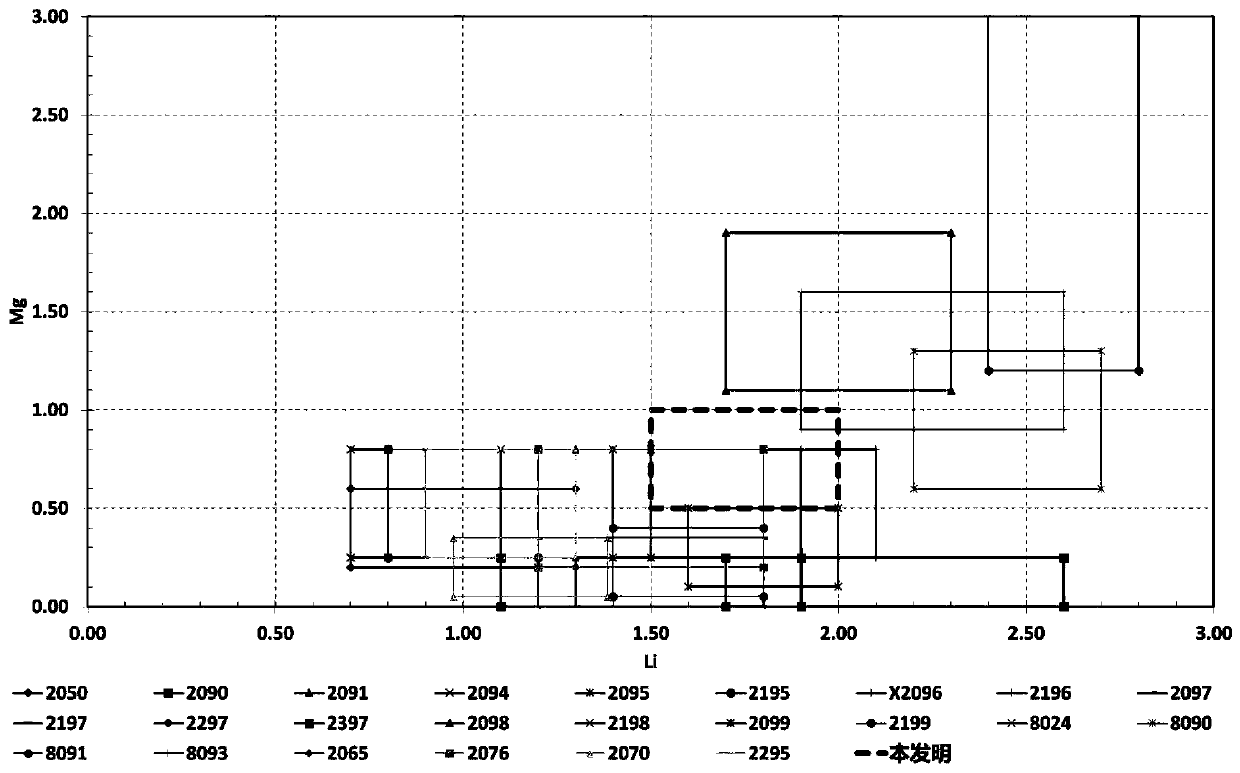

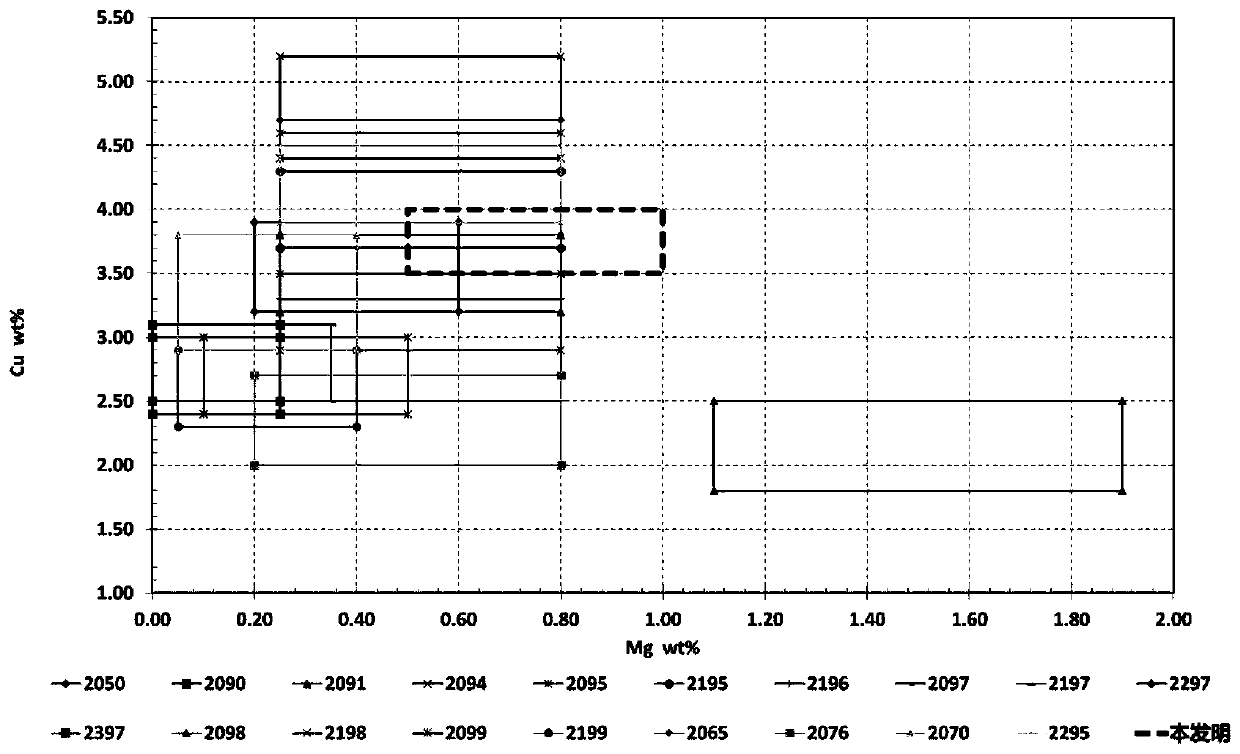

Low-cost and high-toughness aluminum lithium alloy

A technology of aluminum-lithium alloy and deformed aluminum alloy, which is applied in the composition field of low-cost lithium-containing aluminum alloy, can solve problems such as low strength, and achieve the effect of improving stress corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

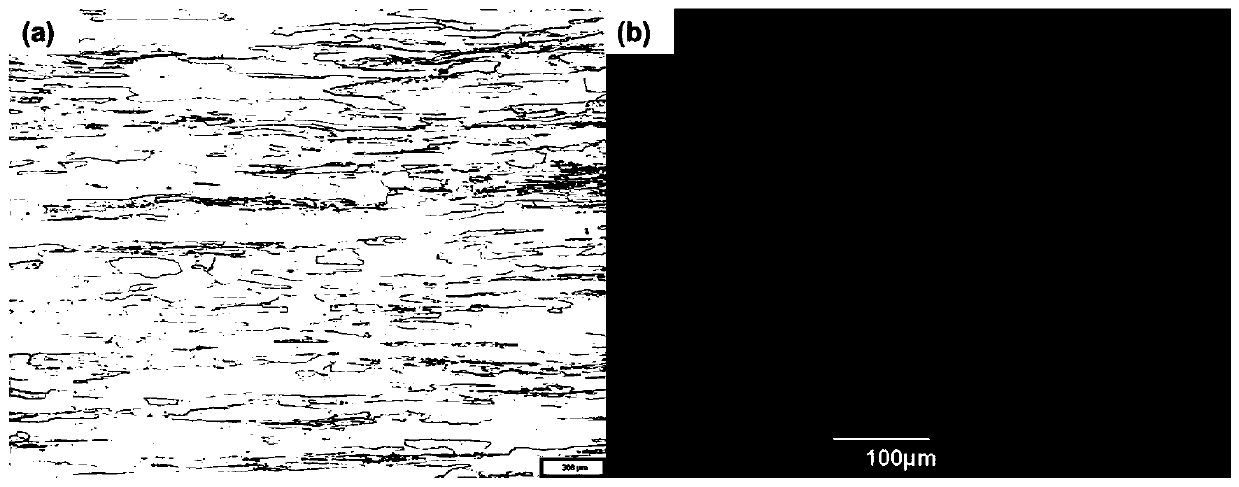

Examples

Embodiment 1

[0054] (1) Induction melting:

[0055] The chemical composition of the alloy without Li, Ti and Zr is weighed according to the mass percentage, then put into the induction melting furnace, and the raw materials are melted by electric heating. Wrap the lithium with aluminum foil and put it into another argon-protected induction melting furnace, and heat it to 740°C to melt after power on.

[0056] (2) Refining degassing:

[0057] The lithium-free aluminum alloy and pure lithium are diverted to the dehydrogenation chamber under the atmosphere of argon protection, and the argon gas is introduced for degassing. At the same time, Ti and Zr are added in the form of an intermediate titanium-boron refiner alloy, and heated While maintaining the temperature, the melt is filtered to remove slag.

[0058] (3) Semi-continuous casting:

[0059] The degassed, slag-removed, and fully stirred aluminum-lithium alloy solution is sent to a semi-continuous casting table for casting, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com