Patents

Literature

432results about How to "Small size error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

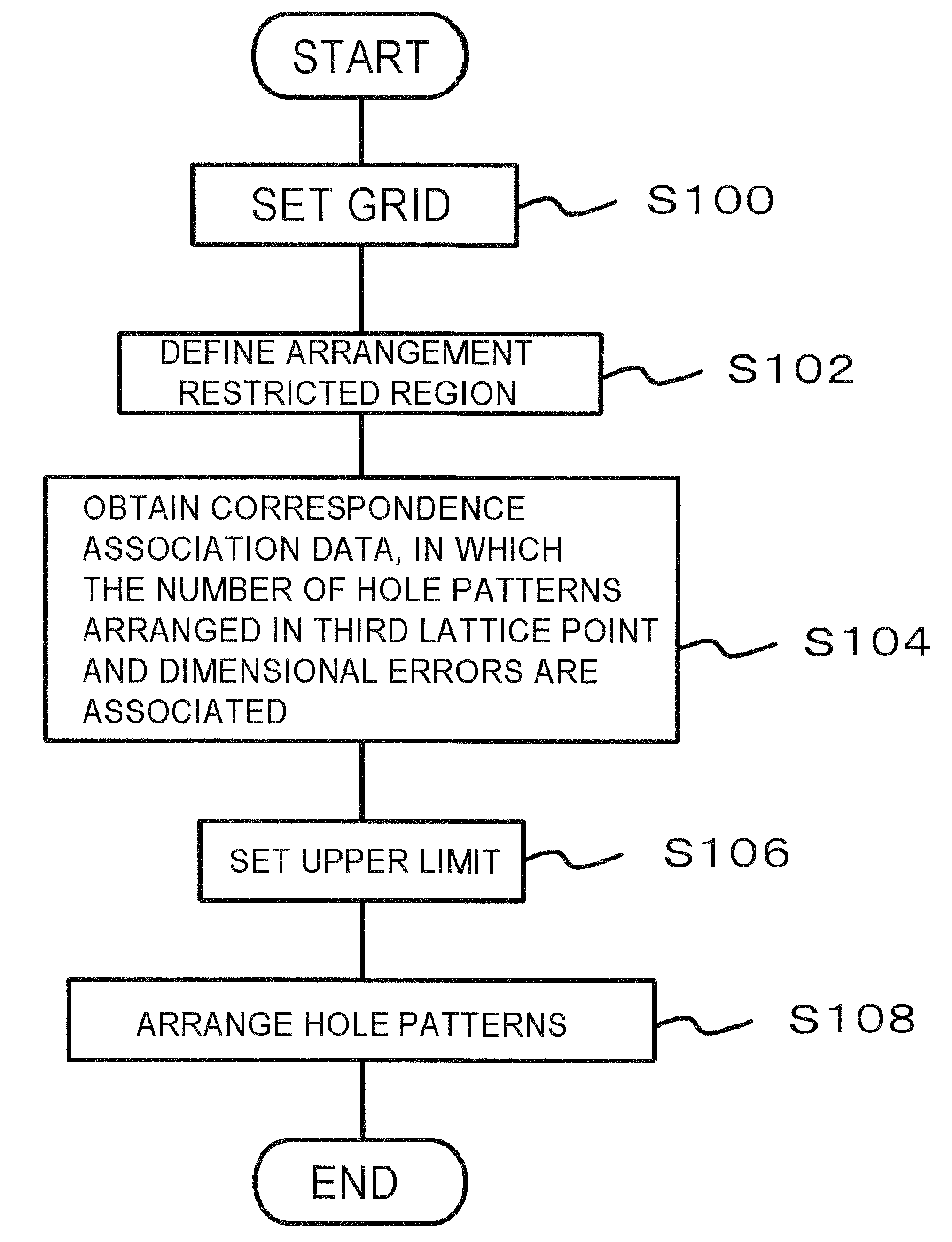

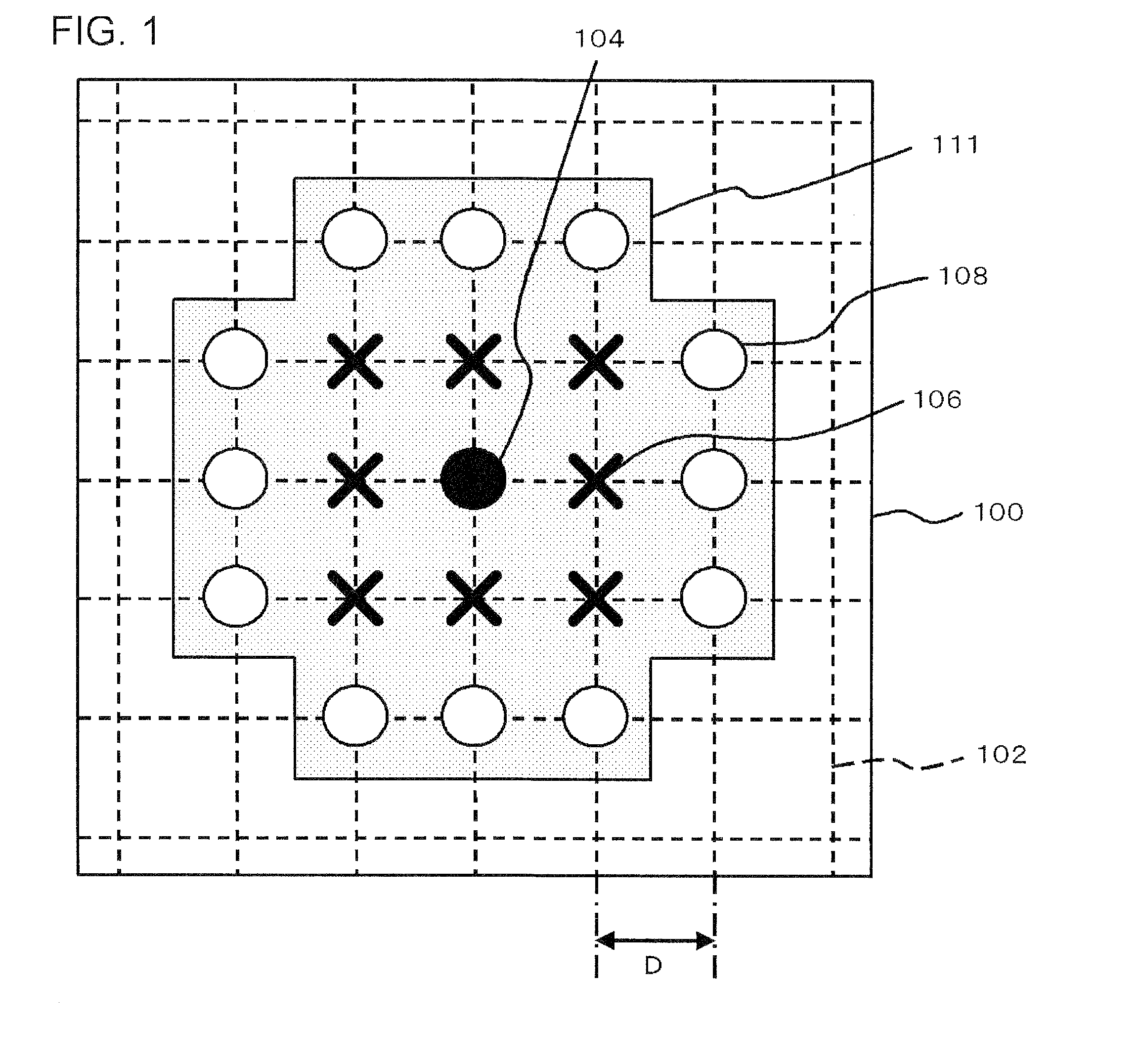

Method of designing a pattern

ActiveUS20080086712A1Reduce areaSmall size errorSemiconductor/solid-state device manufacturingCAD circuit designEngineeringSemiconductor

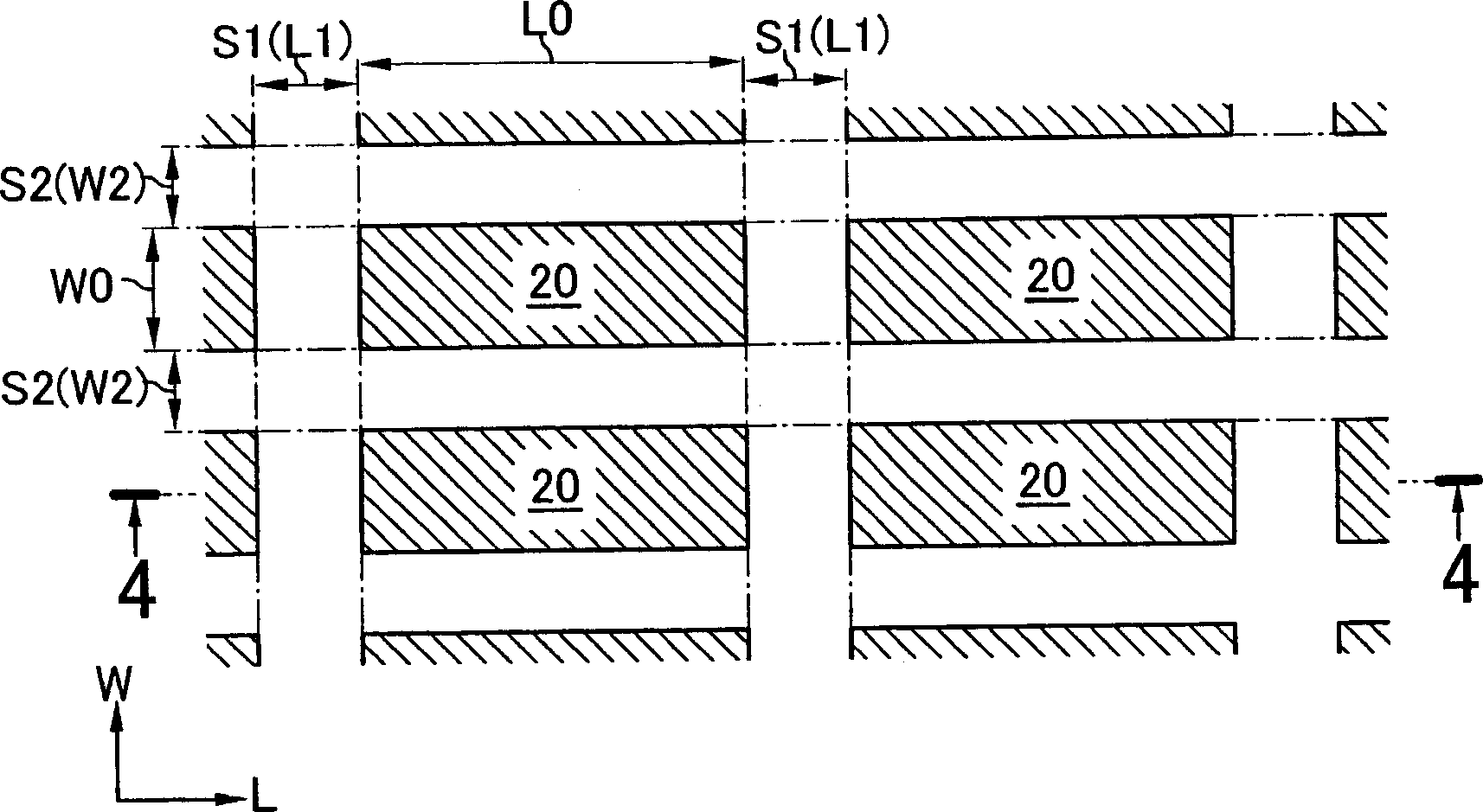

A method of designing a pattern of a hole pattern having a configuration, in which grid of interval smaller than a minimum permissible pitch according to a design rule for a semiconductor integrated circuit is provided in a pattern drawing, a hole pattern is arranged on a first lattice point which is an intersection of the grid, and, at the same time, other hole patterns are not arranged on a second lattice point group which is on the periphery of the first lattice point, and is adjacent to the first lattice point is provided. And, the number of hole patterns, which may be arranged in a third lattice point group of a plurality of lattice points which are on the periphery of a second lattice point group and are within a predetermined distance from the first lattice point, is controlled.

