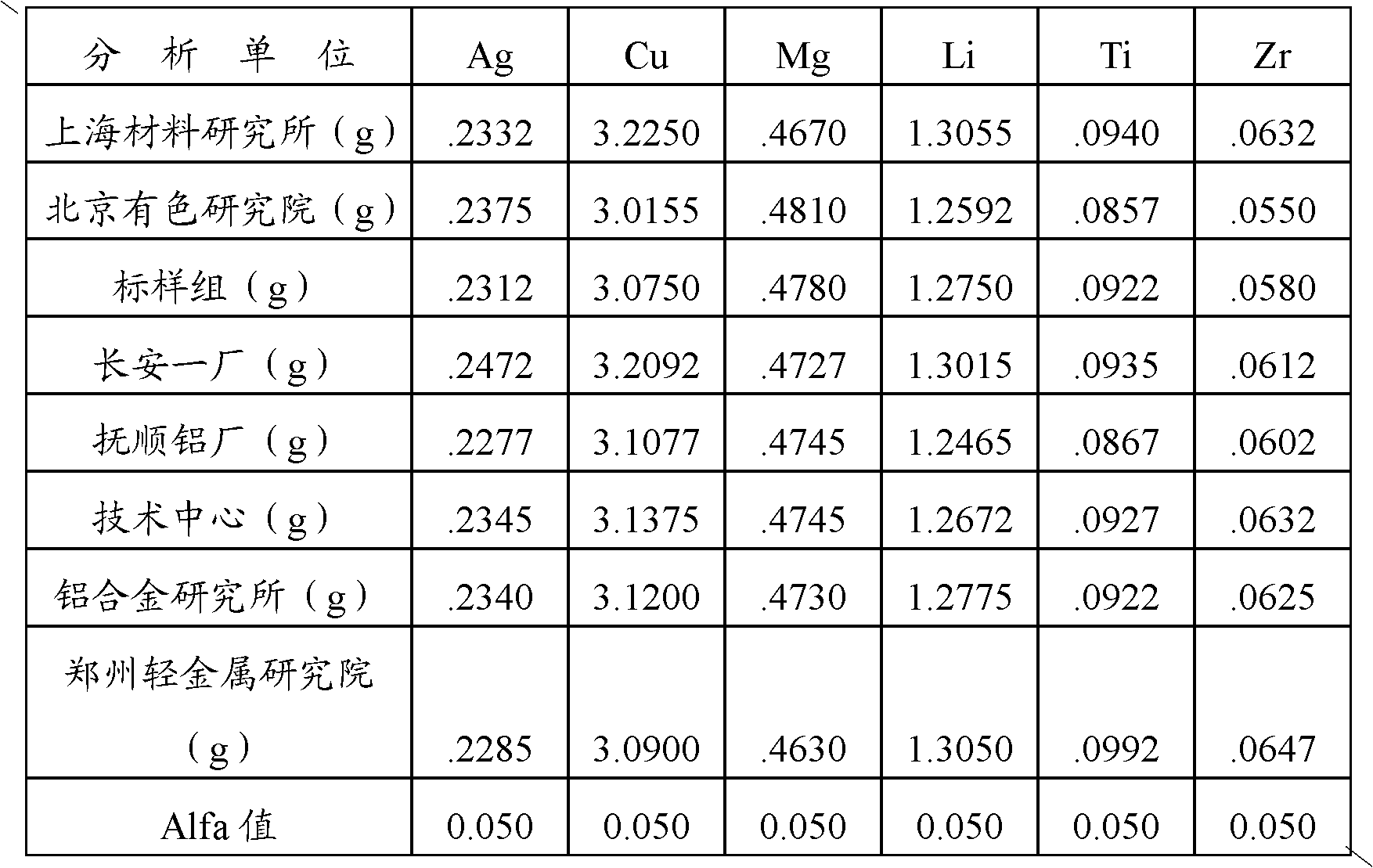

Aluminum lithium alloy spectrum standard sample containing silver, and preparation method thereof

