Dual-seal ball valve seat compact in structure

A double-sealed, compact structure technology, applied to the valve housing structure, valve details, valve device, etc., can solve the problems of high manufacturing cost and complex structure, and achieve the effects of reducing manufacturing cost, saving volume, and simple and reliable detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

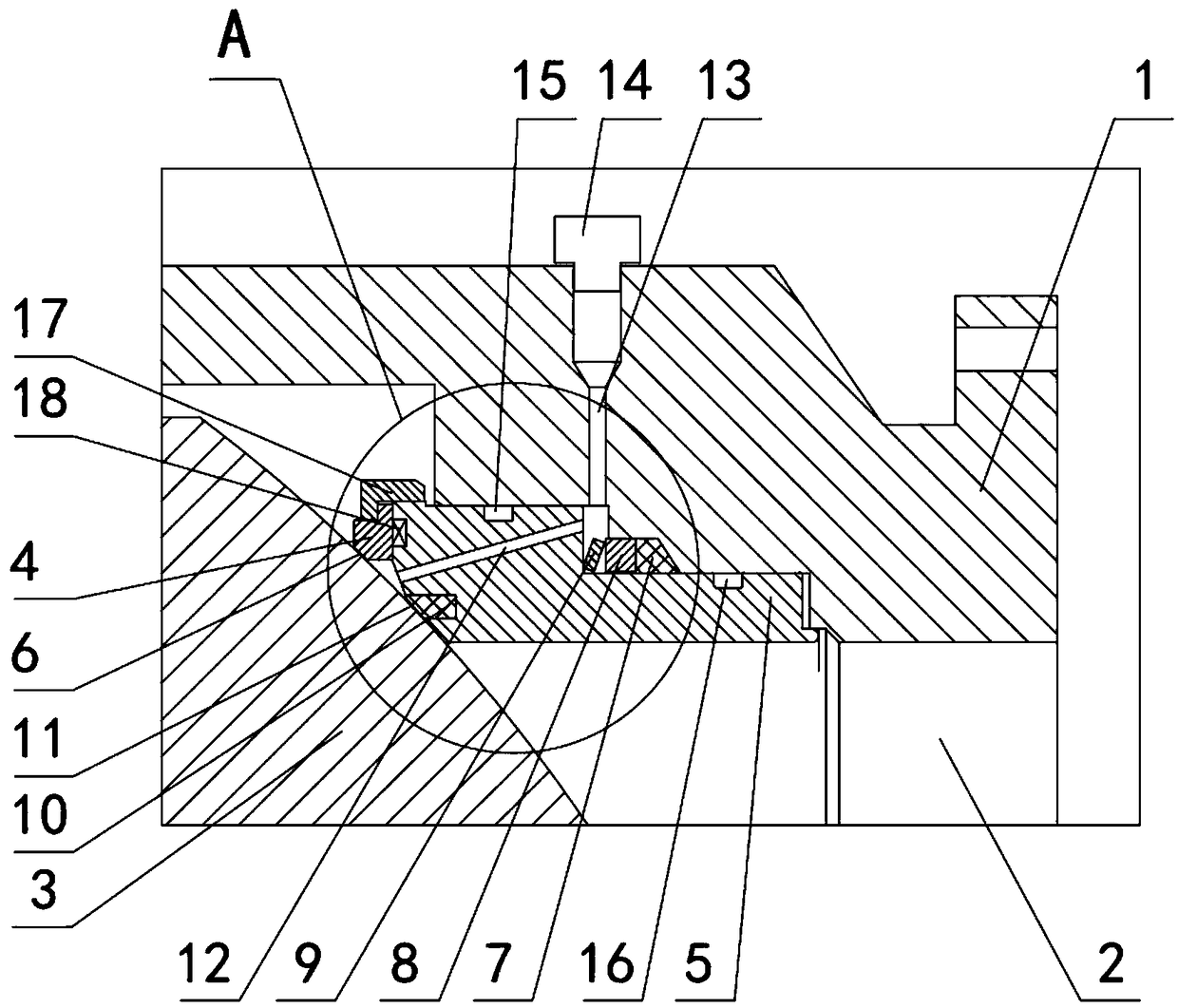

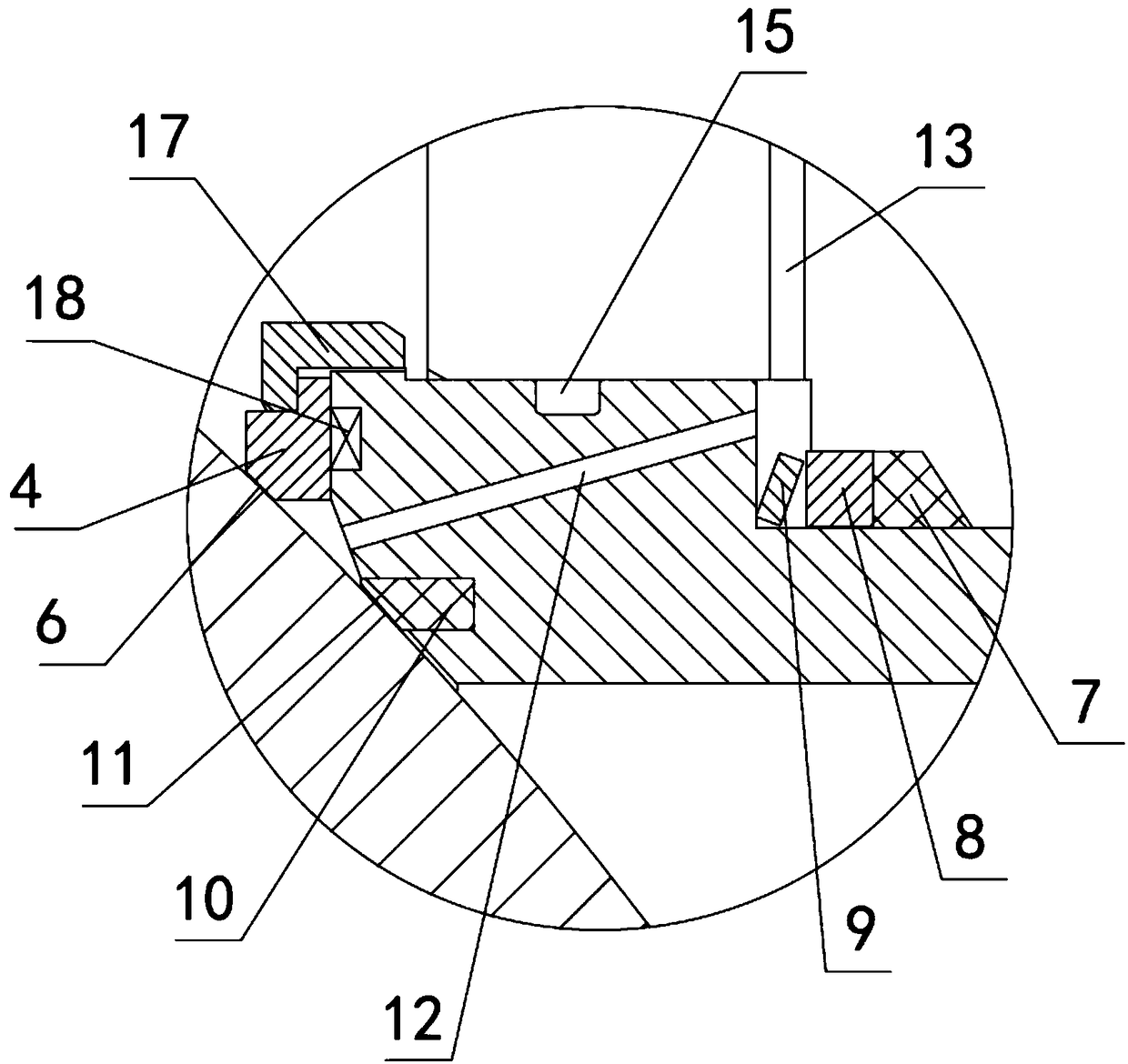

[0024] Such as Figure 1 ~ Figure 2 As shown, a compact double-sealed ball valve seat is characterized in that it includes a valve body 1 with a channel 2, a ball 3 inside the valve body 1, and a limit ring 17; the inner wall of the channel 2 is provided with a The outer valve seat 4 and the inner valve seat 5 between the ball 3 and the valve body 1, the outer valve seat 4 is arranged at one end of the inner valve seat 5 close to the ball 3; one end of the outer valve seat 4 is formed against the ball 3 The hard sealing surface 6, the other end is against the end face of the inner valve seat 5; the outer valve seat 4 has a circumferential protrusion, and one end of the limit ring 17 is stuck on the protrusion to limit the inner valve seat 5 Axial displacement, the other end is fixedly connected with the inner valve seat 5.

[0025] The double sealing structure of the inner valve seat 5 and the outer valve seat 4 is adopted to ensure the sealing reliability and have better sea...

no. 2 example

[0027] Such as Figure 1 ~ Figure 2 As shown, a compact double-sealed ball valve seat is characterized in that it includes a valve body 1 with a channel 2, a ball 3 inside the valve body 1, and a limit ring 17; the inner wall of the channel 2 is provided with a The outer valve seat 