Owner:RENESAS ELECTRONICS CORP

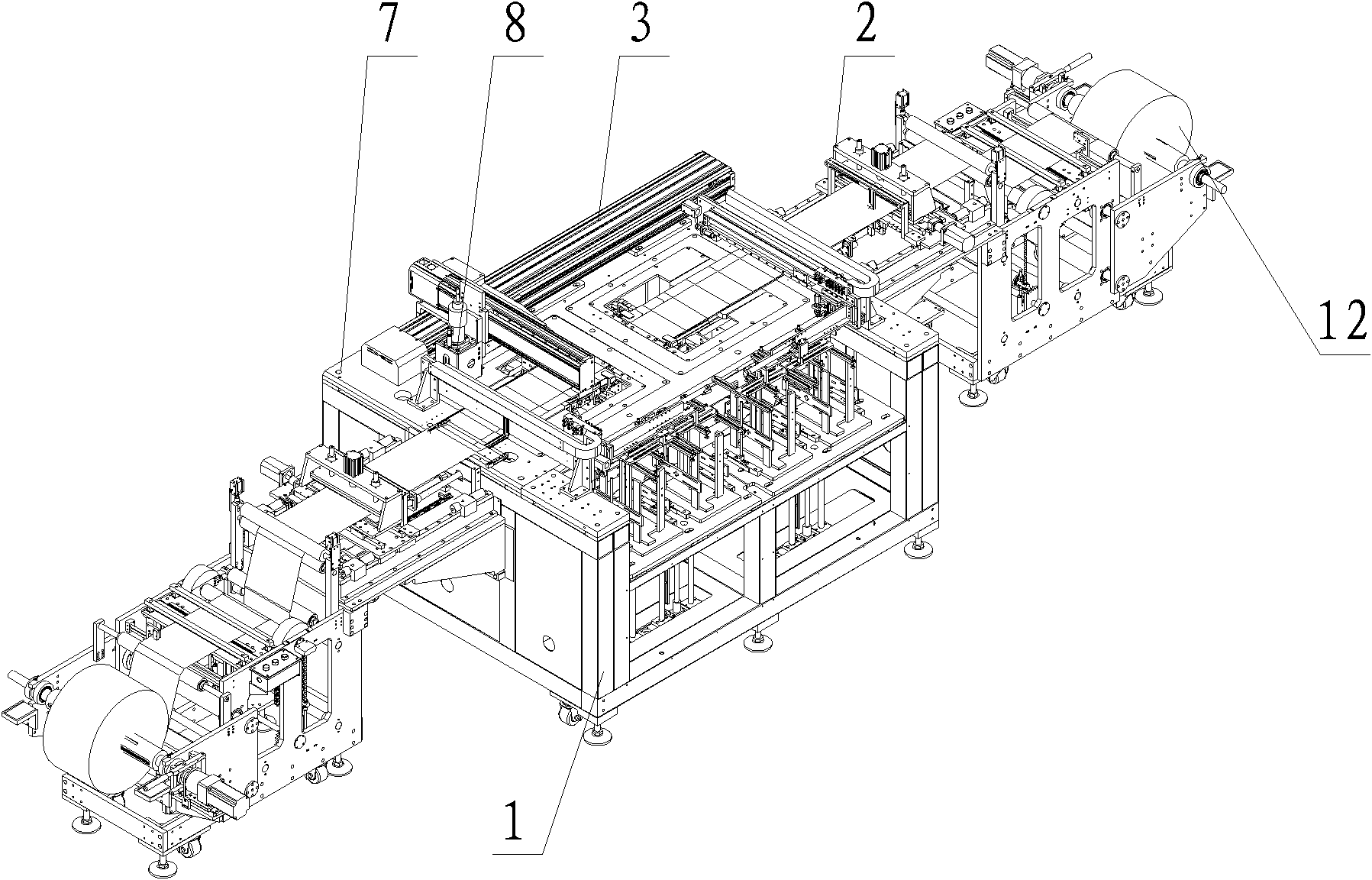

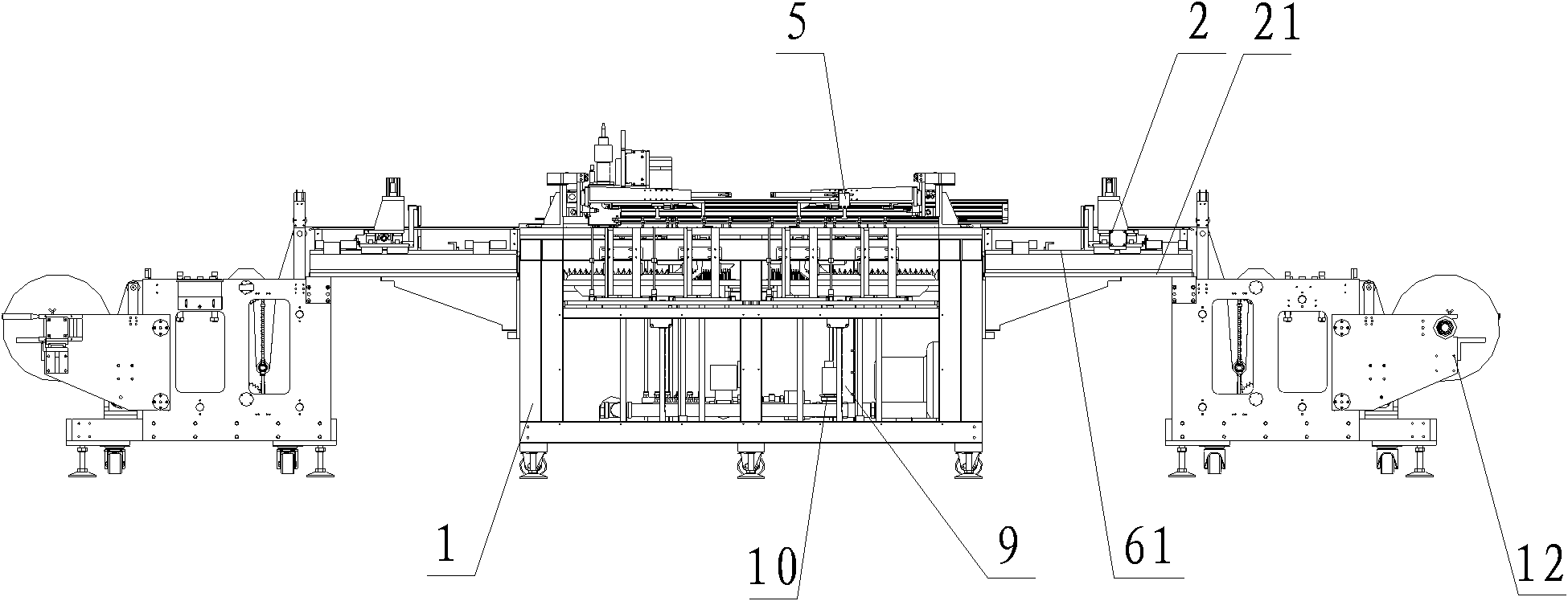

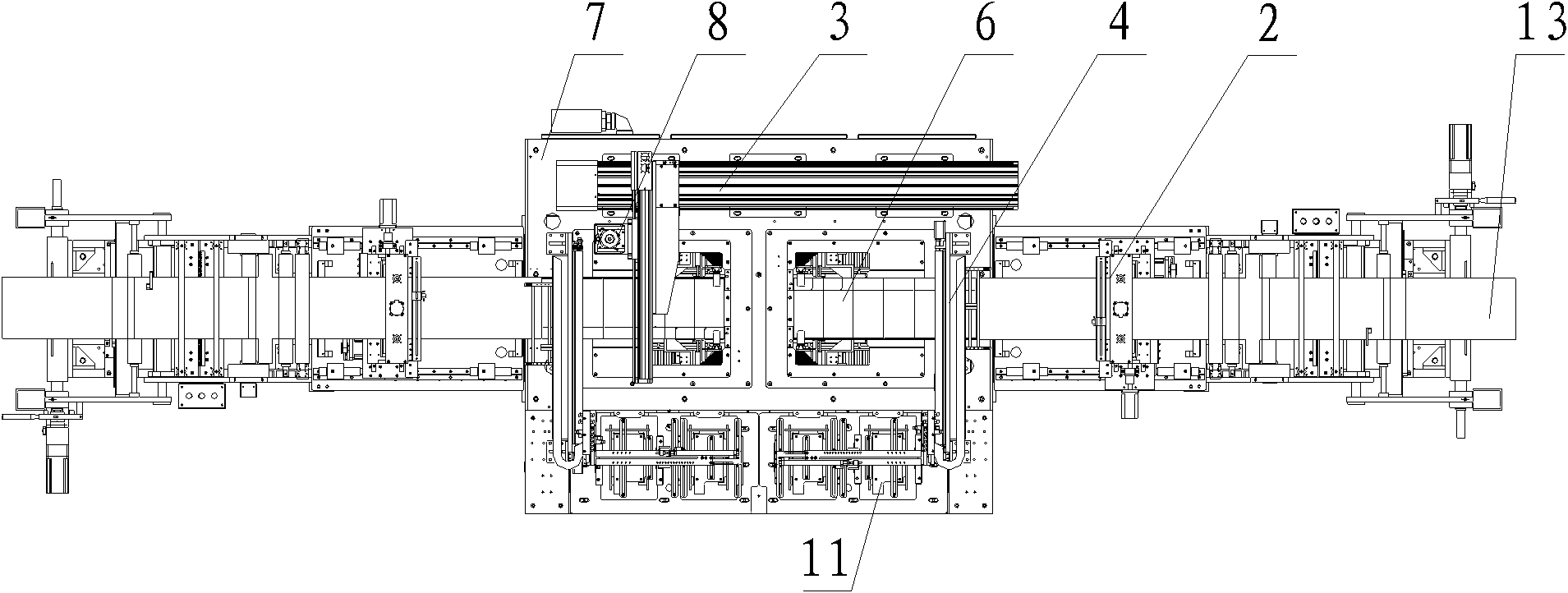

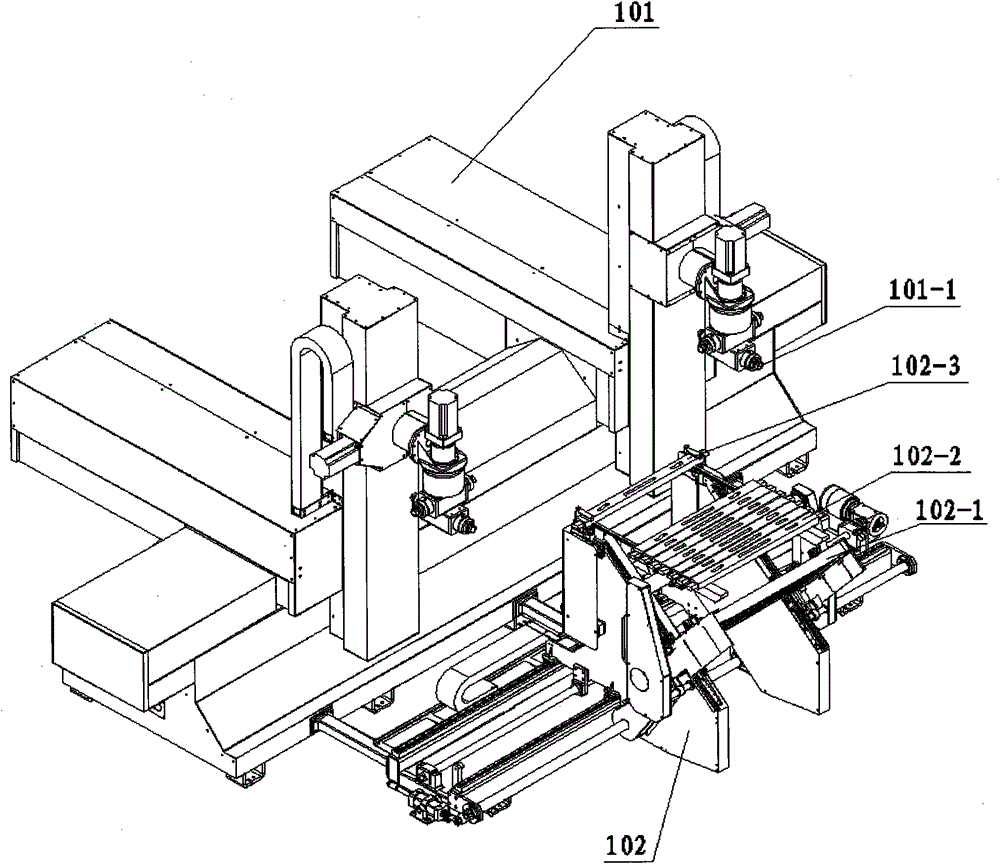

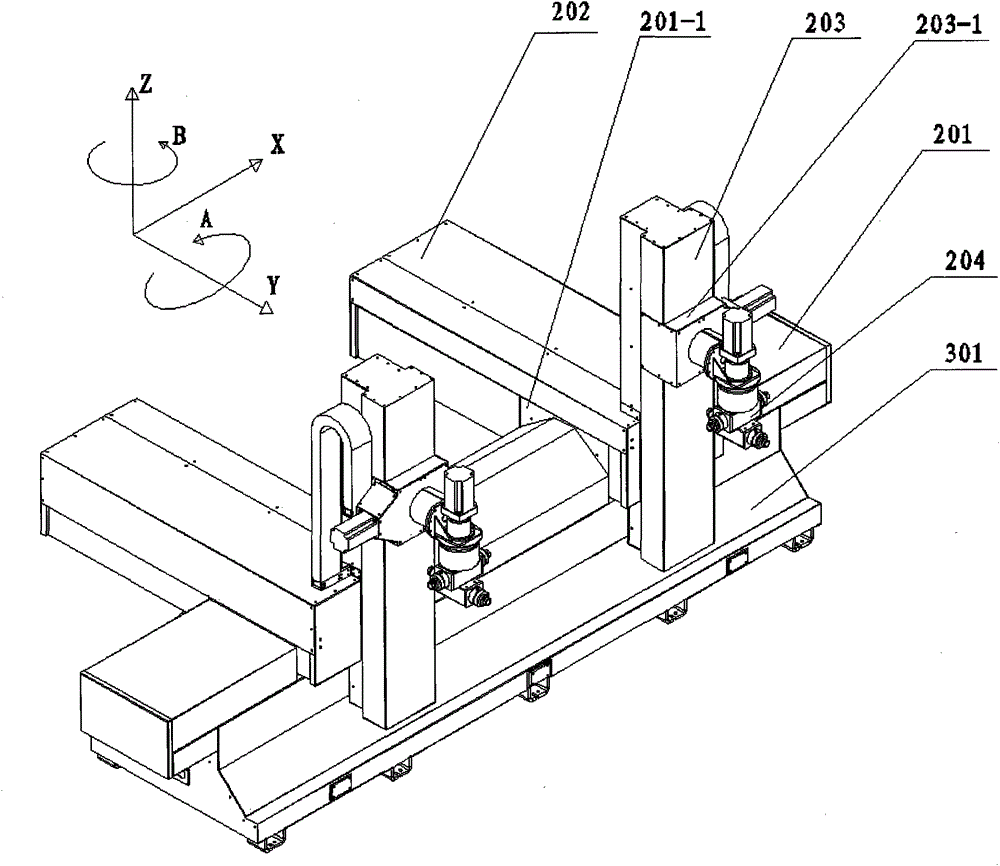

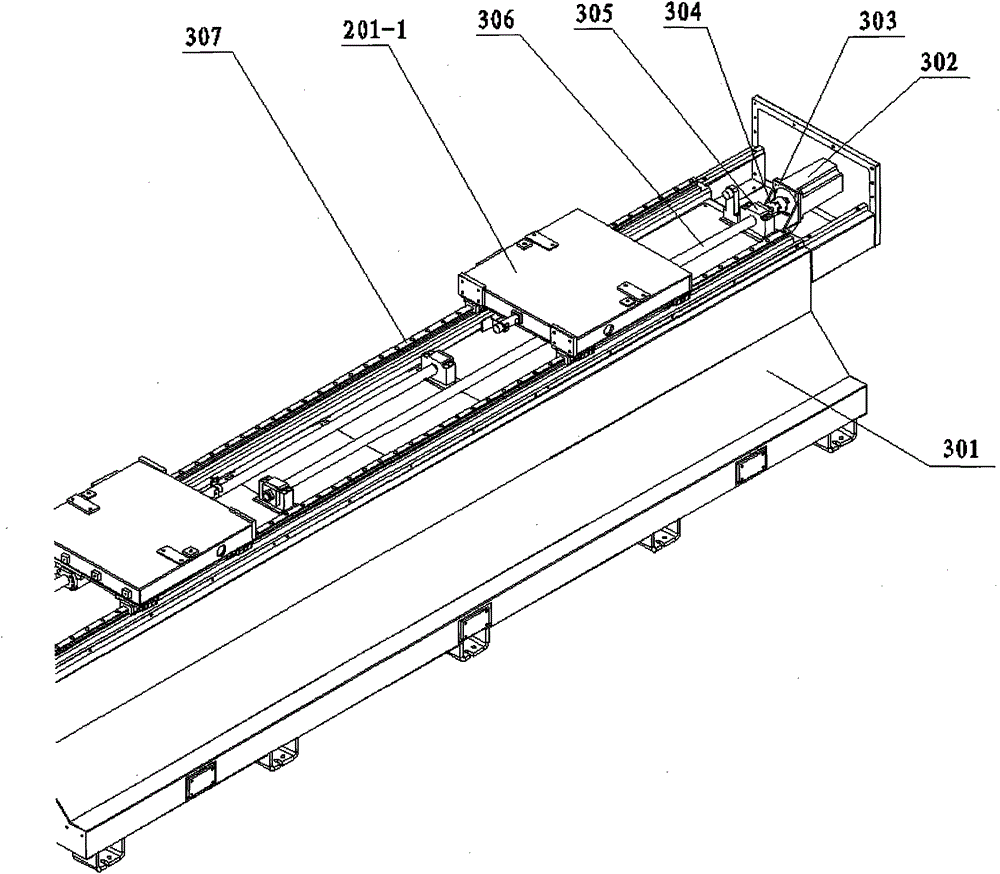

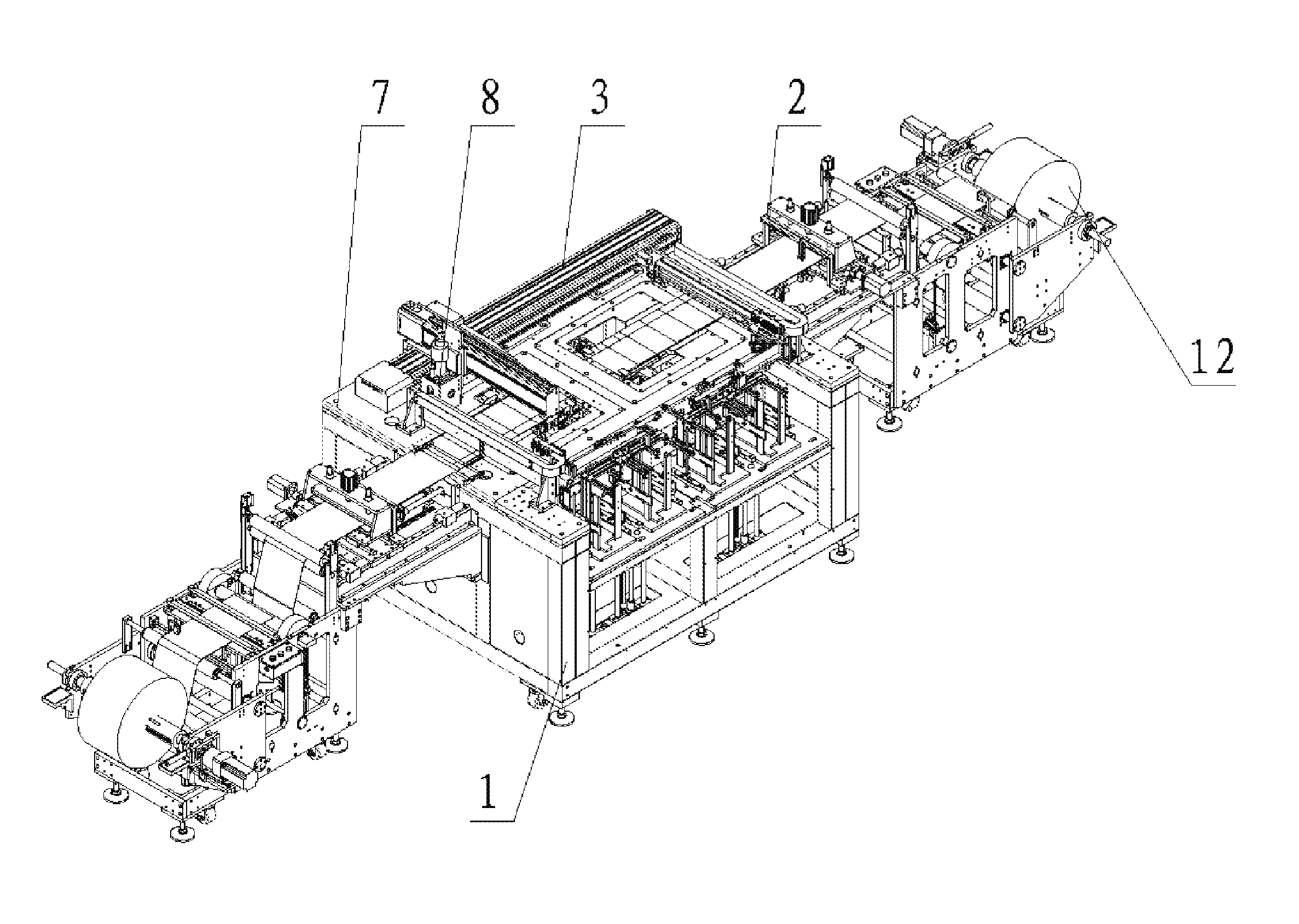

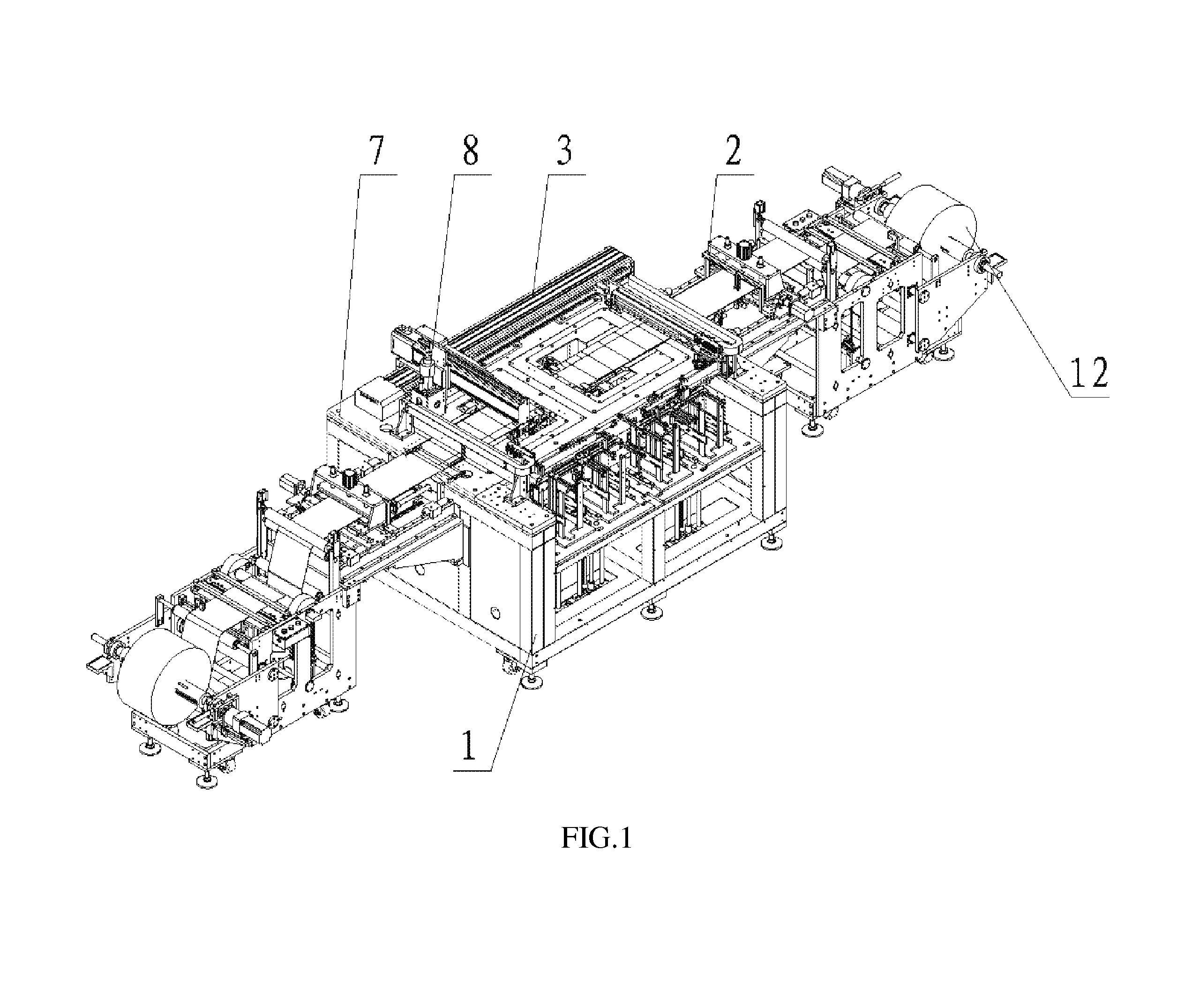

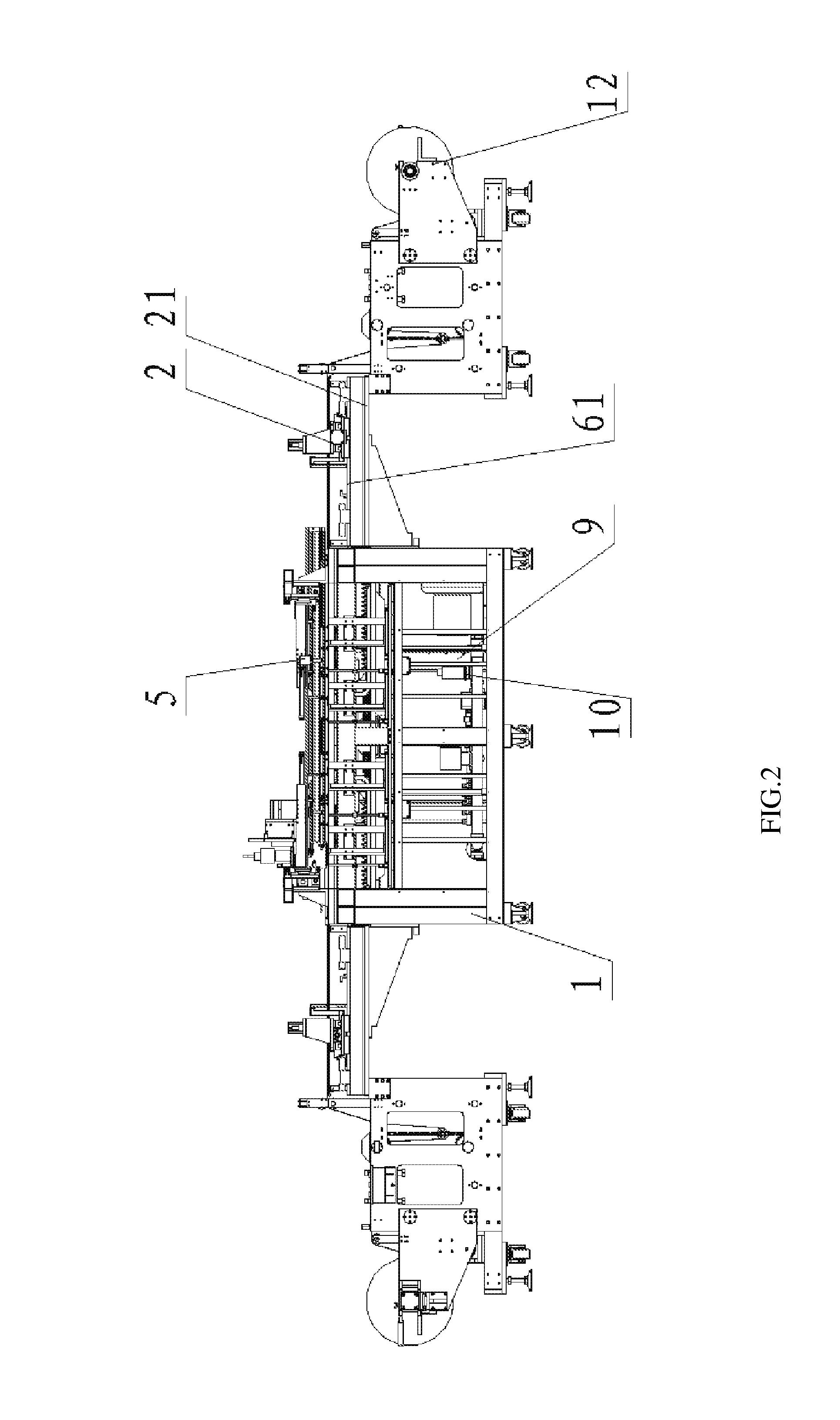

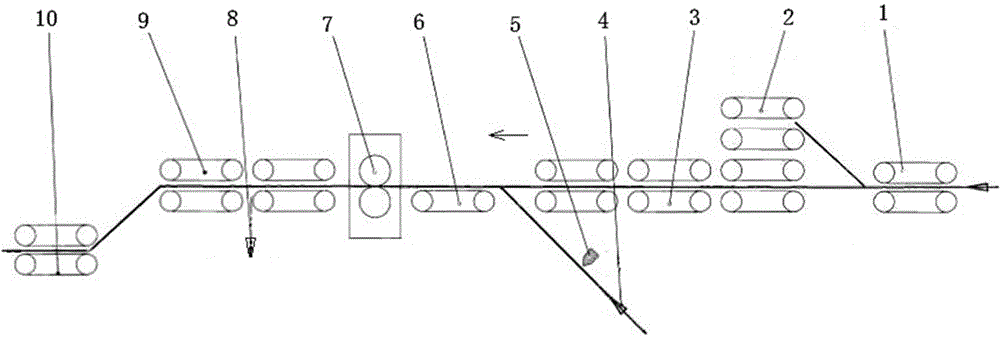

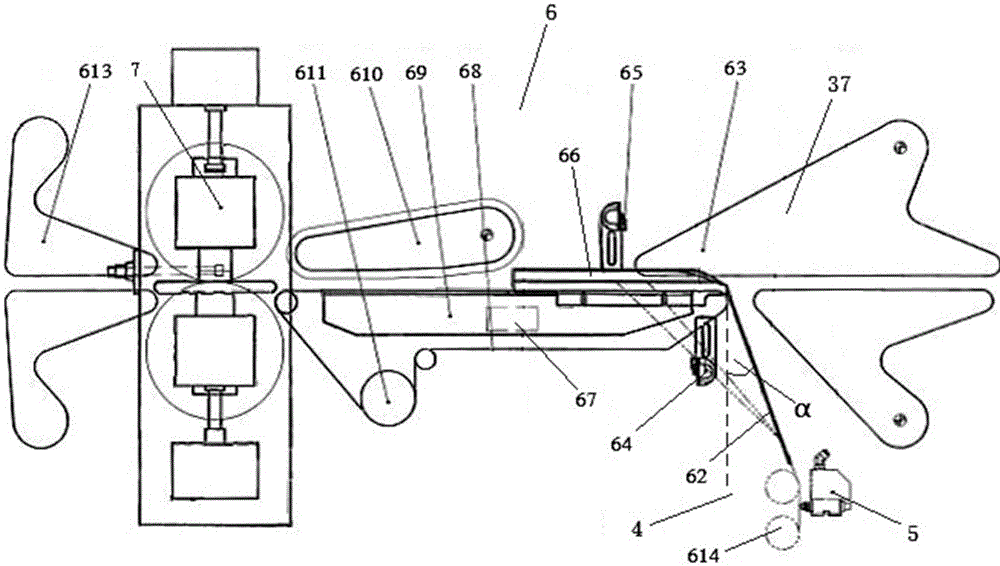

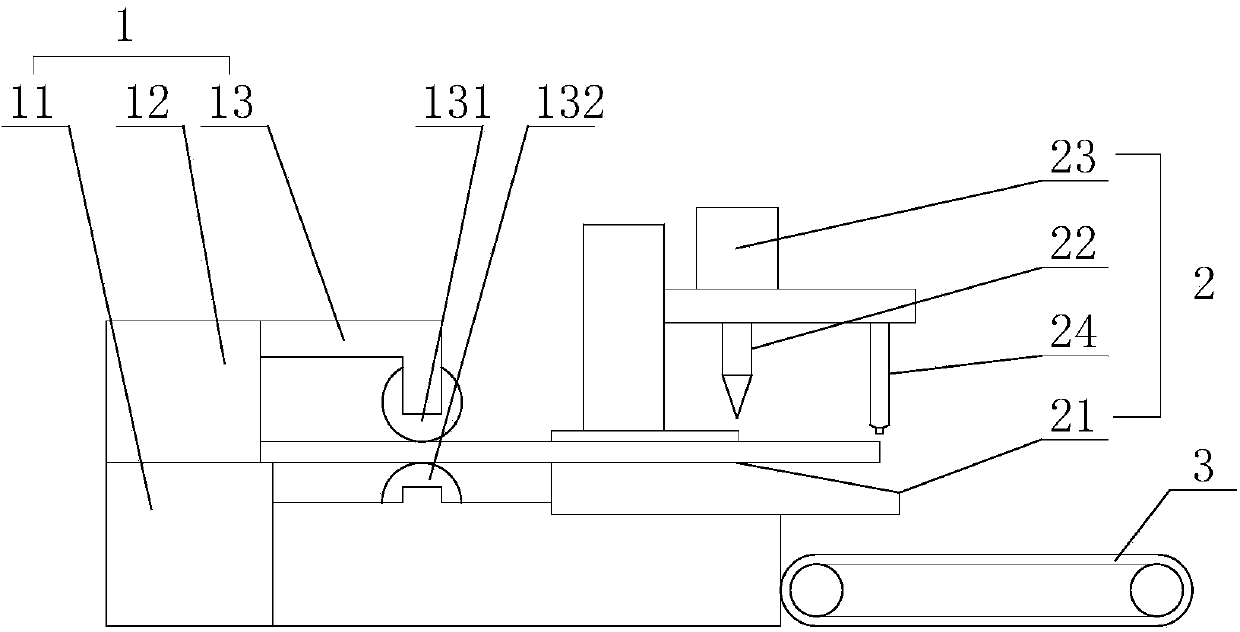

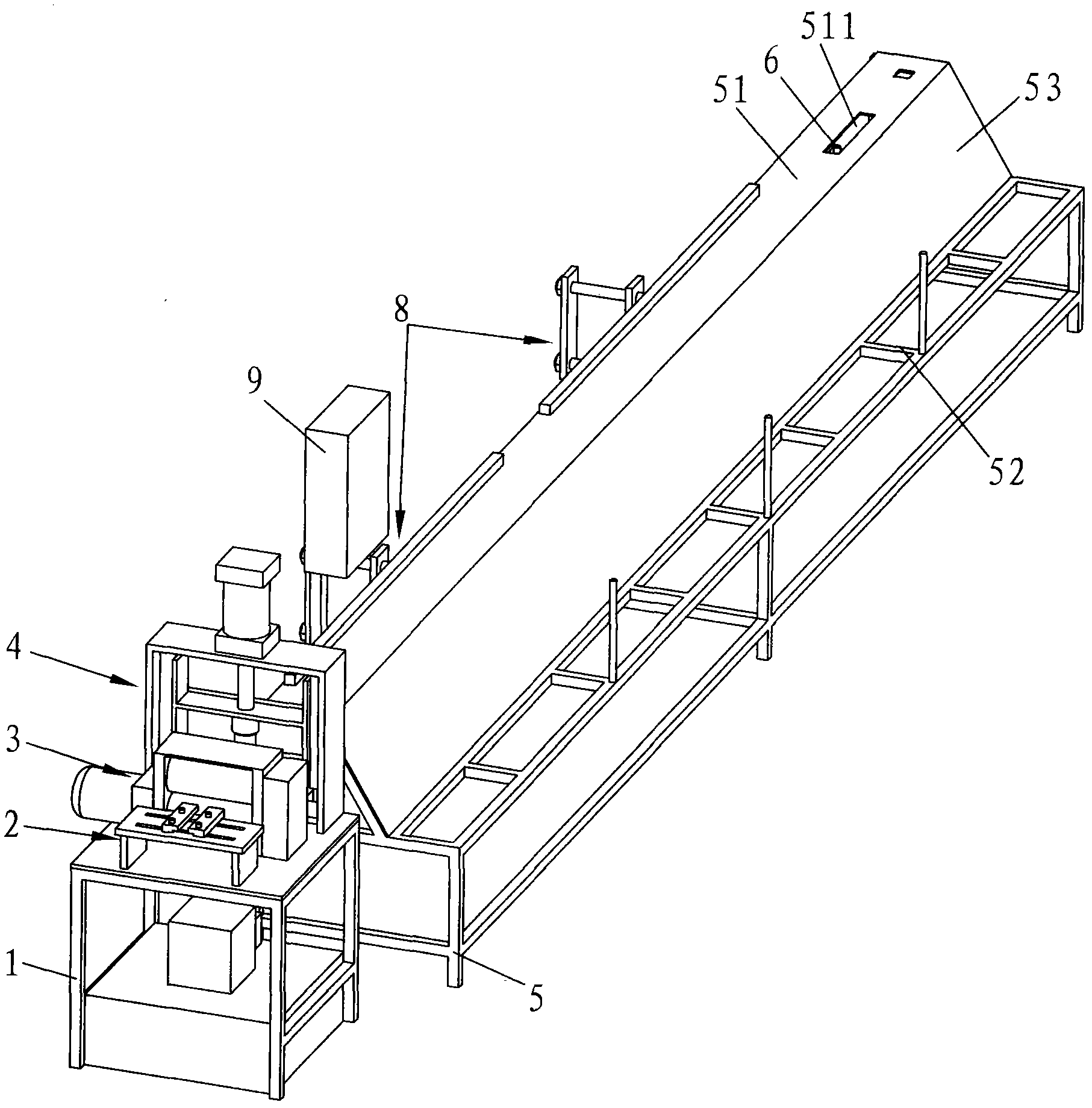

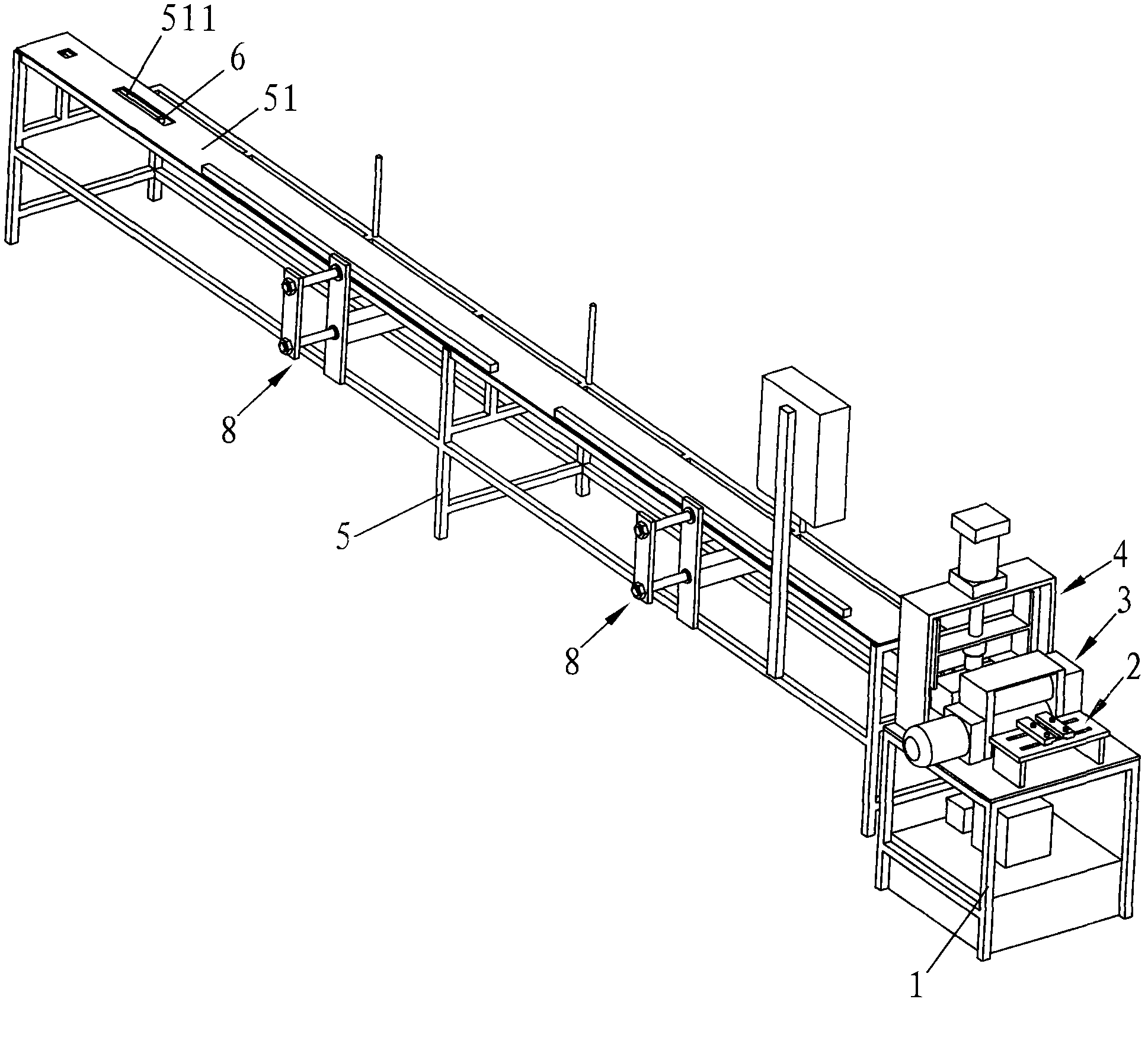

Pole piece laser cutting machine

ActiveCN102642089AOvercome deformationSmall size errorProgramme-controlled manipulatorElectrode manufacturing processesCapacitanceLaser technology

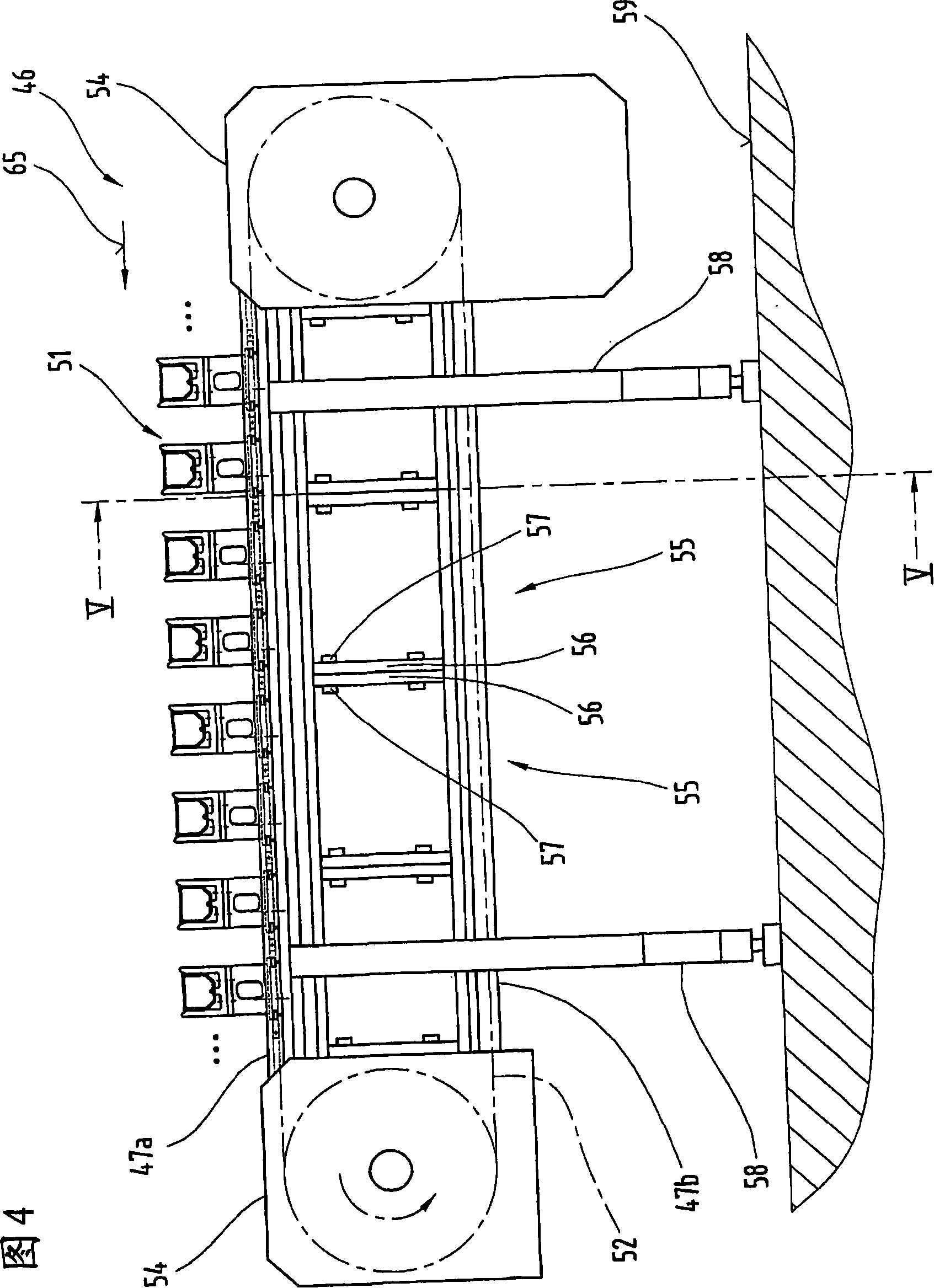

The invention discloses a pole piece laser cutting machine. The machine comprises a base frame part, a laser cutter, a cutting manipulator part, a control system and at least a piece feeding component, wherein the cutting manipulator part is used for driving the laser cutter; each piece feeding component comprises a material clamping manipulator part, a feeding fixed-length part and an emptying part; the cutting manipulator part and the material clamping manipulator part are installed on the base frame part; the feeding fixed-length part is arranged between the material clamping manipulator part and the emptying part; and the control system is connected with the cutting manipulator part, the material clamping manipulator part and the feeding fixed-length part. The machine has the following beneficial effects: the machine realizes the piece preparation processes of the lithium ion batteries or super capacitors by adopting the laser technology, can solve the problem that the pole pieces are easy to deform and have bigger burrs as the traditional cutting processes are adopted in the prior art, simultaneously improves the piece preparation process quality under the control of the control system and increases the yield.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

Double-station numerical control machining center

ActiveCN104802037AStable structureReduce management costsMetal working apparatusNumerical controlElectric machinery

The invention discloses a double-station numerical control machining center which comprises a main machine tool component and an upper discharging component, wherein the upper discharging component comprises two material storing shelf components, two feeding mechanisms, two discharging mechanisms and two material clamping mechanisms symmetrically mounted on a mounting frame at the left side and the right side for forming the material storing, feeding, clamping and discharging function; a structure on a pedestal component is used for adjusting the distance of the mounting frame and used for offering the power output for feeding and discharging operation; the main machine tool component can be driven by the motor lead screw driving mechanism for moving in X axis direction, two Y axis components are mounted on the X axis mobile pedestal and driven by the motor lead screw driving mechanism for moving in Y axis direction; two Z axis components are respectively fixed at the ends of two Y axis components, and rotating shaft components are mounted on the Z axis moving plate; the AB rotating shaft components are connected with the an electric main shaft in a driving mode, and the electric main shaft is four-end electric main shaft; four cutters are arranged on each of two four-end electric main shaft, and eight different cutters are used for processing the wood.