The embodiment of the invention discloses a preparation method of an aluminum lithium alloy spectrum standard sample containing silver. In the preparation method of the invention, the Ag is added independently and the mode of stirring is adopted during the adding process of the Ag. The preparation method comprises the following steps: getting a part of a first alloy melt, adding the Ag into the part of the first alloy melt, and stirring to obtain a mixed melt; putting the mixed melt into a smelting furnace, and stirring to obtain a second alloy melt, wherein the volume of the part of the first alloy melt is 0.1 to 1 L. Due to the fact that the part of the first alloy melt has small volume, the stirring is easily, thereby facilitating the mixing of the Ag and the part of the first alloy melt; in addition, the casting is performed under the condition of stirring, thereby avoiding the occurrence of the precipitation phenomenon and ensuring the uniformity of the cast ingot composition. The experimental result indicates that the aluminum lithium alloy spectrum standard sample containing the silver of the invention is the 2195 aluminum lithium alloy spectrum standard sample, and the composition is uniform.

Owner:SOUTHWEST ALUMINUM GRP

Method for aluminum-lithium alloy water-splitting hydrogen production

The invention provides a method for preparing hydrogen from aluminum lithium alloy cracking water. The method is to take aluminum lithium alloy as a raw material for hydrogen preparation, make the aluminum lithium alloy react with pure water or water in an aqueous solution, and quickly generate the hydrogen. The aluminum lithium alloy comprises 0.5 to 40 weight percent of metallic lithium in percentage by mass, and the granularity of the alloy is unlimited; and the lithium in the alloy greatly improves the reaction activity of aluminum and the water. The application scope of hydrogen preparation by the alloy is wide; the hydrogen can be generated in the water or the aqueous solution at various temperatures; and the hydrogen yield is high by utilization of the alloy for hydrogen preparation.