4 and the inner valve seat 5 between the ball 3 and the valve body 1, the outer valve seat 4 is arranged at one end of the inner valve seat 5 close to the ball 3; one end of the outer valve seat 4 is formed against the ball 3 The hard sealing surface 6, the other end is against the end face of the inner valve seat 5; the outer valve seat 4 has a circumferential protrusion, and one end of the limit ring 17 is stuck on the protrusion to limit the inner valve seat 5 Axial displacement, the other end is fixedly connected with the inner valve seat 5.

[0028] A sealing ring 10 is arranged between one end of the inner valve seat 5 and the sphere 3, the end face of the sealing surface is a soft sealing su...

no. 3 example

[0030] Such as Figure 1 ~ Figure 2 As shown, a compact double-sealed ball valve seat is characterized in that it includes a valve body 1 with a channel 2, a ball 3 inside the valve body 1, and a limit ring 17; the inner wall of the channel 2 is provided with a The outer valve seat 4 and the inner valve seat 5 between the ball 3 and the valve body 1, the outer valve seat 4 is arranged at one end of the inner valve seat 5 close to the ball 3; one end of the outer valve seat 4 is formed against the ball 3 The hard sealing surface 6, the other end is against the end face of the inner valve seat 5; the outer valve seat 4 has a circumferential protrusion, and one end of the limit ring 17 is stuck on the protrusion to limit the inner valve seat 5 Axial displacement, the other end is fixedly connected with the inner valve seat 5.

[0031] A sealing ring 10 is arranged between one end of the inner valve seat 5 and the sphere 3, the end face of the sealing surface is a soft sealing su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com