Patents

Literature

241results about How to "Guaranteed sealing reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

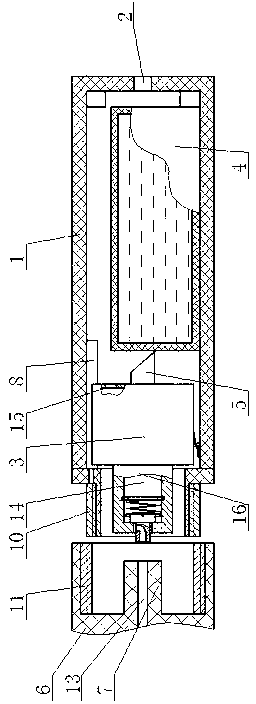

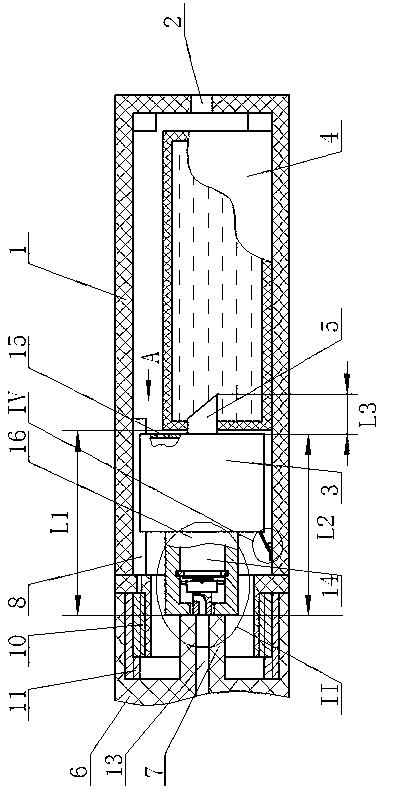

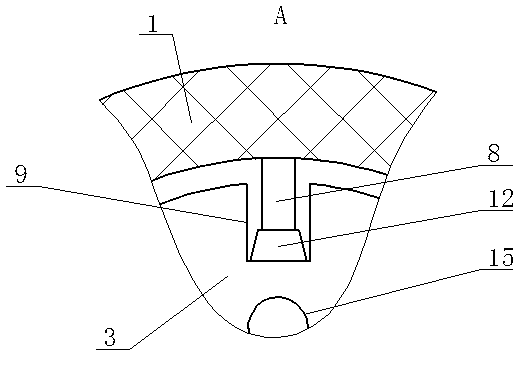

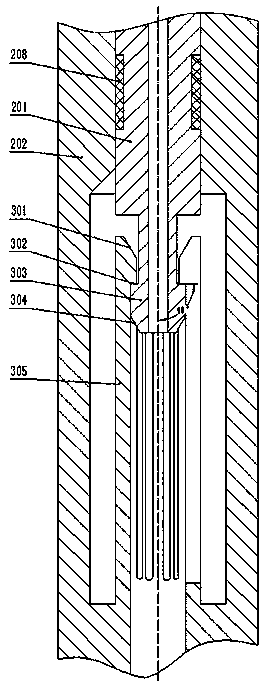

Screw-driven sliding piercing type electronic smoking set

ActiveCN103315402ANo outflowAvoid pollutionTobacco devicesMedical atomisersEngineeringMechanical engineering

The invention provides a screw-driven sliding piercing type electronic smoking set comprising a smoking set shell. A cigarette liquid capsule and an atomizer are mounted in the smoking set shell, an air inlet passage is formed in the atomizer, a smoking orifice is formed in the side wall of the shell, the atomizer is mounted on the other side of the shell, a piercing liquid guide frame on the atomizer is positioned on one side of the cigarette liquid capsule, and a thread is arranged on the inner or outer peripheral wall, at one end of the atomizer, of the shell. A guide block is mounted on the inner wall of one end, provided with the atomizer, of the smoking set shell axially, and a guide groove is formed in the outer wall of the atomizer and matches with the guide block. The atomizer can be completely isolated from the outside when not used, impurities are thoroughly prevented from being ignited by a heating wire to generate naked flame after dust and the impurities enter the atomizer, and harmful substances in the impurities are prevented from being inhaled into human bodies; the atomizer is prevented from being separated from the cigarette liquid capsule, so that sealing reliability between the atomizer and the cigarette liquid capsule is further kept.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

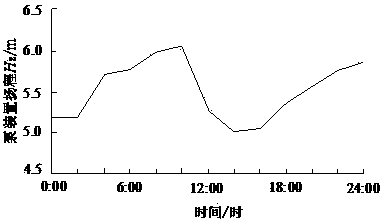

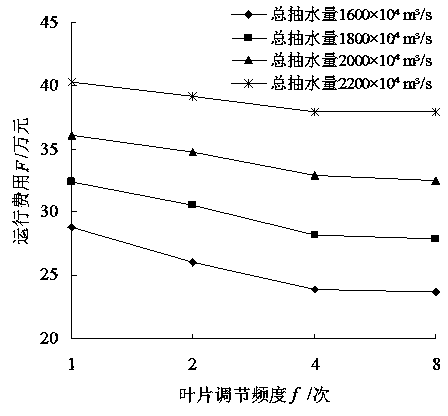

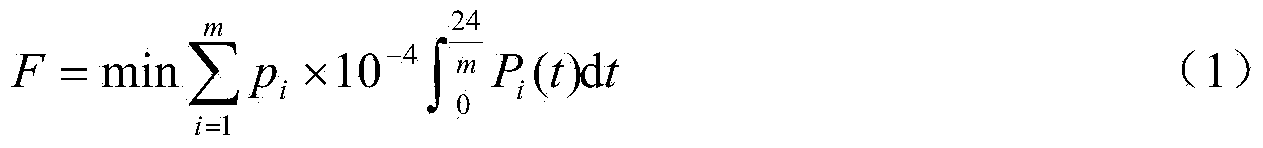

Method for determining blade adjustment frequency of variable-angle optimized operation of large fully-adjustable water pump station

InactiveCN103807184AIncreased durabilityGuaranteed sealing reliabilityPump controlNon-positive displacement fluid enginesElectricity priceTime of use

The invention provides a method for determining the blade adjustment frequency of variable-angle optimized operation of a large fully-adjustable water pump station, and belongs to the field of operation optimization and energy conservation of engineering systems. Factors of pump unit lift continuous changes, time-of-use electricity prices and the like are taken into consideration, and the variable-angle adjustment frequency is given; under the situation that the requirement for the quantity of daily pumped water is met, a mathematical optimization model is built by aiming at making system daily operating cost minimum, the simulated annealing-particle swarm optimization algorithm is adopted for determining optimal system operation schemes in a solved mode, the optimal operation schemes and total operation cost of a pump station system in various operation periods are calculated when water pump blades have different types of adjustment frequency, influence of the blade adjustment frequency on the operation cost is analyzed, and the reasonable blade adjustment frequency of the pump station system is determined. The water pump blade adjustment frequency and the optimal operation schemes in all the periods determined in the method can not only guarantee that the pump station achieves the variable-angle optimized operation effect and the purpose of saving the operation cost is achieved, but also guarantee reliable durability of a water pump blade adjusting mechanism and blade root seals thereof.