Owner:广东威德力机械实业股份有限公司

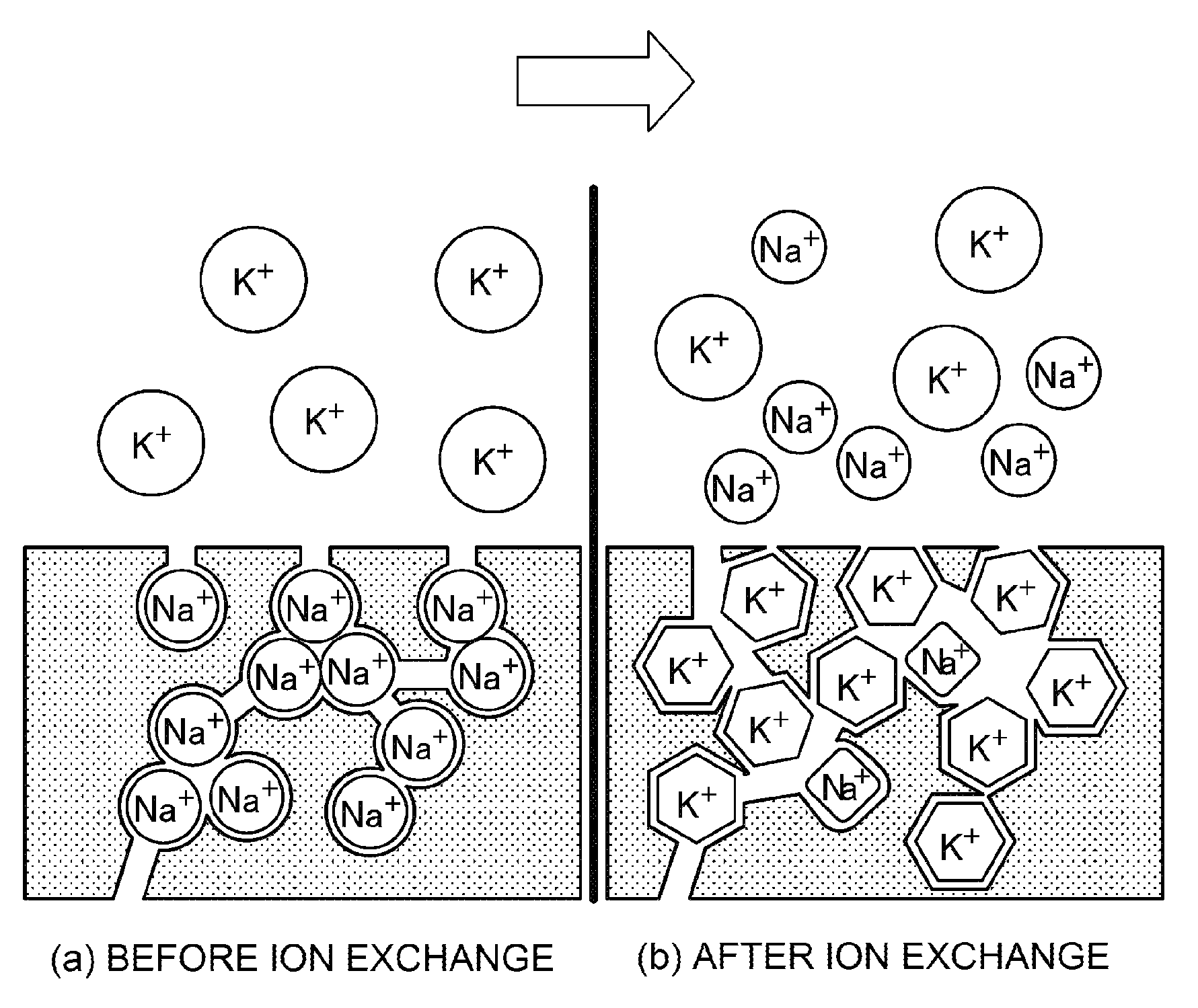

Method of manufacturing a glass substrate for use as a cover glass for a mobile electronic device, glass substrate for use as a cover glass for a mobile electronic device, and mobile electronic device

InactiveUS20120214004A1Reduce dimensional errorSmall size errorSubstation equipmentGlass/slag layered productsIon exchangeMobile electronics

A glass substrate manufacturing method of this invention includes a first chemical strengthening process for chemically strengthening a plate-like glass member by ion exchange, a cutting process for cutting the plate-like glass member into small pieces after the first chemical strengthening process, thereby obtaining a plurality of glass substrates, and a second chemical strengthening process for chemically strengthening the glass substrates by ion exchange after the cutting process.

Owner:HOYA CORP

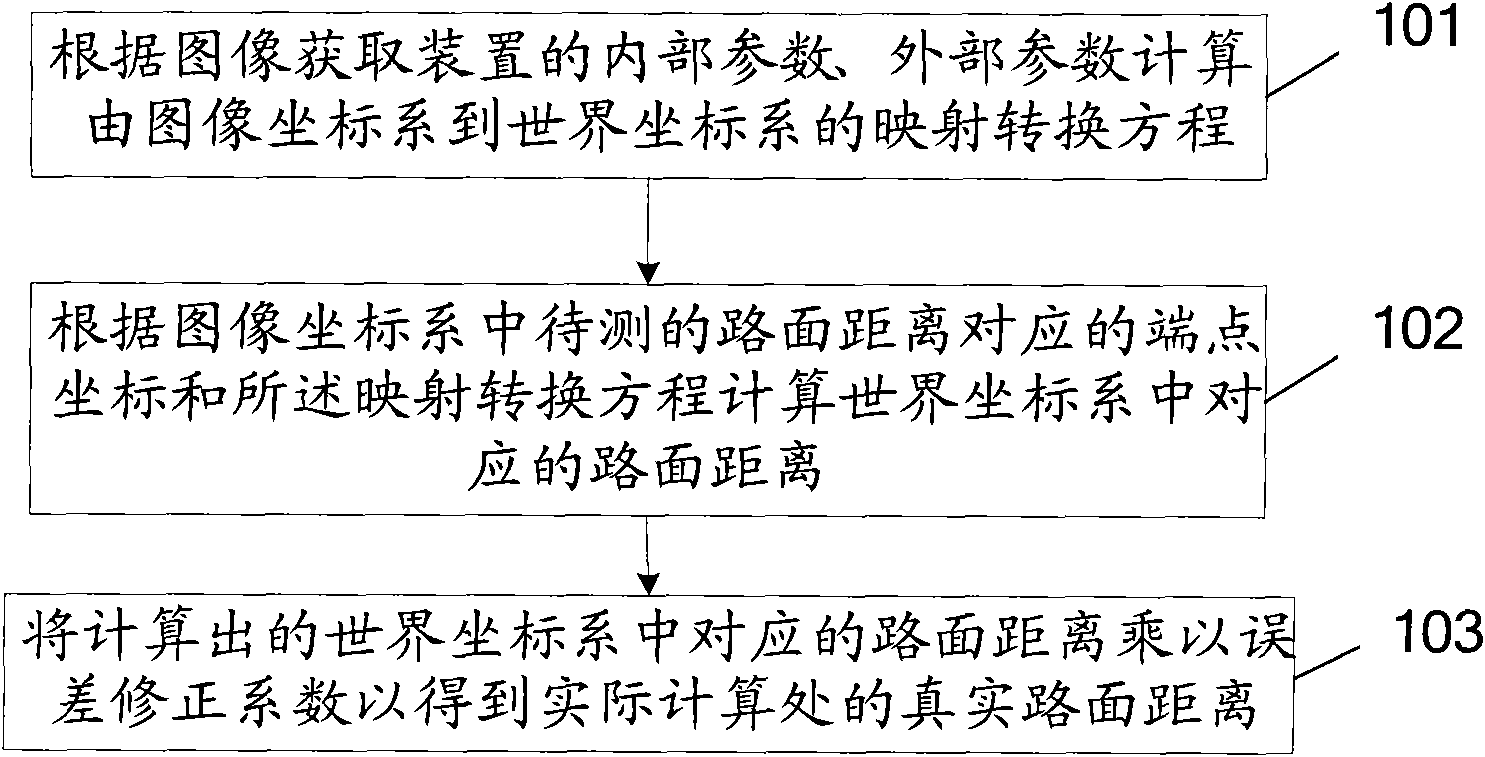

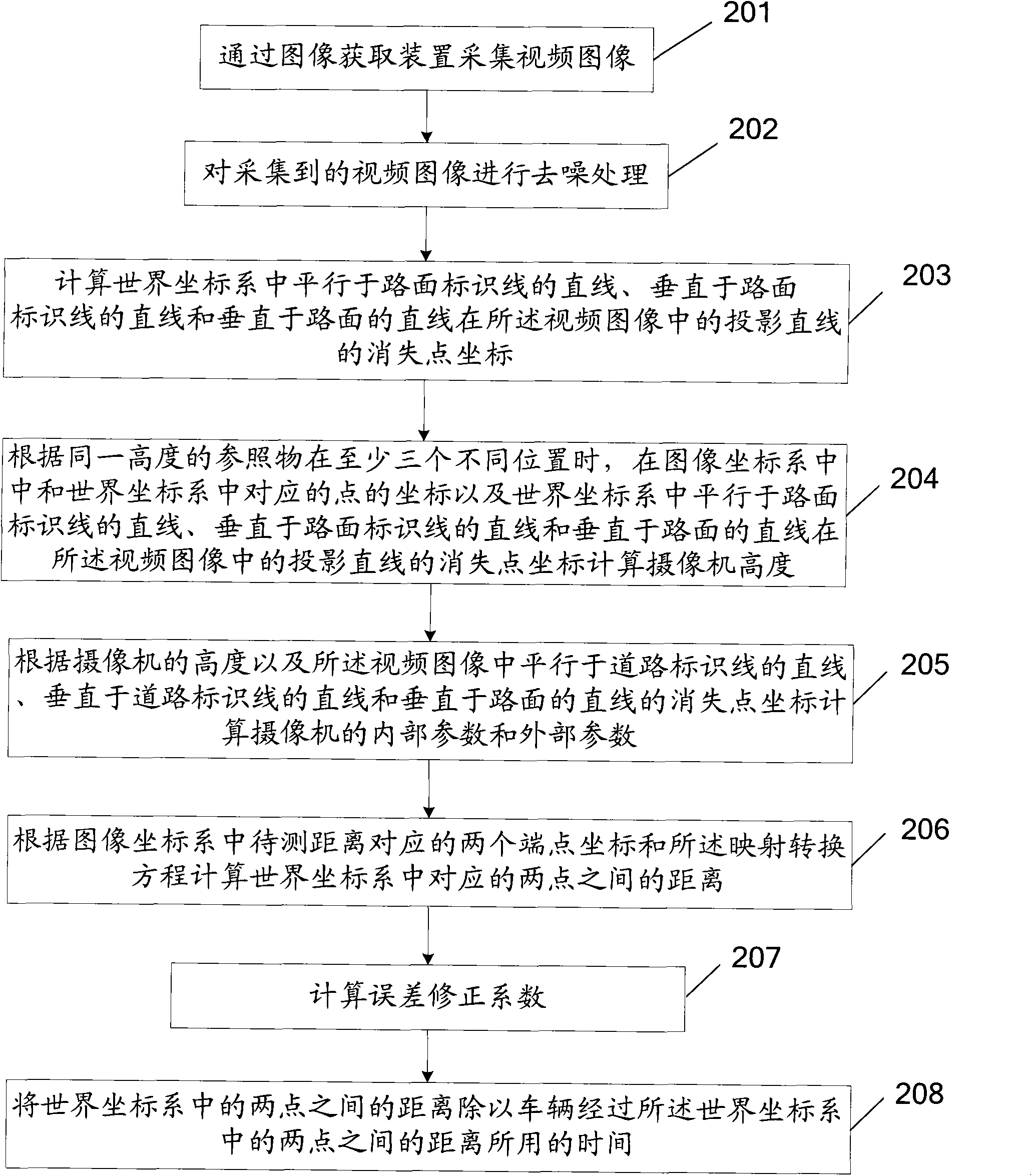

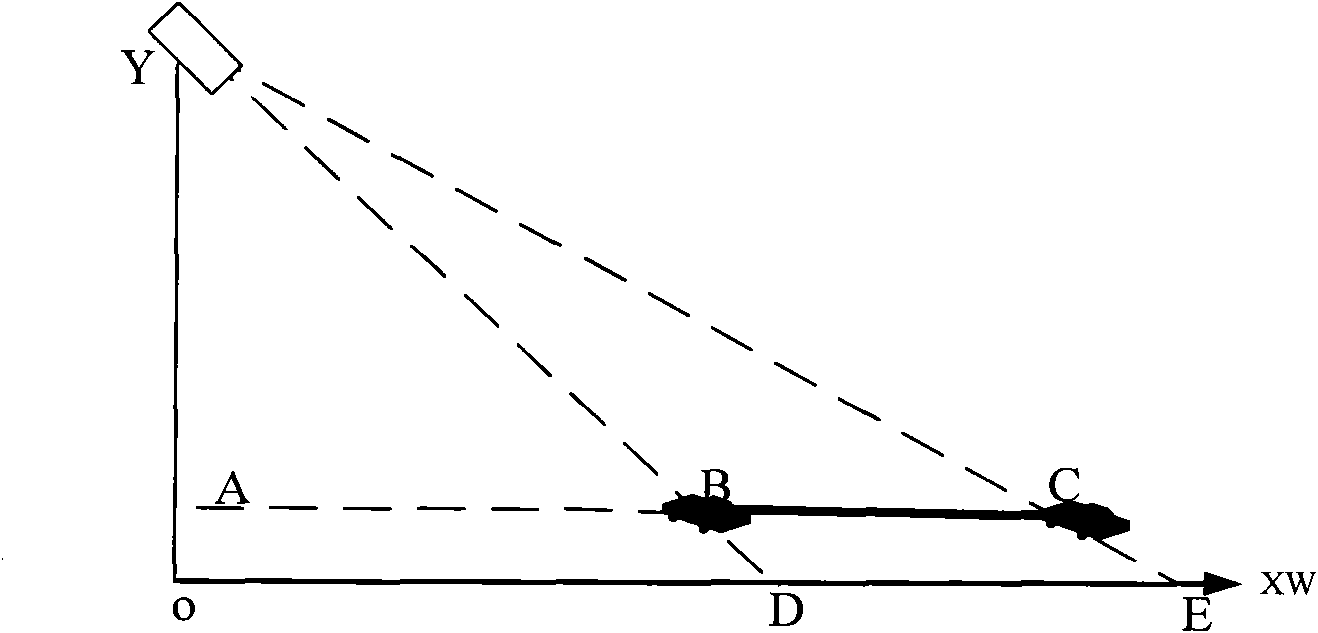

Road distance detection method based on video image and apparatus thereof

ActiveCN102467821ARealize detectionImprove accuracyImage analysisOptical rangefindersDistance detectionRoad surface

An embodiment of the invention discloses a road distance detection method based on a video image and an apparatus thereof, relating to the intelligent traffic field. Cost is low, maintenance is easy, and accuracy of vehicle detection is high. The method comprises the following steps: according to an internal parameter and an external parameter of an image acquisition apparatus, calculating a mapping conversion equation from an image coordinate system to a world coordinate system; according to an end point coordinate corresponding to a road distance to be measured in the image coordinate system and the mapping conversion equation, calculating a corresponding road distance in the world coordinate system; multiplying the corresponding road distance in the world coordinate system with an error correction coefficient to obtain a real road distance of an actual calculation position. The method and the apparatus are mainly applied to inspection of video range finding, vehicle distance and vehicle speed.

Owner:北京数字智通科技有限公司

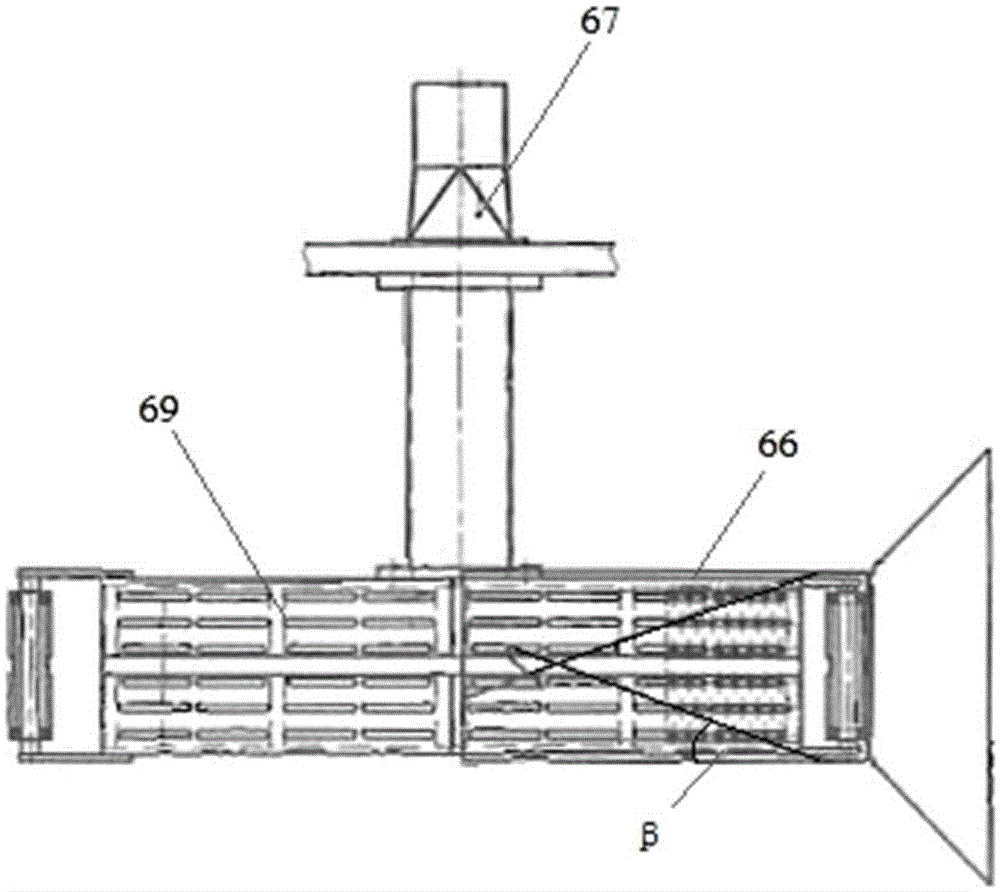

Pole sheet laser cutting machine

ActiveUS20140014633A1Good monochromaticitySmall divergence angleElectrode manufacturing processesFinal product manufactureManipulatorLithium electrode

Disclosed is a pole sheet laser cutting machine. It comprises a base frame component, a laser cutting device, a cutting manipulator component for driving the laser cutting device, a control system, and at least one sheet feeding assembly; the sheet feeding assembly comprises a material grabbing manipulator component, a fixed length feeding component and a material releasing component, with both the cutting manipulator component and the material grabbing manipulator component being mounted on the base frame component, the fixed length feeding component being arranged between the material grabbing manipulator component and the material releasing component, and the control system being connected to the cutting manipulator component, the material grabbing manipulator component and the fixed length feeding component. The present invention achieves the sheet making process for lithium ion batteries or super capacitors by applying laser technology, which is able to overcome the problems that existed in the prior art through applying a traditional cutting process so that the pole sheets were easily deformed and the burrs were relatively large, etc., and at the same time, the quality of the sheet making process and hence the rate of acceptable products are improved through the control of the control system.

Owner:GEESUN AUTOMATION TECH

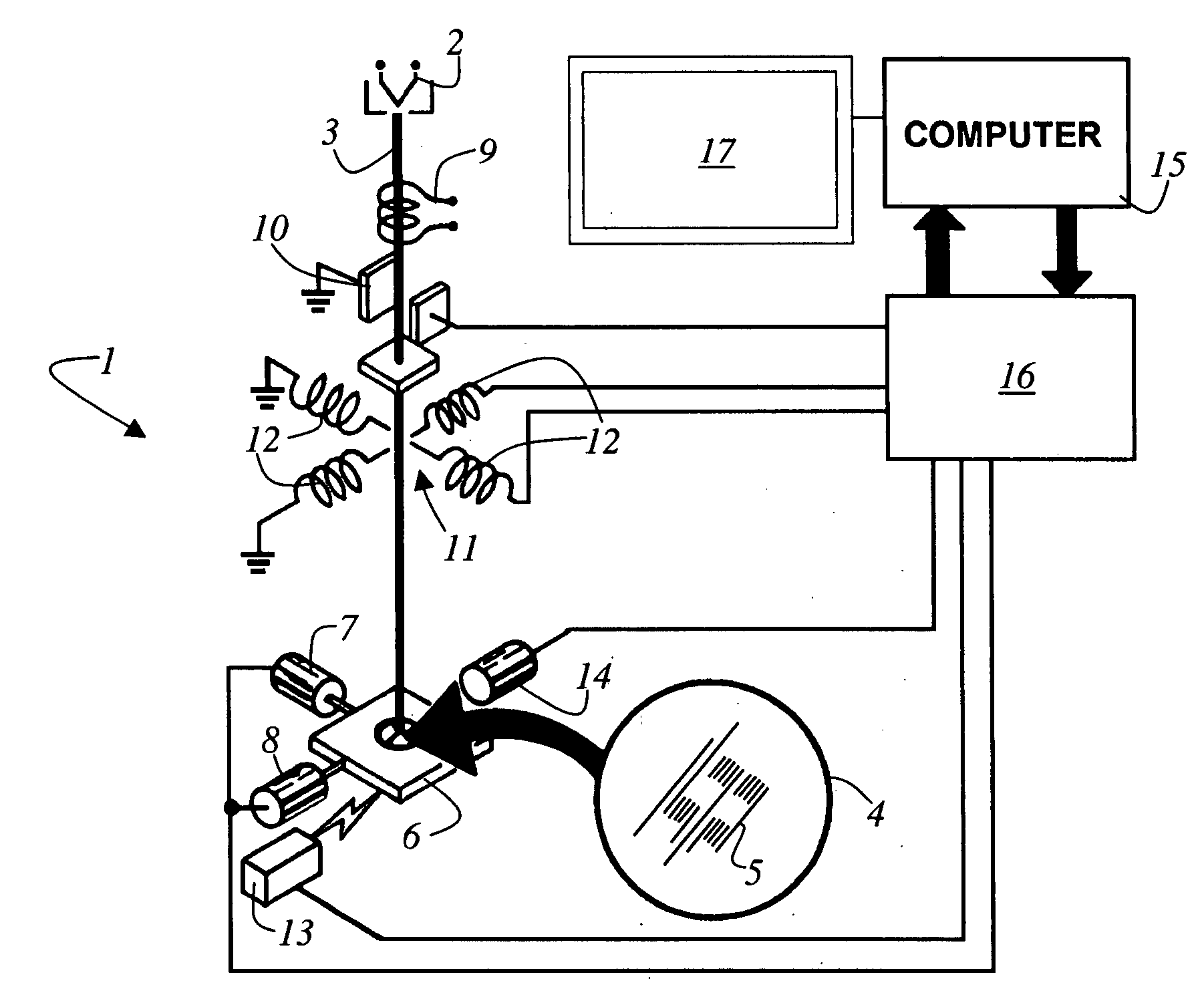

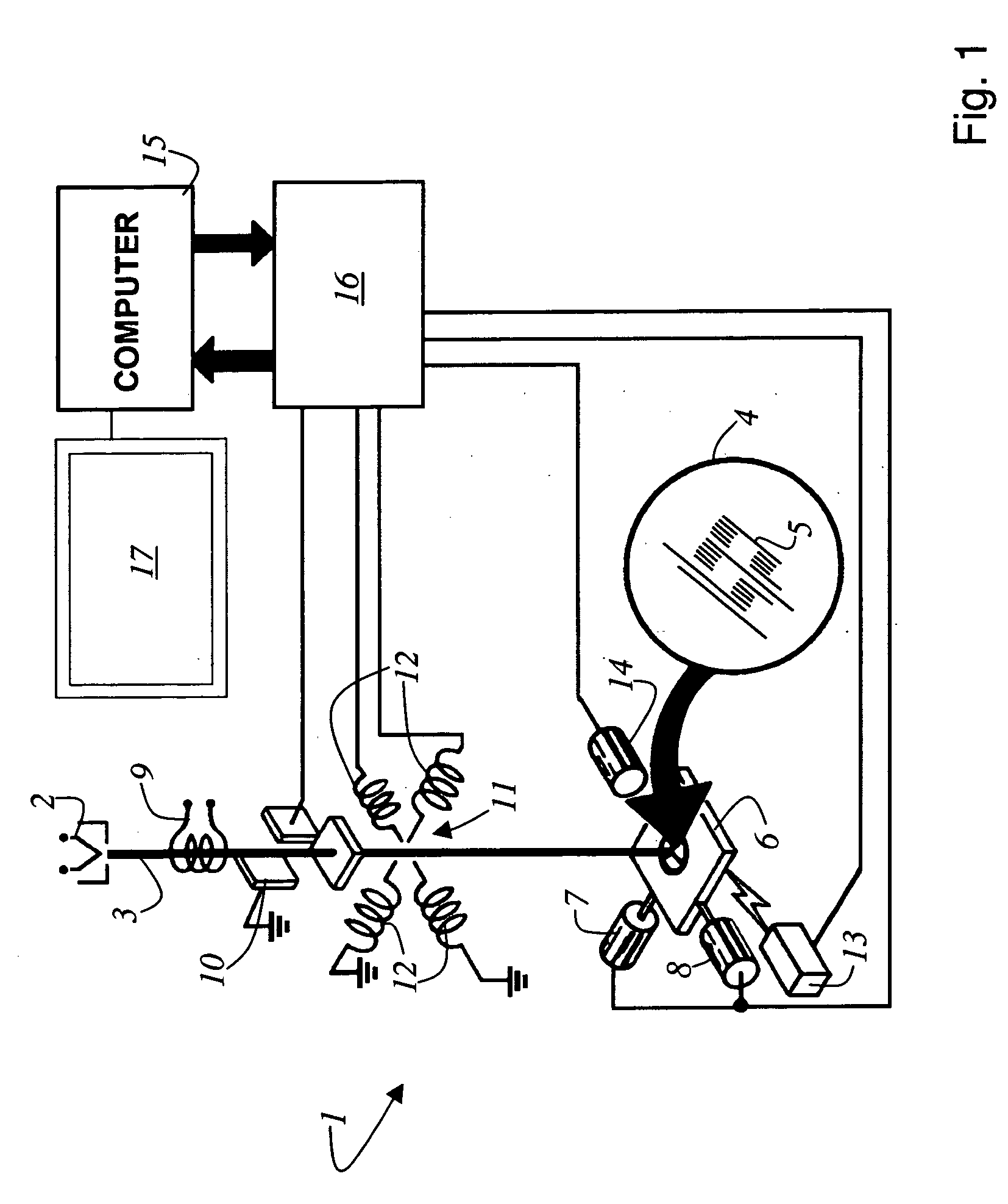

Method for reducing the fogging effect

InactiveUS20050287451A1Promote resultsSmall size errorElectric discharge tubesRadiation applicationsEngineeringElectron-beam lithography

Method for reducing the fogging effect in an electron beam lithography system wherein the exposure is controlled in order to obtain resulting pattern after processing which are conform to design data. A model for the fogging effect is fitted by individually changing at least the basic input parameters of the control function, the function type is chosen in accordance to the Kernel type used in the proximity corrector. The proximity effect is considered as well and an optimised set of parameters is obtained in order to gain a common control function for the proximity and fogging effect. The pattern writing with an e-beam lithographic system is controlled by the single combined proximity effect control function and the fogging effect control function in only one data-processing step using the same algorithms as are implemented in a standard proximity corrector.

