Patents

Literature

671results about How to "Little resistance loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

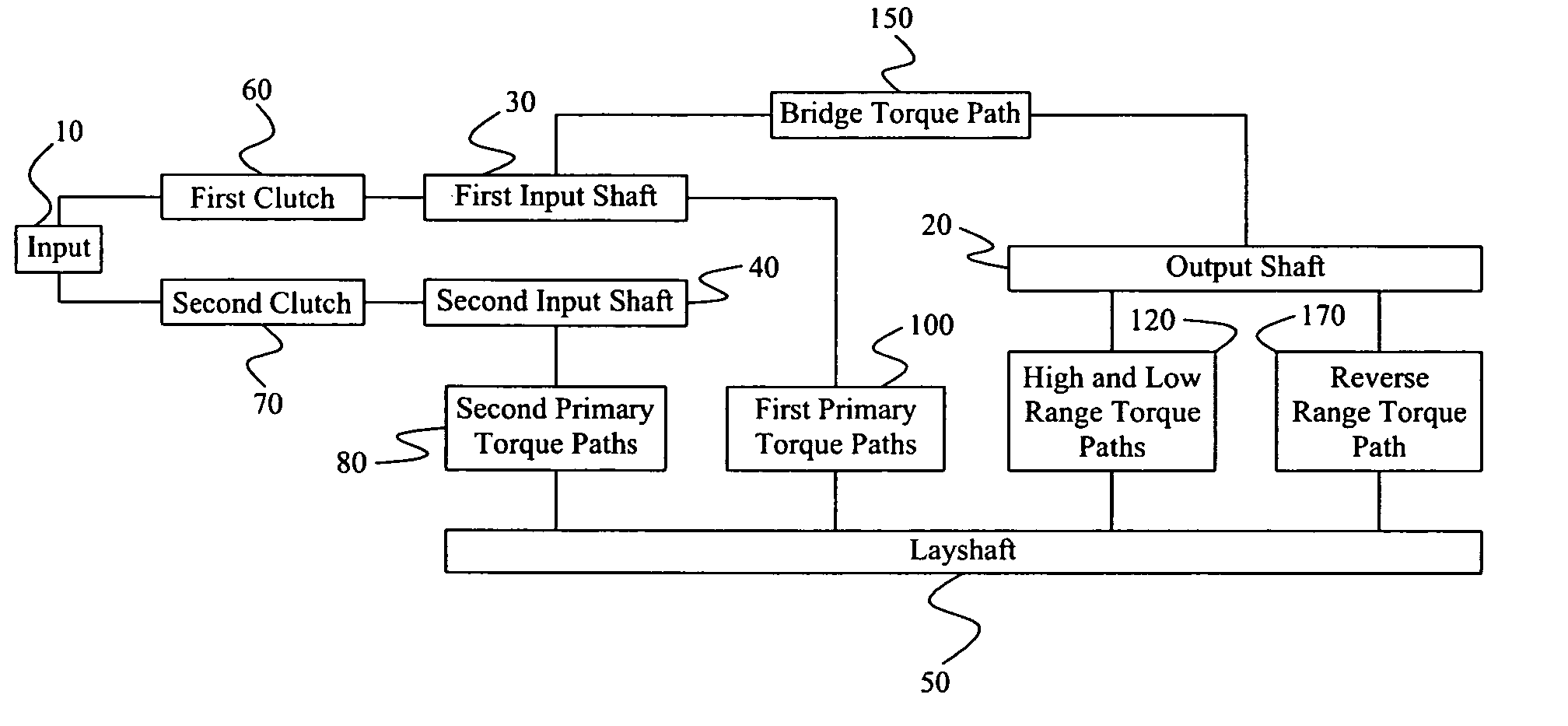

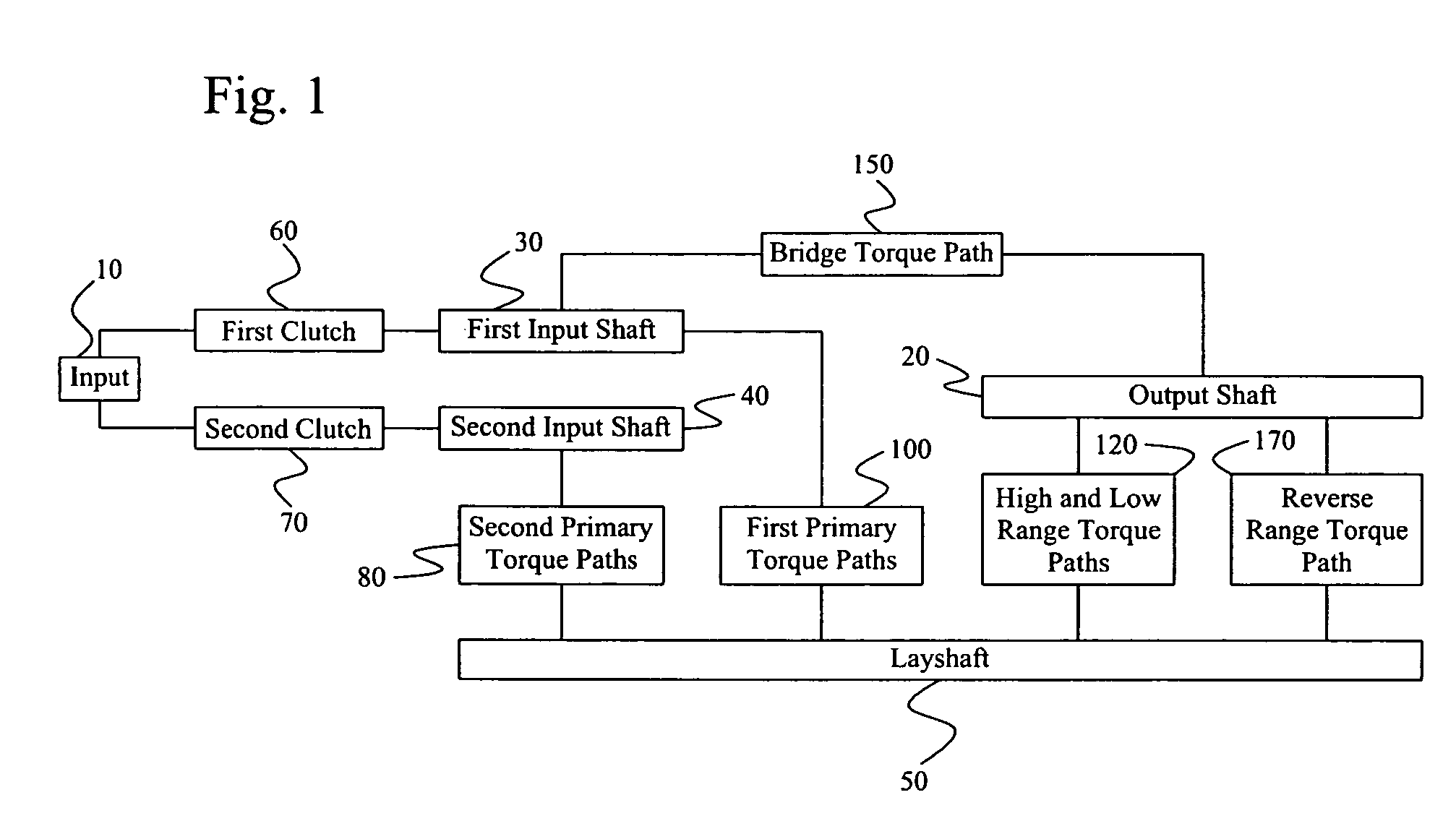

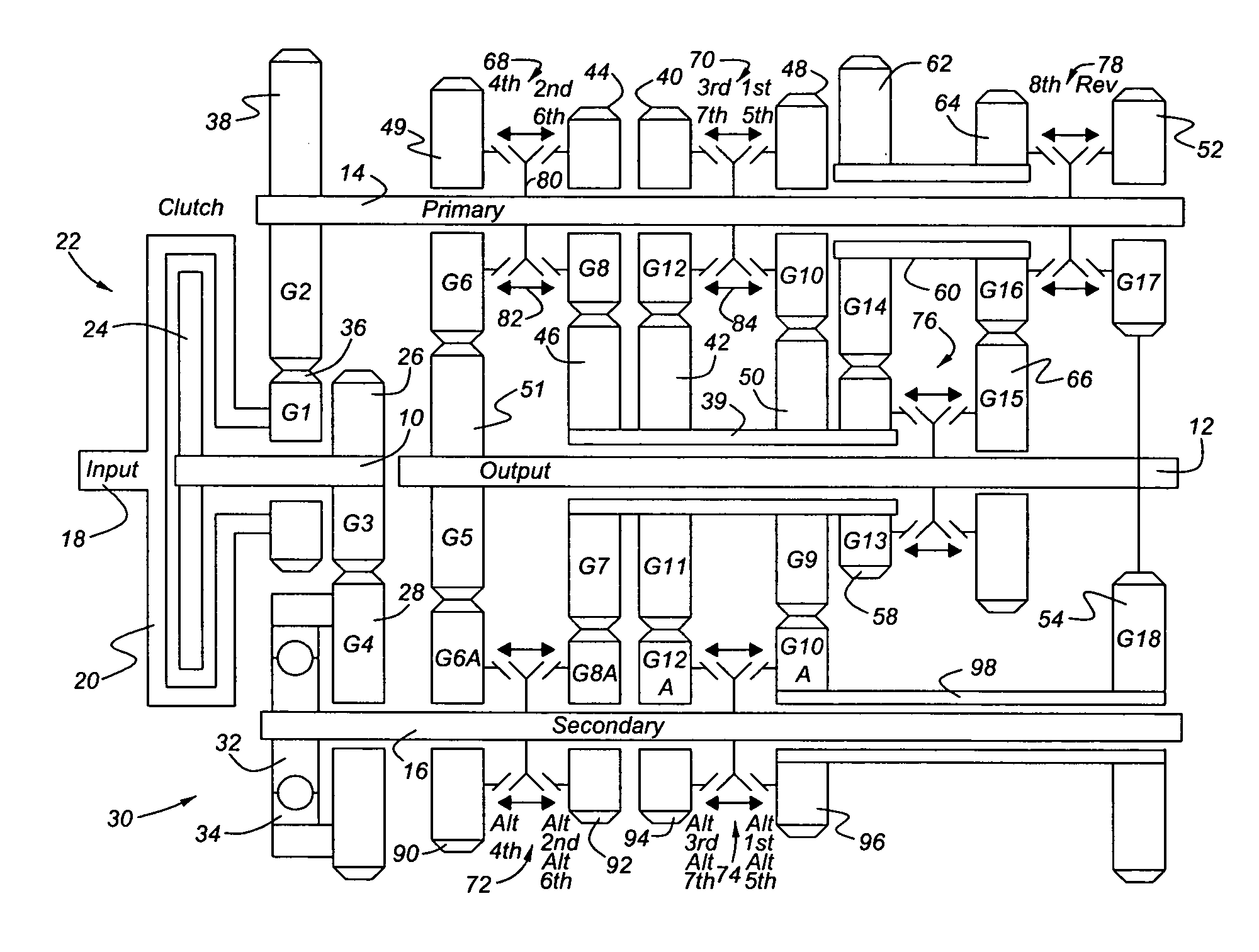

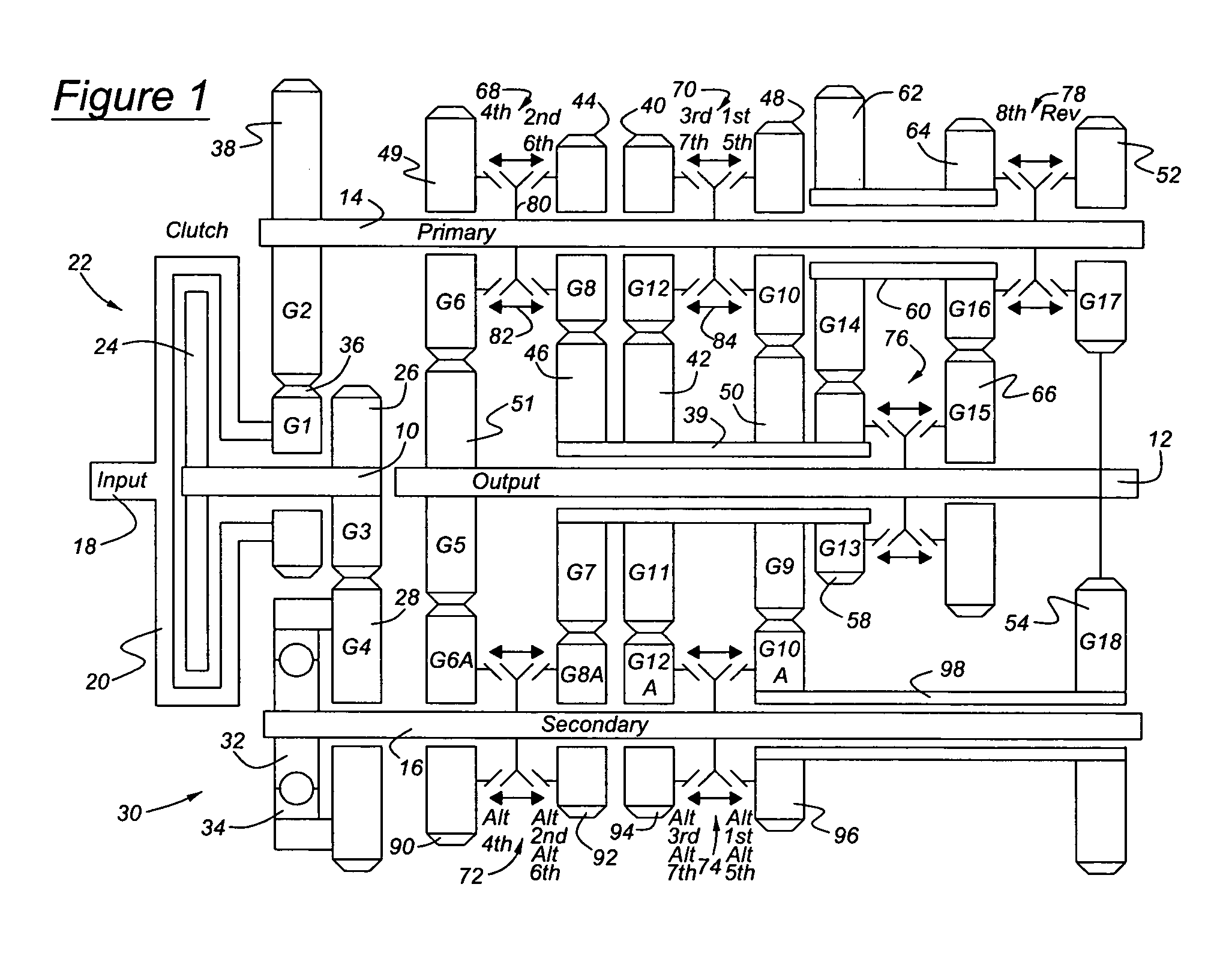

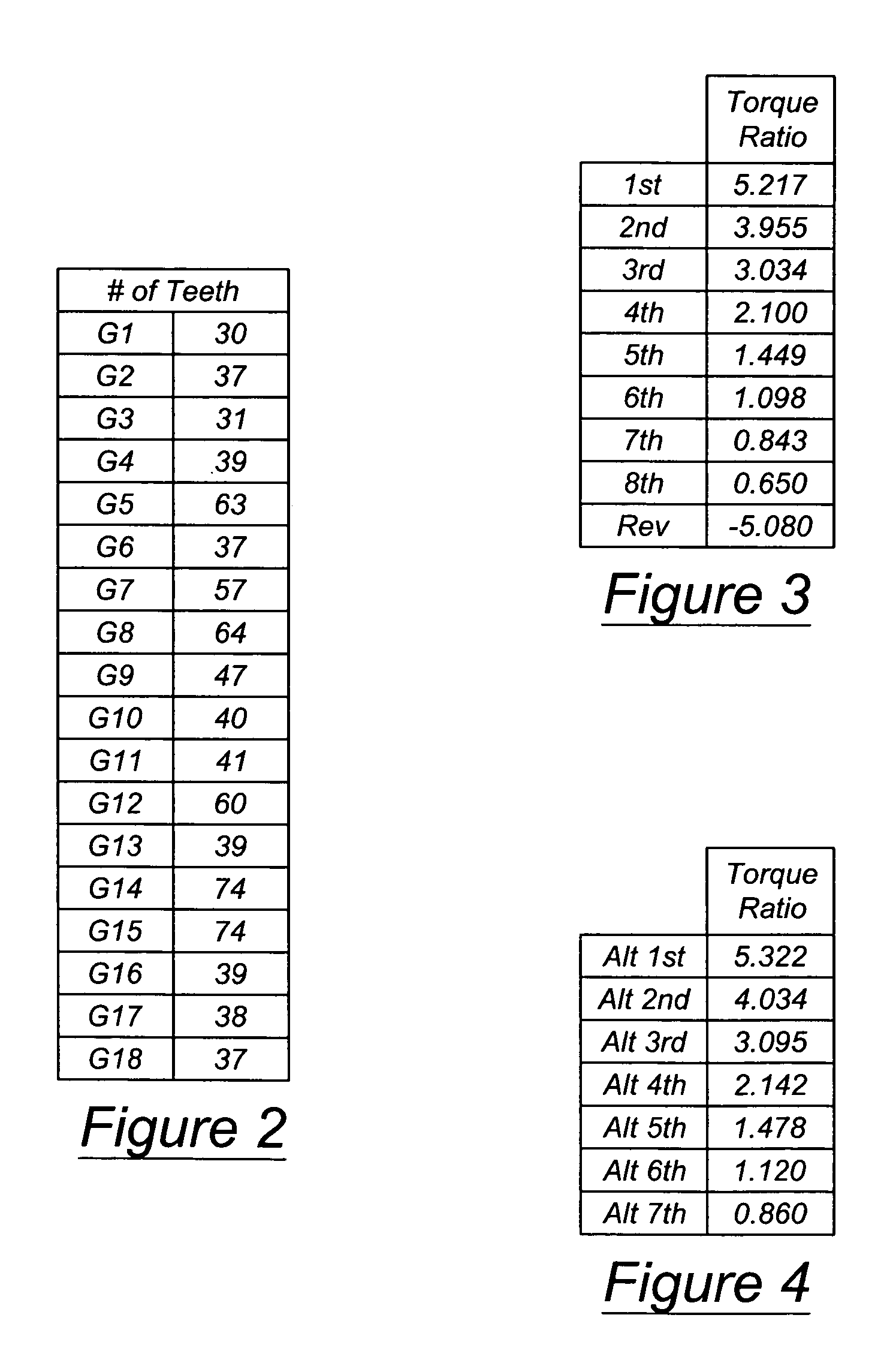

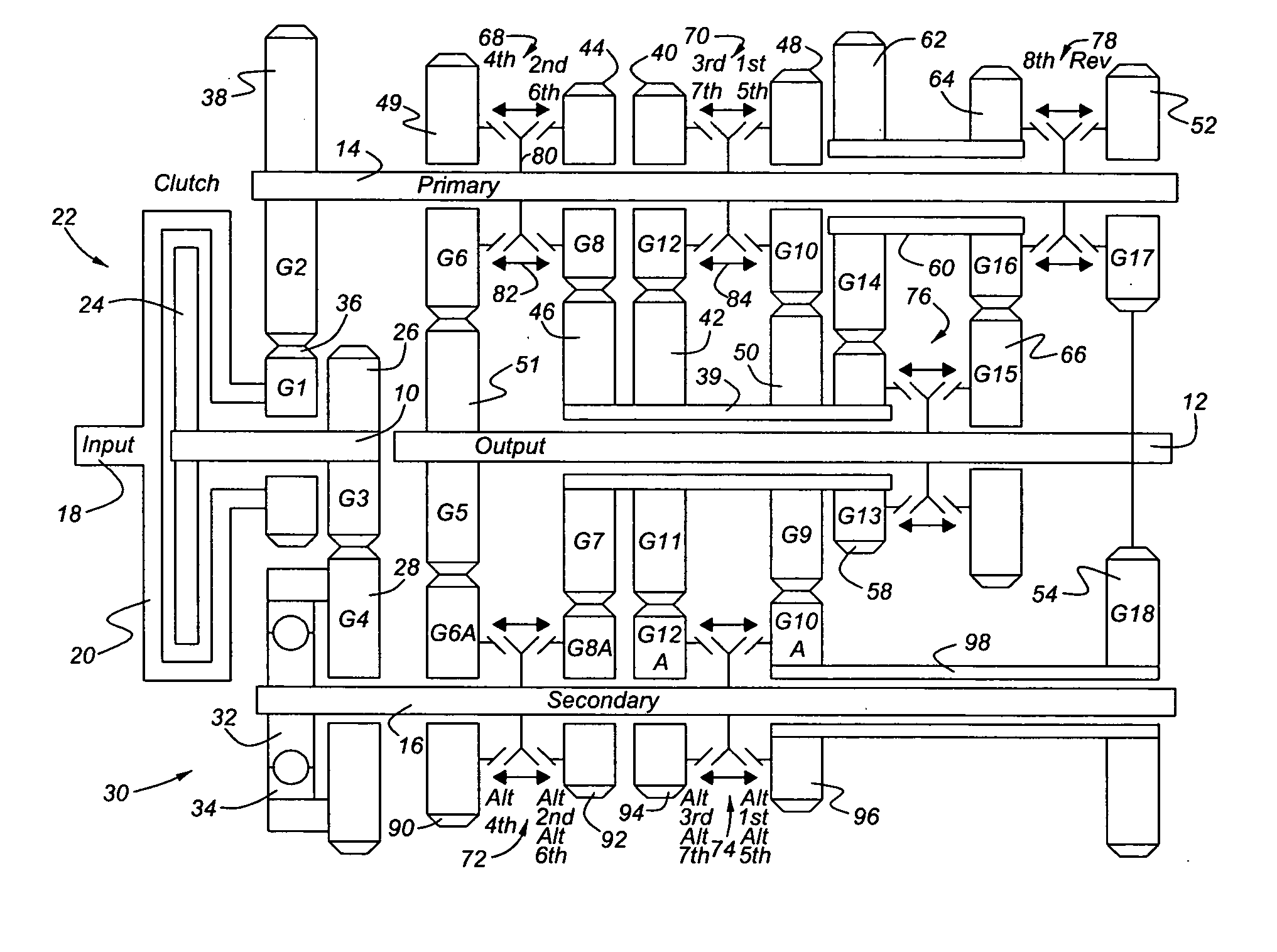

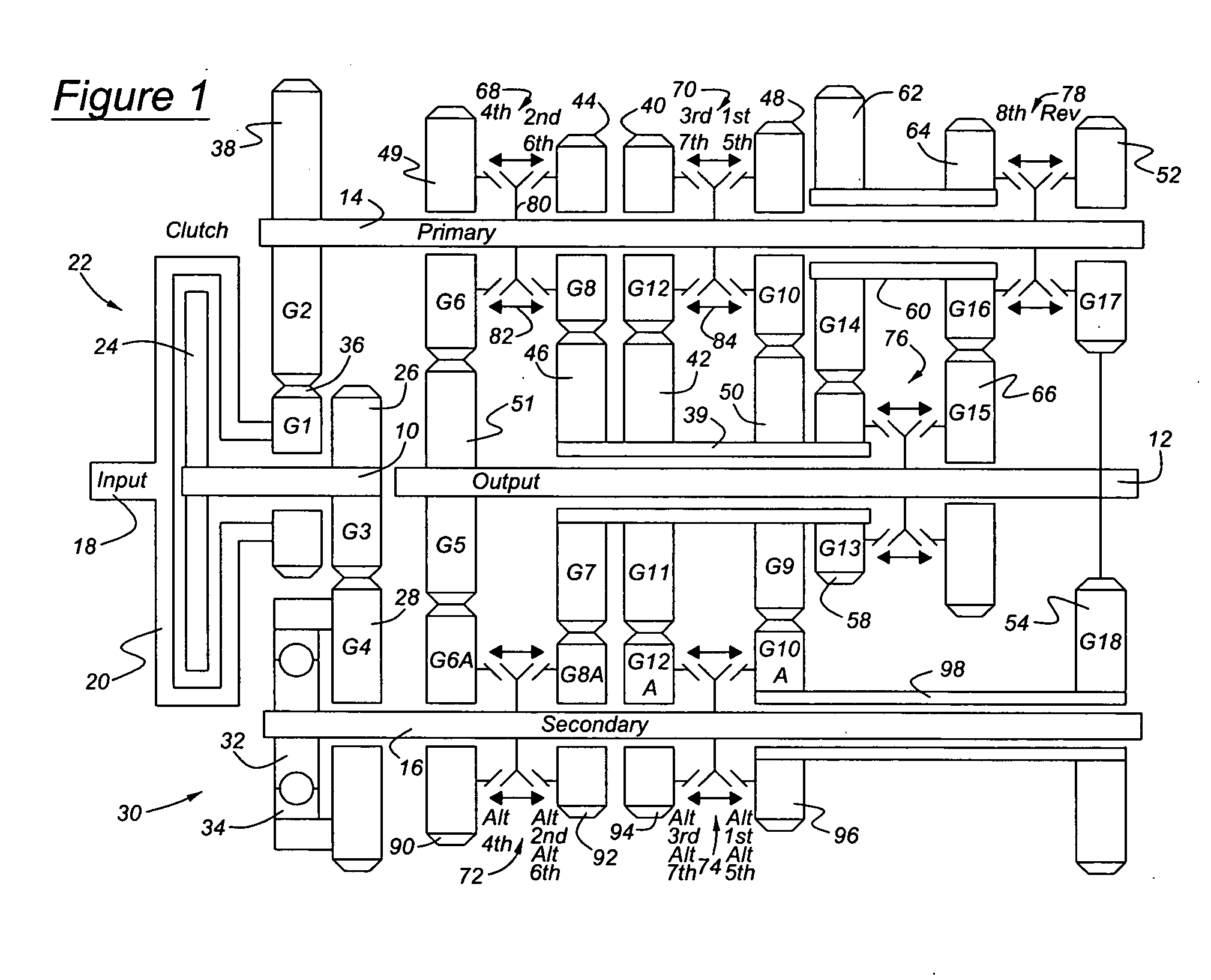

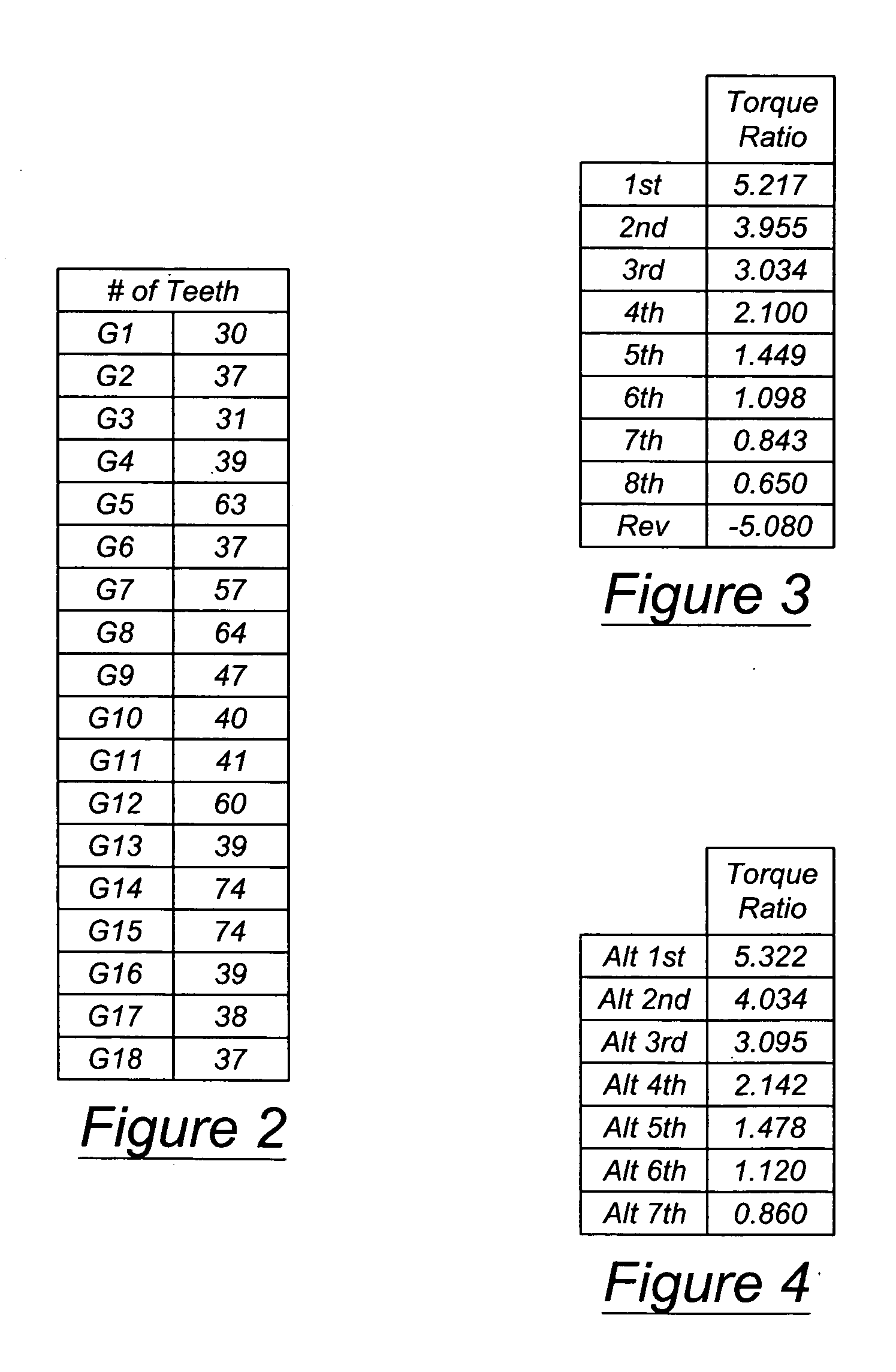

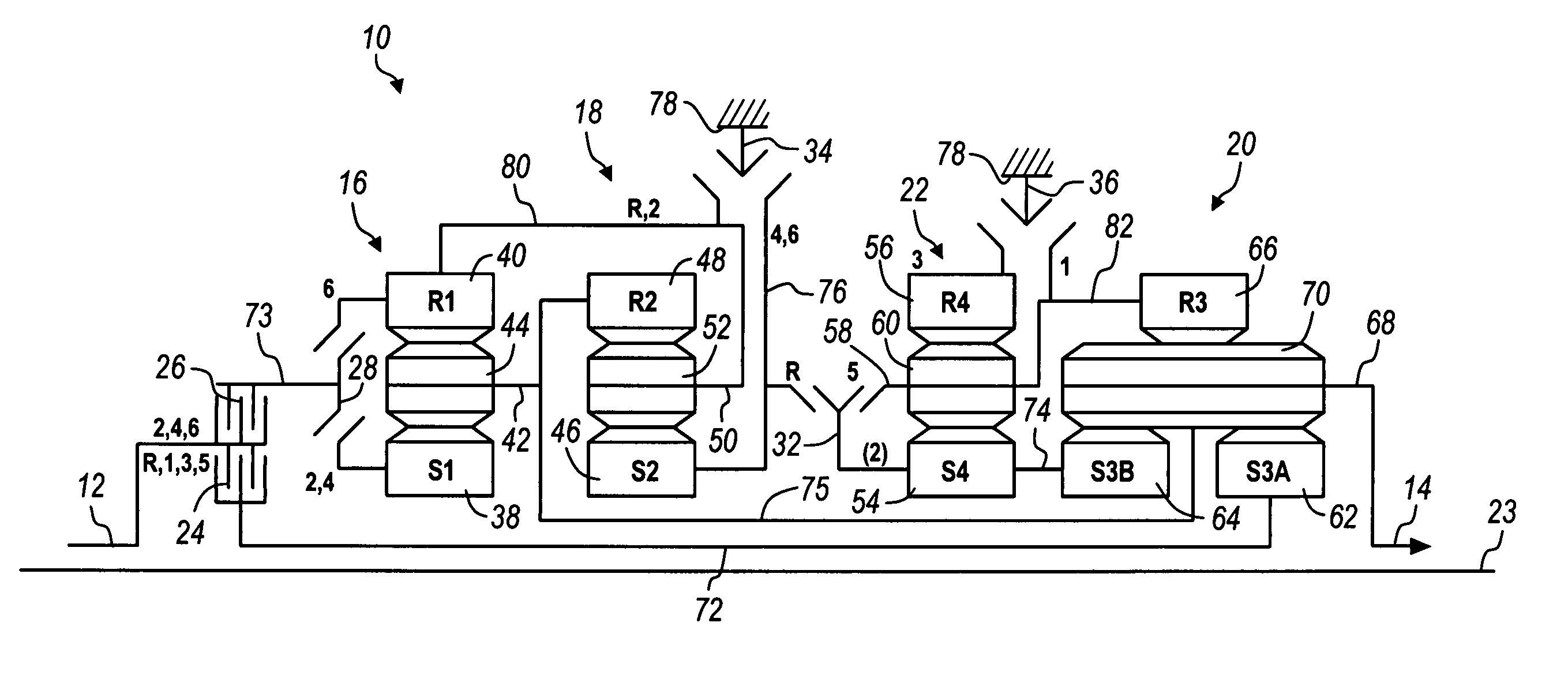

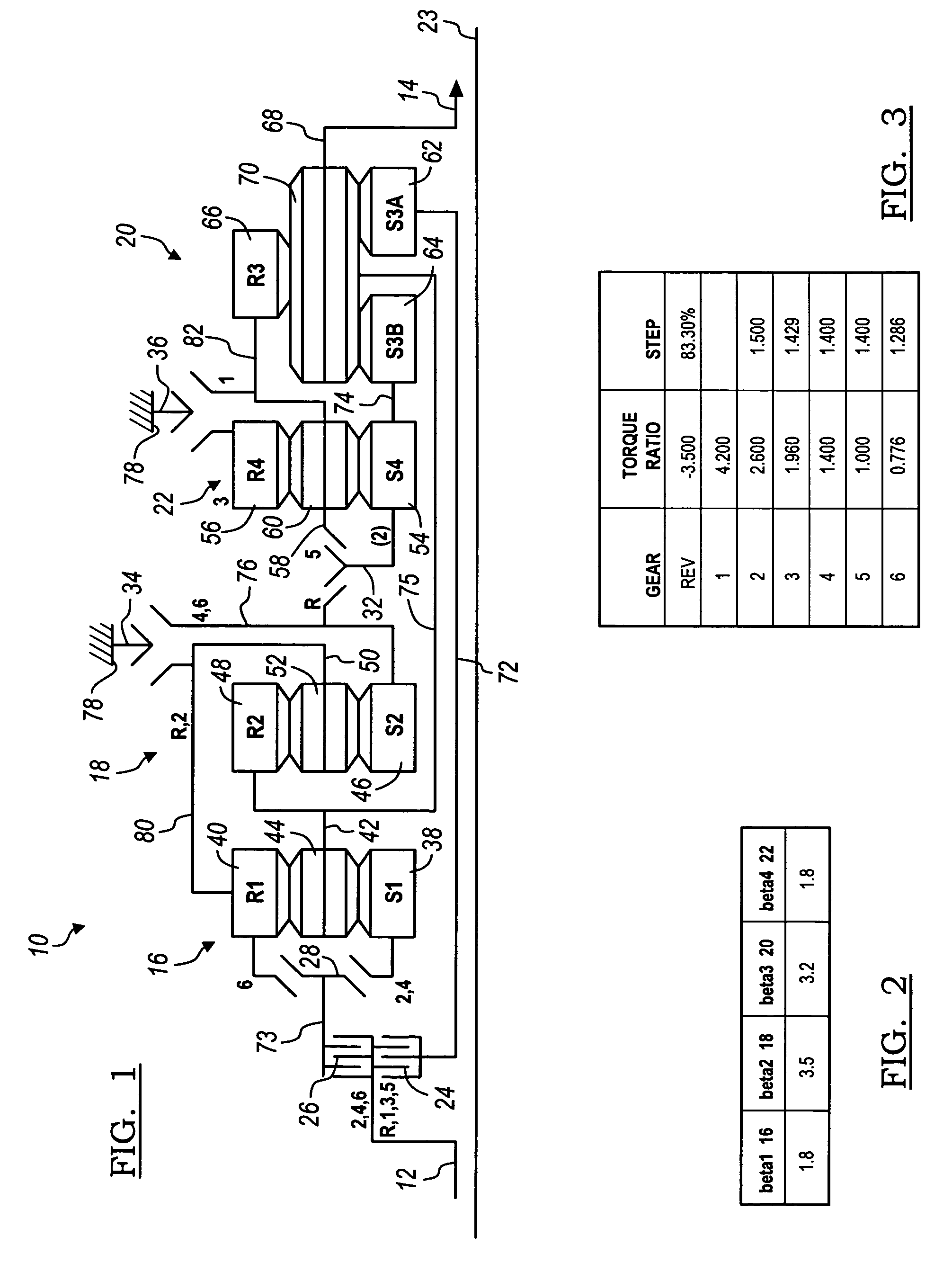

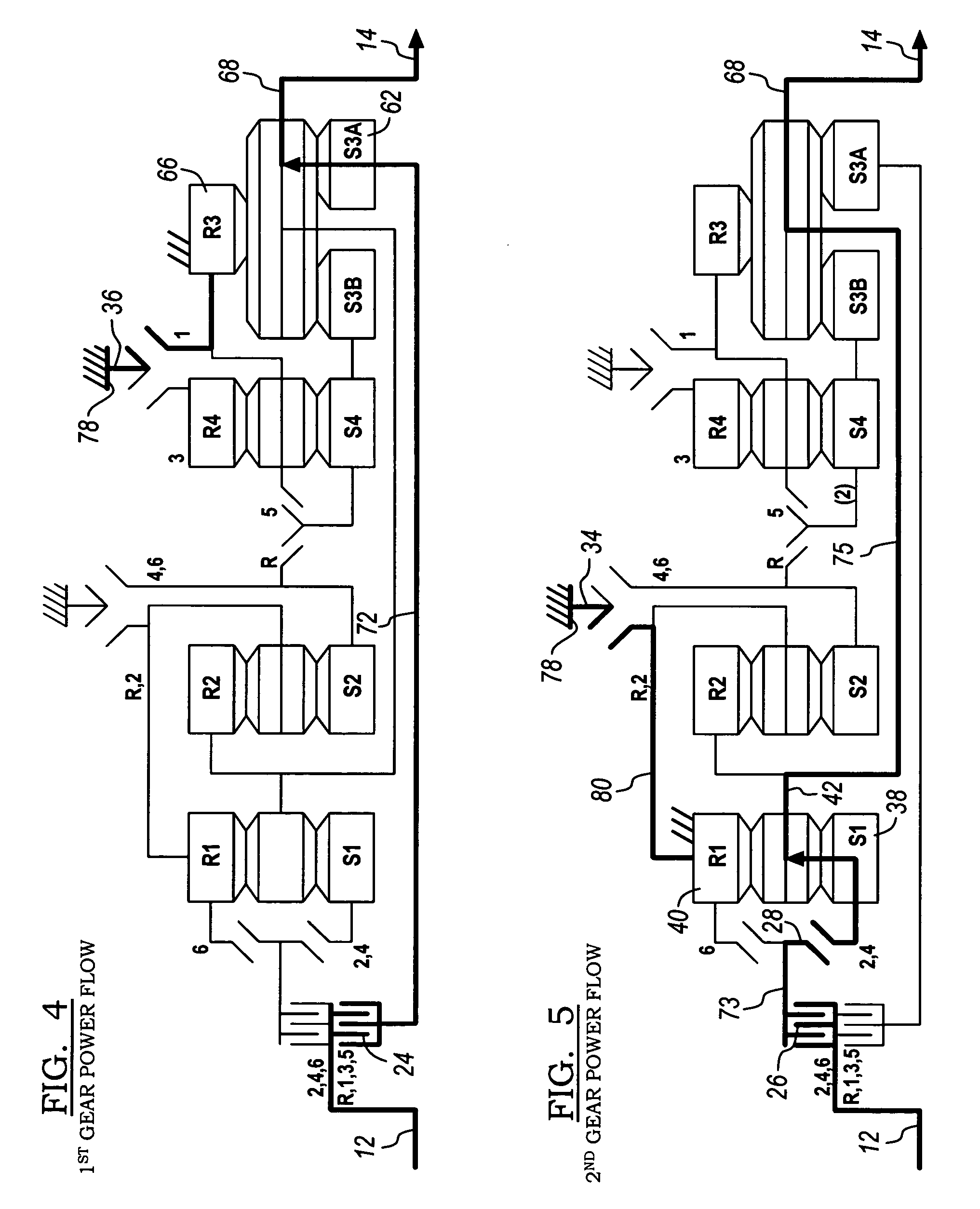

Ranged dual clutch transmission for motor vehicles

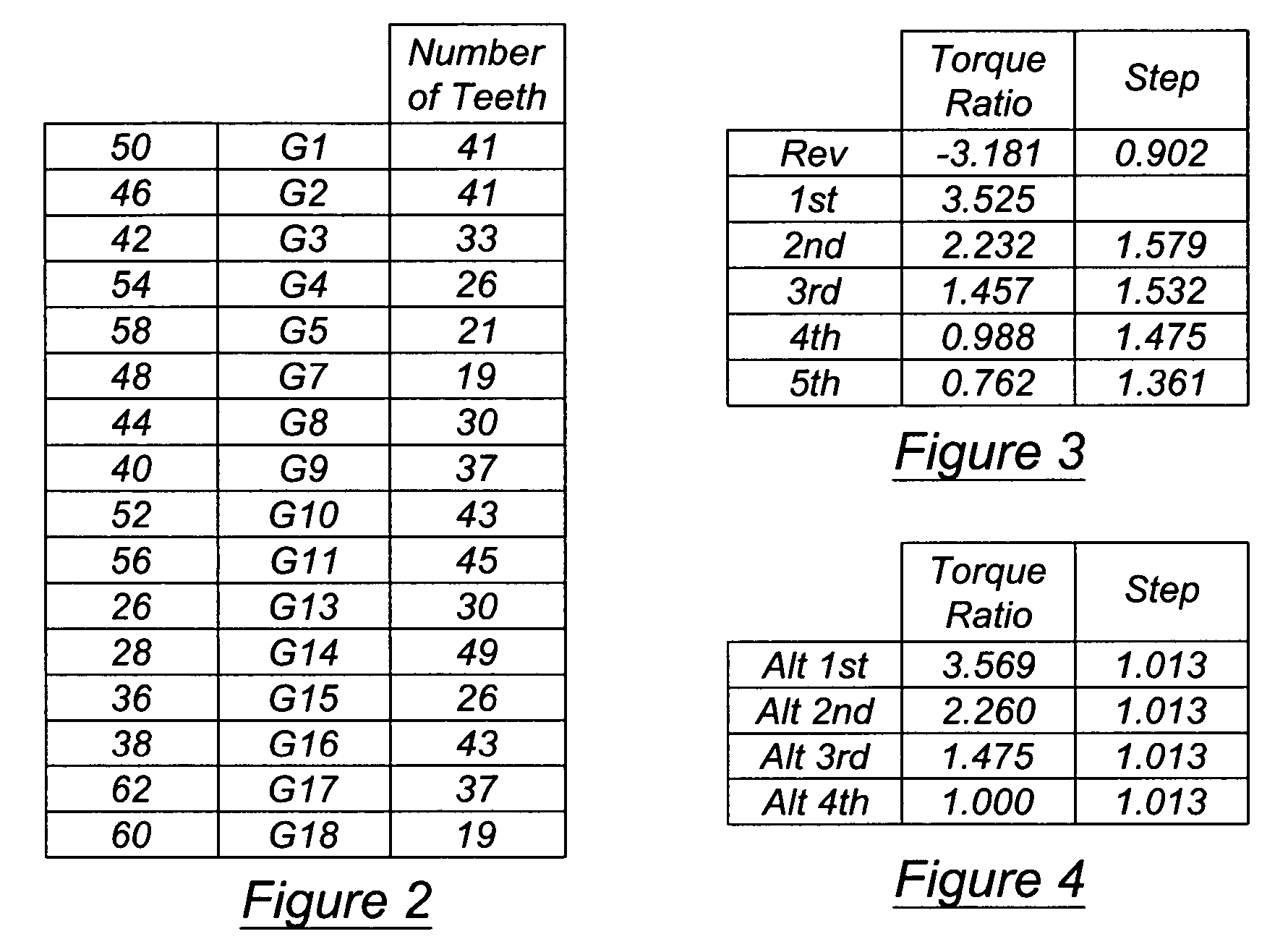

InactiveUS6958028B2Small torque ratioAvoid choiceToothed gearingsTransmission elementsMobile vehicleEngineering

