Reactor internal on lower part of reactor

A technology for reactors and internal components, which is applied in the directions of reactor fuel elements, reactors, moderators/core structures, etc., can solve the problems of high structural resistance coefficient and high risk, reduce the resistance loss along the way, improve the distribution effect, The effect of meeting the allowable value of ingress flow distribution deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

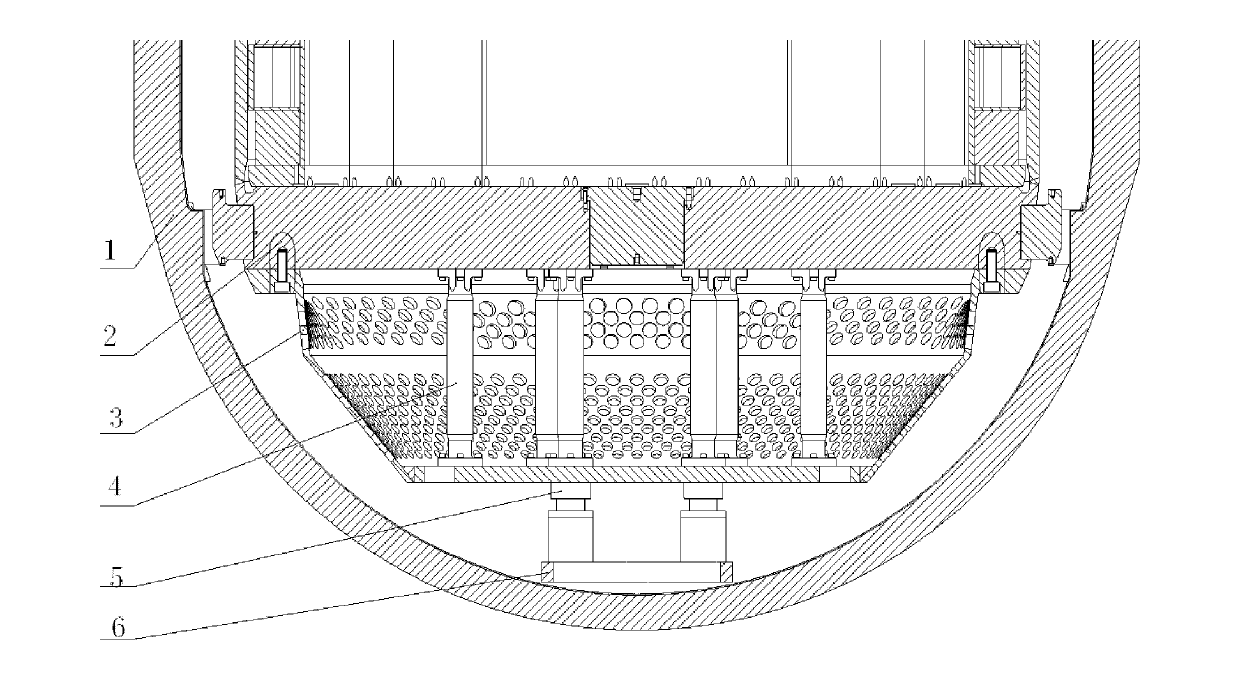

[0023] The present invention includes a reactor pressure vessel 1 , a core and a flow distribution device 3 .

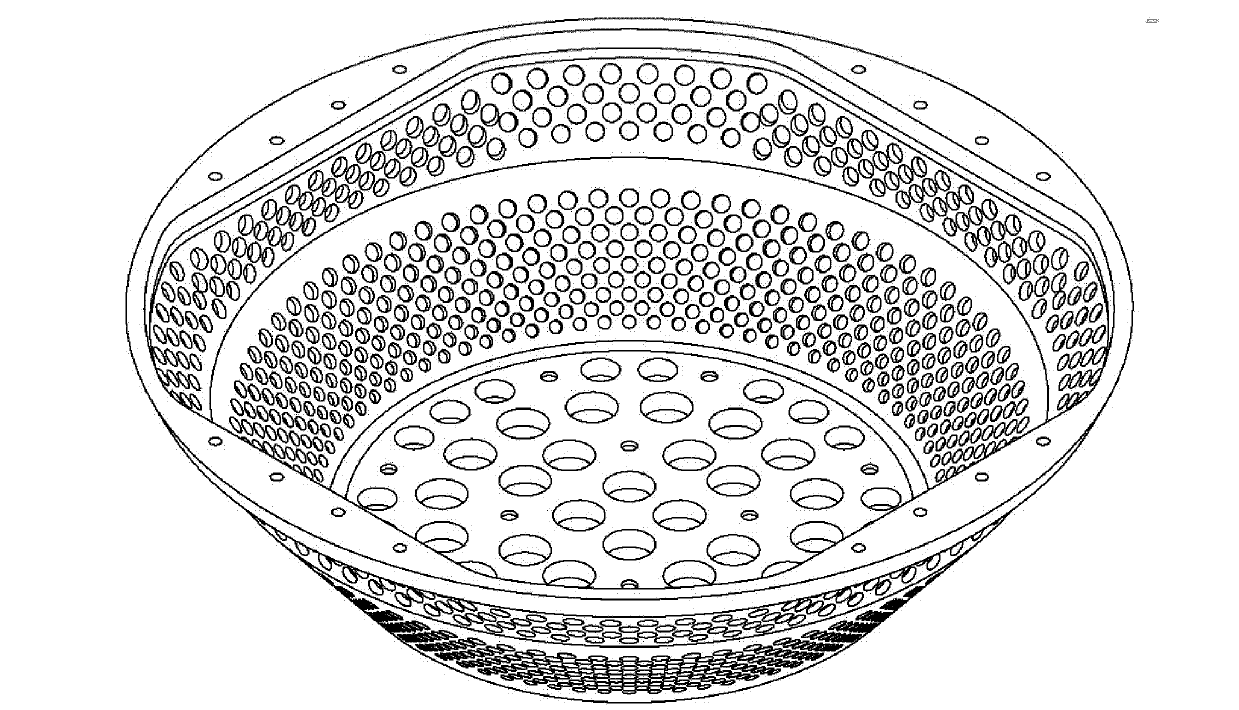

[0024] The core is placed inside the reactor pressure vessel 1 . The core supporting lower plate 2 is usually a large-diameter circular plate, and the fuel assembly positioning pins are placed on the plate to support the fuel assembly. A large number of through holes are machined on the lower plate 2 of the core support, usually four for one set of fuel assemblies. The coolant enters the core through these through holes and cools the core.

[0025] The flow distribution device 3 includes an upper distribution ring, a middle distribution ring and a lower distribution plate. The circumferential side wall of the upper distributing ring is provided with circular holes of continuous distribution with equal diameters, and the top circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com