Patents

Literature

183 results about "Propane gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

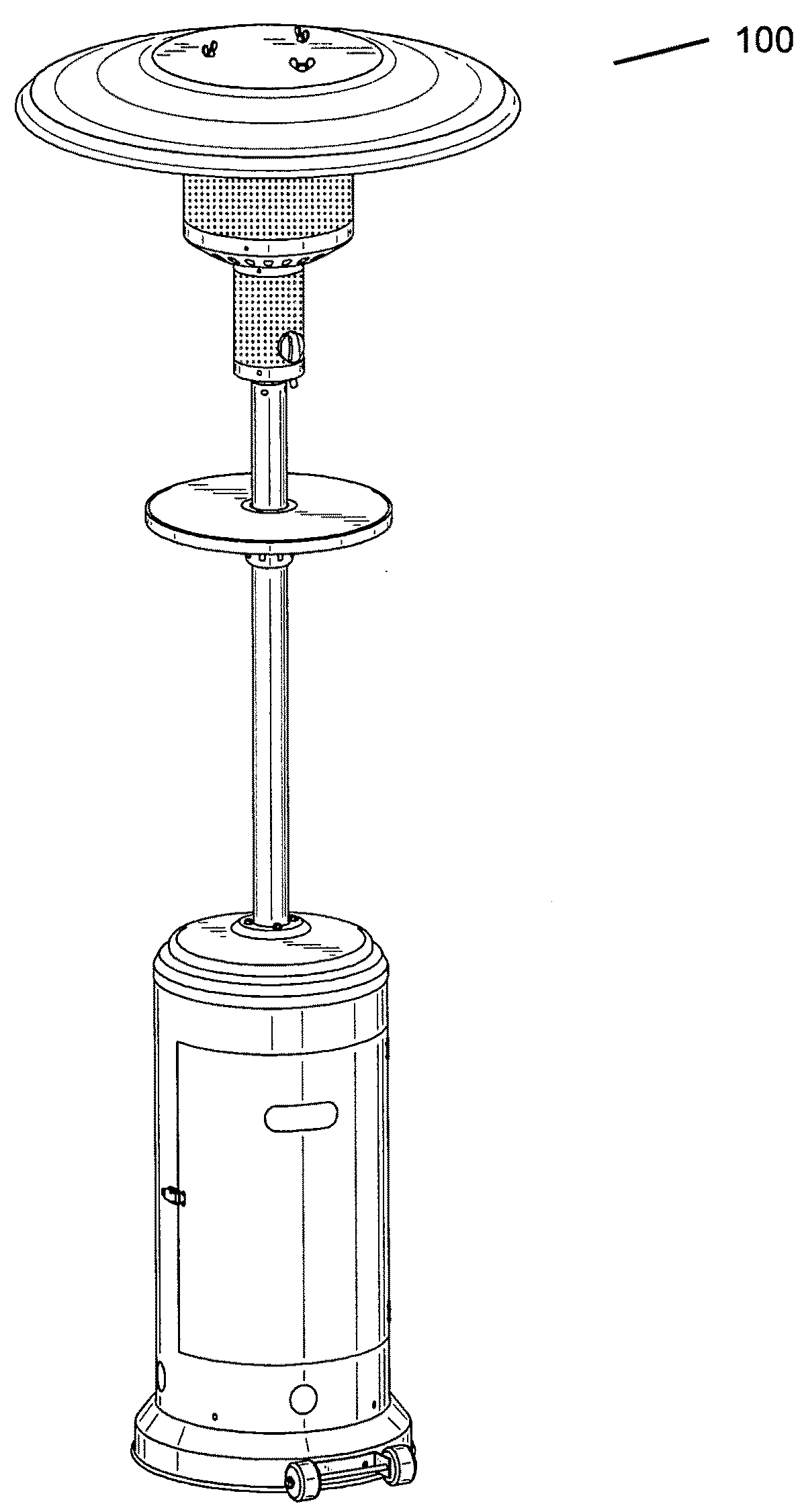

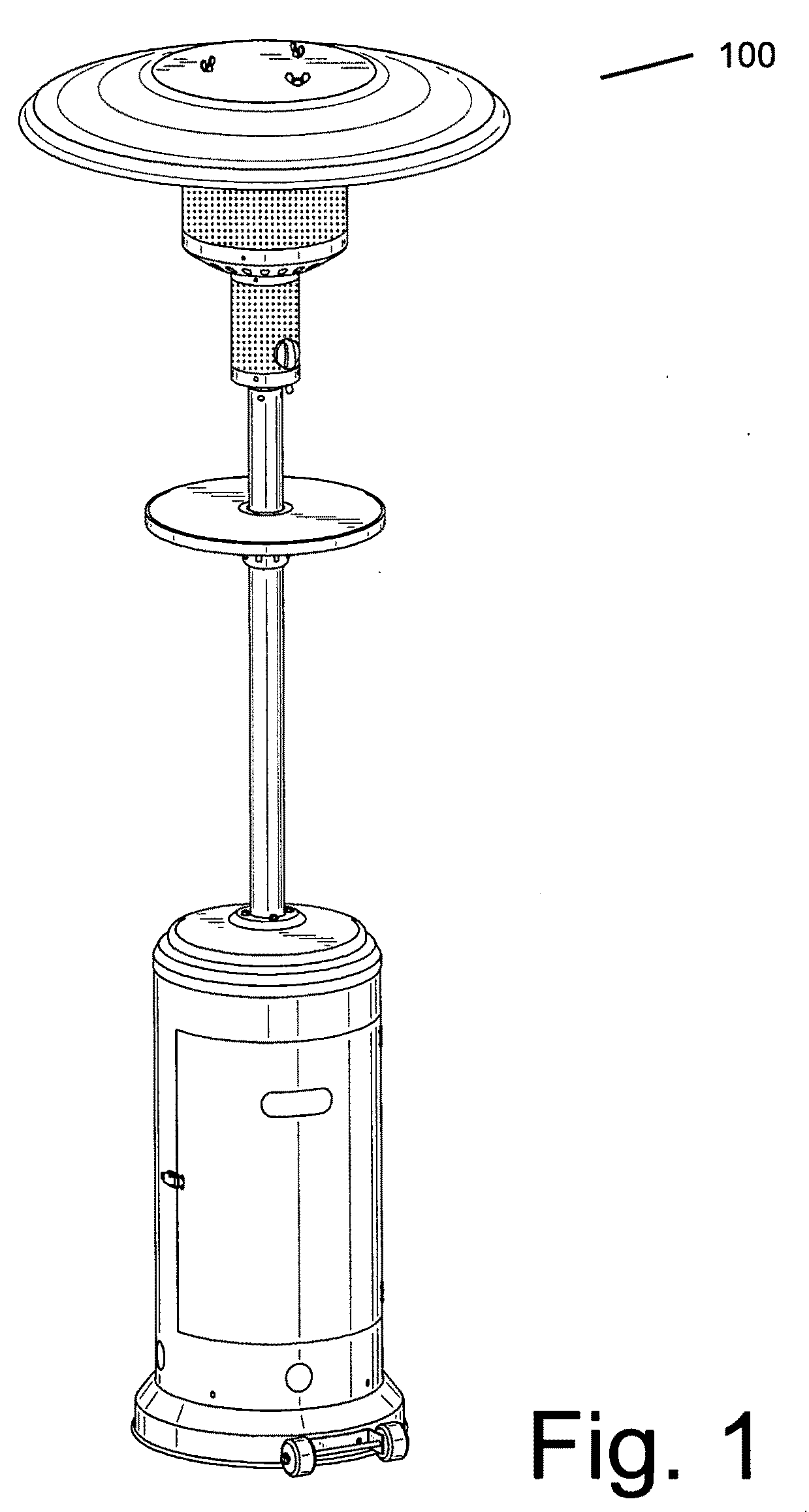