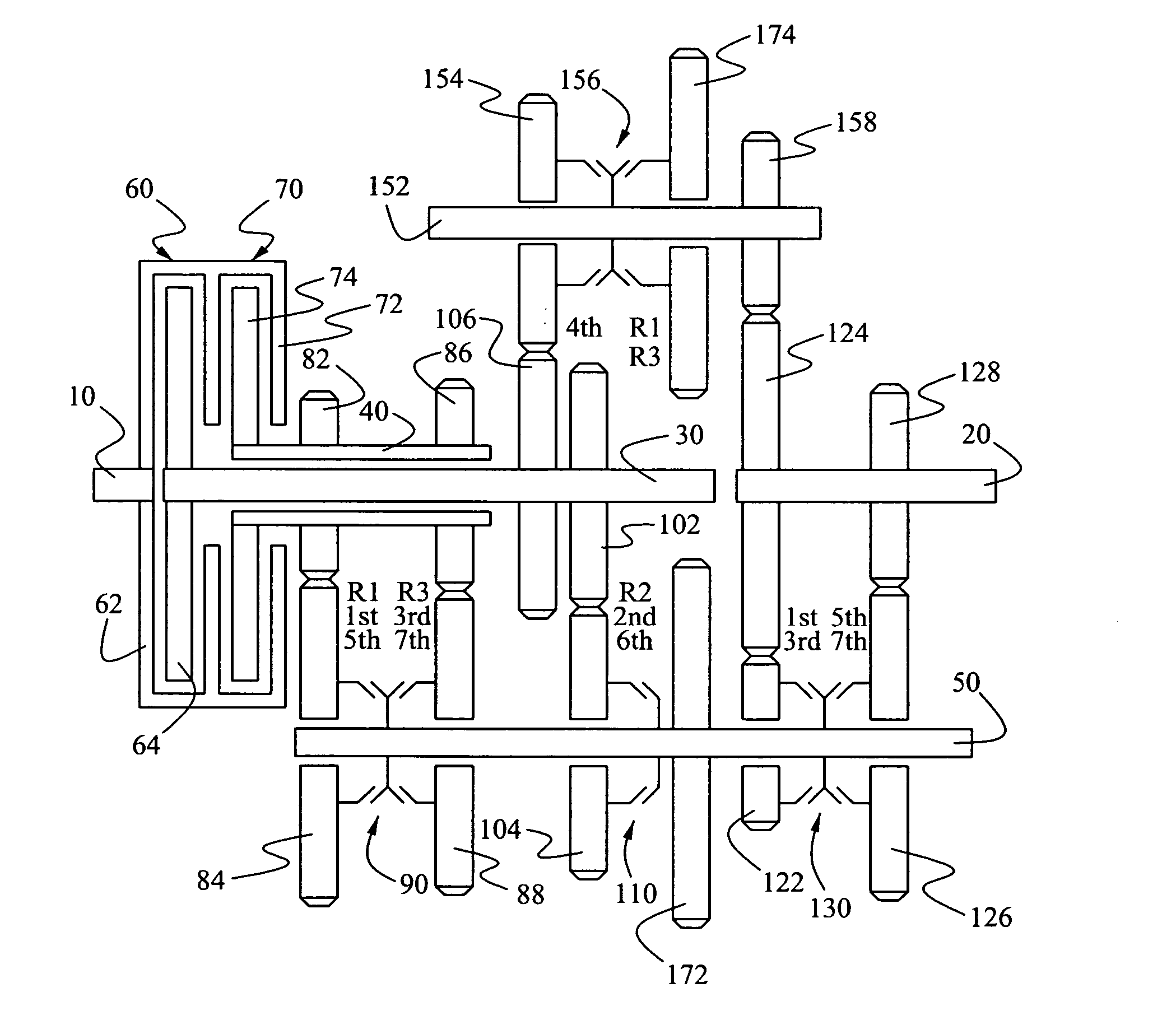

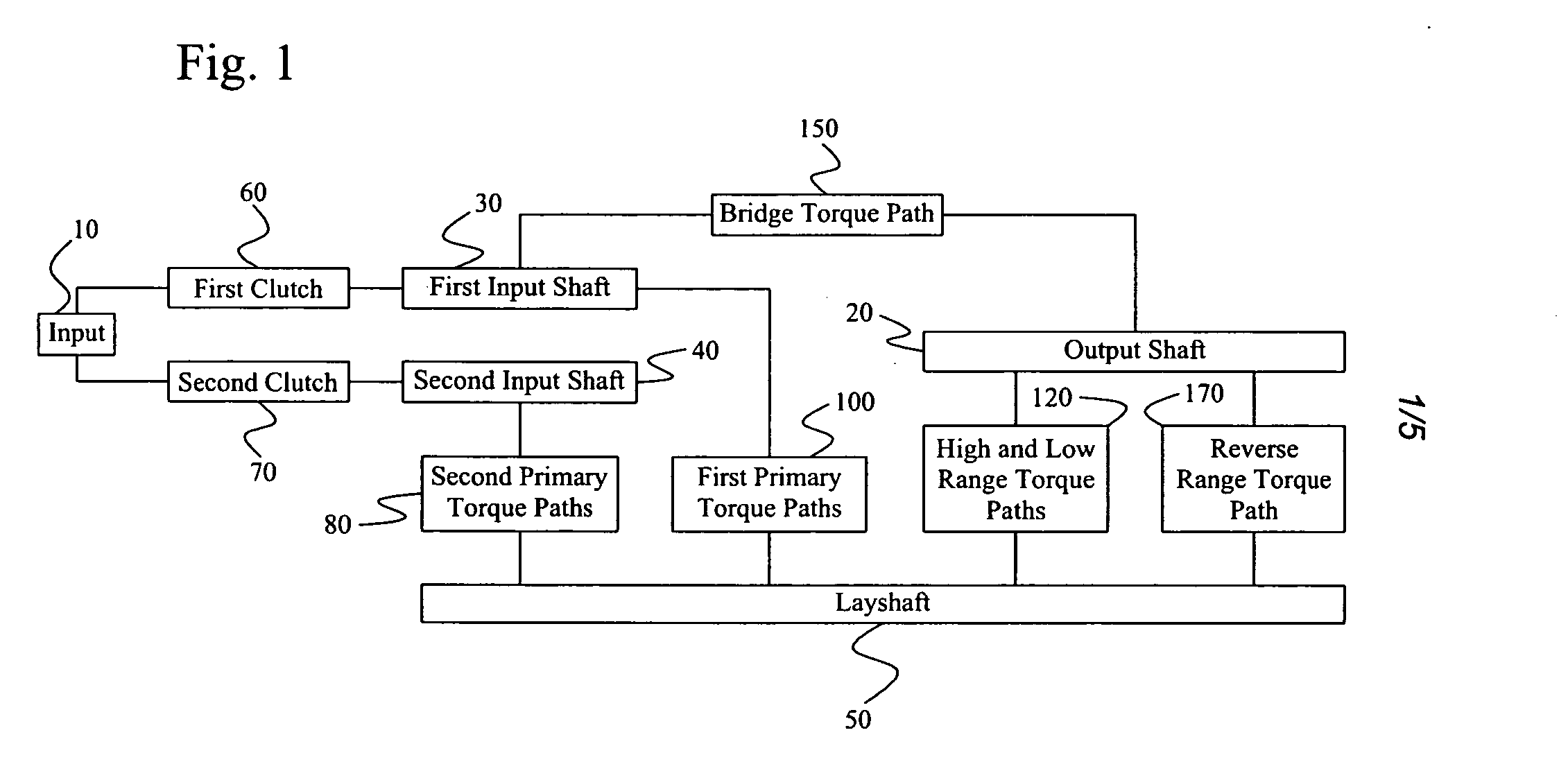

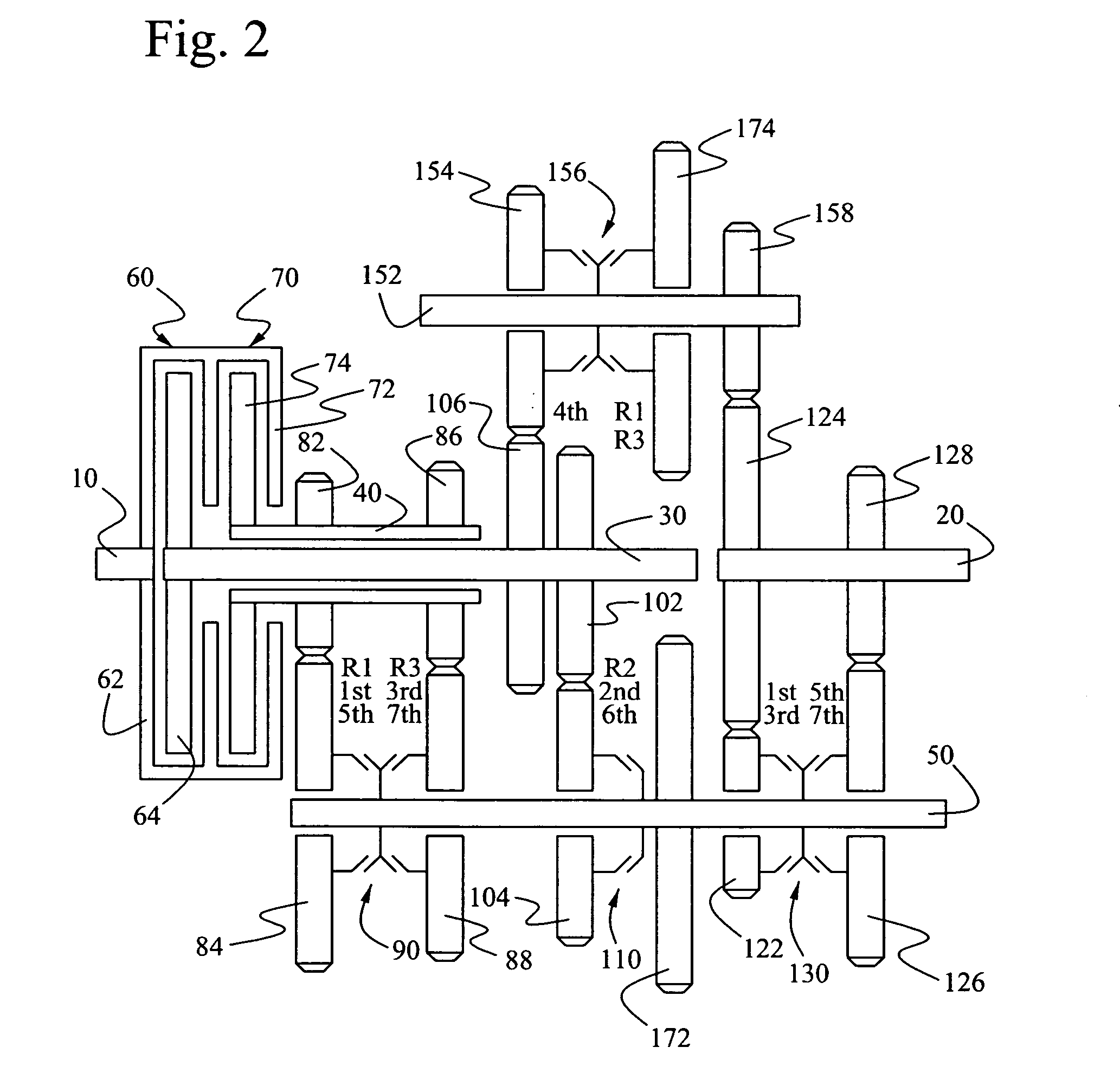

A power transmission for a motor vehicle includes an input, first and second input shafts, a layshaft, drive elements connecting the input shafts to the output and layshaft, couplers, a first clutch for connecting and disconnecting the input and the first input shaft, and a second clutch for connecting and disconnecting the input and the second input shaft. A first torque path driveably connects the first input shaft to the layshaft. A second torque path driveably connects the second input shaft to the layshaft. A third torque path driveably connects the layshaft and output. A bridge torque path driveably connects the first input shaft and the output.

