Spot welding method and application thereof in aluminum alloy and steel

An aluminum alloy sheet, aluminum alloy technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problems of large expansion coefficient, easy generation of pores and cracks, poor weldability of aluminum alloys, etc., to achieve improved fatigue performance, The effect of increased tensile strength and increased connection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

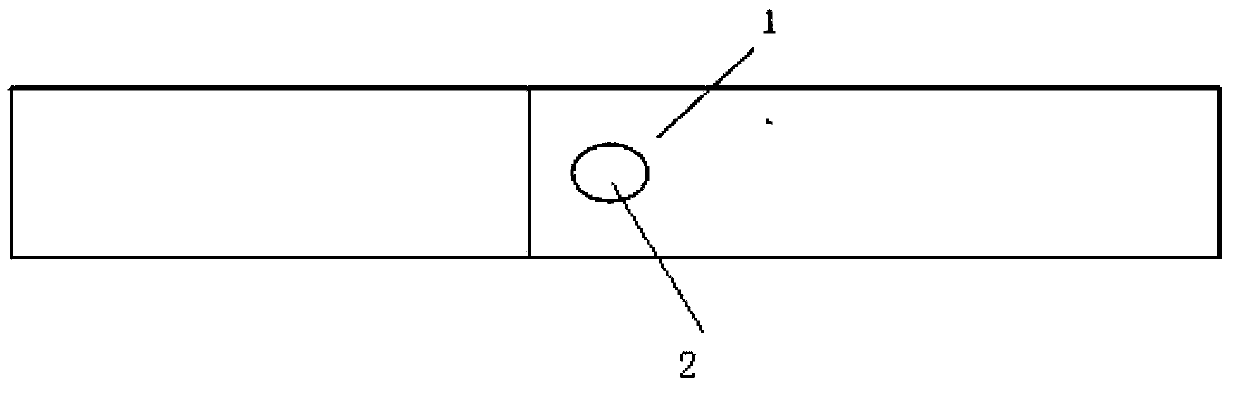

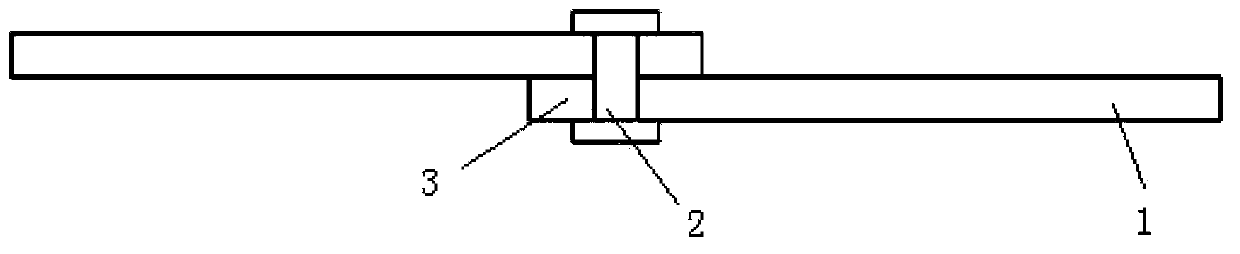

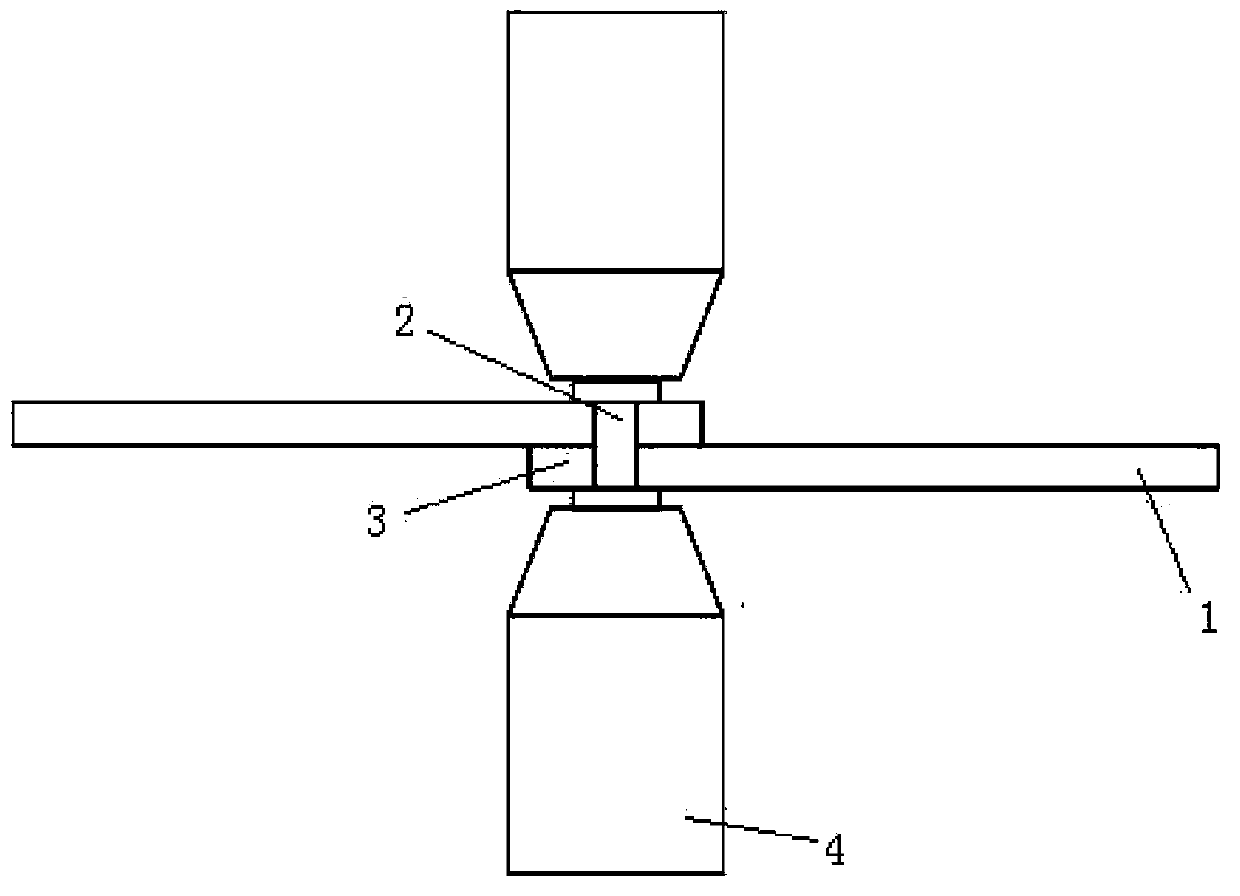

[0015] The first group, welding 7075 aluminum alloy sheet (thickness 1mm, length 100mm, width 30mm, lap joint length 30mm), according to the lap joint method, drill a hole at the center of the lap joint and then press the metal rod into it. The metal rod material is 5052 aluminum Alloy, diameter 3mm, length 3mm

[0016] The second group, welding Q235 steel (thickness 2mm, length 100mm, width 30mm, lap joint length 30mm), filled metal rod Q235 steel (diameter 3mm, length 6mm)

[0017] The third group, welding 5052 aluminum alloy (thickness 2mm, length 100mm, width 30mm, lap joint length 30mm), filler metal rod 5052 aluminum alloy (diameter 3mm, length 6mm)

[0018] The fourth group, welding DP600 super-strength steel (thickness 2mm, length 100mm, width 30mm, lap joint length 30mm), filler metal rod Q235 steel (diameter 3mm, length 6mm)

[0019] C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com