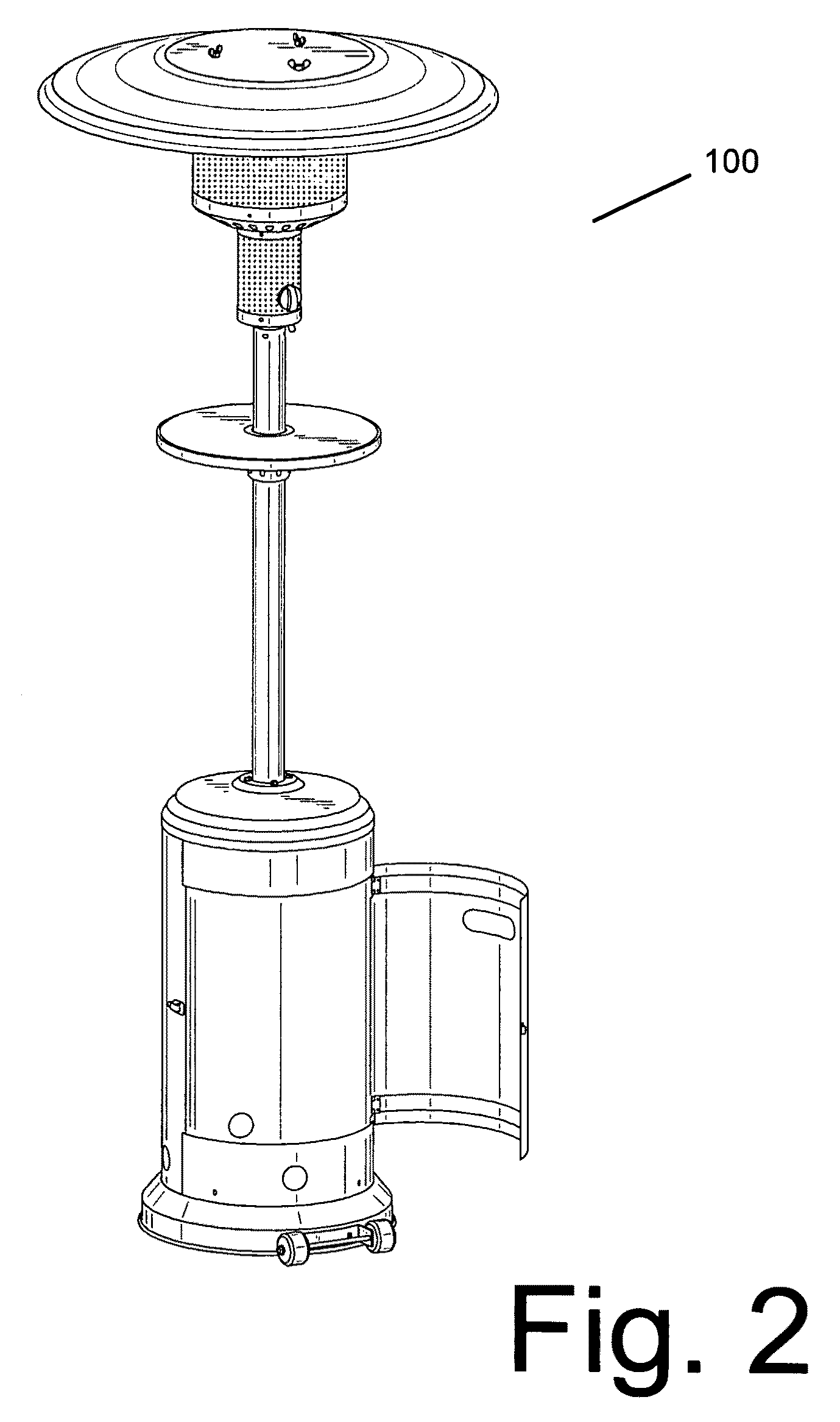

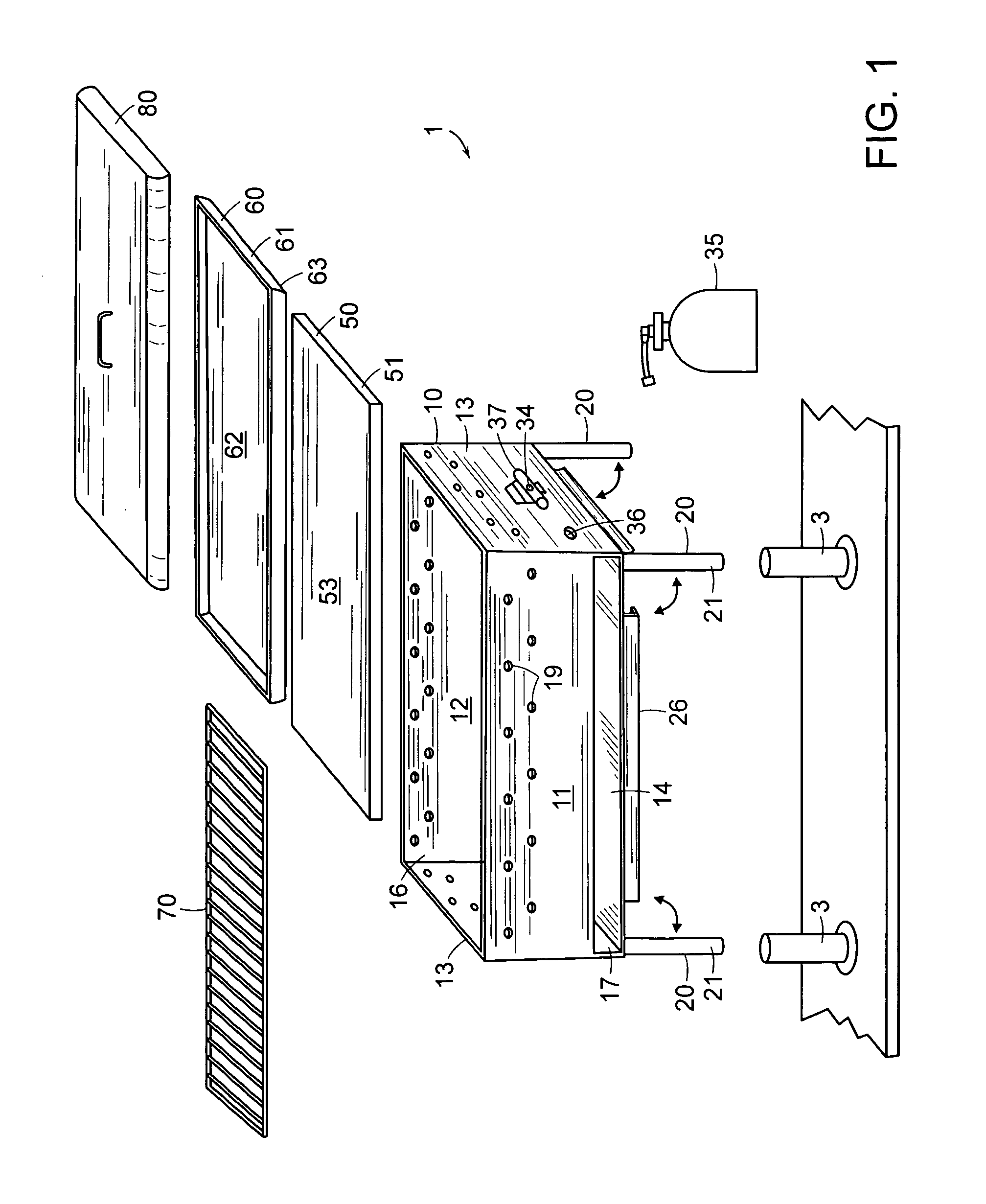

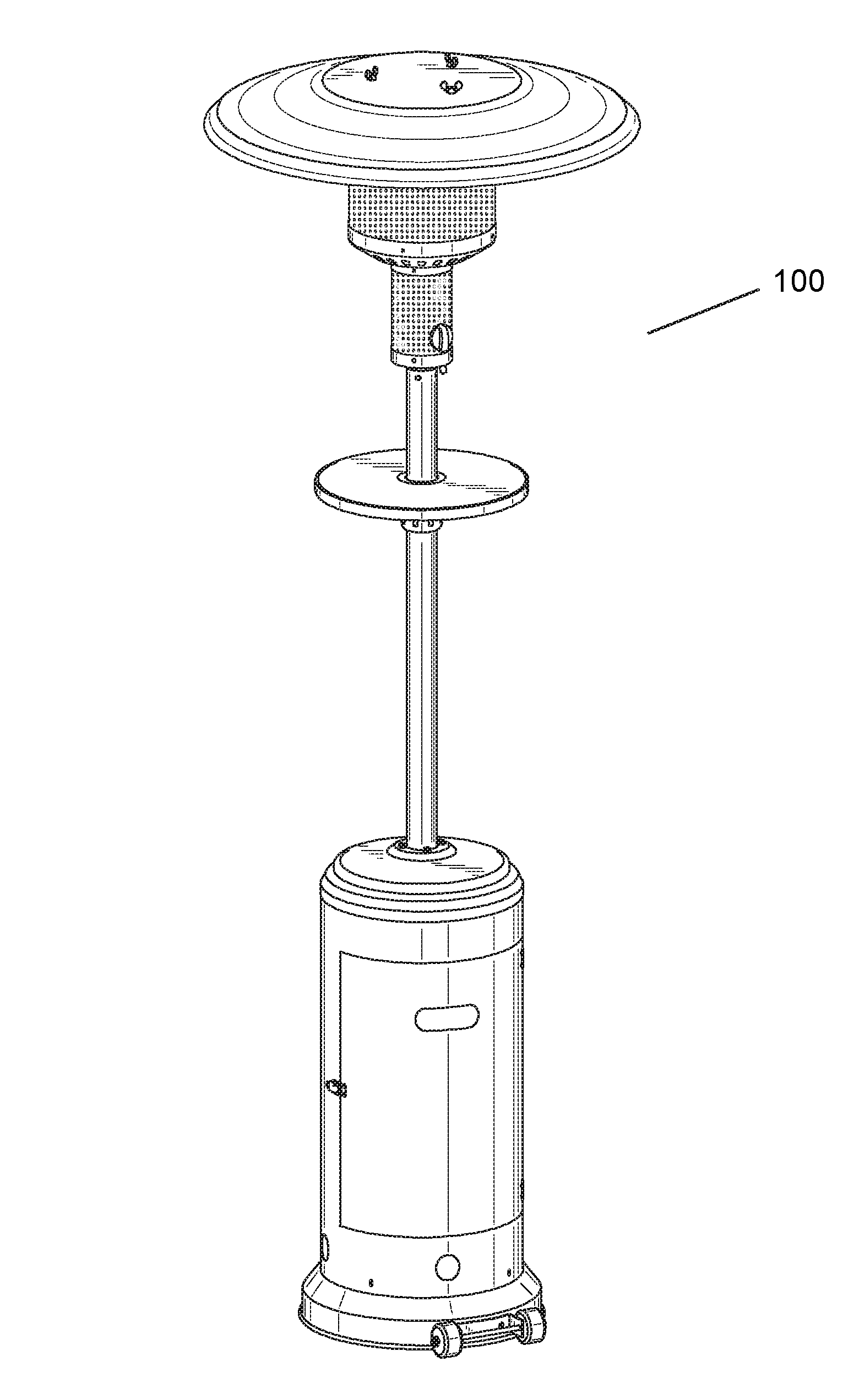

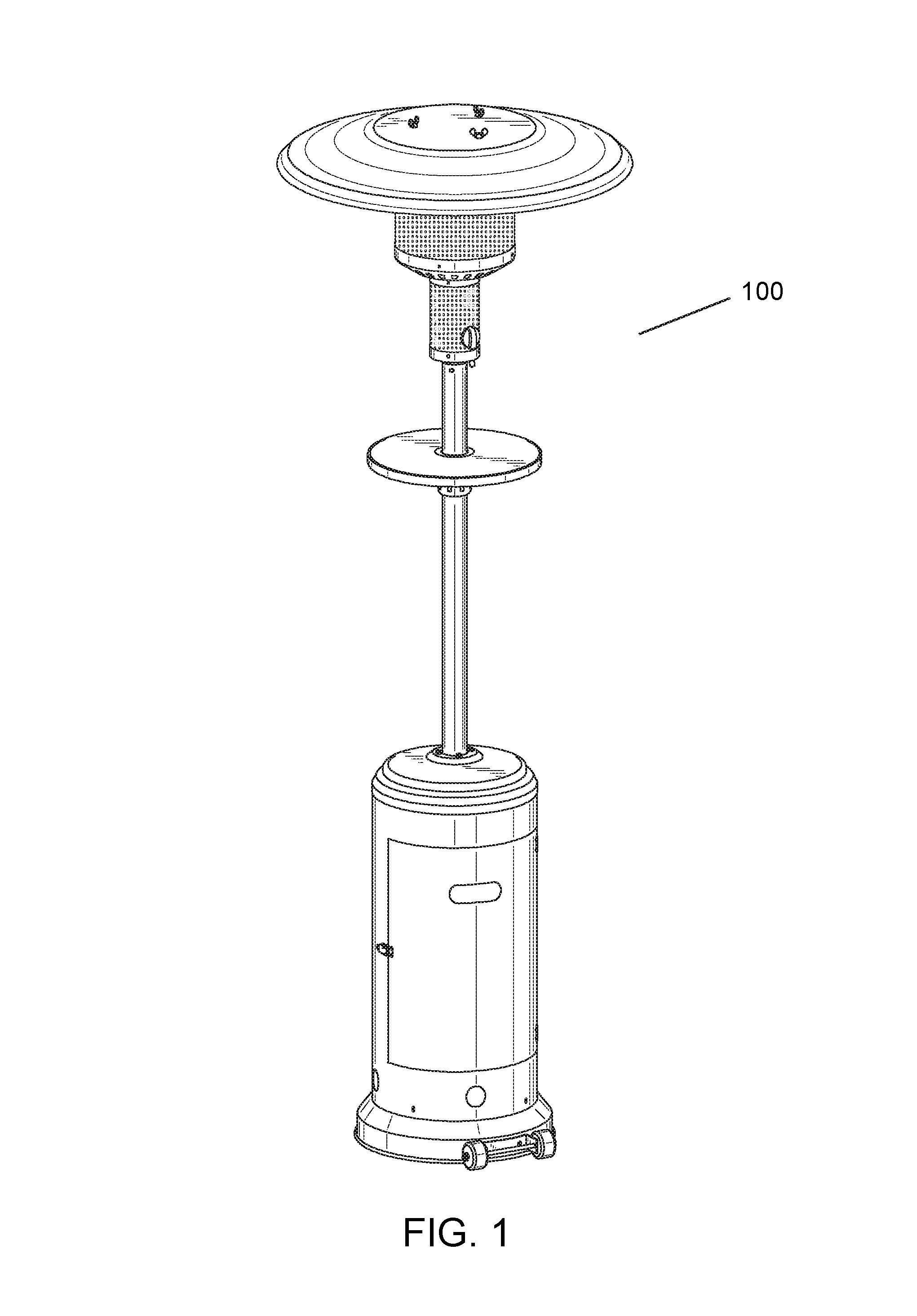

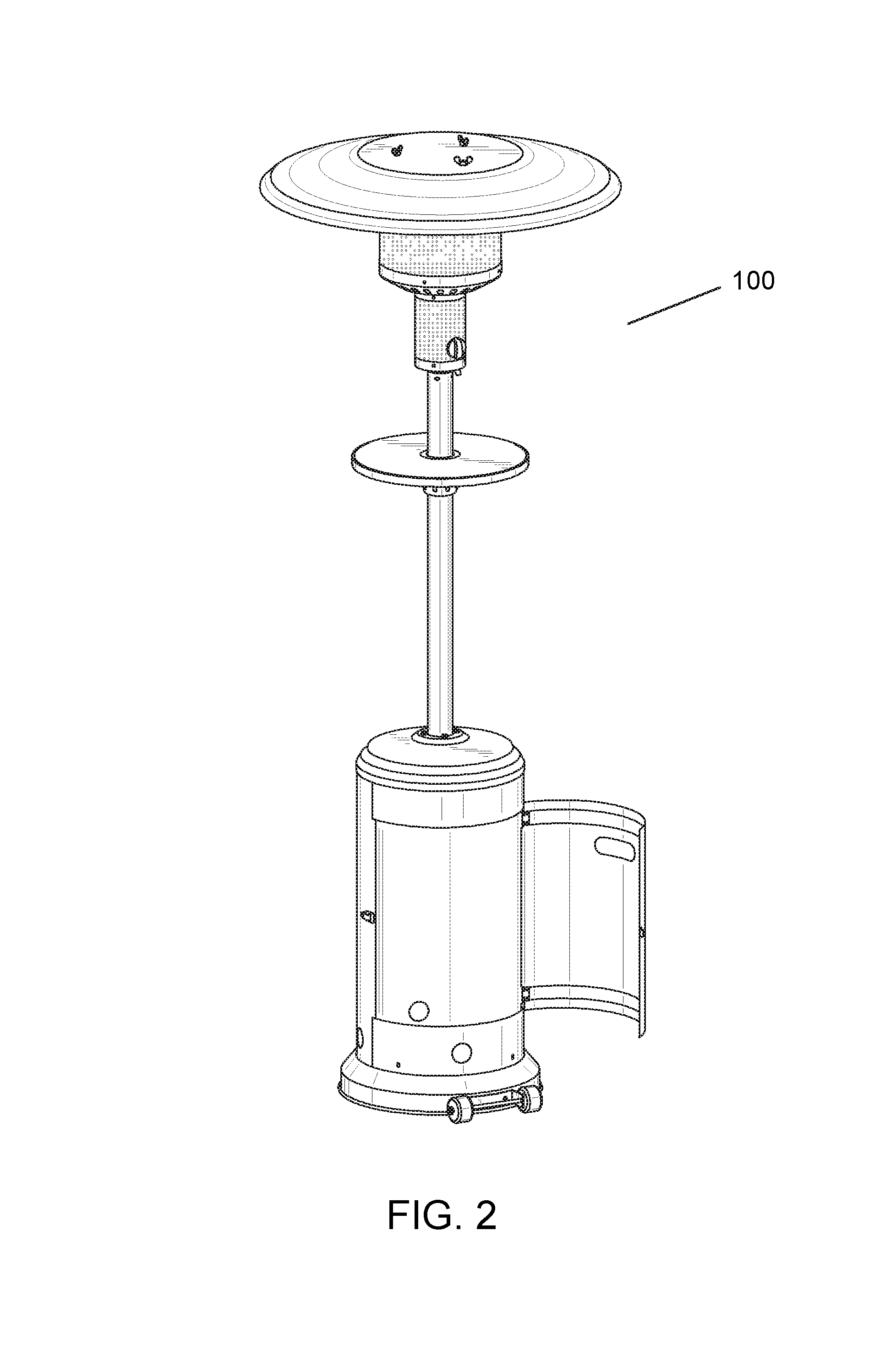

All around radiation heating apparatus

InactiveUS20100065047A1Prevent unintended tippingLower center of gravityDomestic stoves or rangesGaseous fuel burnerLiquid propaneEngineering

The present invention provides a safer all-around radiation heating assembly than similar traditional heaters. As typical with traditional heaters, a shroud is used to surroundably cover a portable liquid propane tank. To replace the portable liquid propane tank, the shroud must be continuously raised to a predetermined height while a service person accesses the propane tank. There is a danger that if and when the shroud drops, a spark could be created resulting in igniting highly flammable escaped propane gas. The present invention overcomes dangers associated with the traditional heaters by eliminating the spark creation danger and by introducing a ventilation system to allow any leaked propane gas to escape away from the heater.