Owner:YANGZHOU UNIV

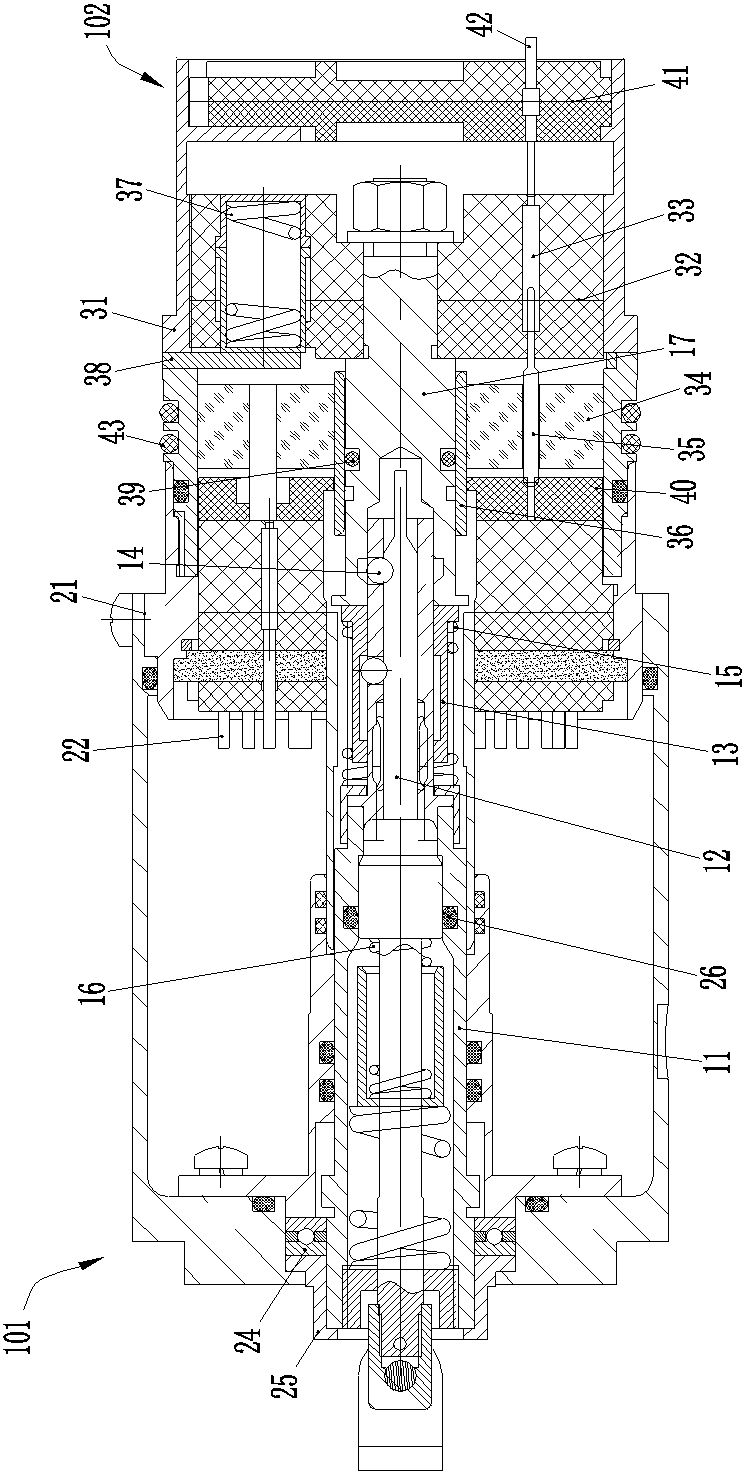

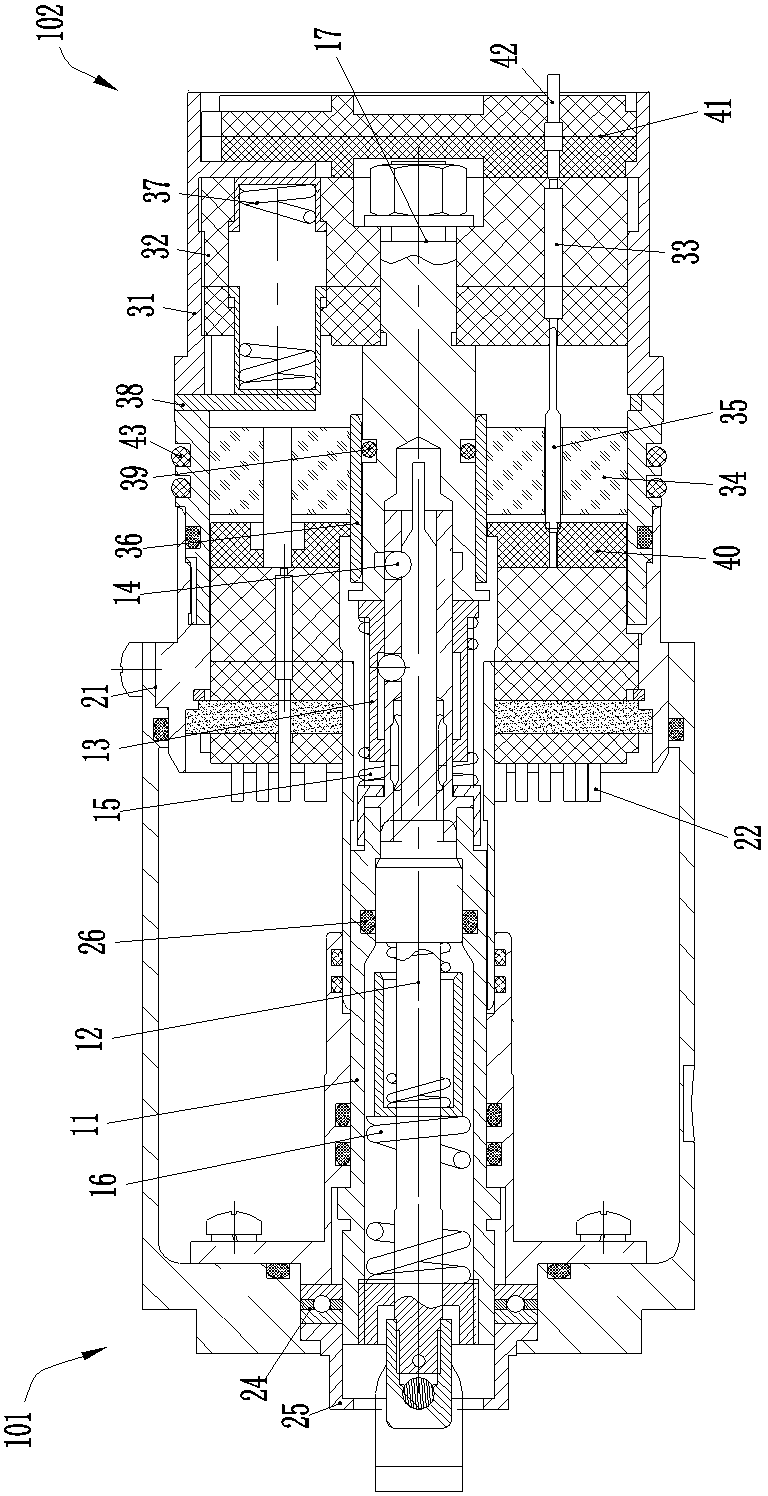

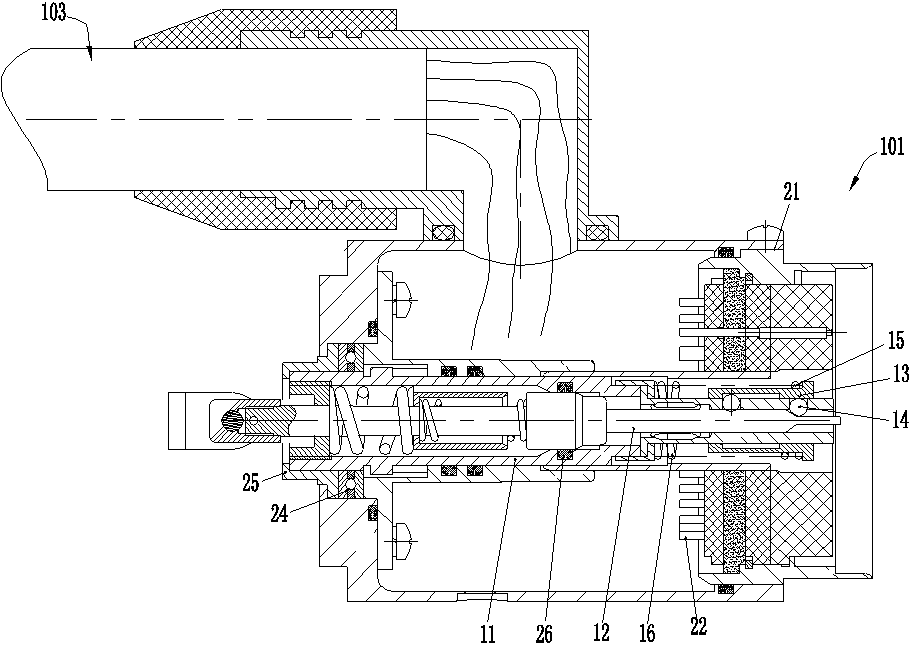

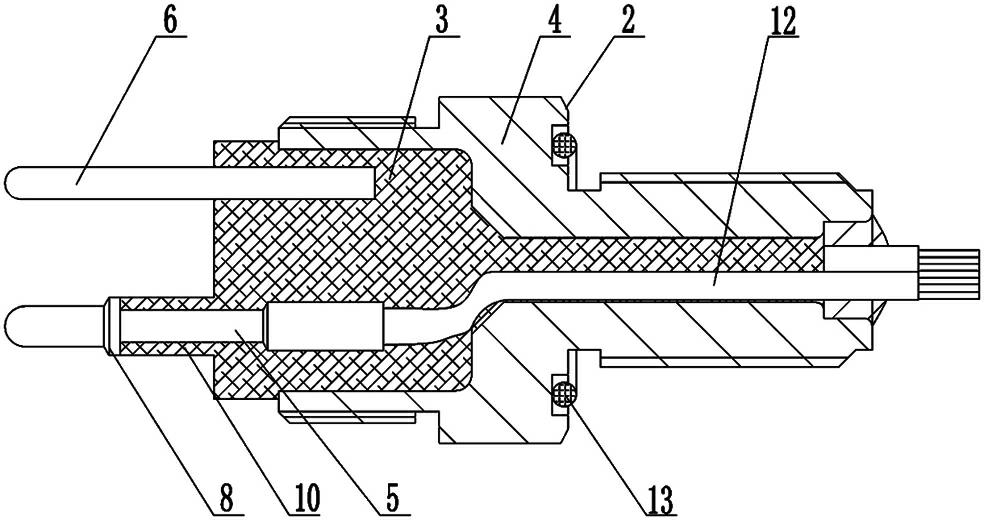

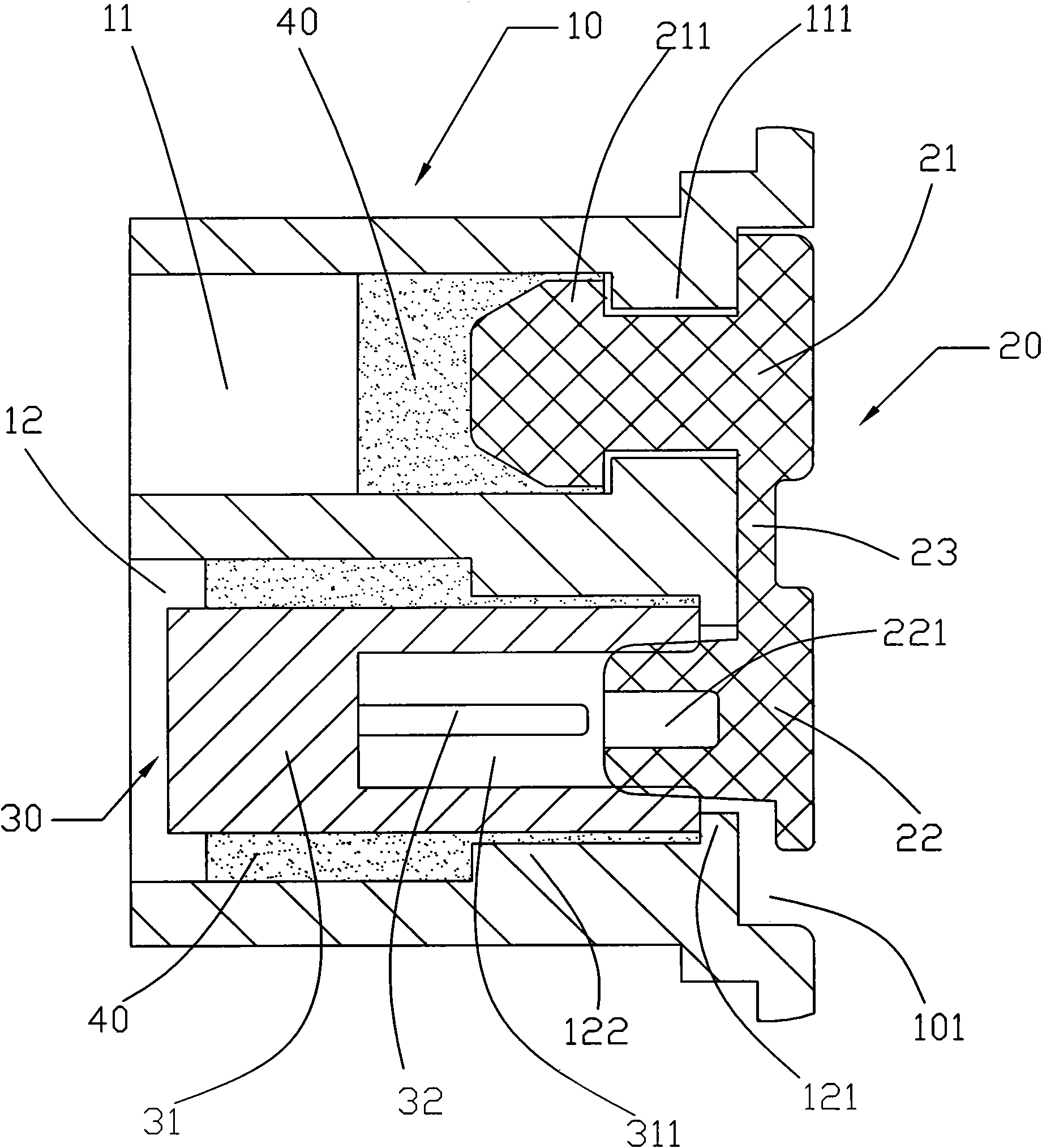

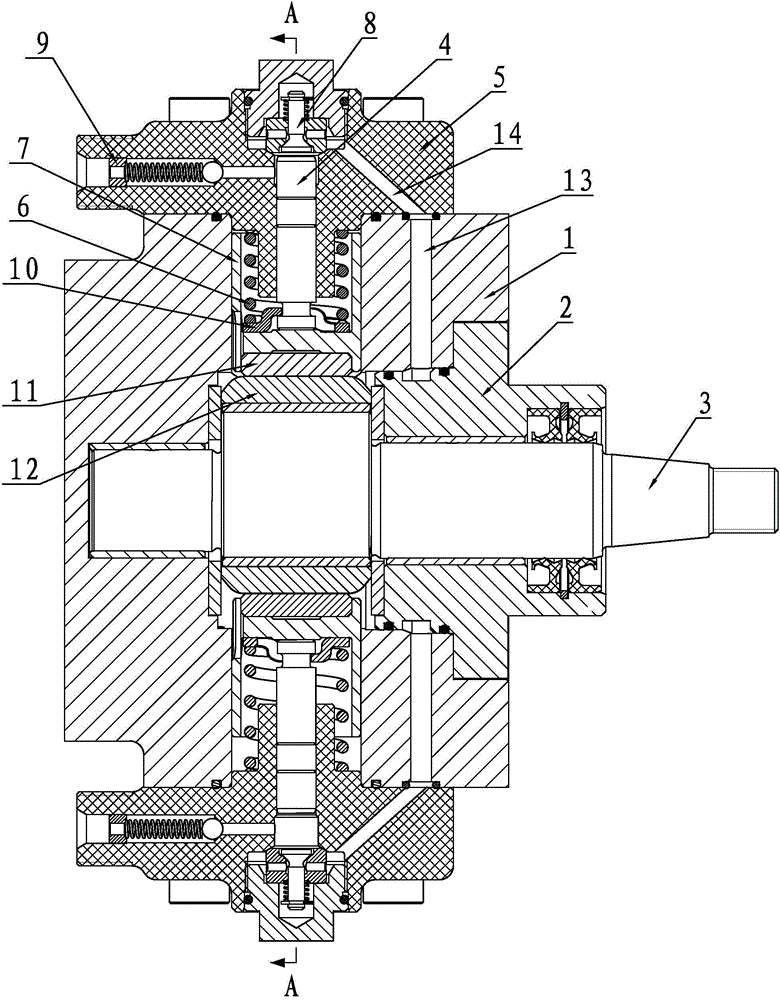

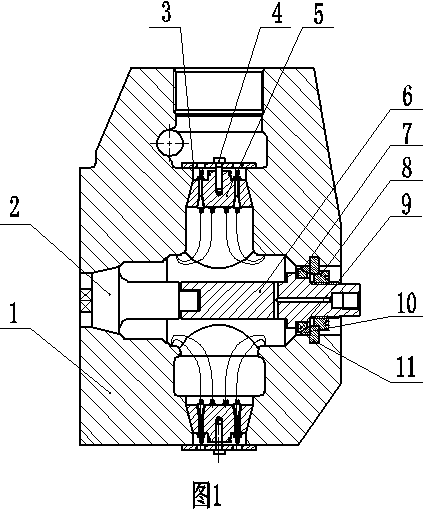

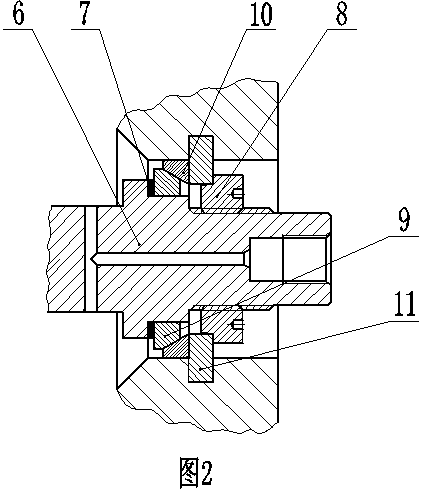

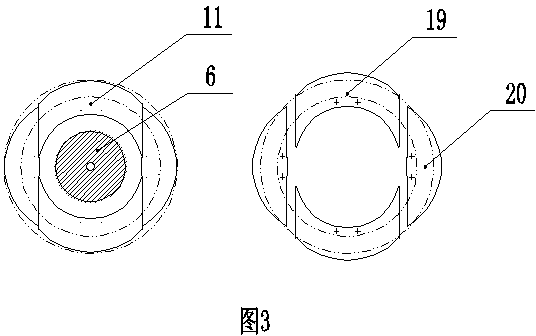

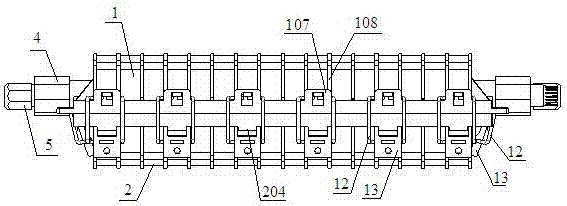

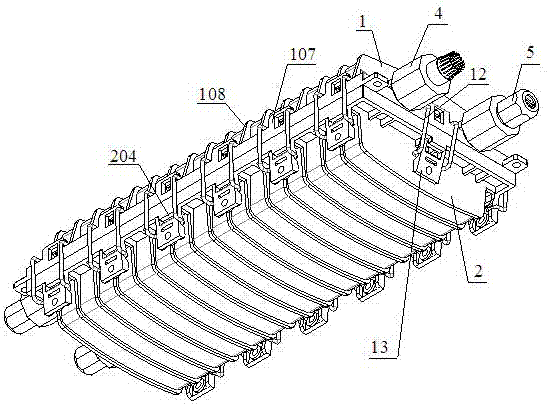

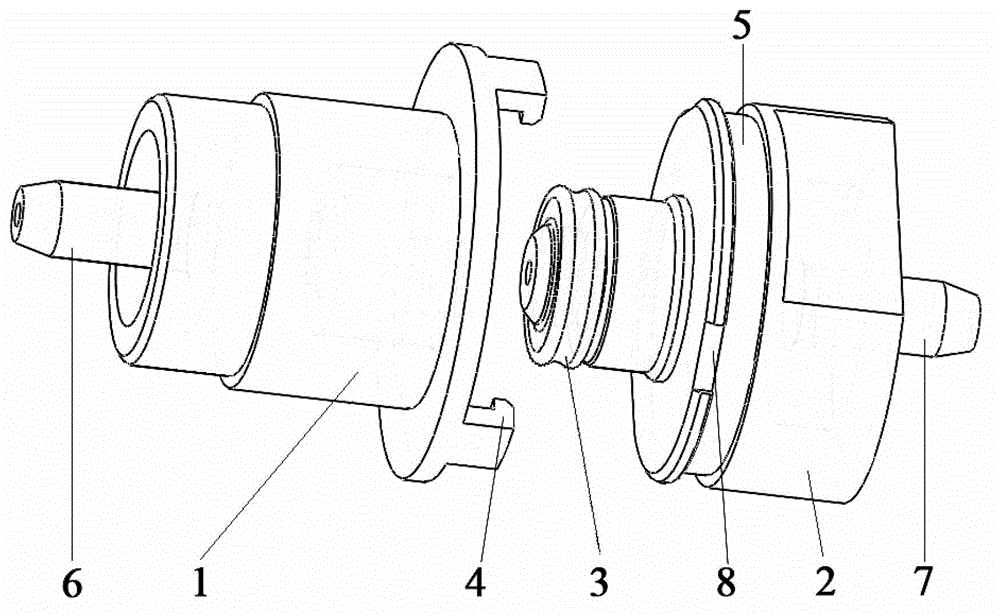

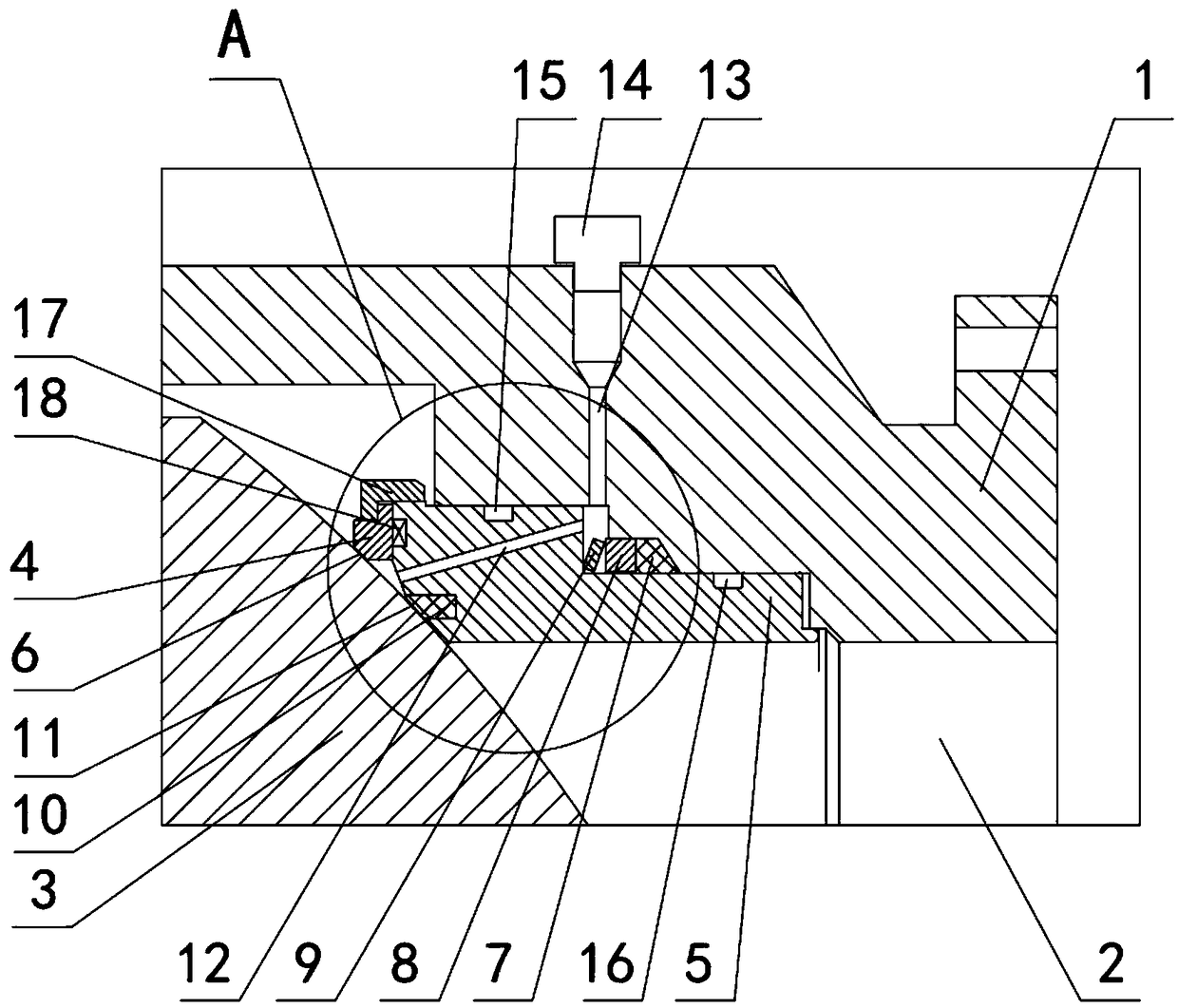

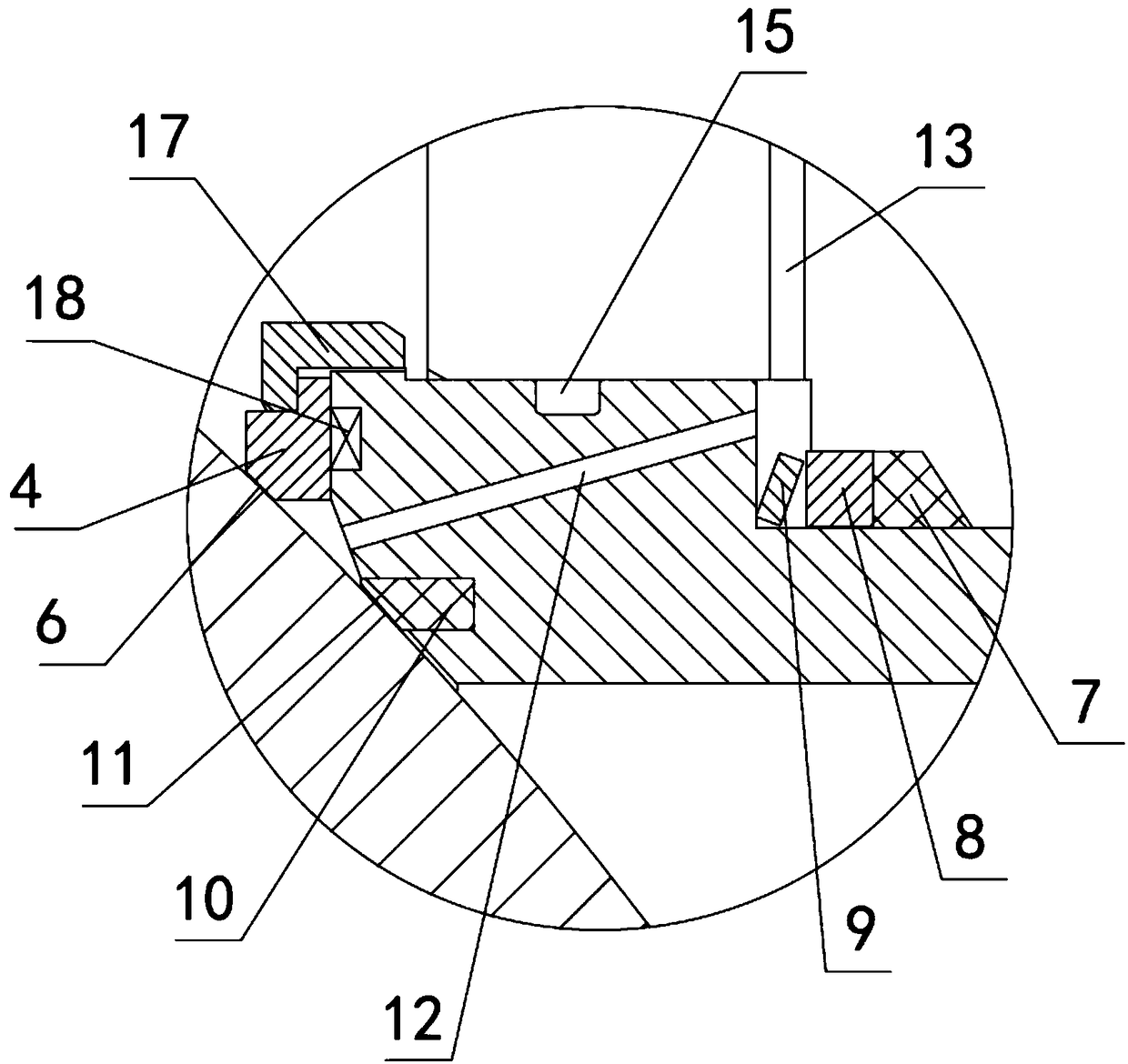

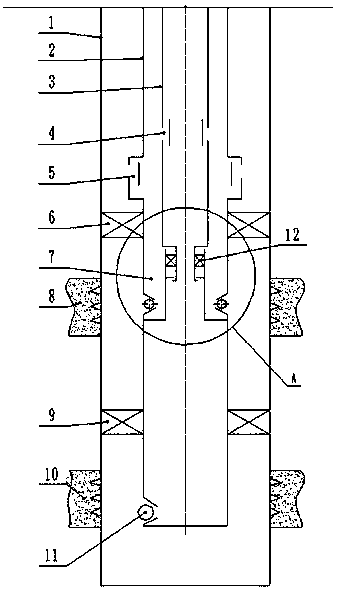

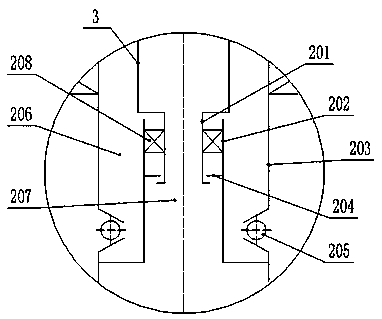

Underwater separation electric connector and plug thereof

ActiveCN103280666AAvoid short circuitTo achieve short-circuit proofCoupling device detailsElectricitySteel ball

The invention relates to the field of electric connectors, in particular to an underwater separation electric connector and a plug thereof. The plug comprises a plug casing, wherein a mandrel casing pipe, a mandrel, a sliding sleeve, a steel ball, a pushing and pressing spring and a locking spring are arranged in the plug casing; a rotating part is also arranged on the plug casing; the mandrel casing pipe is arranged in the plug casing in a laterally slidable manner; the rotating part and the mandrel casing pipe form a lead screw nut mechanism for driving an adapted locking ring to reciprocate; a sealing section is arranged on one of the mandrel and the mandrel casing pipe; a sealing matched structure is arranged on the other one of the mandrel and the mandrel casing pipe; the sealing section and the sealing matched structure are mutually matched to block off the front part and the rear part of an inner hole in the mandrel casing pipe; and when the mandrel casing pipe and the adopted locking ring are unlocked and continuously pull the mandrel backwards, the sealing section and the sealing matched structure are staggered at the front part and the rear part and two ends of the inner hole in the mandrel casing pipe are communicated. According to the underwater separation electric connector assembly, the pressure relief separation is realized and the prevention of short circuit in the process that a socket is separated from the plug and after the socket is separated from the plug can be also realized.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

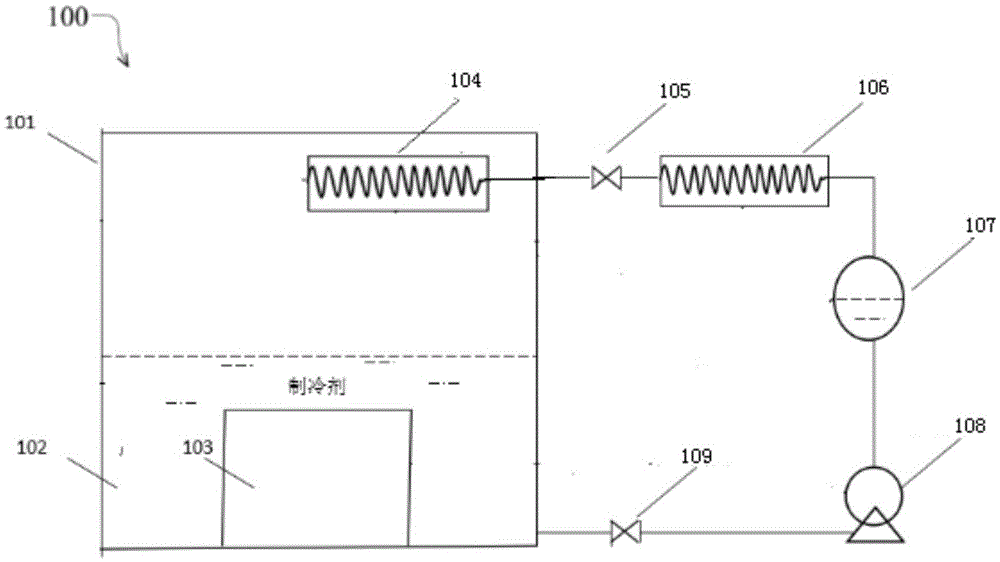

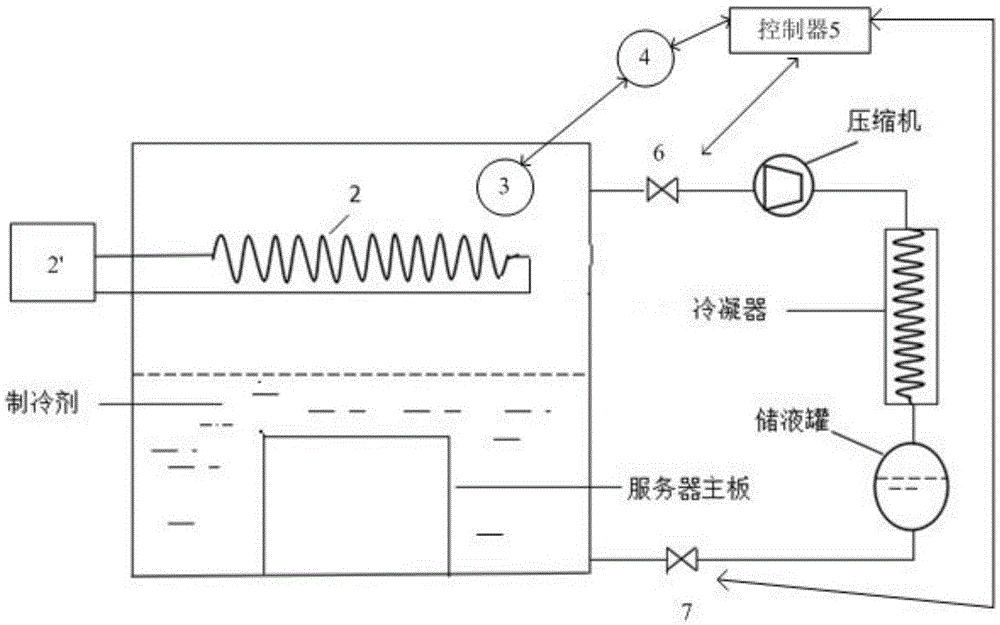

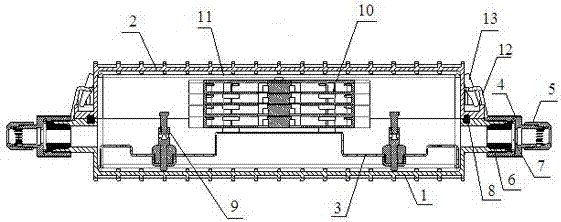

Liquid-cooling system of server

ActiveCN105607715AAchieve recyclingGuaranteed sealing reliabilityDigital data processing detailsLiquid cooling systemElectrical and Electronics engineering

The invention proposes a liquid-cooling system of a server. The system comprises a housing, a cooling apparatus arranged in the housing and used for cooling the server, and a pressure adjustment apparatus arranged outside the housing, connected with the housing and used for adjusting the pressure in the housing. According to the system, the pressure in the liquid-cooling system is automatically maintained by integrating the pressure adjustment apparatus and the liquid-cooling system, so that the server can be effectively refrigerated and the sealing reliability of the housing can be ensured.

