Thermal flowmeter

A thermal flow meter and flow technology, applied in the field of flow meters, can solve problems such as errors and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

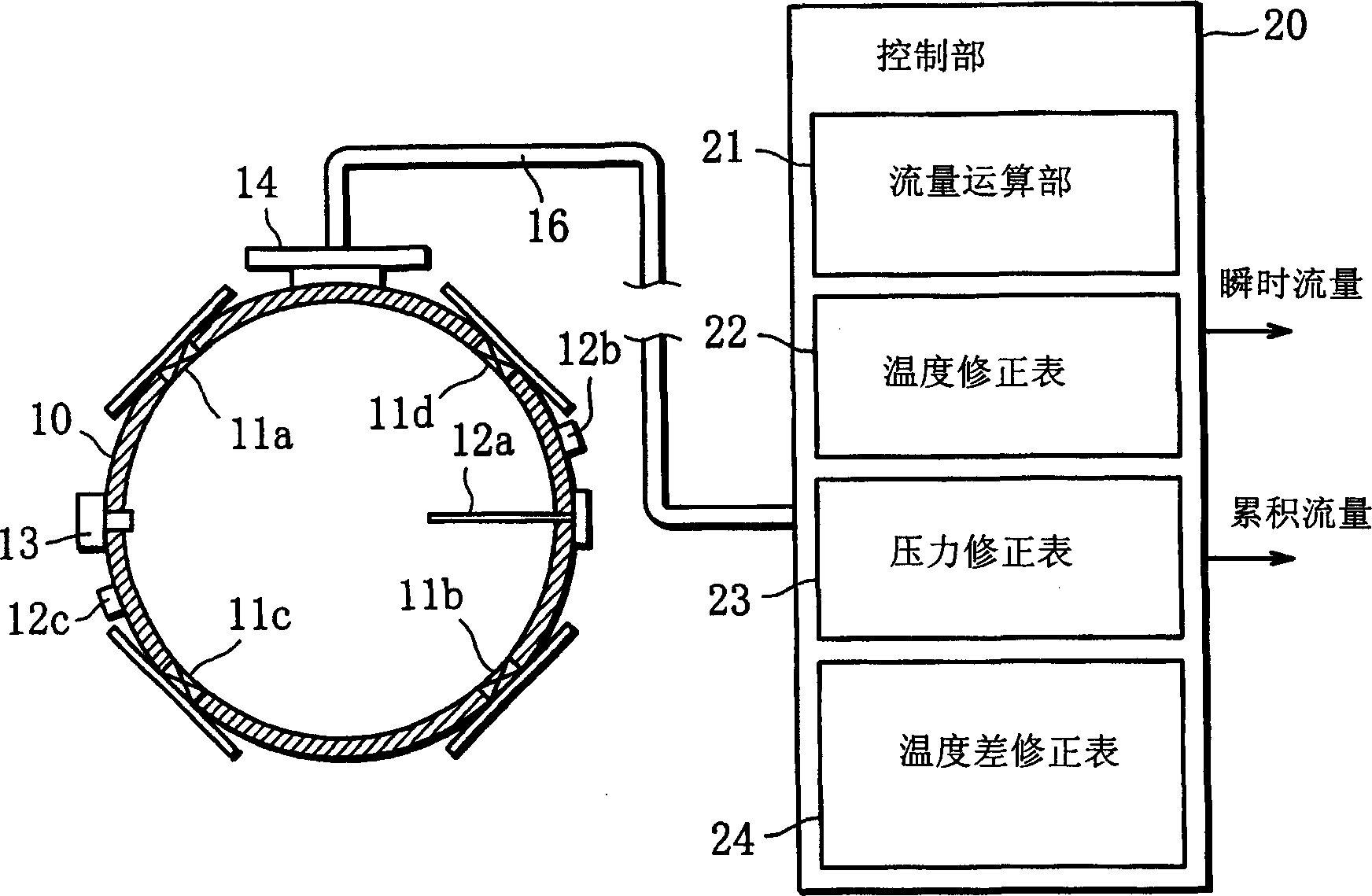

[0035] Hereinafter, a thermal flowmeter according to one embodiment of the present invention will be described with reference to the drawings.

[0036] The thermal flow meter of the present embodiment is configured as a gas meter for measuring the flow rate of gas flowing through a fluid passage formed by pipes. Such as figure 1 As shown, the gas meter includes a plurality of, for example, four thermal flow sensors 11a, 11b that are arranged on the outer wall of the pipeline 10 and respectively send outputs indicating the gas flow rate (more generally, the fluid flow rate) flowing through the pipeline 10. , 11c, 11d; the first temperature sensor 12a for detecting the gas temperature; the second temperature sensor 12b, 12c for detecting the temperature of the pipeline 10; and the pressure sensor 13 for detecting the gas pressure.

[0037] More specifically, each of the thermal flow sensors 11a to 11d basically has a Figure 5 The sensor strip 1 shown has the same structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com