Owner:VISTEC ELECTRON BEAM

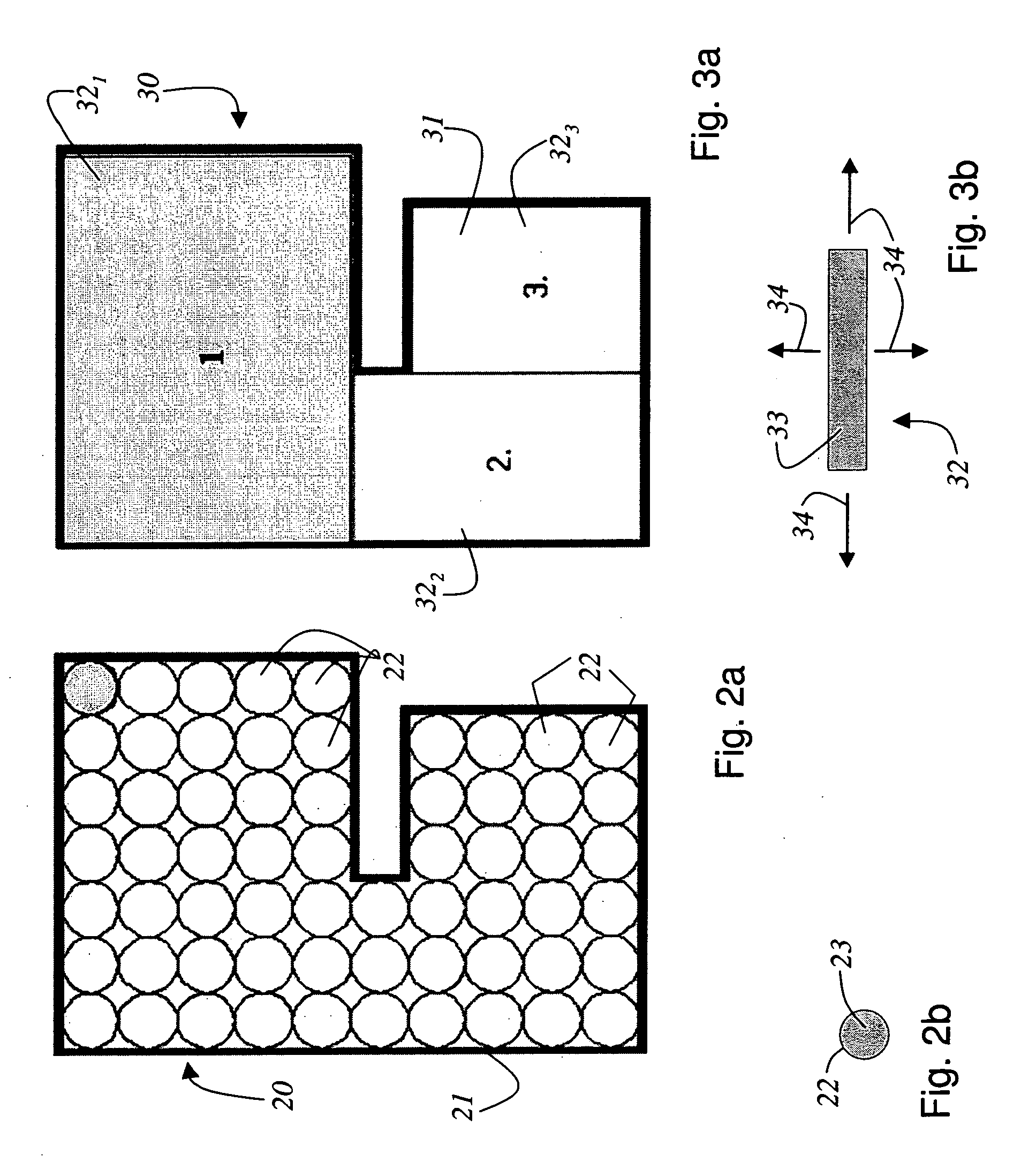

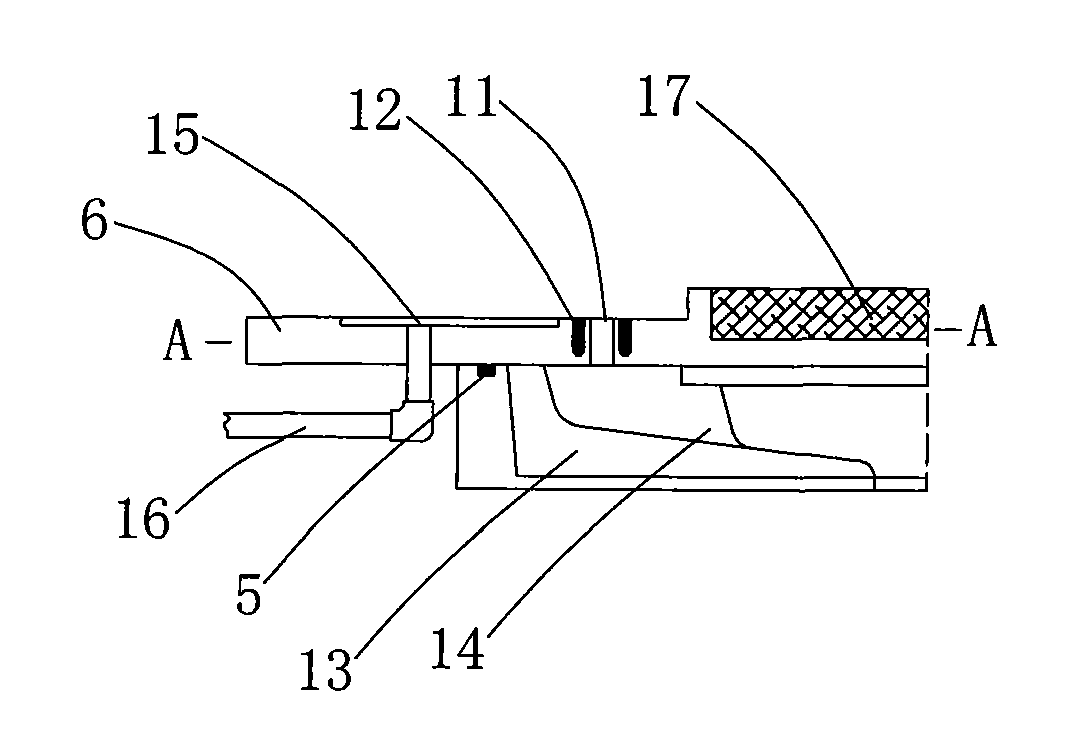

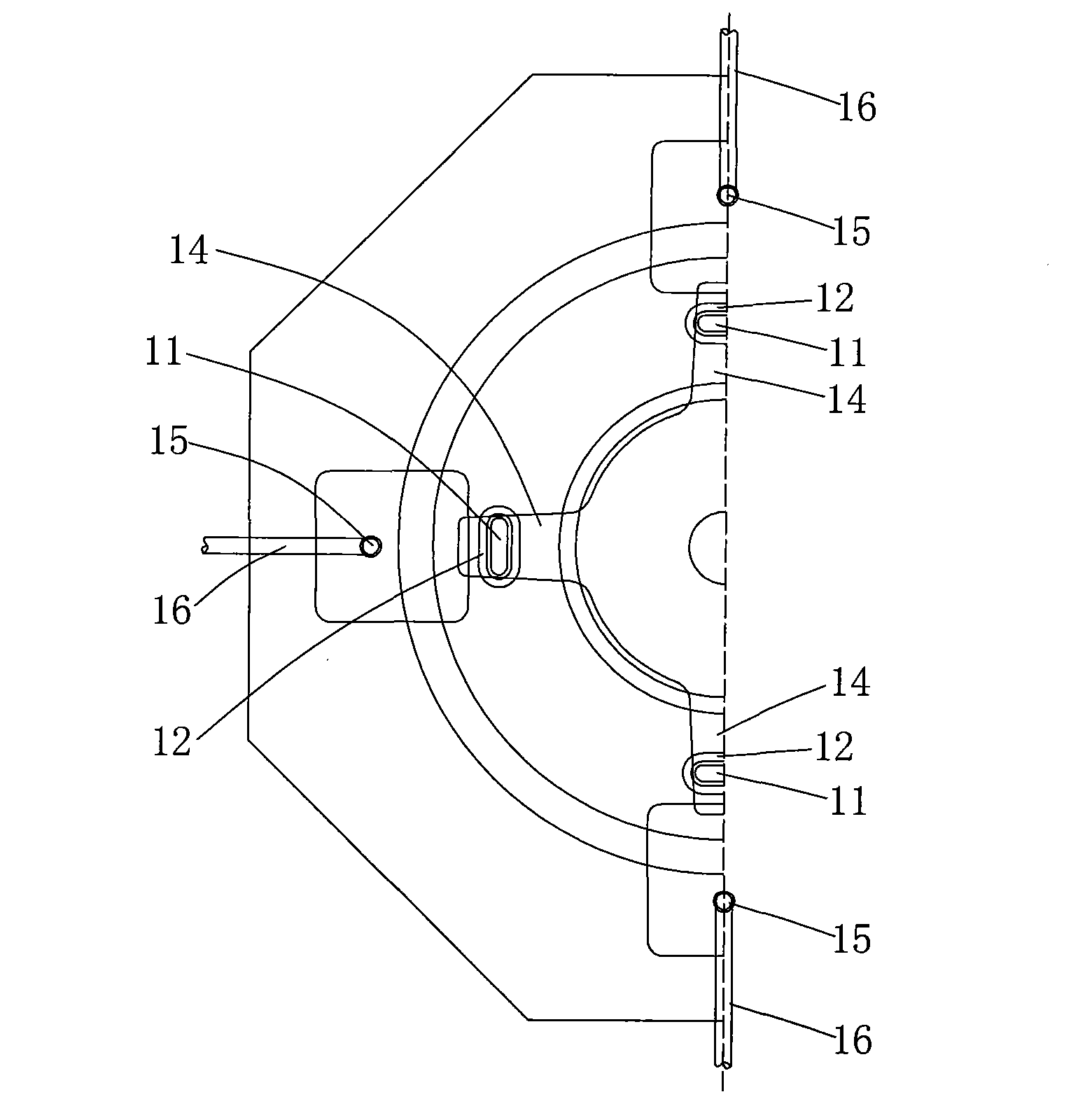

Multi-piece part composed of metal element and manufacturing method thereof

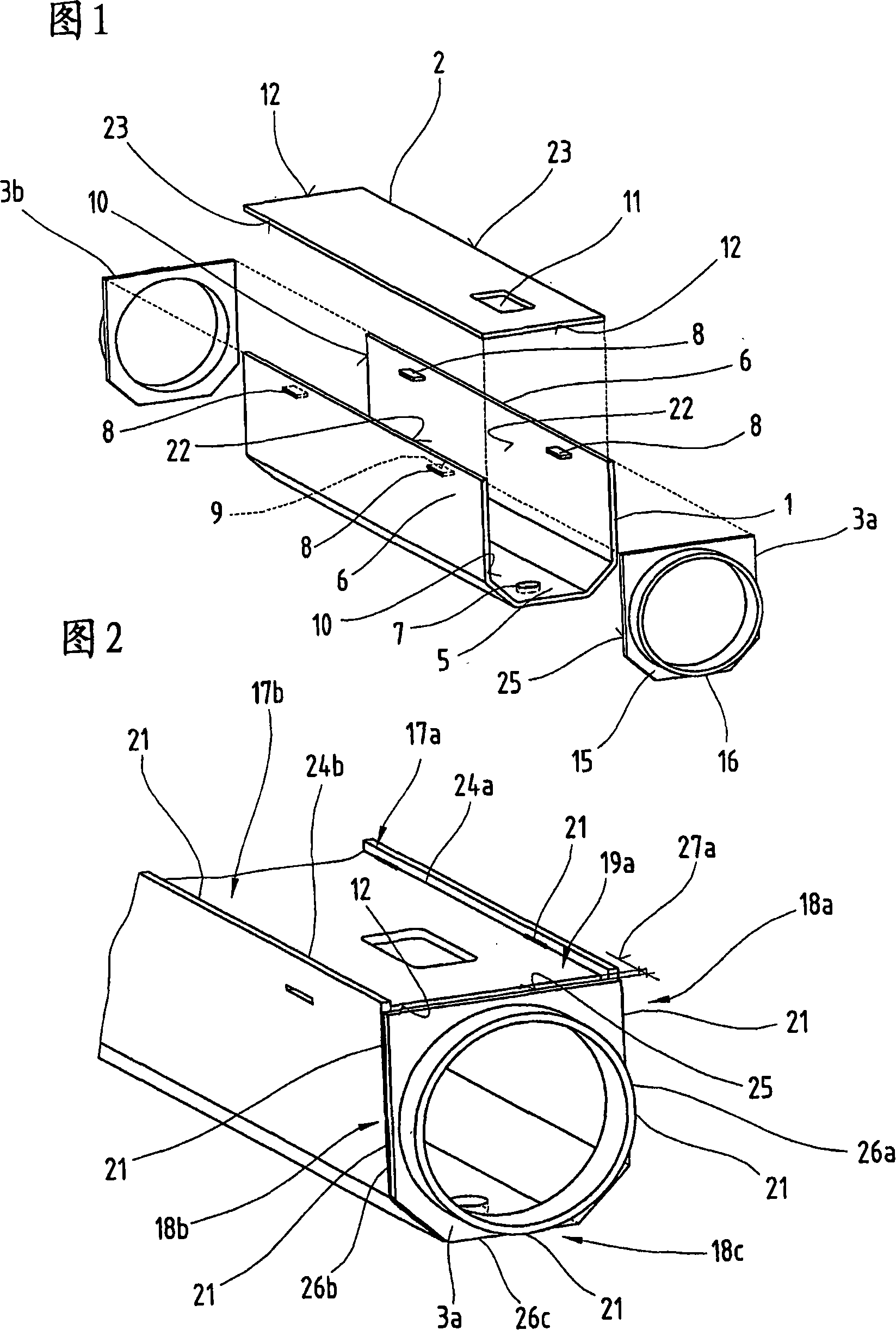

InactiveCN101048257APrevent agingAvoid brittlenessThin material handlingLaser beam welding apparatusCold formedButt joint

The invention relates to a subassembly (1) and a method for the production thereof. Said subassembly (1) comprises a first and a second part (2, 3), the first (2, 3) of which is cold-formed. Said parts (2, 3) are provided with parallel planar pieces (20, 21) and contact areas that extend at an angle therefrom in order to place the two parts (2, 3) against each other without leaving a gap therebetween while being joined to each other at the butt joint (16) via a welded seam (17) created by means of beam welding. The planar pieces (20, 21) are disposed so as to be misaligned relative to each other by an offset (19). One of the parts (2, 3) is provided with a contacting projection (6) which embodies the contact area of the first part (2). The parts (2, 3) are positioned relative to each other in such a way that the second part (3) forms the butt joint (16) along with the first part (2) in the section of the first part (2) in which an offset thickness of the basic material is smaller than the offset thickness of the structure in a deformation zone (18) created on the first part (2) by cold forming.

Owner:STIWA HLDG

Automatic packaging mechanism for single-piece absorptive hygienic product

ActiveCN105083629AAdjust intervalImprove pass ratePaper article packagingWrappingMechanical engineeringFast speed

The invention belongs to the technical field of production equipment of absorptive hygienic products, and discloses an automatic packaging mechanism for a single-piece absorptive hygienic product. A packing system is sequentially provided with a multi-stage conveying unit, a film packaging and folding device and a heat sealing and cutting combination unit in the conveying direction. The multi-stage conveying unit sequentially comprises a front portion conveying unit, a middle conveying unit in the middle and a rear portion conveying unit which are operated independently. The middle conveying unit is provided with a synchronous conveying belt, baffles which protrude out of the surface of the conveying belt are evenly arranged on the surface of the conveying belt at intervals, and the hygienic product is conveyed on the portion, between the adjacent baffles, of the synchronous conveying belt. The automatic packaging mechanism for the single-piece absorptive hygienic product can be applied to single-piece packaging of the larger and thicker hygienic product such as sweat pants, has the beneficial effects of being high in packaging yield, low in size deviation, high in production speed and the like, and can adapt to high-speed development requirements of the hygienic products.

Owner:ZUIKO (SHANGHAI) CORP

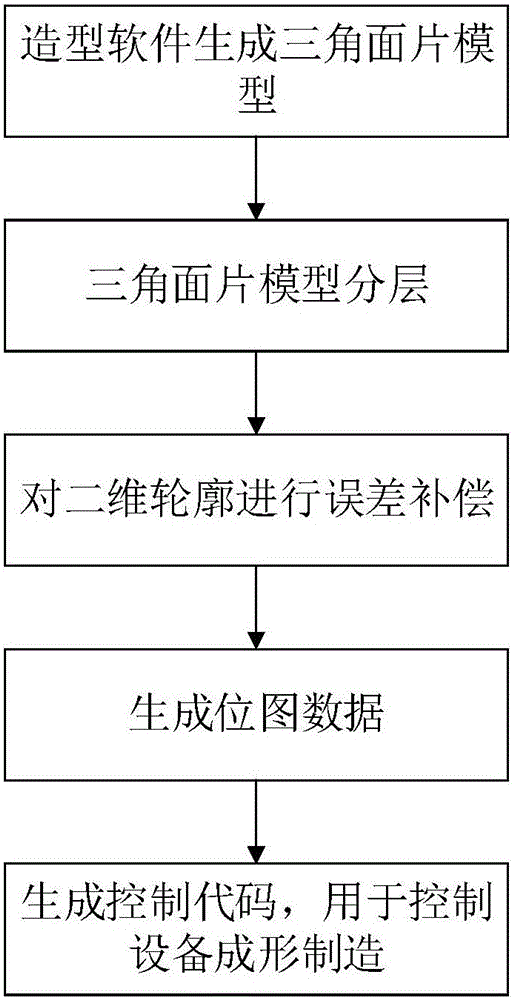

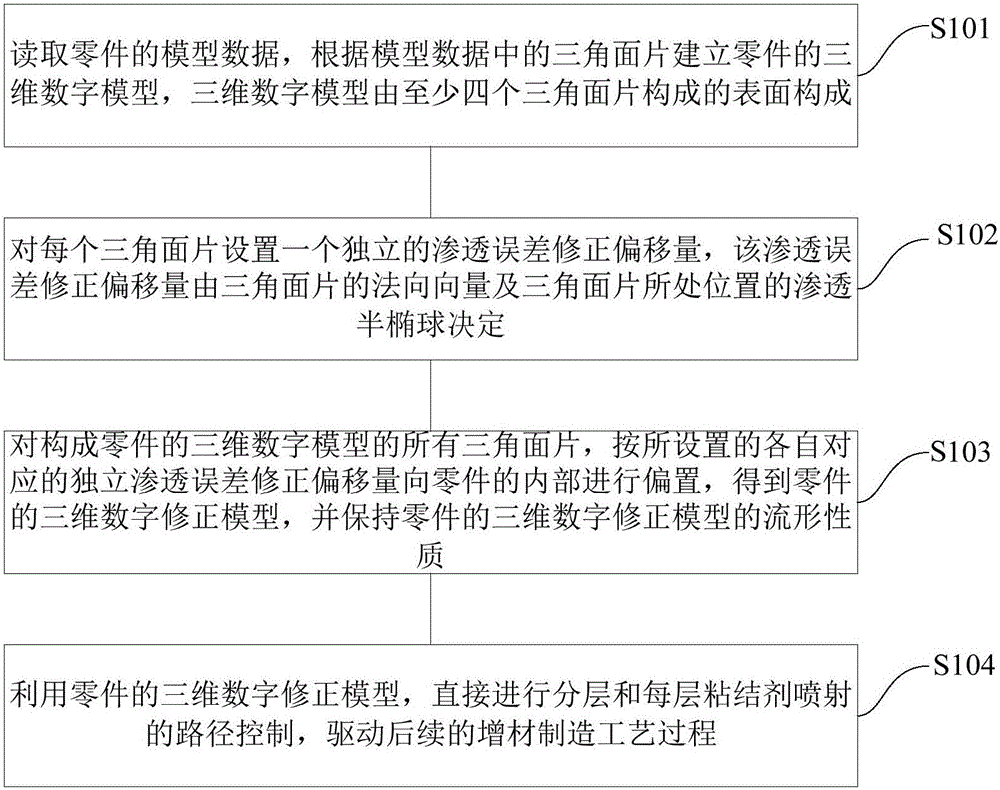

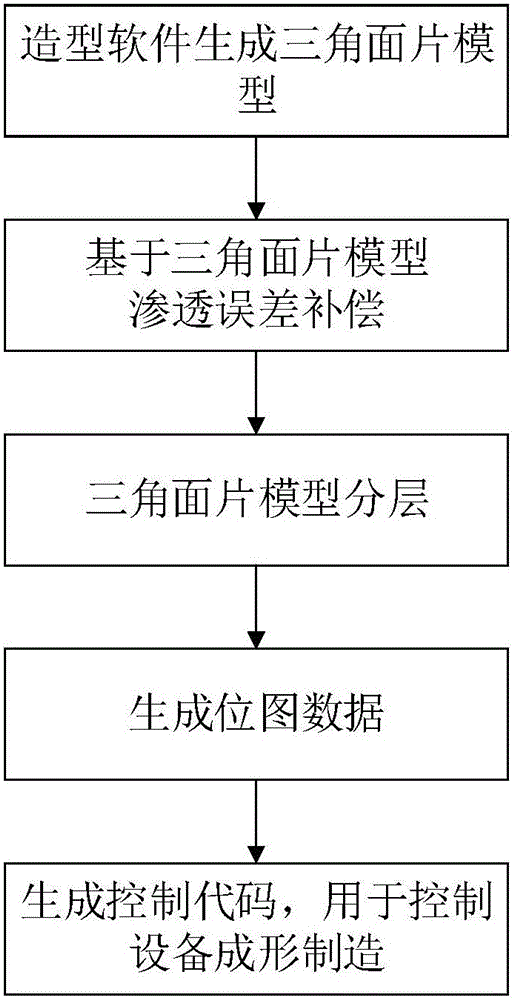

Error compensating method for material-increase manufacturing

ActiveCN105058795AHigh precisionImprove forming qualityAdditive manufacturing apparatusEngineeringAdditive layer manufacturing

The invention provides an error compensating method for material-increase manufacturing. The method includes the steps that model data of a part are read, and a three-dimensional digital model of the part is established according to triangular face sheets; an independent correction offset is set for each triangular face sheet and determined by a normal vector of the triangular face sheet and the semi-ellipsoidal shape of a sedimentation unit at the position where the triangular face sheet is located; all the triangular face sheets forming the three-dimensional digital model of the part are deflected to the interior of the part according to the set independent correction offsets corresponding to the triangular face sheets, a three-dimensional digital correction model of the part is obtained, and the manifold property of the three-dimensional digital correction model of the part is maintained; and layering and material-increase manufacturing of each layer are directly performed to achieve path control of a sedimentation path according to the three-dimensional digital correction model of the part, and a subsequent material-increase manufacturing craft process is driven. The error compensating method can reduce anisotropy forming errors caused by anisotropy of the size of the sedimentation unit during material-increase manufacturing and increase material-increase manufacturing precision and forming quality.

Owner:TSINGHUA UNIV

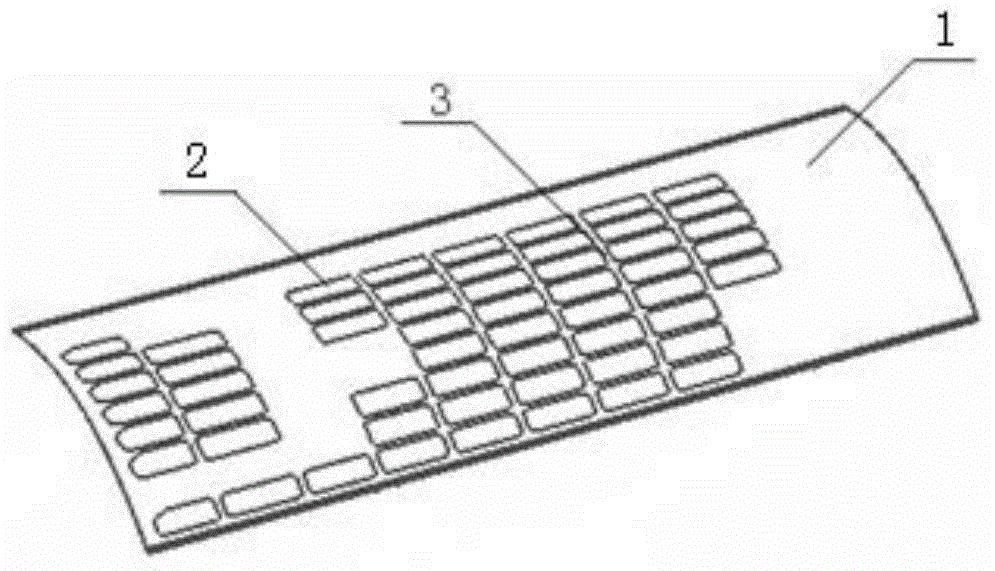

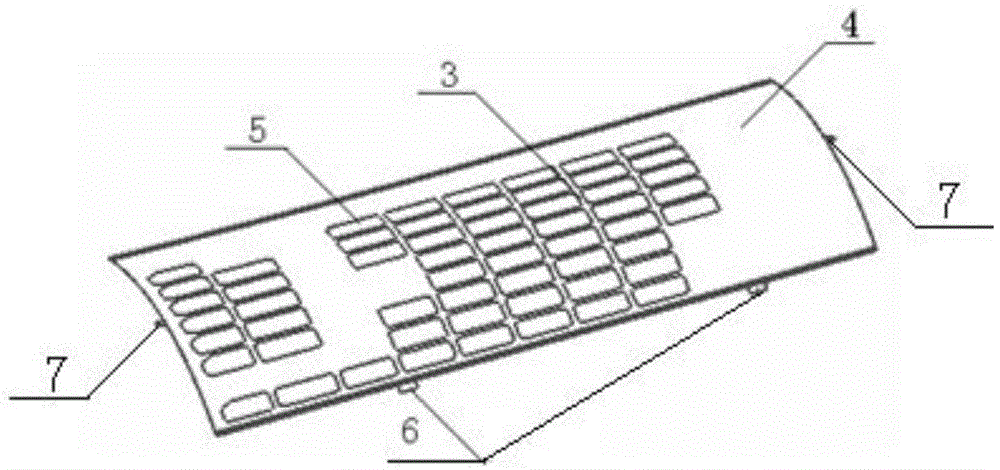

Manufacturing method of airplane chemical milling skin three-dimensional chemical milling sample plate

InactiveCN104476118ASmall size errorDimensional Error GuaranteeAircraft componentsStandard samplesAirplane

The invention belongs to the technical field of chemical milling, and relates to improvement of a manufacturing method of a large-sized airplane chemical milling skin three-dimensional chemical milling sample plate. The method is characterized in that the three-dimensional chemical milling sample plate is manufactured through the following steps: establishing a standard sample board technological digital-analog data set; manufacturing a standard sample board; establishing a chemical milling sample template technological digital-analog data set; manufacturing the three-dimensional chemical milling sample board. According to the improved manufacturing method of the airplane chemical milling skin three-dimensional chemical milling sample plate, the dimensional error of a perspective hole in the three-dimensional chemical milling sample plate can be greatly reduced, and the mold scribing accuracy and the sample plate forming accuracy are improved, so that the dimensional accuracy of the airplane chemical milling skin is guaranteed.