Owner:SUGON DATAENERGYBEIJING CO LTD

Novel high-pressure-resistant sealing system for automobile engine and manufacture method thereof

InactiveCN102558717ADimensionally stableReduce pollutionOther chemical processesChemical industryAdhesiveReciprocating motion

The invention relates to a novel high-pressure-resistant sealing system for an automobile engine and a manufacture method thereof. The manufacture method includes: step 1, improving definite elongation of rubber, adjusting proportion of raw materials of the rubber, adjusting a reinforcement system and improving definite elongation of the rubber so as to improve pressure resistance of the rubber by specifically increasing 3-4 parts by weight of white carbon black and reducing1-2 parts by weight of carbon black; and step 2, improving hardness of the rubber and increasing abrasion resistance of the rubber by increasing 30-40 parts by weight of wollastonite. The novel high-pressure-resistant sealing system has the advantages of being stable in size, oil resistant and anti-aging in engine oil, being low in friction factor, slow in temperature rise in unit time and abrasion resistant in valve guide rod reciprocating motion, enabling medium and high pressure resistance of a turbine to be increased, being capable of using environment-friendly adhesive for bonding, reducing pollution on environment, shortening vulcanizing time of an oil seal, saving energy, ensuring sealing reliability, prolonging service life of the oil seal and the like.

Owner:HUNAN MASTER SEALING

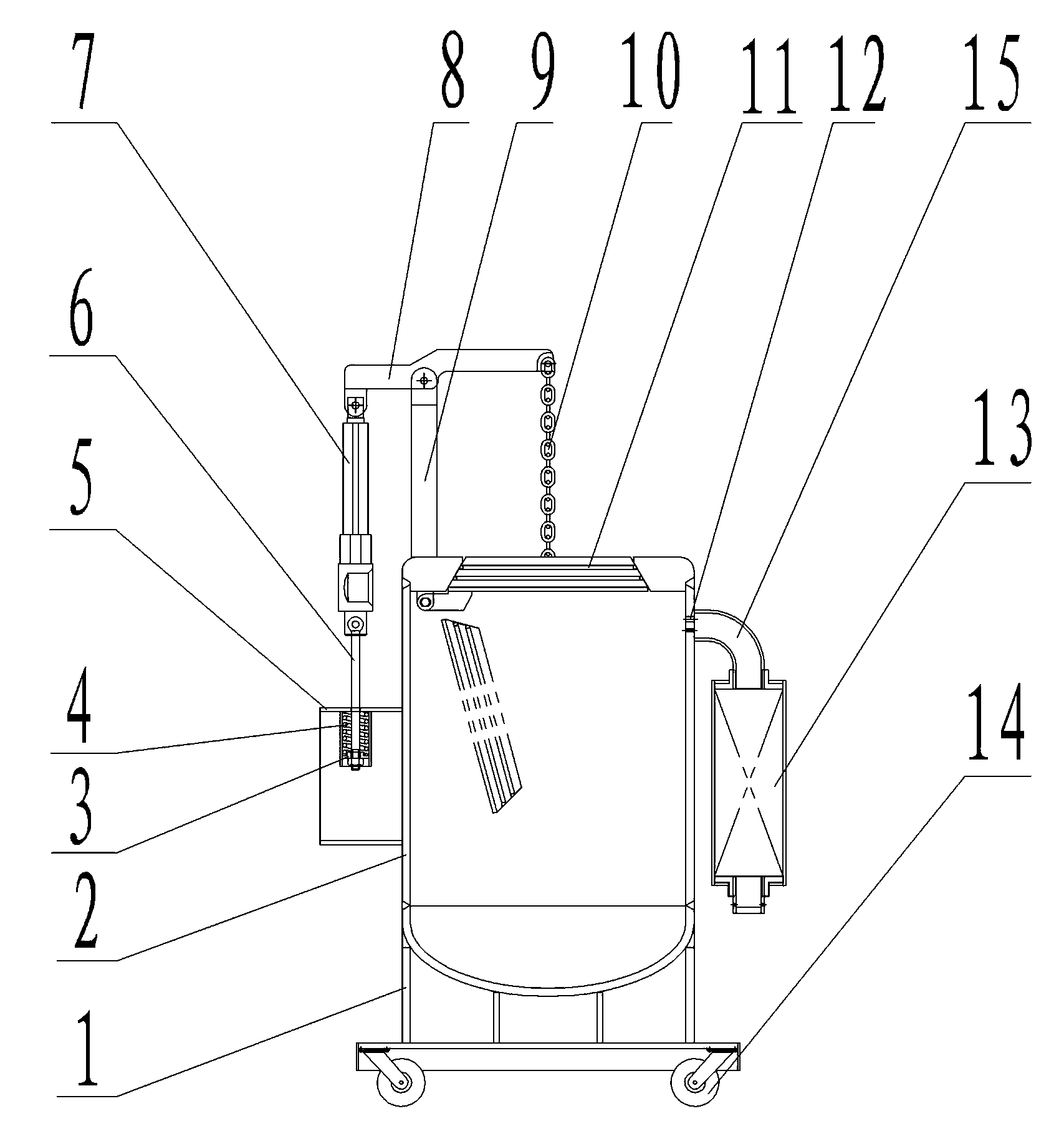

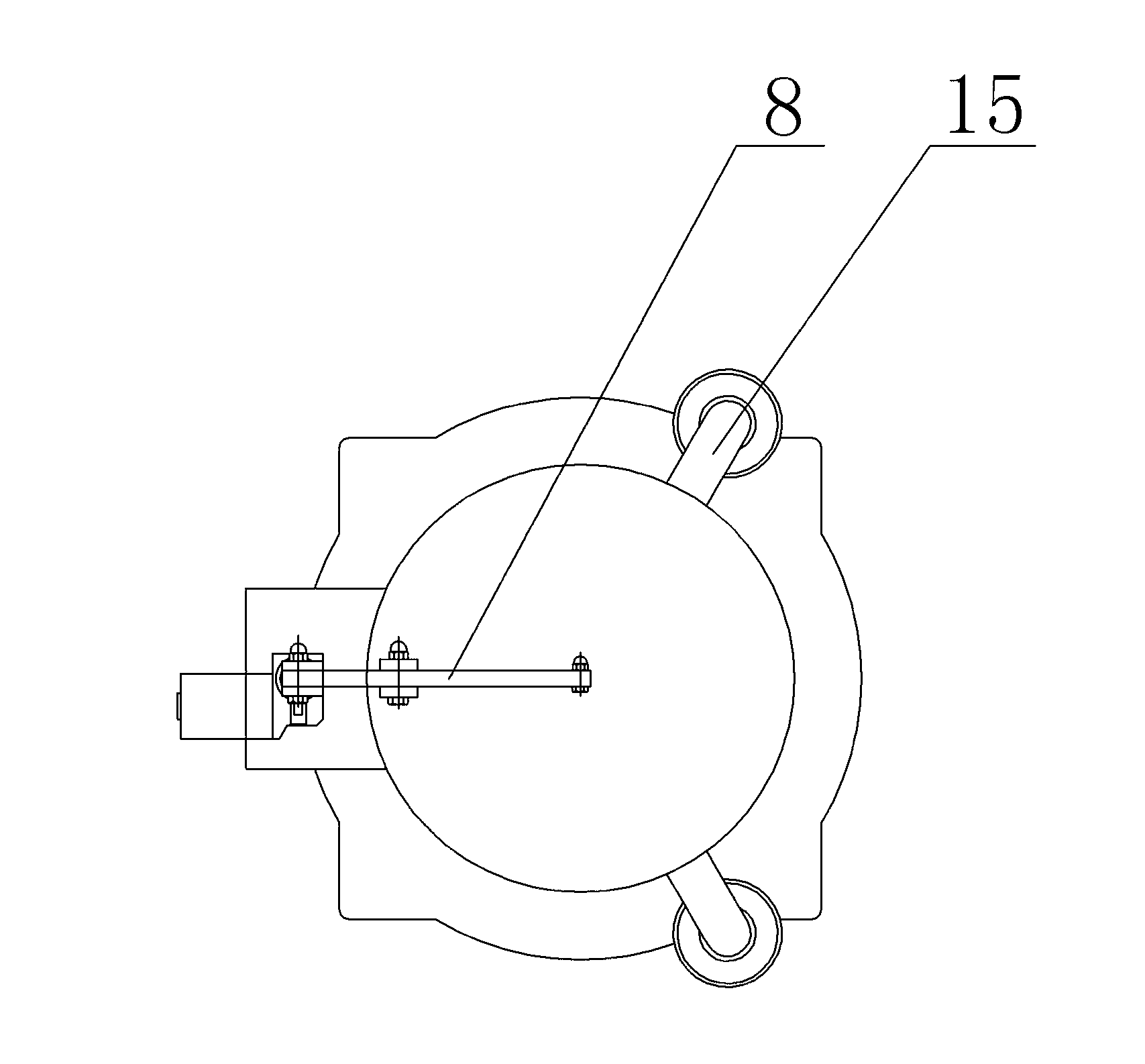

Anti-biochemical pot

ActiveCN103072745AImprove sealingIncrease the itineraryLidsNon-removalbe lids/coversEngineeringMechanical engineering

The invention relates to an anti-biochemical pot which comprises a pot body, wherein the pot body is provided with a pot opening and a pot opening channel communicated with the pot opening; a pot cover used for closing or opening the pot opening is arranged on the inner side of the pot body; a driving device used for driving the pot cover to move is connected above the pot cover through a flexible connecting body; and the driving device comprises an actuating mechanism, wherein the actuating mechanism is used for outputting rectilinear motion and provided with a first end and a second end relative to the first end, the first end is in transmission connection with the pot cover through a transmission mechanism or directly, and the first end or the second end is connected with a tensioning spring used for applying acting force to the pot cover, so that the pot opening is closed by the pot cover. The anti-biochemical pot has the advantage of simple structure, the stroke of the driving device can be prolonged, the pot cover is kept in the state that the pot opening is closed all the time, and the sealing reliability of the pot cover is guaranteed.

Owner:三门峡市天康成套设备有限责任公司

Liquid cooling system of server

ActiveCN105468117AGuaranteed sealing reliabilityAchieve recyclingDigital data processing detailsInternal pressureLiquid cooling system

Owner:SUGON DATAENERGYBEIJING CO LTD

Anti-oxidation high pressure seal stuffing box component

InactiveCN101498383AMaintain Seal ReliabilityReduce coefficient of frictionSpindle sealingsEngine sealsProduct gasZinc

The invention relates to an anti-oxidation high-pressure sealing stuffing box assembly, in particular to a stuffing box assembly for valves, which is especially suitable for industrial fluids and gases in high-pressure conditions. The anti-oxidation high-pressure sealing stuffing box assembly is characterized by comprising a sealing main body and a compensation mechanism; wherein the sealing main body is sequentially laminated with a first threadlike stuffing, a first zinc sheet, a first sheet stuffing, a second zinc sheet, a second sheet stuffing, a second threadlike stuffing and a spacer from bottom; the spacer is also sequentially laminated with a third threadlike stuffing, a third zinc sheet, a third sheet stuffing, a fourth zinc sheet, a fourth sheet stuffing and a fourth threadlike stuffing, wherein a stuffing gland bush is arranged above the fourth threadlike stuffing; a dish-shaped spring is arranged above the stuffing gland bush; and a gland bush flange is arranged above the dish-shaped flange. The invention has the advantages of excellent sealing effect, reliable comprehensive sealing performance, capability of working for long time, good self-wetting performance and wide application for transporting various gases and liquids.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

Integrated high-temperature high-pressure metal seal ball valve

InactiveCN101813201AReasonable structureFlexible opening and closingSpindle sealingsPlug valvesHigh pressureMetal

The invention relates to a valve, in particular to an integrated high-temperature high-pressure metal seal ball valve. The invention adopts the following scheme that: the integrated high-temperature high-pressure metal seal ball valve comprises a valve rod, a valve body, a valve seat and a valve core ball. The valve is characterized in that the valve seat and the valve body are integrally arranged, and a transversal ripple structure is formed at the integral joint of the valve seat and the valve body. By adopting the scheme, the invention overcomes the defects of the prior art and provides a novel integrated high-temperature high-pressure metal seal ball valve with reasonable structure, flexible opening and closing, high efficiency and good seal effect.

Owner:浙江宏明阀门有限公司

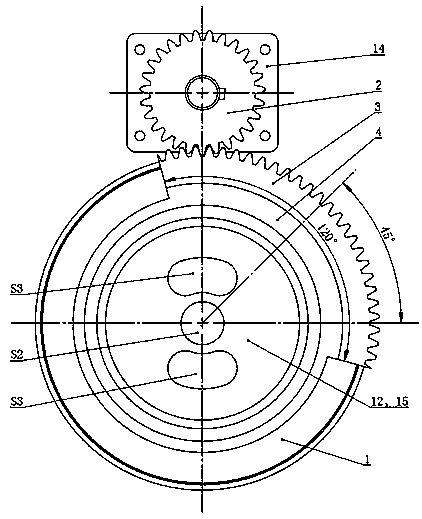

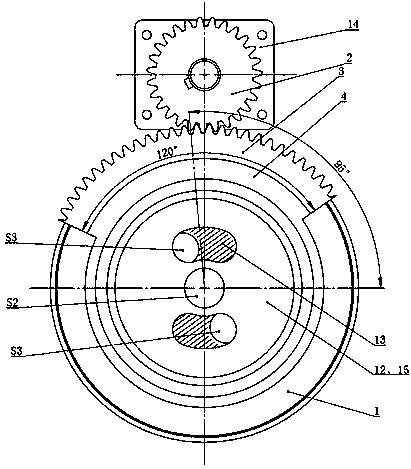

Gas flow regulation device for rotary spray pipe value of solid rocket-ramjet engine

PendingCN111577484AImprove thermal protection performanceCompact structureRocket engine plantsRam jet enginesRamjetCombustion chamber

The invention discloses a gas flow regulation device for a rotary spray pipe value of a solid rocket-ramjet engine. Each of a first fixed part and a rotating part is provided with one central hole andtwo arc-shaped holes in the axial direction; the front end of a transmission shell and an axial outlet section of a rear sealing head shell of a combustion chamber form a dynamic sealing structure; the tail end of the transmission shell and the head end of a spray pipe shell form a dynamic sealing structure; an outer ring of a thrust self-aligning roller bearing is mounted and fixed to the interior of a shell hole in the head end of the spray pipe shell; and the inner ring of the thrust self-aligning roller bearing is fixed to a shaft neck of the tail end of the transmission shell in a matched manner. A driving motor drives a driven gear to rotate to determine a corresponding angle of a transmission ratio, and finally, drives the rotating part to rotate at a corresponding angle relative to the first fixed part, so that the two arc-shaped holes of the rotating part and the fixed part are staggered and sheltered in the axial direction, thereby changing the effective outlet circulation area of the gas of the combustion chamber and realizing gas flow regulation with determined accuracy. The gas flow regulation device for the rotary spray pipe value of the solid rocket-ramjet engine isbetter in transmission mechanism thermal protection, more compact in structure and has higher work reliability, and can realize higher-precision and larger-range gas flow regulation.

Owner:湖南宏大日晟航天动力技术有限公司

Multilevel control valve

InactiveCN101173609AExtend your lifeEasy to transformMine roof supportsProps/chocksControl valvesSafety valve

The invention discloses a multilevel control valve, comprising a reversing valve component, a safety valve component and a valve body; wherein, the reversing valve component comprises a reversing valve liquid intake cavity communicated to a balance cylinder of a hydraulic support, a reversing valve control cavity communicated to an upright column cylinder of the hydraulic support and reversing valve liquid return cavity communicated to the safety valve component, a valve core and a valve sleeve positioned inside the reversing valve component, an adjusting spring for the reversing valve component which is arranged inside the reversing joint of the reversing valve component and puts the predetermined load on the reversing valve core through the a spring base and an ejection pin, and a reversing joint matched with the reversing ejector pin under the action of the predetermined load of the adjusting spring in the reversing valve component; the safety valve component comprises a liquid intake cavity connected with the reversing valve liquid outlet cavity used to empty the reversing valve liquid return cavity, a valve core of the safety valve, a valve spring of the safety valve and a safety valve guiding piston matched with the valve core of the safety valve under the action of the predetermined load of the valve spring of the safety valve. The invention has the advantages of prolonging the service life of the high hydraulic support balance cylinder, improving the stability of the gesture adjusting of the hydraulic support and guaranteeing the safe operation of the hydraulic support.

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

Watertight connector with skeleton-free structure

InactiveCN102509943APin insertionJack embeddedCoupling contact membersCouplings bases/casesBiomedical engineering

Owner:CHENGDU OUXUN TECH CO LTD

Steam valve, upper cover and cooking appliance

ActiveCN106308449ACompact structureMeet the use requirementsCooking-vessel lids/coversPressure-cookersEngineeringSurface cover

The invention provides a steam valve, an upper cover and a cooking appliance, wherein the steam valve comprises a valve seat and a valve cover; a steam inlet is formed in the valve seat; the valve seat is arranged on an inner cover and the valve seat is in sealing connection to a surface cover; a steam outlet is formed in the valve cover; the valve cover is arranged on the surface cover; and the valve cover and the valve seat are relatively arranged, and a steam passage is formed, wherein the steam passage communicates with the steam inlet and the steam outlet. According to the steam valve provided by the invention, under the condition of achieving the functions of preventing spillover and discharging steam of the finished product (the steam valve), the valve seat of the steam valve is arranged on the inner cover of the upper cover and the valve seat is in sealing connection to the surface cover, so that stable installation between the valve seat and the upper cover is achieved under the precondition of not increasing an assembly area between the upper cover and the steam valve; and meanwhile, the upper cover is more compact in structure, so that the overall thickness of the upper cover is reduced, the weight of the upper cover is reduced and consumables of the upper cover are reduced.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Charging port sealing structure and lamp with sealing structure

InactiveCN102055110AGuaranteed sealing reliabilityGuaranteed reliabilityElectric discharge tubesCouplings bases/casesEngineeringSealant

The invention relates to a charging port sealing structure and a lamp with the sealing structure. The sealing structure comprises a shell provided with a first accommodating cavity and a second accommodating cavity, and a flexible sealing plug, wherein the flexible sealing plug comprises a base, a plug head and a connecting part connecting the base and the plug head; and the sealing structure also comprises a charging interface, wherein the charging interface comprises an insulating substrate, and a metal electrode extending out of the insulating substrate; the charging interface is positioned in the second accommodating cavity; the base of the flexible sealing plug is plugged and fixed in the first accommodating cavity; the plug head is plugged in an opening of the second accommodating cavity; the charging interface is sealed in the second accommodating cavity; and sealants are filled in a gap between the base and the first accommodating cavity and between a gap between the charging interface and the second accommodating cavity. In the charging port sealing structure, the sealants and the flexible sealing plug are adopted for double seal, the sealing reliability of the charging port in a severe environment and the functional reliability of the charging port are ensured.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

