High-pressure water jet conveying device

A high-pressure water jet and conveying device technology, which is applied in the direction of liquid/gas jet drilling, casing, drill pipe, etc., can solve the problems of insufficient hydrodynamic force of the jet, large friction resistance of the transport mode, and large hydraulic loss along the way. Achieve the effects of increasing hydraulic power, improving rock-breaking efficiency, and solving large hydraulic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

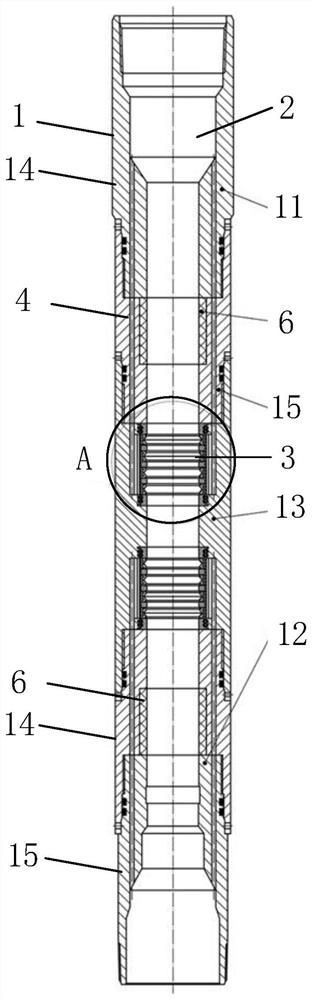

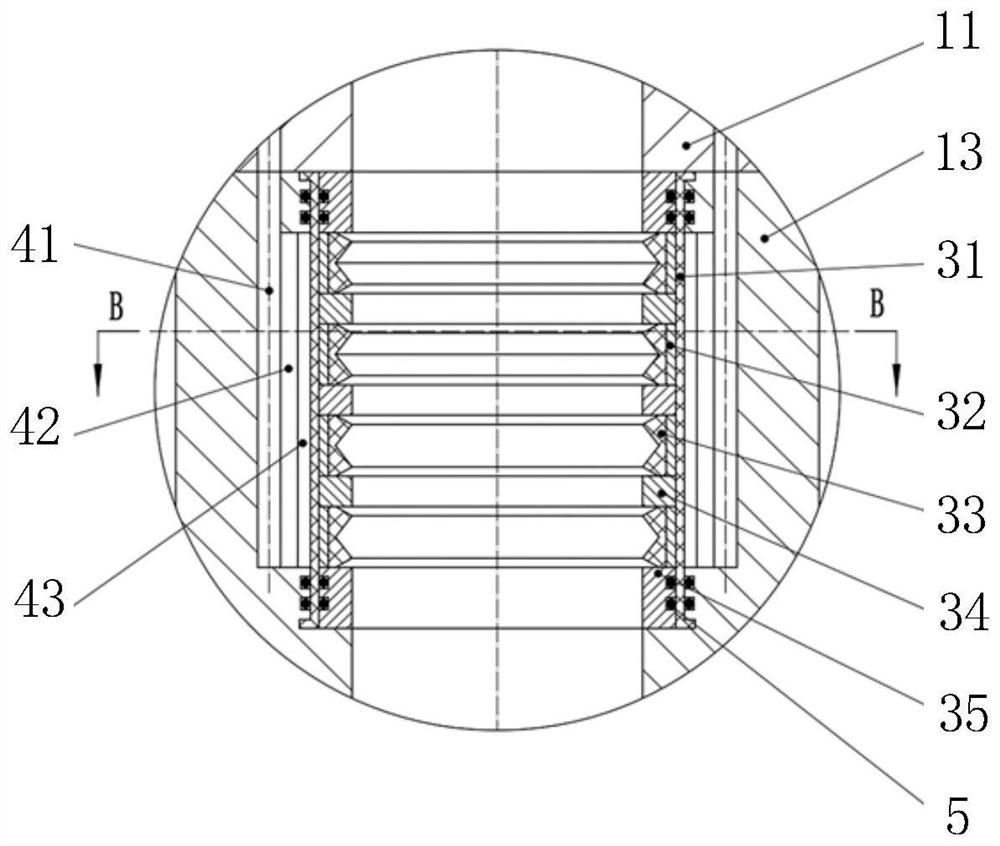

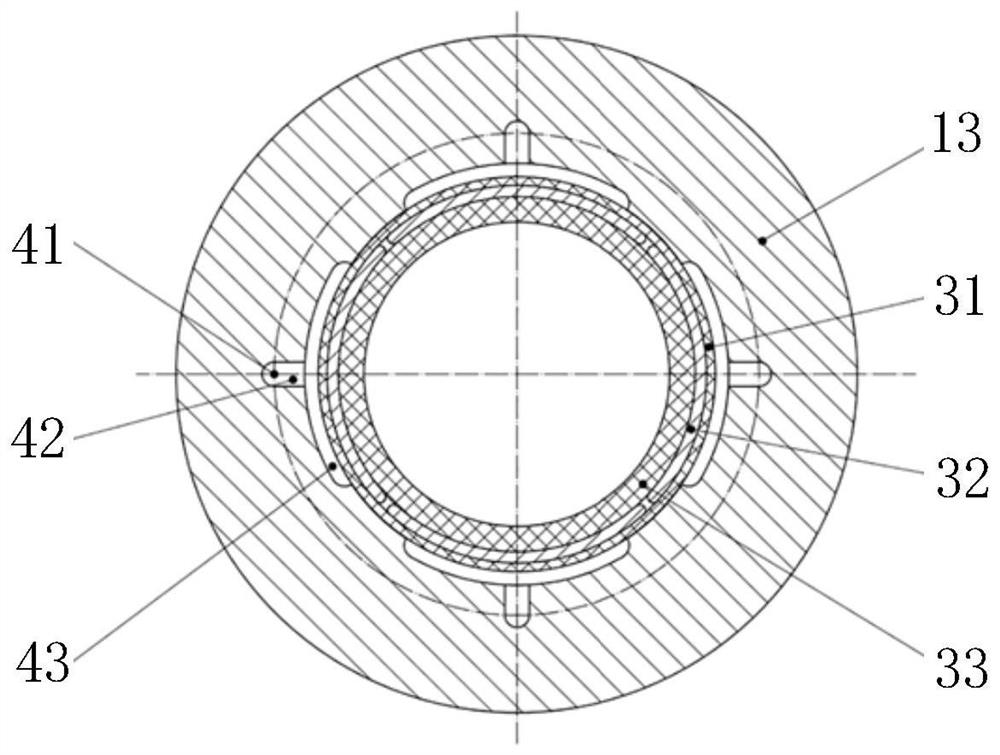

[0029] Such as figure 1 As shown, the high-pressure water jet delivery device of this embodiment includes a continuous pipe string, an external pipe string 1 , a dynamic sealing assembly 3 and a pressure transmission channel 4 . Among them, the external pipe string 1 is sleeved outside the continuous pipe string to enclose and form the injection annulus 2 of the high-pressure water jet; the pressure transmission channel 4 and the dynamic sealing assembly 3 are both arranged on the external pipe string 1, and the pressure transmission channel 4 and the The dynamic seal assembly 3 is connected to provide the sealing pressure of the dynamic seal assembly 3; when the fluid is injected into the pressure transmission channel 4, the dynamic seal assembly 3 radially shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com