Gas-liquid two-phase flow metering device and method

A gas-liquid two-phase flow and metering device technology, applied to measuring devices, instruments, etc., can solve the problems of phase separation and measurement error increase, and achieve the effect of small resistance loss and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

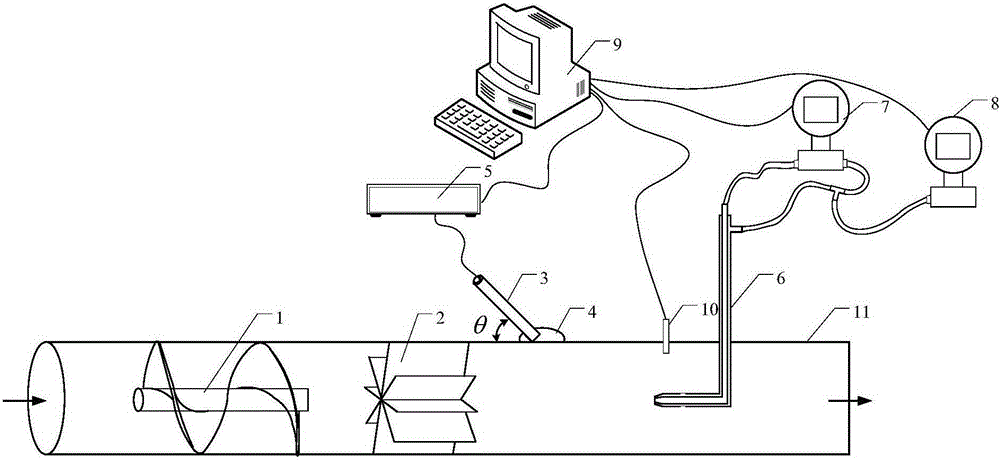

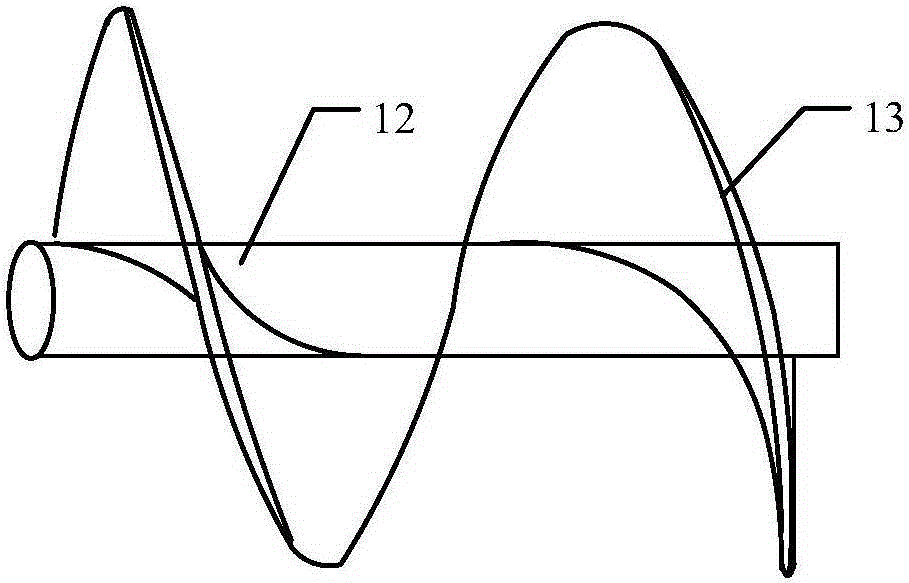

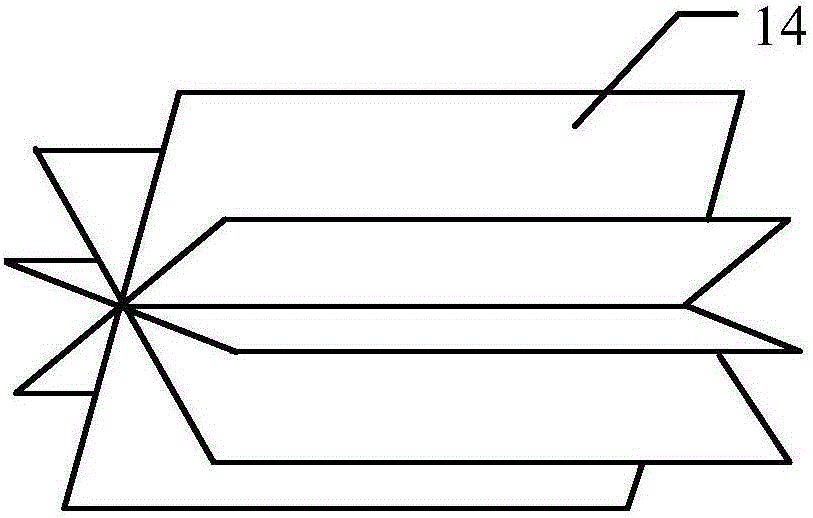

[0039] Such as figure 1 As shown, a gas-liquid two-phase flow metering device according to the present invention mainly includes a cyclone 1, a rectifier 2, an ultrasonic probe 3, an ultrasonic Doppler flow meter 5, a pitot tube 6, a differential pressure sensor 7 and data The acquisition computer 9, the cyclone 1, the rectifier 2, and the pitot tube 6 are sequentially arranged inside the pipeline 11 to be tested along the flow direction of the gas-liquid two-phase fluid. The Doppler flow meter 5 and the differential pressure sensor 7 are respectively connected to the data acquisition computer 9 through data lines.

[0040] The ultrasonic probe 3 is located on the outer wall of the pipeline 11 to be tested between the rectifier 2 and the pitot tube 6, and the angle θ between the ultrasonic probe 3 and the direction of the gas-liquid two-phase flow in the pipeline 11 to be tested is 50° to 70°. °. In order to enhance the ultrasound transmission effect, the gap between the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com