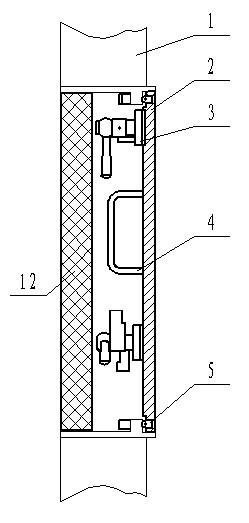

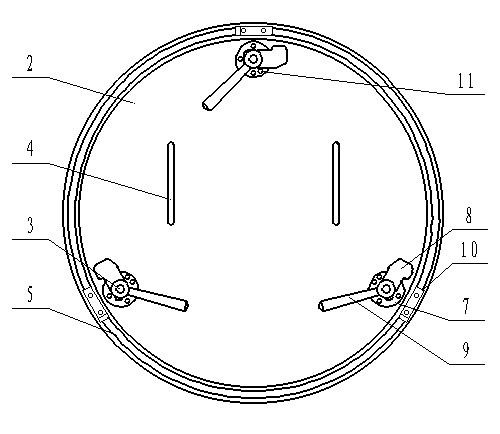

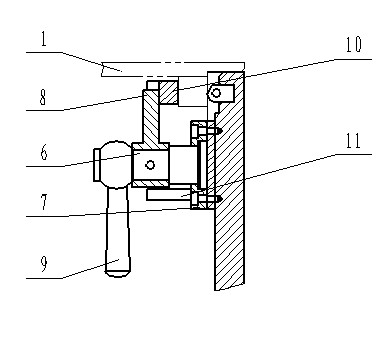

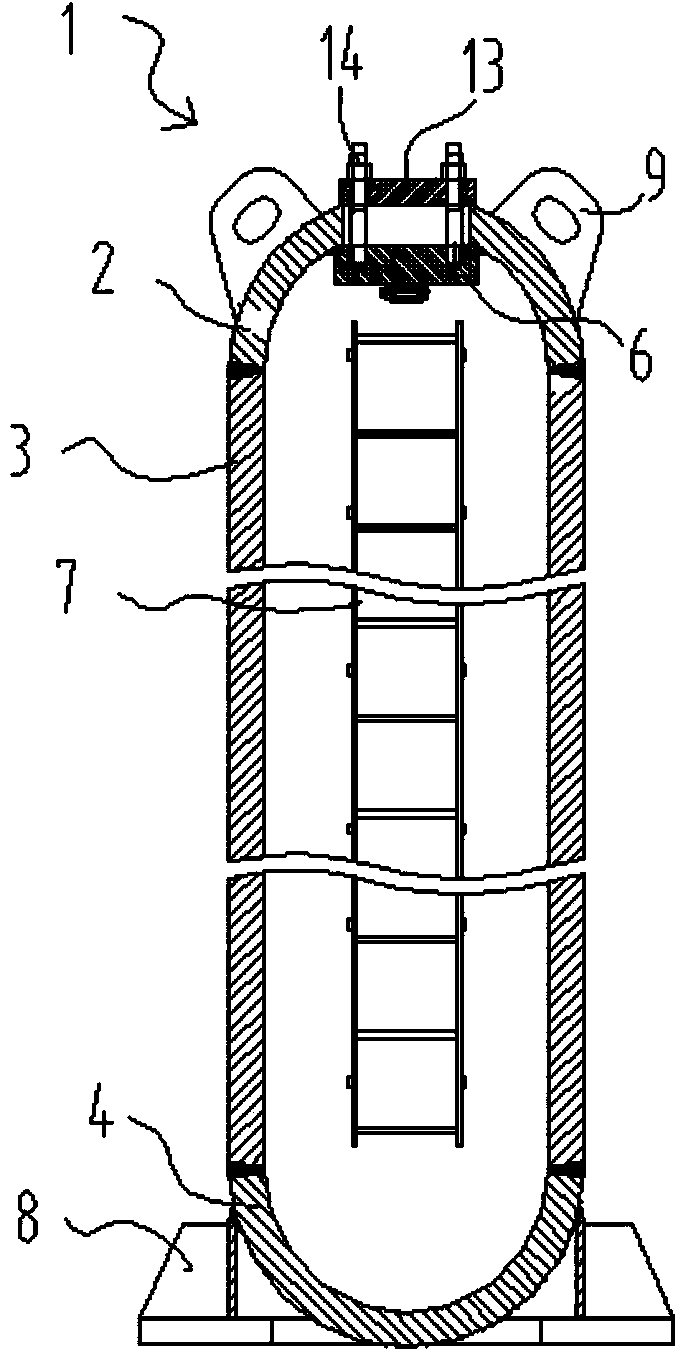

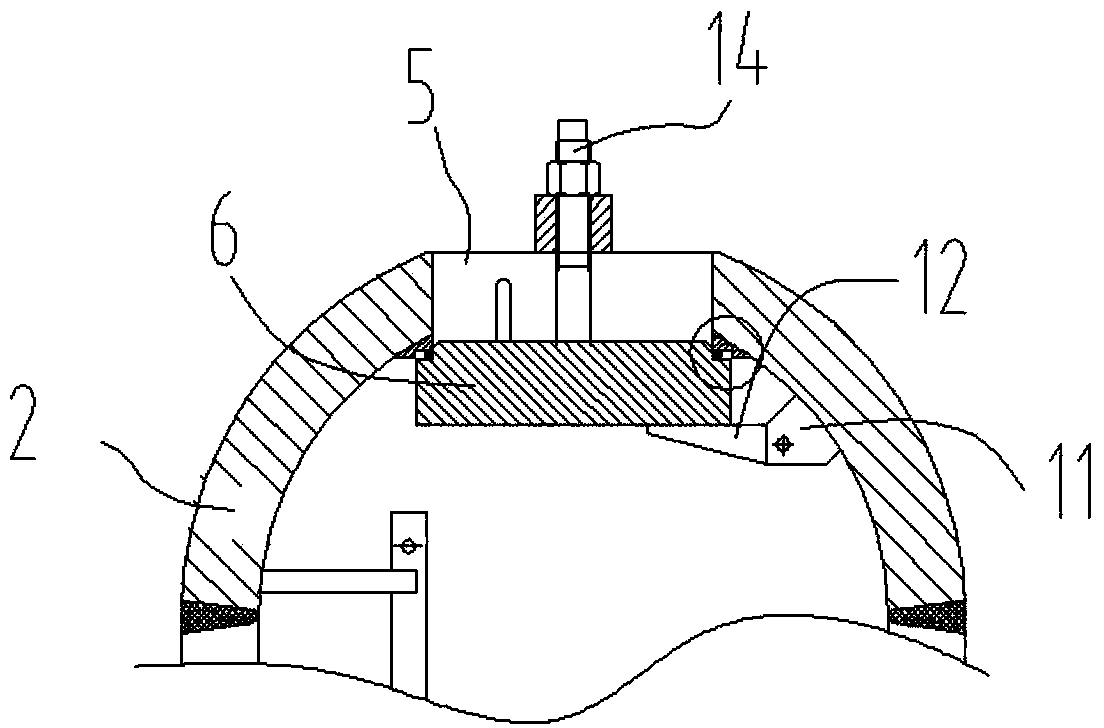

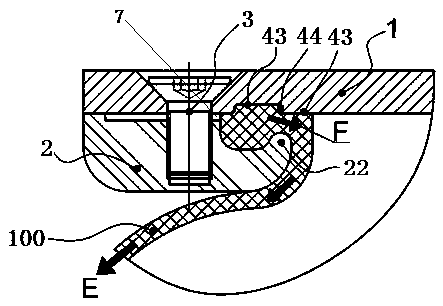

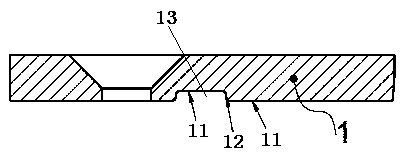

Movable type escape capsule emergency escape door for mine

ActiveCN102635298AEnsure positioning reliabilityGuaranteed sealing reliabilityGasproof doorsConstruction fastening devicesMovable typeEngineering

The invention provides a movable type escape capsule emergency escape door for a mine and belongs to the technical field of escape capsule equipment for the mine. Aiming to the solve the technical problem, the invention provides the movable type escape capsule emergency escape door for the mine, which has the advantages of reliability in sealing, simplicity in operation, strong anti-knocking and anti-impacting performance and high-temperature resistance and is convenient for people in a capsule to use when the people actively go out of the capsule. The technical scheme disclosed by the invention is as follows: a circumferential edge of the door is uniformly provided with three manual locking devices and the door is mounted on the capsule body through the manual locking devices; a handle is arranged at the inner side of the door; a sealing strip is arranged on the circumference on which the door is contacted with the capsule body; and the capsule body in the door is provided with a heat-preservation and heat-insulating cover. The invention provides the emergency escape door for the mine escape capsule.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