Owner:CENT SOUTH UNIV

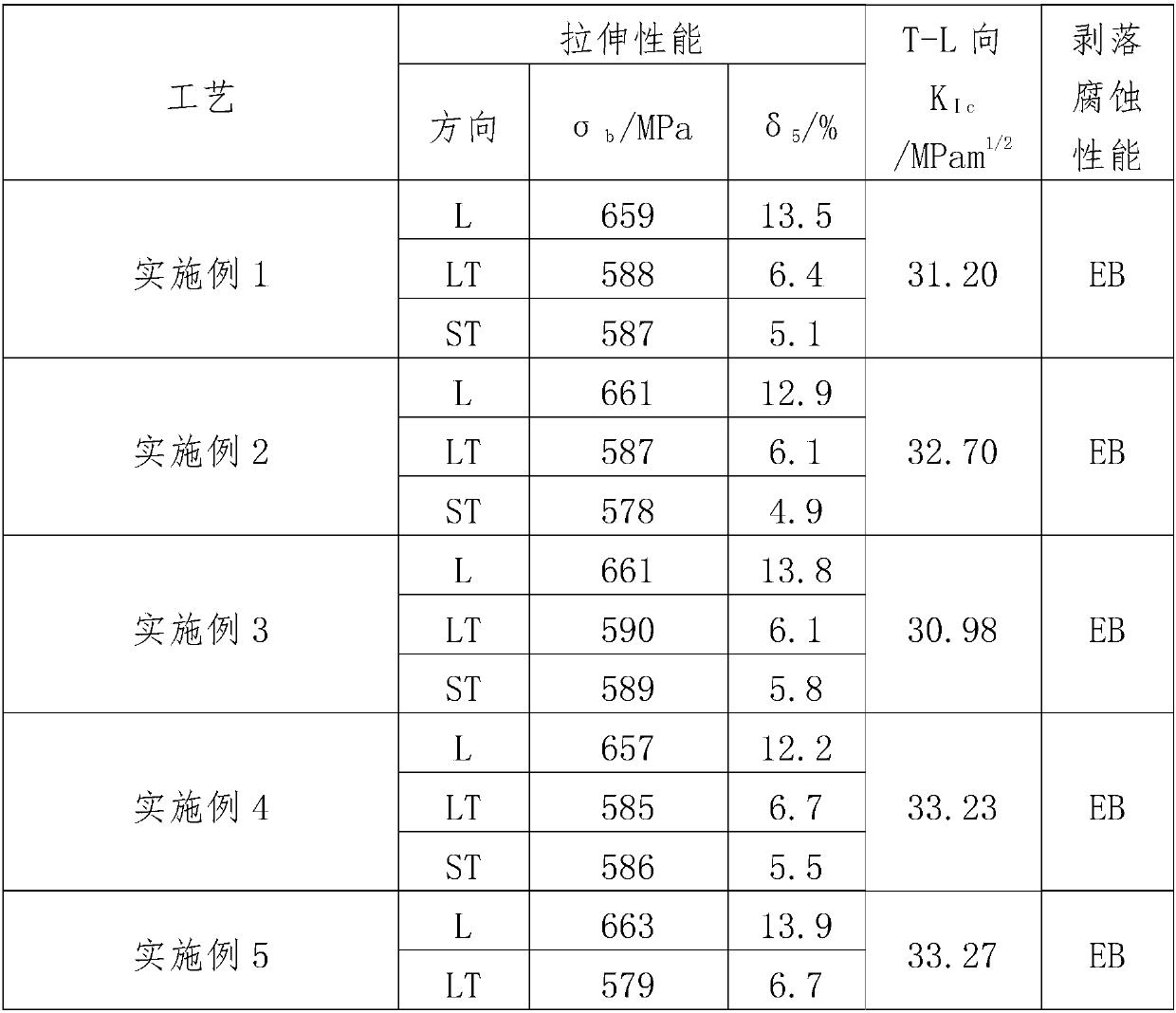

Al (aluminum) and Li (lithium) alloy material and extrusion method thereof

ActiveCN107779706AAvoid leaving the original grain boundaryImprove high elongationMetal-working apparatusManganeseMetallic materials

The invention belongs to the field of metal material engineering, and relates to an Al (aluminum) and Li (lithium) alloy material and an extrusion method thereof. The Al and Li alloy material is prepared from the following components in percentage by mass: 3% to 4.2% of Cu (copper), 0.2% to 1.4% of Mg (magnesium), 0.6% to 1.5% of Li, 0 to 1% of Ag (silver), 0.06% to 0.15% of Zr (zirconium), 0.2% to 0.6% of Mn (manganese), 0 to 0.8% of Zn (zinc), less than or equal to 0.08% of Si (silicon), less than or equal to 0.10% of Fe (ferrum), less than or equal to 0.05% of single impurity, and the balance of Al, wherein the total amount of other impurities is less than or equal to 0.15%. The extrusion method comprises the following steps of equalizing; extruding. The Al and Li alloy material and theextrusion method have the advantages that a large amount of original intercrystalline residues due to production of a large amount of intercrystalline precipitation phase by the critical saturated alloy element can be avoided; the high-direction elongation rate is improved, and the manufacturing requirement of large and thick specification parts being 40mm or more is met.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

