Alignment instrument measurement and adjustment method for generator coupled wheel shaft system

An adjustment method and generator technology, applied in the direction of measuring devices, measuring instruments, instruments, etc., can solve the problems of time-consuming and manpower, and achieve the effects of high accuracy, high calculation accuracy, and fast and convenient centering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

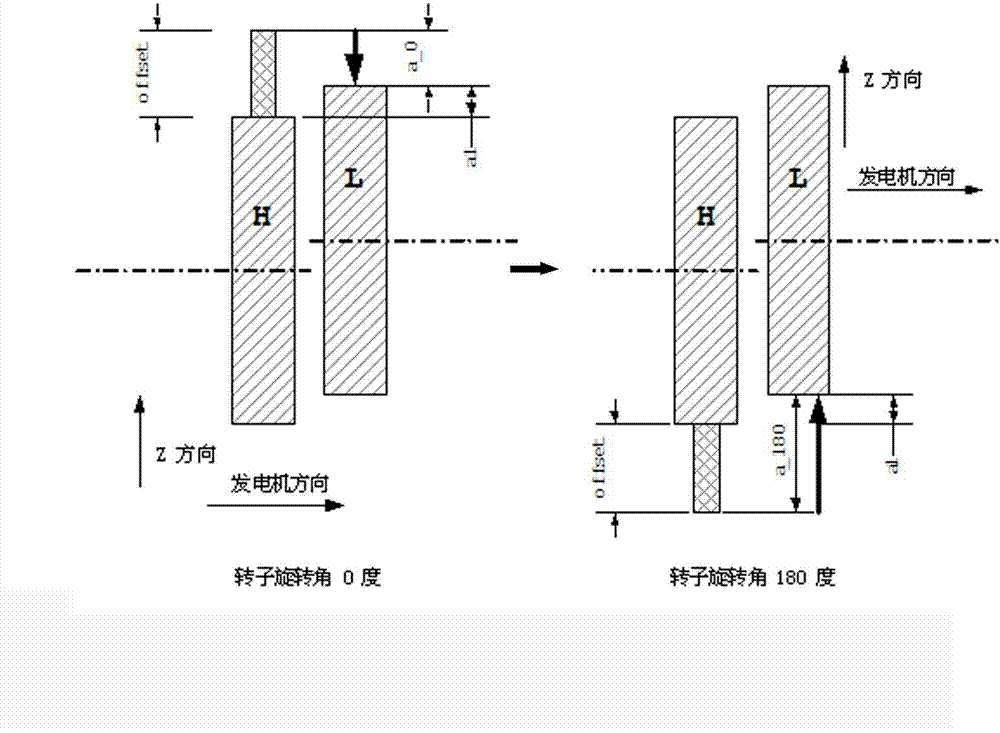

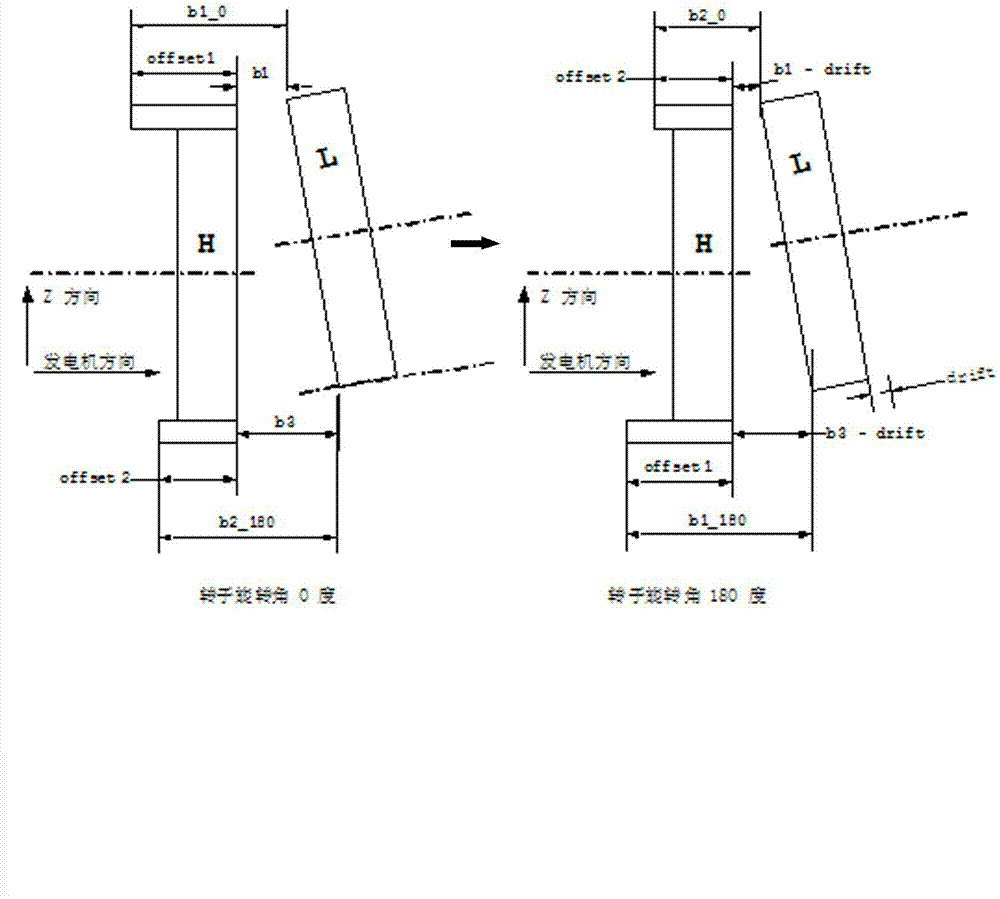

[0018] As we all know, there are the following four parameters to be measured for the offset of the two shaft centers of a set of counter wheels. The up and down offset a1 of the center of the two axes, and the left