Automobile front-end module loading frame

A front-end module and carrier technology, which is applied to the installation structure of vehicle front-end modules and the field of automotive front-end module carriers, can solve the problems of heavy weight and achieve the effects of light weight, cost reduction, and enhanced overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

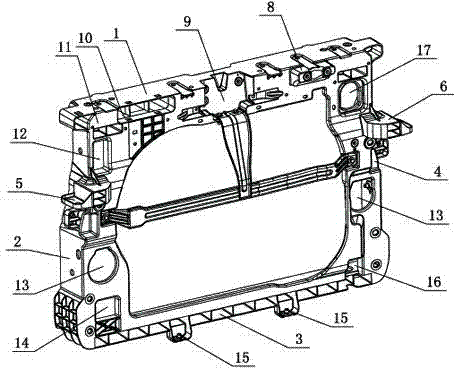

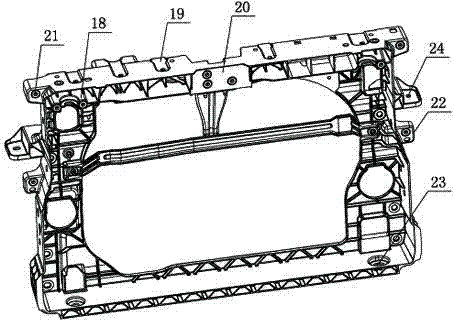

[0038] This embodiment is an automobile front-end module carrier, which includes a main body frame with a square frame structure that is injection molded at one time. The material is PP-LGF35, which is made of polypropylene raw material and 35% long glass fiber reinforced material.

[0039] The main body frame is formed by connecting the upper beam 1, the left beam 2, the lower beam 3, and the right beam 4 in sequence, corresponding to the upper, right, lower, and left parts of the vehicle respectively during installation.

[0040] In this embodiment, to the rear of the vehicle body, extending to the right and above to be +X direction, +Y direction and +Z direction as a benchmark, refer to figure 1 and figure 2 Make a corresponding specific description.

[0041] The end module carrier also includes an inverted T-shaped metal reinforcement beam 7, which is made of high-strength spring steel, and is fixedly connected to the upper beam 1, the left beam 2, and the right beam 4 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com