Pole piece laser cutting machine

一种激光切割机、激光切割的技术,应用在激光焊接设备、焊接/切割辅助设备、焊接/焊接/切割物品等方向,能够解决锂离子电池和超级电容大规模生产影响、极片平整度不符合要求、制片工序合格率低等问题,达到改善制片工艺质量、提高制片效率、改善加工精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

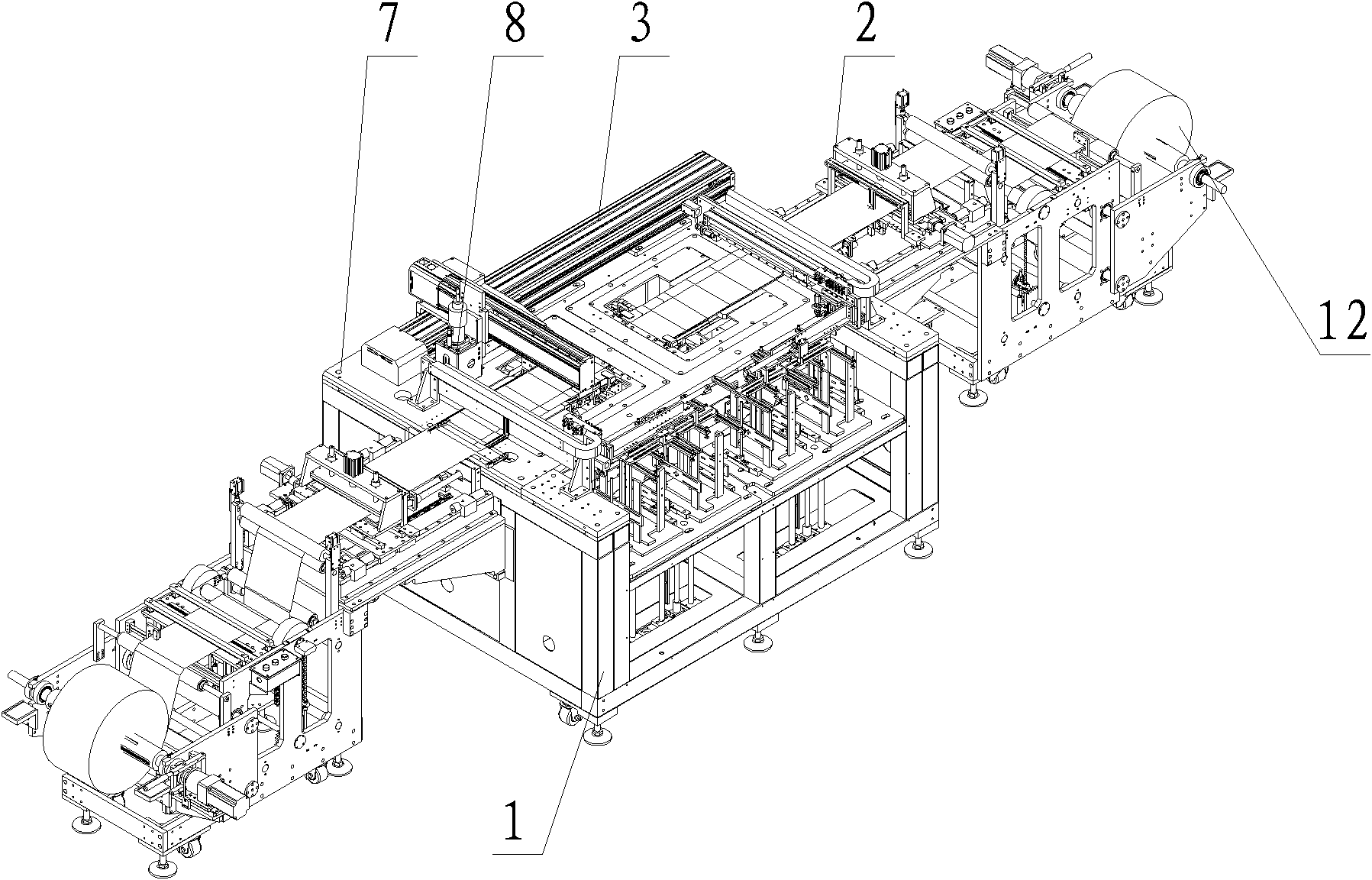

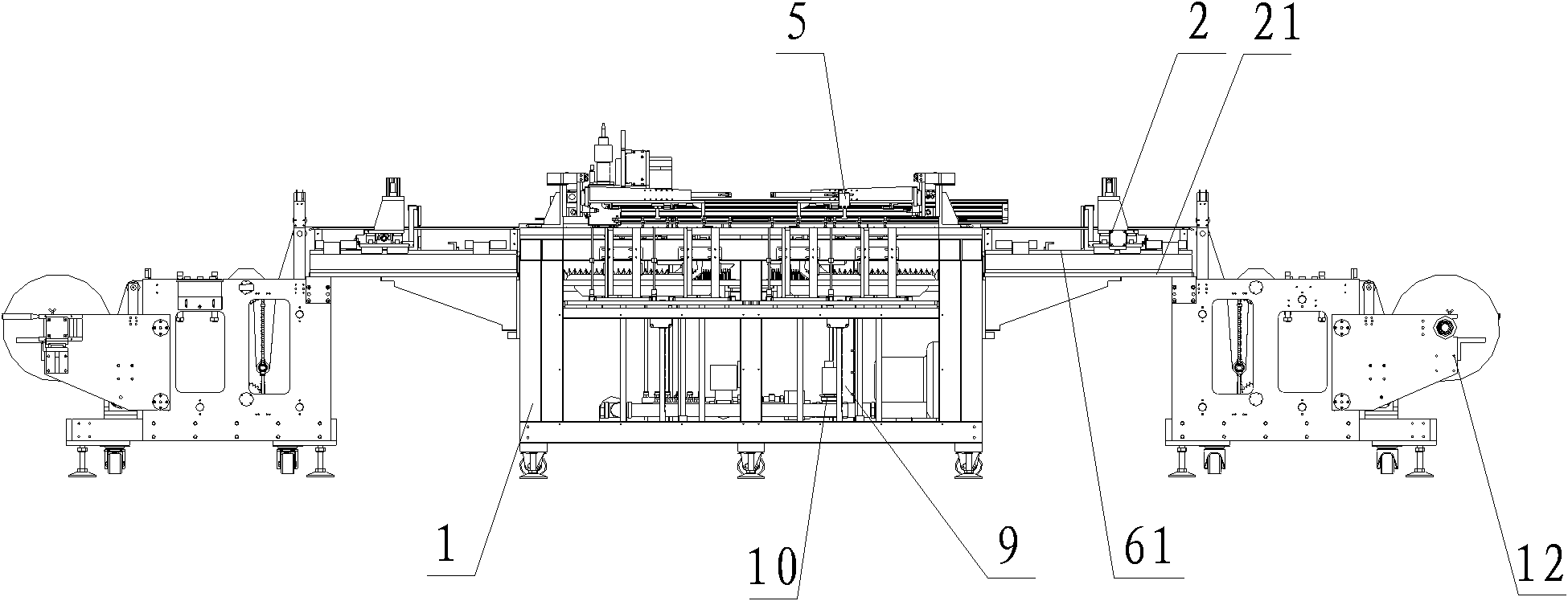

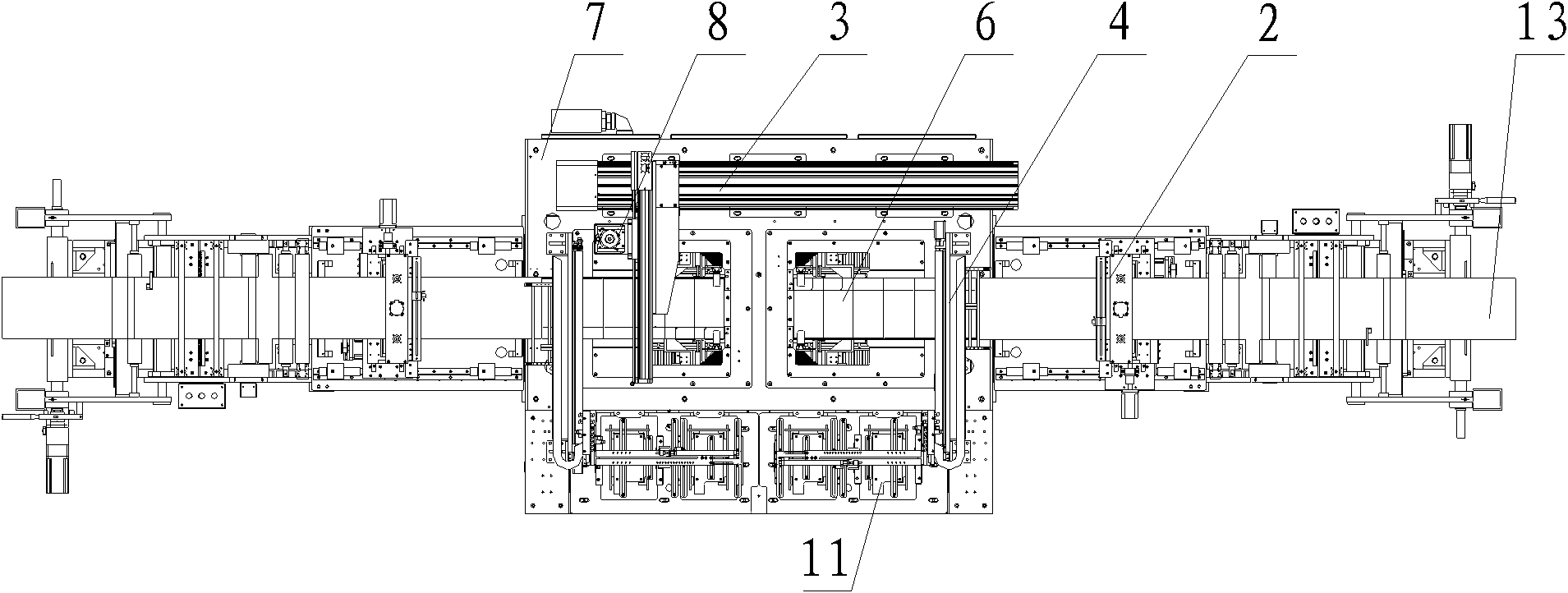

[0024] Please refer to Figure 1 to Figure 3 , the pole piece laser cutting machine of this embodiment includes a base frame component 1, a laser cutter 8, a cutting manipulator component 3 for driving the laser cutter 8 to move so as to cut the pole piece 13, a control system, and at least one sheet feeding components. Wherein, the sheet feeding assembly is used to move the pole piece 13 to be cut to the cutting platform 7 above the base frame component 1 so as to be cut into a certain size and shape. According to specific needs, a single-station laser cutting machine includes a sheet feeding assembly, a double-station laser cutting machine or a multi-station laser cutting machine can include two or more sheet feeding assemblies, and each station can achieve single-width cutting or double cut. The sheet feeding assembly specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com