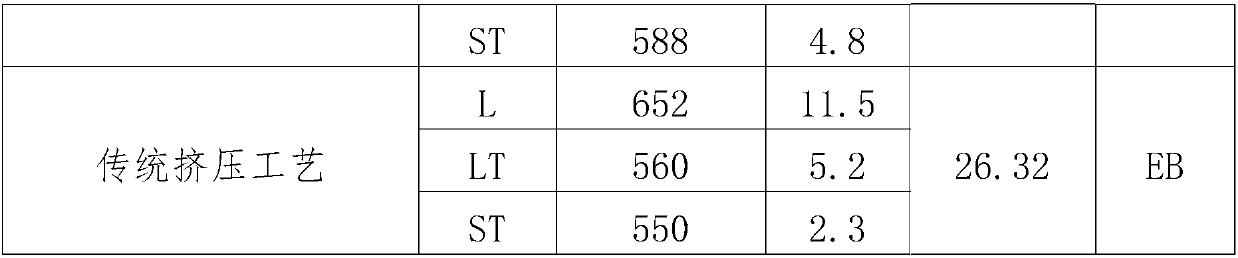

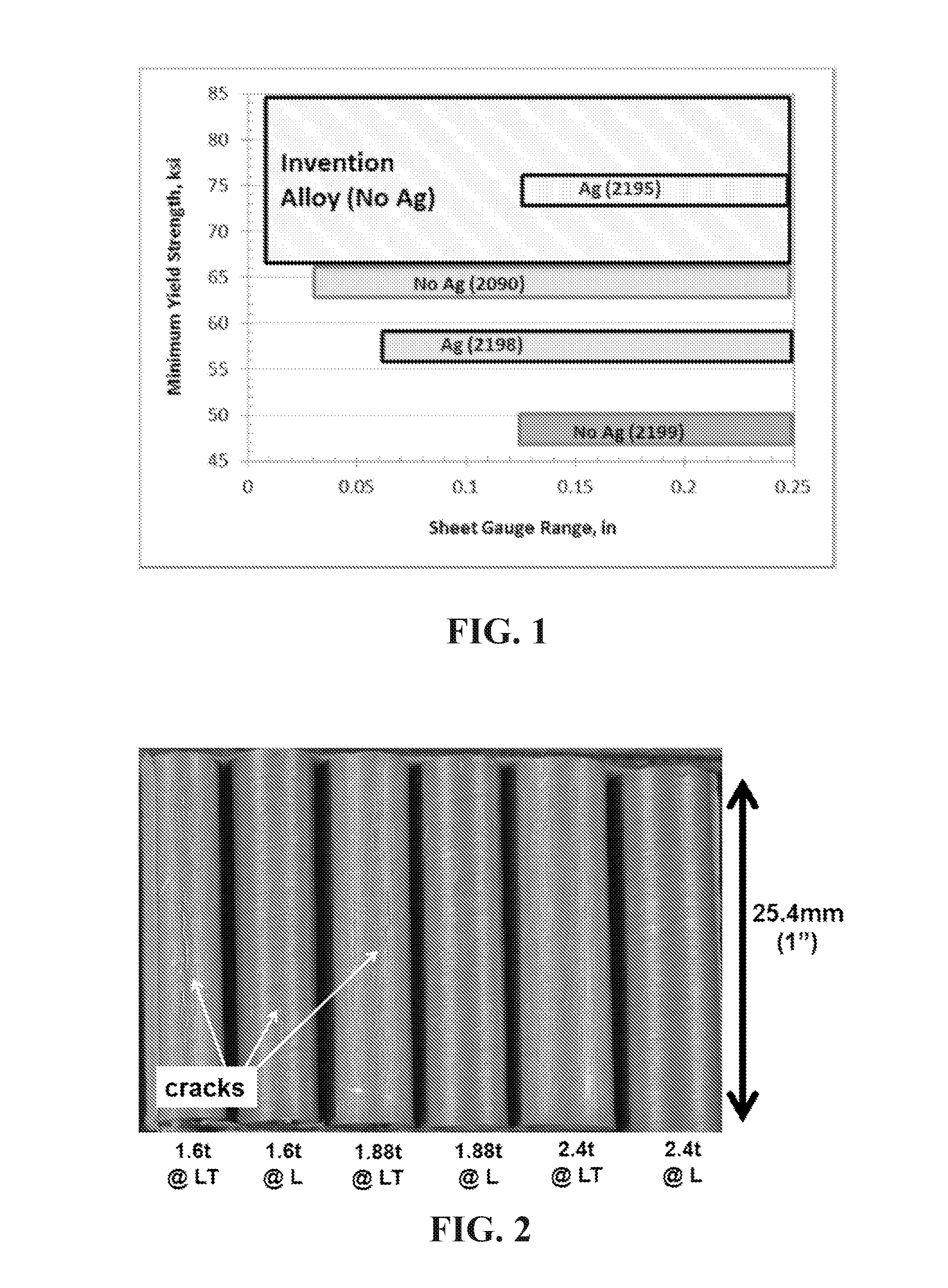

High Strength, High Formability, and Low Cost Aluminum-Lithium Alloys

A high strength, high formability and low cost 2xxx aluminum-lithium alloy is disclosed. The aluminum-lithium alloy is capable of being formed into wrought products with a thickness of from about 0.01″ to about 0.249″. Aluminum-lithium alloys of the invention generally comprise from about 3.5 to 4.5 wt. % Cu, 0.8 to 1.6 wt. % Li, 0.6 to 1.5 wt. % Mg, from 0.03 to 0.6 wt. % of at least one grain structure control element selected from the group consisting of Zr, Sc, Cr, V, Hf, and other rare earth elements, and up to 1.0 wt. % Zn, up to 1.0 wt. % Mn, up to 0.12 wt. % Si, up to 0.15 wt. % Fe, up to 0.15 wt. % Ti, up to 0.05 wt. % of any other element, with the total of these other elements not exceeding 0.15 wt. %, and the balance being aluminum. Ag should not be more than 0.5 wt. % and is preferably not intentionally added. Mg is at least equal or higher than Zn in weight percent in the invented alloy. Further provided are methods for manufacturing wrought products including the aluminum-lithium alloys of the present invention.