Owner:FORD GLOBAL TECH LLC

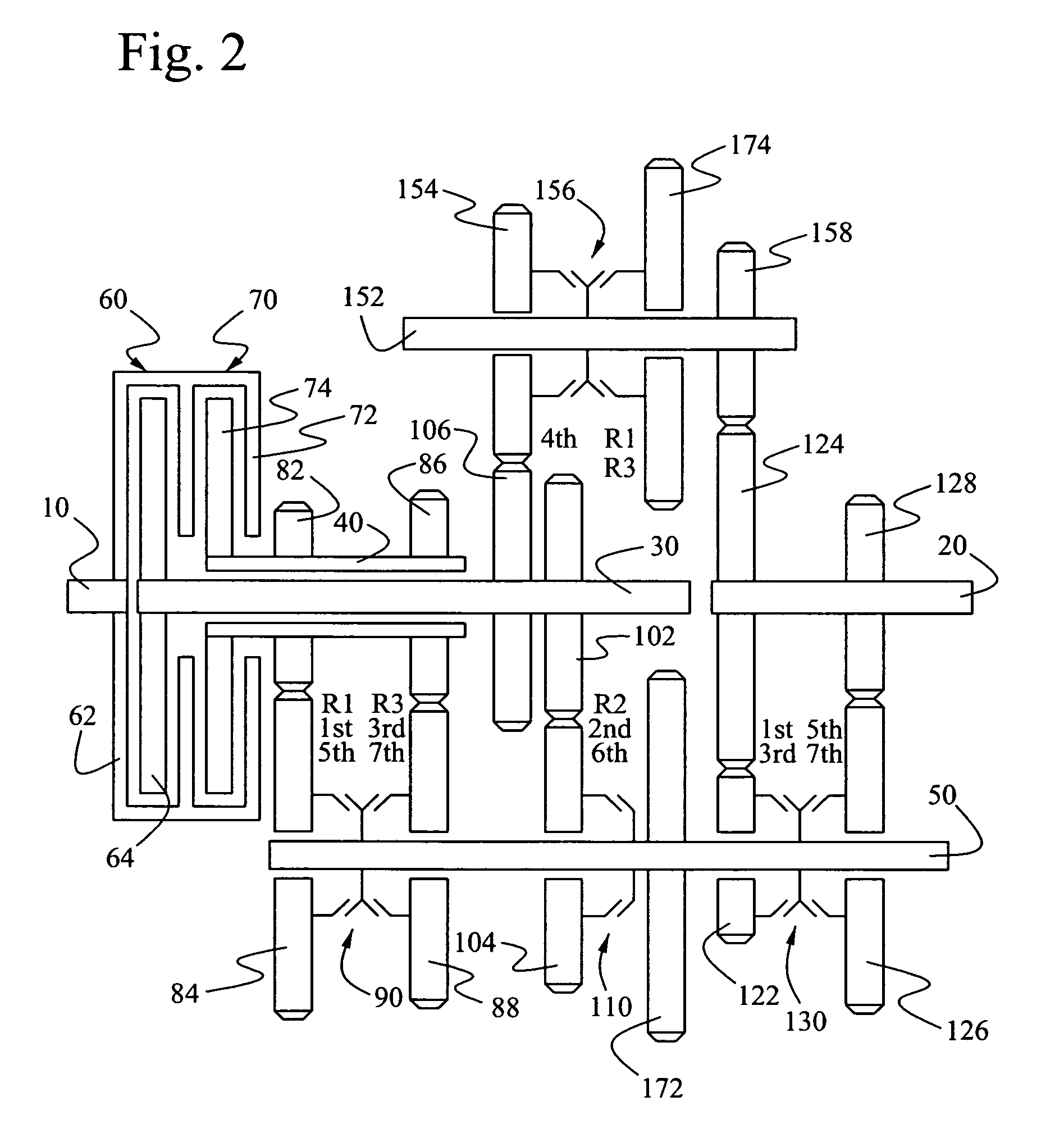

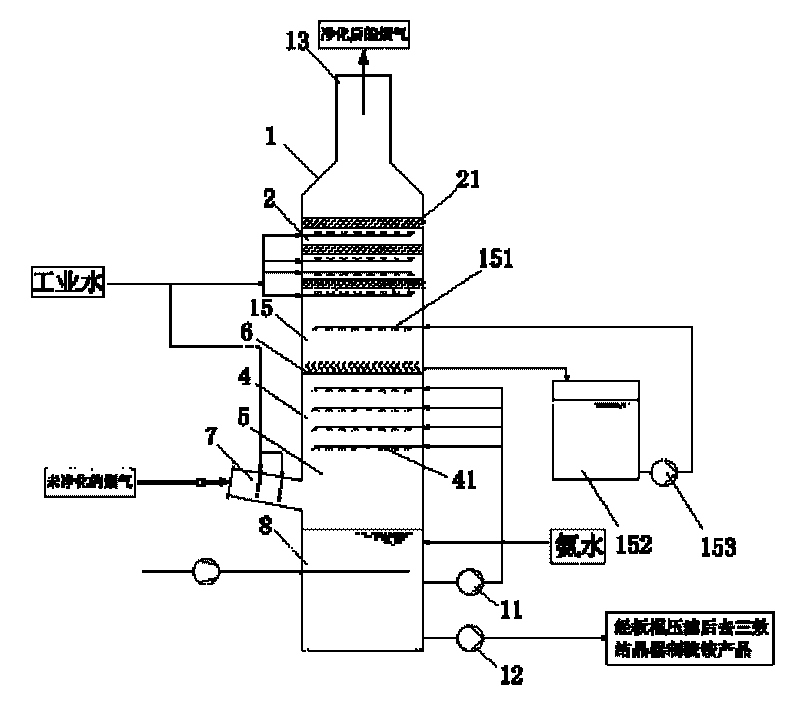

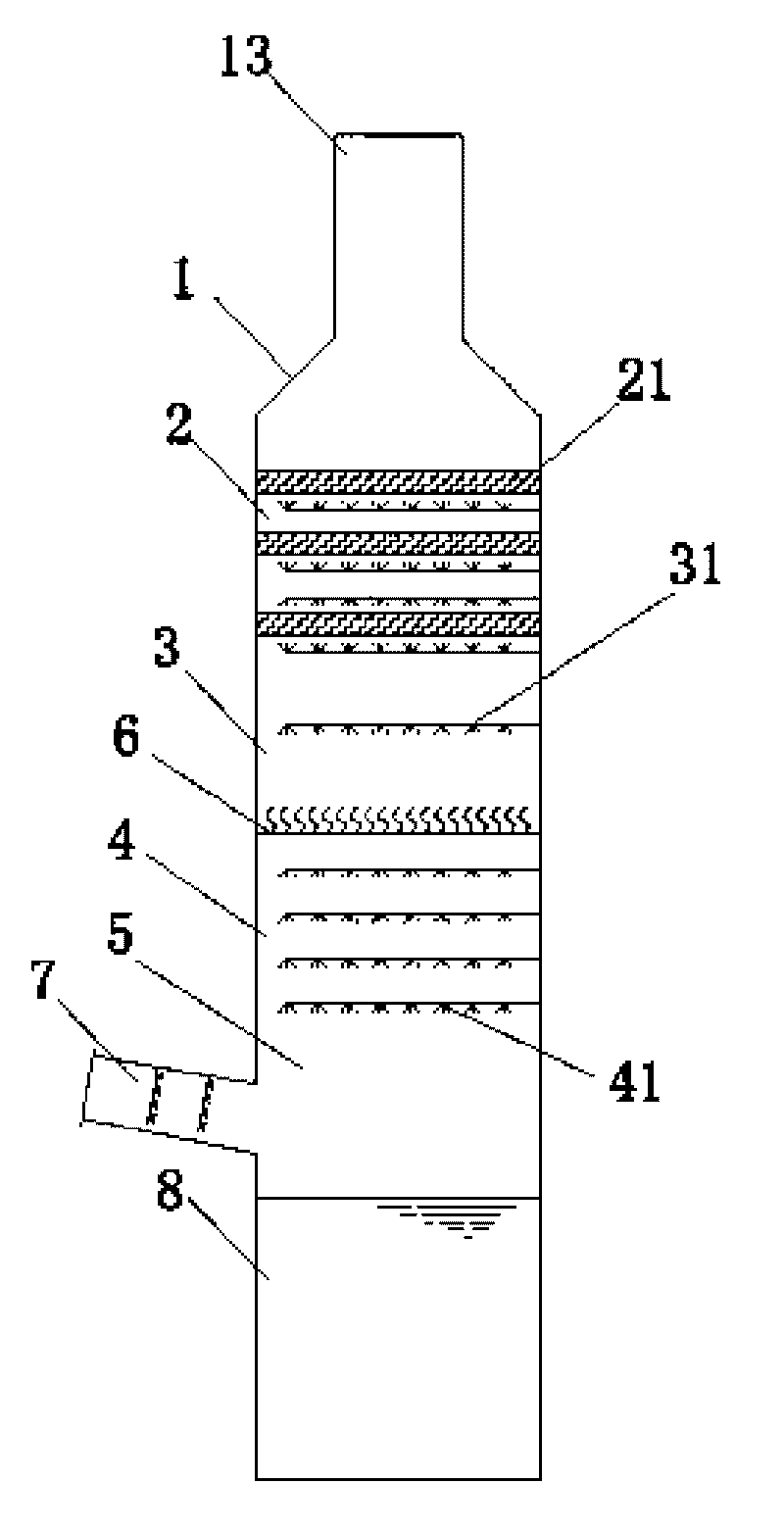

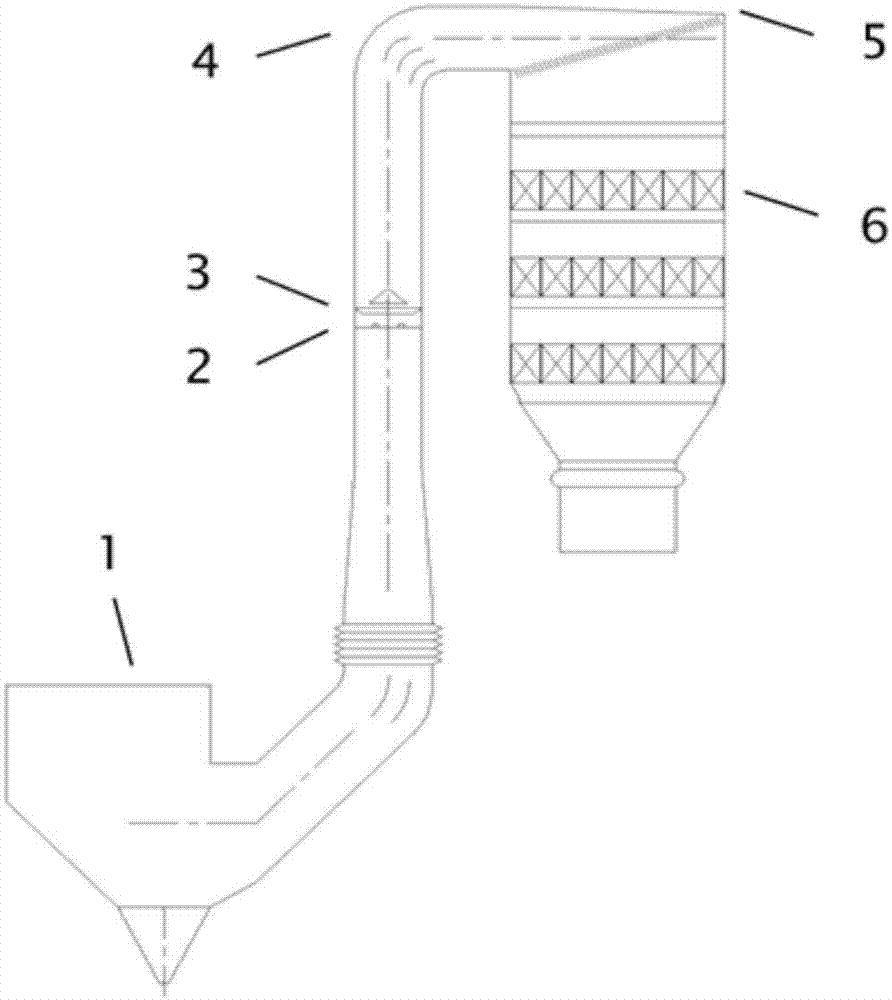

Treatment technique for pollutants in sinter fume and spraying and absorbing tower thereof

InactiveCN101708420AEasy to handleQuality improvementLighting and heating apparatusDispersed particle separationMulti pollutantEngineering

The invention discloses a treatment technique for pollutants in sinter fume and a spraying and absorbing tower thereof. After cooling and dedusting, the sinter fume is led into the spraying and absorbing tower, moves upwards to pass through at least two spraying and absorbing sections partitioned from up down in the spraying and absorbing tower, each spraying and absorbing section sprays and absorbs more than one pollutant in the sinter fume and the spraying and absorbing solution does not fall into the absorbing section of next layer, after passing through all the spraying and absorbing sections, the fume is demisted and exhausted from the top of the spraying and absorbing tower. The spraying and absorbing tower comprises a tower body, the tower body is partitioned into a demisting section, more than two spraying and absorbing sections and a fume inlet section from up down and a seriflux pool on the bottom of the tower body, and the adjacent spraying and absorbing sections are partitioned by a tower board assembly. The invention has the advantages that the loss of system resistance is small, the structure is simpler and more compact, the operation is convenient, the absorption effect is good, the treatment capacity is high and the like, and the invention can treat various pollutants in sinter fume.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

