Laser and electric arc combined welding method for thick high-strength steel plates and clamp for method

A laser arc and hybrid welding technology, which is applied in the field of material processing, can solve the problems of low utilization rate of carbon dioxide laser energy, high cost of carbon dioxide laser, and unsatisfactory welding depth, so as to improve the weld composition and microstructure, reduce Welding defects, effects of increased solidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

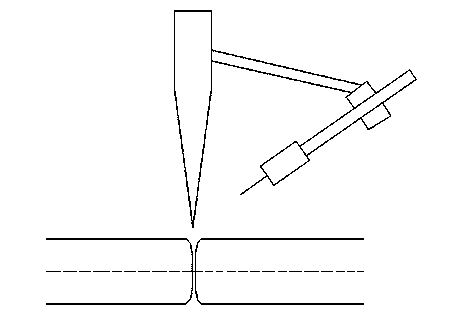

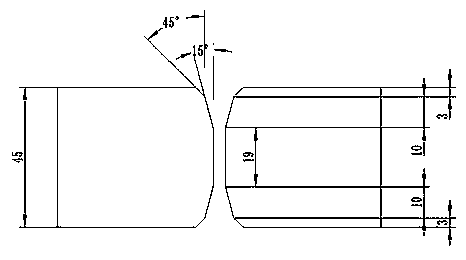

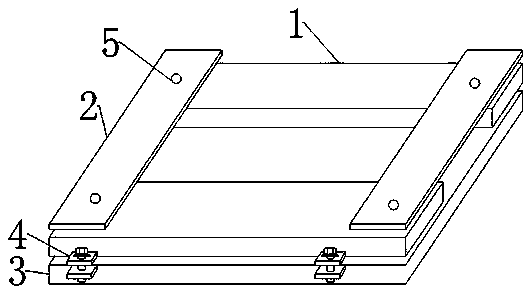

[0017]Domestic 45mm thick ZG30SiMn, and imported 45mm thick wear-resistant plate AR400, straight seam butt welding of dissimilar materials; workpiece groove form: choose 45mm plate, first open a 10mm, 15-degree groove on one side, and then open a 3mm, 45-degree groove, blunt edge 19mm; pre-welding preparation: before welding, grind the welding part to remove the oxide layer, oil stains, stains, etc. on the part to be welded, and clamp the welding workpiece, and the calibration gap is 1.2mm. After the clamping is completed, spot-fix the necessary positions to control the influence of welding deformation on the clamping gap; preheating before welding: laser preheating is adopted, no other preheating devices are needed, and welding can be performed directly after preheating. The heating method is intermittently repeated, and the preheating temperature is about 200 degrees Celsius. Usually, the heating part is scanned twice, each time is 5-8 minutes, and each time is intermittent f...

Embodiment 2

[0022] As an improvement of the present invention, the preheating treatment and welding operations are all completed by robots. It is necessary to compile the robot programs for preheating, bottoming and covering, and teach them. After adopting this design, welding can Straight line welding seam, circular welding seam, curved welding seam, and welding of various joint forms such as butt joint, T joint and fillet joint can be realized, and the welding accuracy and production efficiency are guaranteed. The rest of the structural features and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0024] As an improvement of the present invention, it is necessary to pay attention to heat preservation between layers during processing, and the temperature difference between layers is controlled at 1-3°. After adopting this design, the quality and welding effect of the welded parts can be guaranteed. All the other structures and advantages are identical to Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com