Horizontal overflow forming device for ultra-thin sheet glass

A technology of ultra-thin flat glass and forming device, applied in glass forming, glass forming, glass manufacturing equipment and other directions, can solve the problems of reducing production cost, difficulty in debugging, long cycle, etc., so as to reduce production cost and shorten debugging. Period, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

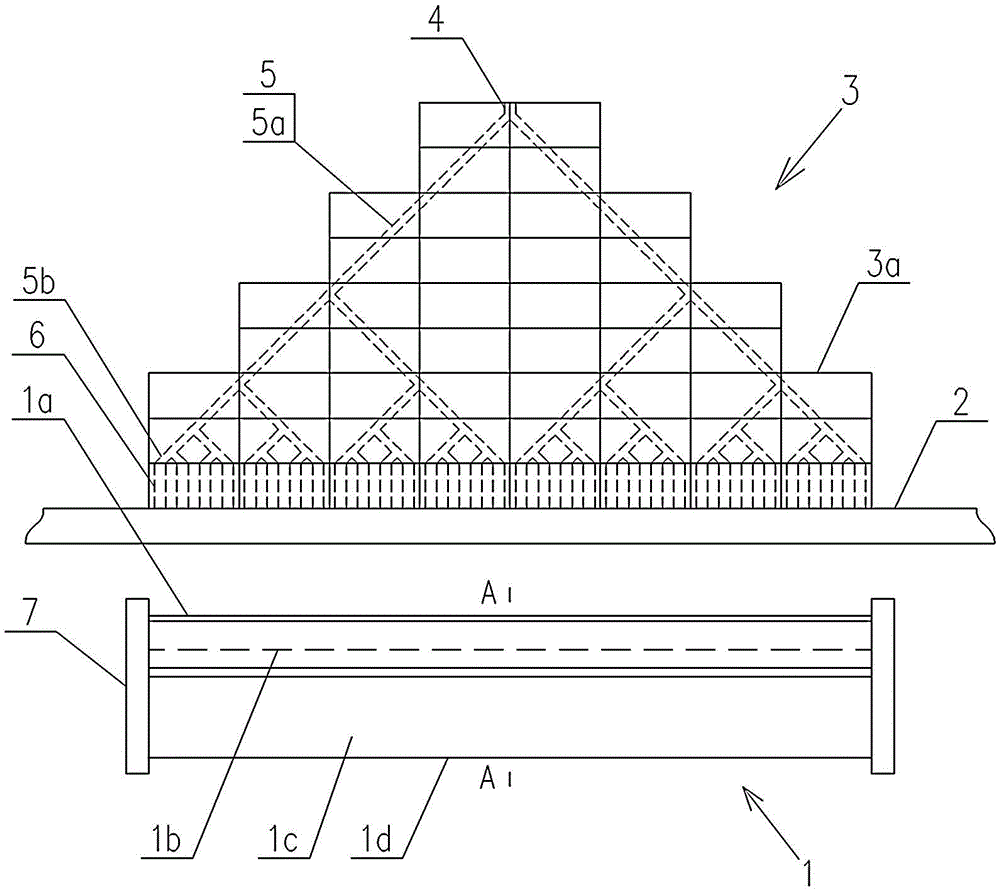

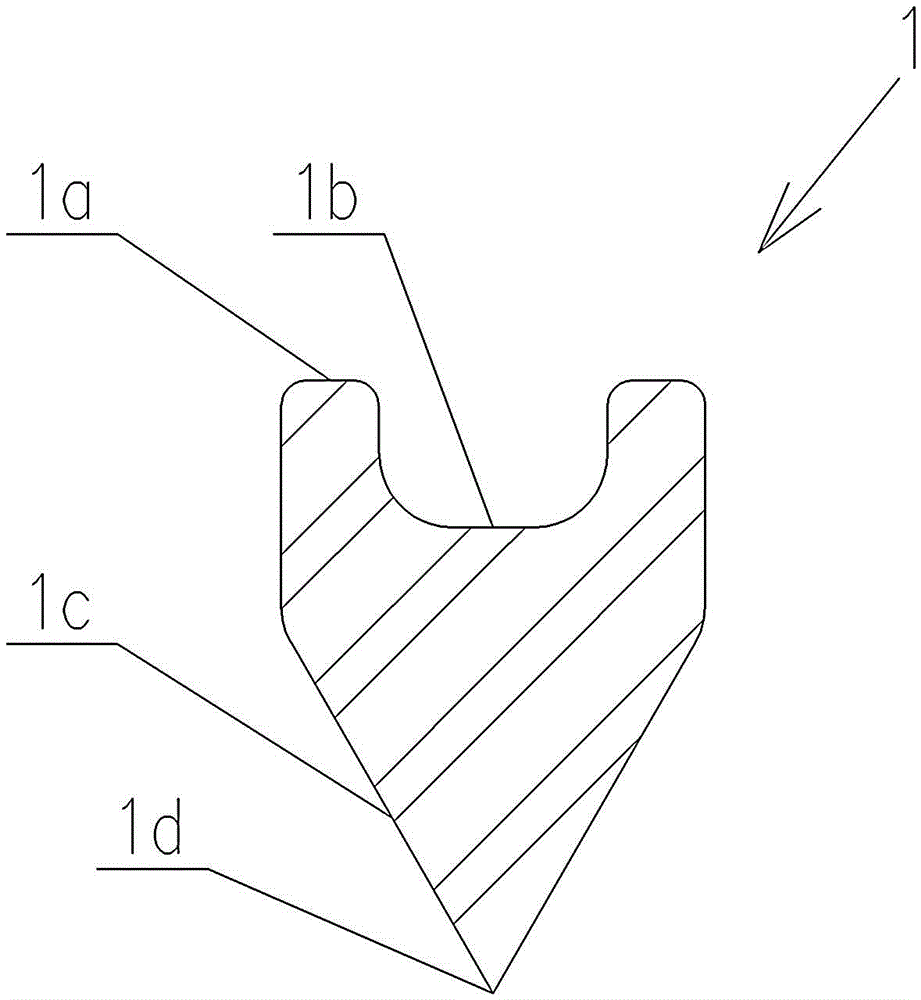

[0014] Such as figure 1 and figure 2 As shown, a horizontal overflow forming device for ultra-thin flat glass provided by the present invention includes a base body 1, two ends of the base body 1 are respectively provided with retaining walls 7, and the lower side of the base body 1 is provided with two symmetrically arranged The diversion slope 1c, the lower ends of the corresponding diversion slopes 1c are connected to each other, and form a forming edge 1d, the top of the seat body 1 is provided with an overflow groove 1b, and the two sides of the overflow groove 1b at the top of the seat body 1 are also provided with an overflow slope 1a , the bottom surface of the overflow tank 1b and the overflow surface 1a are parallel to each other, a support 2 is provided above the seat body 1, and a flow guide device 3 is provided on the support 2. The flow guide device 3 is composed of a group of refractory bricks 3a, and the flow guide The upper side of the device is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com