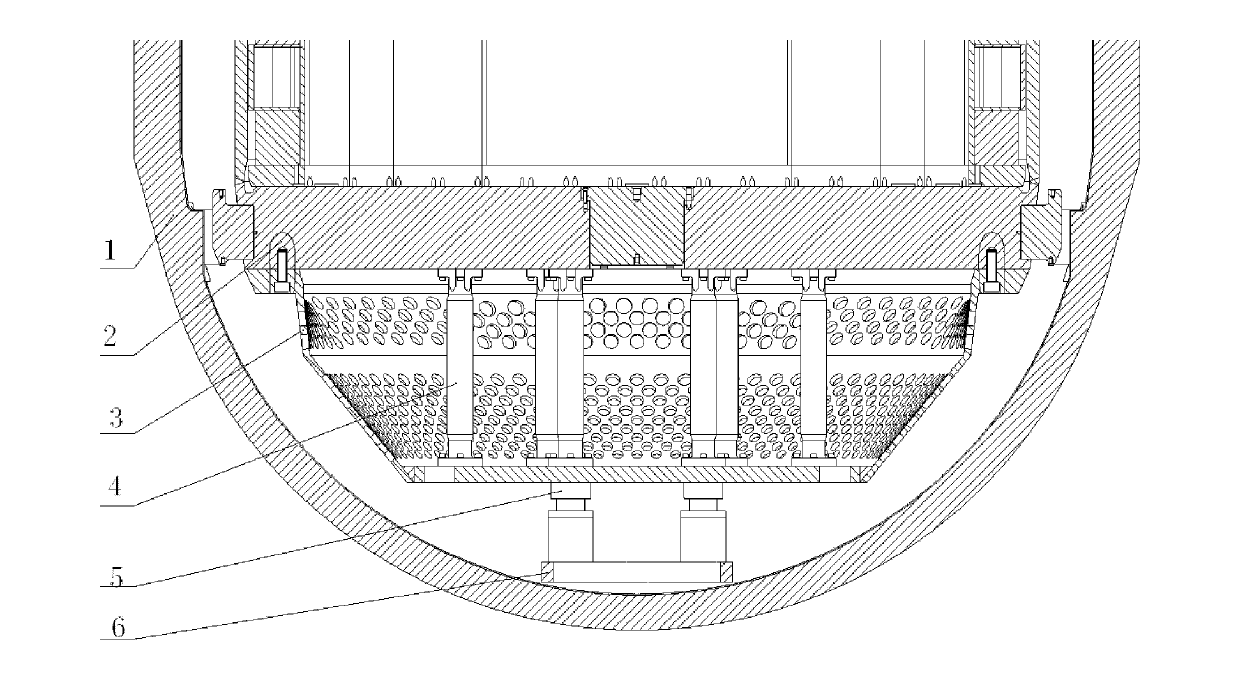

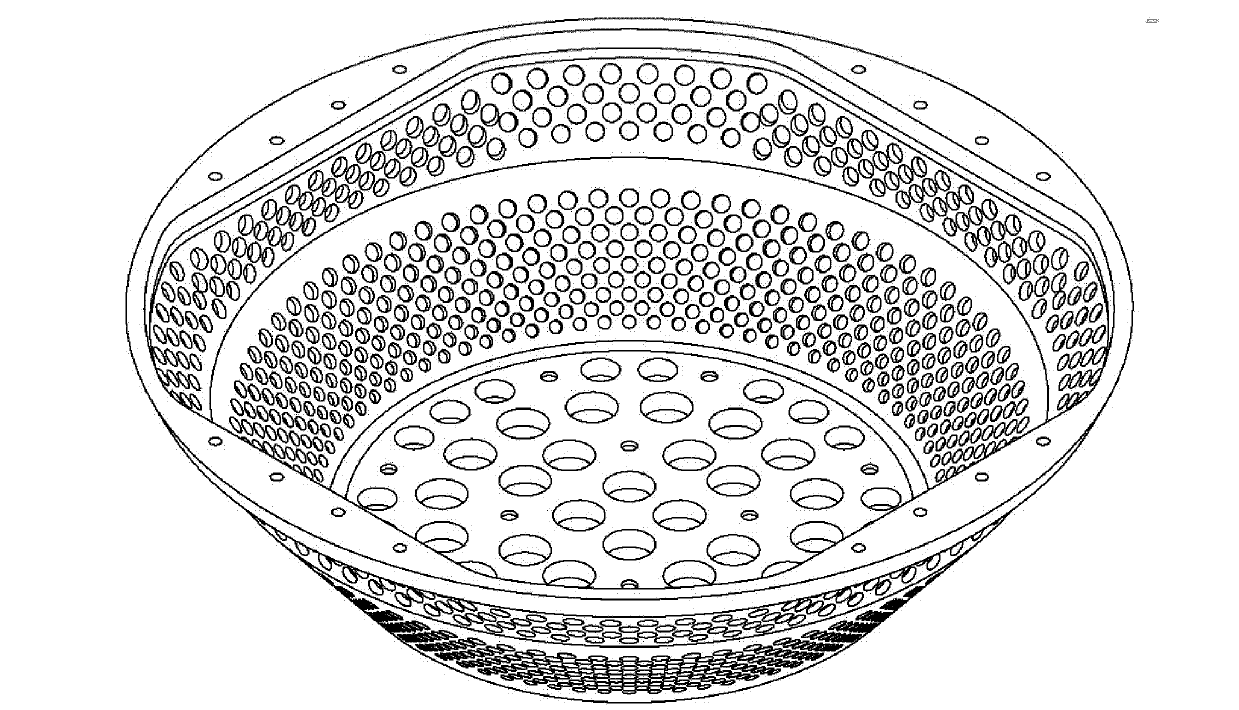

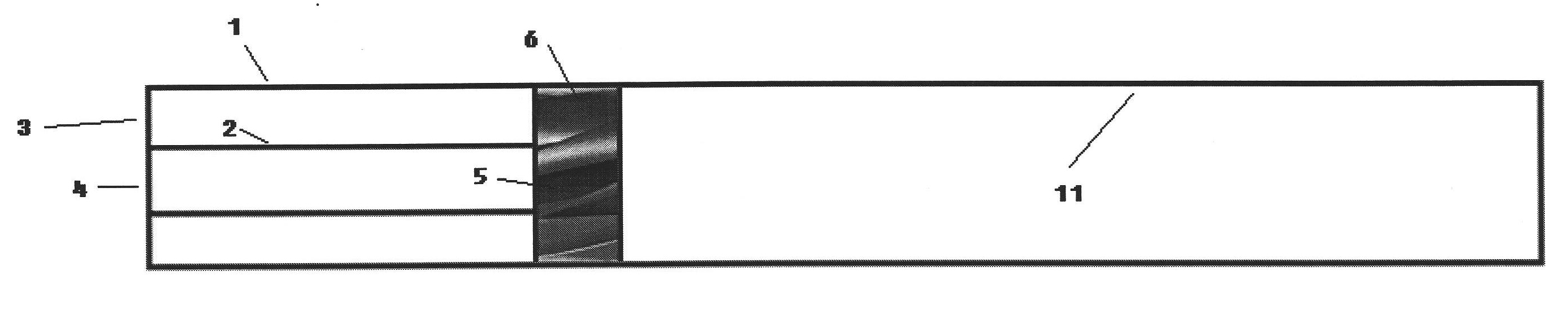

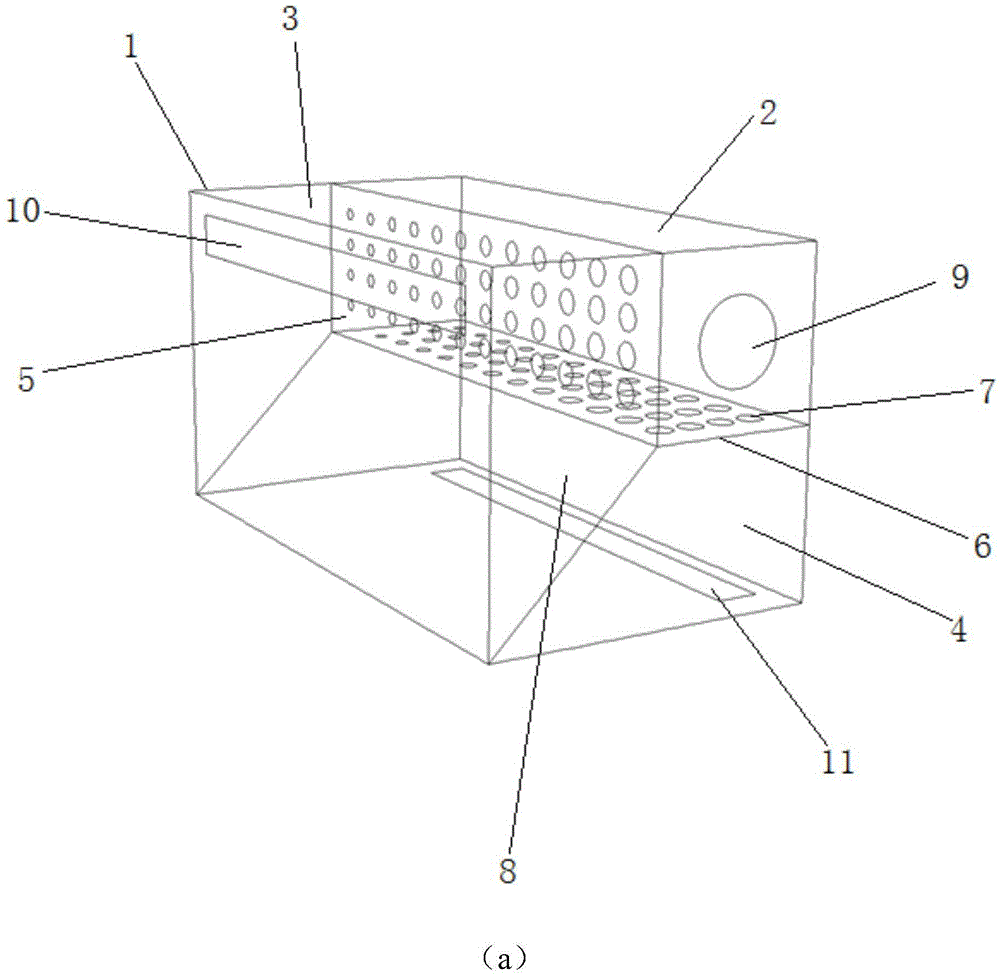

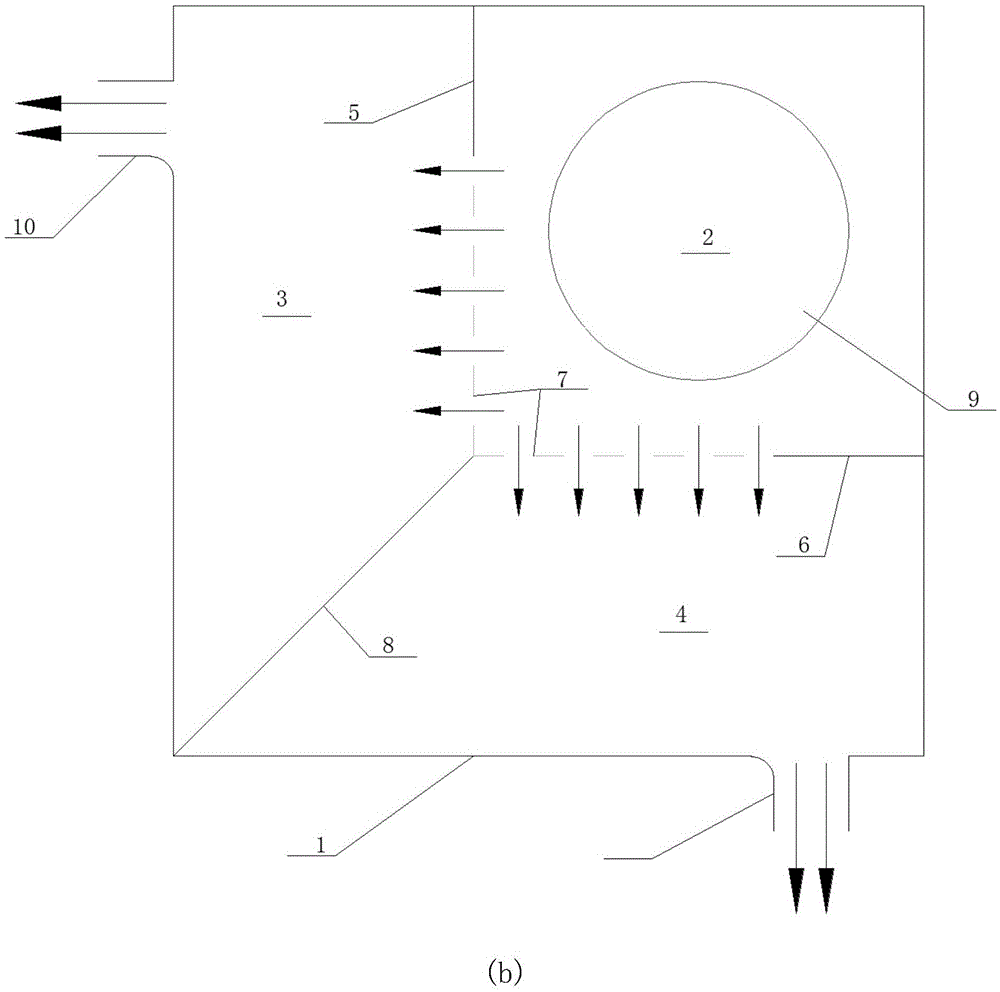

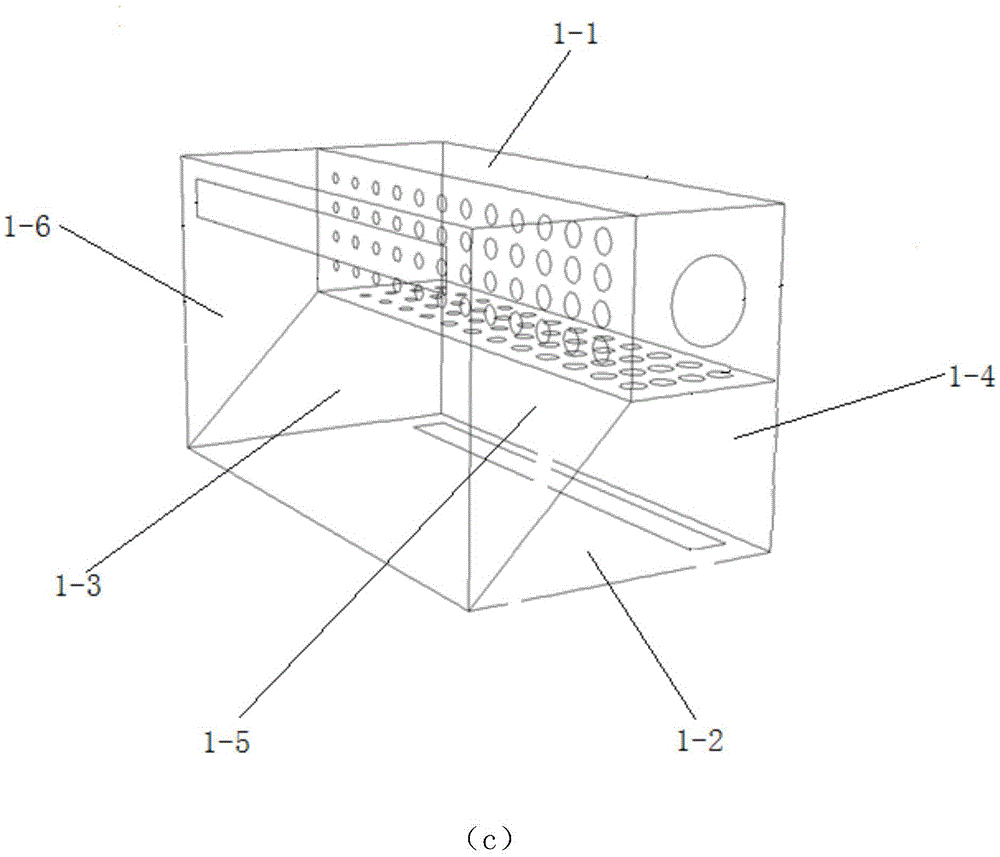

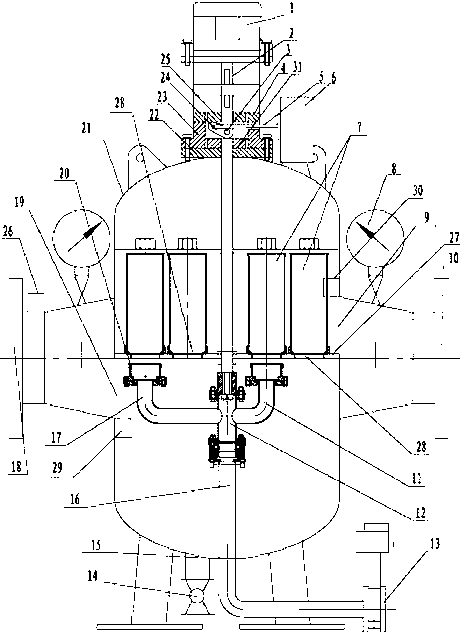

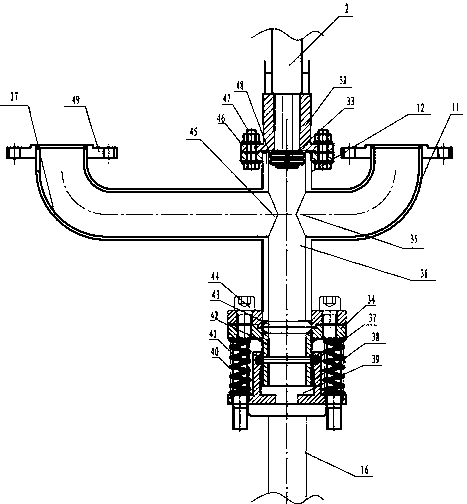

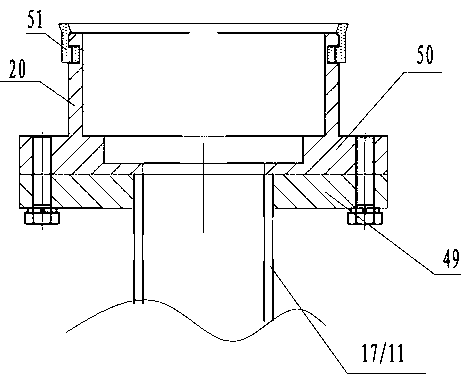

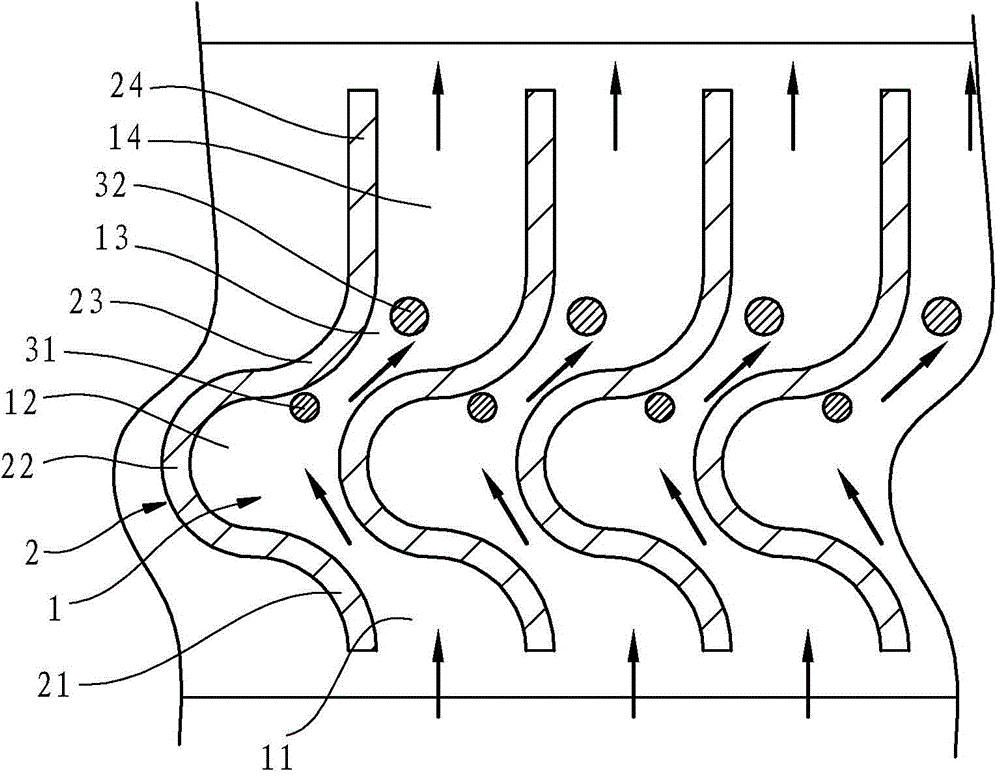

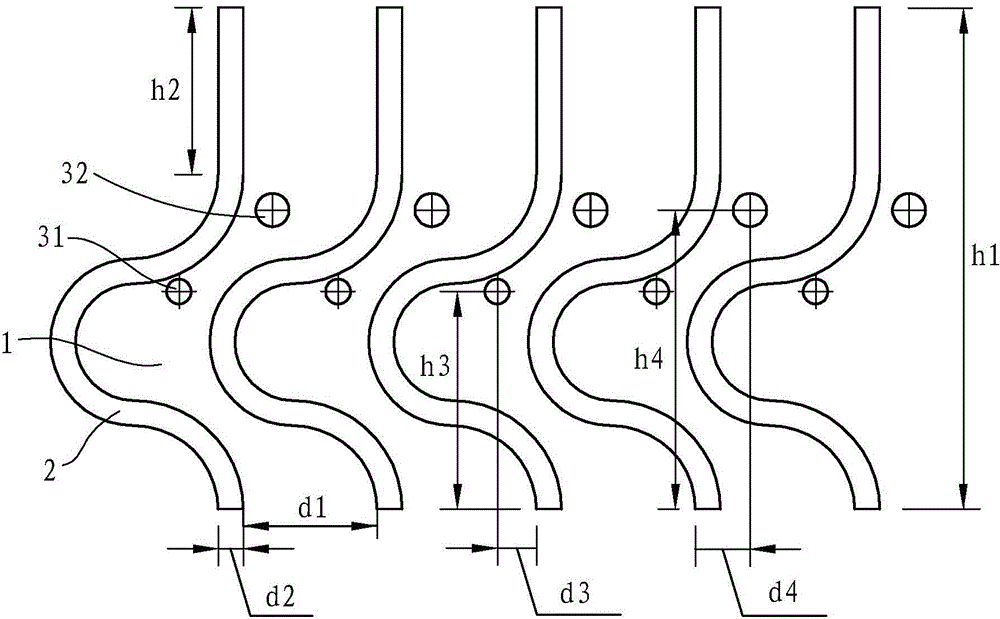

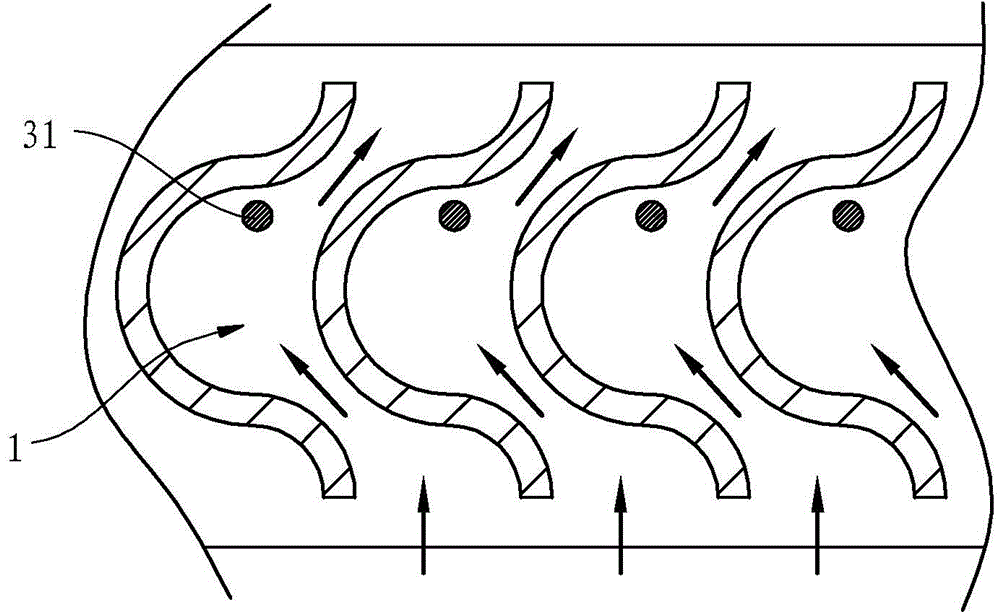

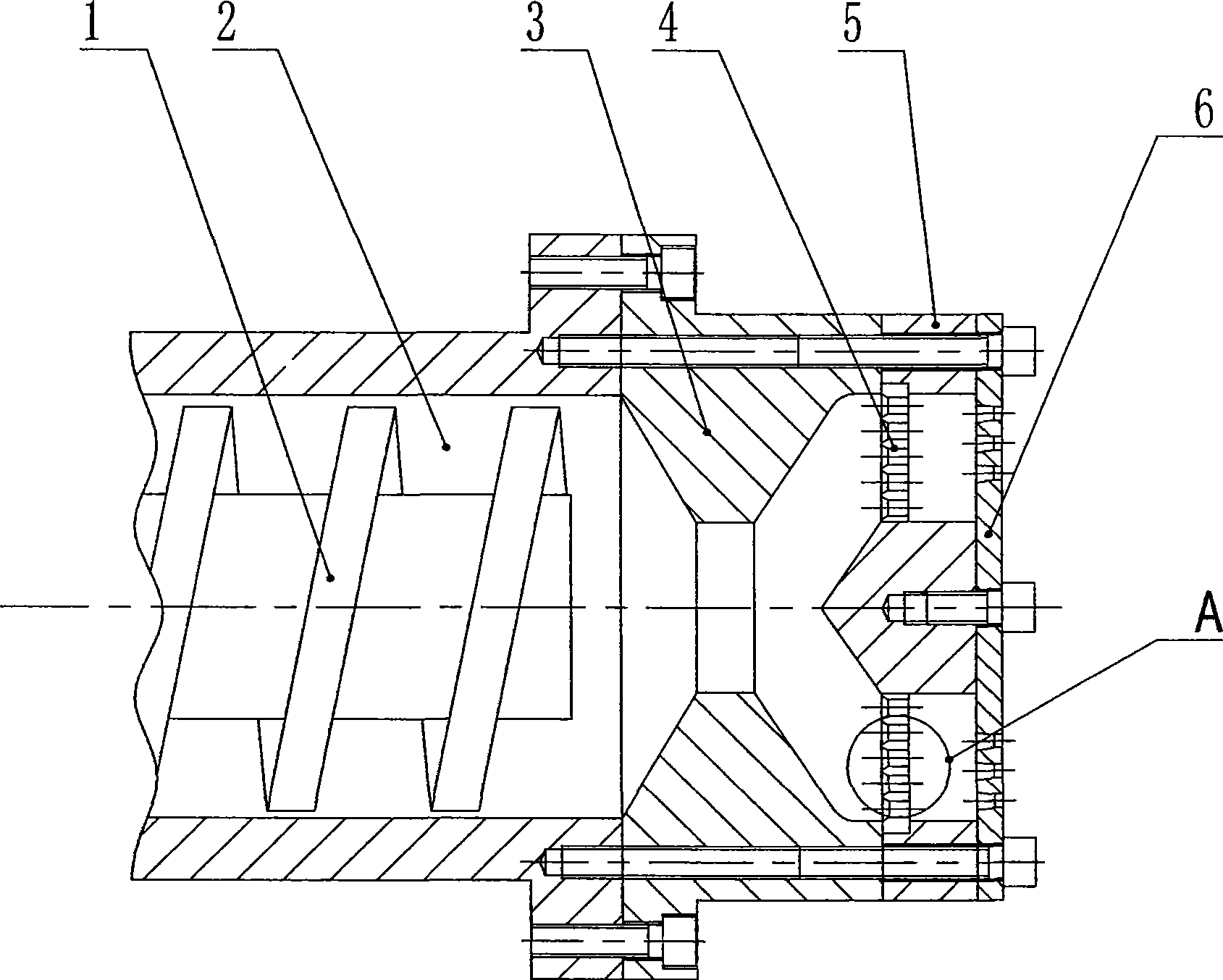

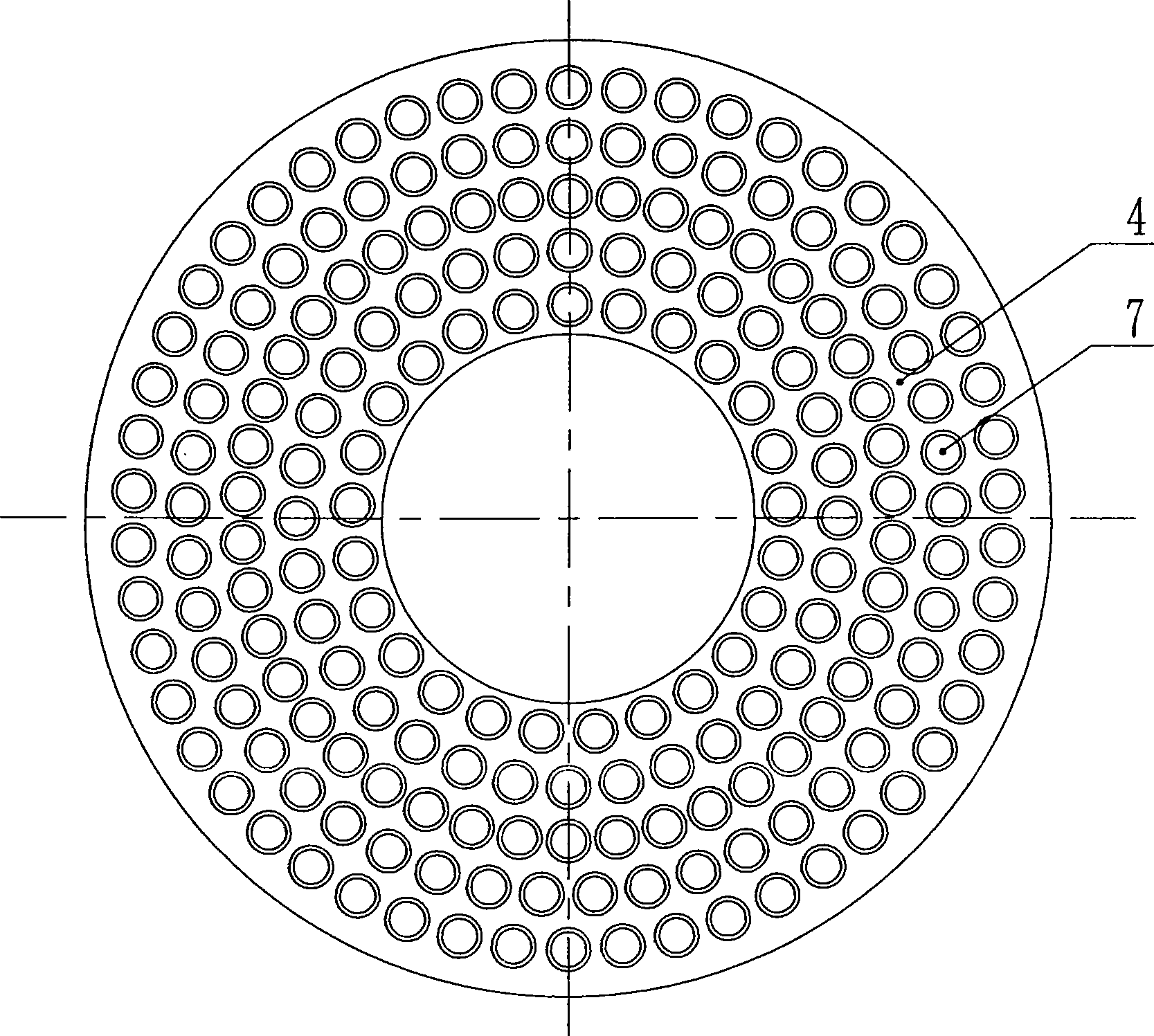

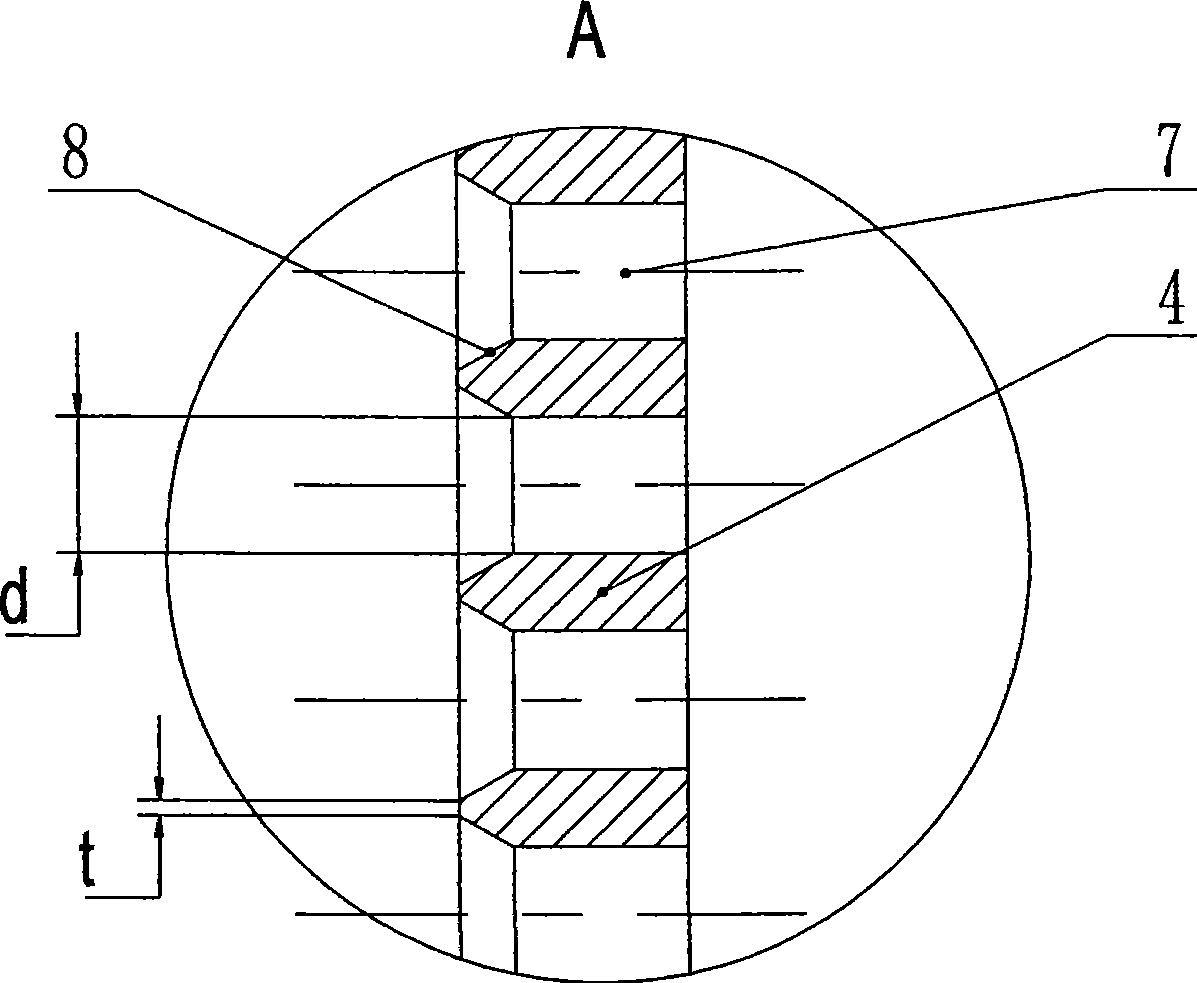

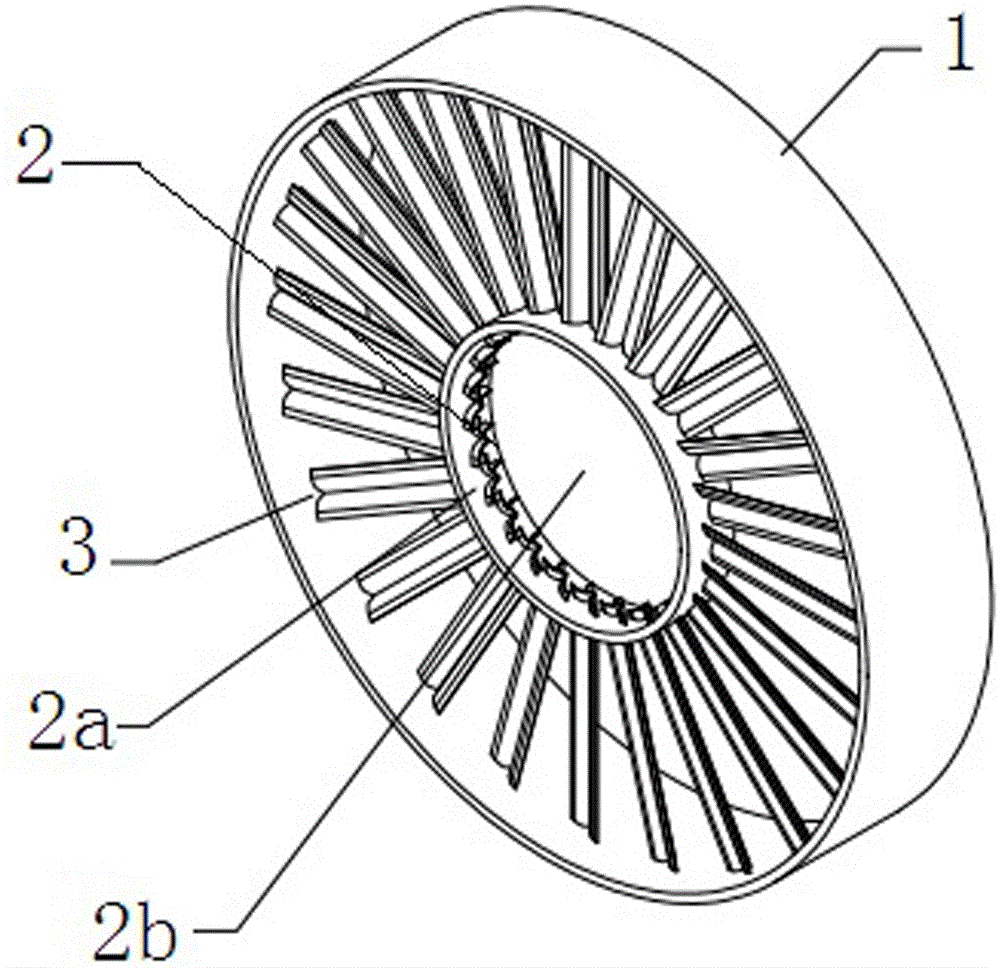

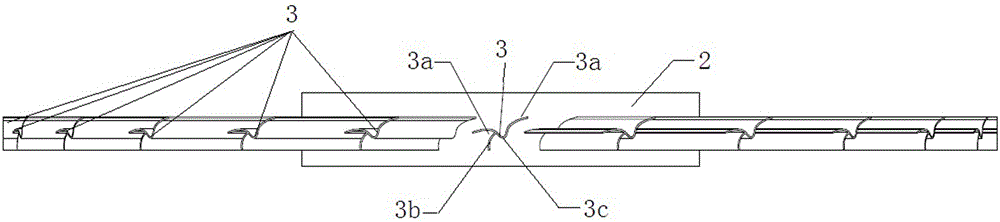

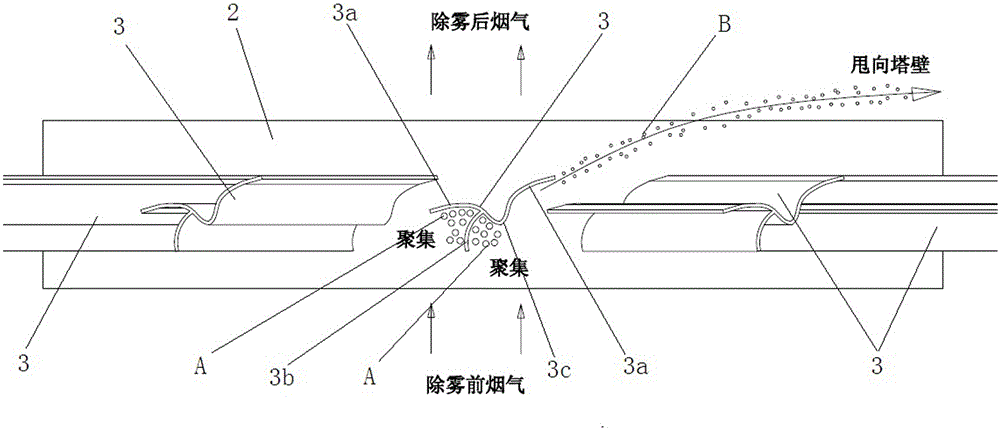

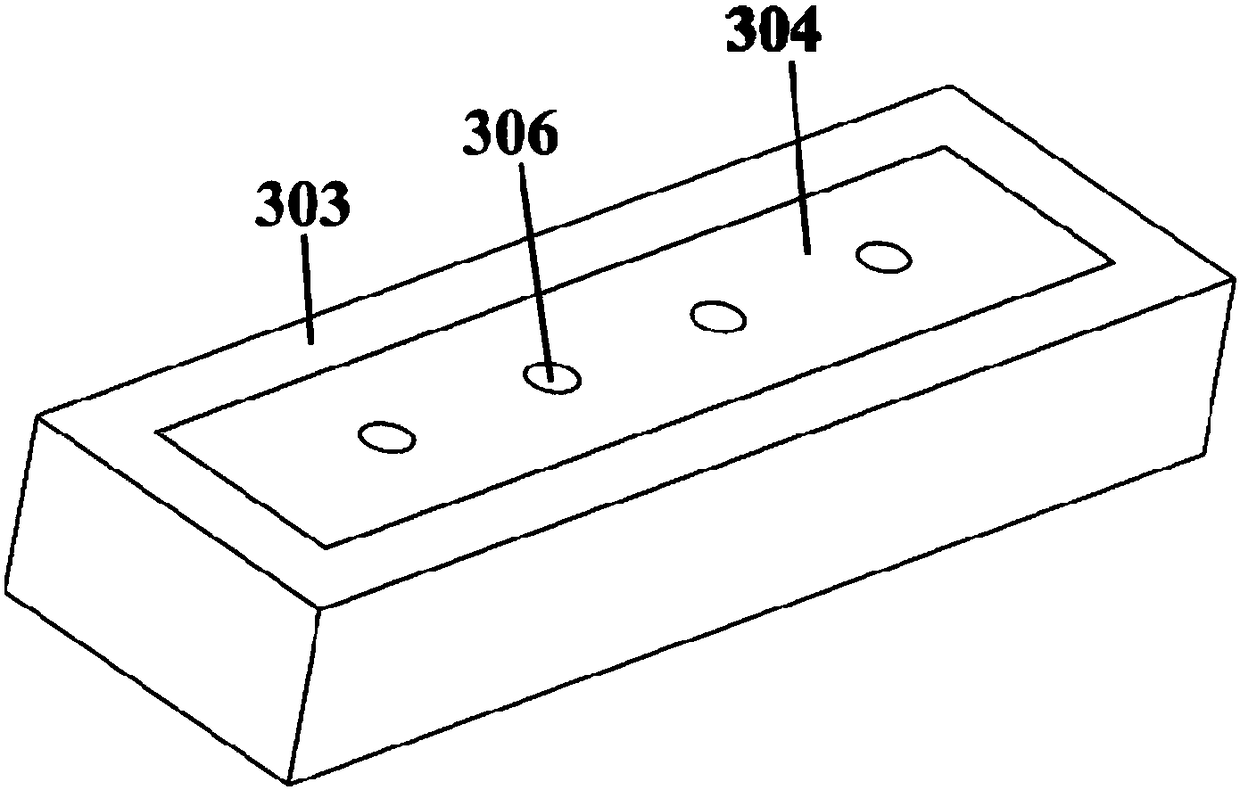

Reactor internal on lower part of reactor

ActiveCN103377735ADistribution effect is goodReduce drag loss along the wayNuclear energy generationReactor fuel elementsReactor pressure vesselEngineering

Reactor internals in a lower reactor comprise a reactor pressure vessel(1), a reactor core provided in the reactor pressure vessel(1), a supporting lower plate(2) of the reactor core fixed to the bottom of the reactor core and a flow distribution device(3) provided with several circular openings. The flow distribution device(3) comprises an upper distribution plate, a middle distribution ring fixedly connected to the bottom of the upper distribution plate along the periphery direction, a lower distribution plate fixedly connected to the bottom of the middle distribution ring along the periphery direction. Several evaginable protruding sections are provided on the top of the upper distribution ring. The evaginable protruding sections of the upper distribution ring are fixedly connected to the supporting lower plate (2) of the reactor core. The reactor internals in a lower reactor have a simple structure, an even flow distribution and a small resistance coefficient, and are easy to replace and repair.

Owner:上海核工程研究设计院股份有限公司

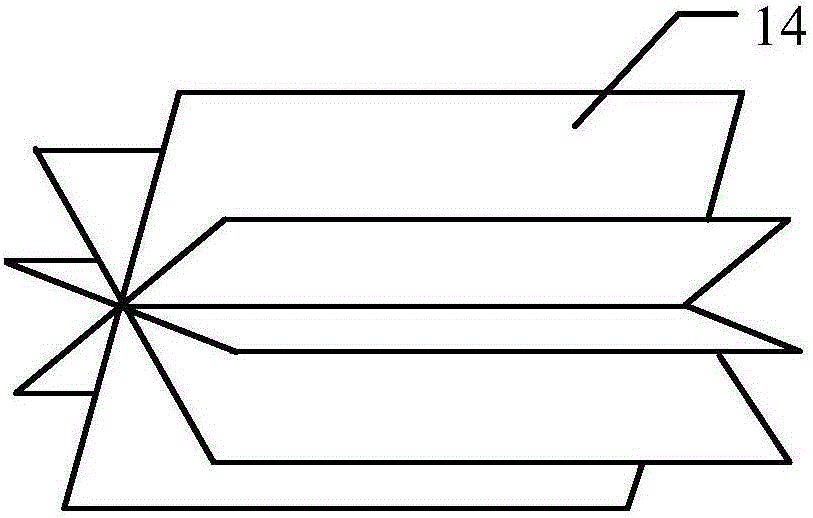

Ranged dual clutch transmission for motor vehicles

InactiveUS20050204837A1Small torque ratioNumber be smallToothed gearingsTransmission elementsDriven elementPower transmission

A power transmission for a motor vehicle includes an input, first and second input shafts, a layshaft, drive elements connecting the input shafts to the output and layshaft, couplers, a first clutch for connecting and disconnecting the input and the first input shaft, and a second clutch for connecting and disconnecting the input and the second input shaft. A first torque path driveably connects the first input shaft to the layshaft. A second torque path driveably connects the second input shaft to the layshaft. A third torque path driveably connects the layshaft and output. A bridge torque path driveably connects the first input shaft and the output.

Owner:FORD GLOBAL TECH LLC

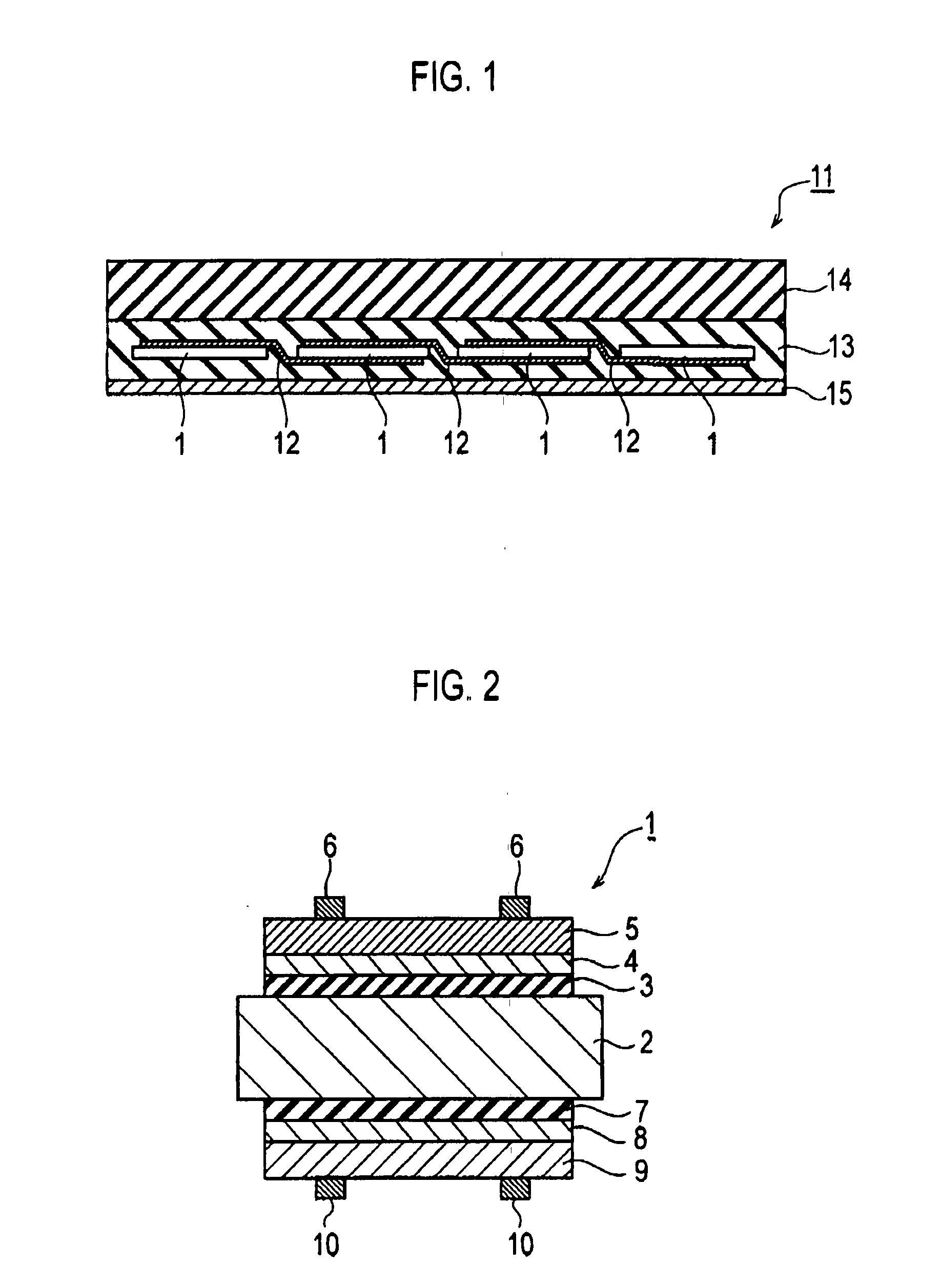

Solar cell module

InactiveUS20080023068A1Improve conductivityHigh light transmittancePhotovoltaic energy generationSemiconductor devicesIndiumEngineering

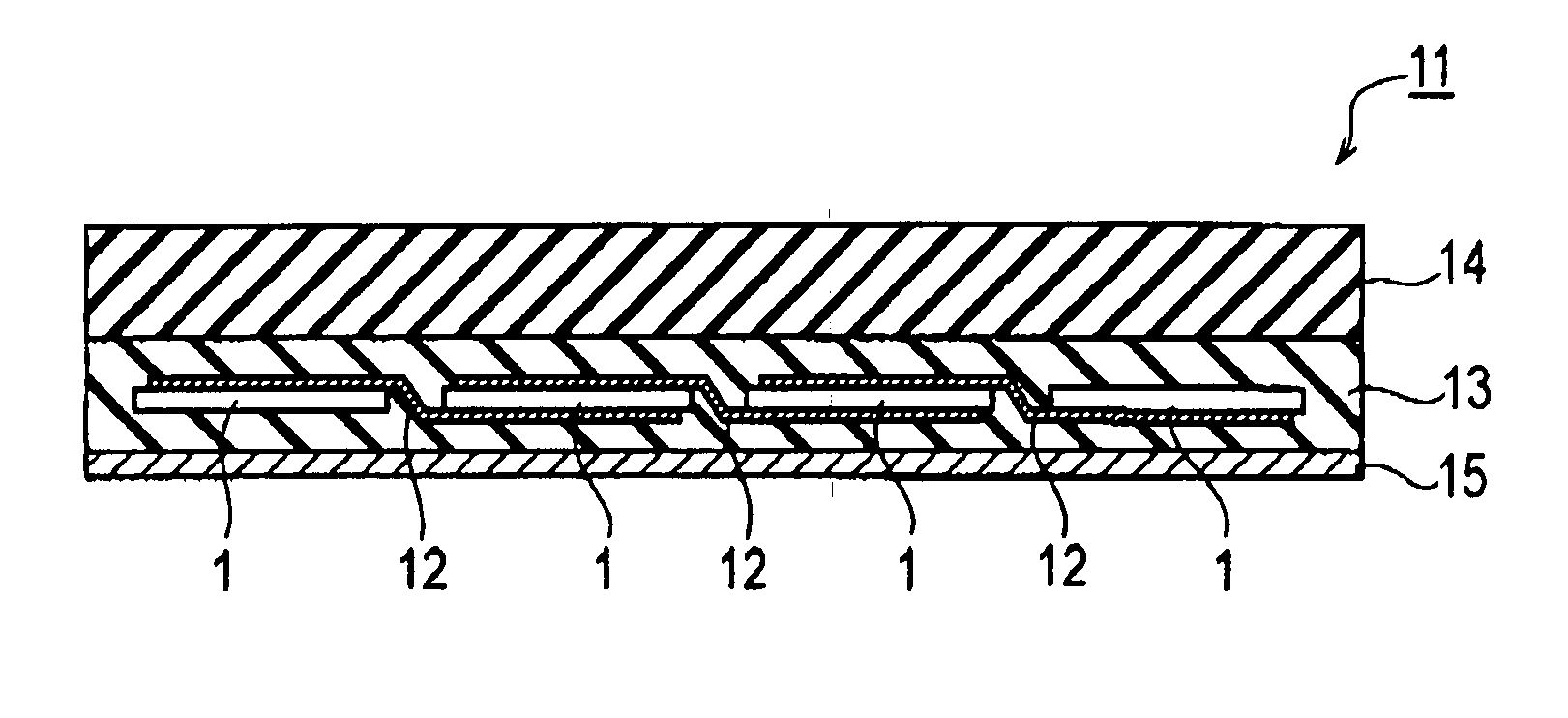

A solar cell module includes a photovoltaic element, a light receiving surface side protective member disposed above a light receiving surface of the photovoltaic element, and a back surface side protective member disposed above a back surface opposite to the light receiving surface side of the photovoltaic element. The photovoltaic element includes an indium oxide layer formed on a surface facing the back surface side protective member and another indium oxide layer formed on a surface facing the light receiving surface side protective member. An arithmetic mean roughness (Ra) on a surface of the indium oxide layer on the back surface of the photovoltaic element is larger than an arithmetic mean roughness (Ra) on the light receiving surface of the photovoltaic element.