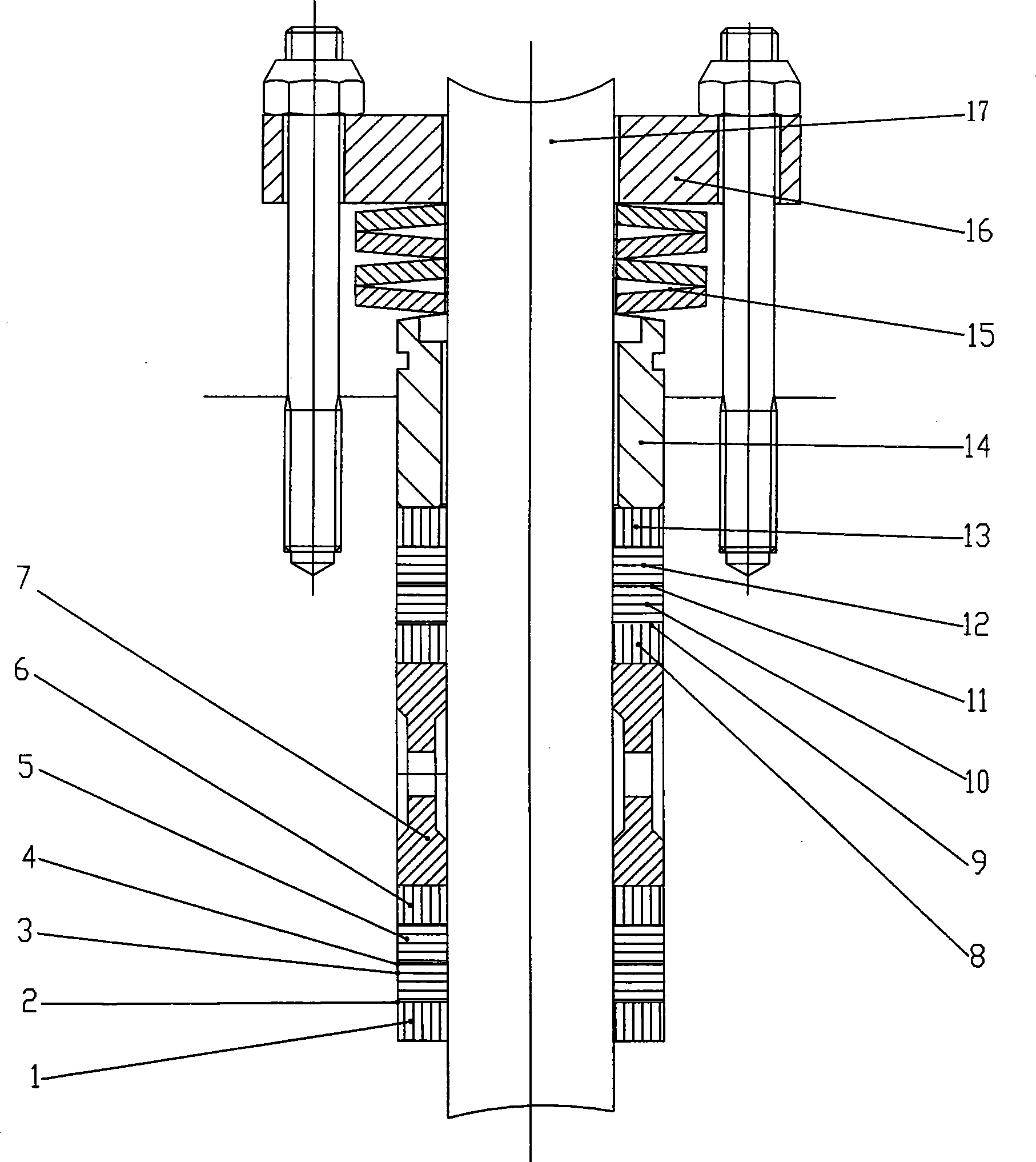

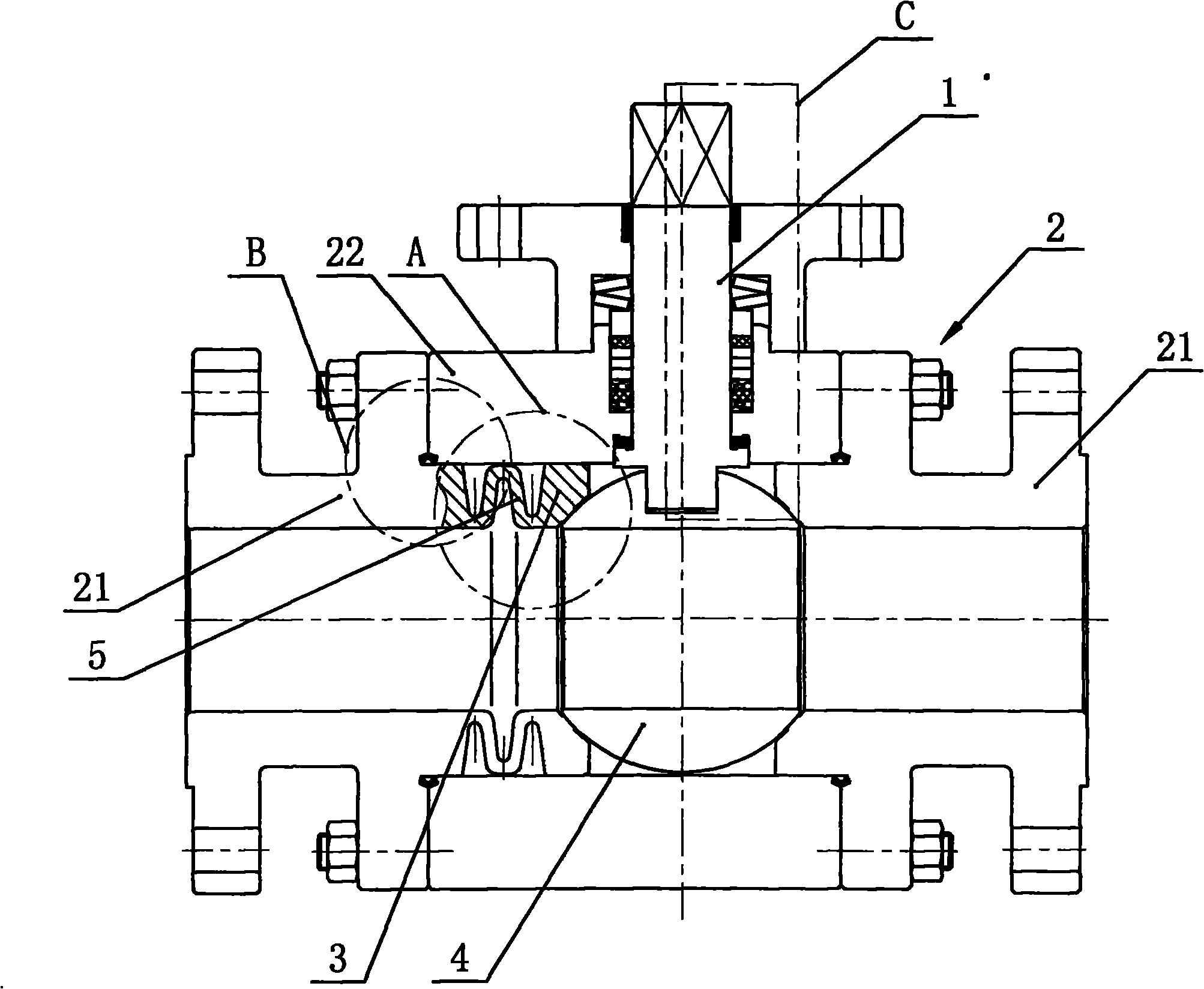

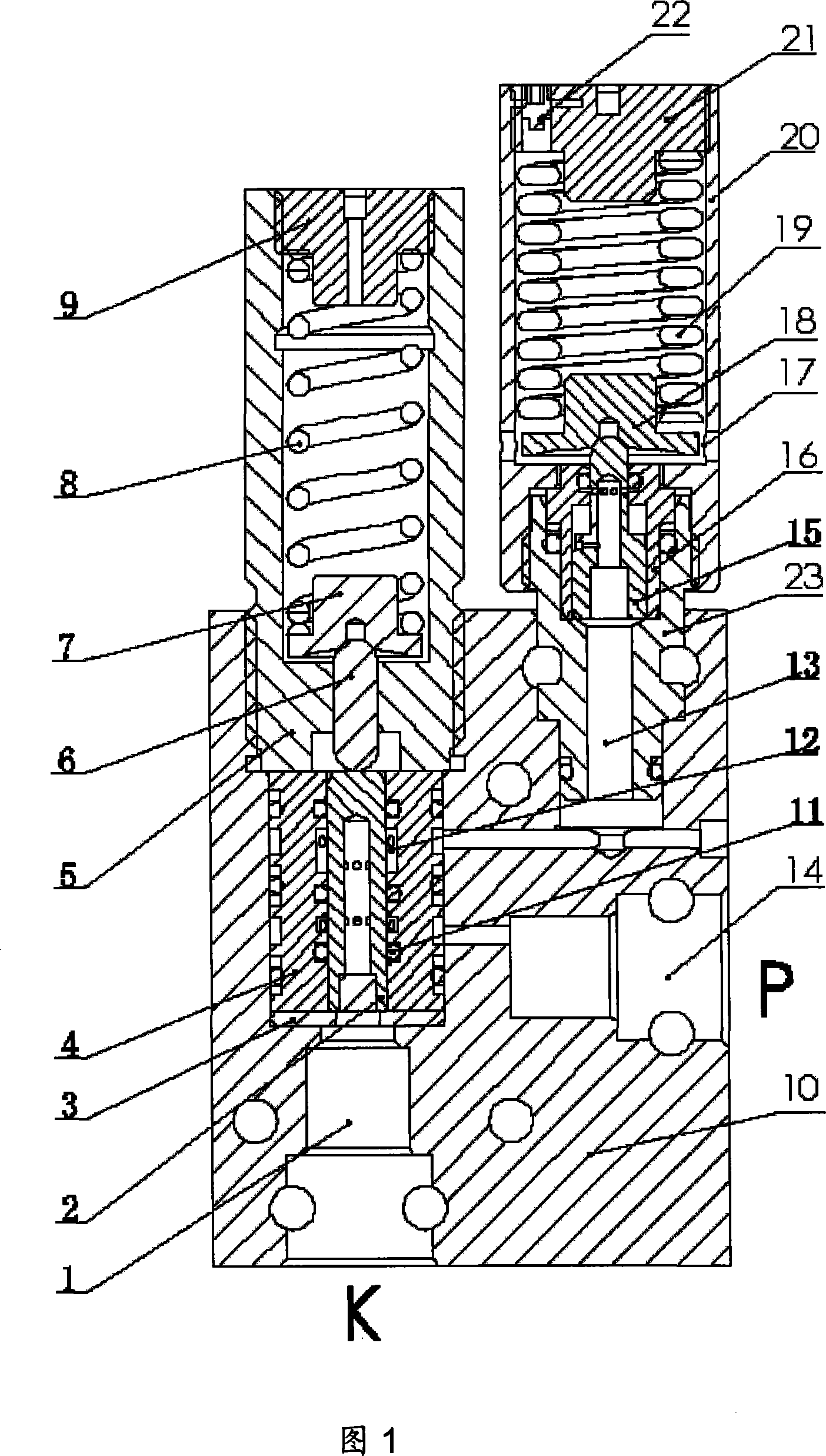

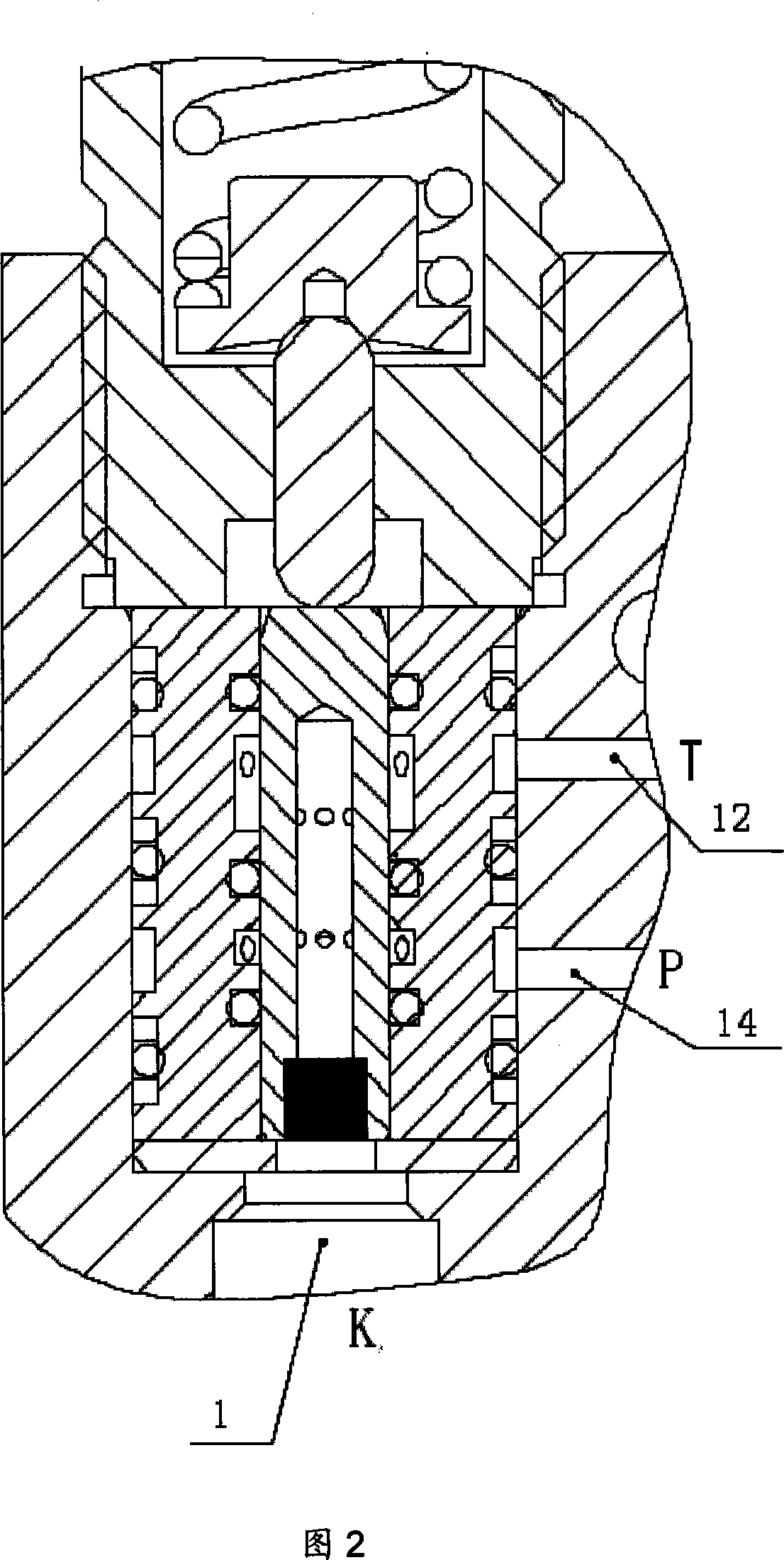

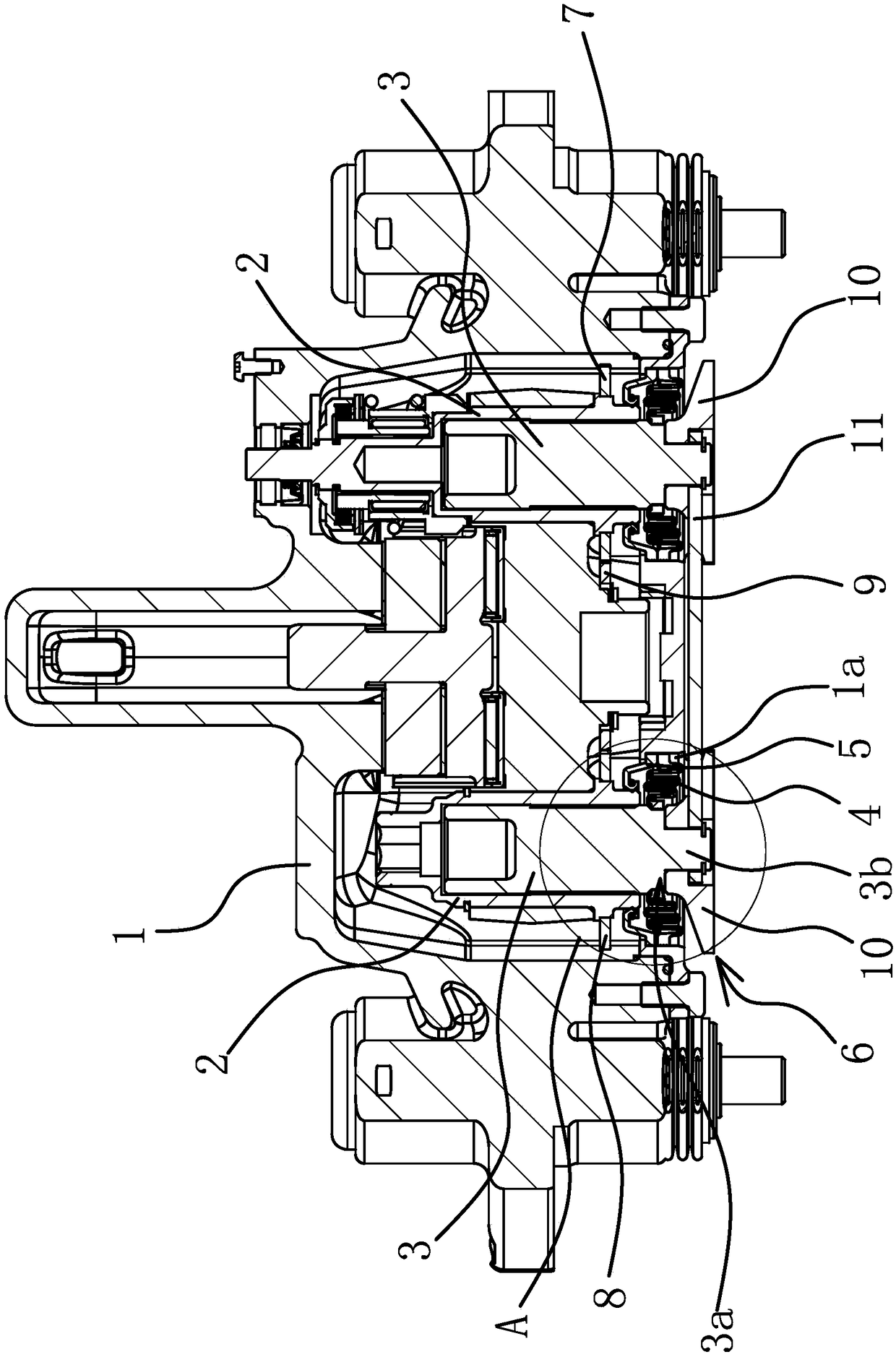

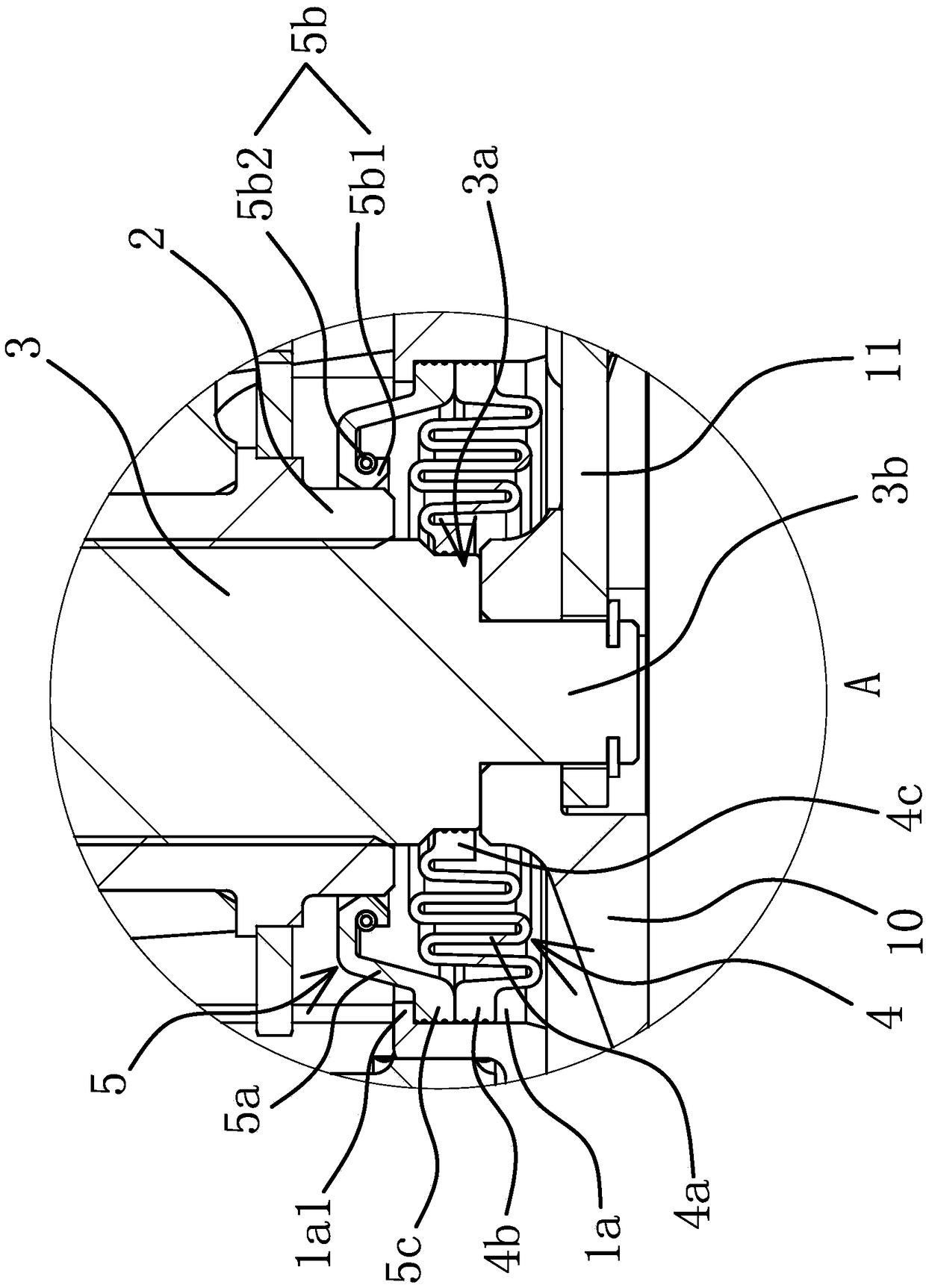

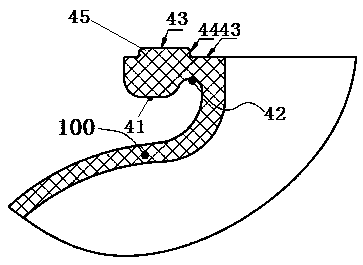

Double sealing structure of disc brake

The invention provides a double sealing structure of a disc brake and belongs to the technical field of machinery. A problem that the sealing effect obtained by an existing double sealing structure ofthe disc brake is not ideal can be solved by the structure. The disc brake comprises a caliper body, rotating units axially limited into the caliper body, and screw rods connected to the interiors of the rotating unit by threads, the lower ends of the screw rods penetrate out of the lower end of the caliper body and the rotating units can rotate relative to the screw rods; the double sealing structure comprises a sealing unit II and a sealing unit I which is positioned between the caliper body and the lower ends of the screw rods and can deform along with the movement of the screw rods, therotating units are sleeved with the sealing unit II, the outer side of the sealing unit II is fixed in the caliper body, the inner side of the sealing unit II is provided with an annular sealing portion with elasticity, and the inner wall of the annular sealing portion always abuts against the outer side walls of the rotating units under the elastic force. The double sealing structure of the discbrake has the advantages of simple structure, long service life, good sealing effect and the like.

Owner:LONGZHONG HLDG GRP

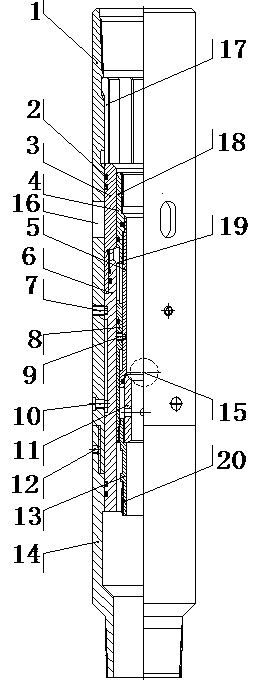

Multi-level pitch fracturing sliding sleeve capable of fishing ball seats

ActiveCN103590800AIncrease productionRealize fracturing and acidizing operationsFluid removalWell/borehole valve arrangementsCoiled tubingSelf locking

The invention discloses a multi-level pitch fracturing sliding sleeve capable of fishing ball seats. The multi-level fracturing sliding sleeve capable of fishing the ball seats comprises connectors, elastic claws and an elastic claw pipe. The connectors comprise the upper connector and the lower connector. The upper connector is connected with the lower connector, and the upper end of the upper connector is provided with an upper locating groove, a lower locating groove and a side hole. The multi-level pitch fracturing sliding sleeve further comprises a sliding sleeve mechanism and a ball seat fishing mechanism. When the sliding sleeve mechanism and the ball seat fishing mechanism move downwards for opening the sliding sleeve, elastic claw gaps in the sliding sleeve mechanism correspond to the side hole, and the elastic claw pipe is communicated inside and outside. Self-locking elastic claws which are matched with a ball seat fishing mechanism inside an upper-level sliding sleeve and a ball seat fishing mechanism in a lower-level sliding sleeve to be used for fishing the ball seats are arranged at the two ends of the ball seat fishing mechanism respectively. By means of the multi-level fracturing sliding sleeve, the effect that the sliding sleeve on the lower portion can realize fracture acidizing operation through sequential opening of pitches can be guaranteed, multiple levels of sliding sleeve ball seats and balls can be fished out at a time through a continuous oil pipe after the fracture acidizing operation, and therefore a drift diameter as large as possible can be obtained inside the pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Inwards-opened sealed manhole structure

InactiveCN104019231AImprove sealingReduce occupancyPressure vesselsHigh pressureMechanical engineering

Owner:NANJING DUBLE METAL EQUIP ENG

Low-temperature-resistant air spring upper seam allowance sealing structure, method and product

PendingCN109944894AMeet sealing requirementsImproves sealing reliabilitySpringsGas based dampersAir springAir suspension

The invention discloses a low-temperature-resistant air spring upper seam allowance sealing structure. The sealing structure comprises an upper cover plate, a buckle ring, a connecting bolt and an upper seam allowance; the upper seam allowance is compressed between the upper cover plate and the buckle ring, the buckle ring and the connecting bolt are arranged on the radial outer side of the upperseam allowance, a bag body below the upper seam allowance is attached to the inner wall of the buckle ring and is attached to the bottom surface of the buckle ring downwards; a sealing structure formed by radial sealing and axial seal which are arranged alternately and connected in sequence is adopted between the upper cover plate and the upper seam allowance and between the upper seam allowance and the buckle ring, the sealing pressure of at least one axial sealing surface of the upper seam allowance to the upper cover plate faces the inner direction which is away from the connecting bolt, and the sealing pressure and the compression amount of the upper seam allowance are increased along with the loading and the displacement of the air spring. The sealing reliability of the upper seam allowance of the air spring in the loading process is guaranteed, effective sealing of the upper seam allowance in a low-temperature state is realized, and the sealing requirement of the air spring underthe low-temperature state is met. The invention further provides a low-temperature-resistant air spring upper seam allowance sealing method and a low-temperature-resistant air spring.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

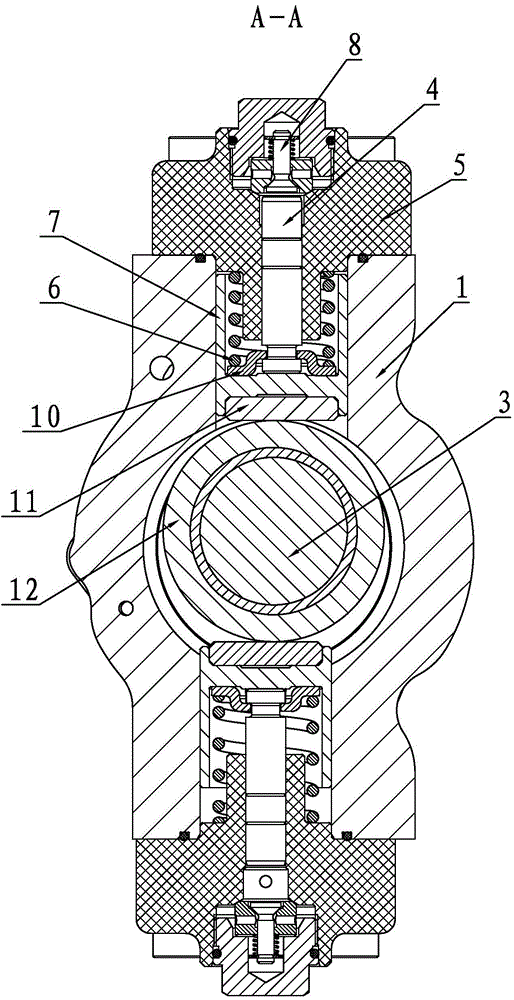

High-pressure common rail pump high reliability and long service life single-way check valve

InactiveCN104314724AAvoid contactEnsure effective oil supplyMachines/enginesFuel injecting pumpsInlet channelCommon rail

The invention provides a high-pressure common rail pump high reliability and long service life single-way check valve which comprises an oil outlet hole, a spring base, a returning spring and a sealing ball, wherein a sliding guiding sleeve is additionally arranged between the returning spring and the sealing ball, the right end surface of the sliding guiding sleeve is provided with a ball body supporting surface, a reset oil hole in the bottom of the ball body supporting surface is communicated with a spring limit hole, a side surface oil inlet channel is arranged on the cone surface of a cone segment, the side surface oil inlet channel is communicated with the spring limit hole, and the sealing ball, the sliding guiding sleeve, the returning spring and the spring base are sequentially arranged inside the oil outlet hole. The sealing ball is in sealing contact with a sealing cone surface under the centering supporting of the ball body supporting surface under the effect of the returning spring, and an opening and closing distance of the check valve is axially formed between the sliding guiding sleeve and the spring base. The sealing ball is supported by the ball body supporting surface in the moving process in a centering mode, the sealing ball can guide and cannot be damaged, the sealing belt formed between the sealing ball and the sealing cone surface is stable and reliable, the flowing back of high pressure oil can be prevented, and the high-pressure oil supply performance and the service life of a common rail pump are improved.

