Fast large-cross-section tunnel construction method adapting to complicated and variable geological conditions

A construction method and technology for geological conditions, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems affecting construction progress, reducing single excavation span, surrounding rock disturbance, etc., to facilitate medium-sized mechanical construction and shorten closure Time, the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

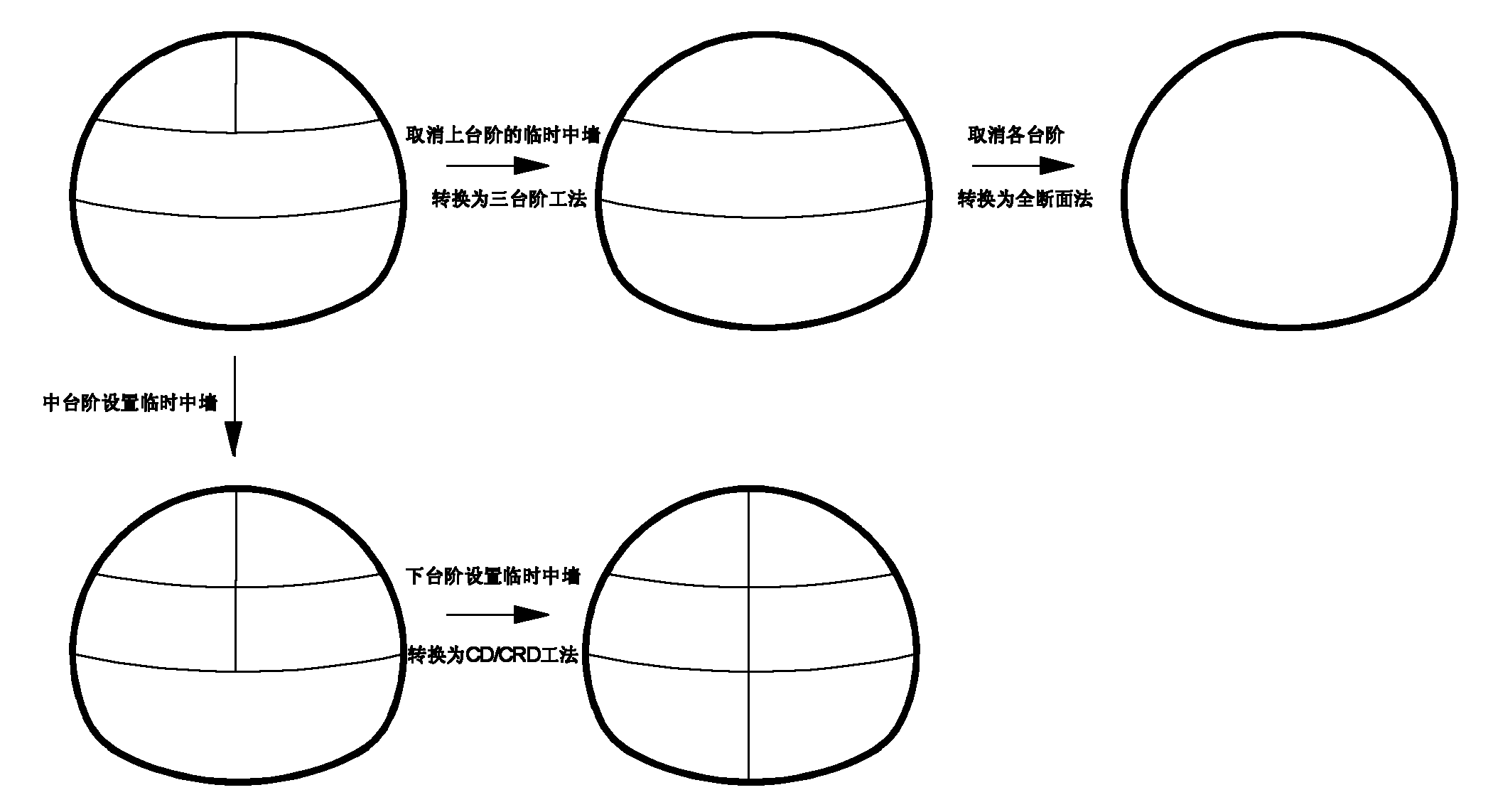

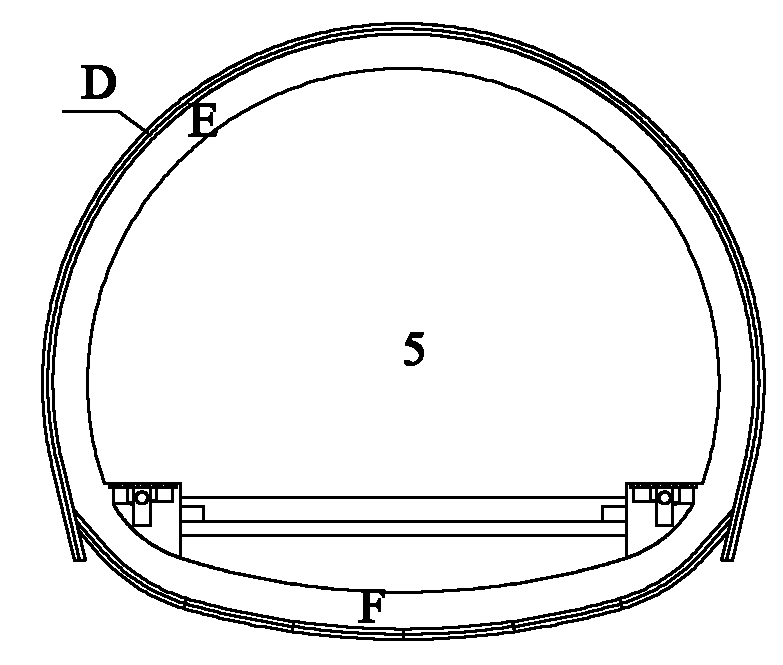

[0028] like figure 2 As shown in , when the excavation section of the entire tunnel is in a good rock stratum and is equipped with large-scale mechanical equipment, the entire tunnel shall be excavated at one time without dividing into small excavation sections. At this time, the upper, middle, and lower steps The temporary mid-wall and the temporary inverted arches of each step do not need to be constructed.

Embodiment 2

[0030] like image 3 As shown, when the excavation section of the entire tunnel is in a good rock formation and there are medium-sized mechanical equipment, the step method can be used for construction. The temporary partition walls of the upper, middle and lower steps of the tunnel and the temporary inverted arches of each step Can not be applied, the specific construction process is as follows:

[0031] ① Excavate a step, implement the initial support of a cave body structure, and install lock-foot anchors. The lock-foot anchors are required to be welded to the steel frame with Φ22 steel bars in L shape, 2 for each truss.