Owner:SHAANXI AIRCRAFT CORPORATION

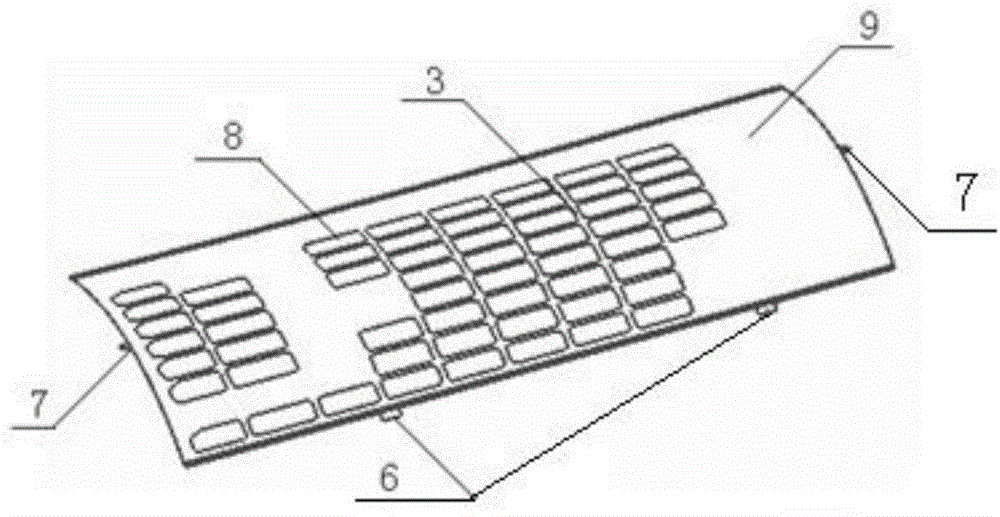

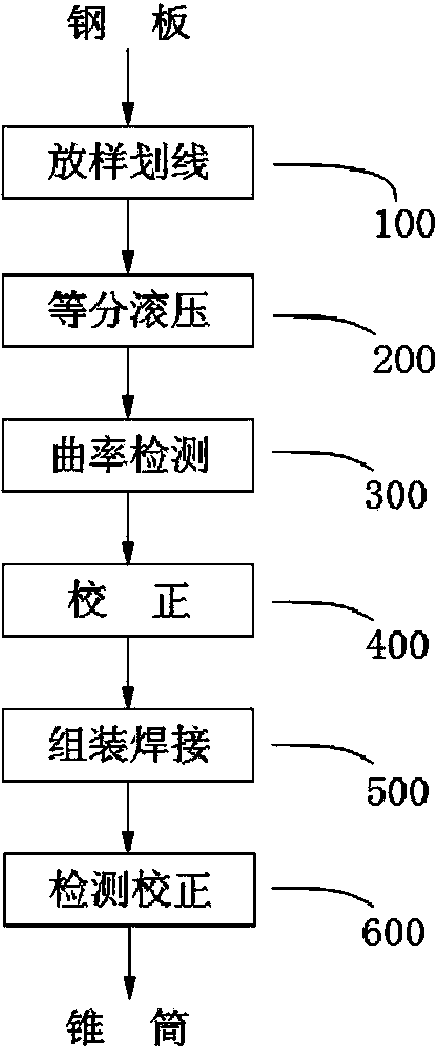

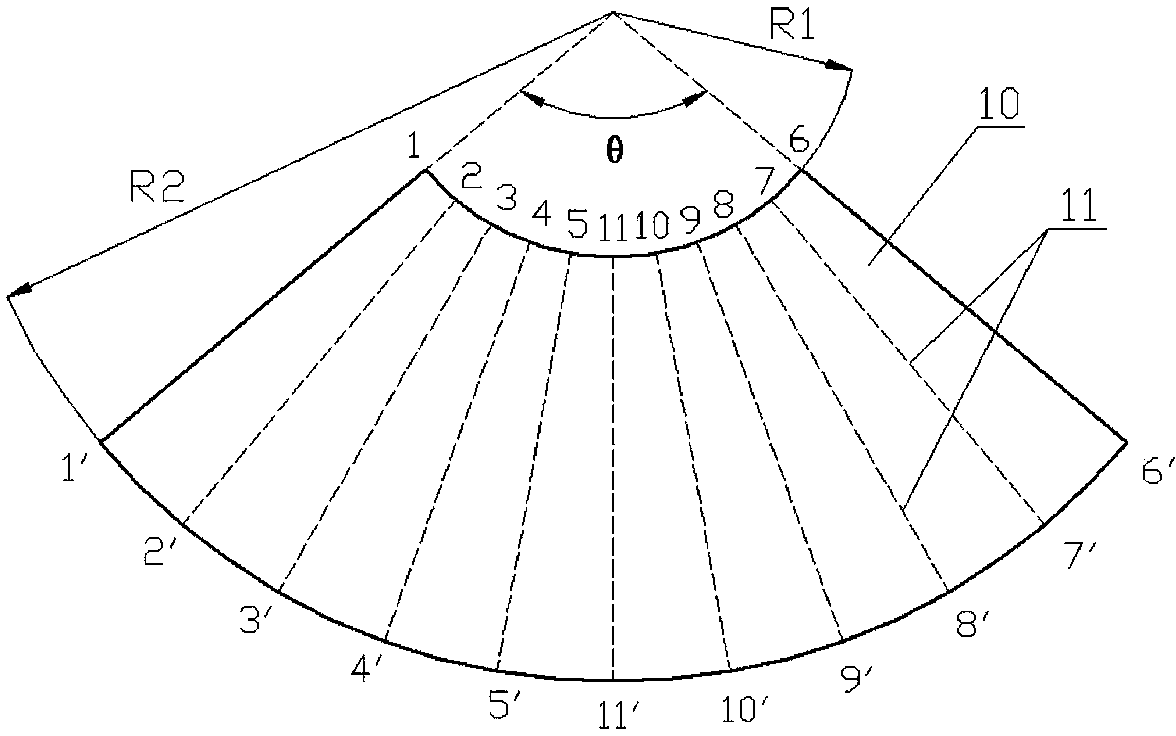

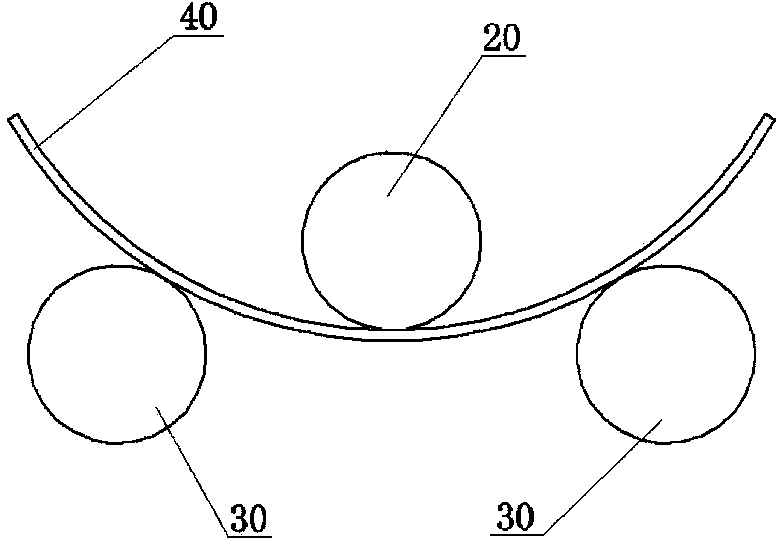

Efficient roll forming method for large medium-thickness-plate conical cylinder

Owner:YUNNAN HEAVY EQUIP MFG GRP

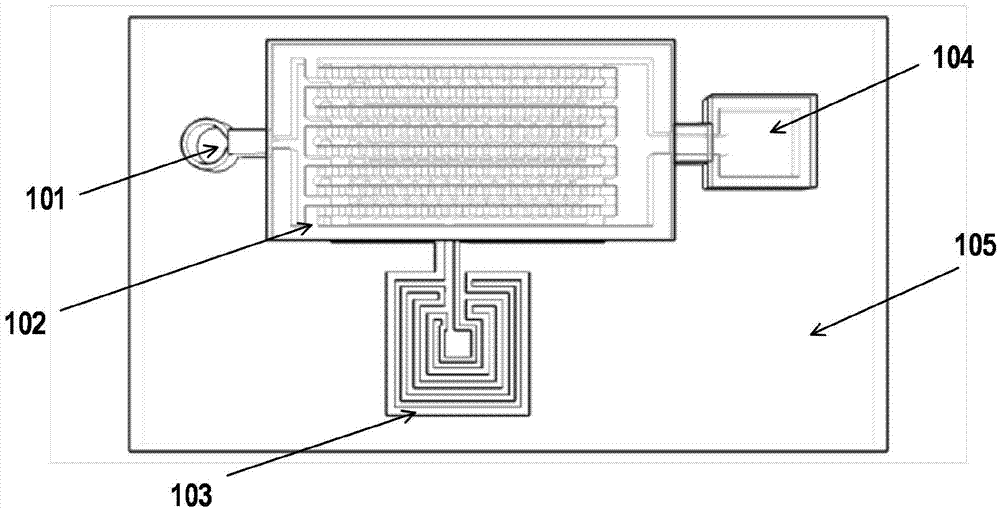

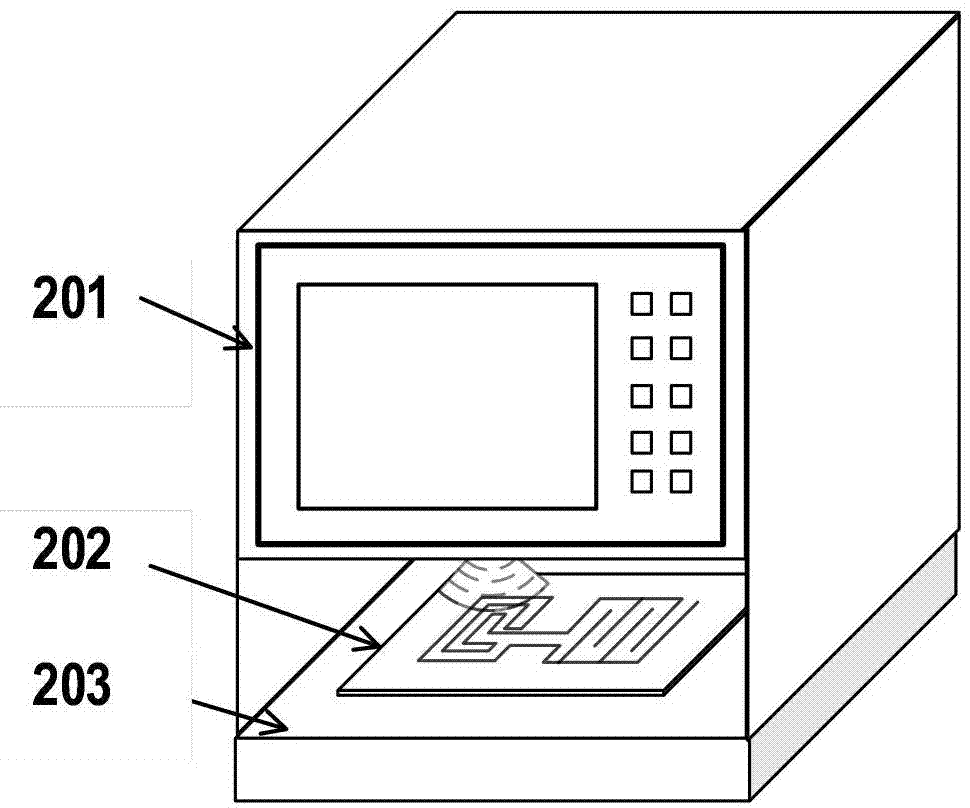

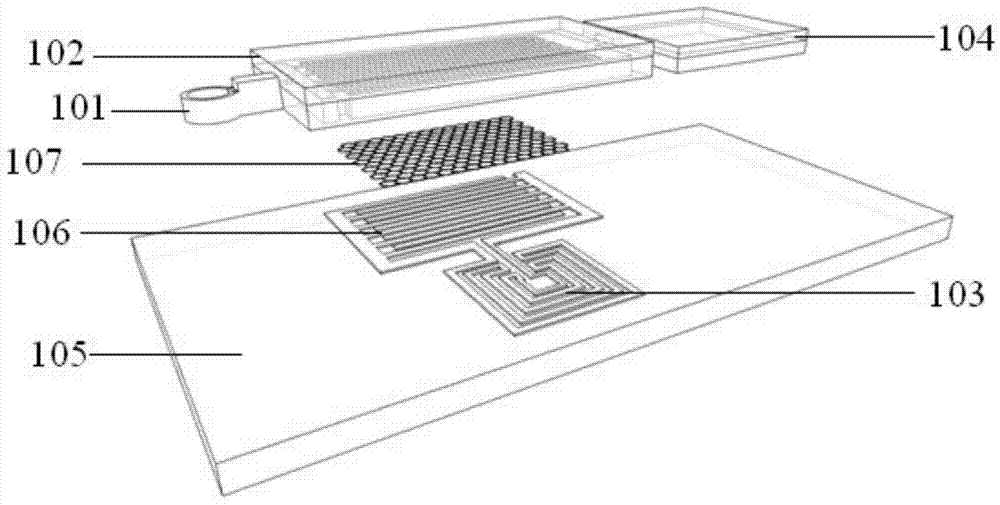

Peripheral blood circulation tumor cell detection chip and system thereof

InactiveCN104297298AStrong anti-interference abilitySmall size errorMaterial impedanceSingle layer grapheneMicro fluidic

The invention relates to a peripheral blood circulation tumor cell detection chip and a system thereof. The detection chip comprises a substrate, and the substrate is provided with an interdigital capacitance circuit and a spiral inductor metal circuit connected with the interdigital capacitor circuit; the interdigital capacitor circuit tightly laminated with a single layer graphene film; the graphene film is laminated with a micro-fluidic control channel; the micro-fluidic control channel and the single layer graphene film form an integrated graphene micro-fluidic pipe screening microchip for screening tumor cells; the single layer graphene film, the interdigital capacitor circuit and the spiral inductor circuit form a whole RCL resonance network; the spiral inductor circuit is also used as a cross coupling antenna. The detection system comprises a detection signal reading and analysis device, and the peripheral blood circulation tumor cell detection chip. The chip and the system can realize the fast, sensitive, accurate and cheap detection of tumor cells.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Photocurable resin-based ceramic composite material and ceramic green body degreasing method

ActiveCN108218440AReduce disengagementHigh affinityAdditive manufacturing apparatusCeramic compositeMetallurgy

The invention discloses a photocurable resin-based ceramic composite material and a ceramic green body degreasing method. By optimizing the design of a resin system, the method increases the penetration depth of a ceramic slurry system and reduces the molding dimensional error while maintaining the system reaction activity; furthermore, the interlayer bonding force of a ceramic green body and theadhesion between the ceramic green body and a printing platform are improved, and the detachment between the ceramic green body and the platform as well as the cracks on the surface of the ceramic green body are reduced.

Owner:深圳长朗智能科技有限公司

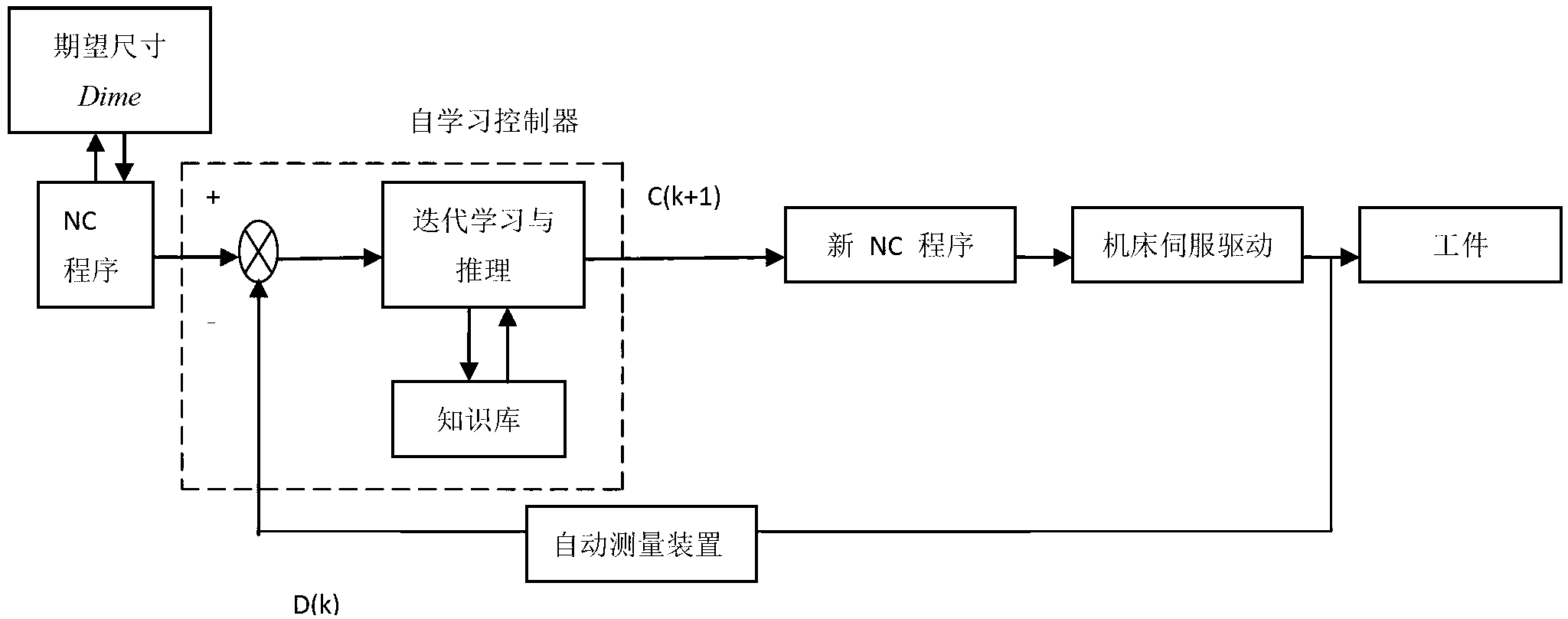

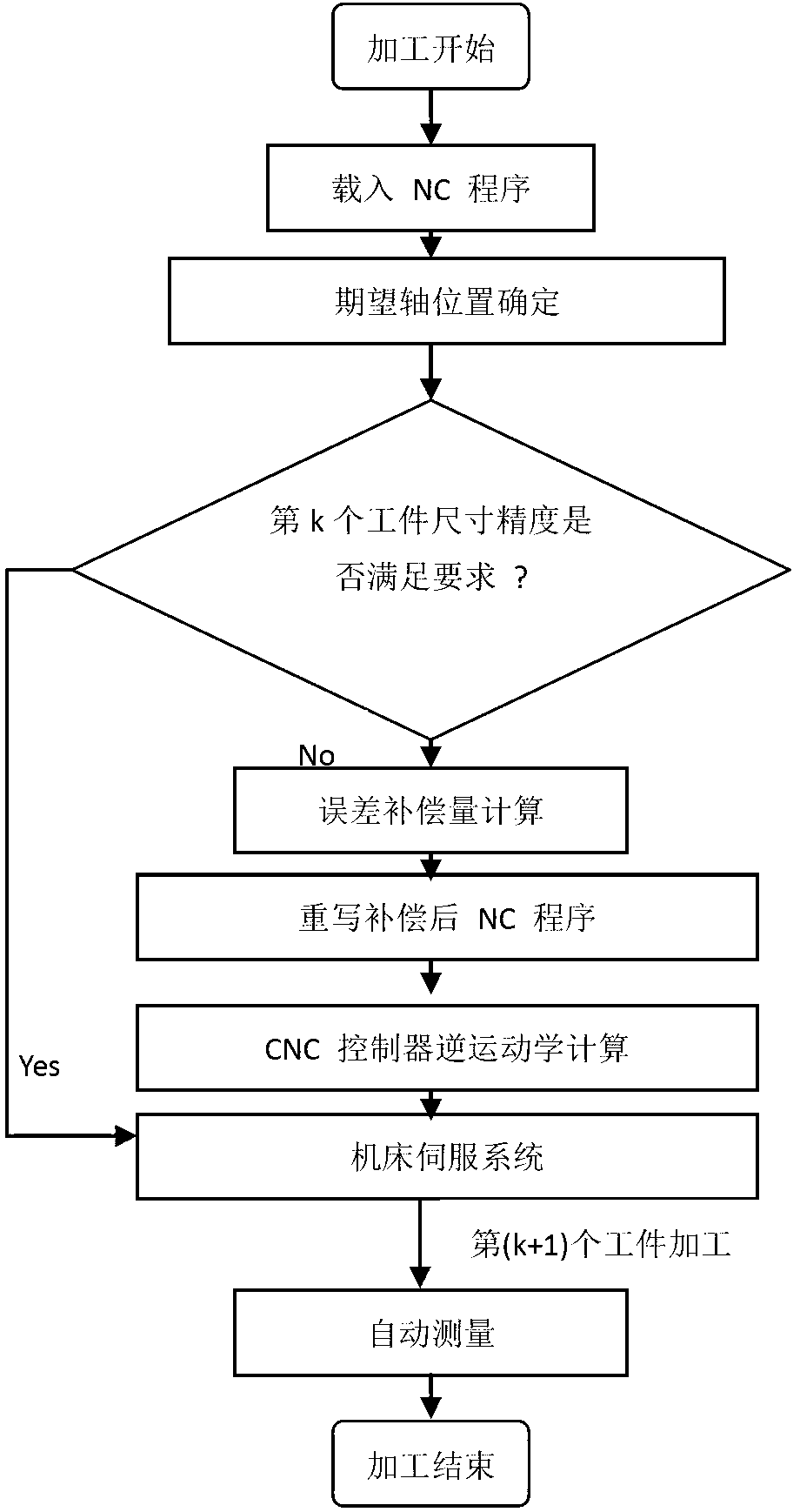

Method for automatically compensating numerical control machining size error based on fractional order

InactiveCN103235553ASmall size errorImprove pass rateProgramme controlComputer controlNumerical controlCompensation effect

The invention discloses a method for automatically compensating a numerical control machining size error based on a fractional order. The method comprises the following steps of performing machining, and measuring the size of a machined workpiece to obtain actual machining size data; comparing expected size data with the actual size data to solve a size error, and analyzing the error to identify a system order; calculating the amount of error compensation to be applied before the machining of the next workpiece according to the system order and a size error generated during the machining of the previous workpiece by adopting an iterative learning control law; and correcting a numerical control machining program for the workpiece by using the amount of error compensation before the machining of the next workpiece, and performing numerical control machining on the next workpiece by adopting the corrected numerical control machining program. The size error is automatically compensated by programming and developing numerical control machining size error compensation processing software based on the steps. The size error of the machined workpiece is integrally reduced, the machining accuracy is improved, the qualified rate of the workpiece is remarkably increased, and the remarkable error compensation effect is achieved.

Owner:SHANDONG UNIV

Nickel-based superalloy GH4169 hexagon socket bolt machining technology

ActiveCN103111808AReasonable arrangementImprove connection strengthBoltsSand blastingUltimate tensile strength

The invention discloses a nickel-based superalloy GH4169 hexagon socket bolt machining technology. The machining technology includes blanking, cascading grinding, lubricating, upsetting, coining, heat treating, cooling, sand blasting, machining, plugging grinding, aging treating, thread rolling, R circular arc rolling, flaw detecting and surface treating. The nickel-based superalloy GH4169 hexagon socket bolt machining technology is reasonable in arrangement of a process route, and improves connecting strength of the joint between the head portion of a bolt and a rod portion due to the fact that two-time hot upsetting forming and the R rolling process are adopted for the head portion of the bolt. Meanwhile, reasonable hot upsetting die materials and punch materials are adopted, and consequently manufacturing cost is reduced. Through adoption of upsetting forming of an upsetting die, the machining cycle of parts is greatly shortened, and size errors generated from repeated clamping in machining are reduced. Through adoption of combined machining of the upsetting process and the grinding process, the size uniformity of the parts and the quality stability of the parts are guaranteed.

Owner:GUIZHOU JINGLI HANGTAI TECH

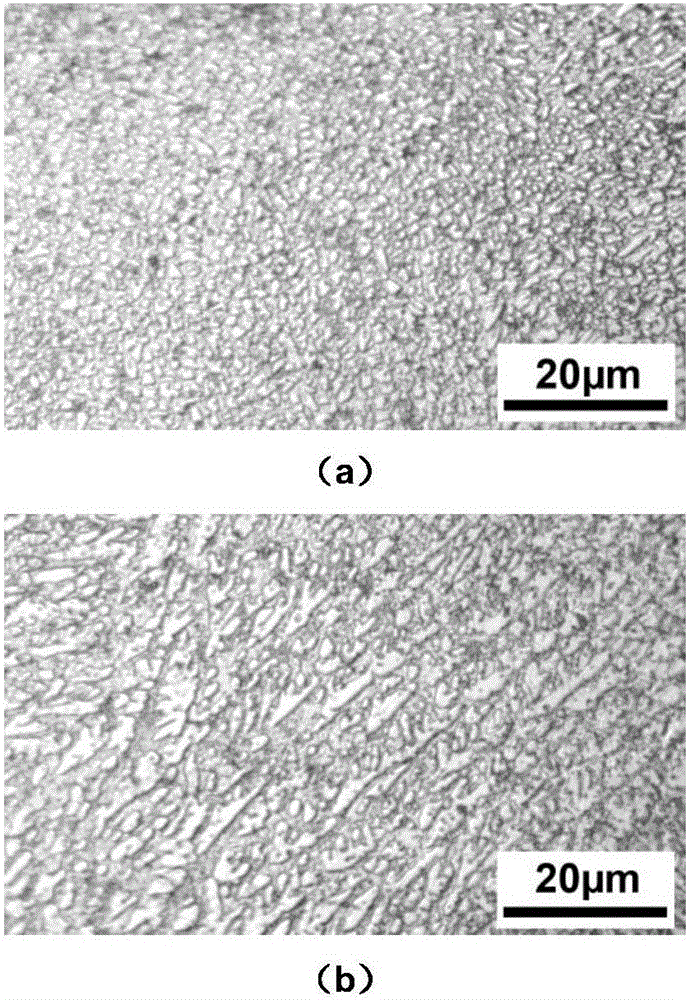

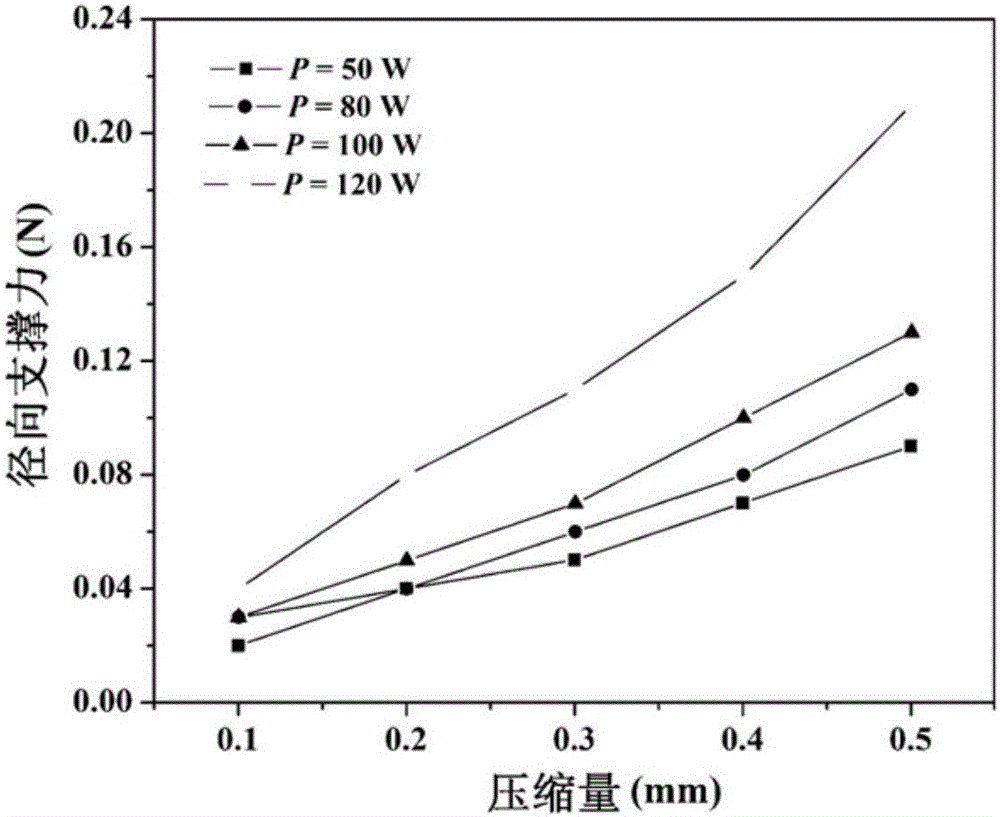

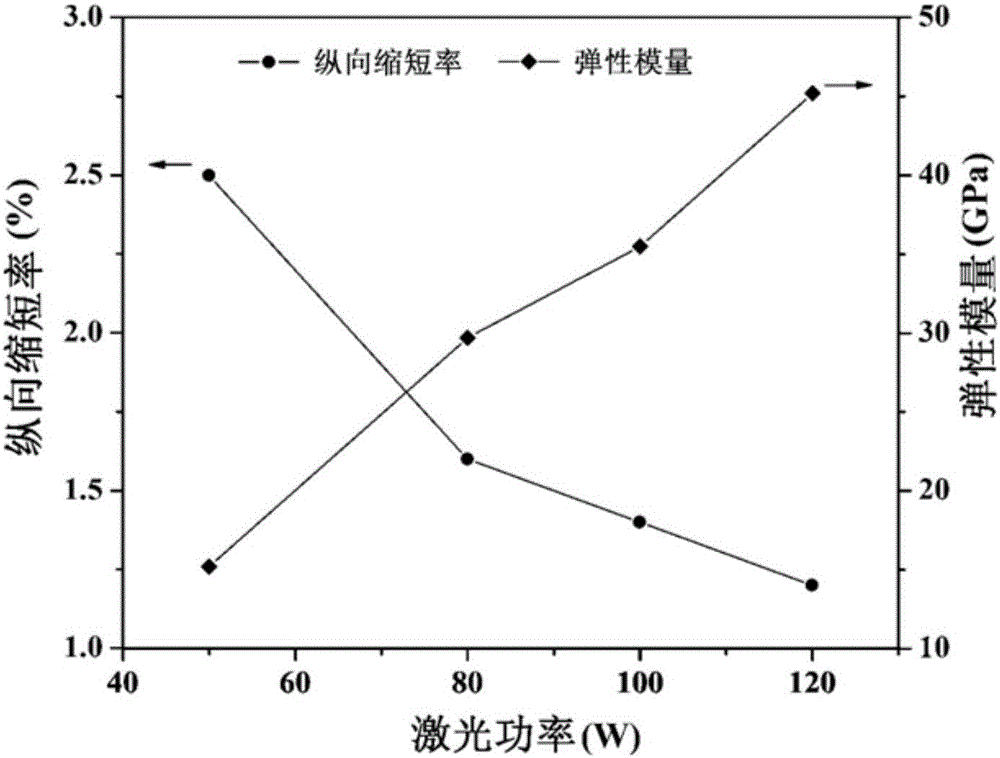

Method for preparing shape memory alloy intravascular stent based on automatic powder laying laser combination machining technology

ActiveCN105033252AReduce trauma areaSmall size errorAdditive manufacturing apparatusIncreasing energy efficiencyBiological tissuePercent Diameter Stenosis

The invention discloses a method for preparing a shape memory alloy intravascular stent based on the automatic powder laying laser combination machining technology. The method comprises the steps that according to a three-dimensional data model of a part to be machined, a high-energy laser beam melting and mixing powder system is utilized, the manner of laying powder layer by layer and carrying out fusing overlaying accumulation layer by layer is carried out until a intravascular stent blank of a mesh structure is formed finally, and then electrochemical polishing is carried out to reach the specific surface roughness requirement. The intravascular stent prepared through the method is based on the unique superelasticity function and the shape memory effect of shape memory alloy, and the occurrence rate of vascular restenosis of the intravascular stent in clinical application can be effectively reduced; by means of mechanical performance and living body environment simulation tests, the intravascular stent has the good biological tissue and blood compatibility and meets the medical application condition; furthermore, based on the advantage of superhigh manufacturing precision of the laser combination machining technology and protection of inert gas in the forming process, the problems of surface roughness, burr, oxidation and the like of a traditional intravascular stent in the preparing process are effectively solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

