Combustion chamber of paver

A combustion chamber and paver technology, applied to roads, road repairs, roads, etc., can solve the problems of uneven heating, slow heating, and easy deformation of the screed floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

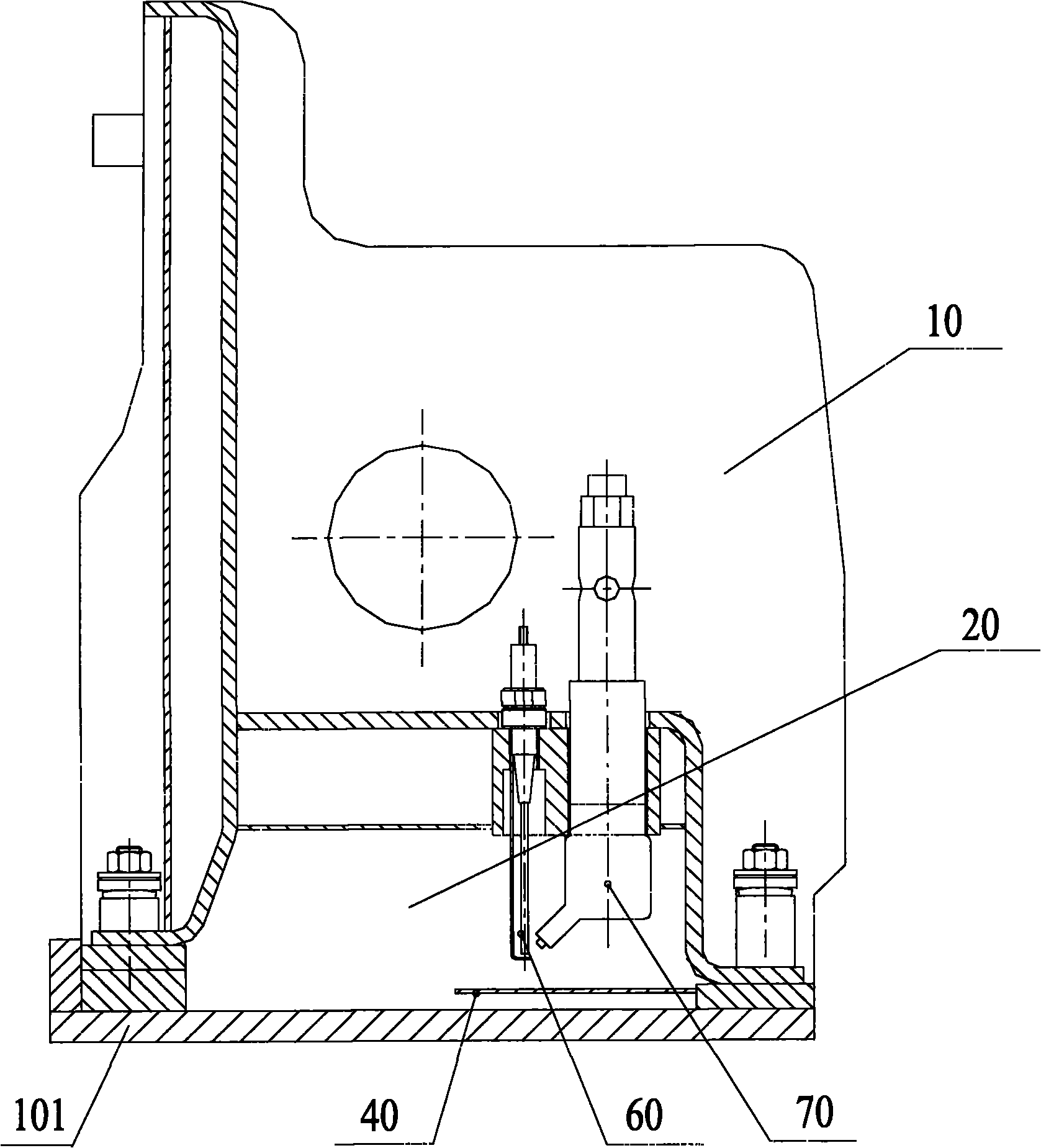

Image

Examples

Embodiment approach

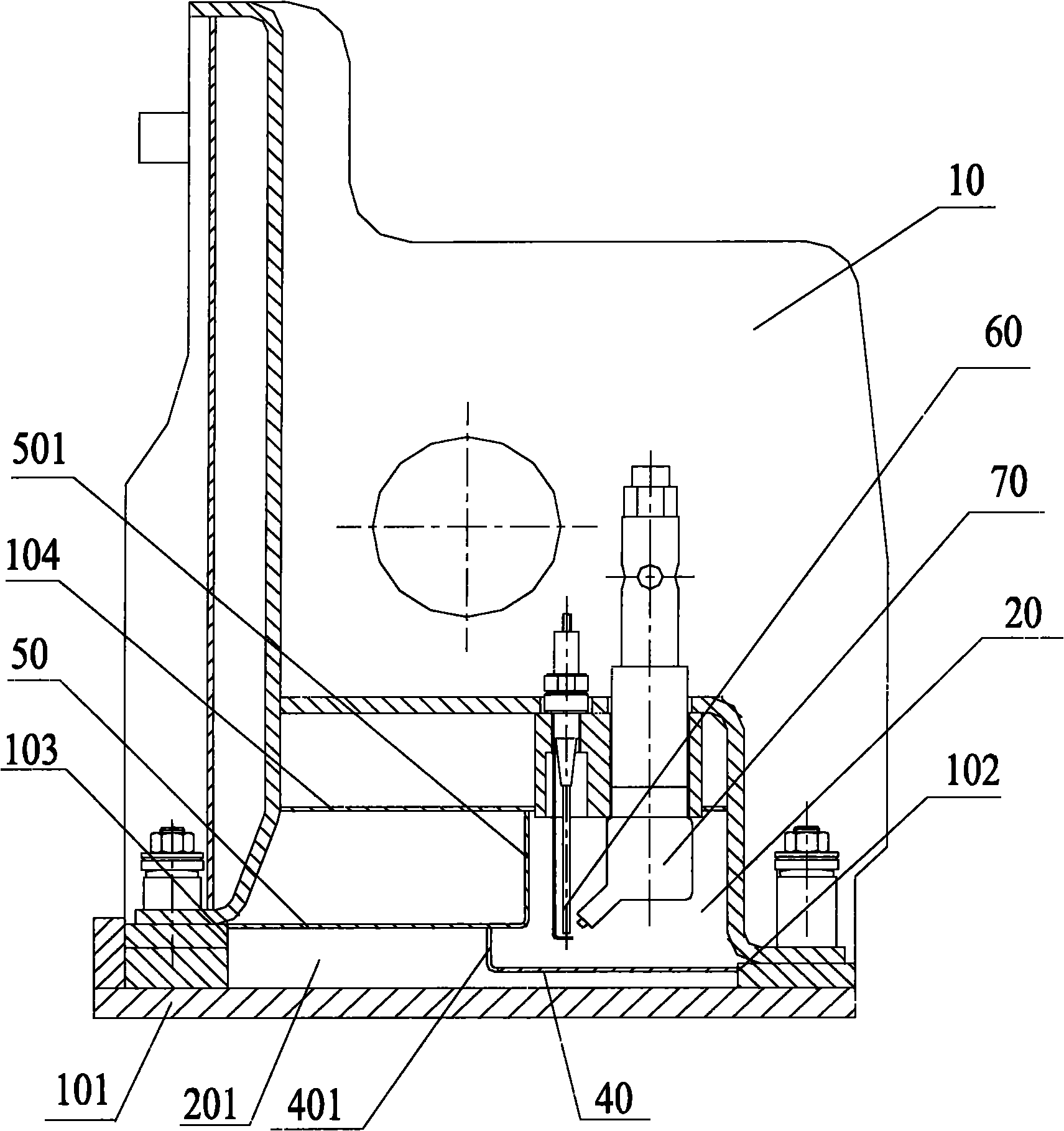

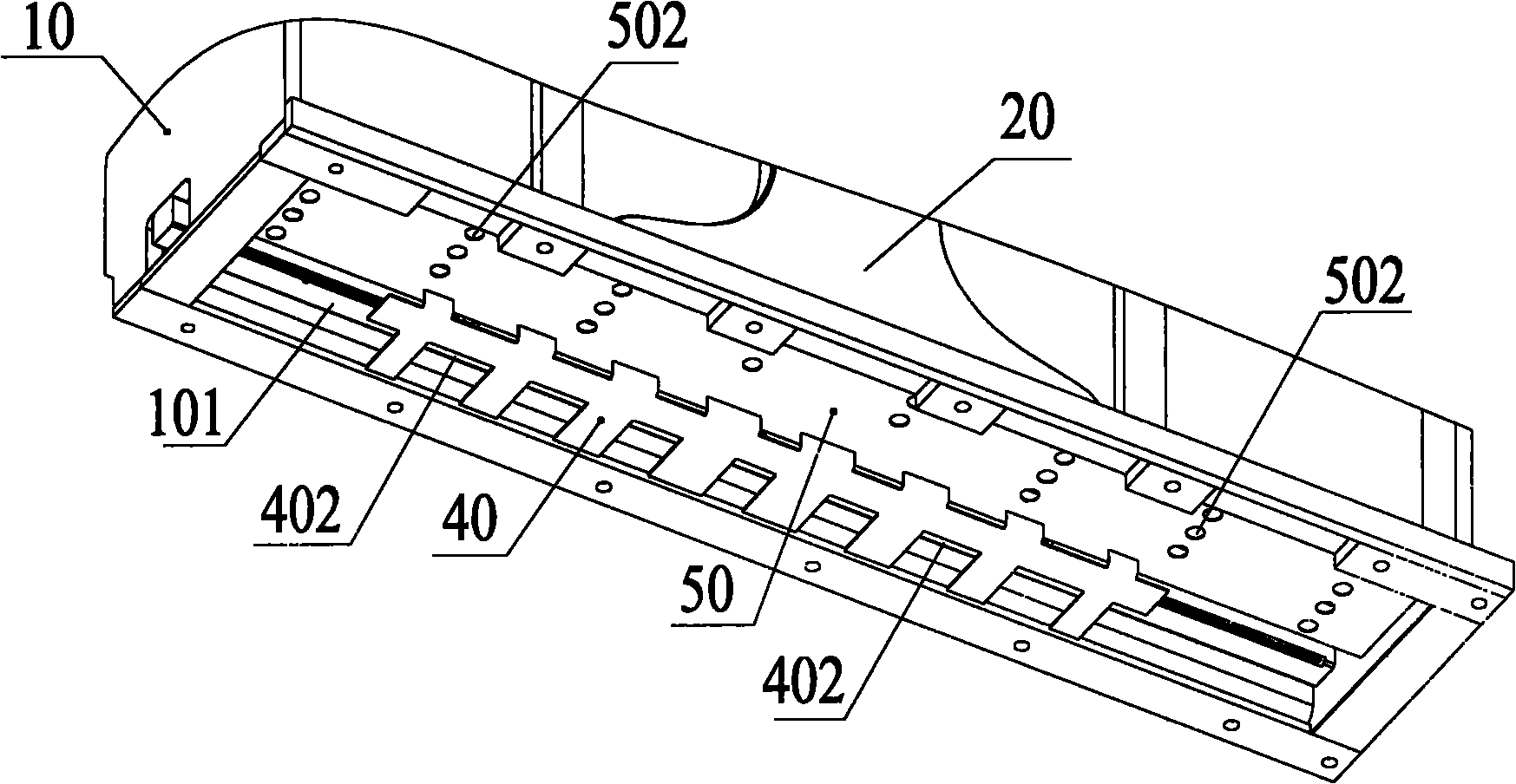

[0031] In order to make the connection between the heat conduction plate and the heat insulation plate and the screed box body stable and reliable, the structure of the heat conduction plate 50 and the heat insulation plate 40 in the embodiment can have a variety of structures besides the parallel plate structure in the above embodiment Embodiments, for example, the heat conducting plate is in the shape of a flat plate, the heat insulating plate 40 extends a first flange 401 in the direction of the heat conducting plate 50, the first flange 401 is welded on the heat conducting plate 50, and at the same time, a A plurality of through holes with larger areas are provided to facilitate the flow of hot air to the first space 201 .

[0032] The structure of the heat conducting plate and the heat insulating plate may be, for example, as figure 2 As shown, the end of the heat conduction plate 50 protruding into the combustion chamber 20 has a second flange 501 , and the second flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com