Method for installing abnormal-shape curve steel box girder

An installation method and technology of steel box girders, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as failure to meet production requirements, increased difficulty in installation and construction requirements of special-shaped steel box girders, etc., and achieve good welding effects, The structure is complete and reliable, and the effect of reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0032] Any feature disclosed in this specification (including any appended claims, abstract and drawings), unless expressly stated otherwise, may be replaced by alternative features which are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

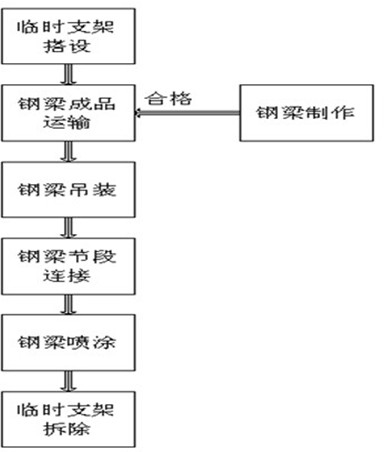

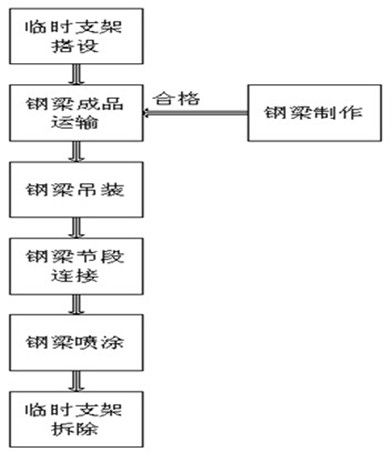

[0033] The special-shaped curved steel box girder installation method of the present invention, it comprises the following steps:

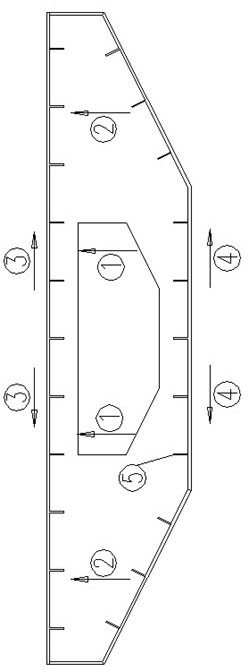

[0034] Step 1. Manufacture and pre-assemble each section of the steel box girder, detect and compensate the lateral shrinkage of welding; specifically: manufacture each section of the steel box girder and perform pre-assembly. During the pre-assembly process, the distance between 300mm and The cross-section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com