Owner:常州博瑞油泵油嘴有限公司

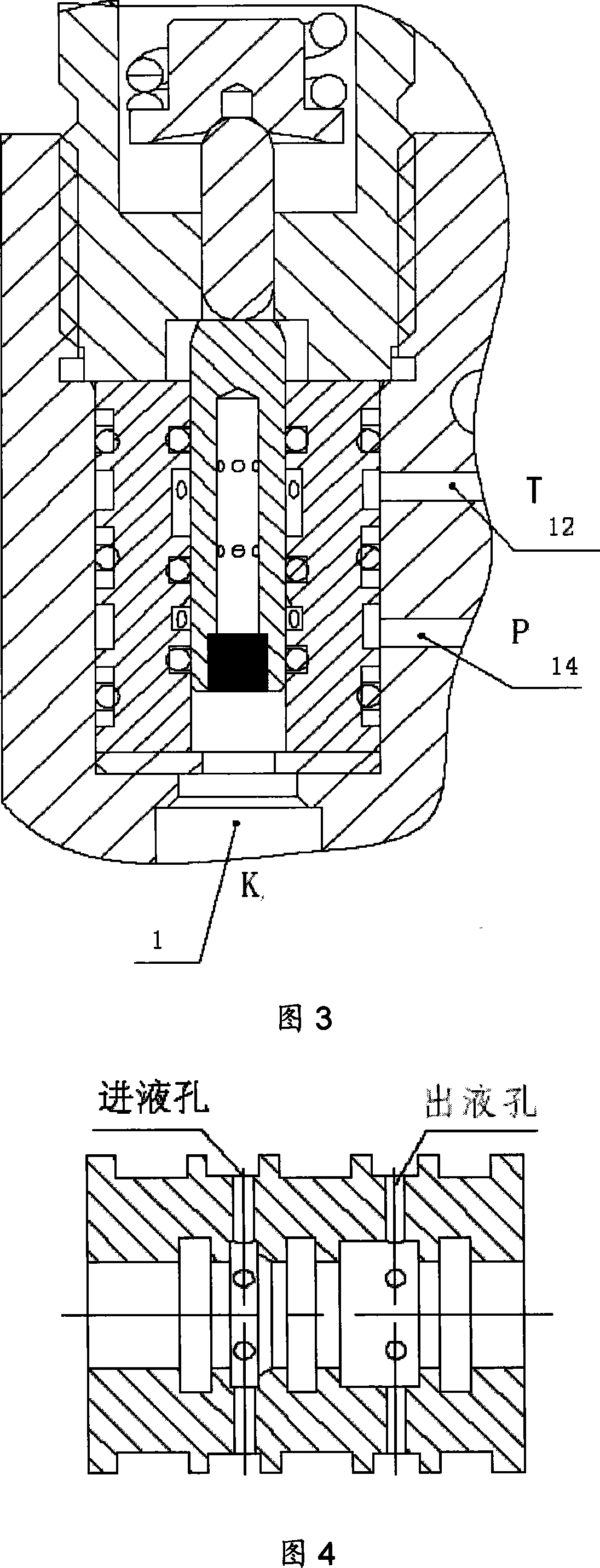

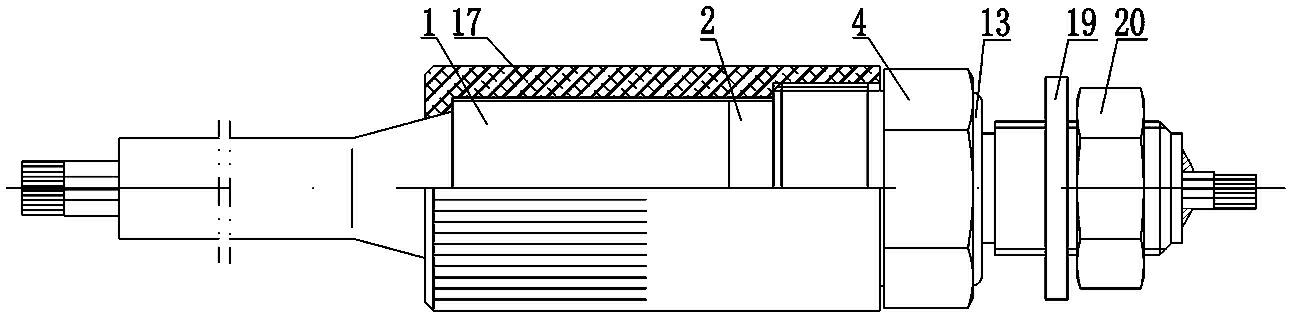

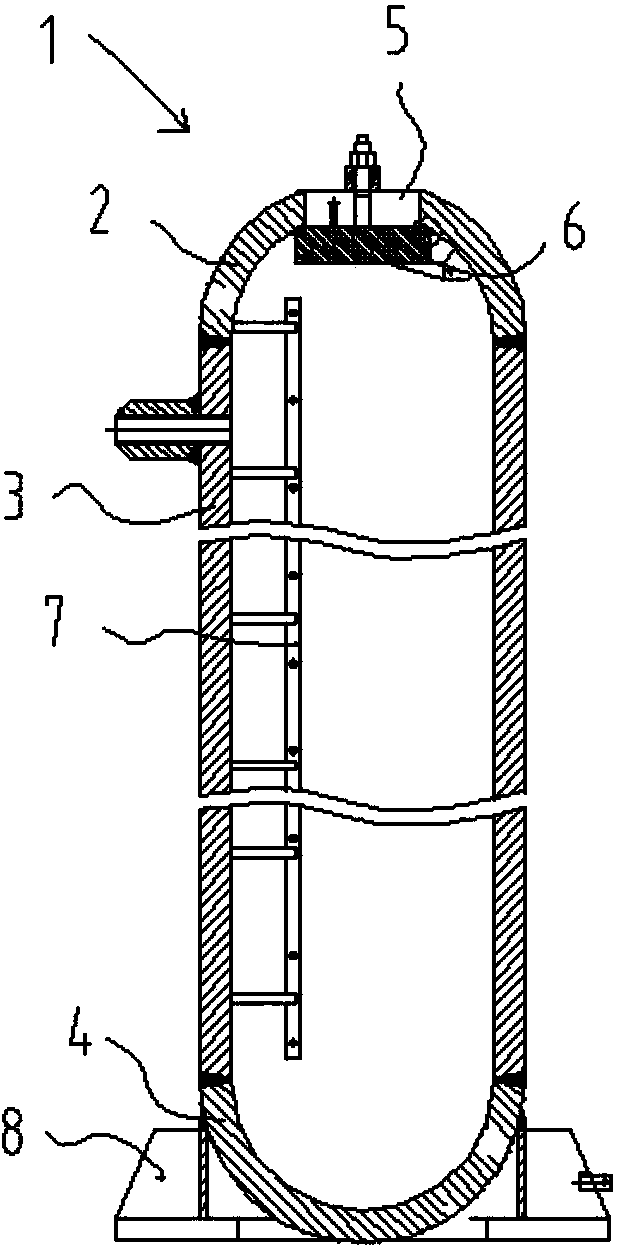

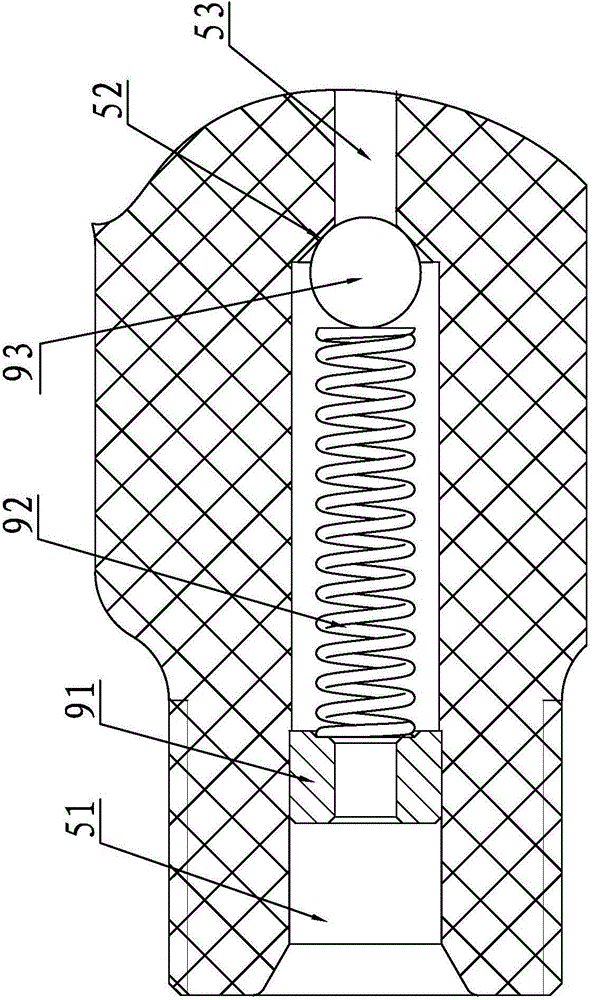

Self-tightening sealing and stress testing device for self-enhancing of ultrahigh-pressure pump head body

ActiveCN103711688AGuaranteed sealing reliabilityReduce local stressPump testingPositive displacement pump componentsCombined usePump head

The invention relates to a self-tightening sealing and stress testing device for self-enhancing of an ultrahigh-pressure pump head body, belonging to the technical field of self-enhancing of a pump head body of an ultrahigh-pressure container. The self-tightening sealing and stress testing device comprises an ultrahigh-pressure pump head body, a horizontal sealed taper rod, a signal lead-out seal taper, a horizontally sealed adjusting rod, an O-shaped seal ring, a signal lead-out rod, an organic glass sealed taper ring, quick-plugging joints, high-strength enameled wires, a strain gauge and a wiring transition plate. All sealing surfaces of the device adopt taper surface hard sealing, the higher the hydraulic pressure in the inner cavity of the pump head body is, the larger the pressure on the sealing surfaces is, and the reliability of sealing under ultrahigh pressure can be guaranteed; in assembling, the sealing of the sealing surfaces in low-pressure or non-pressure state can be controlled by thread pretightening force. The self-tightening sealing and stress testing device has the characteristics of being convenient to install, and convenient and fast to wire. According to the device, the difficulty in testing the stress of the container wall by leading out a wire from the ultrahigh-pressure sealed container can be solved by adopting the combined use of the organic glass sealed taper ring, the O-shaped seal ring and the wire lead-out rod.

Owner:YANGTZE UNIVERSITY +1

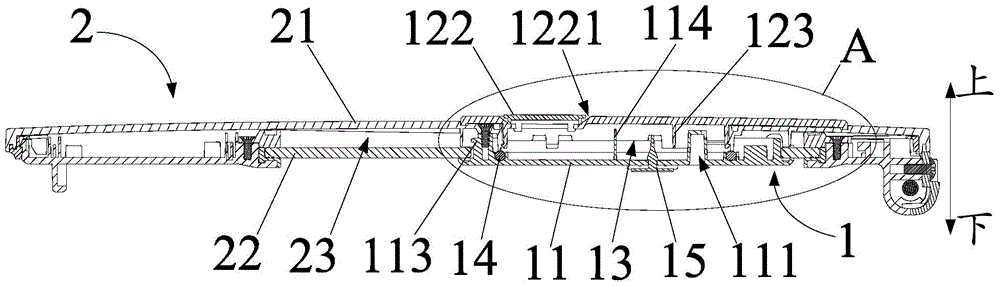

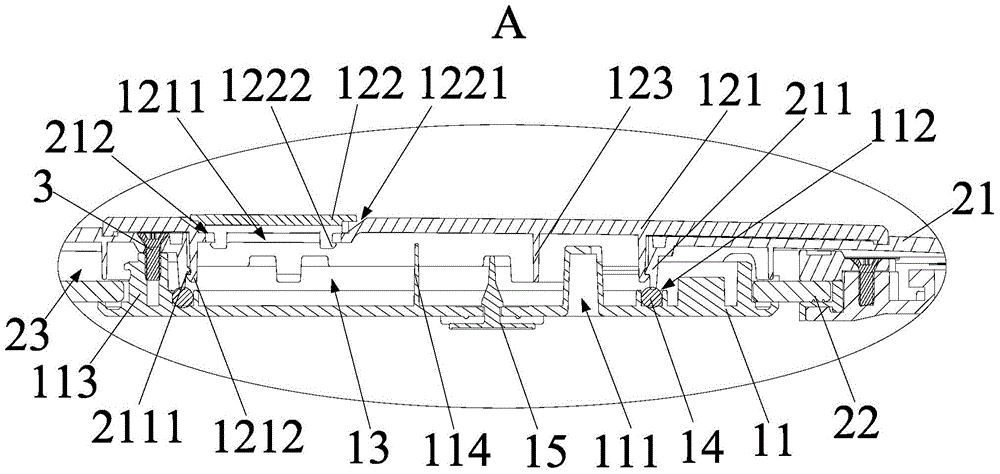

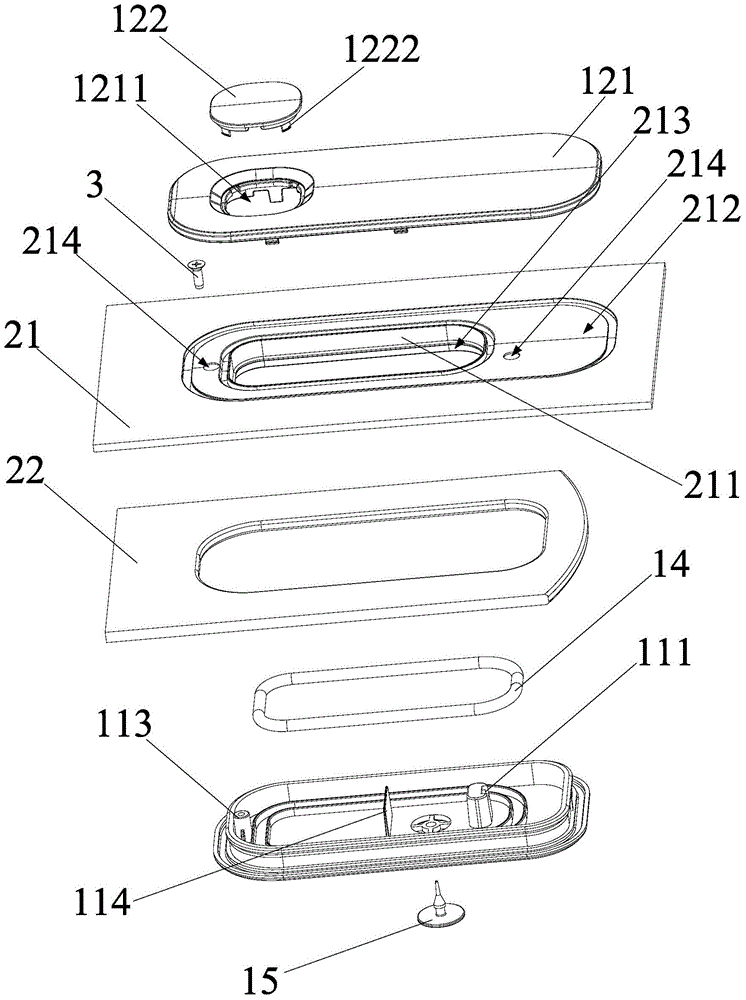

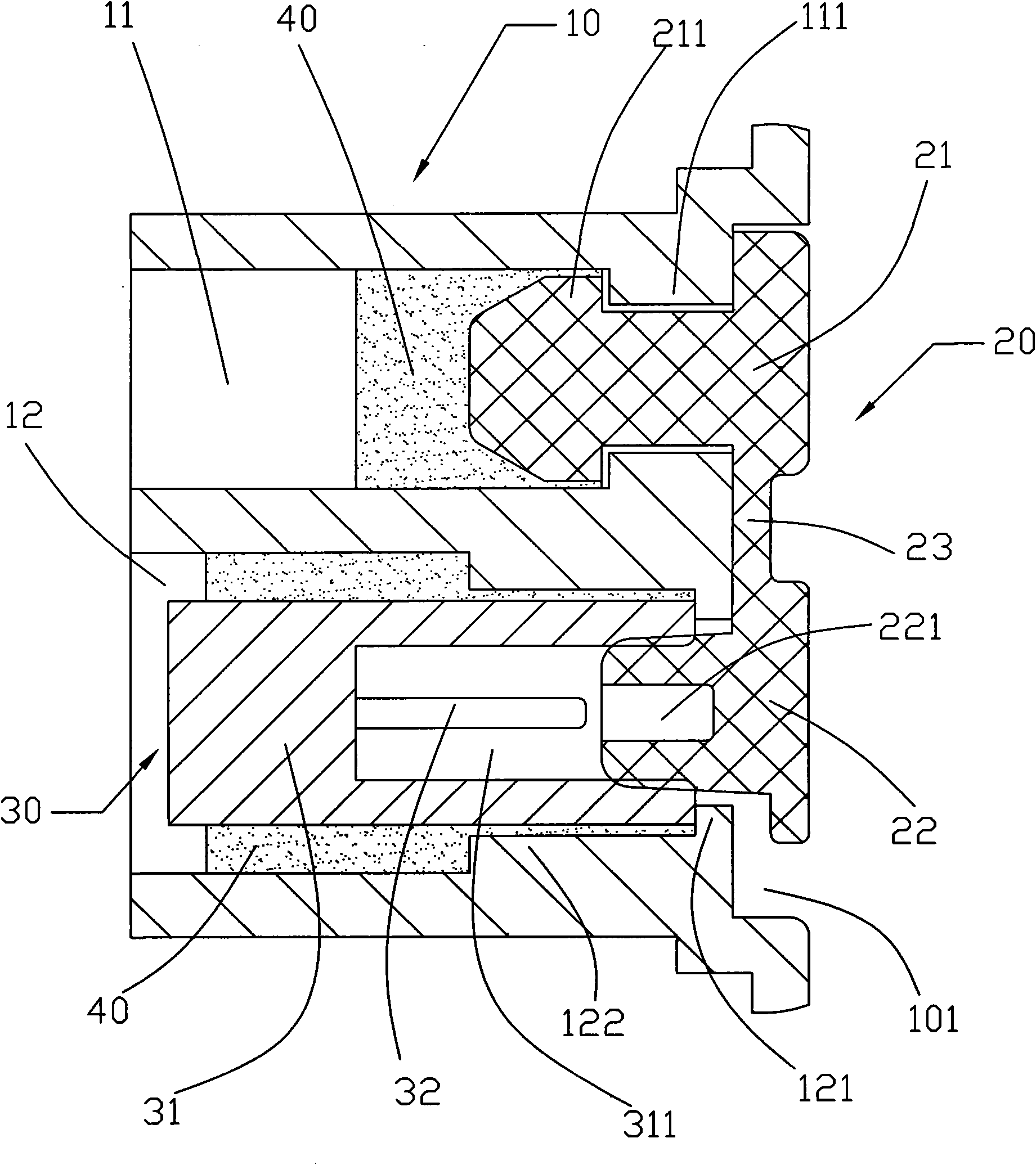

Humidifier and continuous positive-pressure ventilation therapy machine

ActiveCN104941047ASolve the technical problem of poor airtightnessImprove reliabilityRespiratorsLighting and heating apparatusEngineeringMechanical engineering

The invention discloses a humidifier and a continuous positive-pressure ventilation therapy machine. The humidifier comprises an outer shell and a sealing ring. The outer shell comprises a first outer shell body, a second outer shell body and a buckling assembly. The second outer shell body and the first outer shell body are buckled through the buckling assembly. A floating sealing groove is formed between the first outer shell body and the second outer shell body. The sealing ring is arranged in the outer shell and comprises an elastic fork-shaped structure arranged at the edge of the sealing ring. The elastic fork-shaped structure is located in the floating sealing groove. When the first outer shell body and the second outer shell body are buckled, the floating sealing groove and the elastic fork-shaped structure is compressed, the elastic fork-shaped structure generates elastic force for expanding the floating sealing groove, and the sealing ring is matched with the buckling assembly to seal the buckled position. By means of the humidifier and the continuous positive-pressure ventilation therapy machine, the sealing reliability of the humidifier is improved.