Owner:SANYO ELECTRIC CO LTD

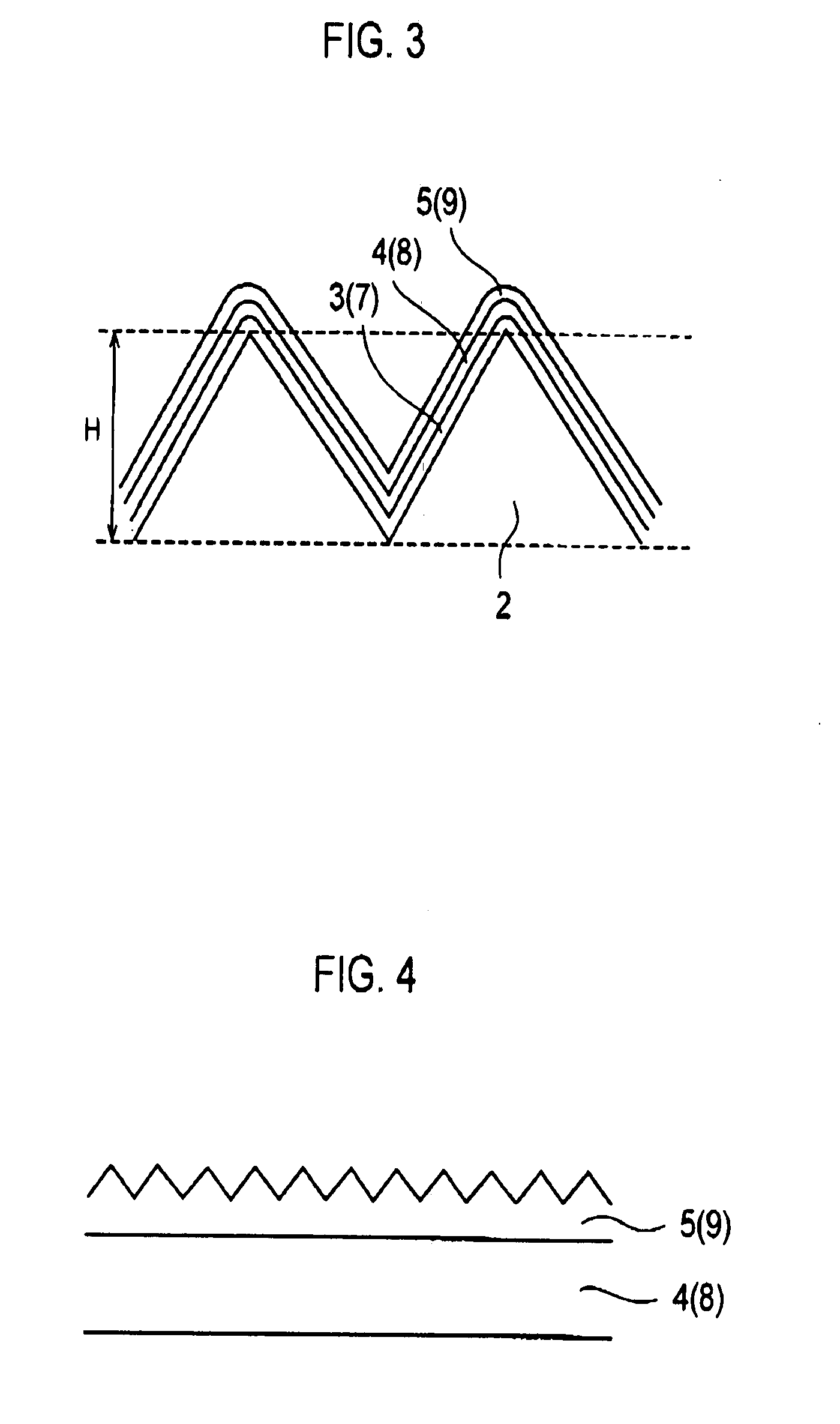

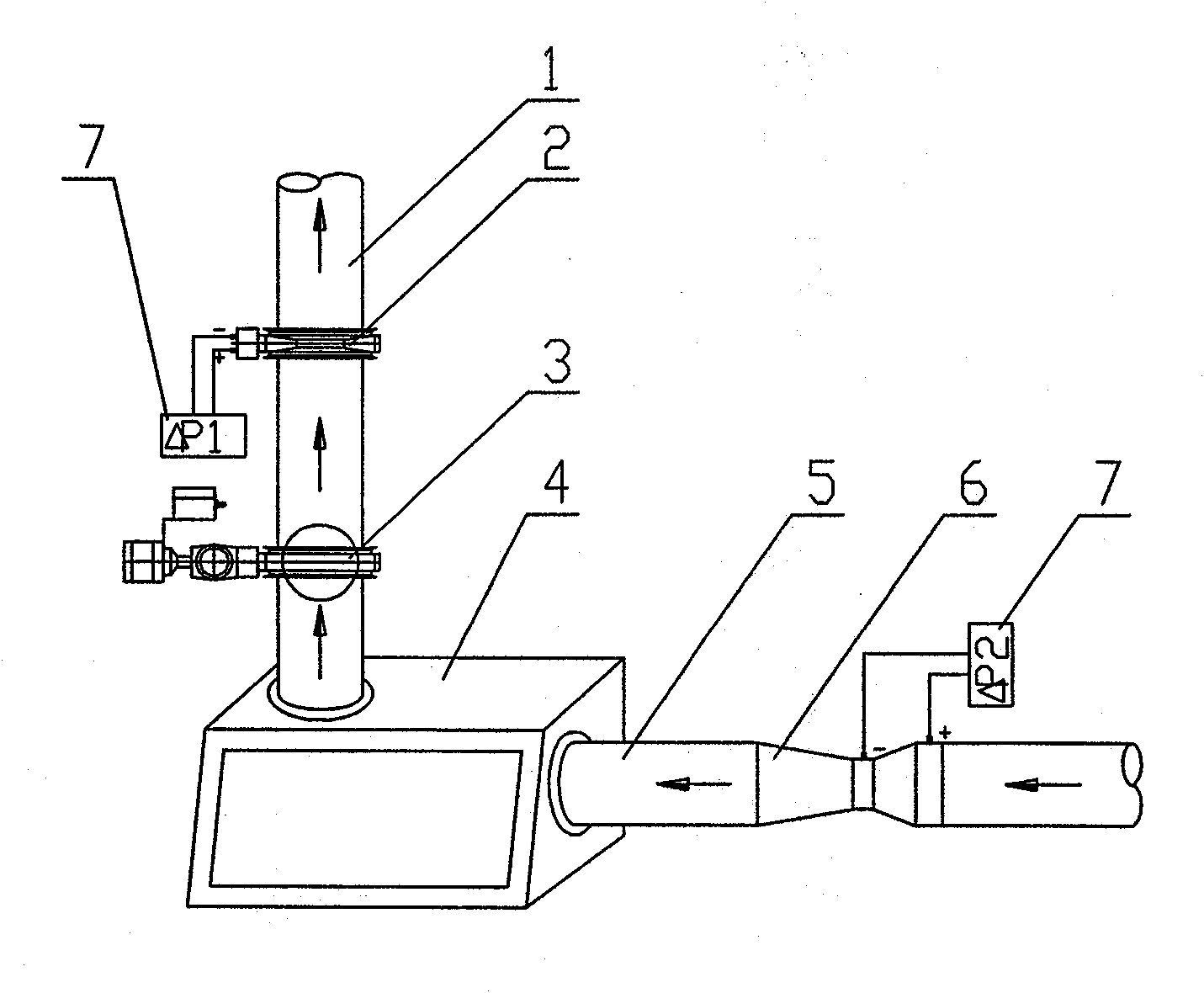

Gas-liquid two-phase flow metering device and method

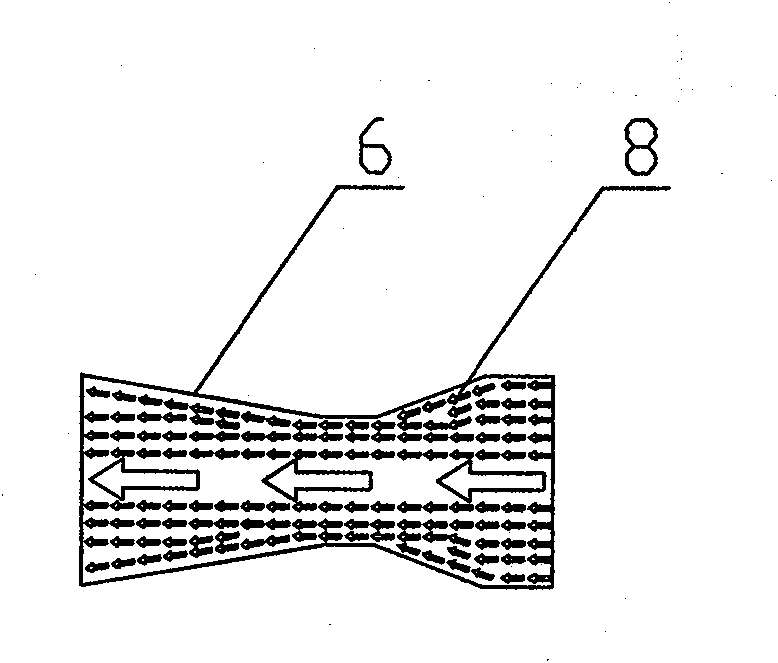

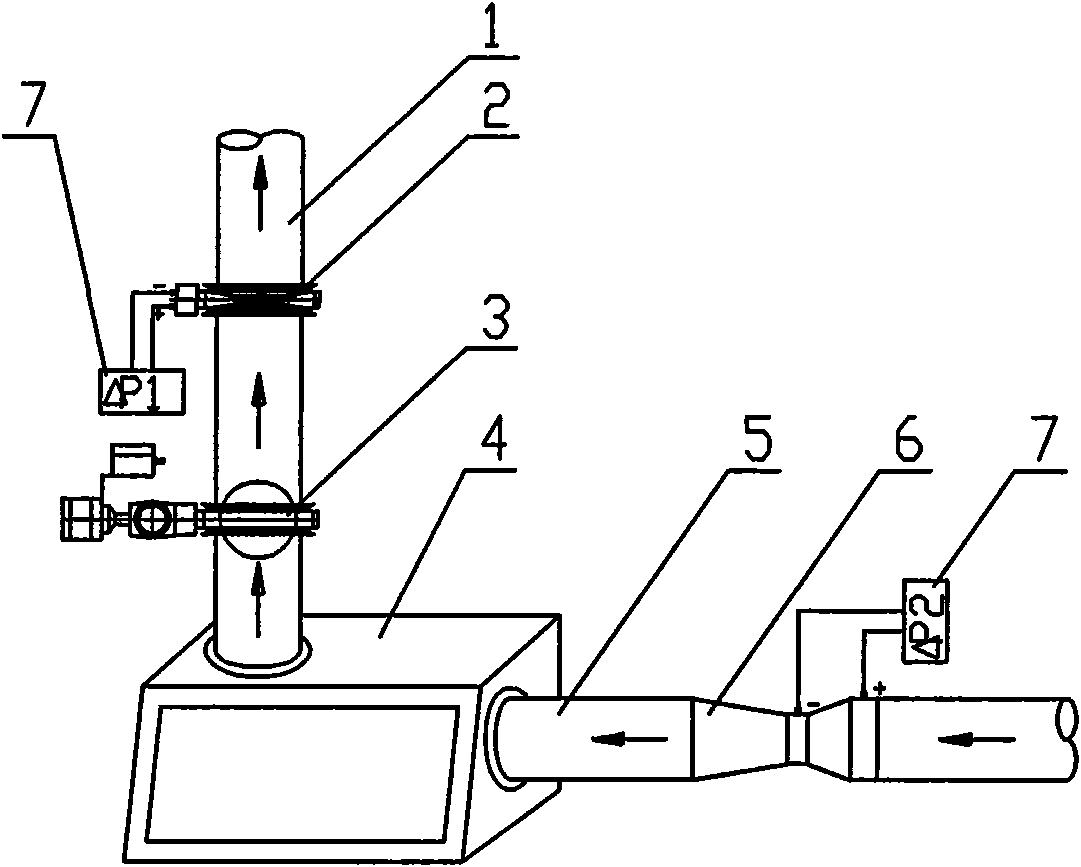

InactiveCN105222831AEliminate measurement effectsHigh measurement accuracyMeasurement devicesDifferential pressureFriction loss

The invention provides a gas-liquid two-phase flow metering device, which mainly comprises a cyclone, a rectifier, an ultrasonic probe, an ultrasonic Doppler velocimeter, a Pitot tube, a differential pressure transducer, a pressure transducer, a temperature transducer, a data acquisition computer, and the like. A flow metering method provided by the invention comprises the steps of separating a gas-liquid two-phase flow in a tube by means of the cyclone to form an annular liquid film region and a central gas region, measuring the liquid flow in a liquid film by means of the ultrasonic Doppler velocimeter, and measuring the gas flow by means of the Pitot tube. Compared with a multiphase flowmeter in the prior art, the above gas-liquid two-phase flow metering device is small in size, compact in structure, small in resistance loss, wide in measurement range, and high in measurement precision.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

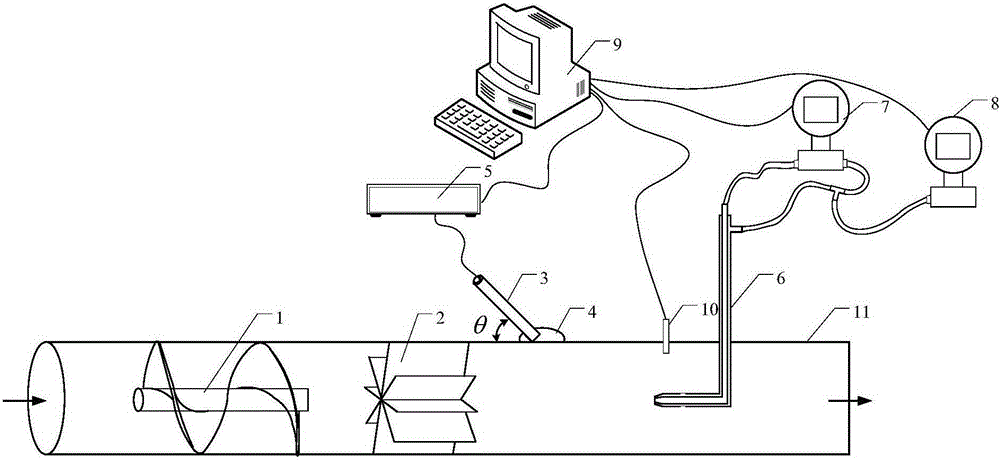

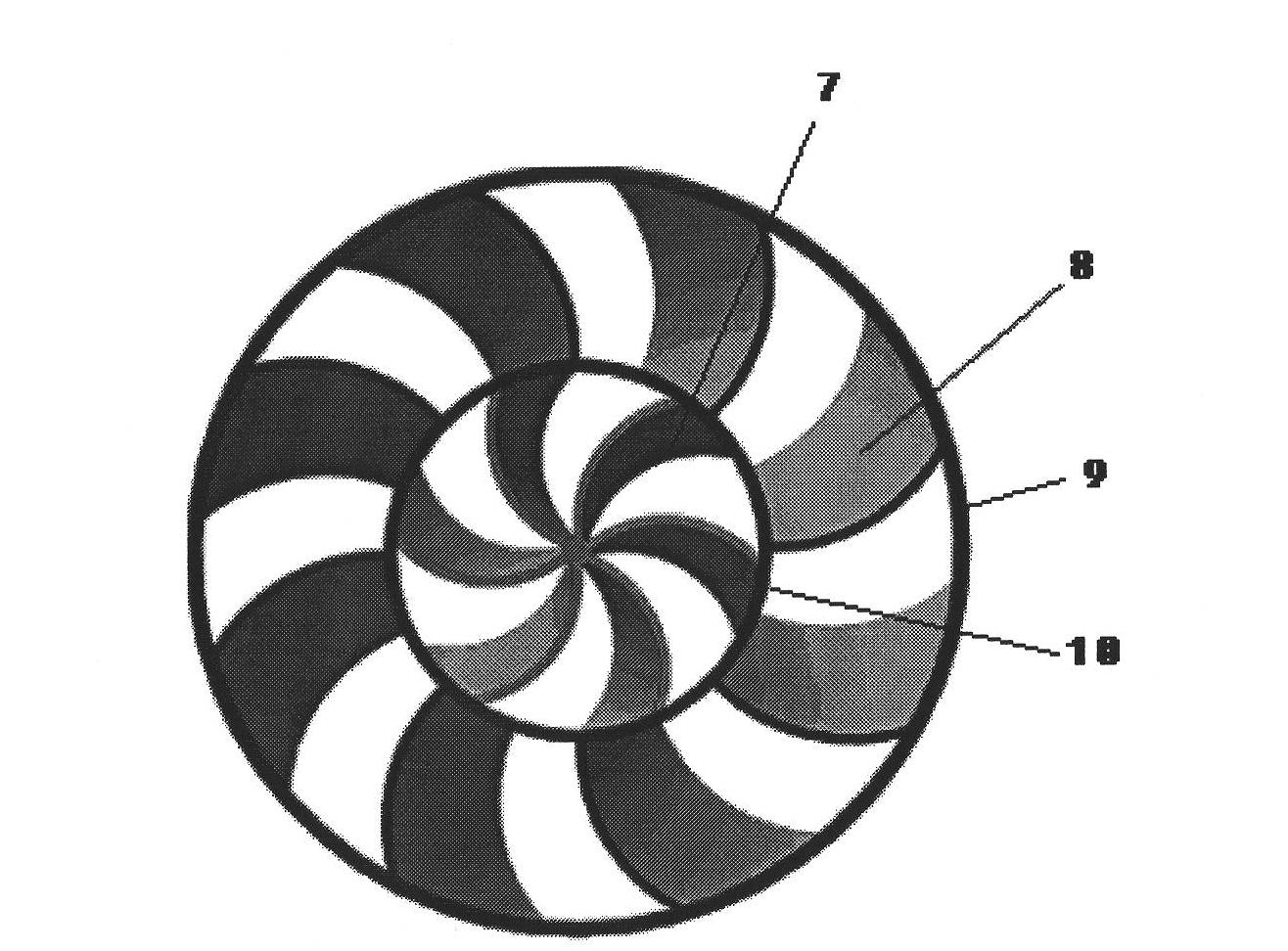

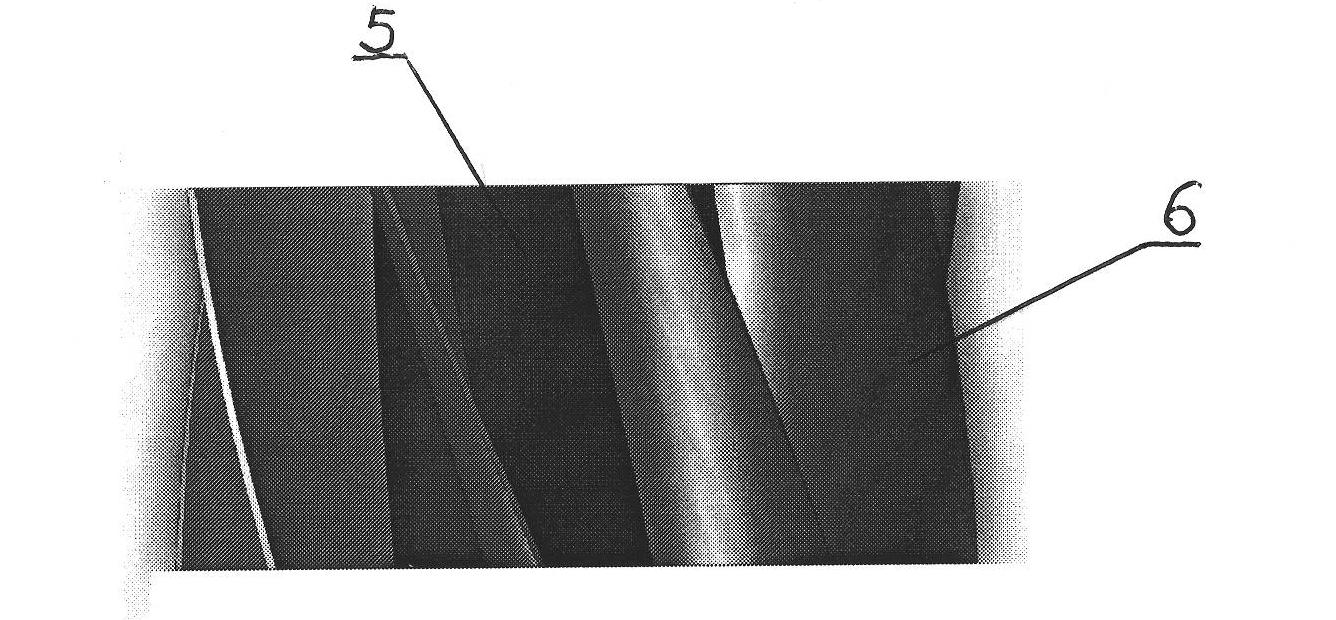

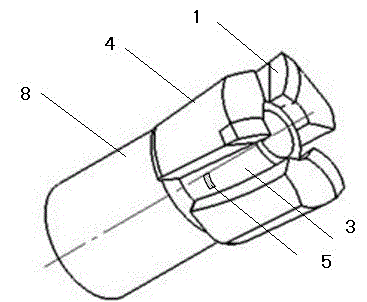

Rapid gas hybrid reactor for high temperature cracking and application thereof

ActiveCN101982227ALittle resistance lossFast mixingFlow mixersGas-gas reaction processesFriction lossProduct gas

The invention relates to a rapid gas hybrid reactor for high temperature cracking and an application thereof. Two types of gases are transported by a concentric bilayer circular tube, one type of the gas is transported by an inner tube, the other type of the gas is transported by a tube annular space between an outer tube and the inner tube, and the two types of the gases can be subject to mutualtemperature regulation in the transportation process, the gases are pre-tempered; and one type of the gas is transported to the inner turbine of a mixing nozzle by the inner tube, the other type of the gas is transported to the annular turbine of the mixing nozzle by the tube annular space between the outer tube and the inner tube, the rotation direction of the turbine blades of the inner turbineand the annular turbine are opposite so as to lead the rotation direction of the two types of the gases to be opposite, thus generating a huge velocity difference to cause large shear force, intensive turbulence, small resistance loss and high hybrid speed, and enabling the two types of the gases to be evenly mixed instantly and then enter in a reaction tube for reaction immediately. The gases are mixed in the mixing nozzle and directly enter the reactor for reaction, thus a mixing section is not required to be additionally arranged.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

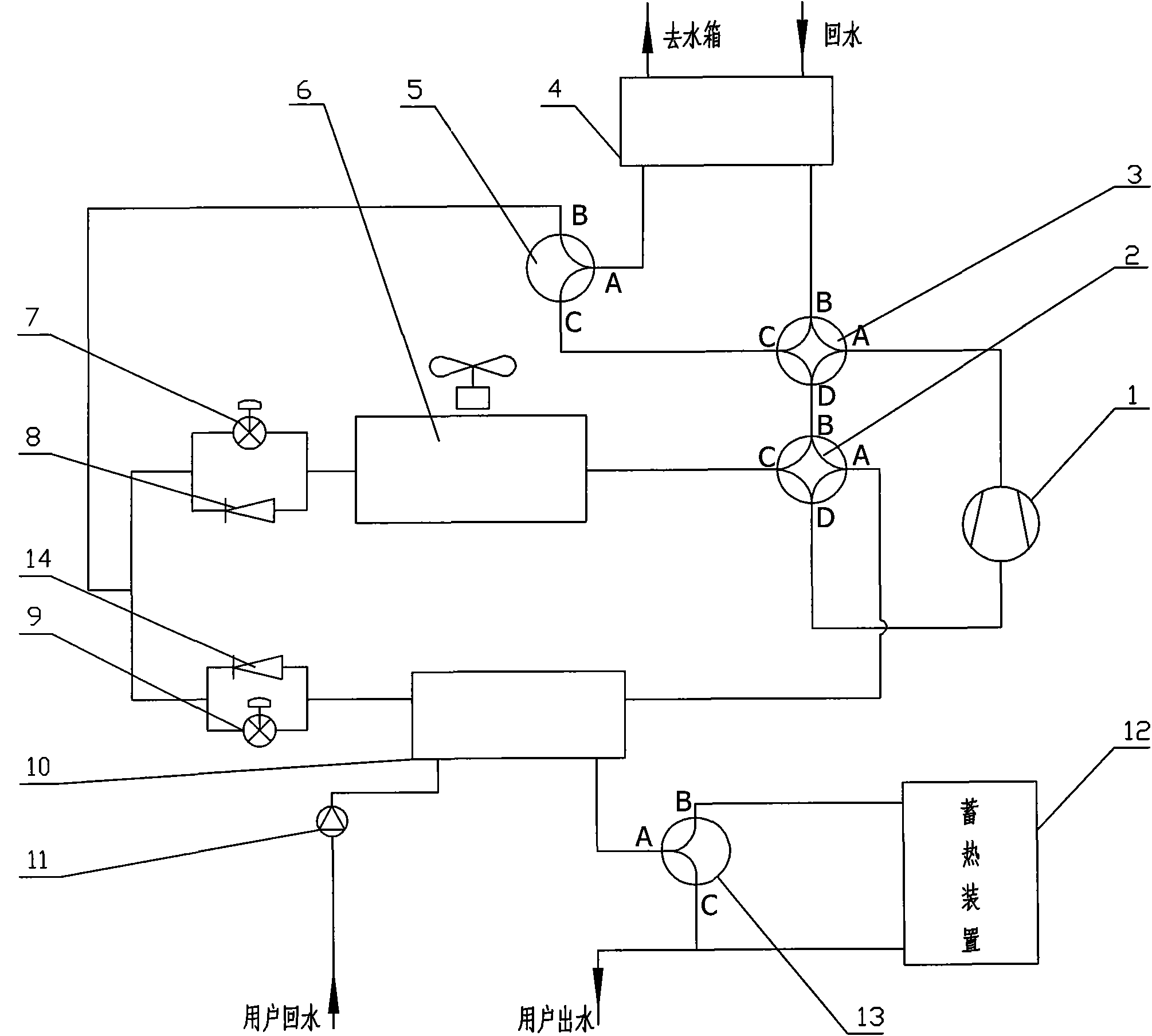

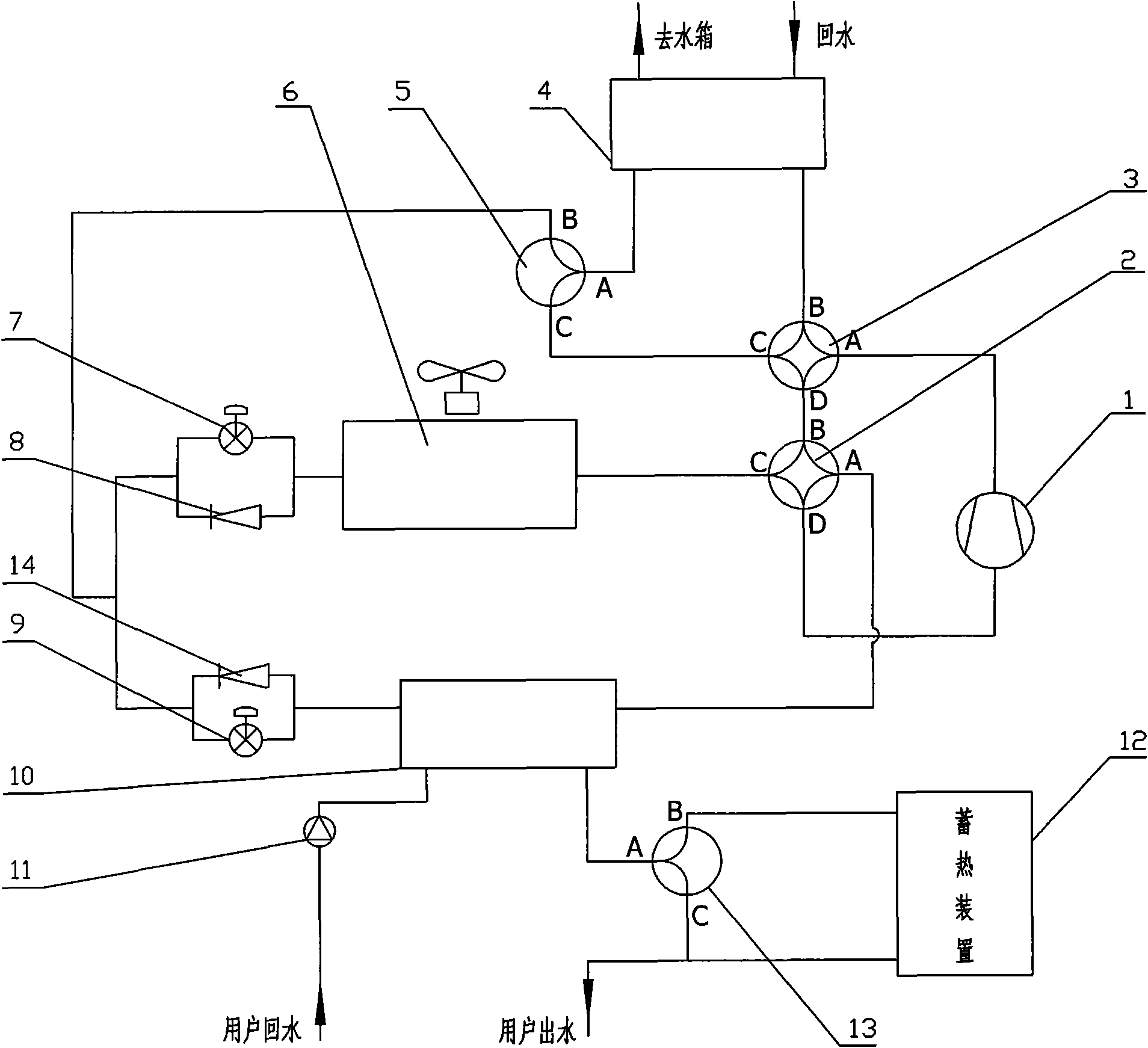

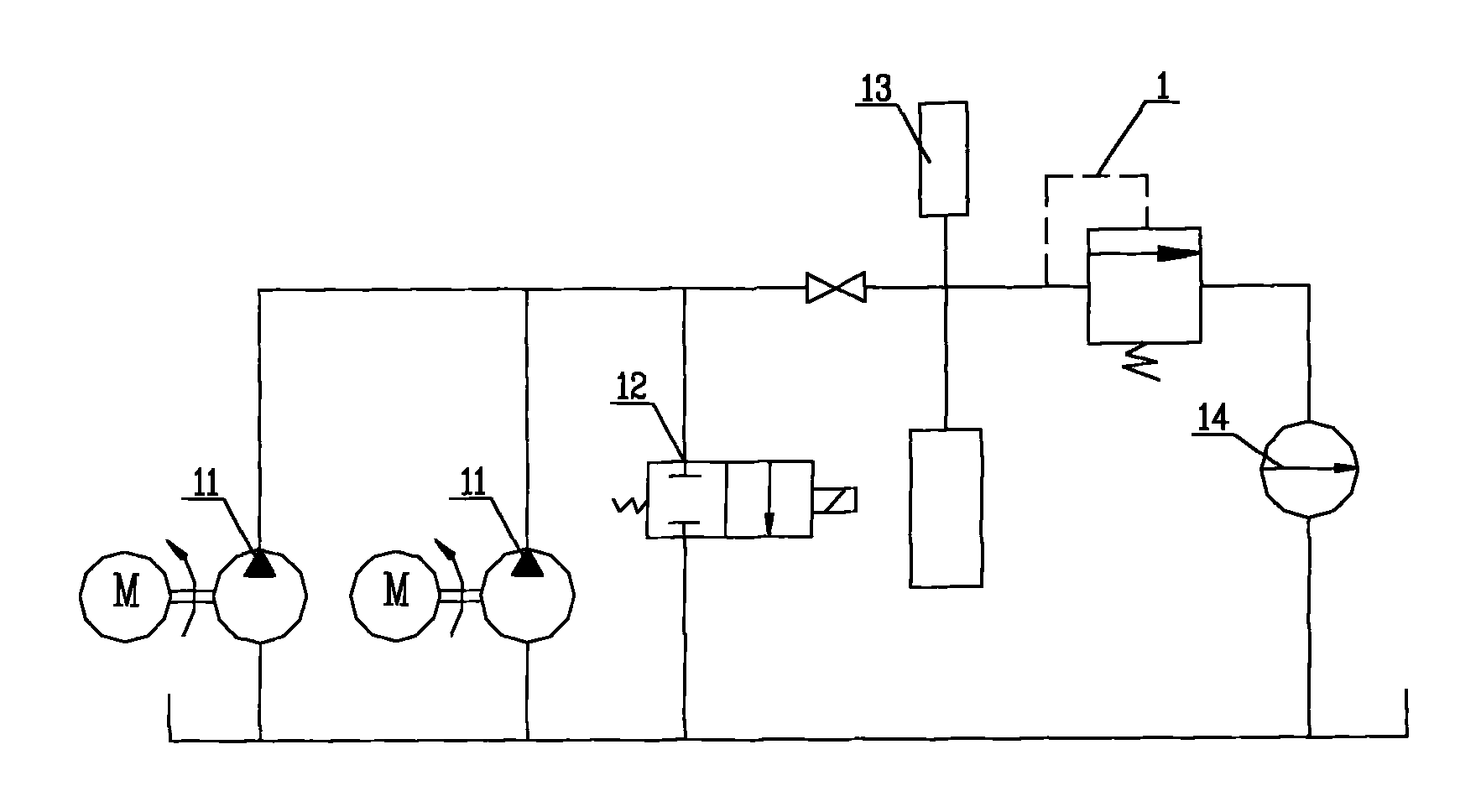

Energy-saving air-conditioning/hot water triple-supply system

InactiveCN101813401AOvercome efficiencyOvercome stabilityEnergy industryHeating and refrigeration combinationsBusiness efficiencyWater quality

The invention discloses an energy-saving air-conditioning / hot water triple-supply system, comprising a compressor (1), a hot water heat exchanger (4), an air heat exchanger (6), an air conditioning heat exchanger (10) and other parts; using main components of a heat pump system, the system adopts a structure with three heat exchangers interconnected in a mixed manner and double four-way reversing valves and has four working modes including refrigeration and water heating, water heating, heating and water heating, and defrosting, thus the triple supply of refrigeration, heating and clean hot water can be realized; the system has high heat exchange efficiency and simultaneously enhances energy efficiency ratio of system as well; by adopting the heat pipe exchangers, the system solves the problem that the heat exchanger is liable to leakage so as to pollute water, and overcomes the deficiency of large resistance when a plurality of heat exchangers are connected with each other in series.

