Signal processing method of automatic zero-point electromagnetic flow meter system thereof

An electromagnetic flowmeter and signal processing technology, applied in the application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effect, and measure flow/mass flow, etc. Correction, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

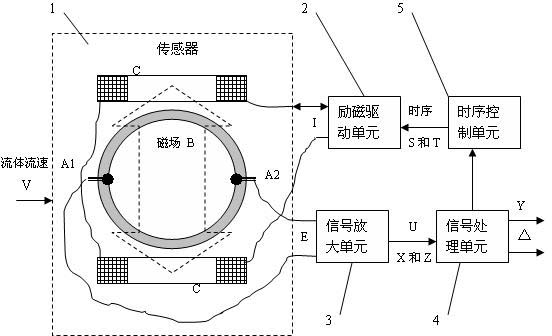

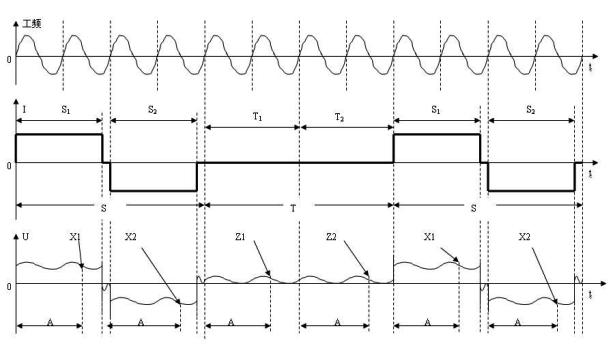

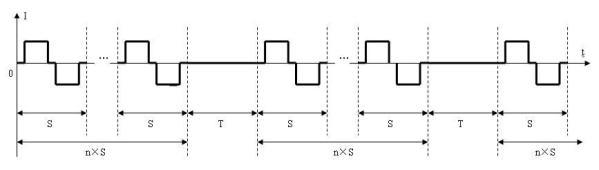

[0024] see figure 1 , the electromagnetic flowmeter signal processing method of automatic zero point, the processing system that adopts comprises a sensor 1, an excitation drive unit 2, a signal amplification unit 3, a signal processing unit 4 and a sequence control unit 5; Make described excitation drive unit 2 Output the excitation current I according to the timing S of the timing control unit 5 to generate an excitation magnetic field B in the sensor 1; the measured fluid with a flow velocity V flows through the sensor 1 so that the sensor 1 outputs an induced potential signal E, and the signal amplification unit 3 After the induced potential signal E is amplified, the signal U=X is output, and the value of the signal U=X is collected by the signal processing unit 4 to estimate the value of the fluid velocity V flowing through the sensor 1; it is characterized in that the timing S of the timing control unit 5 In this working period T, the excitation current I=0 of the excit...

Embodiment 2

[0029] see figure 1 , the automatic zero point electromagnetic flowmeter signal processing system, used for the above automatic zero point electromagnetic flowmeter signal processing method, including a sensor 1, an excitation drive unit 2, a signal amplification unit 3, a signal processing unit 4 and a sequence control unit 5. The output of the sensor 1 is output to the signal processing unit 4 after the signal amplifying unit 3, and the signal processing unit 4 is connected to the excitation driving unit 2 through the timing control unit 5, and the excitation driving unit 2 Outputting the excitation current I causes the excitation magnetic field B to be generated in the sensor 1; the timing control unit 5 outputs the timing S so that the excitation drive unit 2 is divided into working periods S 1 and S 2 Use I=I respectively 1 The constant current sum with I=I 2 =- I 1 The constant current works in the forward and reverse constant current excitation mode, so that the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com