Self-tightening sealing and stress testing device for self-enhancing of ultrahigh-pressure pump head body

A stress test and self-tightening sealing technology, which is applied in pump testing, parts of pumping devices for elastic fluids, pump components, etc., can solve the problem of sealing methods, pressure-bearing areas and deformation areas, and limit self-reinforcing technology Application, difficult sealing and pressurization, etc., to achieve the effect of protecting material and inner diameter cylindricity, small annular space, and reducing local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

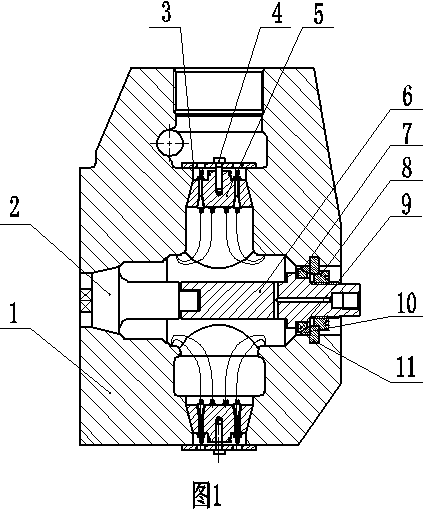

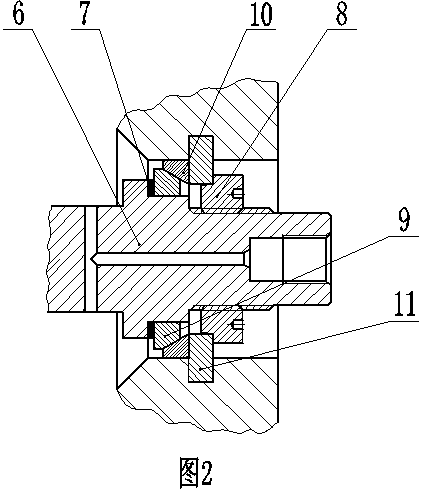

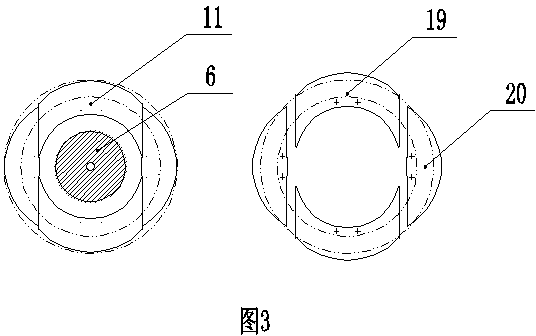

[0021] The ultra-high pressure pump head body self-tightening self-tightening seal and stress test device consists of an ultra-high pressure pump head body 1, a horizontal sealing cone rod 2, a pre-tightening hole plate 3, a pre-tightening tension bolt 4, a signal lead-out sealing cone 5, and a horizontal Seal adjustment rod 6, seal flat gasket 7, outer cone nut 8, outer cone seal ring 9, inner cone seal ring 10, ring hole axial retaining ring combination 11, hexagonal thin nut 12, nylon gasket 13, O-shaped sealing ring 14, signal lead-out rod 15, plexiglass sealing cone ring 16, quick-plug connector 17, high-strength enameled wire 18, strain gauge 21 and wiring transition plate 23 are formed.

[0022] There are cross-shaped through-holes intersecting horizontally and vertically in the body of the ultra-high pressure pump head. The left end of the horizontal through-hole is a plunger cavity, the right end is a plug cavity, and a horizontal sealing cone rod 2 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com