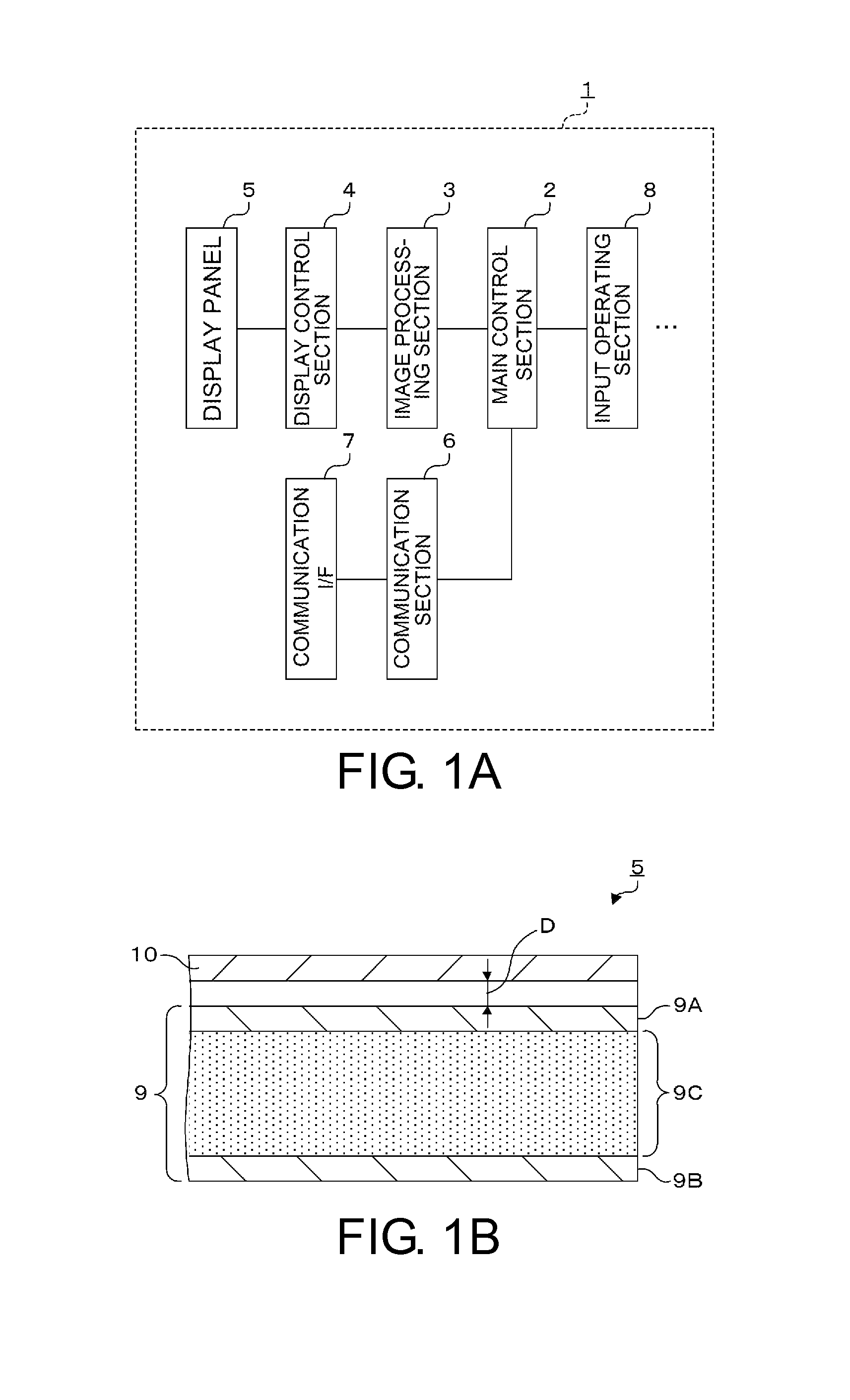

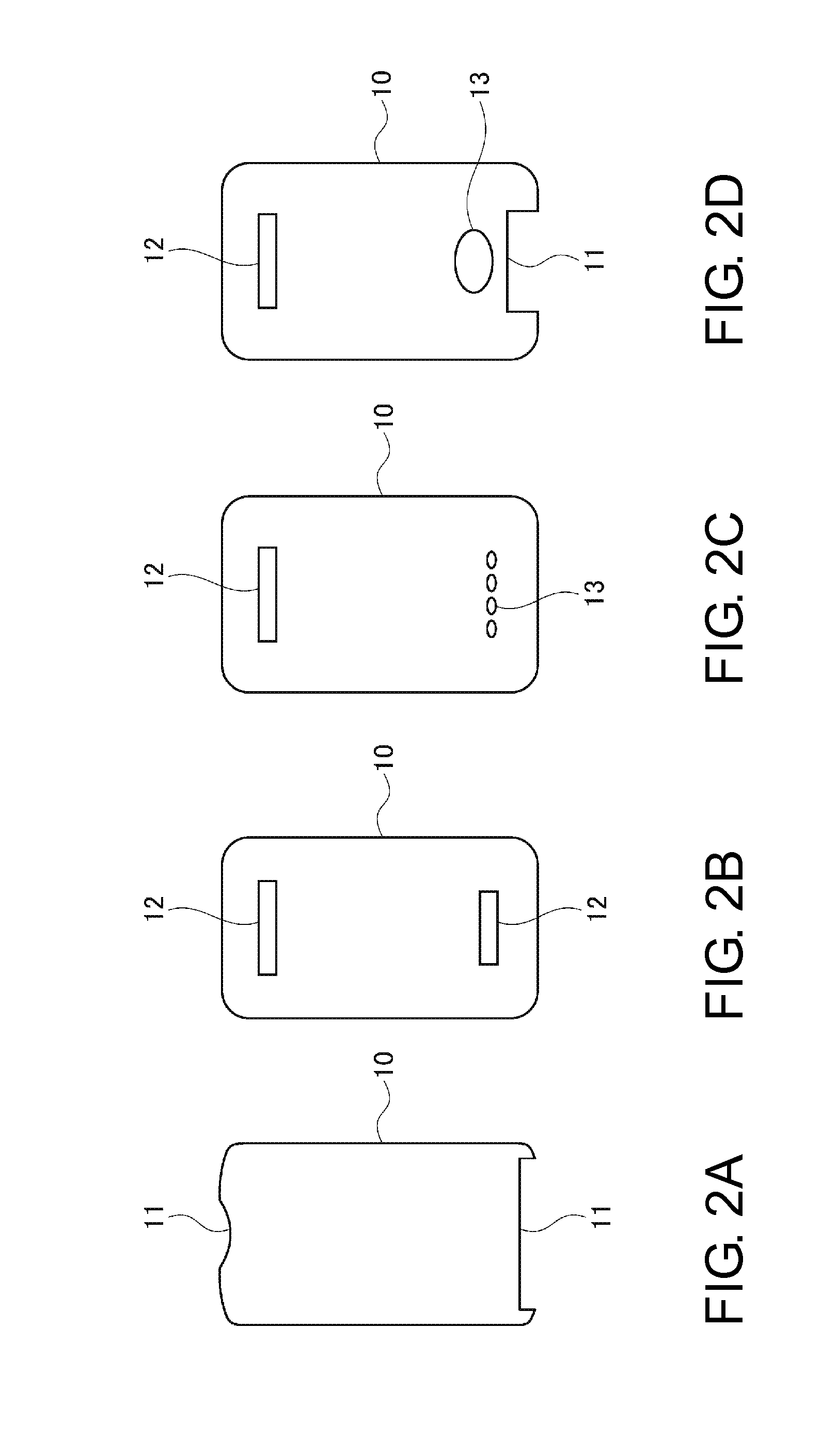

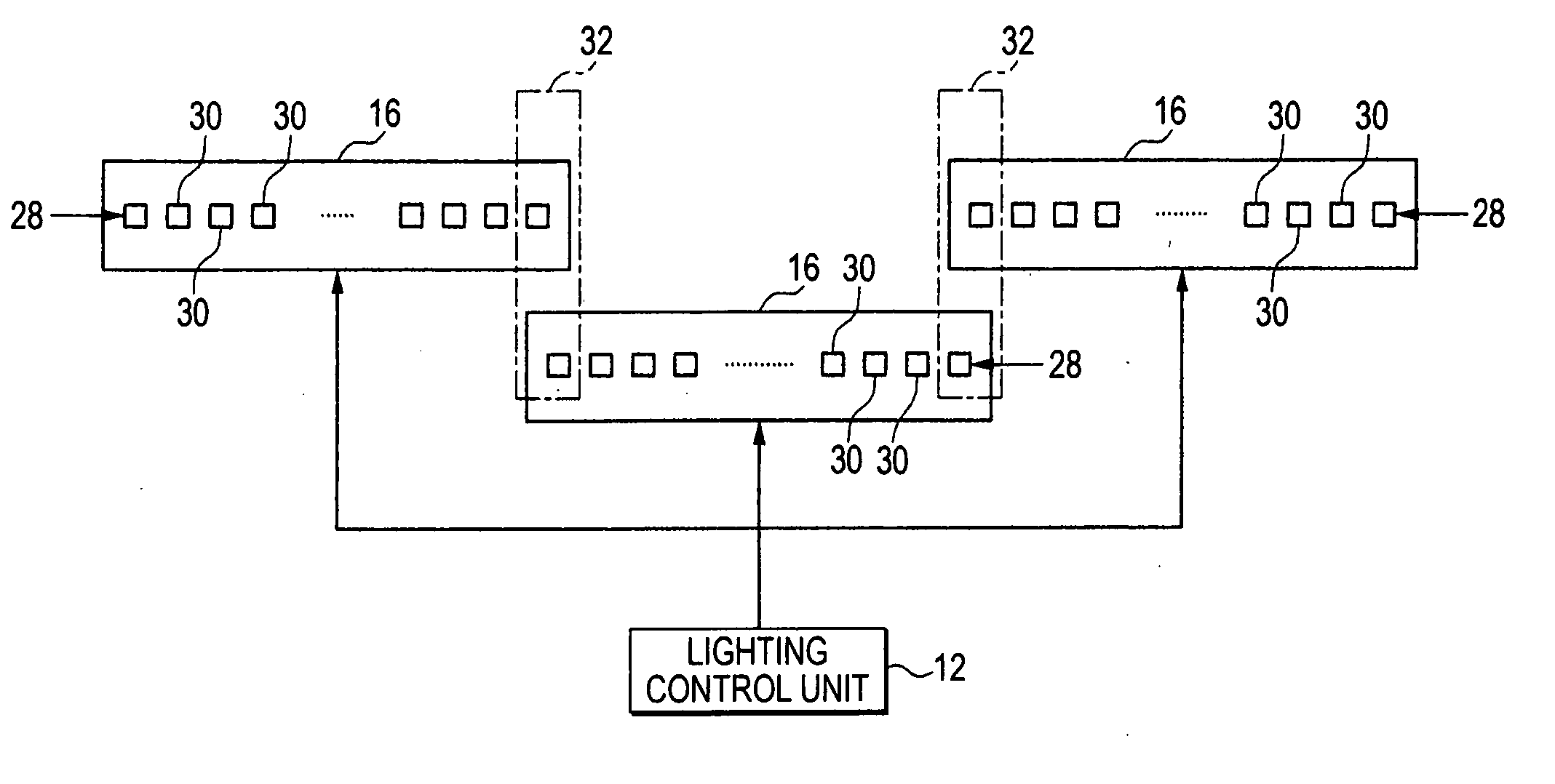

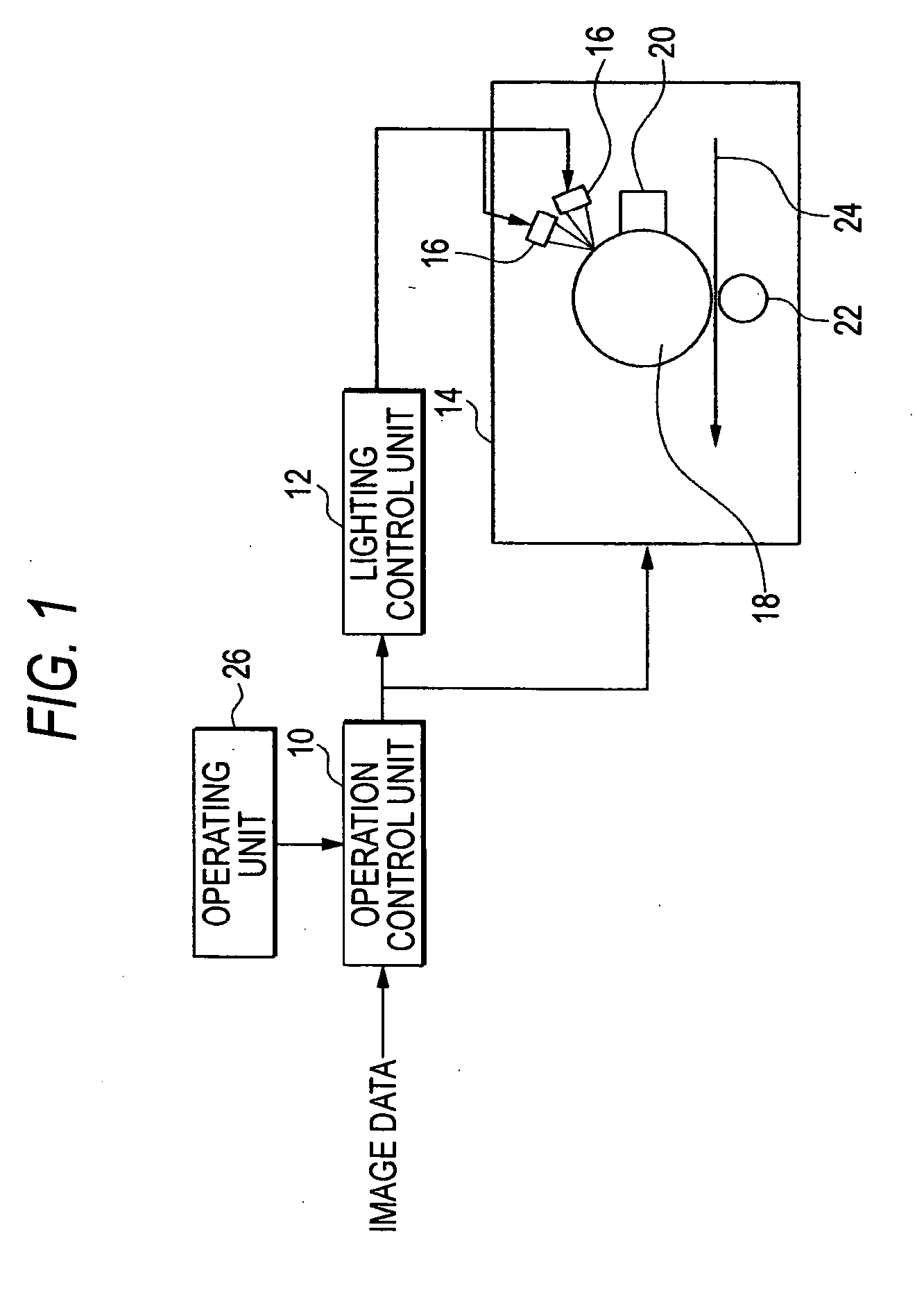

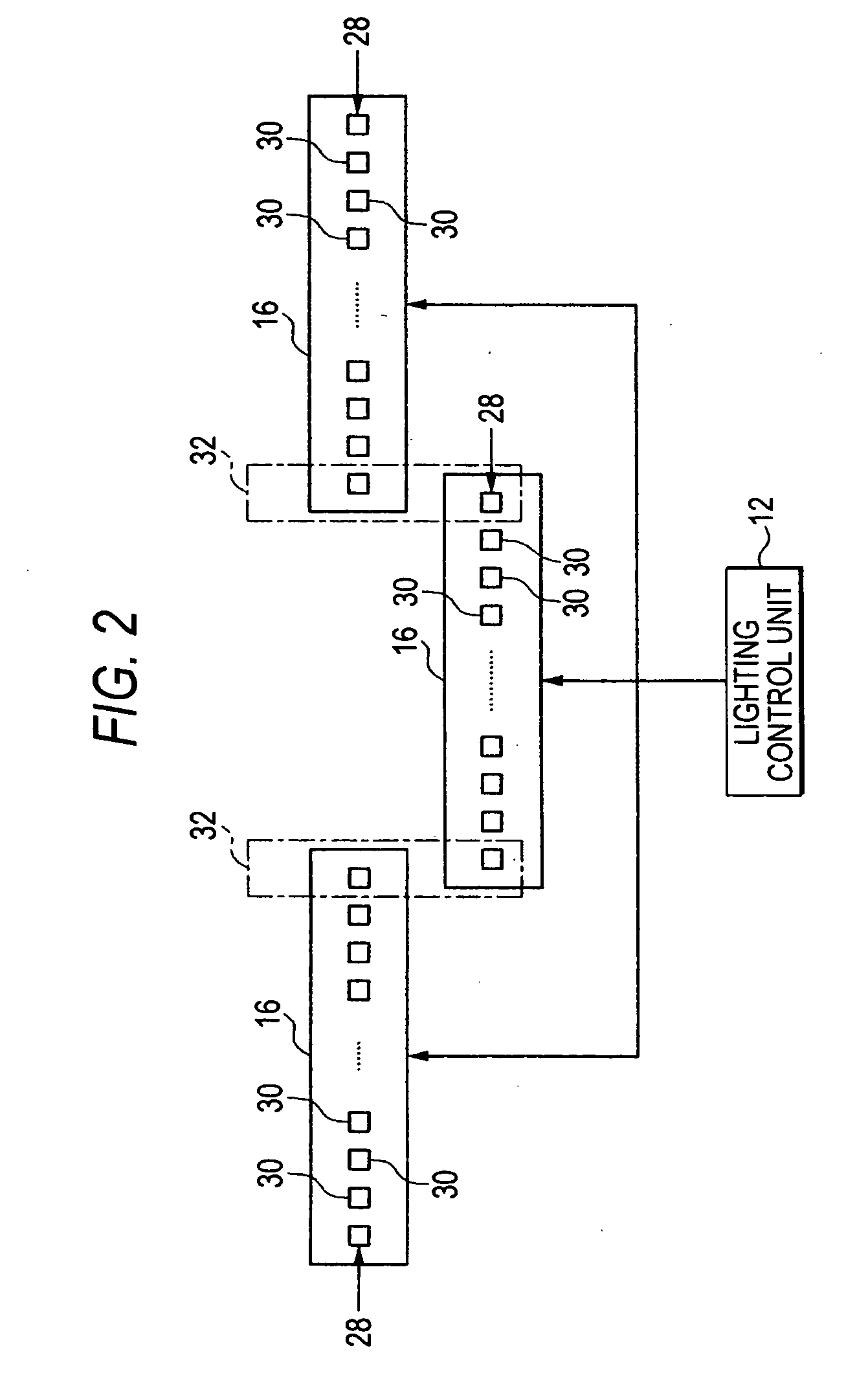

Image forming apparatus

InactiveUS20070070166A1Small size errorImprove accuracyElectrographic processes using charge patternPrintingImage resolutionImage formation

An image forming apparatus capable of forming wide images, includes: an exposing unit having a plurality of LED (light-emitting diode) heads arranged alternately in a main scanning direction, in which the resolution of an LED row formed in at least one of the plurality of LED heads is higher than the resolution of image data in a main scanning direction; and a lighting control unit that controls to turn on or turn off dots in the LED row such that the exposing position of a photoconductive drum is moved in the unit of dots of the high resolution LED row.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Light-cured resin based ceramic composite material capable of providing bright and clean contour and blank degreasing method

ActiveCN108249930AIncrease penetration depthImprove the finishAdditive manufacturing apparatusCeramic compositeSlurry

The invention discloses a light-cured resin based ceramic composite material capable of providing the bright and clean contour of a formed part and a blank degreasing method of a ceramic blank. By optimally designing the resin system, the transmission depth of the ceramic slurry system can be improved and the dimension errors of the formed part are reduced while the reaction activity of the systemis maintained; the interlayer binding force of the ceramic blank and the adhesive property between the ceramic blank and a printing platform are increased, and the distance between the ceramic blankand the platform and cracks on the surface of the ceramic blank are reduced; moreover, the regularity of powder particles arranged along a model surface is improved, so that the material can be made into a model with improved brightness and cleanness of the contour.

Owner:深圳长朗智能科技有限公司

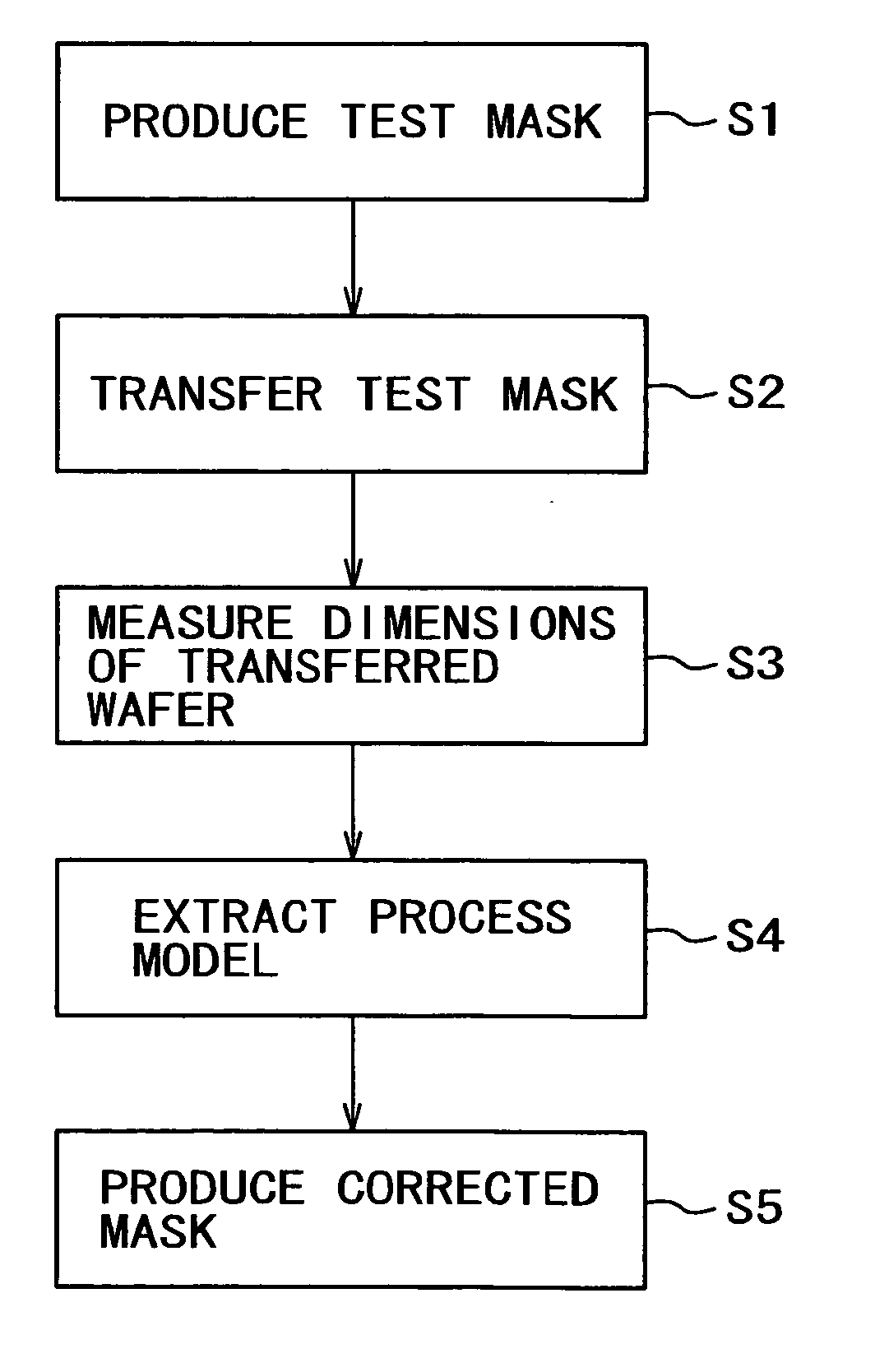

Mask correcting method

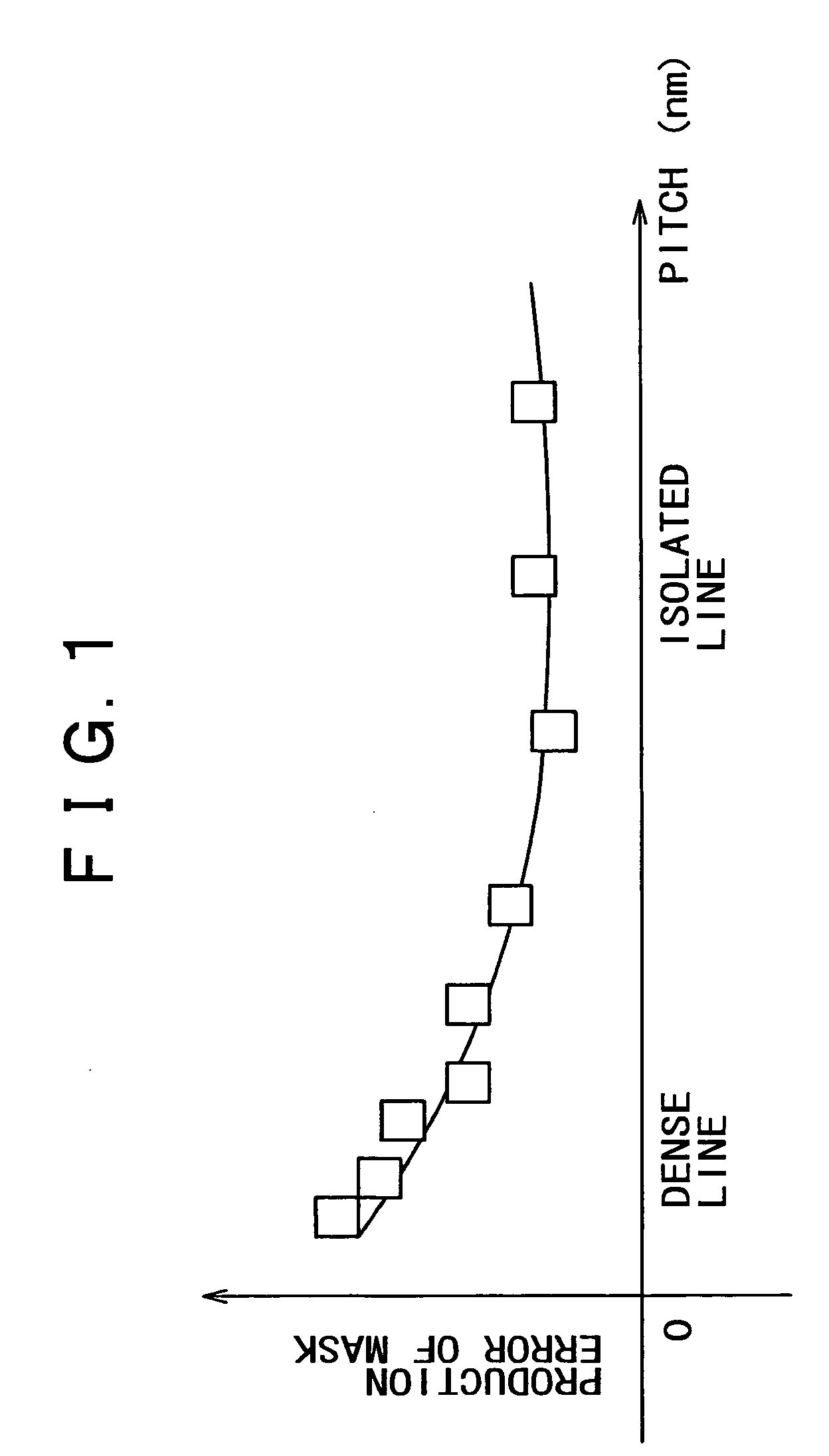

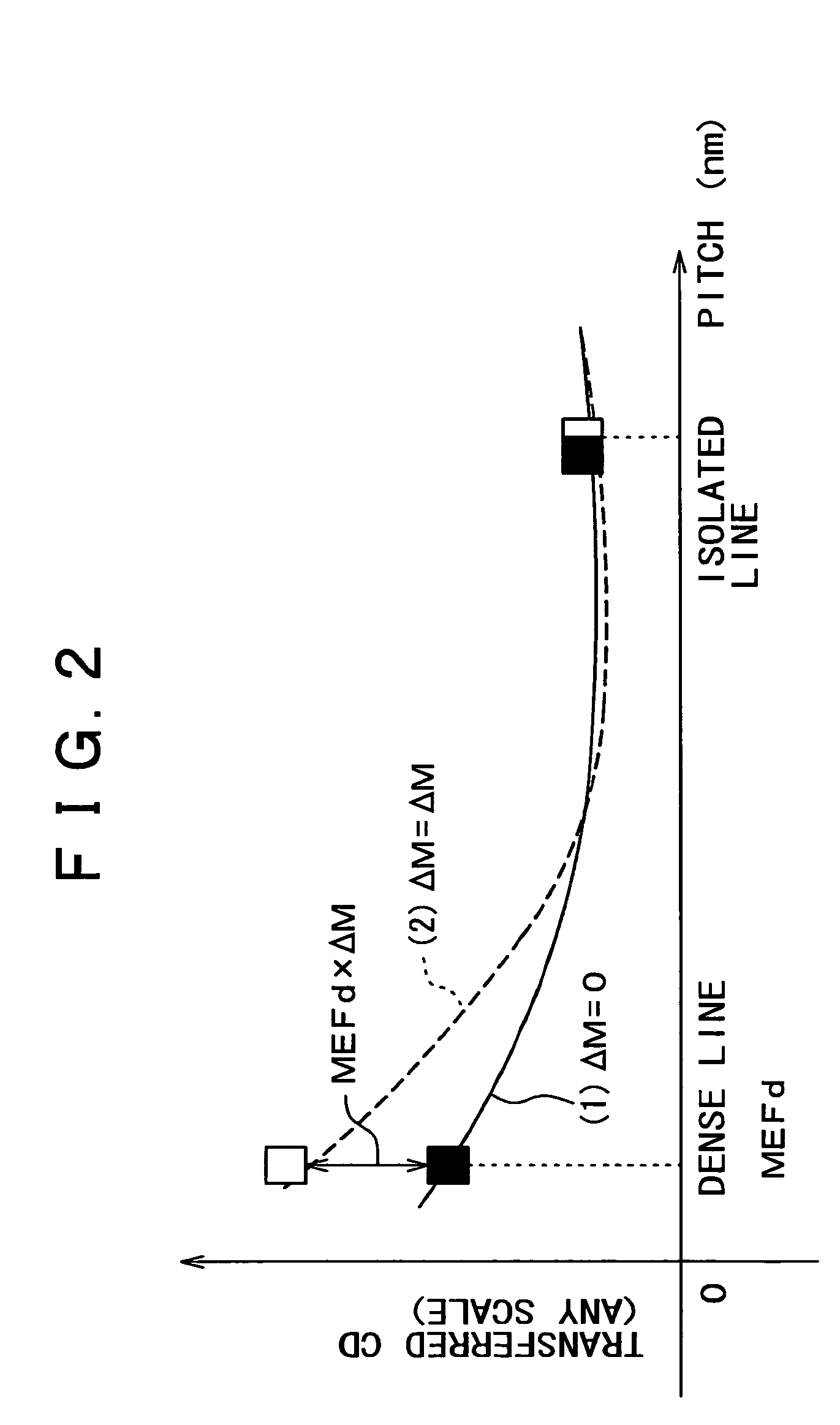

InactiveUS20050164095A1Minimize the differenceImprove calibration accuracyPhotomechanical apparatusSemiconductor/solid-state device manufacturingPresent methodLine width

There is provided a method for correcting a photo mask, which allows the difference between a test mask and a corrected mask with respect to an error of line width depending on coarse / dense pattern to be decreased when the photo masks are corrected by optical proximity effect correction. The present method is consisted of: producing a test mask which acts as a mask for extracting process model for applying an optical proximity effect correction method (s1); transferring and measuring the dimensions of the transferred pattern using the test mask (s2 and s3); obtaining a function model (referred to as process model) of which a simulated result of the transferred pattern of a mask pattern of the photo mask using a function model matches the measured result (s4); obtaining a mask pattern of which a transferred pattern matches a designed pattern using said process model and creating mask data in accordance with the obtained mask pattern (s5); producing a corrected mask in accordance with the created mask data (s5); and setting an exposing condition where an OPE characteristic becomes flat with respect of wide and narrow pitches by adjusting at least one of a numerical aperture (NA) and a coherence factor (σ) of an exposing device when the corrected mask is transferred.

Owner:SONY CORP

Wood tray manufacture method

InactiveCN101417452AThe nailing position is uniform and beautifulImprove the stabilityWood working apparatusProduction lineUltimate tensile strength

The invention relates to a manufacturing method of wood trays, including the following steps of: forming front components of wood trays; turning over the front components of the wood trays; forming back components of the wood trays at back sides of the front components of the wood trays to produce the wood trays; postprocessing procedures; lining up and stacking the wood trays into a block; and exporting and carrying the whole block of wood trays stacked well into a warehouse. Compared with the prior art, the invention has the advantages that only 4 to 6 operators are needed in the whole production line, which equals the production efficiency of 20 operators with manual operation; the amount of labor can be saved by 70 percent and the production efficiency can be increased by more than 5 times; the labor intensity of workers can be reduced; the wood trays are lined up in order and can be staggered positively and negatively to save space; and single-deck trays can save space by more than 40 percent, site and space can be saved, and all processing equipment can be installed on the production line.

