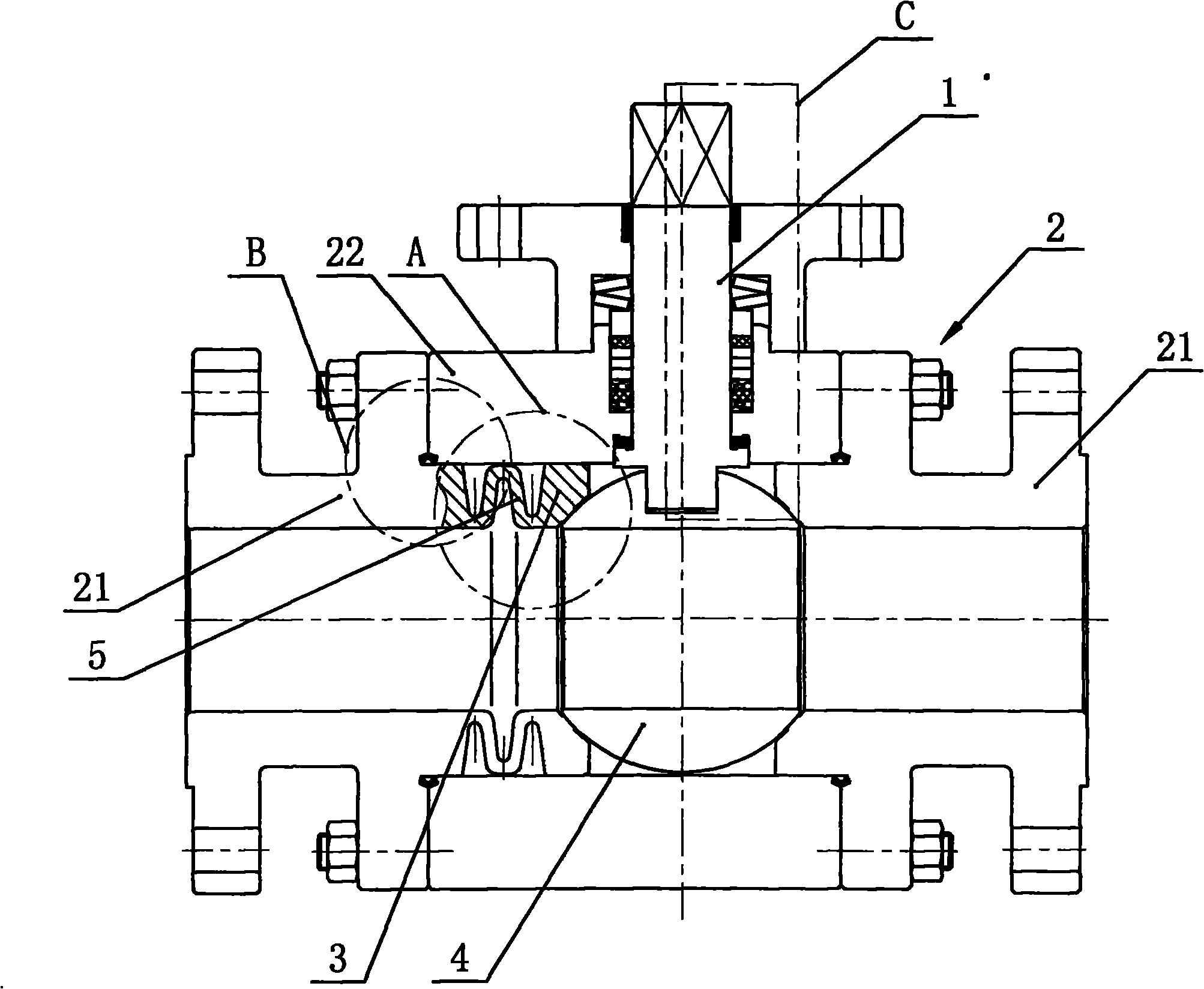

Integrated high-temperature high-pressure metal seal ball valve

A metal sealing, high temperature and high pressure technology, used in shaft seals, valve details, valve devices, etc., can solve problems such as seal failure, valve leakage, susceptibility to erosion, cavitation, and abrasion

Inactive Publication Date: 2010-08-25

浙江宏明阀门有限公司

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, our valve industry has achieved rapid development, but the existing valves similar to the present invention have the following problems due to their unreasonable structure: 1. The valve core ball and valve seat sealing materials are made of hard chrome, alloy steel and hard Alloy materials are susceptible to erosion, cavitation, and scratches under high temperature, high pressure, and high particle conditions, resulting in seal failure; 2. The valve seat and valve body are set separately, which adds a seal between the valve seat and the valve body. It is very easy to cause leakage of the valve; 3. The seal between the valve body, auxiliary valve body and valve stem is easy to leak

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a valve, in particular to an integrated high-temperature high-pressure metal seal ball valve. The invention adopts the following scheme that: the integrated high-temperature high-pressure metal seal ball valve comprises a valve rod, a valve body, a valve seat and a valve core ball. The valve is characterized in that the valve seat and the valve body are integrally arranged, and a transversal ripple structure is formed at the integral joint of the valve seat and the valve body. By adopting the scheme, the invention overcomes the defects of the prior art and provides a novel integrated high-temperature high-pressure metal seal ball valve with reasonable structure, flexible opening and closing, high efficiency and good seal effect.

Description

Integrated high temperature and high pressure metal seal ball valve technical field The invention relates to a valve, in particular to a high temperature and high pressure metal sealing ball valve. Background technique At present, our valve industry has achieved rapid development, but the existing valves similar to the present invention have the following problems due to their unreasonable structure: 1. The valve core ball and valve seat sealing materials are made of hard chrome, alloy steel and hard Alloy materials are susceptible to erosion, cavitation, and scratches under high temperature, high pressure, and high particle conditions, resulting in seal failure; 2. The valve seat and valve body are set separately, which adds a seal between the valve seat and the valve body. It is very easy to cause leakage of the valve; 3, the seal between the valve body, the auxiliary valve body and the valve stem is easy to leak. Contents of the invention The invention overcomes the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16K5/06F16K5/08F16K5/20F16K27/06F16K41/02

Inventor 姜明

Owner 浙江宏明阀门有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com