Owner:刘黎

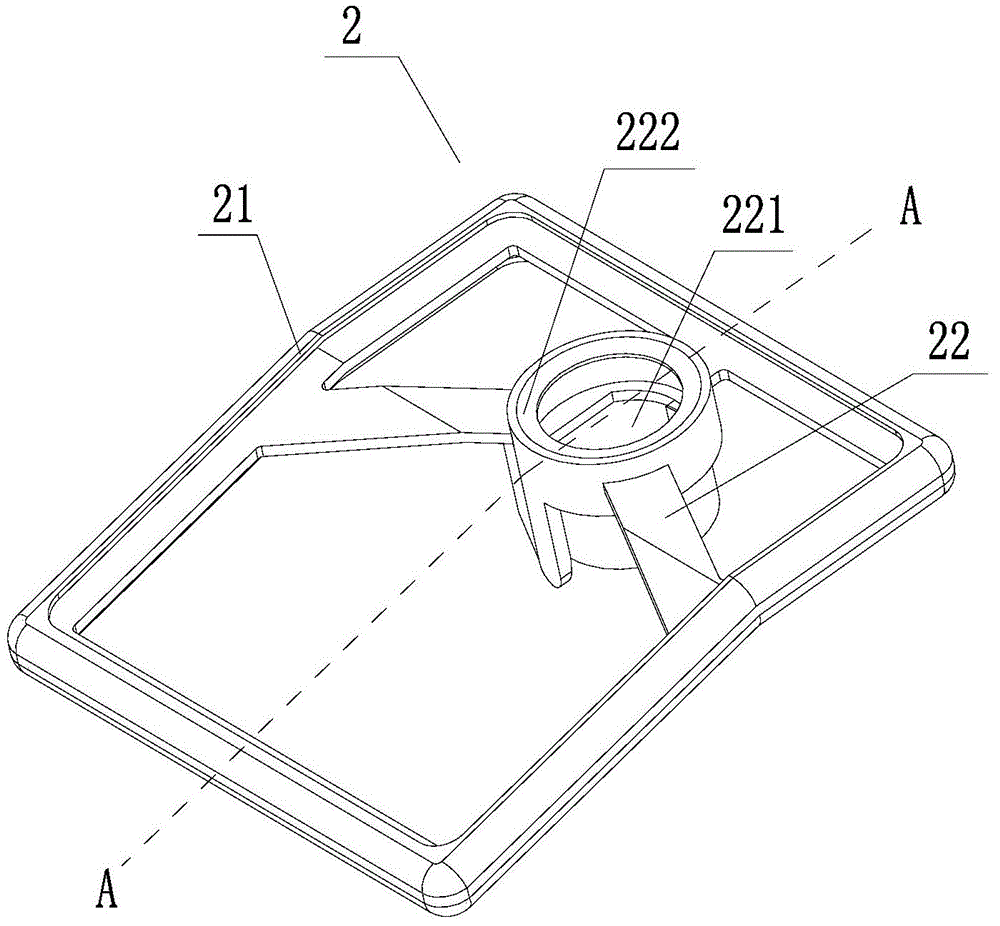

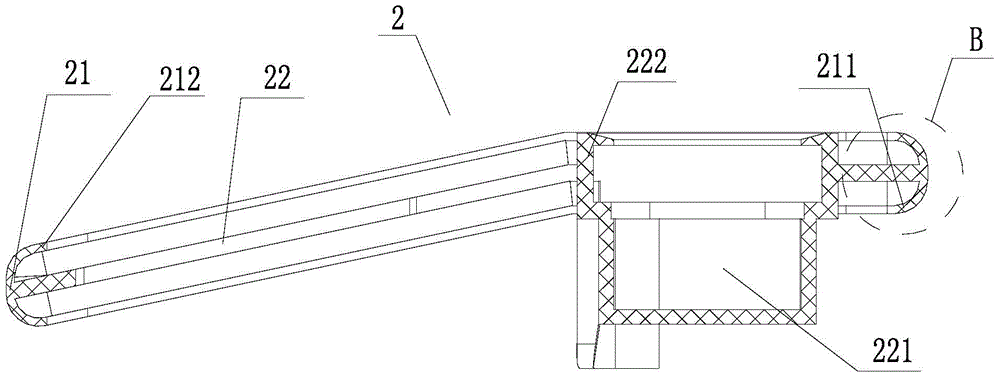

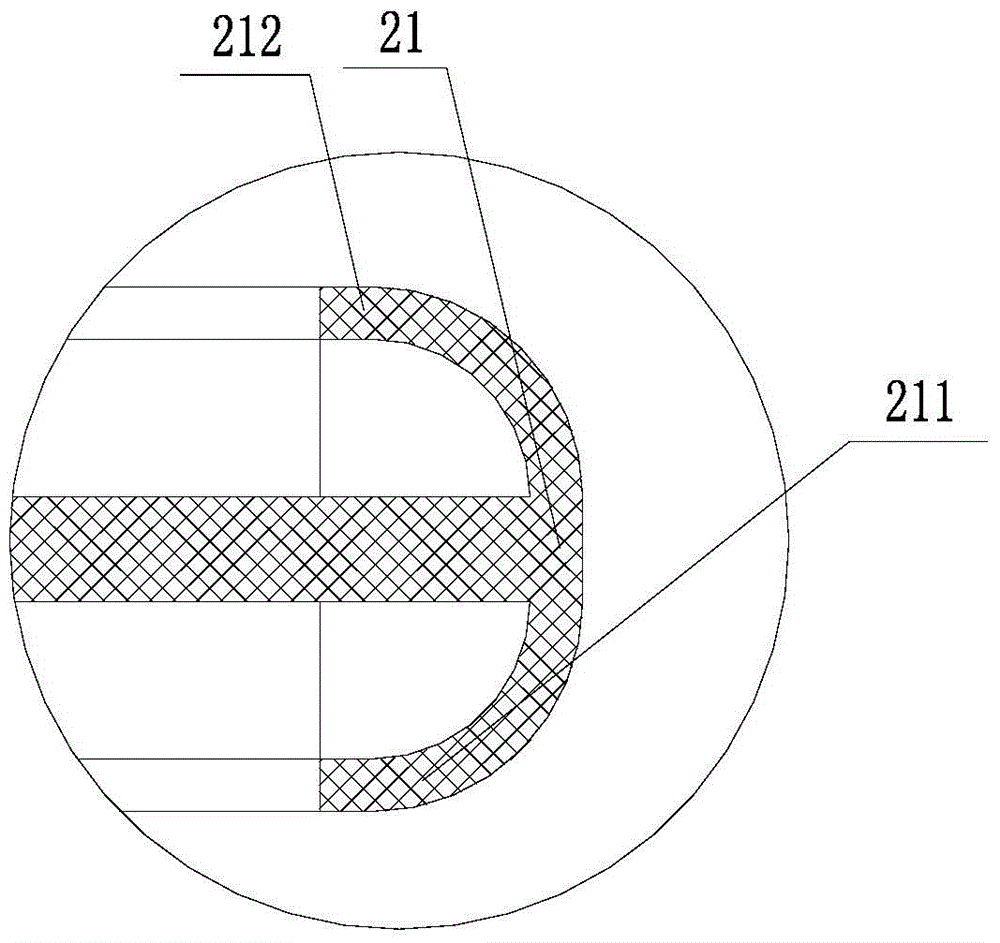

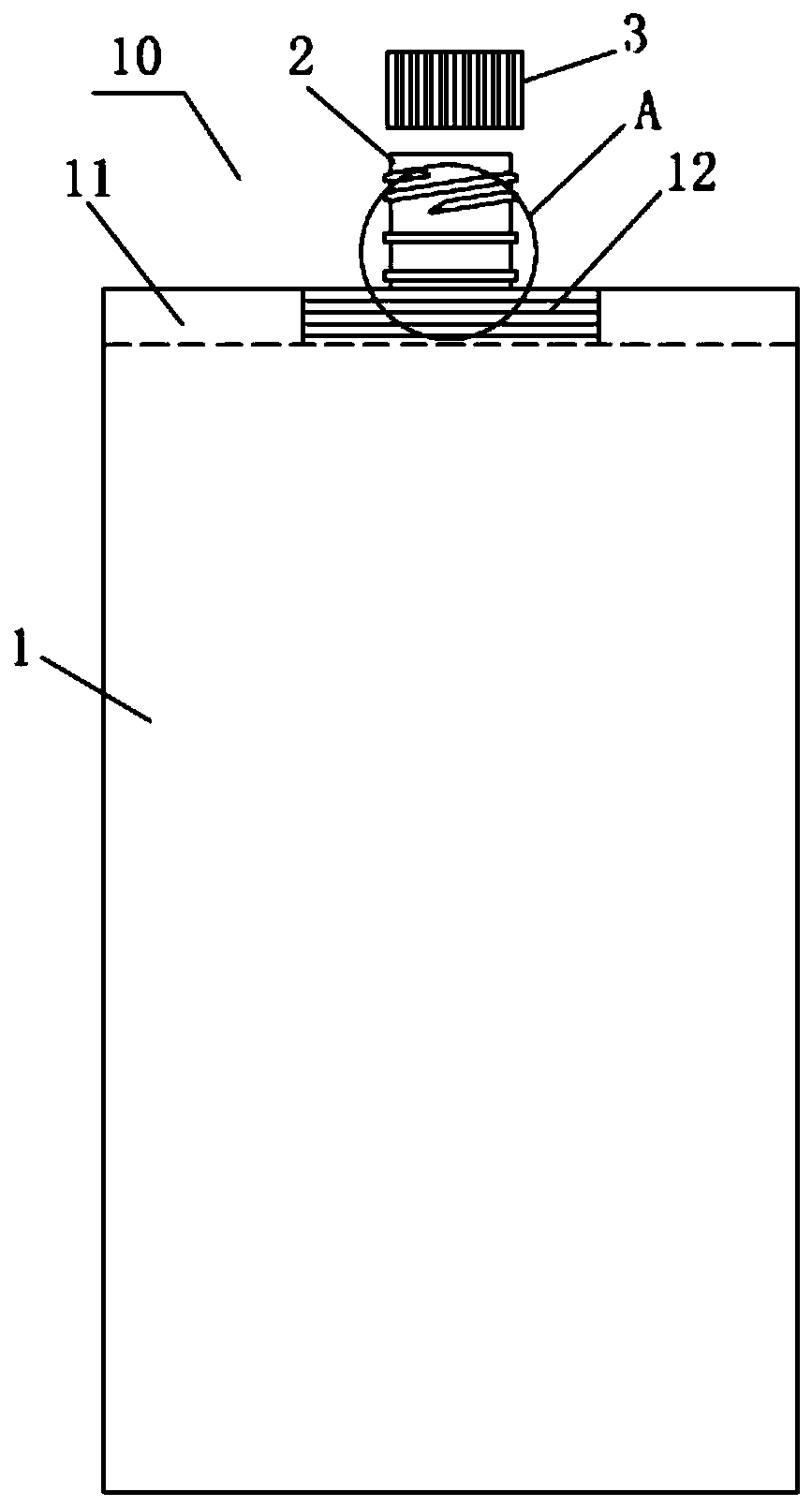

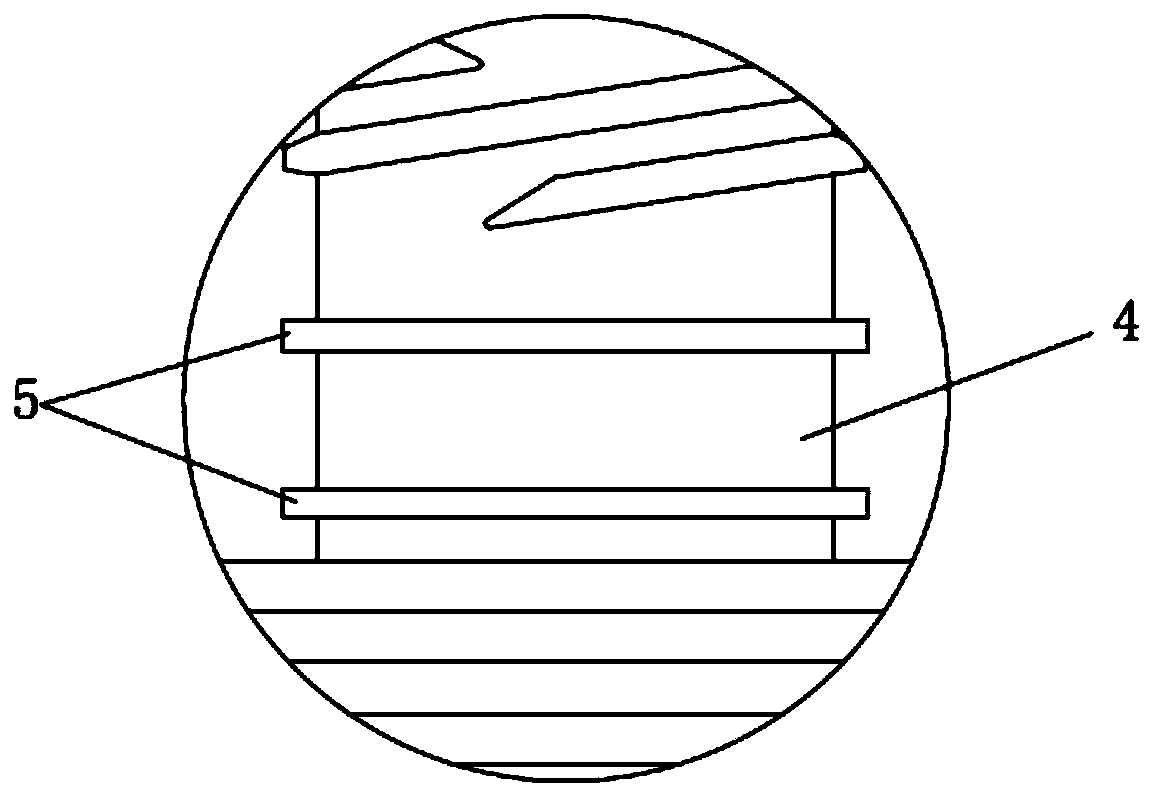

Packaging bag and automatic detergent putting device with packaging bag

ActiveCN110304338AAvoid cloggingAvoid cleaningBagsOther washing machinesLiquid storage tankBiomedical engineering

The invention discloses a packaging bag and an automatic detergent putting device with the packaging bag. The packaging bag comprises a bag body with a bag mouth and a cover covering the bag mouth, the end, close to the bag body, of the bag mouth is provided with an annular bayonet, the cover is positioned on the outer side of the bayonet, and a sealed sealing film is arranged at an opening in thefront end of the bag mouth. The bag mouth structure of the packaging bag is changed, so that the bag mouth can be clamped in a detergent liquid storage tank and is matched with an extracting device inside a washing machine for use, the problem that a detergent needs to be added or put frequently is solved, and the problem that a washing liquid pipeline is blocked and inconvenient to clean due tothe fact that liquid in the detergent liquid storage tank is dried is solved.

Owner:GUANGZHOU LIBY

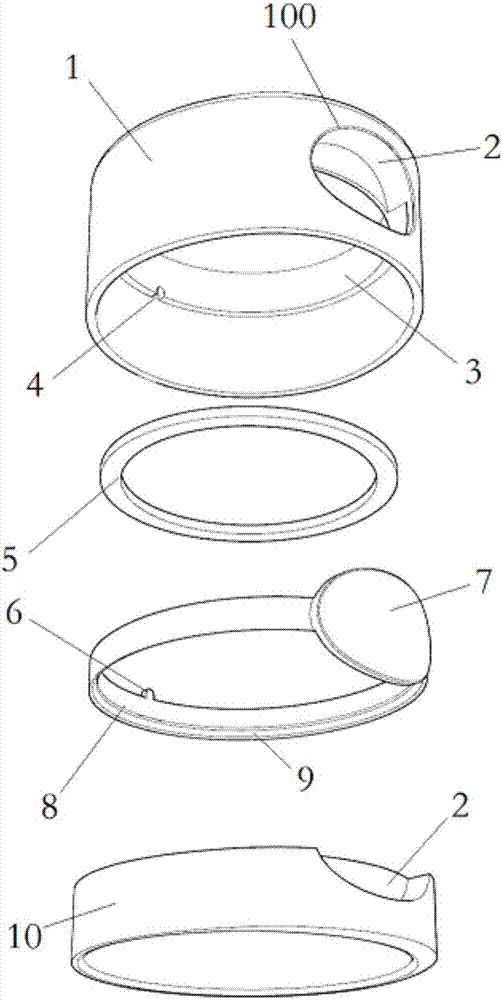

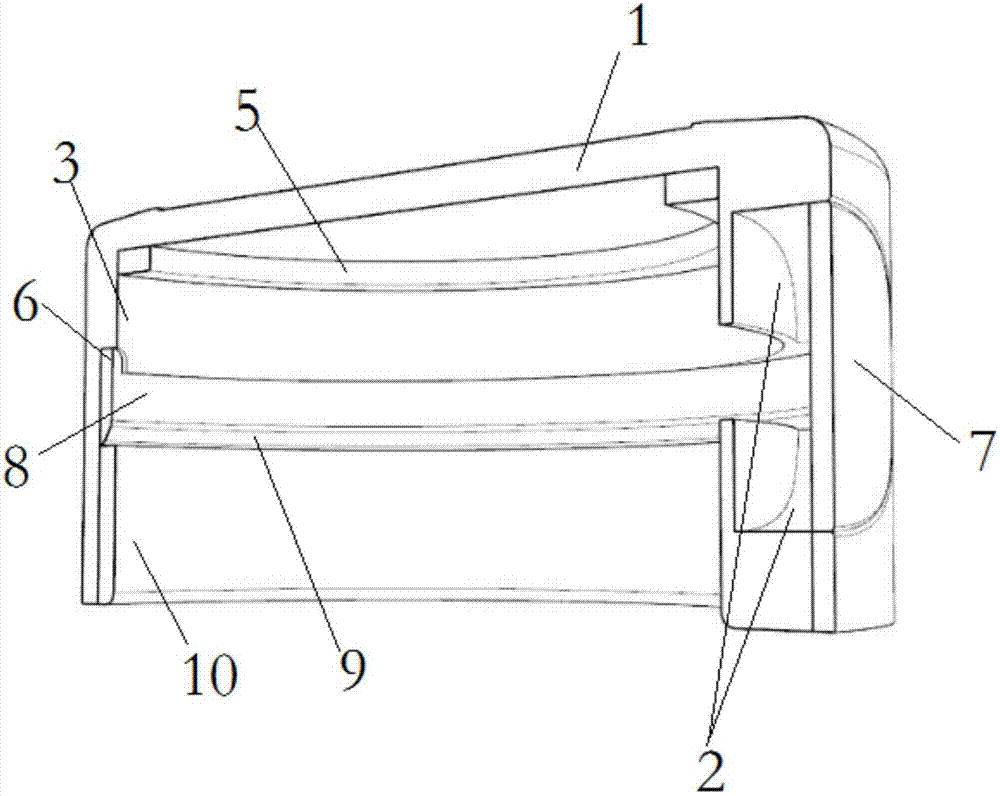

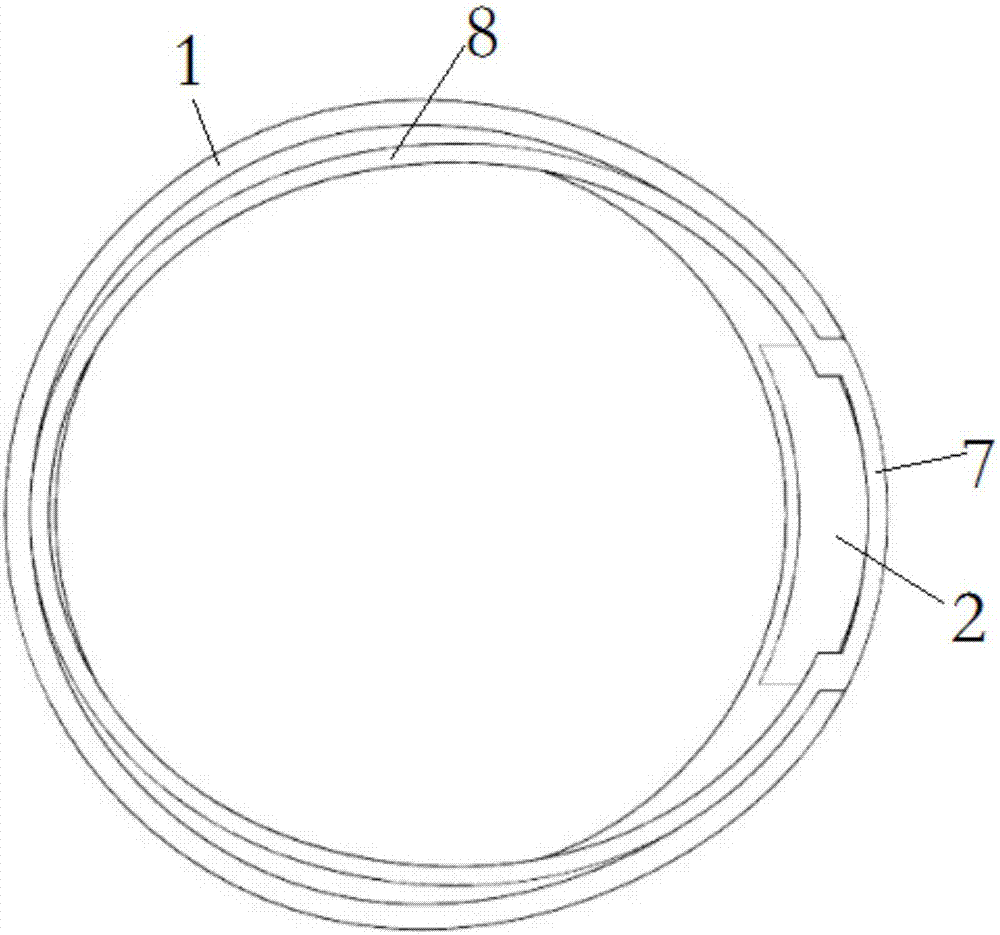

One-key opened bottle cap

The invention relates to a one-key opened bottle cap. The one-key opened bottle cap comprises a bottle opening and a bottle cover. The one-key opened bottle cap also comprises a positioning ring, a fixing ring and an elliptical elastic snap ring. The positioning ring and the fixing ring are successively arranged from top to bottom in the bottle cap, an interdeep is reserved between the positioning ring and the fixing ring, two ends of a long shaft of the elastic snap ring are located in the interdeep, a pressing sheet is arranged at one of the two ends of the long shaft of the elastic snap ring, a cavity for accommodating the pressing sheet is formed in a position of the positioning ring and the fixing ring corresponding to the pressing sheet, the pressing sheet can shift along the radial direction of the bottle cap in the cavity, and a port communicating with the cavity is formed in a position, corresponding to the cavity, of the side wall of the bottle cap; a slot is formed in a position, corresponding to the elastic snap ring, on the side wall surrounding the bottle opening, two ends of a short shaft of the elastic snap ring are located in the slot to lock connection between the bottle cap and the bottle opening, and the elastic snap ring is separated from the slot and enters the interdeep while the pressing sheet is pressed to stretch, so that connection between the bottle cap and the bottle opening is unlocked. The one-key opened bottle cap provided by the invention is simple in structure and simple and labor-saving in operation, and is safe and convenient to uncap.