Owner:KAISER ALUMINUM FABTED PRODS

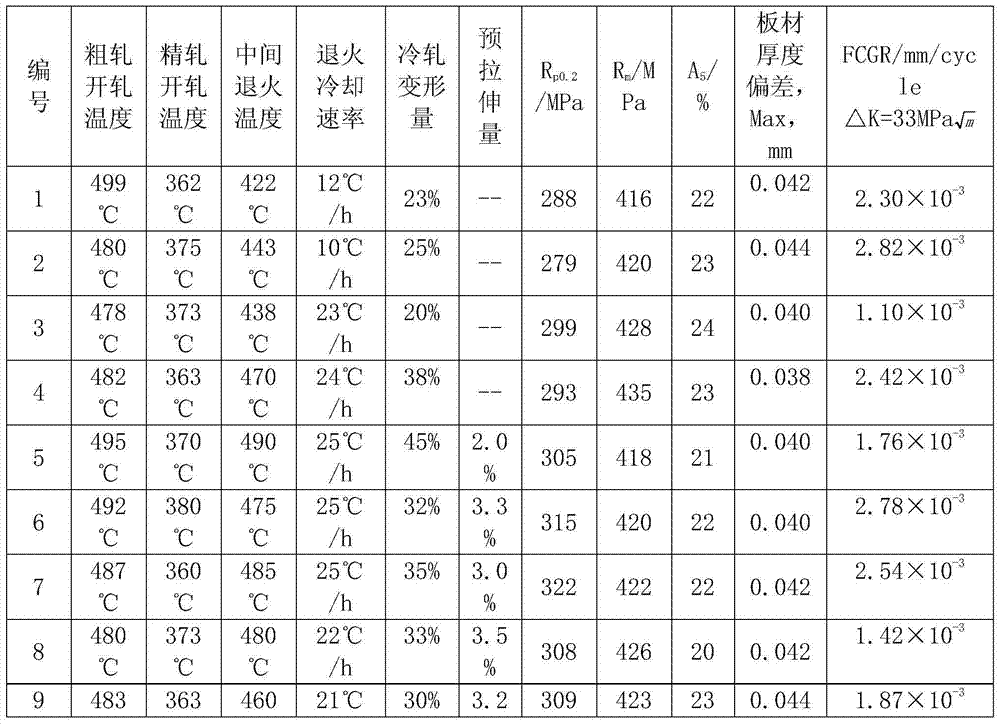

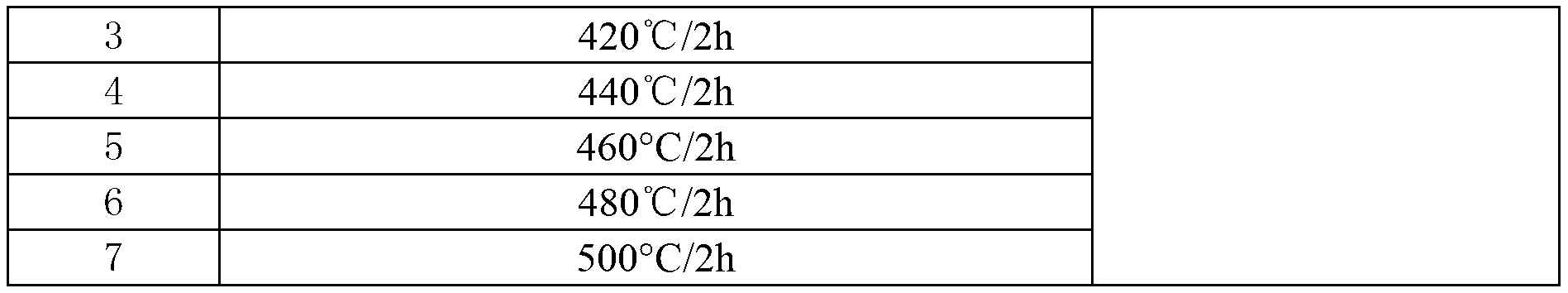

High-temperature annealing method of Al-Li-Cu-X serial aluminum lithium alloy

The invention discloses a high-temperature annealing method of an Al-Li-Cu-X serial aluminum lithium alloy. The Al-Li-Cu-X serial aluminum lithium alloy comprises the following chemical components in percentage by weight: 2.0-5.0% of Cu, 0.8-2.5% of Li, 0.20-0.60% of Mn, 0.20-0.80% of Zn, 0.04-0.20% of Zr, 0.20-0.80% of Mg, 0.1-0.7% of Ag, less than or equal to 0.10% of Si, less than or equal to 0.10% of Fe, less than or equal to 0.12% of Ti, less than or equal to 0.05% of each of other impurities, less than or equal to 0.15% of total amount of other impurities, and the balance of Al. The high-temperature annealing method is characterized by comprising the following steps of: (1) carrying out fusion casting and homogenization according to fusion casting and homogenization processes of 2A97 aluminum lithium alloy; (2) carrying out hot rolling or cold rolling according to a hot rolling or cold rolling process of 2A97 aluminum lithium alloy; (3) carrying out high-temperature annealing process, namely, heating a workpiece to 360-500 DEG C, keeping the temperature for 2h and cooling down, wherein the cooling speed is not greater than 20 DEG C / h, and the workpiece is discharged out of the furnace and cooled with air when the furnace temperature is not higher than the 200 DEG C. Compared with the conventional low-temperature annealing process, the method provided by the invention can ensure that the material has low strength and high toughness, so as to ensure that the material has excellent process properties.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

