Tube pass tandem type tube and shell heat exchanger based on deep sea self-flow circulation cooling system

A technology of circulating cooling system and shell-and-tube heat exchanger, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of occupying outboard space and increasing seawater resistance loss on the tube side. It can ensure the heat exchange function and sealing reliability, reduce the resistance along the seawater side, and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described below.

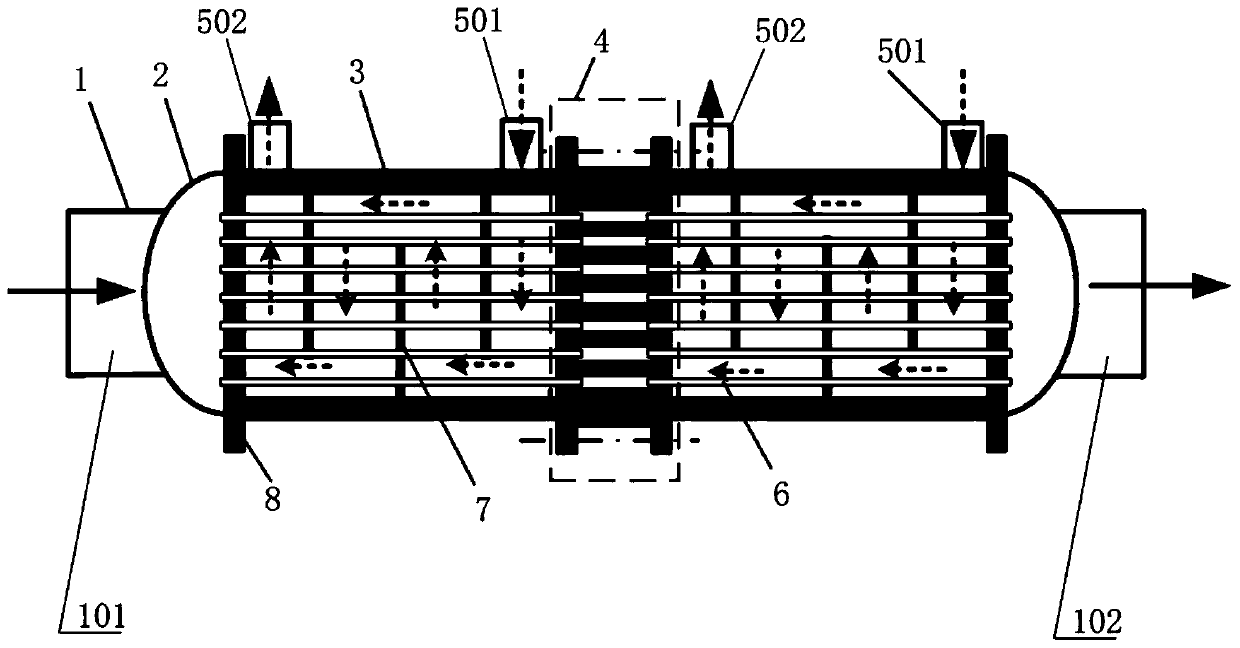

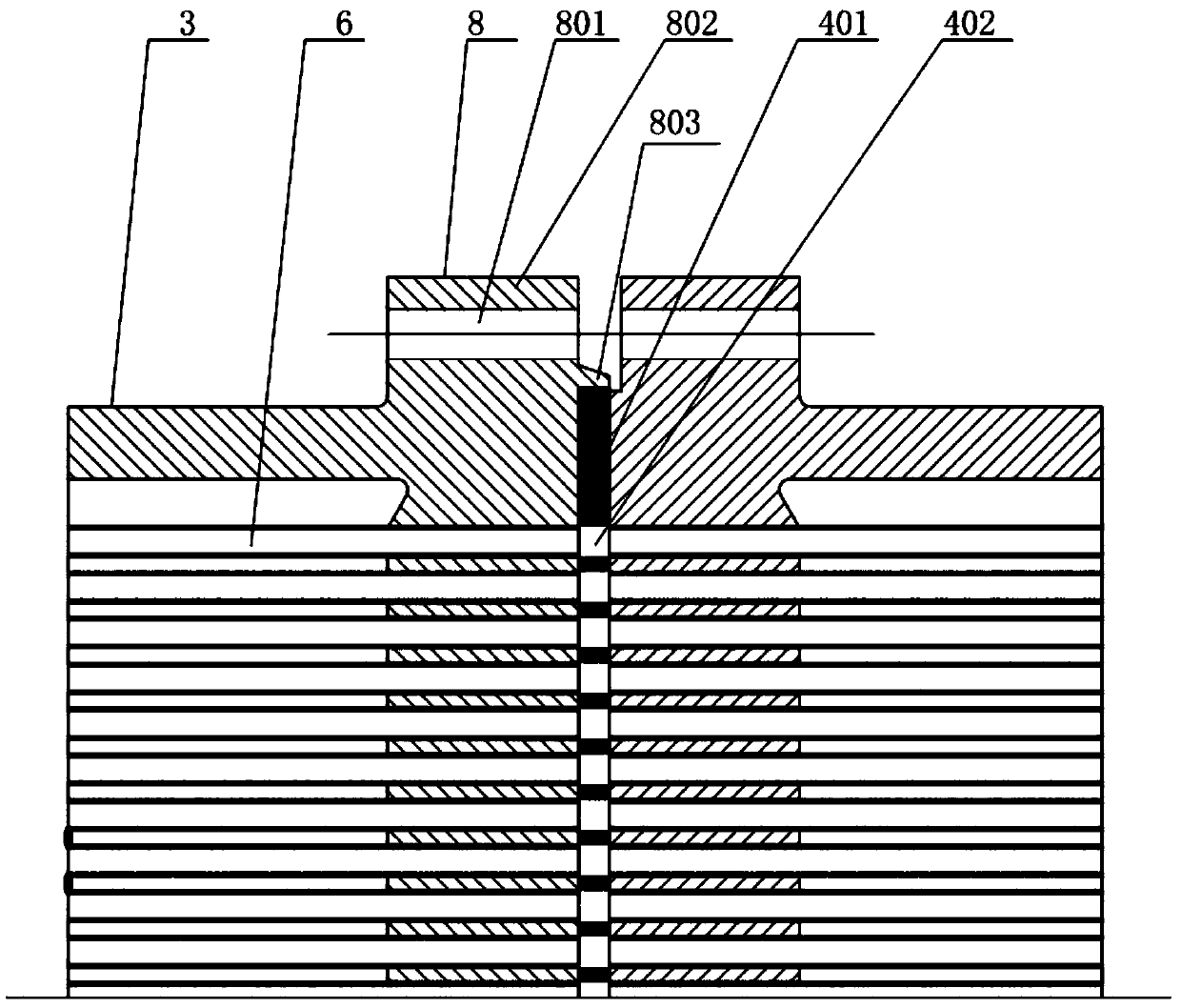

[0019] Such as figure 1 As shown, the tube-side serial shell-and-tube heat exchanger used in the deep-sea artesian circulating cooling system includes a shell 3 with a fresh water inlet pipe 501 and a fresh water outlet pipe 502, a heat exchange tube 6, a baffle plate 7 and a tube sheet 8. The tube sheets 8 are respectively installed at both ends of the casing 3, and a plurality of baffles 7 arranged at intervals are arranged radially inside the casing 3, and each tube sheet 8 and the baffles 7 are provided with Mounting holes, a plurality of heat exchange tubes 6 radially penetrate the mounting holes of the baffle plate 7 and are respectively connected with the tube sheets 8 at both ends of the shell 3. In the present invention, the heat exchange tubes 6 and the tube sheets 8 are connected by expansion welding and way to ensure sealing. It also includes a water collection chamber 2. The water co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com