Owner:CLOWN FISH SHANGHAI IND CO LTD

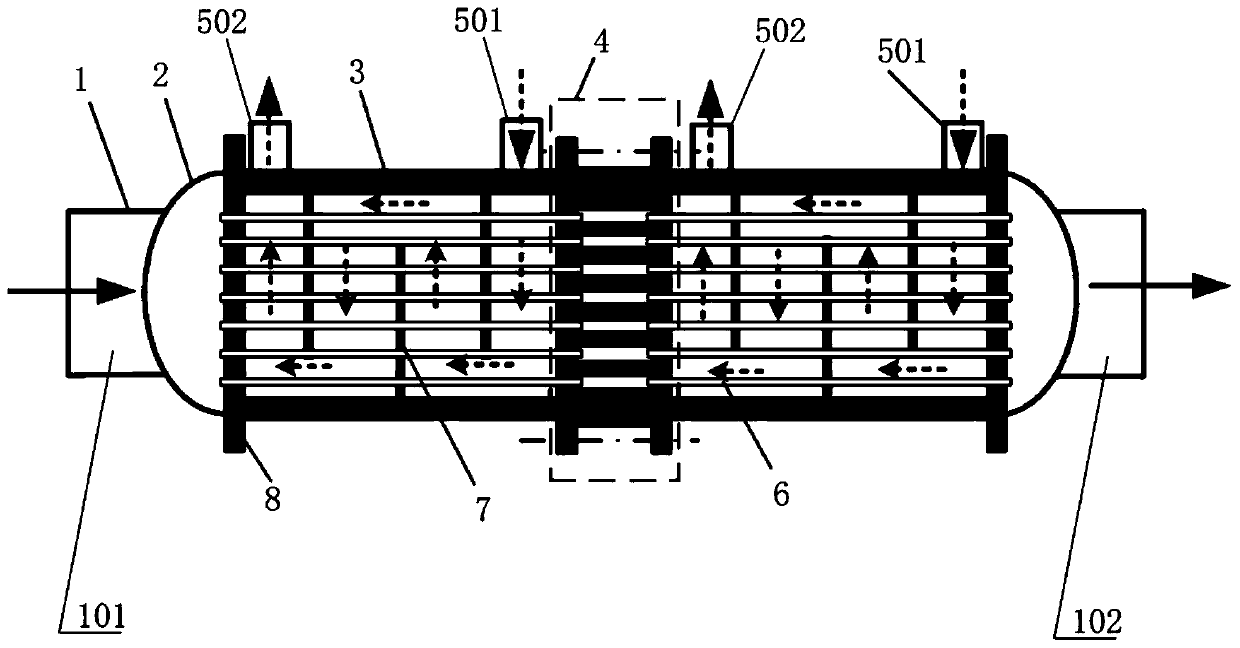

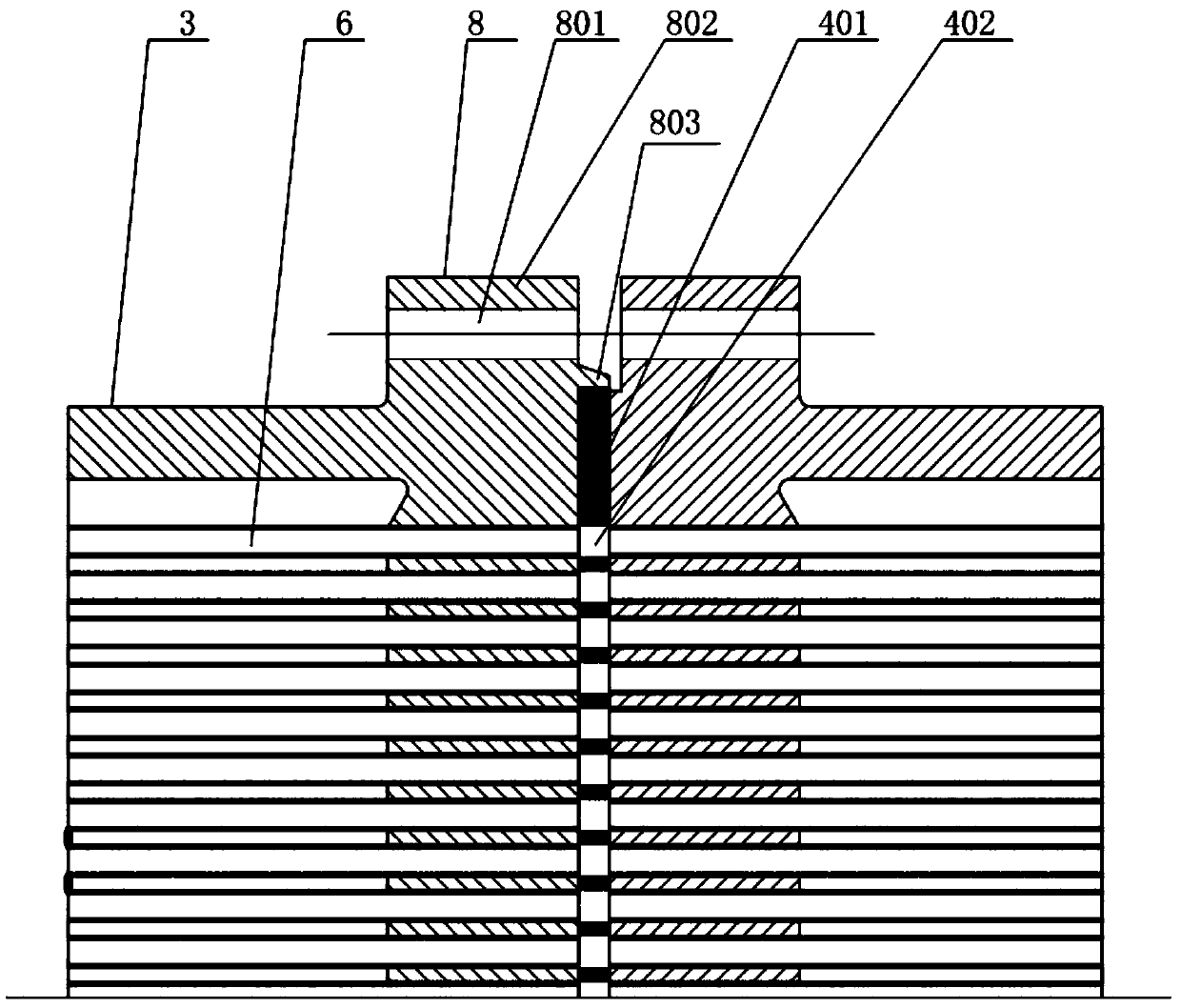

Tube pass tandem type tube and shell heat exchanger based on deep sea self-flow circulation cooling system

InactiveCN110274496ASimple structureEasy to useHeat exchanger casingsStationary tubular conduit assembliesFriction lossEngineering

The invention relates to a tube pass tandem type tube and shell heat exchanger based on a deep sea self-flow circulation cooling system. The tube pass tandem type tube and shell heat exchanger comprises a shell body, heat exchange tubes, baffle plates and tube plates. The tube plates are mounted at the two ends of the shell body separately, the multiple baffle plates are arranged in the shell body in the radial direction, mounting holes are formed in the tube plates and the baffle plates, and the multiple heat exchange tubes penetrate through the mounting holes of the baffle plates and are connected with the tube plates at the two ends of the shell body separately. The tube pass tandem type tube and shell heat exchanger further comprises water collecting chambers. The water collecting chambers are arranged on the outer sides of any tube plates. The water collecting chambers, the shell body, the heat exchange tubes, the baffle plates and the tube plates are combined to form sub heat exchangers, the adjacent sub heat exchangers are connected in series through barrel body connecting devices, and tube passes between the adjacent sub heat exchangers are connected into a whole. Sea water directly flows through the tube passes, so that the resistance loss of the sea water along the passes is reduced, the critical flow velocity point of self-flow circulation is reduced, and the self-flow circulation capacity is improved. The sub heat exchangers are connected in series through the barrel body connecting devices, and therefore the heat exchange function and the sealing reliability of the sub heat exchangers can be guaranteed.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

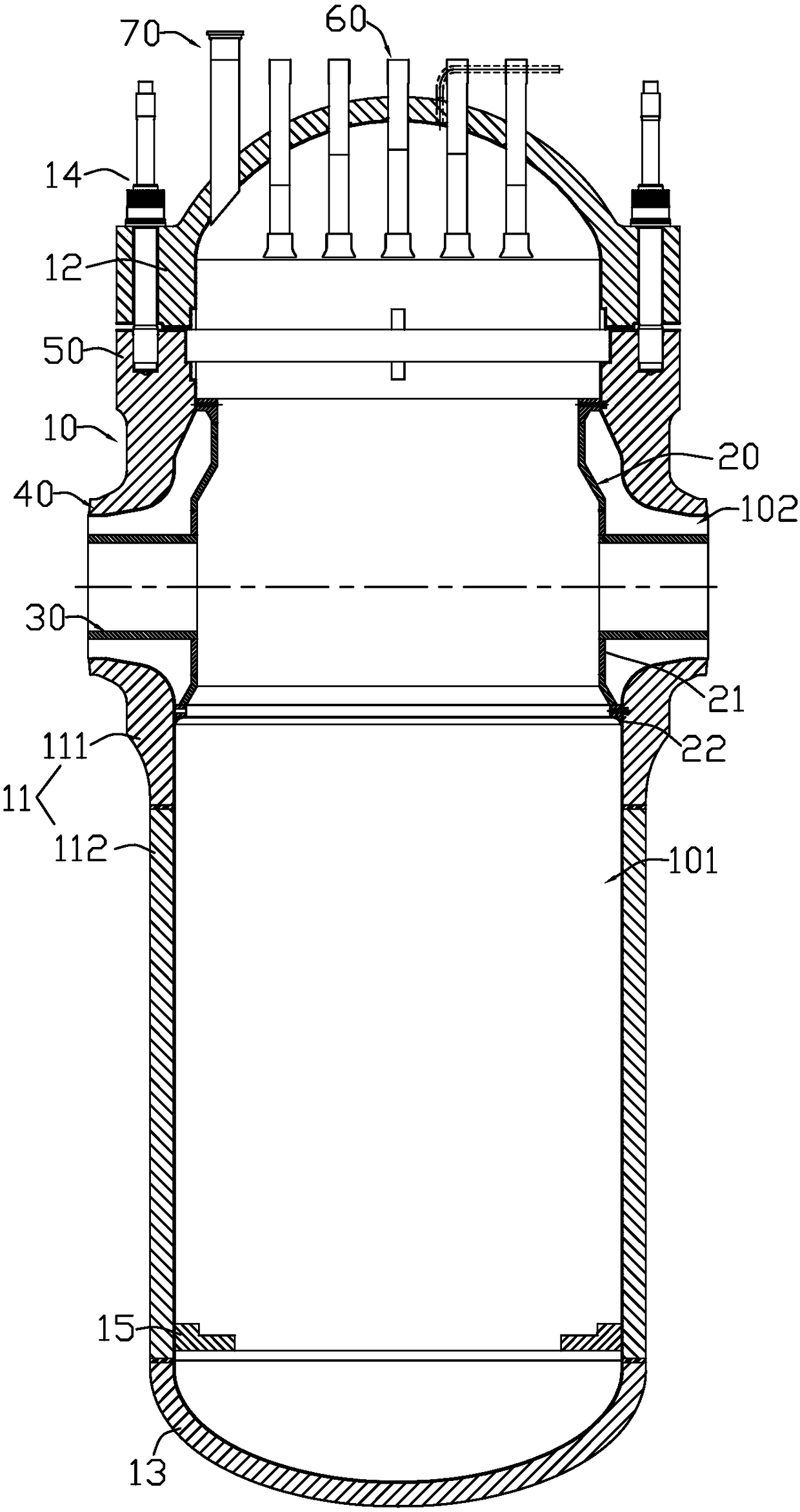

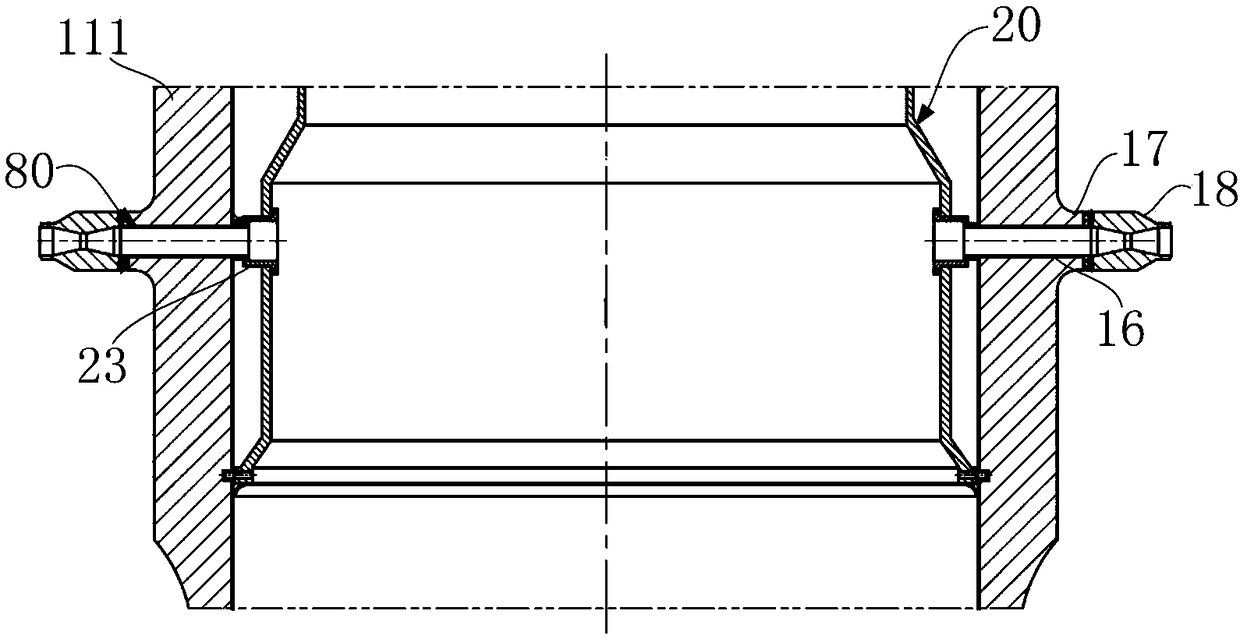

Reactor pressure container and working method thereof

ActiveCN108257684ASmall structureCompact layoutNuclear energy generationContainmentEngineeringPressure vessel

The invention discloses a reactor pressure container and a working method thereof. The pressure container comprises a closed container main body, a flow guide ring cavity assembly and at least one inner connecting pipe; at least one filler neck is arranged on the side surface of the container main body; the flow guide ring cavity assembly is axially arranged in the container main body; the upper end of the flow guide ring cavity assembly is positioned above the filler neck and is connected with the inner wall of the container main body; the lower end of the flow guide ring cavity assembly is positioned below the filler neck and is connected with the inner wall of the container main body; the inner connecting pipe is arranged in the filler neck, one end of the inner connecting pipe is connected with the flow guide ring cavity assembly and the other end of the inner connecting pipe corresponds to the pipe orifice of the filler neck; the space among the periphery of the flow guide ring cavity assembly, the periphery of the inner connecting pipe and the inner wall of the corresponding container main body forms a flow guide ring cavity; an internal channel of the inner connecting pipe,an inner channel of the flow guide ring cavity assembly and the internal space of the container main body are communicated to form an internal flow channel; and the internal flow channel is isolated from the flow guide ring cavity. The reactor pressure container meets the compact type arrangement requirement and is suitable for the working condition of the sea.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Closure capable of being quickly opened

PendingCN107065102AGuaranteed sealing reliabilityOpen quicklyFibre mechanical structuresEngineeringElectrical and Electronics engineering

The invention discloses a closure capable of being quickly opened, which comprises a bottom box, a top cover, an inner support, an optical cable reinforced core fixing device and a welding protection disc, wherein a welding protection disc cover plate is arranged above the welding protection disc, the inner support is arranged below, the optical cable reinforced core fixing device is arranged on the inner support, the inner support is located in the bottom box, the bottom box and the top cover are fixed through an elastic buckling structure, the elastic buckling structure is located at two sides and two ends of the closure, the elastic buckling structure comprises locking elastic buckles fixed on the bottom box and locking pull buckles fixed on the top cover, cable incoming holes are arranged at two ends of the bottom box, the inner side walls of the cable incoming holes are provided with optical cable sealing circles, optical cable sealing circle locking nuts and optical cable locking nuts are arranged outside the cable incoming holes, one end of each optical cable sealing circle locking nut is matched with the cable incoming hole through inner thread, and the other end of the optical cable sealing circle locking nut is matched with the optical cable locking nut through outer thread. According to the closure of the invention, both quick opening and sealing reliability can be ensured.

Owner:ZHONGTIAN BROADBAND TECH

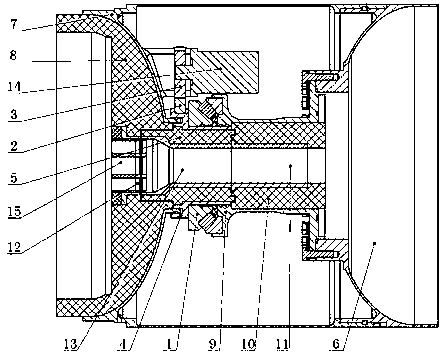

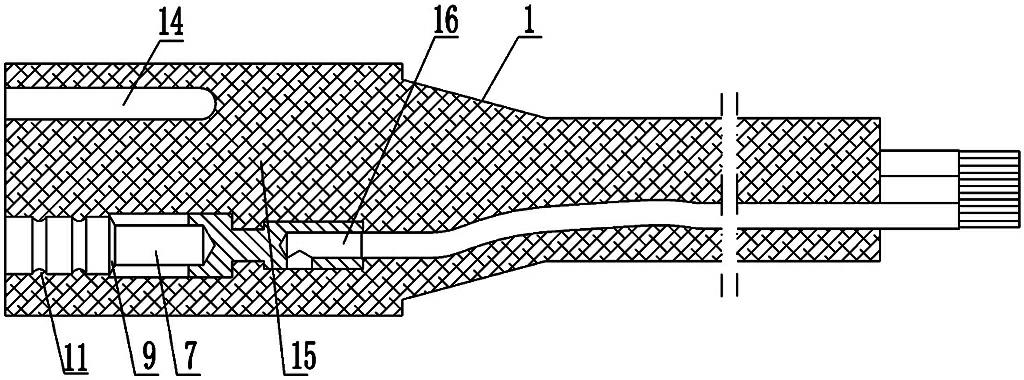

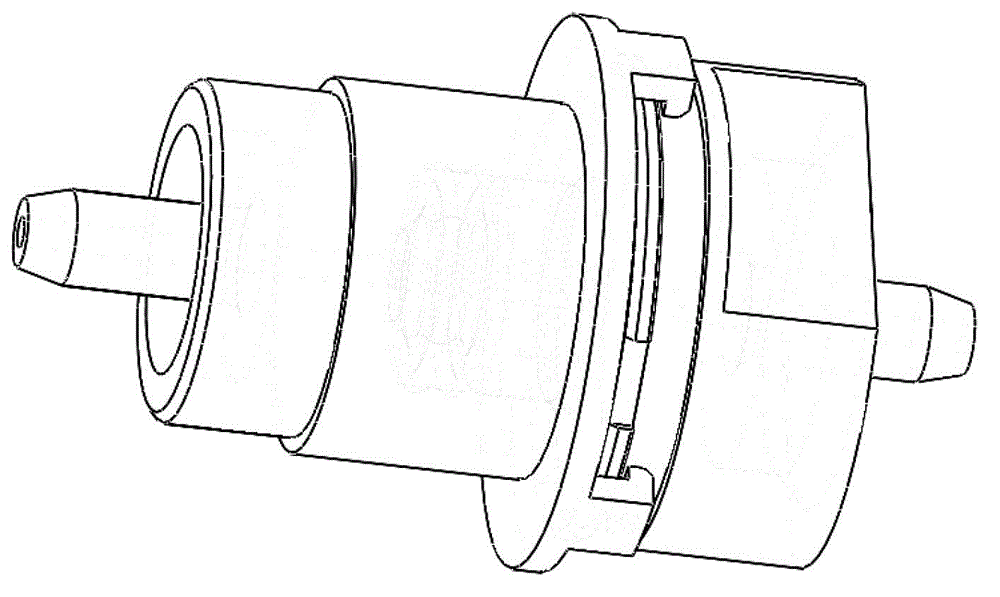

Miniature rotary seal used for bioreactor

InactiveCN102979969AEasy to disassembleEasy to installSleeve/socket jointsMechanical engineeringBioreactor

The invention discloses a miniature rotary seal used for a bioreactor. The miniature rotary seal comprises a seal body and a seal ring; the seal body comprises a hollow seal housing and a seal shaft core; the seal ring is an x-shaped silicone rubber seal ring; both the seal housing and the seal shaft core are provided with a pipeline joint; one end of the seal housing is provided with three stopping cards; an annular slot is arranged in the seal shaft core; notches corresponding to the stopping cards are formed in the annular slot; the seal ring is sleeved at one end of the seal shaft core away from the pipeline joint; and the seal housing is sleeved on the annular slot of the seal shaft core through the stopping cards so as to prevent the seal housing from separating with the shaft core. The seal components of the miniature rotary seal provided by the invention are convenient in assembling and disassembling, and convenience is brought for the replacement and washing operations of the seal ring.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Dual-seal ball valve seat compact in structure

ActiveCN108980398AGuaranteed sealing reliabilityGood sealing performancePlug valvesValve housingsBall valveEngineering

The invention relates to a dual-seal ball valve seat compact in structure and belongs to the technical field of ball valves. The dual-seal ball valve seat compact in structure is characterized by comprising a valve body with a channel, a ball body arranged in the valve body and a limiting ring, wherein the inner wall of the channel is provided with an outer valve seat and an inner valve seat whichare located between the ball body and the valve body, the outer valve seat is arranged at the end, close to the ball body, of the inner valve seat, one end of the outer valve seat abuts against the ball body and forms a hard seal face, the other end of the outer valve seat abuts against the end face of the inner valve seat, the outer valve seat is provided with an annular protrusion, one end of the limiting ring is clamped to the protrusion to limit axial displacement of the inner valve seat, and the other end of the limiting ring is fixedly connected with the inner valve seat. The dual-sealball valve seat compact in structure has the beneficial effects that the dual-seal structure of the inner valve seat and the outer valve seat is adopted, the seal reliability is guaranteed, an more excellent seal performance is achieved; the outer valve seat is fixed through the limiting ring, the structure is compact, the volume of the outer valve seat is greatly reduced, and the manufacturing cost is reduced; and assembling and disassembly are convenient, and maintenance is facilitated in a later period.

Owner:SICHUAN KAITZ VALVE MFG

Concentric dual-tube separated injection CO2 tubular column and application method thereof

PendingCN110159234AAvoid safety accidentsGuaranteed reliabilityDrilling rodsFluid removalGas separationEngineering

The invention relates to the technical field of oilfield development gas injection, in particular to a concentric dual-tube separated injection CO2 tubular column applied to CO2 separated injection. According to the concentric dual-tube separated injection CO2 tubular column, a sleeve pipe, an outer pipe and an inner pipe are sleeved in succession, and an outer door, an upper packer, a gas separation valve, a lower packer and a gas injection valve are connected to the outer pipe in succession; the lower end of the inner pipe is firstly connected with an inner door and then is connected with the gas separation valve; and an inserting sealing mechanism, a locking mechanism and an anti-return mechanism are arranged in the gas separation valve. An application method of the concentric dual-tubeseparated injection CO2 tubular column comprises the steps that an outer tubular column is fed; the packers are packed; the inner pipe is fed to be inserted and sealed and is locked; gas is injected;an inner door press well is opened; the inner pipe is lifted up; an outer door press well is opened; and the packers are unpacked, and the outer tubular column is lifted up. The concentric dual-tubeseparated injection CO2 tubular column is provided with an inner door and an outer door, and the problems about press well channels are solved; the anti-return mechanism is arranged, and production issafe; and the inserting sealing mechanism and the locking mechanism are arranged, and sealing failures are avoided. The gas seal packers provided with anchors and provided with no well washing channel are adopted, reliable separation is guaranteed, and the problem of sealing failures caused by packer upward movement due to the too large lower pressure difference is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com