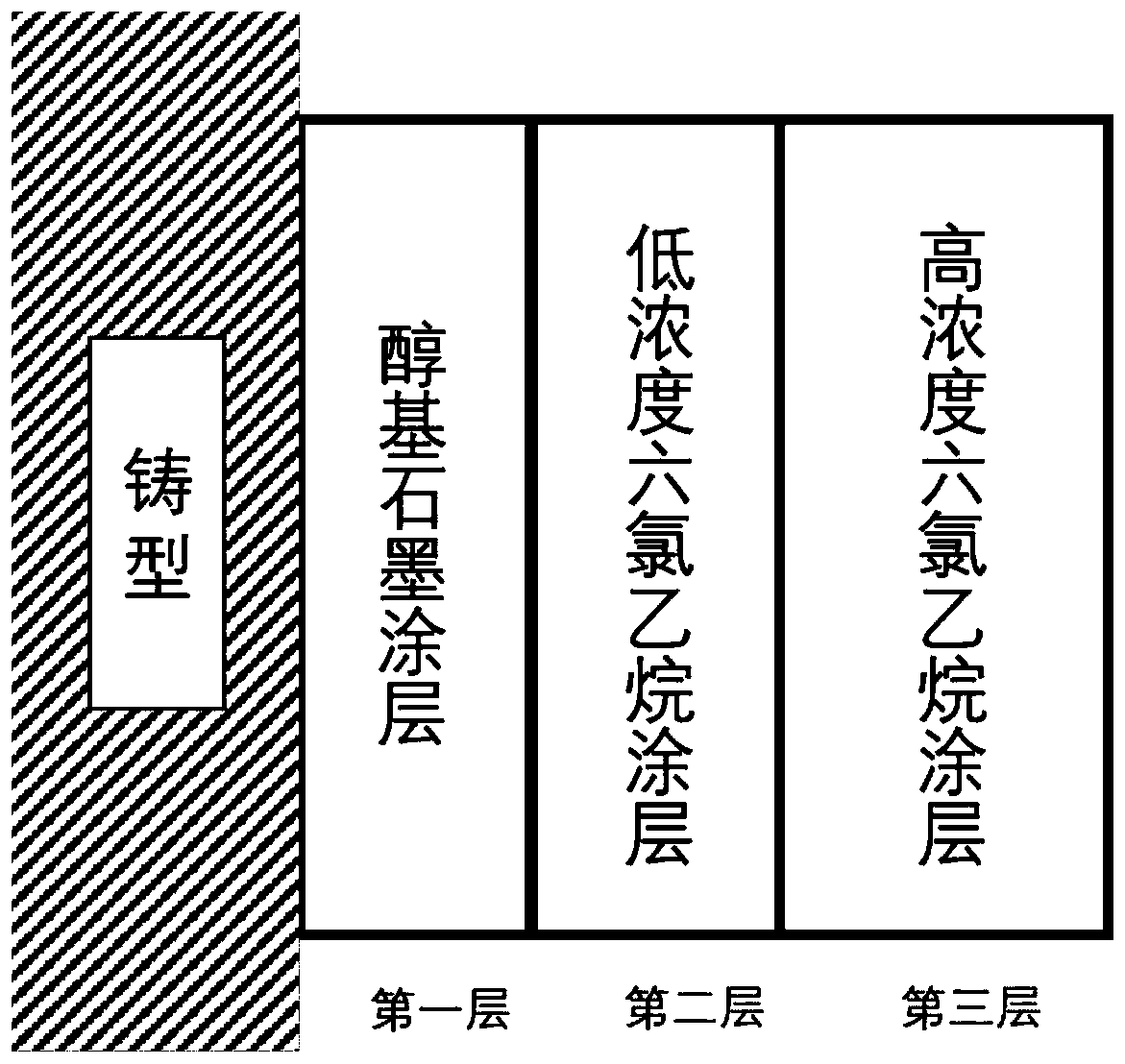

Multi-layer composite mold coating for aluminum-lithium alloy sand casting and coating method thereof

The invention discloses a multi-layer composite mold coating for aluminum-lithium alloy sand casting and a coating method thereof. The multi-layer composite coating comprises an alcohol-based graphitecoating, a low-concentration hexachloroethane coating and a high-concentration hexachloroethane coating which are sequentially arranged. The coating method adopts a combination manner of brushing andspraying, the alcohol-based graphite coating is brushed by adopting a brushing method, and the low-concentration hexachloroethane coating and the high-concentration hexachloroethane coating are sprayed by adopting a spraying method, and waited for natural volatilization and drying of the low-concentration hexachloroethane coating and the high-concentration hexachloroethane coating after the tlcohol-based graphite coating is ignited and dried. According to the coating, the hexachloroethane coating is added to react with aluminum lithium alloy melt to form an air film to prevent the alloy liquid from being in contact with a casting mold, and the problem that the high-activity lithium element is easy to react with a binder, a suspending agent, an auxiliary agent and the like in the sand moldand the coating in the aluminum lithium alloy sand mold casting process is solved. Meanwhile, the hexachloroethane coating can also generate a refining effect on the melt, deslagging and degassing are carried out, and the surface quality of the aluminum lithium alloy casting can be greatly improved.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com