Reactor pressure container and working method thereof

A technology of pressure vessels and reactors, applied in the field of nuclear power, can solve problems such as unsuitable marine working conditions and overturning, and achieve the effects of convenient welding and daily operation and maintenance, increased operating space, and reduced spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

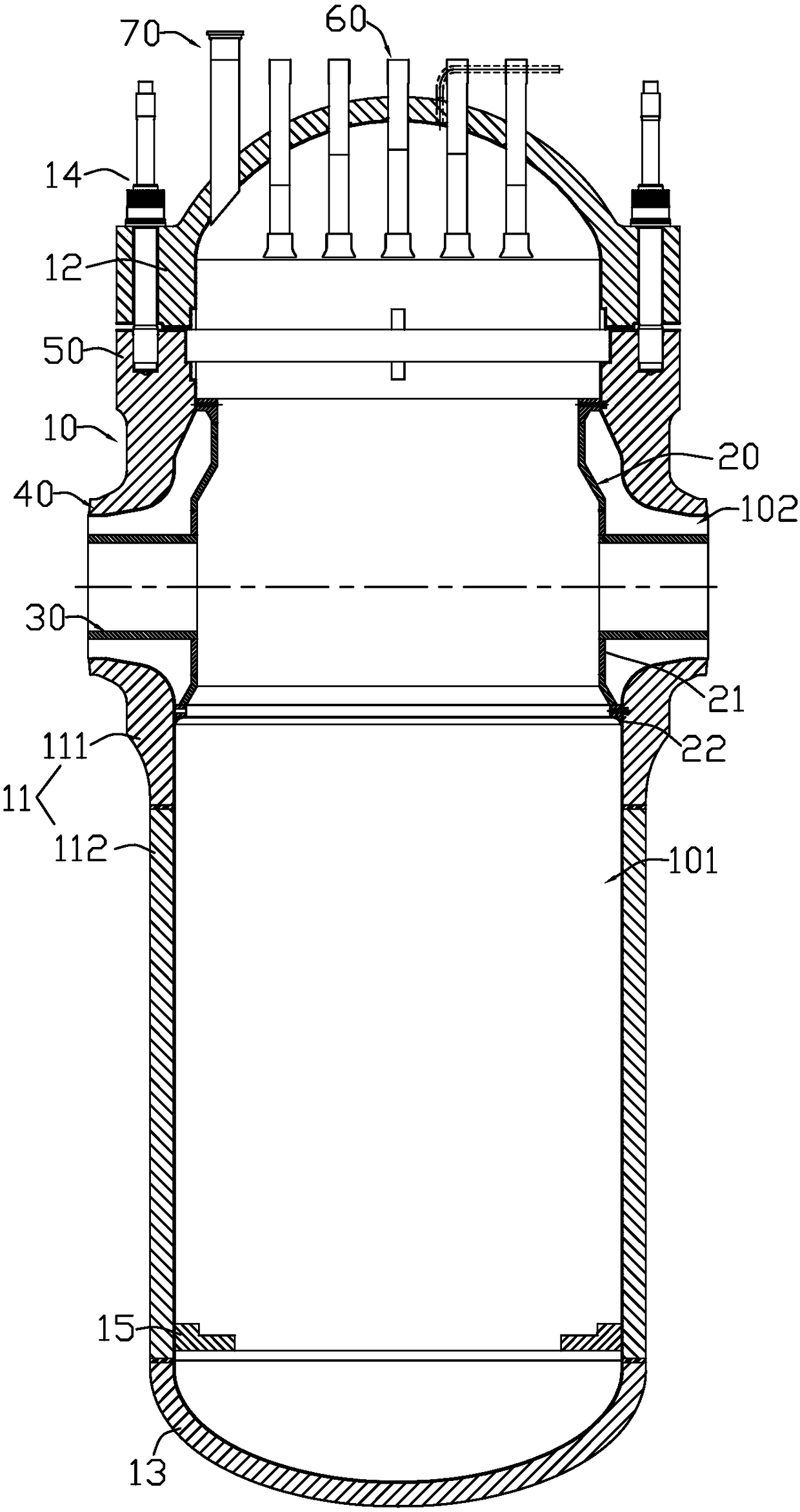

[0029] Such as figure 1 As shown, the reactor pressure vessel according to an embodiment of the present invention includes a sealed vessel body 10, a flow guide ring cavity assembly 20, and at least one internal connecting pipe 30. At least one nozzle 40 is provided on the side of the container body 10, and the guide ring cavity assembly 20 is axially arranged in the container body 10.

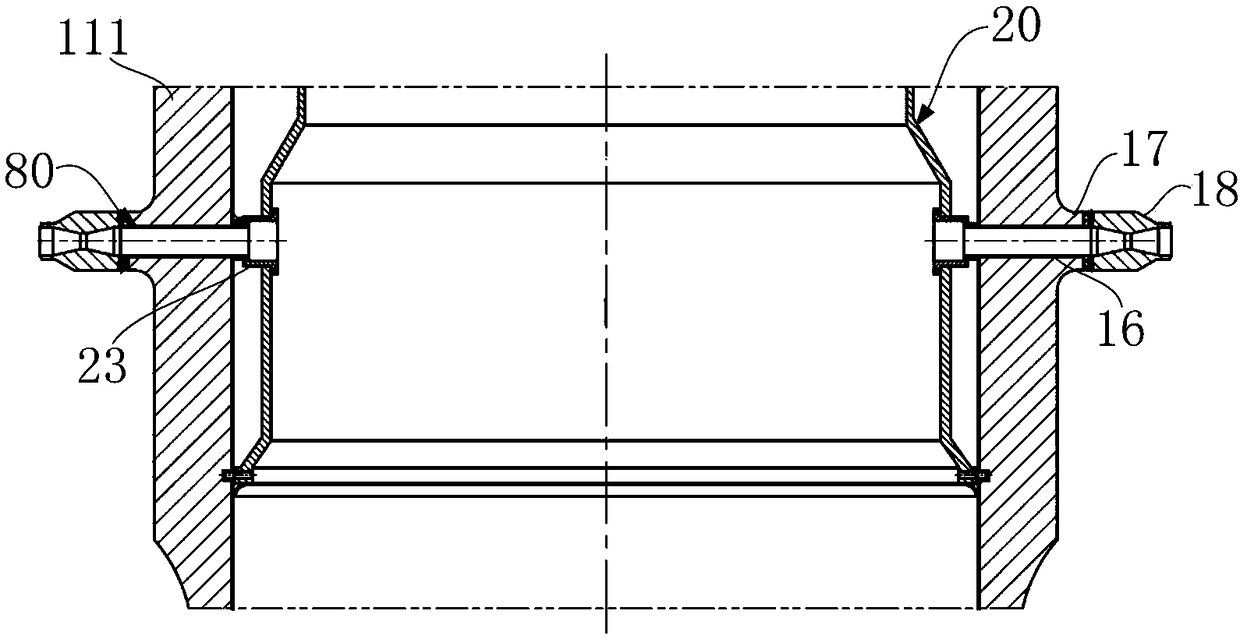

[0030] The upper end of the guide ring cavity assembly 20 is located above the nozzle 40 and is connected to the inner wall of the container body 10, and the lower end is located below the nozzle 40 and is connected to the inner wall of the container body 10. The inner connecting pipe 30 is arranged in the connecting nozzle 40, one end is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com