and right offset a2. The upper and lower openings b1, b3 of both ends, and the left and right openings b2, b4.

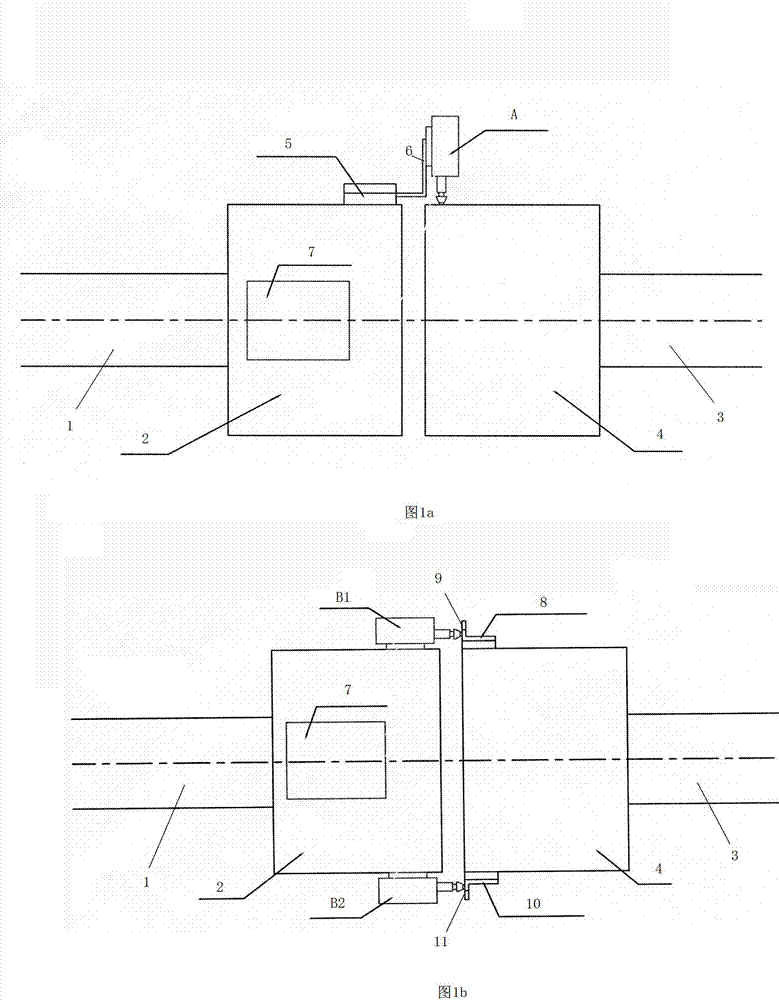

[0019] In order to detect the above-mentioned offset, it is necessary to install a first displacement sensor for measuring the circumferential offset and a second displacement sensor for measuring the displacement of the end face opening on the above-mentioned set of counter wheels. Fix the first displacement sensor A perpendicular to the axial direction on one wheel of the generator pair for measuring the circumferential offset of the other wheel, and fix the second displacement sensor A parallel to the axial direction on one of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com