Owner:江乐新

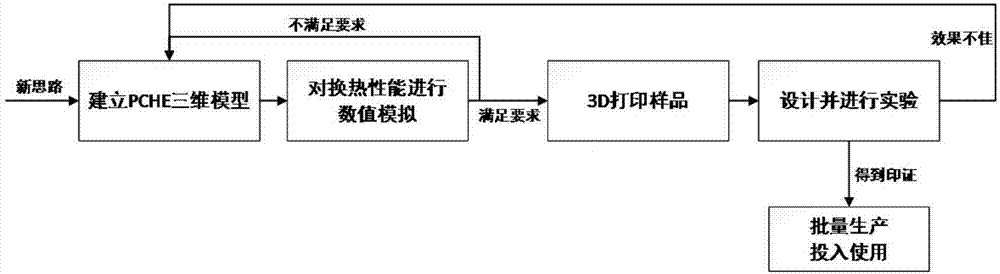

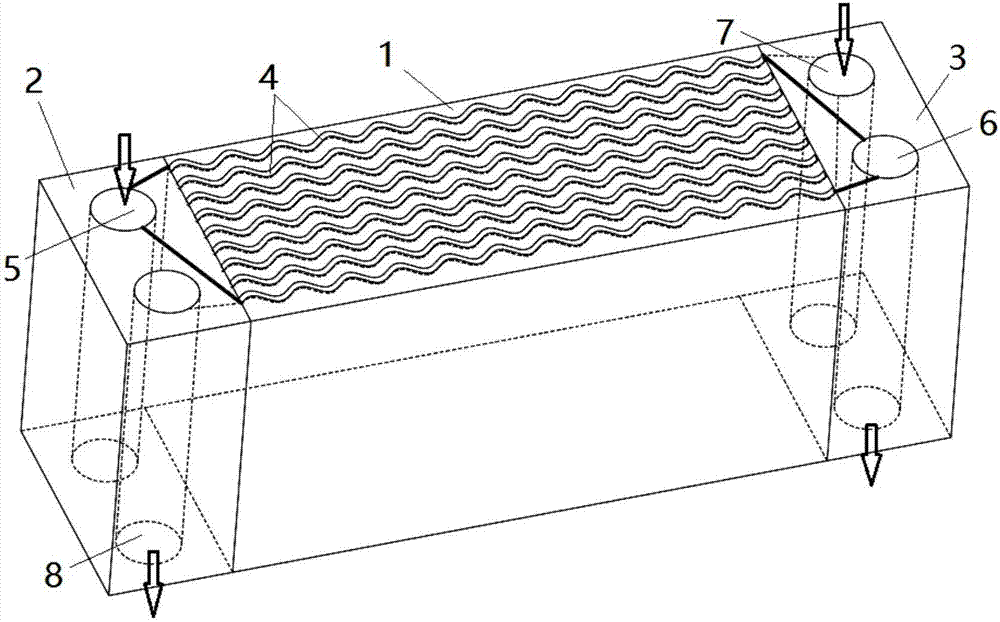

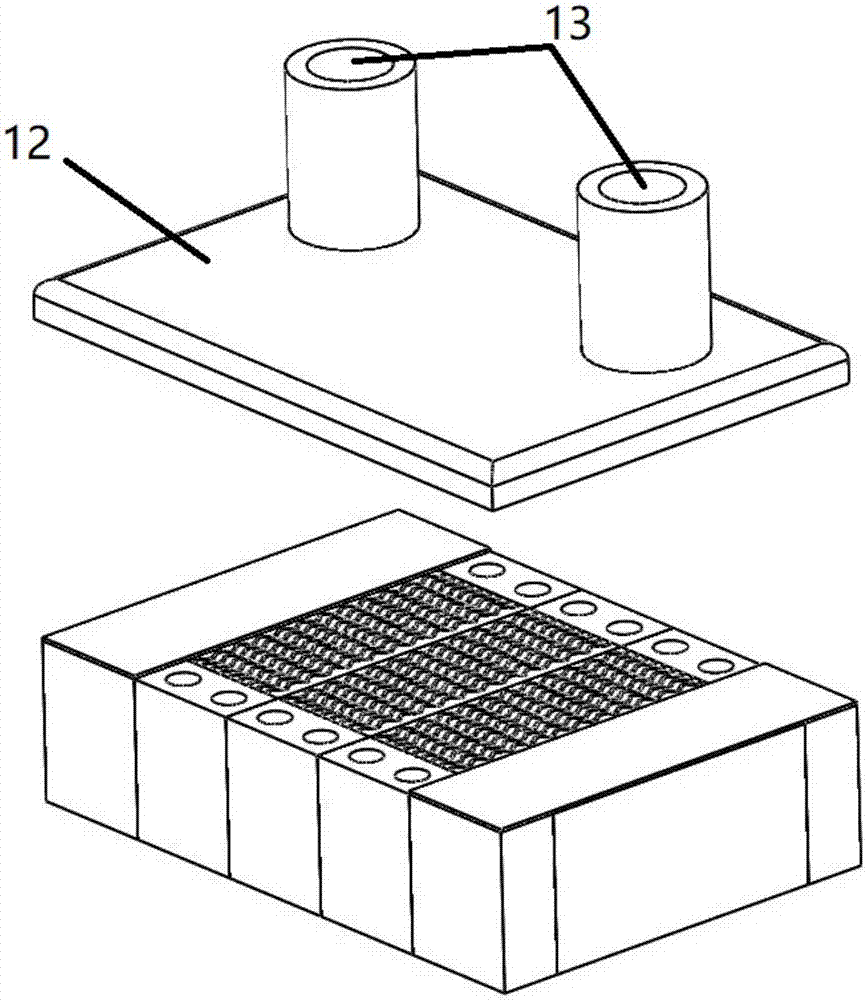

Novel printed circuit board type heat exchanger based on 3D printing technology

InactiveCN107388854AImprove work performanceSimple designHeat exchanger casingsStationary tubular conduit assembliesInlet channelEngineering

The invention discloses a novel printed circuit board type heat exchanger based on a 3D printing technology. The novel printed circuit board type heat exchanger based on the 3D printing technology comprises a heat exchange main body formed on the basis of the 3D printing technology, wherein two ends of the heat exchange main body are a first heat exchanger inlet and outlet section and a second heat exchanger inlet and outlet section separately; a thermal fluid inlet channel and a cold fluid outlet channel are formed in the first heat exchanger inlet and outlet section in the vertical direction; a thermal fluid outlet channel and a cold fluid inlet channel are formed in the second heat exchanger inlet and outlet section in the vertical direction; a plurality of layers of periodic heat exchange channels are formed in the middle of the heat exchange main body from bottom to top; part of the periodic heat exchange channels communicate with the thermal fluid inlet and outlet channel; and the rest of periodic heat exchange channels communicate with the cold fluid inlet and outlet channel. The 3D printing technology is adopted, the whole heat exchanger is formed integrally, and loss of drainage, resistance and the like due to manufacturing errors can be reduced.

Owner:XI AN JIAOTONG UNIV

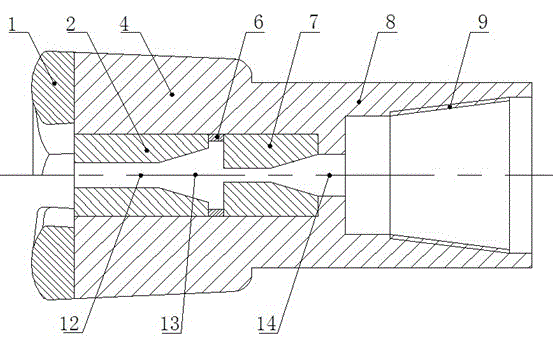

Coal mine underground self-suction abrasive jet flow drill bit and drilling method

ActiveCN103556947ARealize continuous additionSimple structureDrill bitsLiquid/gas jet drillingHole drilling methodCoal

The invention discloses a coal mine underground self-suction abrasive jet flow drill bit which can utilize the combination of abrasive jet flow guiding smash and mechanical smash to increase the drilling speed during the coal mine underground drilling operation. The self-suction abrasive jet flow drill bit comprises an abrasive jet flow nozzle, a self-suction device and a main smashing structure, wherein the self-suction device comprises a cavity, a filter screen, a support ring positioned inside the cavity and an inlet nozzle positioned at the rear end of the cavity. According to the invention, coal debris generated in the drilling process can be sifted by the filter screen, then enters the inside of the cavity of the self-suction device, and is fully mixed with a water jet flow to form an abrasive jet flow, the abrasive jet flow is jetted from the abrasive jet flow nozzle to perform guiding smash on coal and rock mass; the main smashing structure of the drill bit comprises three cutting pieces and three main smashing teeth, and a finished drill-hole can be formed under the mechanical smash action of the main smashing structure. The invention further relates to a method for utilizing the drill bit to drill in an underground coal mine. The drill bit has high drilling speed and little abrasion, and can be widely applied to coal mine underground drilling operation.

Owner:CHONGQING UNIV

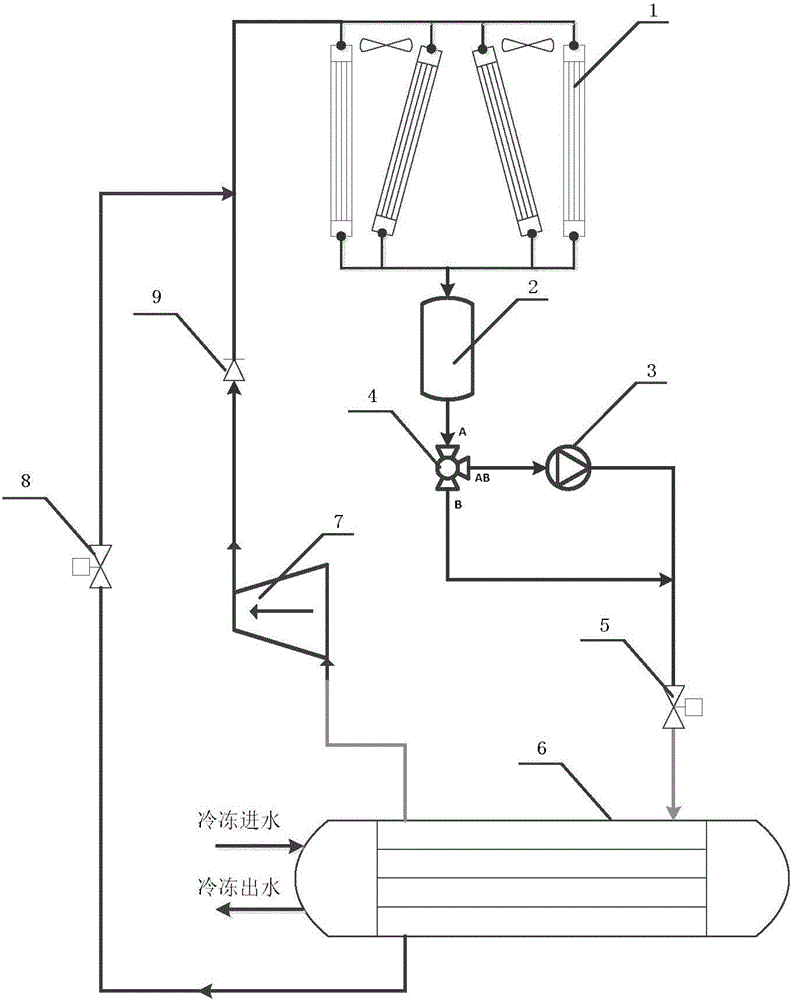

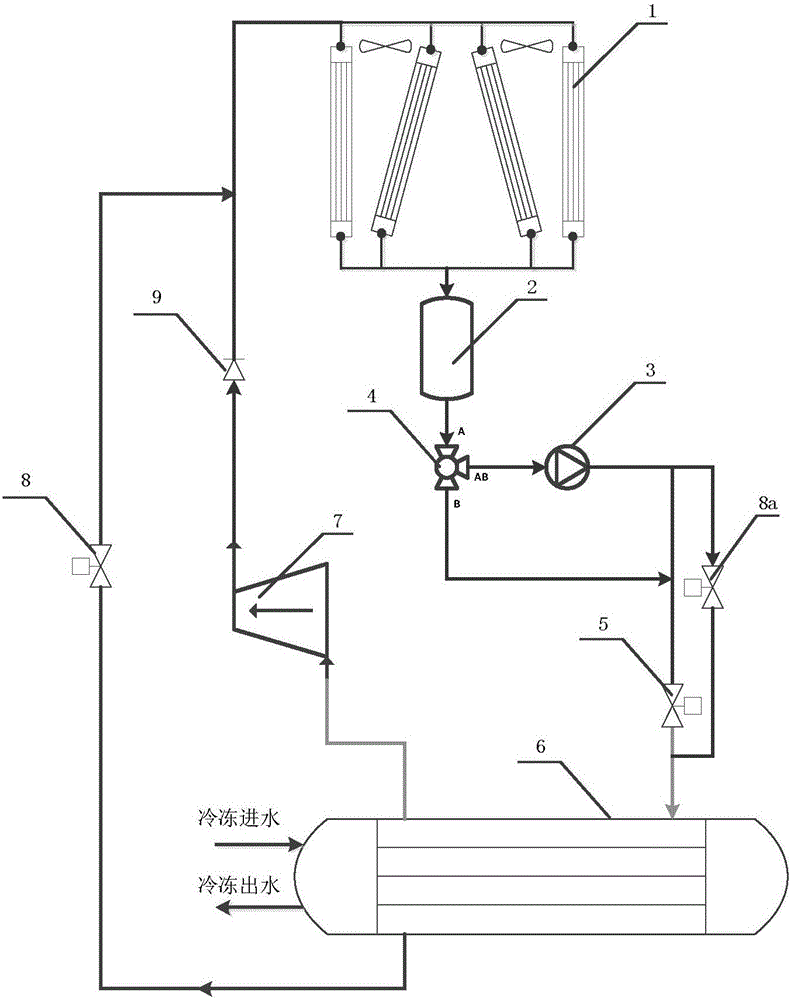

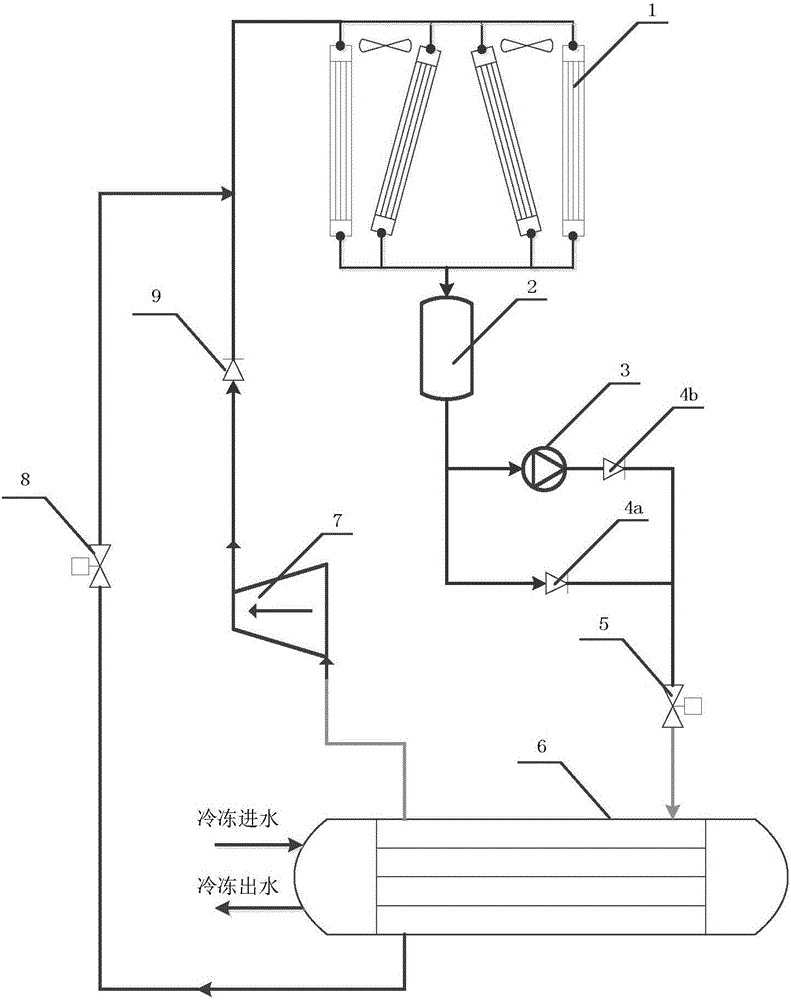

Novel natural cooling resource refrigerating system and control method thereof

ActiveCN106440437ATake advantage ofReduce wind side drag lossCompression machines with non-reversible cycleRefrigeration safety arrangementRefrigeration compressorEngineering

The invention discloses a novel natural cooling resource refrigerating system and a control method thereof. The system comprises a condenser, a liquid accumulator, a freezing medium circulating pump, an electronic expansion valve, an evaporator and a refrigeration compressor. The evaporator, the compressor, the condenser, the liquid accumulator, the freezing medium circulating pump and the electronic expansion valve are connected in sequence to form a circulation loop, wherein the evaporator and the condenser are connected through a first by-pass pipeline, and the liquid accumulator and the electronic expansion valve are connected through a second by-pass pipeline; the refrigeration compressor, the condenser, the liquid accumulator, the electronic expansion valve and the evaporator form an air cooling water chilling unit refrigeration cycle system, and the condenser, the liquid accumulator, the freezing medium circulating pump and the evaporator form a natural cooling resource refrigeration cycle system. Compared with the prior art, a freezing medium is used as a circulating medium, so the novel natural cooling resource refrigerating system has the advantages of an ethylene glycol scheme and a pure water scheme, and no special antifreeze process is needed, the cost can be reduced and the heat exchange efficiency and the convenience of maintenance are improved.

Owner:NANJING CANATAL DATA CENT ENVIRONMENTAL TECH CO LTD

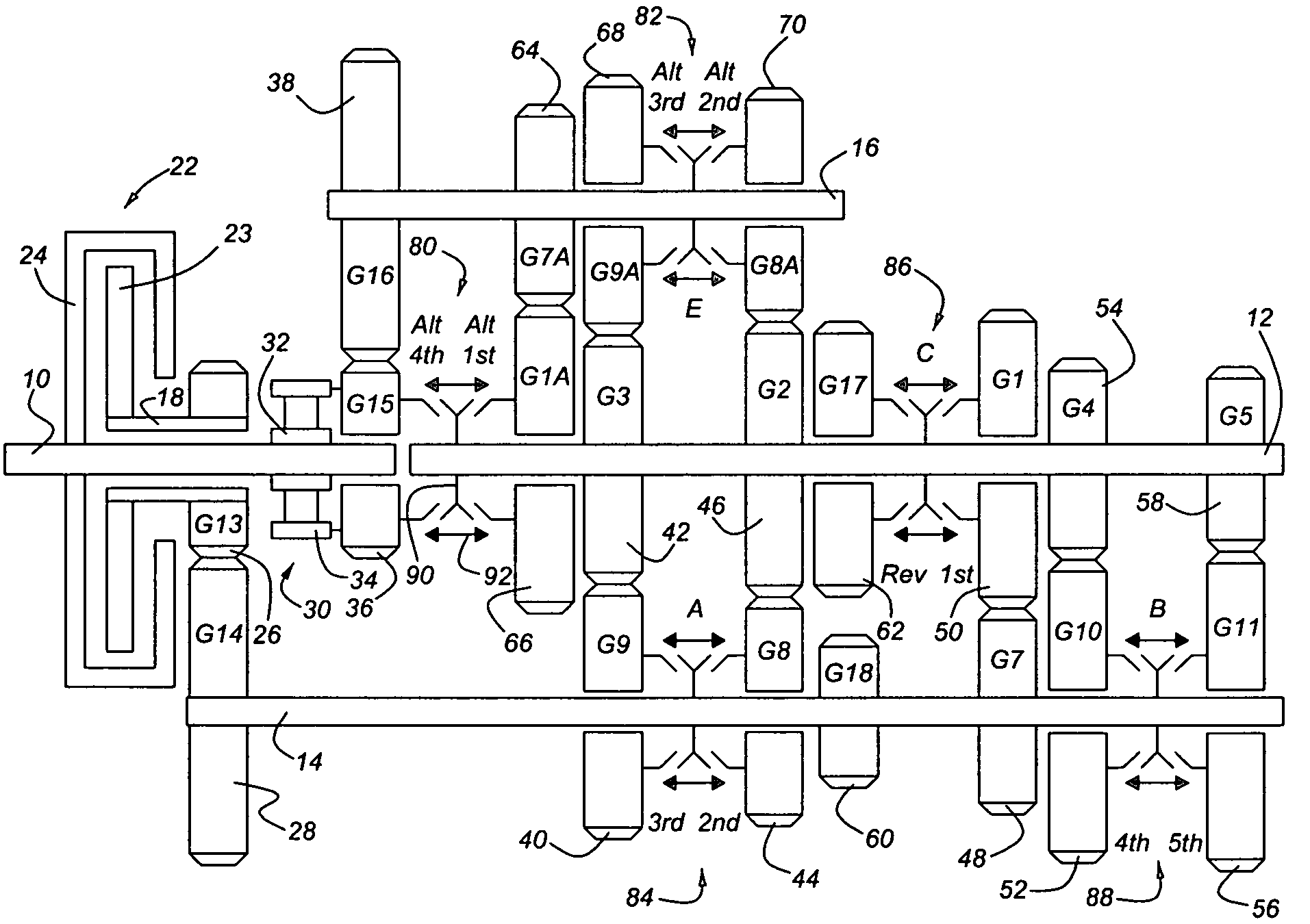

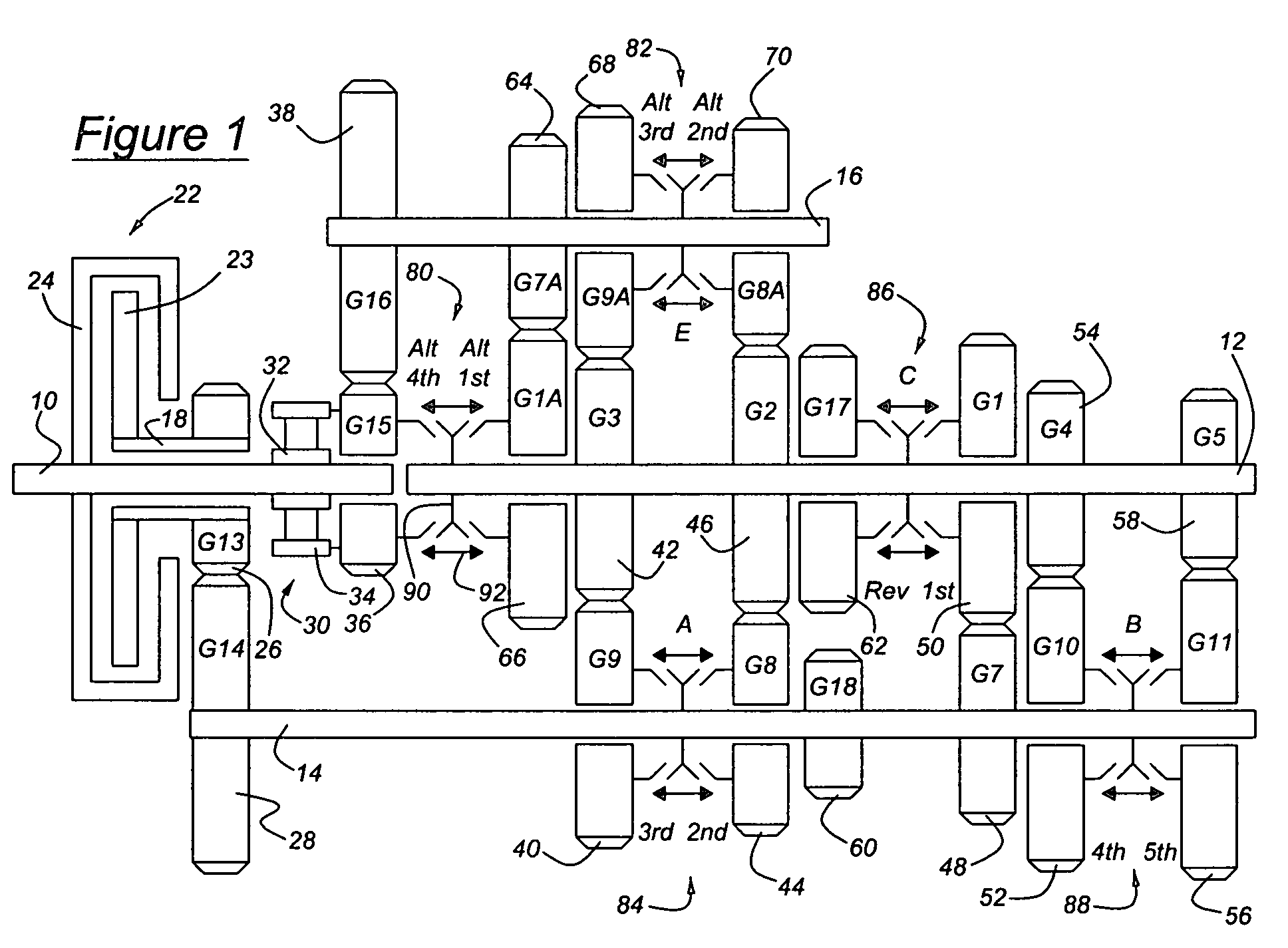

Ranged single clutch layshaft powershift automatic transmission

InactiveUS7080566B2Little resistance lossAvoid power interruptionToothed gearingsTransmission elementsMobile vehicleAutomatic transmission

A power transmission for a motor vehicle includes an input, a first layshaft, a second layshaft, an intermediate layshaft, a first power path for transmitting power between the input and first layshaft and producing a first ratio of a speed of the first layshaft and a corresponding speed of the input, a second power path for transmitting power between the input and second layshaft and producing a second ratio of the speed of the second layshaft and corresponding speed of the input, a speed reduction power path driveably connected to the intermediate layshaft, couplers for the first and second layshafts to various gearsets, a range coupler for coupling the output alternately to the speed reduction power path and the intermediate layshaft, and a clutch for releasably connecting the input and second power path.

Owner:FORD GLOBAL TECH LLC

Single clutch layshaft transmission

InactiveUS7107866B2Little resistance lossAvoid power interruptionToothed gearingsTransmission elementsTransmitted powerControl theory

A transmission includes an input, a first layshaft, a second layshaft, a first power path for transmitting power between the input and first layshaft and producing a first ratio of a speed of the first layshaft and a corresponding speed of the input, a second power path for transmitting power between the input and second layshaft and producing a second ratio of the speed of the second layshaft and corresponding speed of the input; and a clutch for releasably connecting the input and the output.