[0032] ② Excavate 2 parts, drill and set anchor rods, which require L-shaped welding on the steel frame, and spray concrete to the design thickness.

[0033] ③ Excavate 3 parts, and close the initial support in time.

[0034] In the above construction procedures, if the surrounding rock of the working face is relatively weak, the excavation can be carri...

Embodiment 3

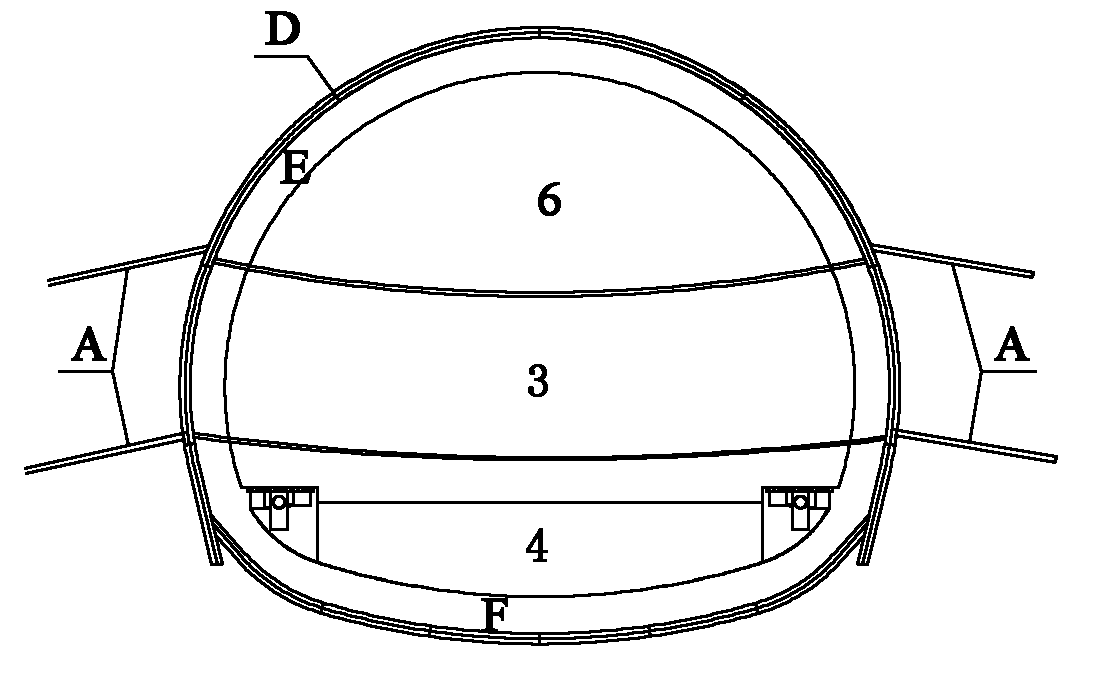

[0036] like Figure 4 As shown, when the upper steps of the tunnel are in poor rock formations and the middle and lower steps are in better rock formations, a temporary partition wall is set during the excavation of the upper steps of the tunnel, that is, the upper steps are divided into two parts by the middle partition wall. , the specific construction process is as follows:

[0037] ① Excavate 1 step and seal the face with primary sprayed concrete. The initial support and temporary support of a cave body structure shall be implemented, and the lock-foot anchor rods shall be installed. The lock-foot anchor rods shall be welded to the steel frame with Φ22 steel bars in L-shape, 2 for each shank.

[0038] ②Follow up two parts of excavation and support, the steps are the same as part one.

[0039] ③ Excavate 3 sections, install steel frames, drill and set anchor rods, and the anchor rods are required to be L-shaped welded on the steel frame. Shotcrete to design thickness.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com