Owner:吴继荣

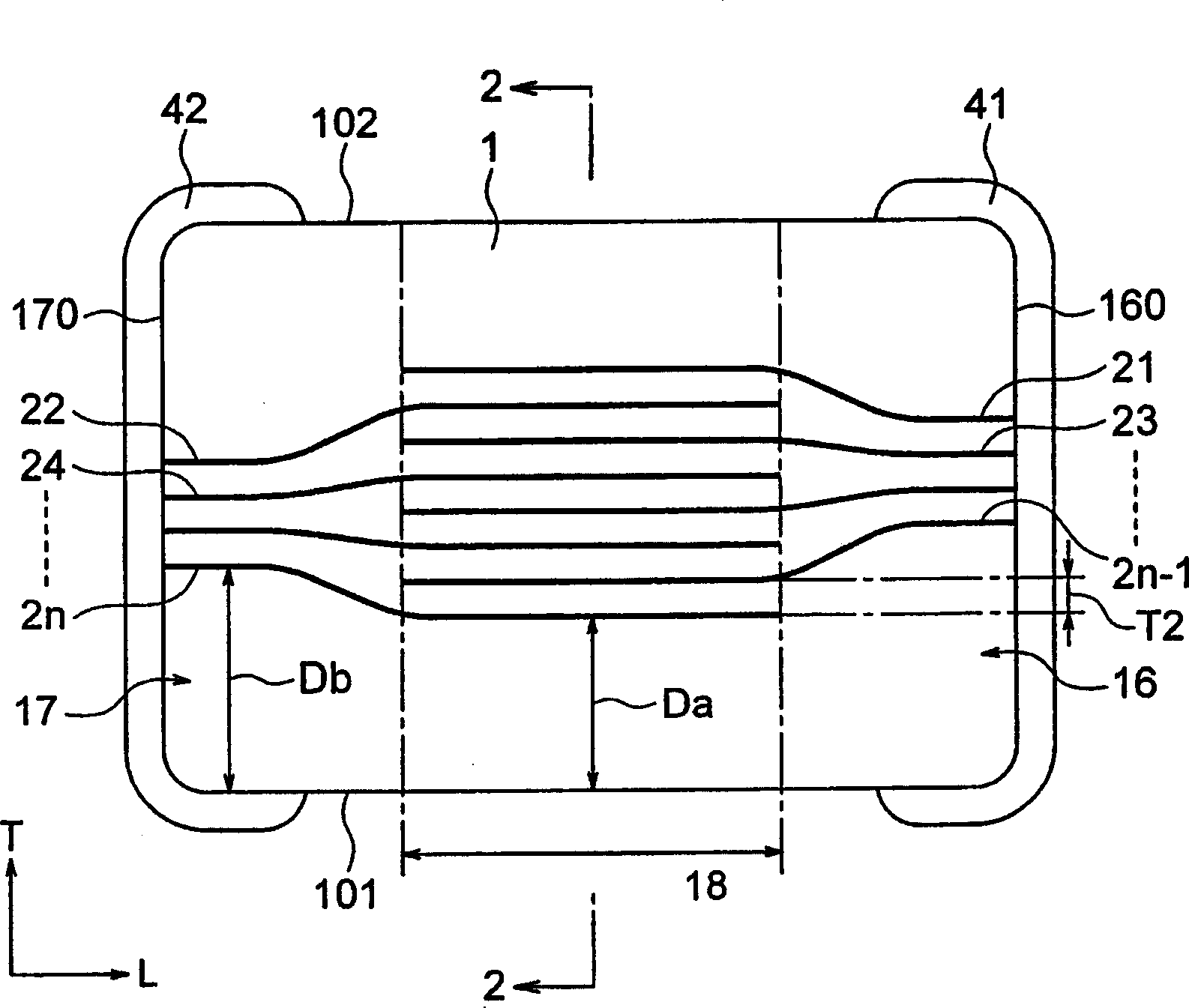

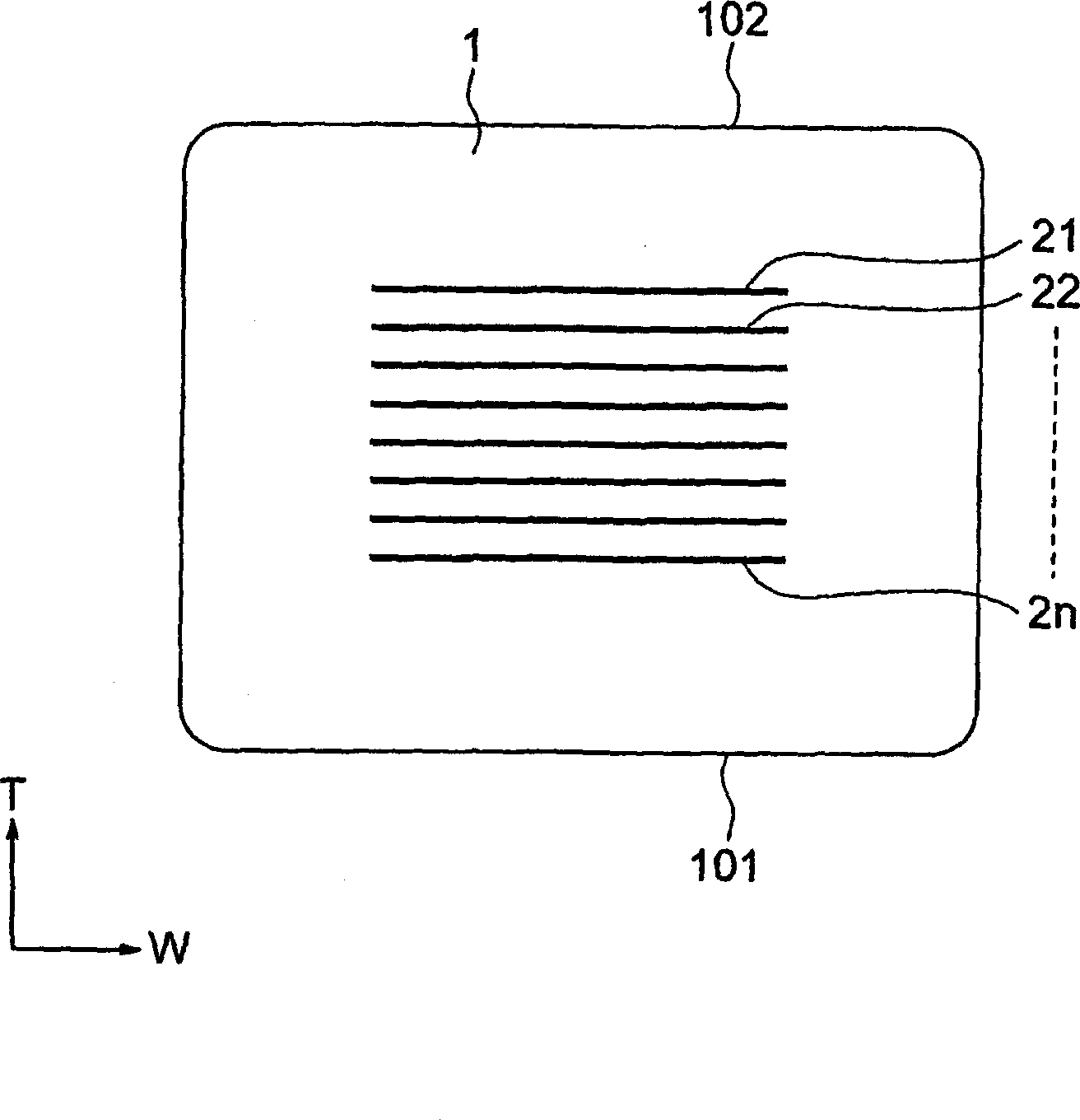

Laminated ceramic capacitor and manufacturing method therefor

InactiveCN1870190ASmall size errorAvoid shockFixed capacitor electrodesFixed capacitor dielectricMetallurgyCeramic capacitor

A laminated ceramic capacitor includes a ceramic substrate and a plurality of internal electrodes. The ceramic substrate is of a shape defined by length, width and thickness directions. The internal electrodes are stacked one over another within the ceramic substrate at spaced intervals in the thickness direction and alternately led out to opposite ends of the ceramic substrate in the length direction. The ceramic substrate has opposite surfaces in the thickness direction, one of which is planar. In the laminated ceramic capacitor, 1 H01G 4 / 30 H01G 4 / 12 5 19 1 2006 / 5 / 24 1870190 2006 / 11 / 29 000000000 TDK Corp. Japan Kojima Tatsuya hu jianxin 72002 NTD Patent & Trademark Agency Ltd. Units 1805-6, 18th Floor, Greenfield Tower, Concordia Plaza, No.1 Science Museum Road, Tsimshatsui, east, Kowloon, Hong Kong 100045 Japan 2005 / 5 / 25 152955 / 2005

Owner:TDK CORPARATION

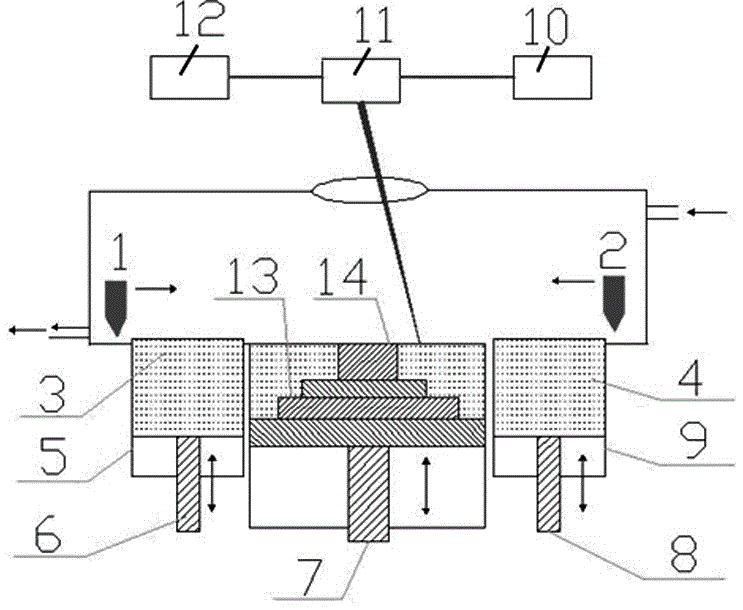

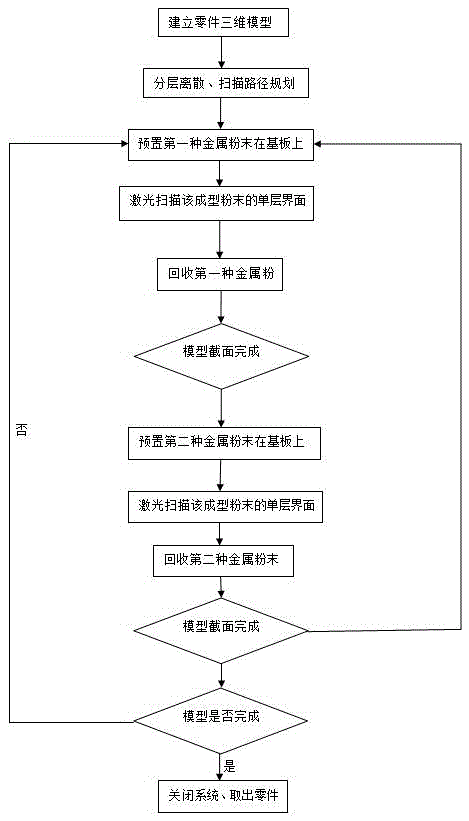

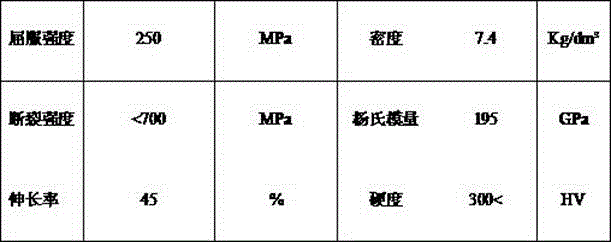

Method for manufacturing laminated steel plate

ActiveCN105478766AReduce micro segregationAvoid problems such as oxidationAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyMetal powder

The invention discloses a method for manufacturing a laminated steel plate. According to the method, two different types of metal powder are used to be laid alternately, the laser selected region layering fusion technology is adopted, and the powder is directly printed and formed into the laminated steel plate. Compared with a traditional laminated steel plate manufacturing process, by the adoption of the method, the laminated steel plate meeting the use requirement can be directly printed. The method has the advantages that the structure, the components and the performance of the laminated steel plate are equivalent to those of a laminated steel plate manufactured through the traditional process, manufacturing cost is low, forming efficiency is high, the types of the powder can be changed and scanning routes can be set according to different requirements, and therefore laminated steel plates of different types can be produced.

Owner:YANGJIANG KNIFESCISSOR HARDWARE RES INSTITUTION OF IND TECH +1

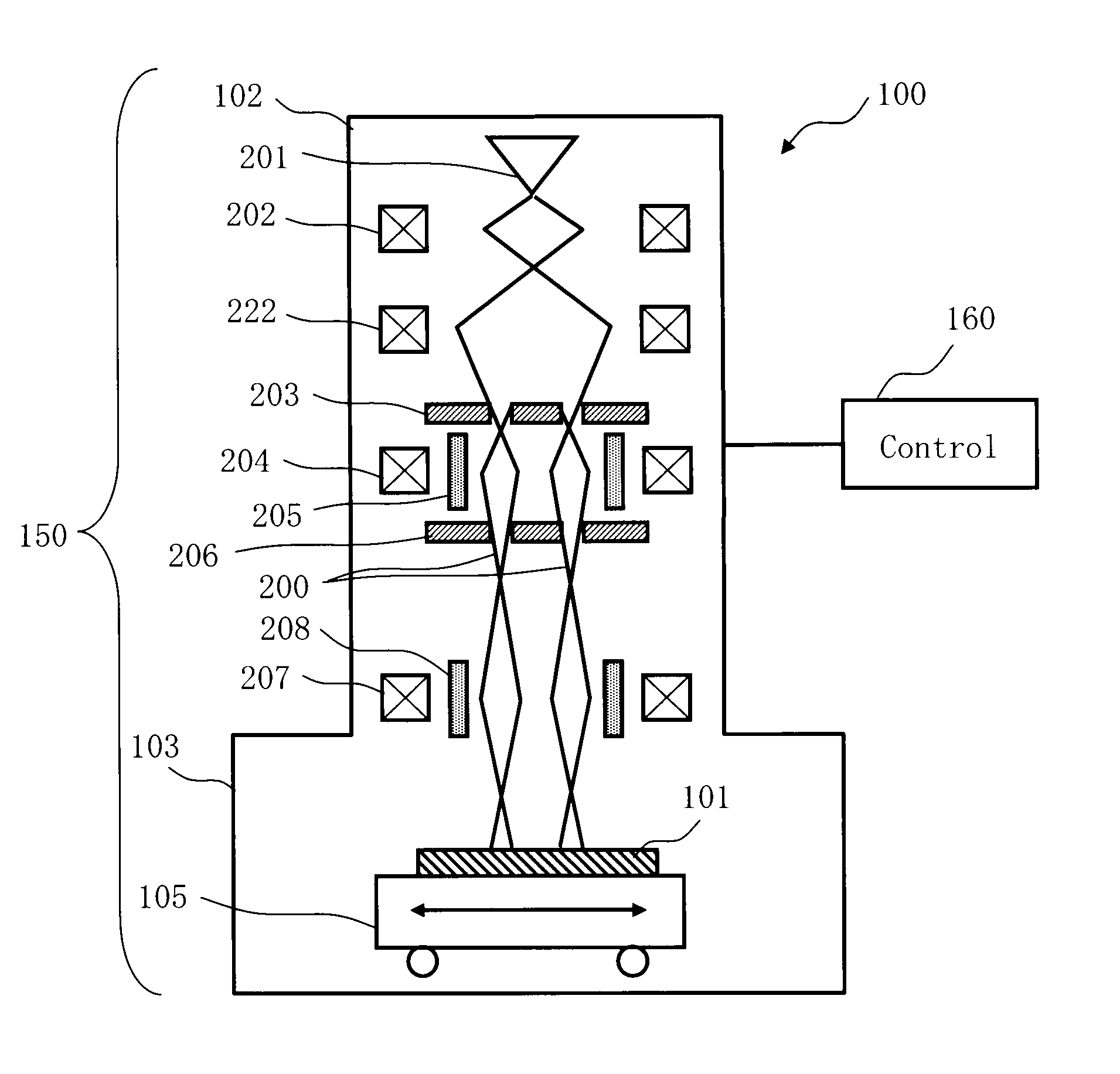

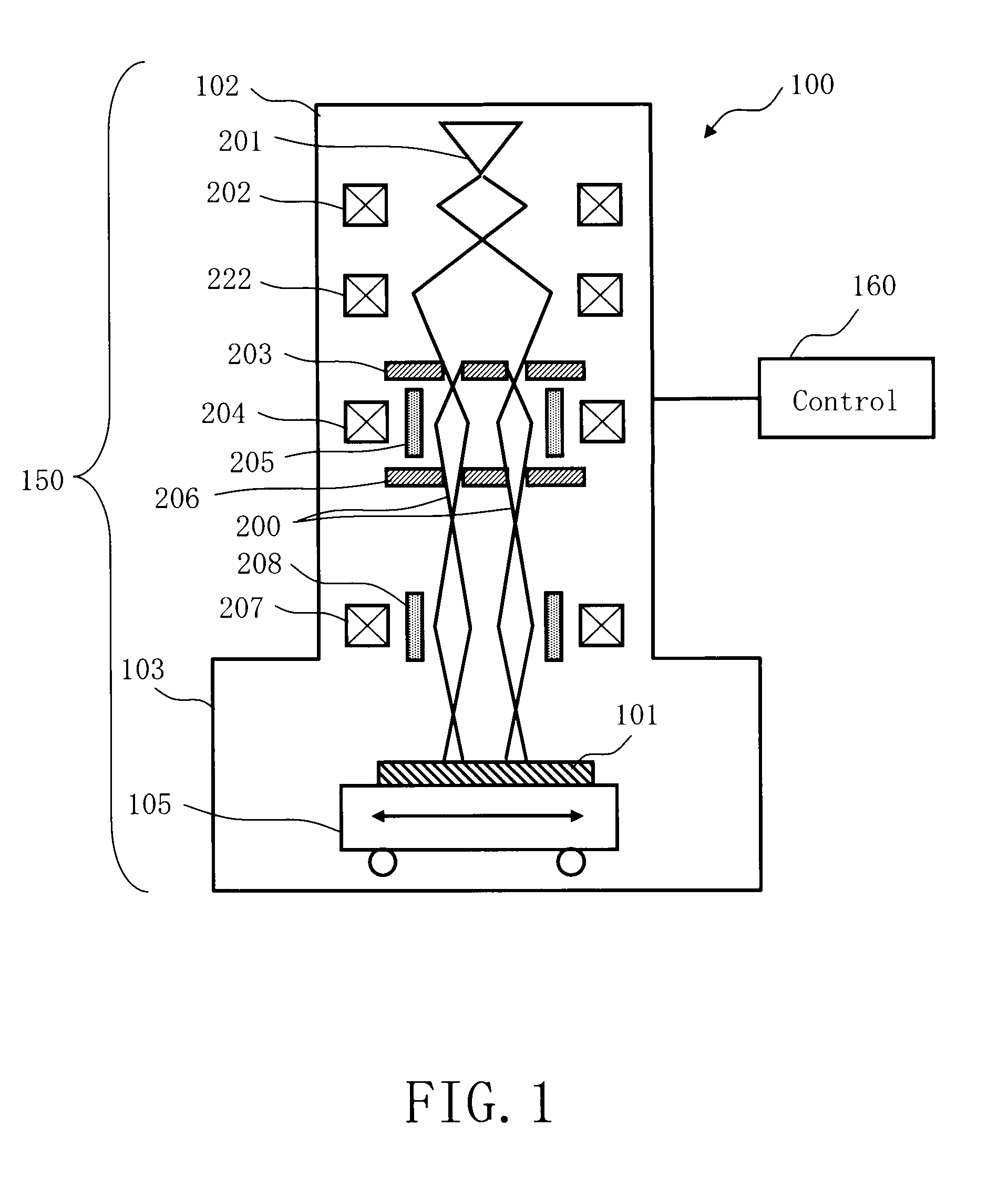

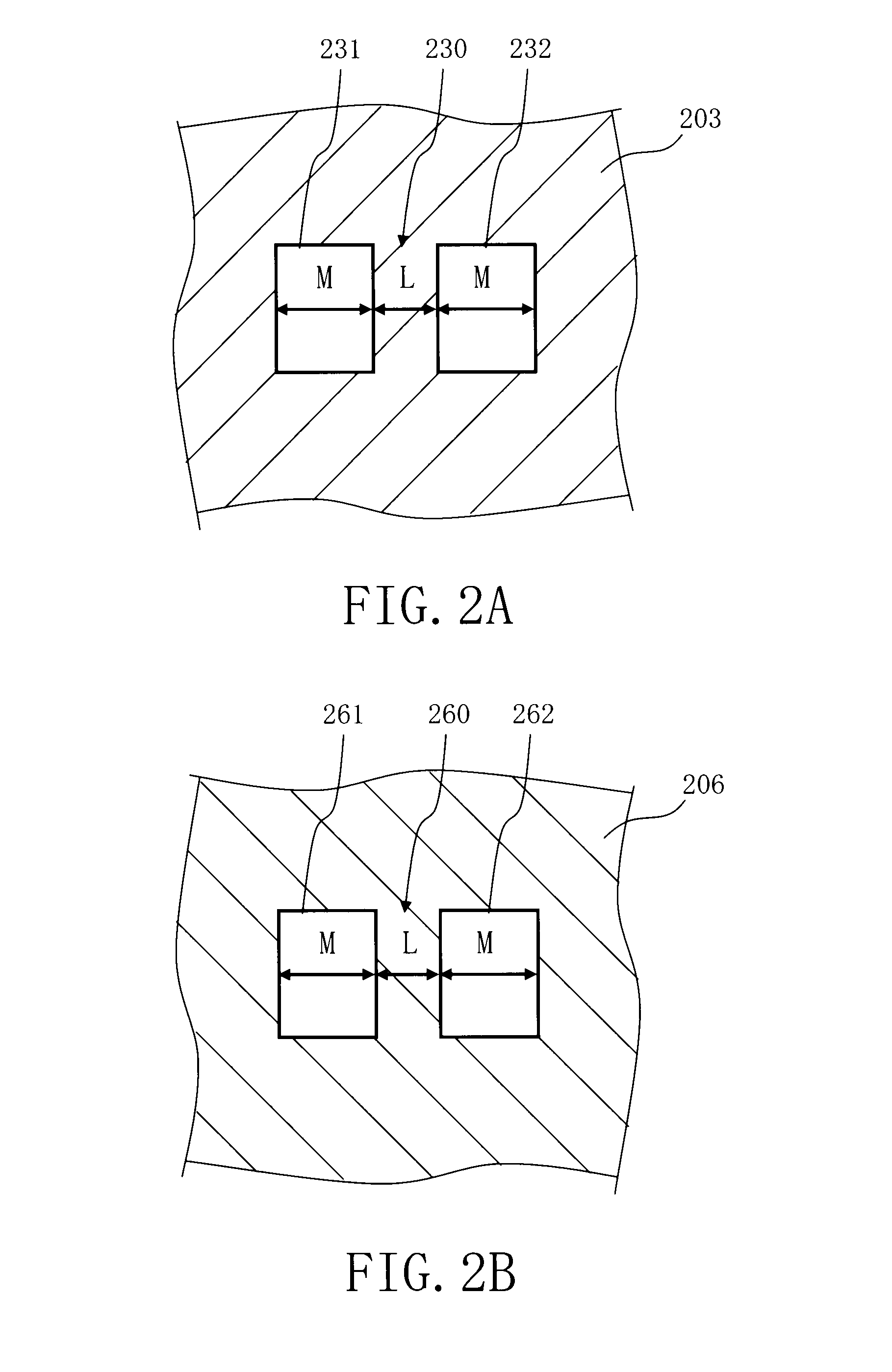

Charged particle beam writing apparatus and charged particle beam writing method

InactiveUS20080217554A1Small size errorThermometer detailsBeam/ray focussing/reflecting arrangementsIrradiationCharged particle beam

A charged particle beam writing apparatus includes an irradiation part configured to irradiate a charged particle beam; a first shaping aperture member having passing areas, that the charged particle beam passes through, on both sides of an area blocking the charged particle beam; a deflection part configured to deflect the charged particle beam that has passed through the first shaping aperture member; a second shaping aperture member having passing areas, that the charged particle beam passes through, on both sides of an area blocking the deflected charged particle beam; and a stage on which a target workpiece irradiated with the charged particle beam that has passed through the second shaping aperture member is placed.

Owner:NUFLARE TECH INC

Full-automatic plate shearing machine

ActiveCN104174920AFeed process smoothSmall size errorShearing machinesEngineeringMechanical engineering

The invention discloses a full-automatic plate shearing machine. The machine comprises a feeding device, a shearing device and a discharging conveying belt, wherein a limiting mechanism is arranged in the feeding device, a proximity switch for controlling a shearing mechanism to work is arranged in the shearing device, and the discharging conveying belt is arranged below a discharging end of the shearing device. According to the full-automatic plate shearing machine, automatic feeding of steel strips, automatic shearing according to preset dimensions and automatic discharging of steel plates can be realized, dimension errors of steel plate products are small, and the percent of pass is high.