Owner:FORD GLOBAL TECH LLC

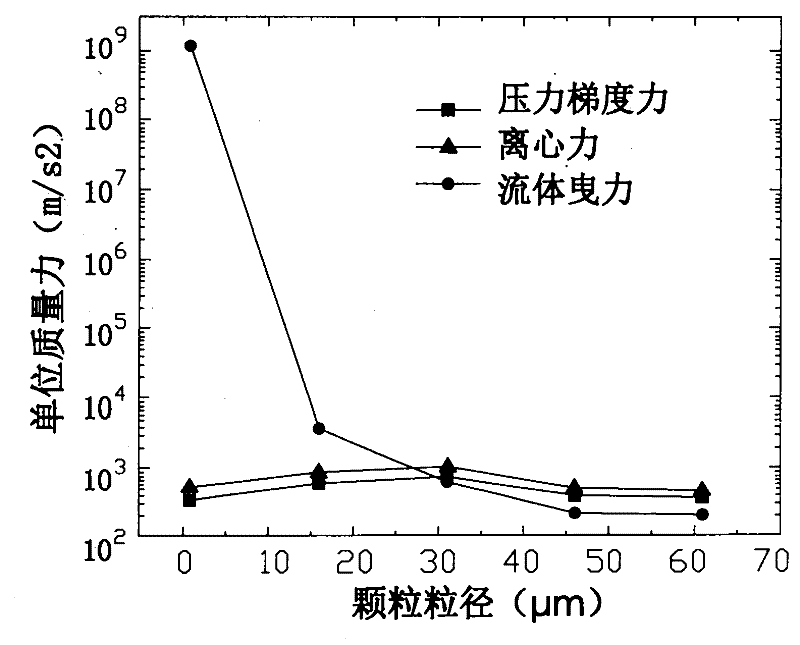

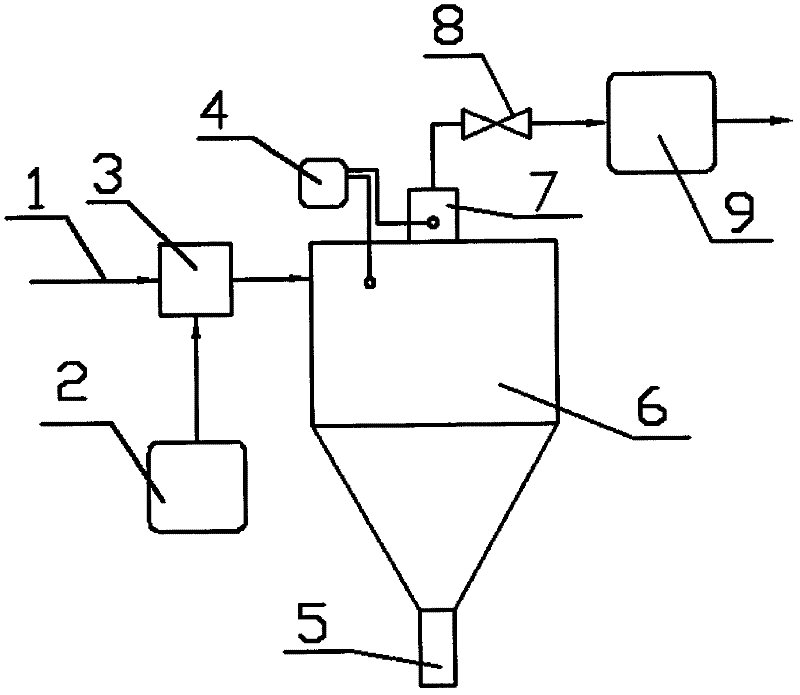

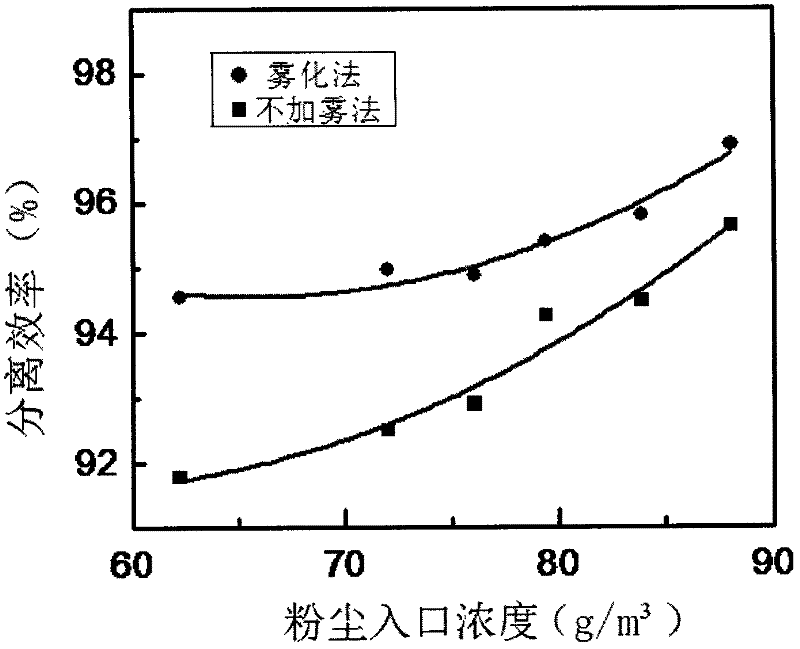

Dedusting device and dedusting method therefor

The invention discloses a dedusting device and a dedusting method therefor. The dedusting device is a cyclone dedusting device with a water atomization device. The dedusting device mainly comprises a cyclone dust collector and also comprises the water atomization device. A water mist outlet of the water atomization device is communicated with the interior of a mixing chamber. An upstream part of the mixing chamber is communicated with a waiting gas pipe. A downstream part of the mixing chamber is communicated with an air inlet of the cyclone dust collector. The water atomization device adopted by the invention is an electroacoustic transduction supersonic atomizing device, and sizes of liquid drops produced by the water atomization device are less than or equal to 5.0 micrometers.

Owner:LANZHOU UNIVERSITY

Plenum chamber capable of achieving balanced ventilation

ActiveCN105546778AIncreased flow distanceReduced mixing abilityDucting arrangementsEngineeringPlenum chamber

The invention discloses a plenum chamber capable of achieving balanced ventilation, comprising a chamber body, wherein an air inlet hole is formed in the lateral wall of the chamber body, a pore plate and a clapboard are arranged in the chamber body, a plurality of orifices are formed in the pore plate, the pore plate and the clapboard divide the internal space of the chamber body into three areas, including an air inlet area, a first turbulence area and a second turbulence area; the air inlet hole is formed in the lateral wall of the air inlet area, a vertical air outlet hole is formed in the lateral wall of the first turbulence area, a horizontal air outlet hole is formed in the lateral wall of the second turbulence area; and air enters the air inlet area via the air inlet hole, respectively enters the first turbulence area and the second turbulence are via the pore plate and are respectively sent out from the vertical air outlet hole and the horizontal air outlet hole. According to the invention, wall-attached jetting uniformity in the horizontal direction and the vertical direction can be improved, the capability of outlet airflow in mixing with indoor pollution (hot air) is weakened, and air sending jetting distance is increased, and blowing feeling of sending airflow to persons is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Ranged single clutch layshaft powershift automatic transmission

InactiveUS20050204841A1Little resistance lossAvoid power interruptionToothed gearingsTransmission elementsAutomatic transmissionTransmitted power

A power transmission for a motor vehicle includes an input, a first layshaft, a second layshaft, an intermediate layshaft, a first power path for transmitting power between the input and first layshaft and producing a first ratio of a speed of the first layshaft and a corresponding speed of the input, a second power path for transmitting power between the input and second layshaft and producing a second ratio of the speed of the second layshaft and corresponding speed of the input, a speed reduction power path driveably connected to the intermediate layshaft, couplers for the first and second layshafts to various gearsets, a range coupler for coupling the output alternately to the speed reduction power path and the intermediate layshaft, and a clutch for releasably connecting the input and second power path.

Owner:FORD GLOBAL TECH LLC

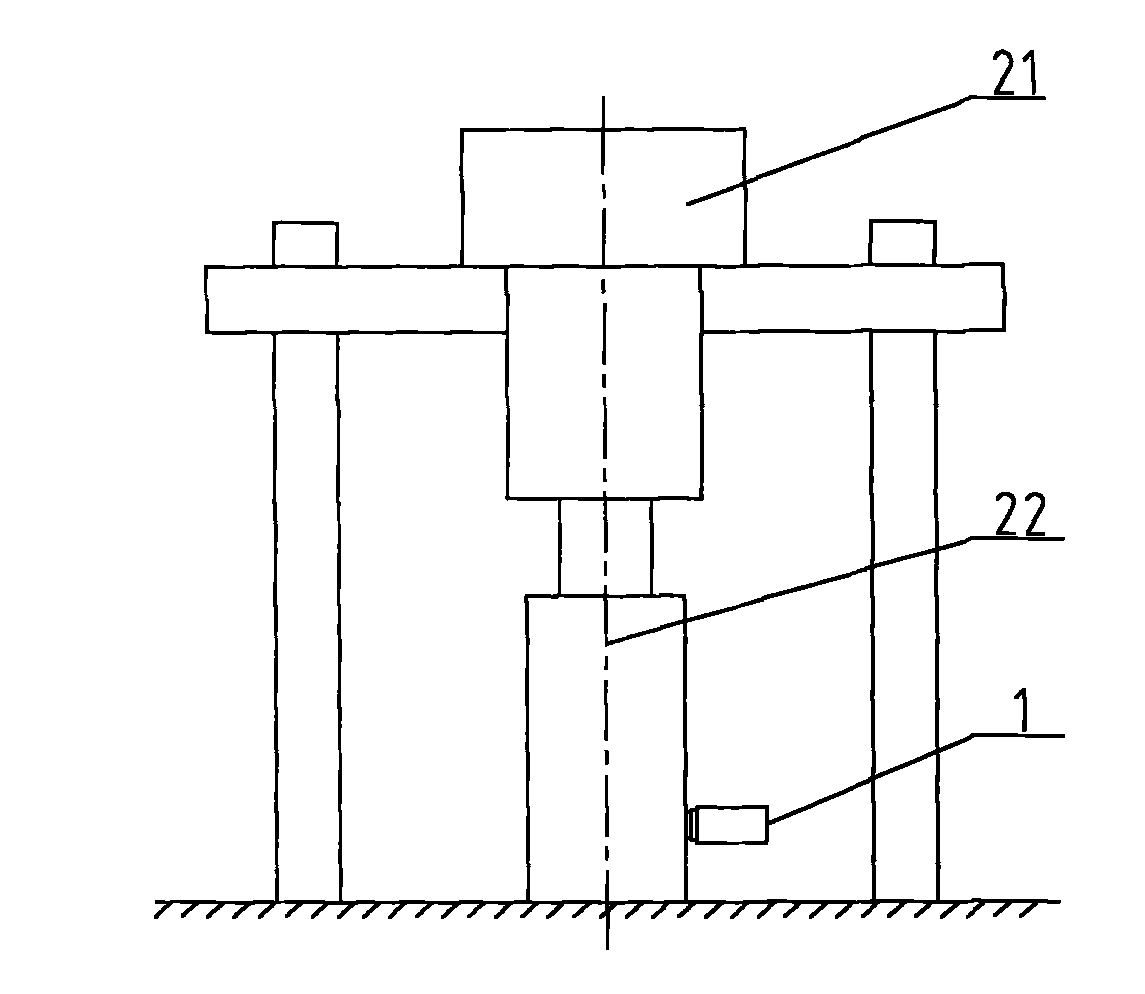

Multi-filter cylinder automatic backwashing filter apparatus

InactiveCN102794044AReduce backwash frequencyMaximum backwash frequencyStationary filtering element filtersElectric machineControl system

The invention discloses a multi-filter cylinder automatic backwashing filter apparatus. A housing is divided into an upper chamber and a lower chamber by a separation plate. The separation plate is provided with filter cylinders in the manner of one, two, or multiple concentric circles. The sidewall of the housing under the separation plate is provided with a sewage inlet, and the sidewall of the housing above the separation plate is provided with a pure water outlet. A motor of a backwashing mechanism drives a main shaft to rotate. A lifting mechanism drives the main shaft to go up and down. A multi-way connection seat connects the main shaft, rotating arms and a waste pipe together. The main shaft drives the rotating arms to lift and rotate. The waste pipe is fixed. Suction nozzles fixed on the upper end port of the rotating arms can be in sealed connection with water inlets on the separation plate. The end part of the waste pipe is connected with an electric drain valve or a pneumatic drain valve. A control system controls the actions of the motor, the lifting mechanism and the electric drain valve or the pneumatic drain valve. The filter apparatus has the advantages of small size, large amount of water filtration, high production efficiency, good filtration effect of filtered water, good backwashing effect, low frequency of backwashing, long-life apparatus, low maintenance rate, and saving backwash water.

Owner:HEBEI AGRICULTURAL UNIV. +1

Oil smoke filtering device

ActiveCN105268249AEasy to separateImprove filtering effectDomestic stoves or rangesLighting and heating apparatusFriction lossFilter effect

The invention discloses an oil smoke filtering device. The oil smoke filtering device comprise at least two vertically arranged filtering channels; the filtering channels are arranged in parallel along the transverse direction; each filtering channel is composed of adjacent vertically arranged separating plates, and possesses at least on zigzag part, so that at least one filtering channel is a zigzag channel; and oil smoke blocking parts are transversely arranged in the filtering channels. Advantages are that: filtering channel area and contact area with oil smoke of the zigzag channels are relatively large, and fluidity of grease obtained via filtering is high; resistance loss of the transverse oil smoke blocking parts arranged in the filtering channels is small, collision filtering effect on particles with different size is excellent, oil smoke separation and filtering effect can be improved effectively without obvious increasing of windage resistance, and excellent oil smoke separation efficiency is obtained via combination with the zigzag channels; the oil smoke filtering device is simple in the whole structure, is convenient for maintenance, and is suitable for oil smoke filtering of a plurality of smoke exhaust ventilators.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Extrusion pressing puffing apparatus capable of removing fibre in materials

InactiveCN101366464AReduce uneven movementLittle resistance lossFeeding-stuffAnimal feeding stuffFiberEngineering

The invention discloses an extrusion expansion device for removing fibers in materials in the feed processing device field, which comprises an extrusion cavity, wherein a screw is arranged in the extruding cavity, an outlet end of the extrusion cavity is provided with a die plate frame, the die plate frame is provided with a discharge die plate, the discharge die plate is provided with a plurality of die holes which run through the discharge die plate, the die holes are communicated with the extrusion cavity, and a blade is arranged outside the discharge die plate; a fiber hooking die plate is arranged in a channel between the discharge die plate and the extrusion cavity and is provided with a plurality of fiber hooking holes, and one side, which faces toward the extrusion cavity, of each of the fiber hooking holes is provided with an inner chamfer angle. When the device works, the fiber hooking die plate can hook the fibers to ensure that the fiber amount of a material passing through the fiber hooking die plate is reduced, material particles formed after the material passes through the fiber hooking die plate and is cut by the blade have smooth and beautiful surfaces, the blade is difficult to hook the fibers, and the abrasion of the blade can be reduced. The device is particularly suitable to be used for the expansion processing of aquatic feed with large fiber amount.

Owner:JIANGSU MUYANG GRP CO LTD

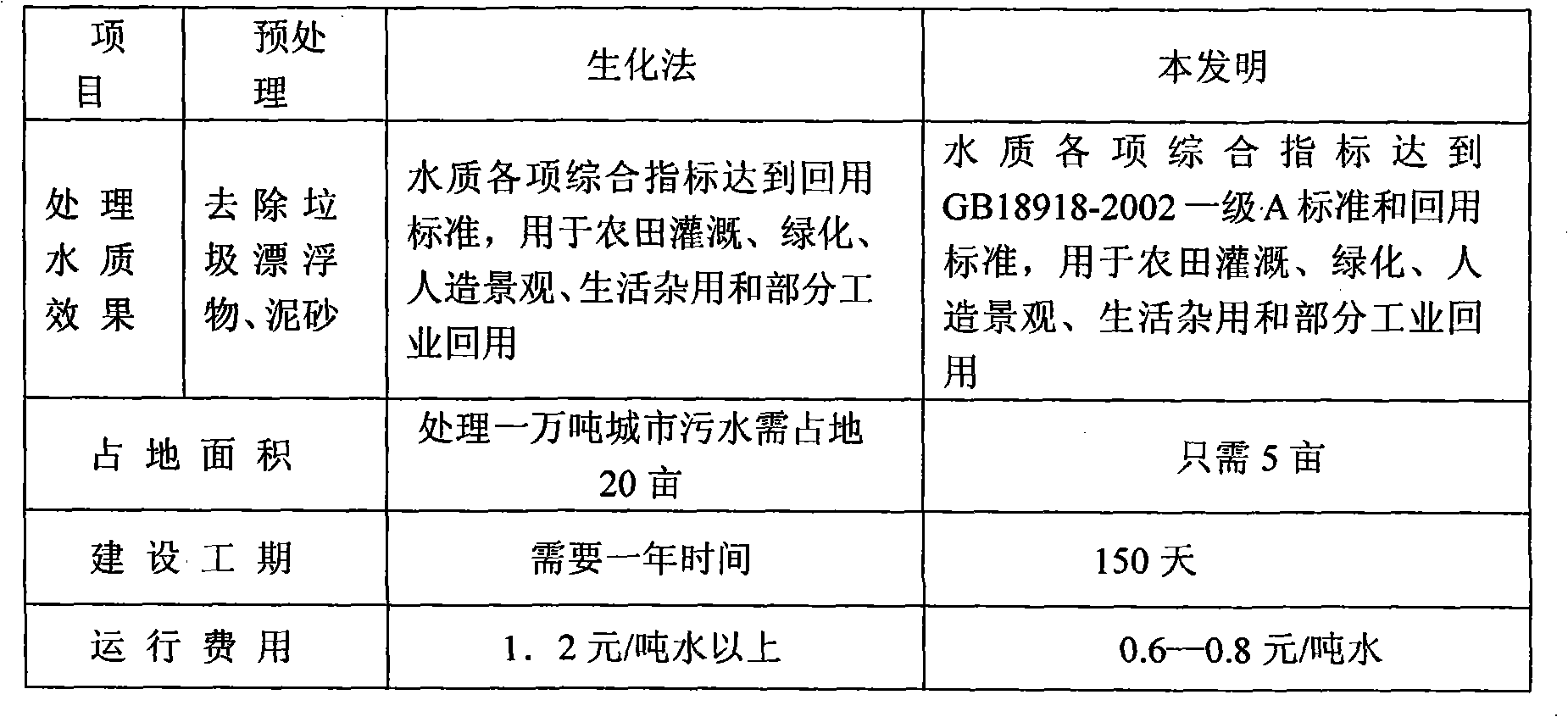

Zero-discharge purifying treatment method for mine wastewater and mine domestic sewage

InactiveCN101565247AHigh densityGood water permeabilityWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFlocculationImpeller

The invention relates to a zero-discharge purifying treatment method for mine wastewater and mine domestic sewage. The method adopts the technical scheme that after the sewage passes through a grid, the supernatant enters in an equalizing tank; the sewage after pretreatment enters in a lifting pump sump for a purifier, when the sewage water level in the lifting pump sump for the purifier is raised to the upper limit water level, a composite water treatment agent in a chemical feeder and the sewage simultaneously pass through a lifting pump impeller and a pipeline mixer and then enter in a nanofihration circulating purifier after being sufficiently mixed, the sewage and the composite water treatment agent rapidly form a flocculation cake layer in the nanofihration circulating purifier and the sewage is filtered through the flocculation cake layer; the filtrate enters in a high-efficiency denitriding purifier through an intermediate pool and stays for 2-4 h; the sewage after secondary treatment enters in a strong-carbon adsorption purifier for purification; the purified water enters in a water purifying tank and a disinfectant is added. The invention has the advantages that the cost is low, and the water quality after treatment can meet the standard of the regenerated recycle-water.

Owner:邢殿满

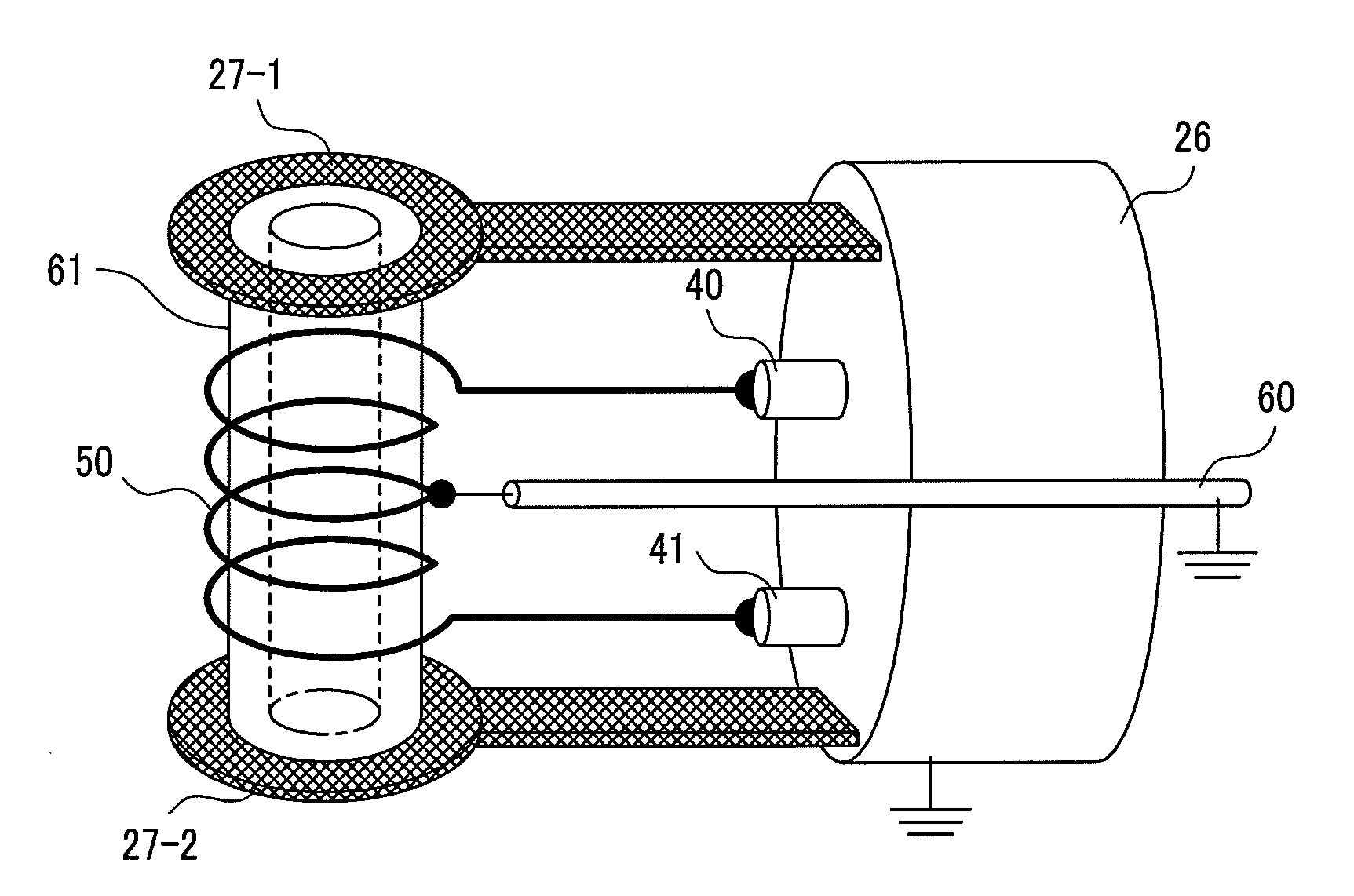

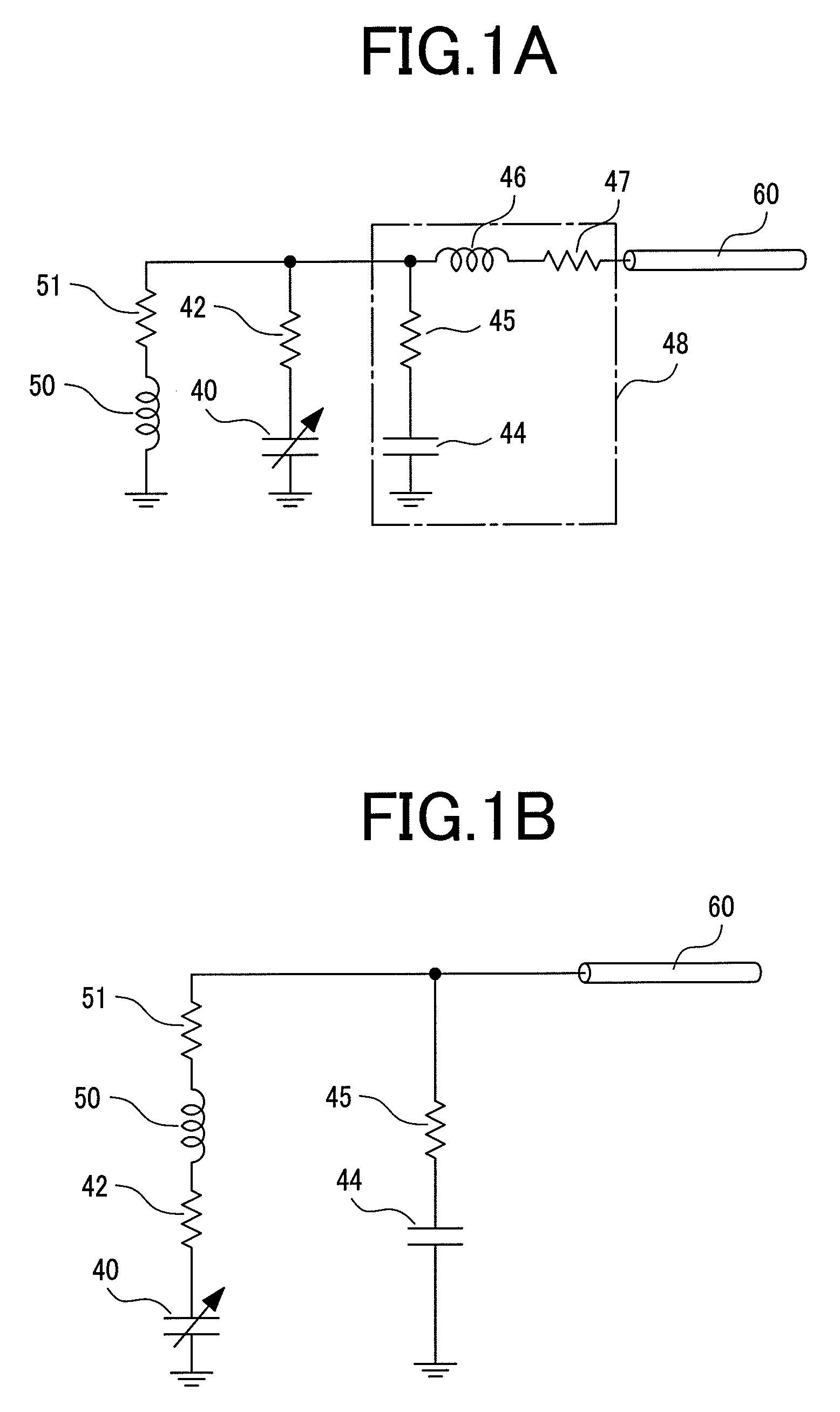

Nmr probe and nmr spectrometer

InactiveUS20080111548A1Little resistance lossIncrease the number of lapsElectric/magnetic detectionMeasurements using magnetic resonanceCapacitanceResonance

A signal line is drawn from a generally middle point of the antenna coil, and a capacitance-variable capacitors are connected at both sides of the antenna coil. This structure realizes a circuit in which a series resonance circuit composed of an antenna coil and a capacitor and an another series resonance circuit composed of an another antenna coil and an another capacitor are connected in parallel to each other across the generally middle point of the antenna coil to which the signal line is connected. Through the control of the resonance frequencies of the series resonance circuits, the parallel resonance frequency of the whole antenna is tuned to a desired frequency, and the resonance characteristic in which the impedance is matched to a specific value, e.g., 50 Ω, can be achieved.

Owner:HITACHI LTD

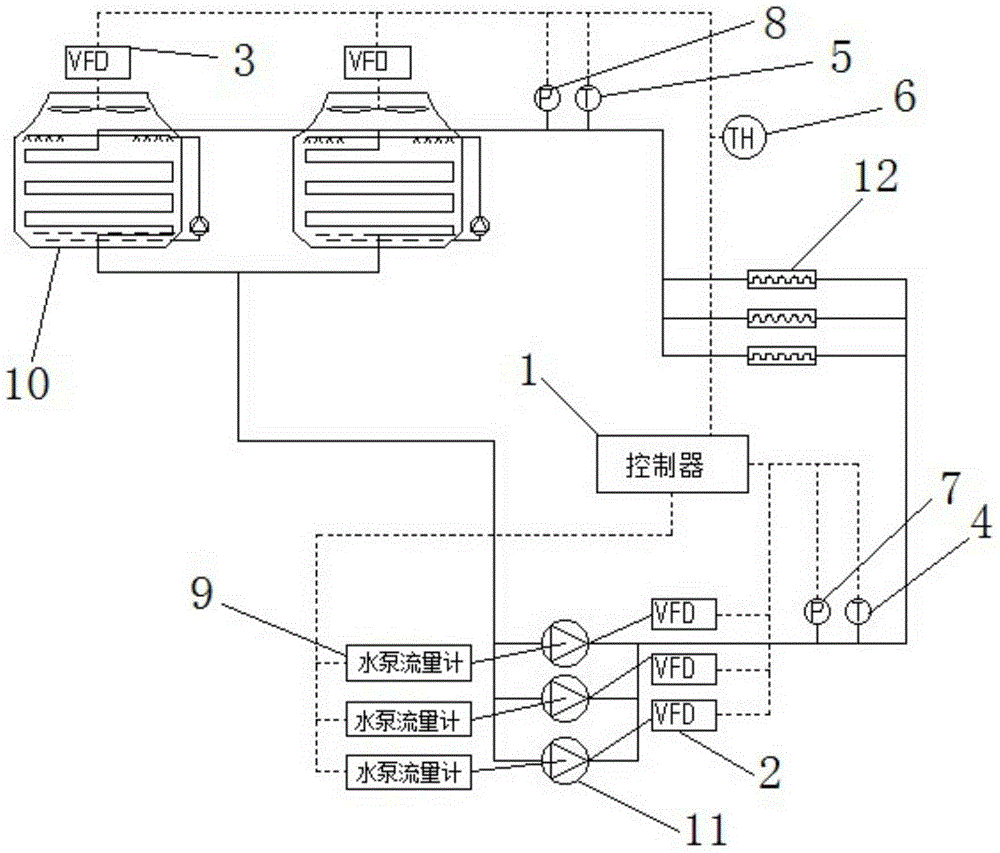

Energy-saving control device and method for closed cooling circulation system

InactiveCN104534917ARealize real-time dynamic controlReduce power consumptionHeat exchange apparatusFrequency changerCooling tower

The invention discloses an energy-saving control device and method for a closed cooling circulation system. The energy-saving control device comprises a controller, frequency converters, water supply pipe temperature sensors, a water return pipe temperature sensor, an outdoor air temperature and humidity sensor, a water supply pipe pressure sensor, a water return pipe pressure sensor and water pump flowmeters, wherein the frequency converters, the water supply pipe temperature sensors, the water return pipe temperature sensor, the outdoor air temperature and humidity sensor, the water supply pipe pressure sensor, the water return pipe pressure sensor and the water pump flowmeters are connected with the controller. The energy-saving control method includes the steps that (1), the flow of cooling water pumps is adjusted and maintained through PID; (2), the operation number of the cooling water pumps is dynamically adjusted; (3), a cooling water supply temperature setting value is dynamically adjusted, and the rotating speed of a closed type cooling tower fan is controlled. Information of operation parameters of the closed cooling circulation system is collected dynamically, the temperature of the cooling water can be controlled stably, the heat dissipating capacity of heat exchange equipment at the tail end is stable, and energy consumption of the closed cooling circulation system is effectively reduced.

