Concentric dual-tube separated injection CO2 tubular column and application method thereof

A concentric double-pipe and pipe-string technology, used in drilling pipes, casings, and earth-moving drilling, etc., can solve problems such as seal failure, safety accidents, poor reliability, etc., to prevent seal failure problems, ensure reliable sealing, and avoid safety. effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

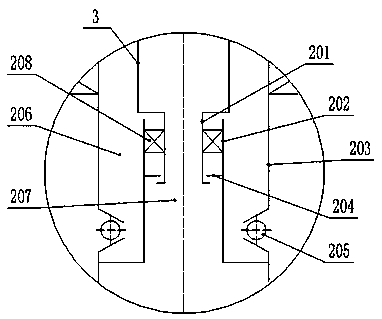

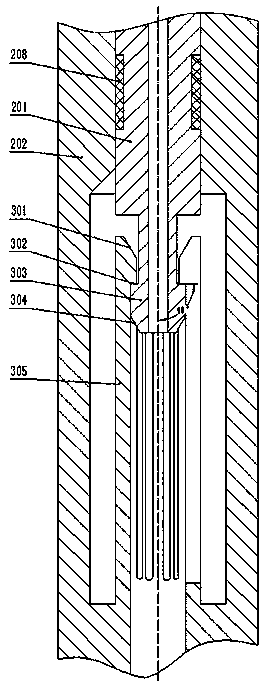

[0070] The "up", "down", "left", and "right" in the positional relationship in this specification and claims refer to the positional relationship from the reader's perspective. The top of the page is up and the bottom of the page is down. , The reader's left hand is left, and the reader's right hand is right. When describing the relationship between the inside, outside, or inside and outside of the pipe, the small radius in the radial direction is regarded as inside or inside, and the large radius is regarded as outside. The "oil sleeve annulus" described below refers to the annular space between the casing and the outer tube. The sealed parts in the drawings are as shown in the figure, and will not be repeated in the following description.

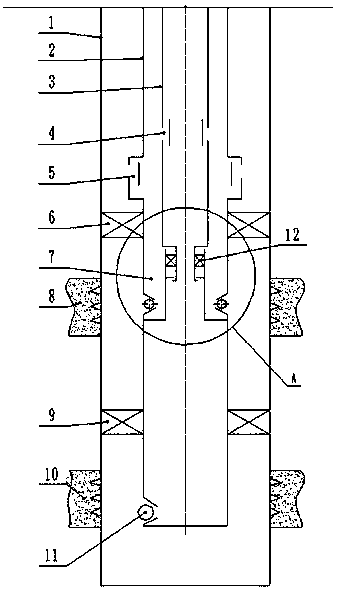

[0071] see figure 1 with figure 2 As shown, the concentric double-tube dispensing CO of the present invention 2 The pipe string, the casing 1, the outer pipe 2 and the inner pipe 3 are sequentially sleeved and coaxially installed, the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com