Owner:ANHUI NINGGUO DONGBO FASTENER

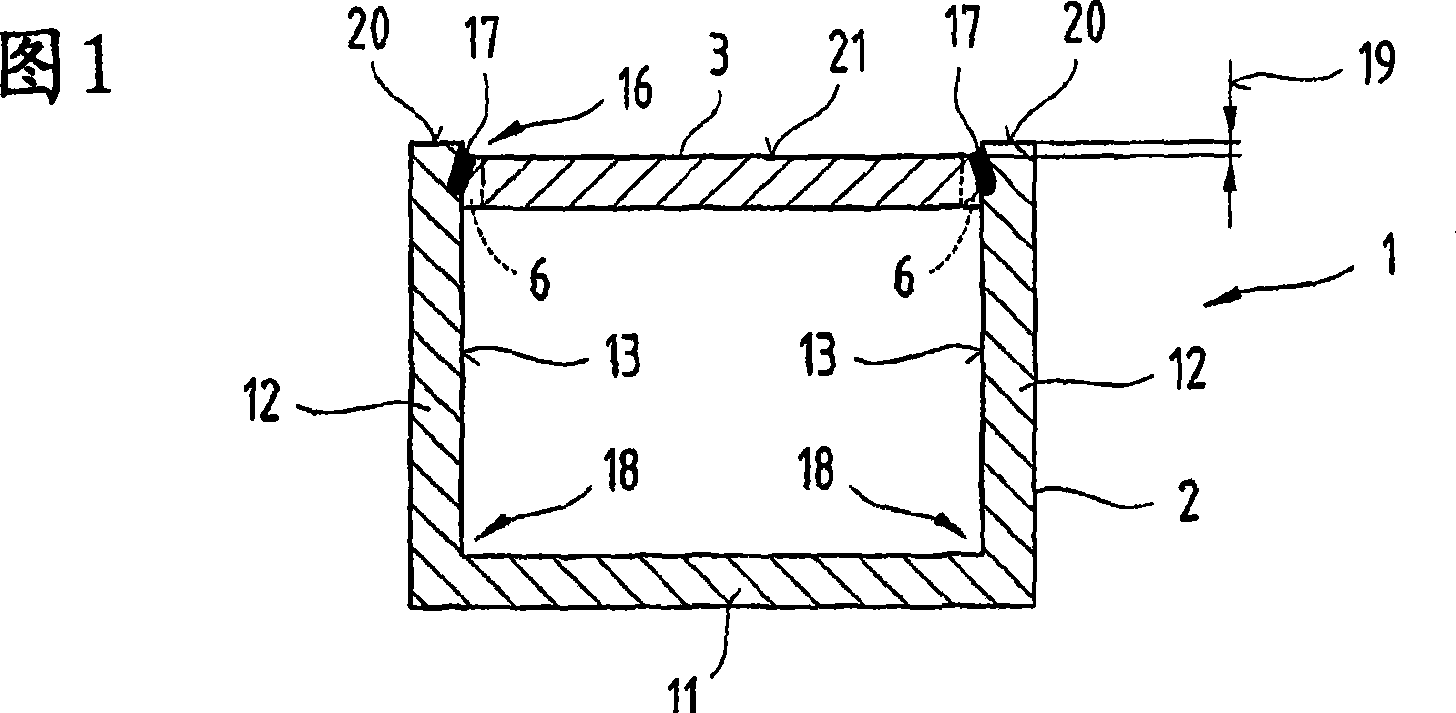

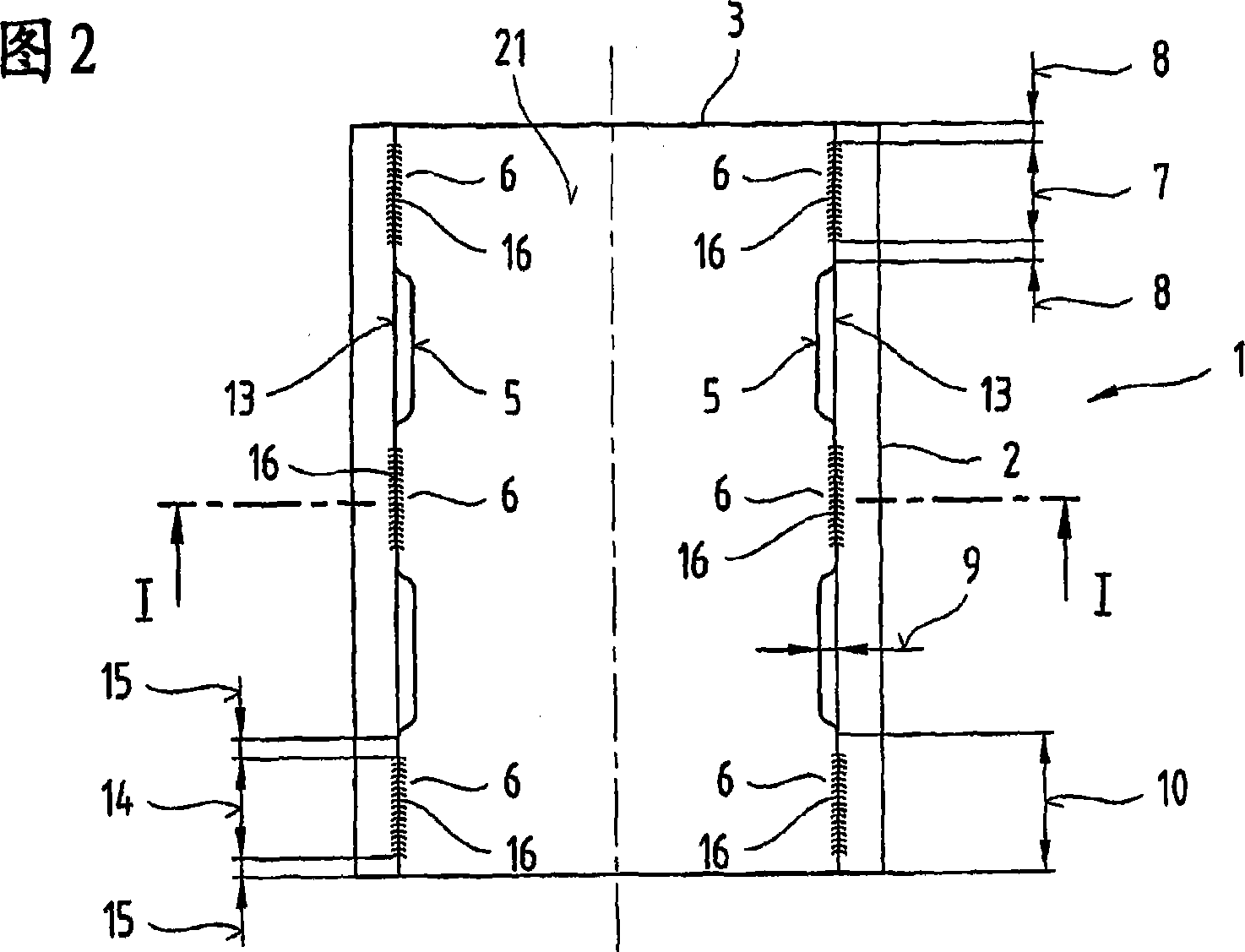

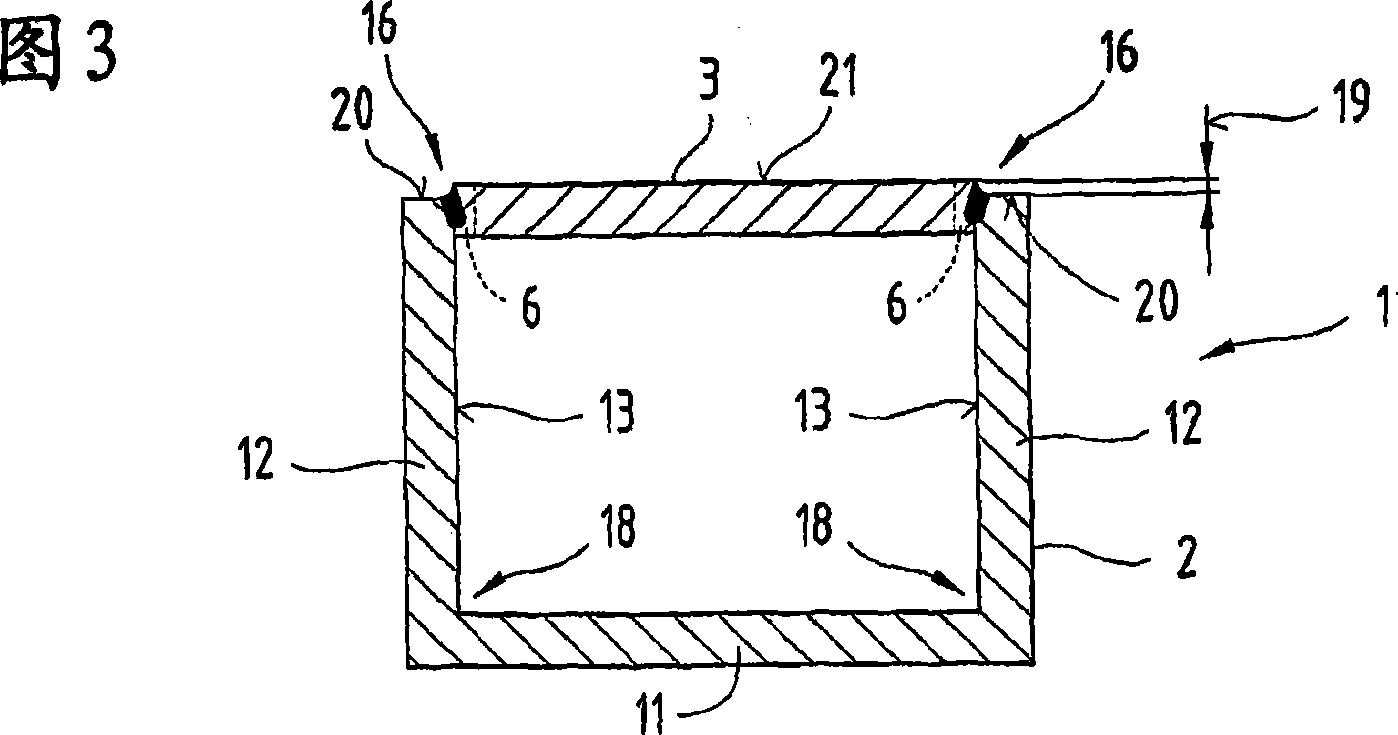

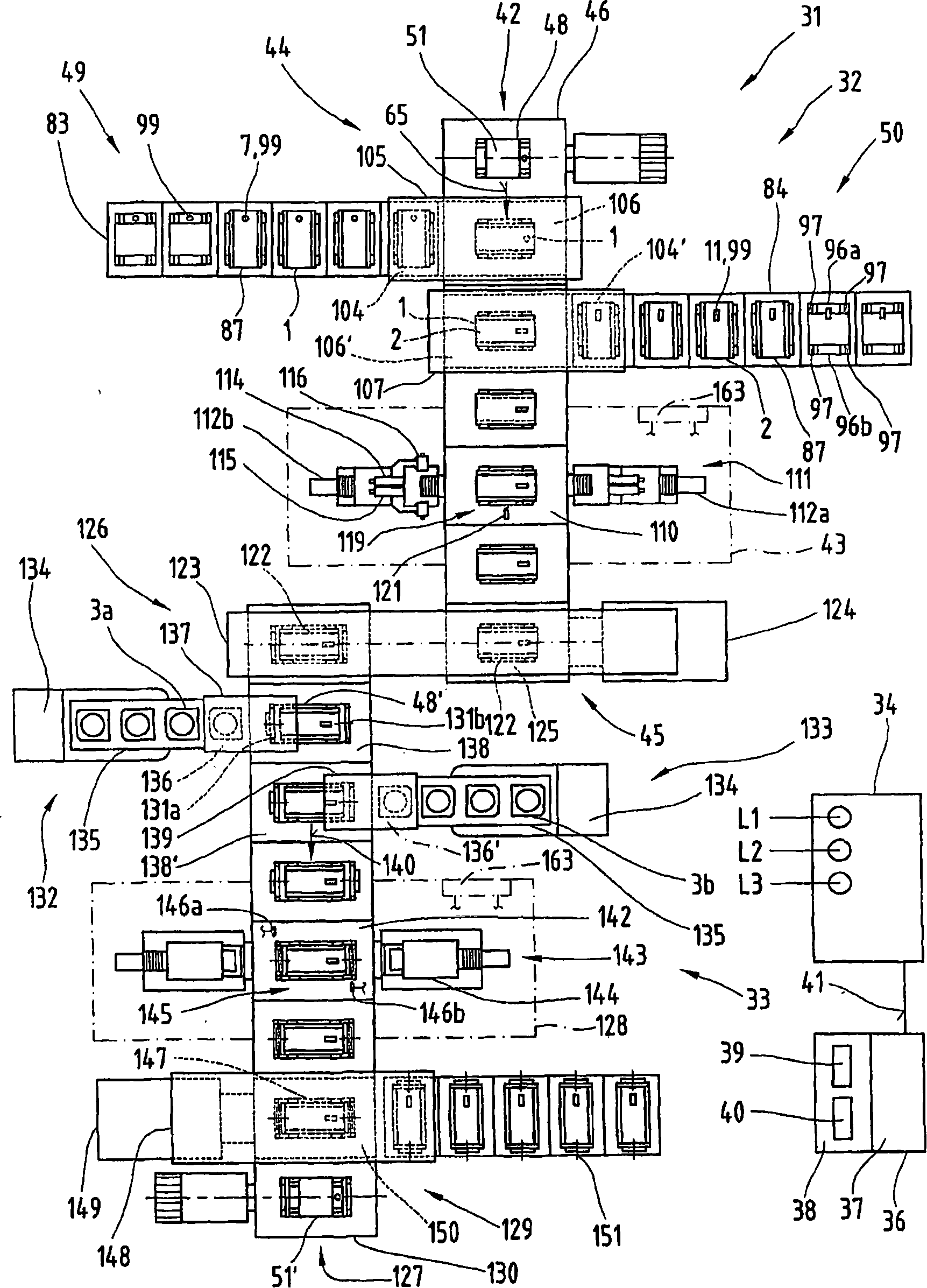

Installation for producing and method for assembling parts

InactiveCN101163567ATakt time optimizationEasy to controlConveyorsWelding/cutting auxillary devicesLocation EquipmentSupport surface

The invention concerns a method and an installation for producing a component consisting of several assembled parts. The first part (1) and the second part (2) are taken from a part delivery site proximate the conveying device and set in mutually oriented position on part conveying supports of the conveying device then conveyed with the part conveying supports to an assembling station. The part conveying device is maintained in a retaining position in the assembling station, the mutually oriented parts (1, 2) are moved by means of a heightwise positioning device (200a, 200b) and simultaneously moved from a conveying position on the part conveying support to a delivering position. Then the parts are positioned relative to each other, fixed and finally assembled to form the component. The assembled component is then set on a part conveying support and carried with said support. The part conveying supports comprise a housing exclusively provided with positioning means for holding a part (1) during its transport and, in the advancing direction of this positioning means, spaced apart supporting lateral guiding surfaces as well as support surfaces for one part (1) resting on the preceding surfaces.

Owner:STIWA HLDG

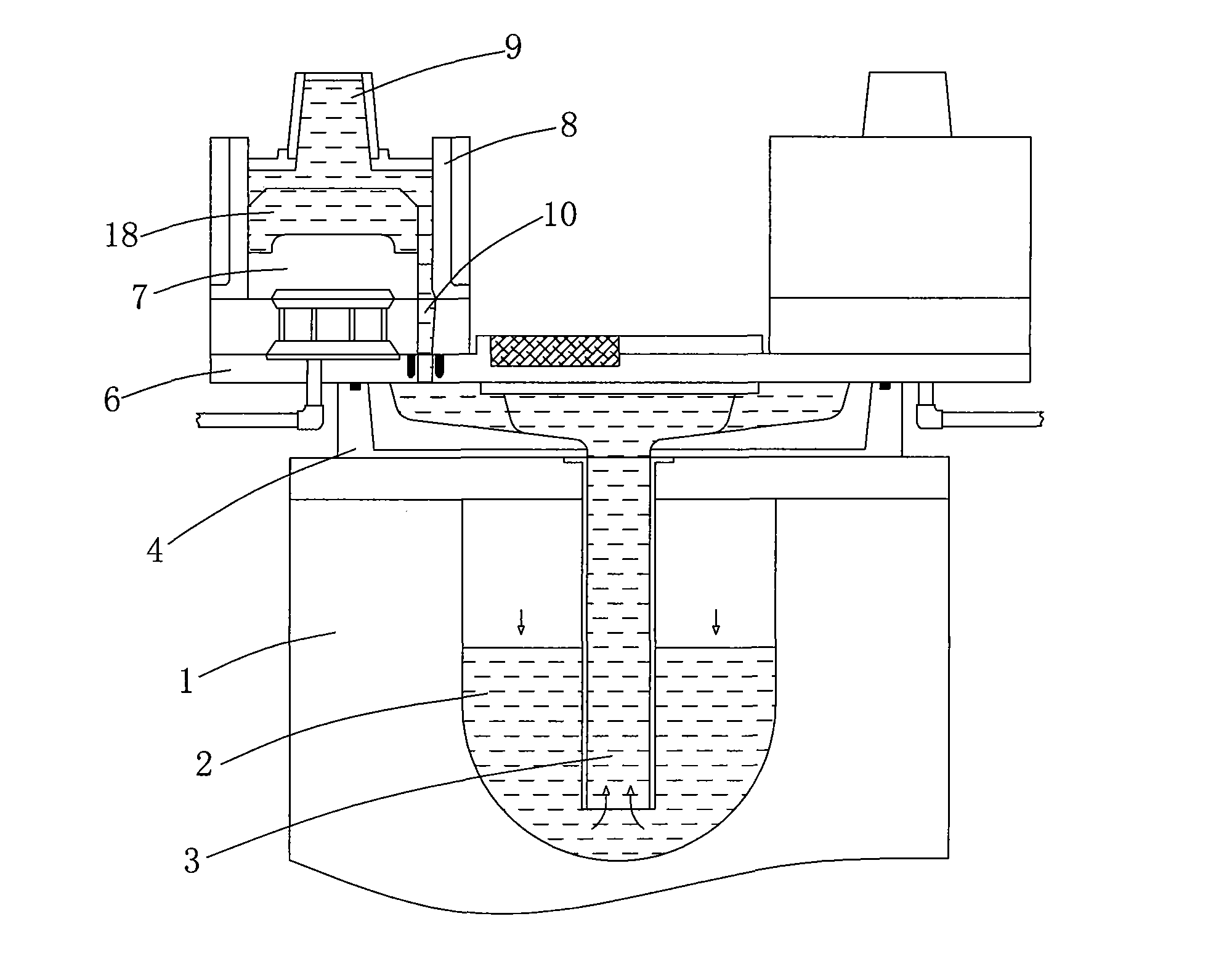

Aluminum alloy pattern block low-pressure casting equipment and low-pressure casting and gravity feeding compound process

The invention discloses aluminum alloy pattern block low-pressure casting equipment. A disk-type runner substrate is arranged on a crucible, and the lower end of a riser tube passes through the center hole of the runner substrate and then stretches into the crucible; a runner cover board is hermetically covered on the runner substrate, a plurality of casting moulds are distributed on the runner cover board, a feed head is arranged at the upper end of each casting mould, and an inner runner is arranged at the lower end of each casting mould; and a main runner is laid in a hollow cavity between the runner substrate and the runner cover board, a plurality of runner channels are distributed on the main runner, and the runner channels are respectively communicated with the inner runners of the casting moulds and the upper port of the riser tube. The invention can solve the secondary pollution problem of aluminum liquid in the partitioning and casting process of aluminum alloy pattern blocks and achieve simultaneously casting a plurality of aluminum alloy pattern block castings, and is beneficial to improving the casting production efficiency.

Owner:合肥大道模具有限责任公司

Strip steel automatic cutting machine

InactiveCN103128356ASmall size errorSave labor productivityShearing machinesShearing machine accessoriesStrip steelEngineering

The invention relates to the technical field of material machining equipment, in particular to a strip steel automatic cutting machine. The strip steel automatic cutting machine comprises a machine frame. A limiting device, a material guiding device and a cutting device are arranged from the front to the back in sequence on the machine frame. A material transmitting frame is arranged at the back of the cutting device. A material transmitting working platform is arranged on the material transmitting frame. A location sensor is arranged on the material transmitting working platform. The strip steel enters from the limiting device when the strip steel automatic cutting machine is operated. The strip steel is pulled and transmitted by the material guiding device and is sent to the material transmitting working platform by the cutting device. The strip steel is cut by the cutting device movement and the cutting movement is completed when the arriving of the strip steel is sensed by the location sensor. Measuring and cutting processing of the strip steel are not needed to be carried out by the manual work. Labor productive force is greatly saved, Labor productivity is improved and the size errors of the strip steel are reduced.

Owner:东莞市长盛刀锯有限公司

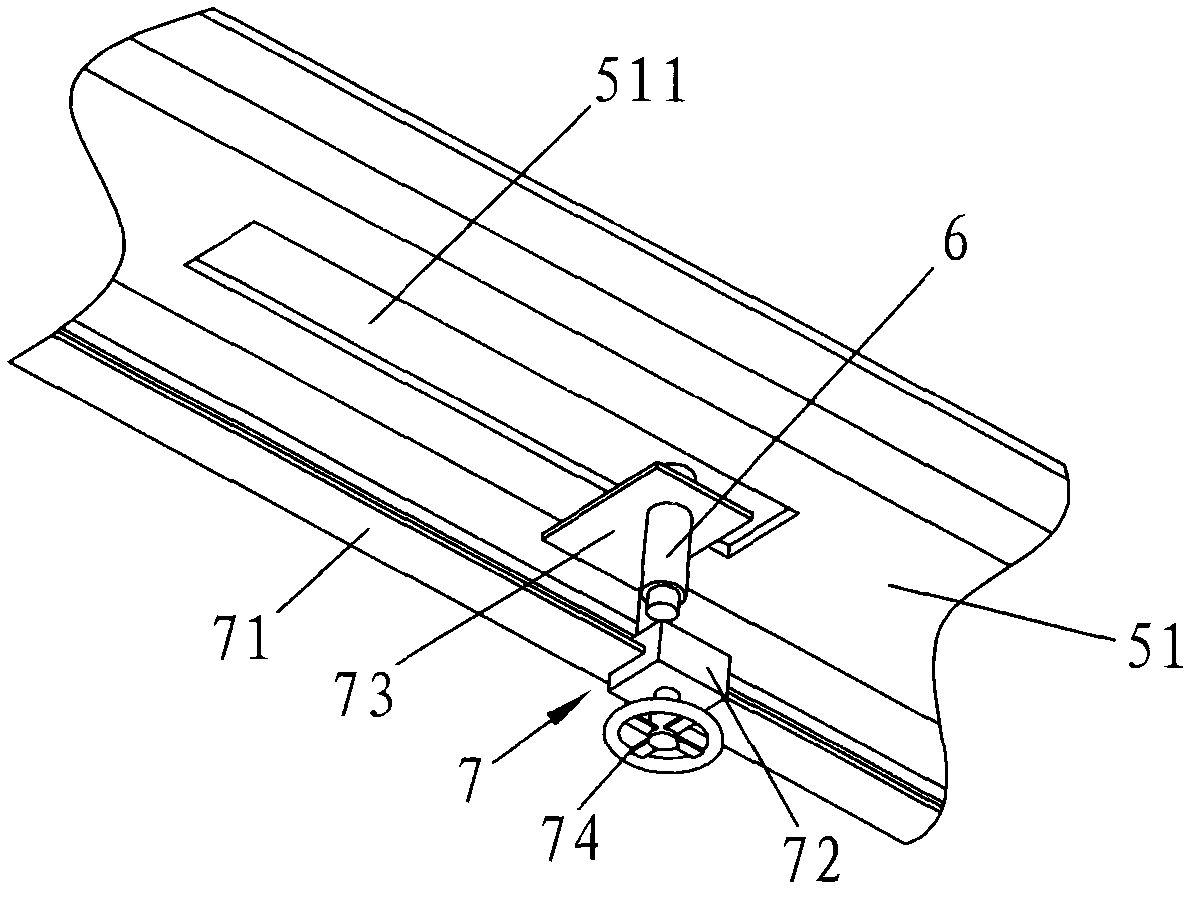

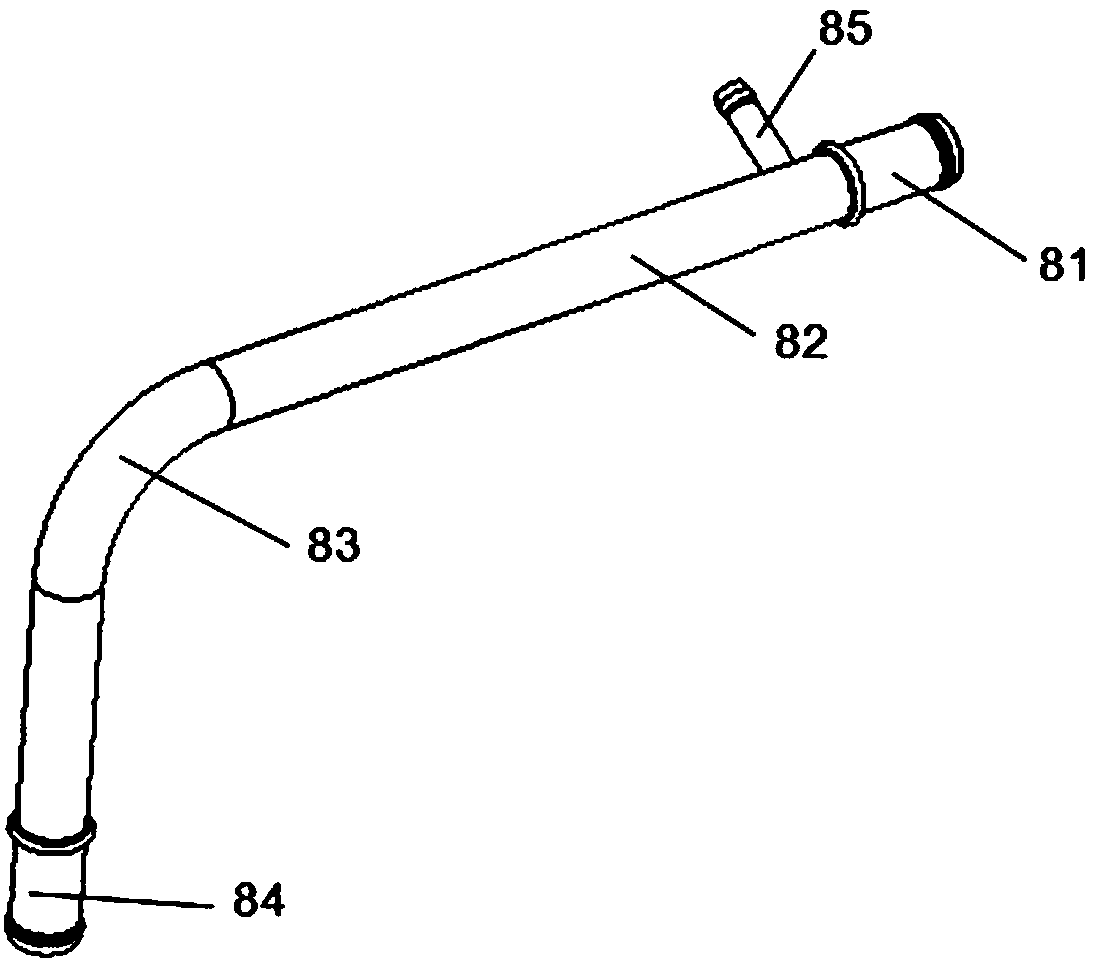

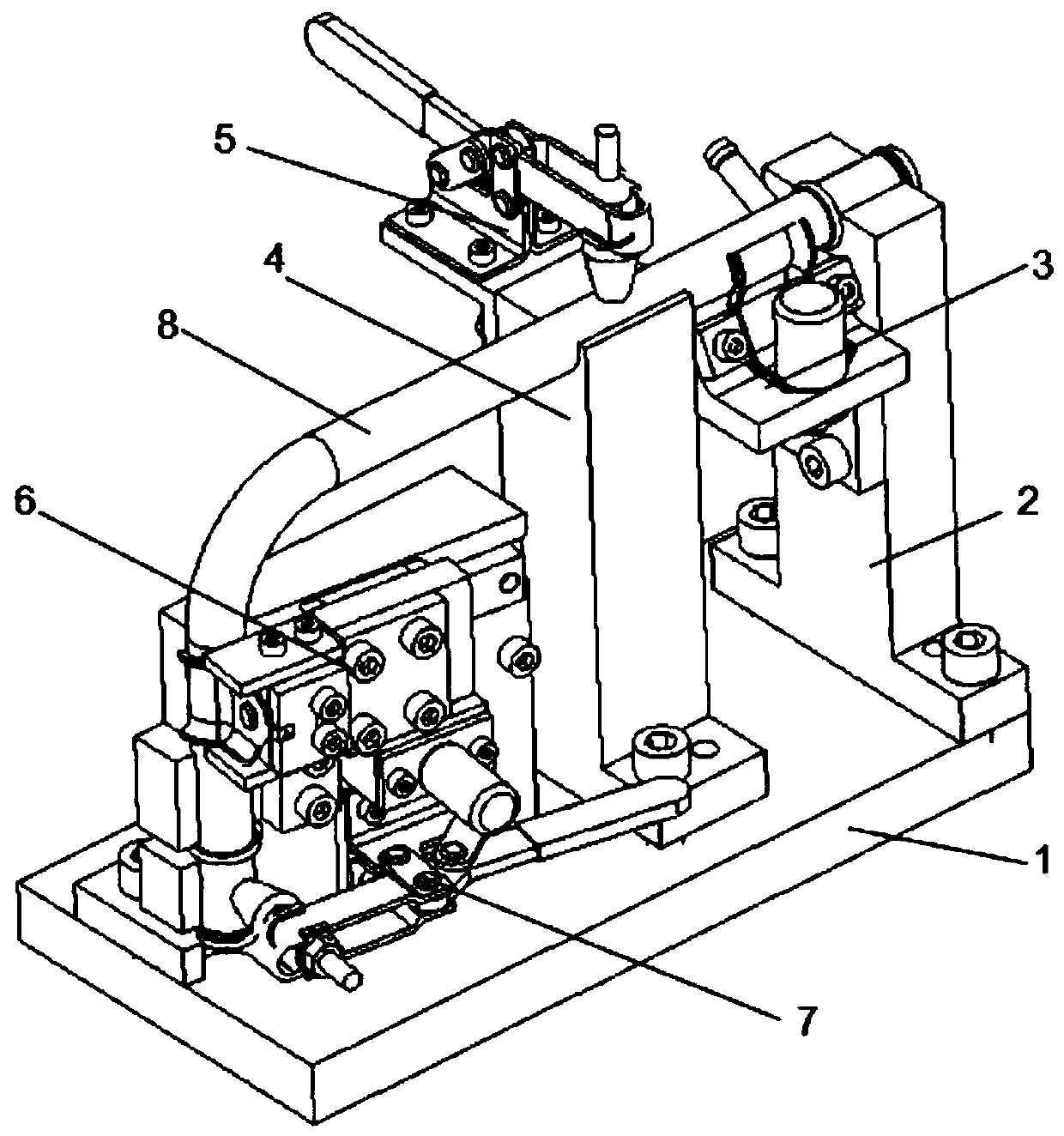

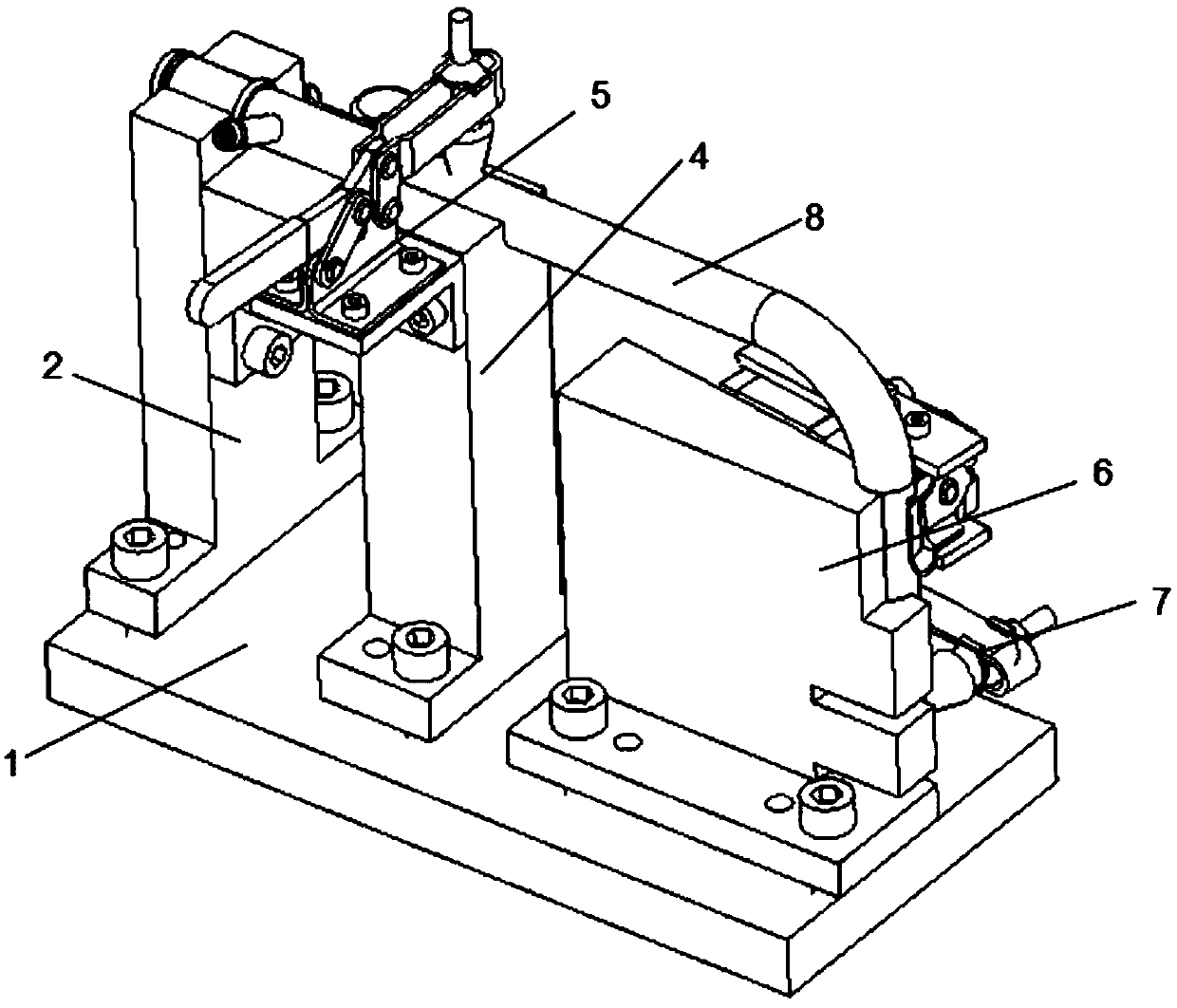

Bent pipe welding, positioning and locking device

ActiveCN107617847AImprove efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesPipe weldingEngineering

The invention provides a bent pipe welding, positioning and locking device. The device comprises a base; a first support base, a second support base and a bent pipe positioning mechanism are mounted on the base in sequence from right to left side by side; a branch pipe positioning mechanism is mounted between the first support base and the second support base; a first locking fixture is mounted onthe second support base; the bent pipe positioning mechanism is mounted on the left side of the second support base; and a second locking fixture is fixed on the side wall of the bent pipe positioning mechanism, and is positioned below a positioning and locking block. The bent pipe welding, positioning and locking device can realize quick positioning and butt joint of pipe fittings with differentshapes and guarantee the butt joint quality through presetting the first support base, the second support base, the first locking fixture, the bent pipe positioning mechanism and the second locking fixture; the branch pipe positioning mechanism can guarantee welding angles of a branch pipe with a first pipe tube and a second pipe tube to meet requirements; and the first locking fixture and the second locking fixture can realize quick locking of a straight pipe and the second pipe tube.

Owner:GUANGDONG JUNCHI TECH HLDG

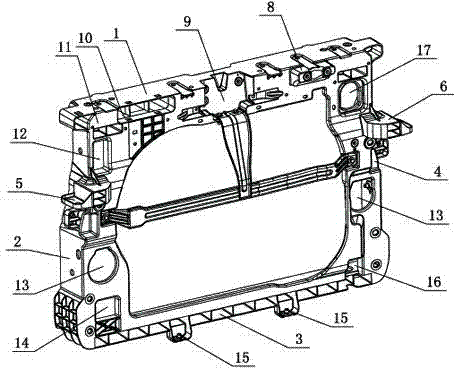

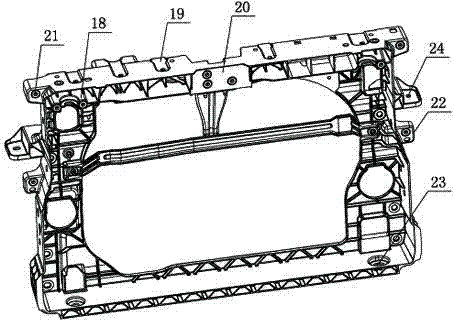

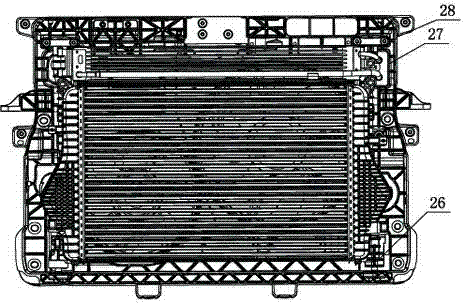

Automobile front-end module loading frame

ActiveCN103661625AHigh strengthRequires minimizationSuperstructure subunitsInverted tInjection moulding

The invention discloses an automobile front-end module loading frame. A main frame body of the automobile front-end module loading frame is of a plastic square frame structure formed in a one-time injection molding mode. Metal-structured inverted T-shaped stiffening beams are added between an upper frame and a left frame of the main frame body and between the upper frame and a right frame of the main frame body, so that the overall weight reduction is achieved, and strength and stability of the automobile front-end module loading frame are both improved. The automobile front-end module loading frame is suitable for integrating and accurate installing of parts and components at the front ends of automobiles.

Owner:GREAT WALL MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com