Owner:SHENZHEN FUWO DESI TECH CO LTD

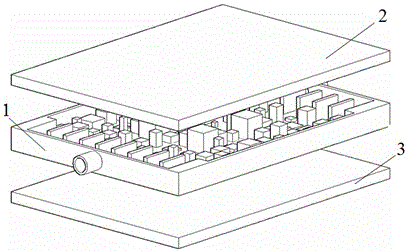

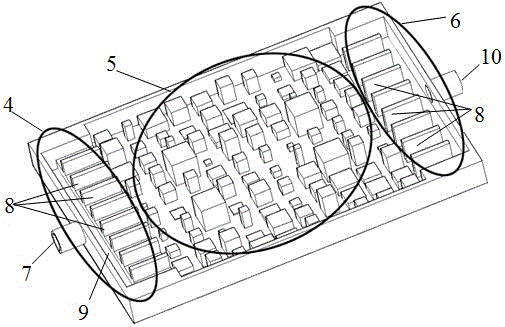

Flowing boiling micro-miniature heat exchanger

ActiveCN106061199AUniform temperatureExtend your lifeCooling/ventilation/heating modificationsEngineeringHeat transfer efficiency

The invention discloses a flowing boiling micro-miniature heat exchanger, which comprises a heat exchanger casing, a heat exchange structure passage, an inlet passage and an outlet passage, wherein the heat exchange structure passage is arranged in the heat exchanger casing; and the inlet passage and the outlet passage are arranged at the two ends of the heat exchange structure passage. The flowing boiling micro-miniature heat exchanger is characterized in that the inlet passage consists of a condensing medium input opening, a flow storage pool and an inlet flow division passage; the flow storage pool is connected between the condensing medium input opening and the inlet flow division passage; the outlet passage consists of a condensing medium output opening and an outlet flow division passage; a micro rib column group and support columns are arranged in the heat exchange structure passage; the micro rib column group consists of micro rib columns; the cross section dimension of the micro rib columns conforms to the fractal Brownian motion features; the micro rib columns are in planar distribution; the height of the micro rib columns meets the normal distribution; and the support columns are distributed in the center of the micro rib column group in an array mode. The flowing boiling micro-miniature heat exchanger has the advantages that the heat transfer efficiency is high; the flowing resistance loss is small; the surface temperature of the heat exchanger is uniform; the work is stable; and the service life is long.

Owner:SOUTHEAST UNIV

Planetary gearing for a dual clutch transmission

ActiveUS7175563B2Significant fuel economy improvementLower gear mesh lossToothed gearingsTransmission elementsGear systemEngineering

A multiple speed transmission includes first and second input clutches driveably connected to an input, and a gear system that includes four planetary gear units, each gear unit including a sun gear, a ring gear, planet pinions meshing with the sun gear and ring gear, and a carrier rotatably supporting the planet pinions. A first coupler releasably engages the first input clutch alternately with the sun gear of the first gear unit and the ring gear of the first gear unit. A second coupler releasably engages the sun gear of the fourth gear unit alternately with the sun gear of the second gear unit and the carrier of the fourth gear unit. A third coupler releasably engages a ground member alternately with the ring gear of the fourth gear unit and the ring gear of the third gear unit. A fourth coupler releasably engages a ground member alternately with the sun gear of the second gear unit and the carrier of the second gear unit. The first and second input clutches and the four couplers are engaged in multiple combinations to establish forward speed ratios and a reverse speed ratio between the input and output.

Owner:FORD GLOBAL TECH LLC

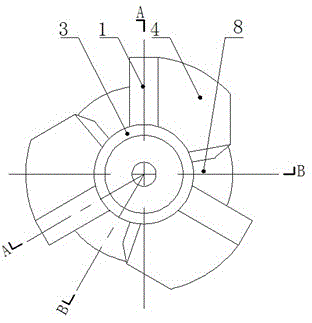

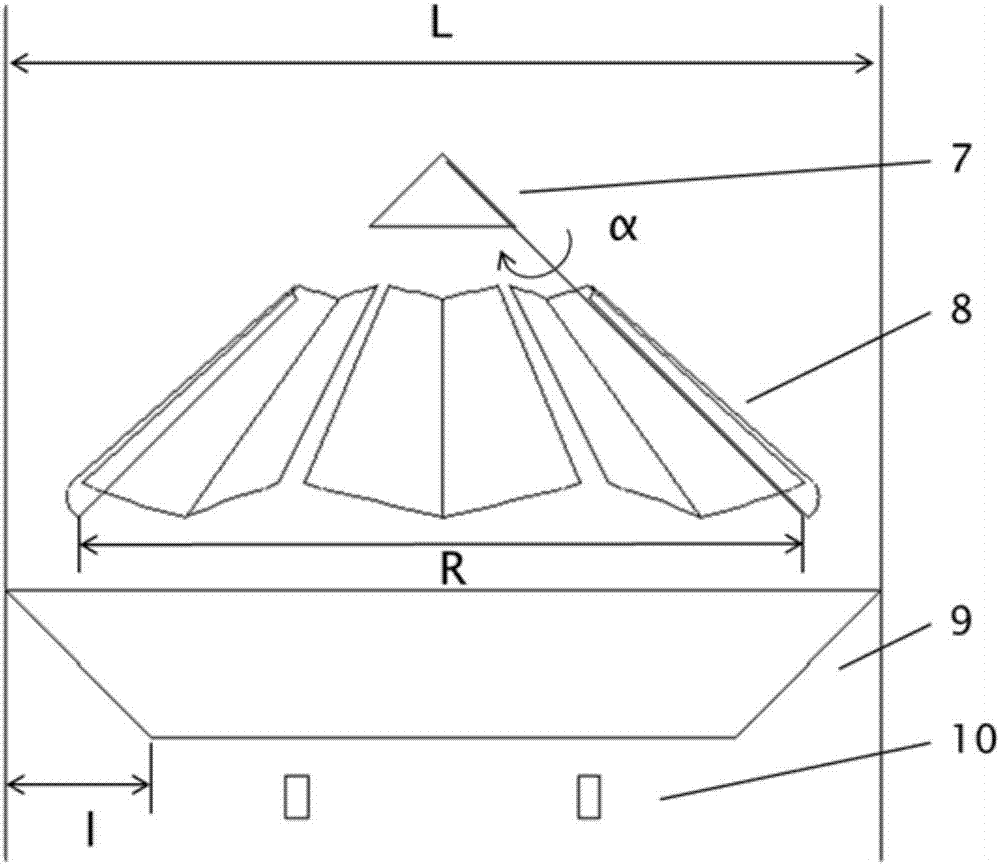

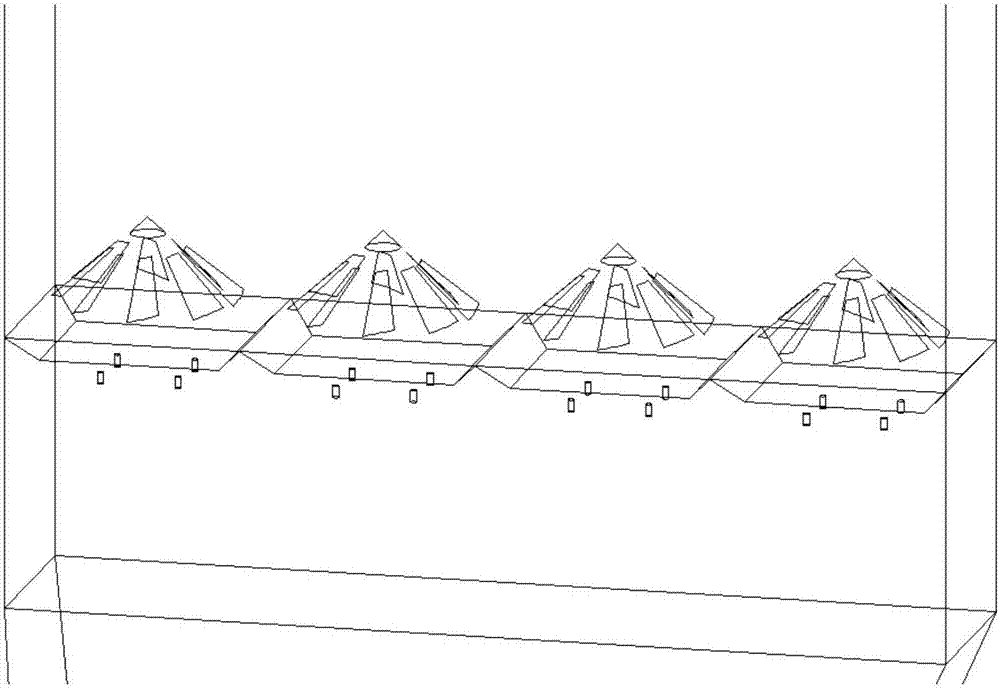

Demister for desulfurization tower

ActiveCN105107277ALittle resistance lossReduce in quantityDispersed particle separationSmall particleLarge particle

Provided is a demister for a desulfurization tower. The demister is characterized by comprising a supporting ring, a supporting shaft located in the middle of the supporting ring, and a plurality of blades which are distributed around the supporting shaft and fixed between the supporting ring and the supporting shaft. Each blade comprises two blade units connected together and a hook blade body bent towards the lower portion of the outer side, the sections of the blade units are in an upwards-protruding arc shape, and each hook blade body is connected below one of the two blade units of each blade. The blades are inclined upwards from the blade units connected with the hook blade bodies to the other blade units. Compared with the prior art, the demister has the advantages that large-particle solids and small-particle solids can be removed at the same time, meanwhile, resistance losses can be reduced, the number of flushing devices can be reduced, the demisting effect of the desulfurization tower can be improved, and the investment cost and running cost of the desulfurization tower are reduced.

Owner:佛山赛因迪环保科技有限公司

Vortex combined SCR static mixer

The invention discloses a vortex combined SCR static mixer, comprising a tip body, a plurality of arc flow deflectors with an axis where the tip body is located as a center axis, and a plurality of baffle plates uniformly distributed, with the axis as a center axis, on the lower ends of the flow deflectors, wherein the baffle plates allows flue gas to gather at an ammonia gas nozzle; the arc flow deflectors allow flue gas and ammonia gas to generate transverse speed and to spirally flow upward; and gas flow located at a central area and not directly influenced by the arc flow deflectors staggerly flows relative to peripheral gas flow after bumping onto the tip body, so flue gas and ammonia gas are mixed. The vortex combined SCR static mixer provided by the invention is beneficial for promoting diffusion of ammonia gas, greatly improves mixing effect, enhances the mol ratio uniformity of ammonia and nitrogen and exerts good effect on optimization and synergism of a SCR denitration system.

Owner:SHANDONG UNIV

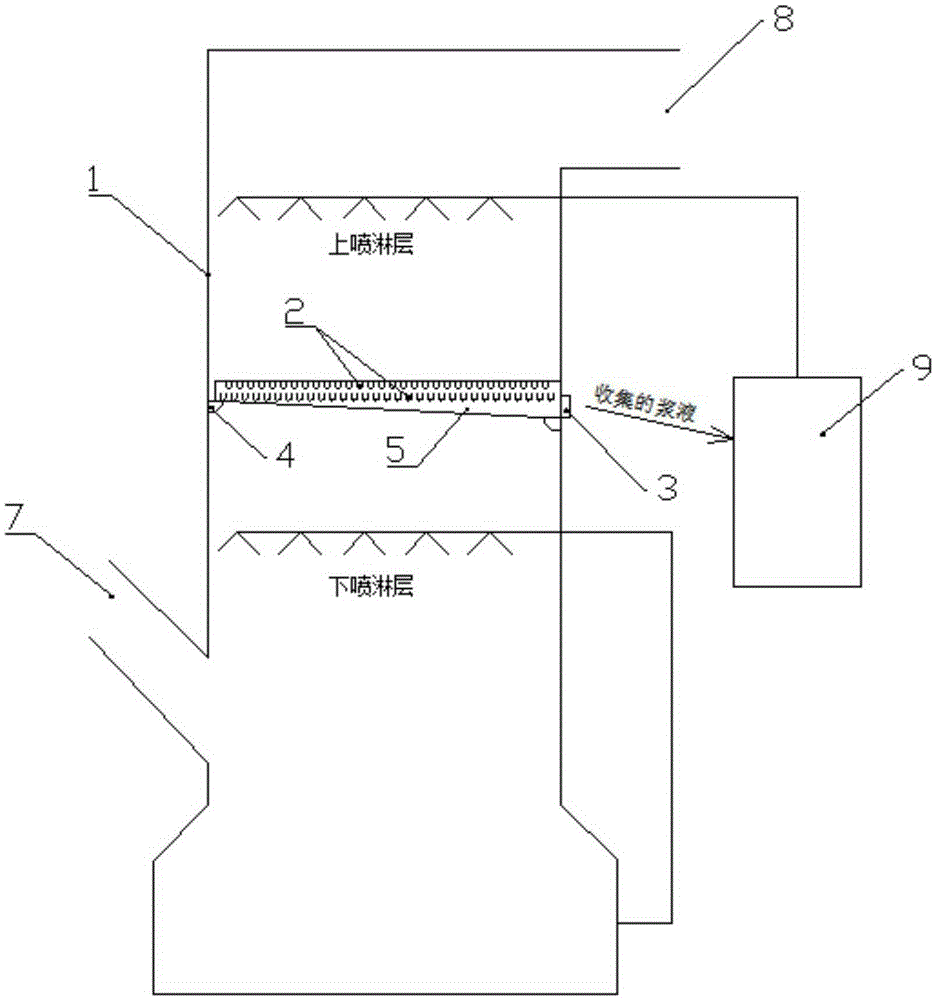

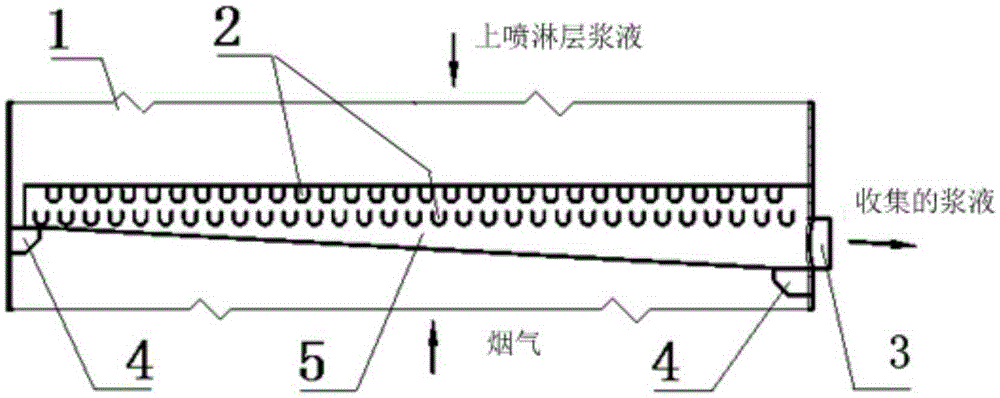

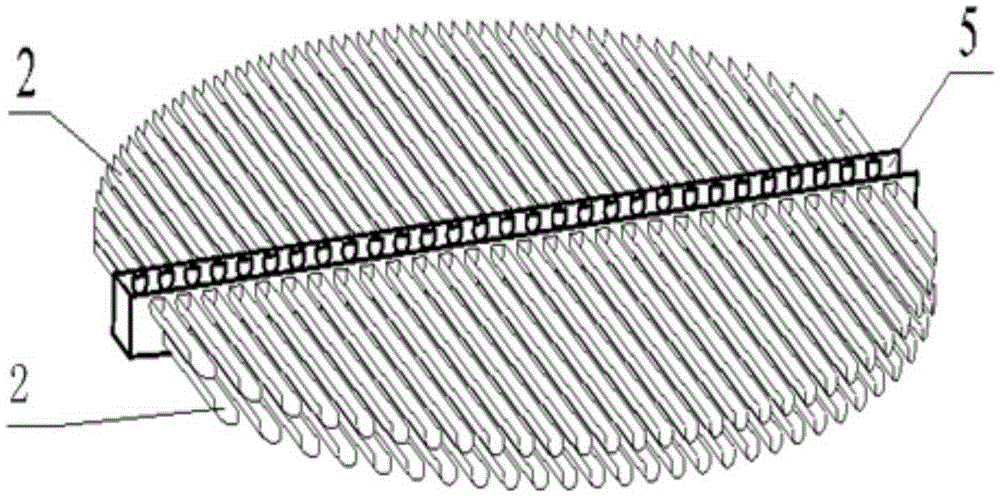

Single-tower dual-cycle wet flue gas desulfurization tower and tube groove type liquid collection device

ActiveCN105413444ALittle resistance lossReduce resistanceGas treatmentDispersed particle separationFlue gasFriction loss

The invention provides a single-tower dual-cycle wet flue gas desulfurization tower and a tube groove type liquid collection device, and belongs to the technical field of flue gas desulfurization. The desulfurization tower comprises a tower body, the bottom of the tower body is provided with a flue gas inlet, the top of the tower body is provided with a flue gas outlet, an upper spray layer and a lower spray layer are arranged on the portion, between the flue gas inlet and the flue gas outlet, inside the tower body, and the tube groove type liquid collection device is installed between the upper spray layer and the lower spray layer and separates slurry of the upper spray layer from slurry of the lower spray layer; the tube groove type liquid collection device comprises multiple liquid collection tube grooves which are formed for multiple layers in the longitudinal direction, the two adjacent layers of the liquid collection tube grooves are arranged in a staggered mode, the liquid collection tube grooves are arranged in an inclined mode, and the lower ends of the liquid collection tube grooves are communicated with a diversion groove. According to the single-tower dual-cycle wet flue gas desulfurization tower and the tube groove type liquid collection device, the flow field is uniformly distributed, the resistance loss of the structural design is small, and the contact effect between the gas and liquid is good. Therefore, the slurry of the upper spray layer can be collected, the system resistance can be reduced, and the desulphurization efficiency is improved.

Owner:SHANDONG UNIV

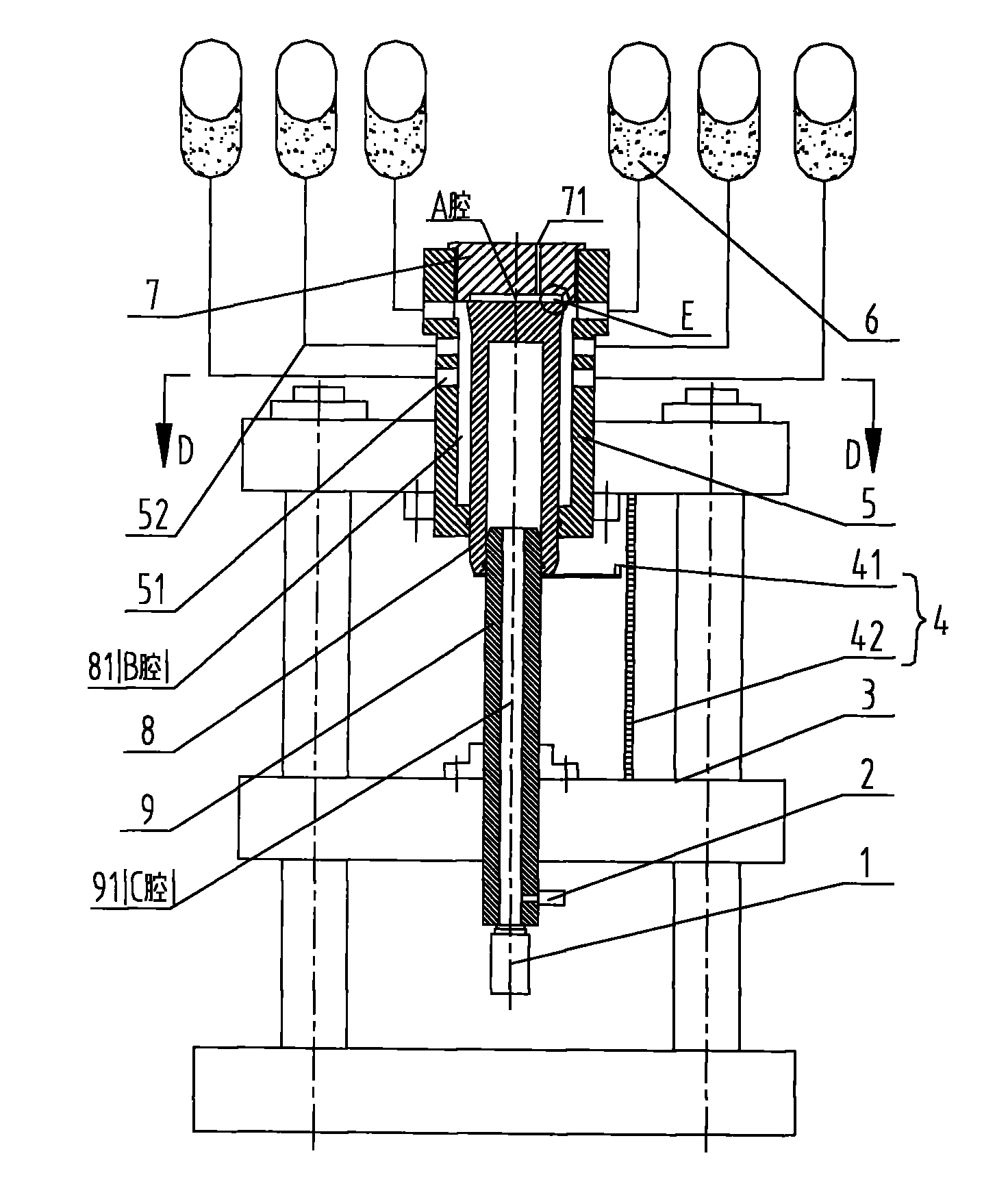

Quickly loading booster cylinder and high-flow safety valve test device using same

ActiveCN102072219ASmall pressure output areaMeet the needs of dynamic testingFluid-pressure actuator testingProps/chocksHydraulic cylinderEngineering

The invention discloses a quickly loading booster cylinder and a high-flow safety valve test device using the same, which relate to the field of hydraulic bracket safety valves for mines and are invented for providing a practical test device for a high-flow safety valve. The quickly loading booster cylinder comprises a hydraulic cylinder (5), wherein an upper plunger (8) is arranged in the hydraulic cylinder (5) in a sliding manner; a lower plunger (9) is arranged in the upper plunger (8); a tested safety valve (1) is arranged at one end of the lower plunger (9); a liquid inlet (51) is formed in the cylinder wall of the hydraulic cylinder (5); and a control port (71) is formed at the cylinder bottom (7) of the hydraulic cylinder (5). The invention also discloses the high-flow safety valve test device. The quickly loading booster cylinder and the high-flow safety valve test device have short raising time of the output pressure and low resistance loss, are quickly started and are applied to the flow and dynamic performance test of the high-flow safety valve.

Owner:CCTEG CHINA COAL RES INST

Differential pressure air speed detection and control device

InactiveCN101862035AStop stayingEliminate adhesionCigarette manufactureBulk conveyorsDifferential pressureEngineering

The invention relates to a differential pressure air speed detection and control device, which comprises an air-conveying de-dusting branch pipe, an electric (pneumatic) adjustment butterfly valve, a cut tobacco collecting box of a cigarette making machine, a cut tobacco conveying pipeline and a differential pressure flowmeter, and is characterized by also comprising a split type orifice flowmeter arranged on the air-conveying de-dusting branch pipe, wherein the differential pressure flowmeter is a split type venturi flowmeter and is arranged on the cut tobacco conveying pipeline, and the speed measuring pipe diameter of the venturi flowmeter gradually becomes small and then gradually becomes large. The invention eliminates the phenomena of cut tobacco retention, adhesion and blockage, is more suitable for detection of cut tobacco material flow in the cut tobacco conveying pipeline, and can maintain long-term operation of high-precision detection to ensure the effective operating ratio and reliability of a system.

Owner:扬州市天宝自动化工程有限公司

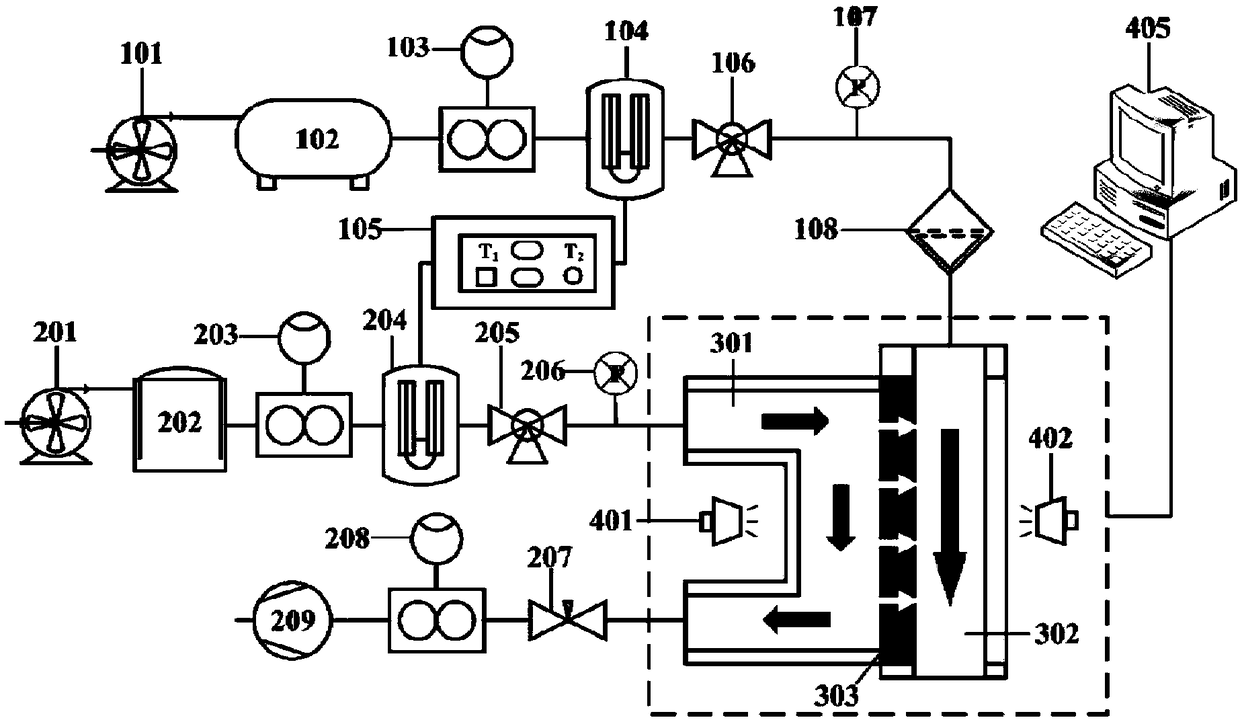

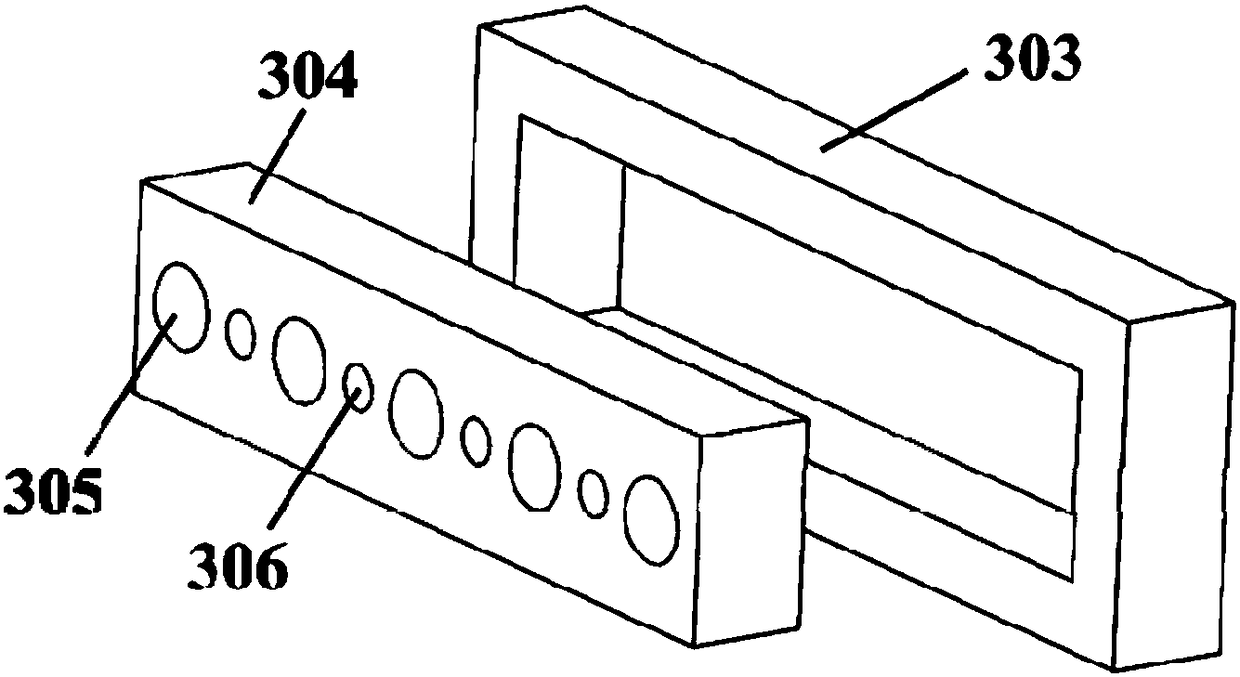

Blade tip coupled cooling experiment system for turbine blades of gas turbine

ActiveCN108613814AExperimental research is simpleFacilitate experimental researchGas-turbine engine testingJet-propulsion engine testingTemperature controlTurbine blade

The invention discloses a blade tip coupled cooling experiment system for turbine blades of a gas turbine. The blade tip coupled cooling experiment system comprises a high temperature main flow channel, a U-shaped cooling channel, an experimental test section and a data acquisition and analysis system, wherein the high temperature main flow channel comprises a temperature control box, and a main flow gas pump, a main flow gas flow stabilization tank, a main flow gas heater and a main flow three-way electromagnetic valve which are sequentially connected; the U-shaped cooling channel comprises acold flow outlet vacuum pump, and a cold flow inlet gas pump, a cooling gas flow stabilization tank, a cooling gas heater and a cold flow inlet three-way electromagnetic valve which are sequentiallyconnected; the experimental test section comprises a U-shaped cooling channel, a high-temperature main flow channel and a blade tip plate with a through hole in the center, and an embedded plate is embedded in the through hole; the data acquisition and analysis system comprises a cooling channel infrared thermal imager, a main flow channel infrared thermal imager, a CCD camera, and a data acquisition and analysis computer connected with the cooling channel infrared thermal imager, the main flow channel infrared thermal imager and the CCD camera; and an outlet of the main flow three-way electromagnetic valve is communicated to an inlet of the high temperature main flow channel, and an outlet of the cold flow inlet three-way electromagnetic valve is communicated to an inlet of the U-shaped cooling channel.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com