Owner:CHANGZHOU GARDENSUN FURNACE

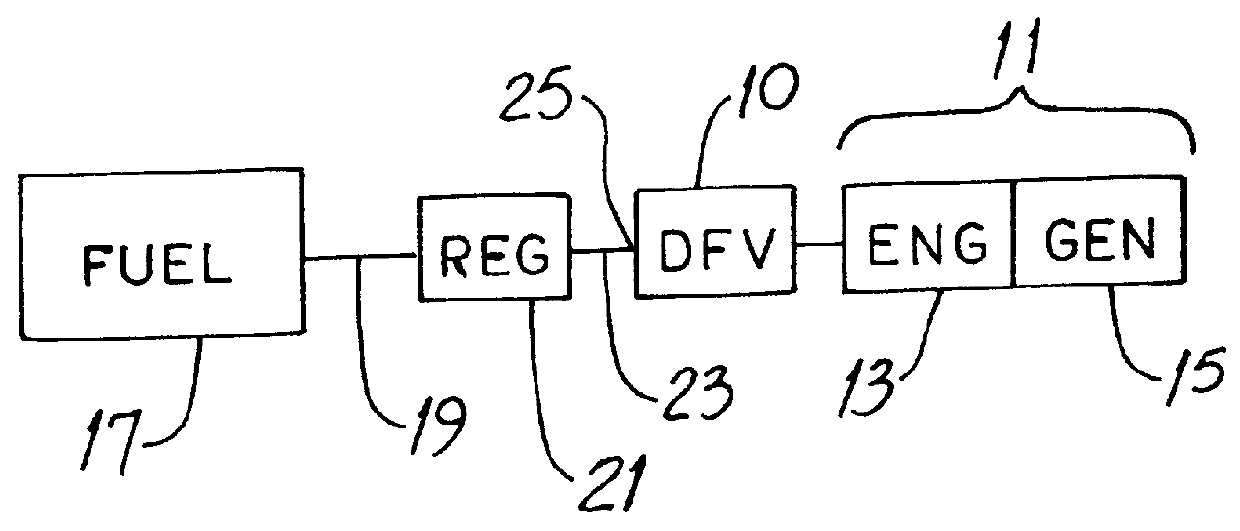

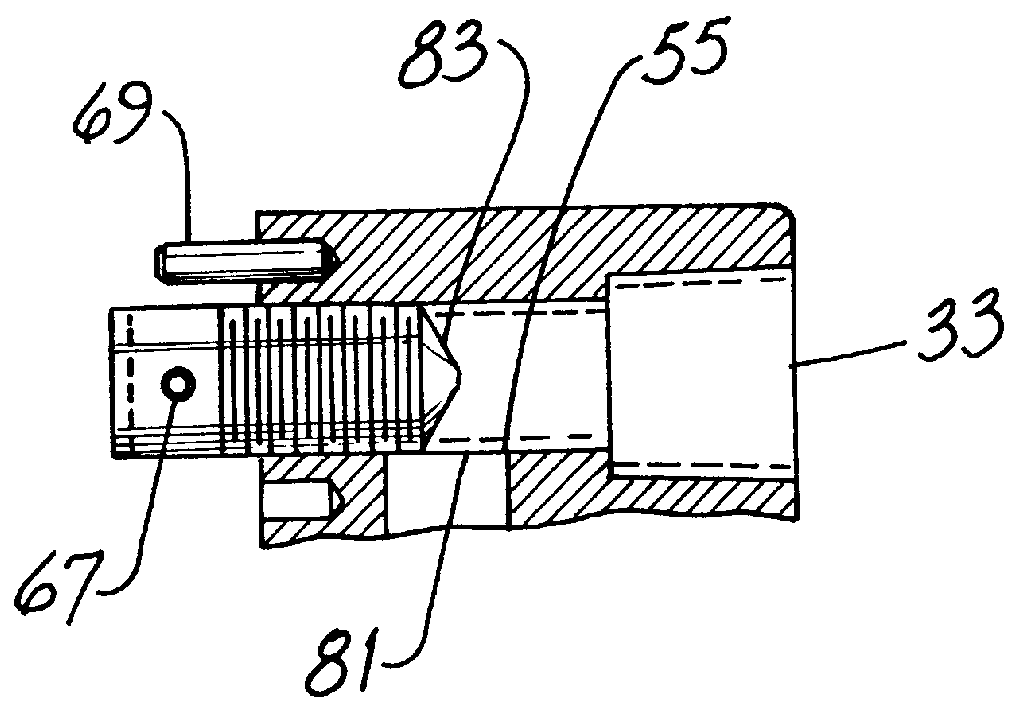

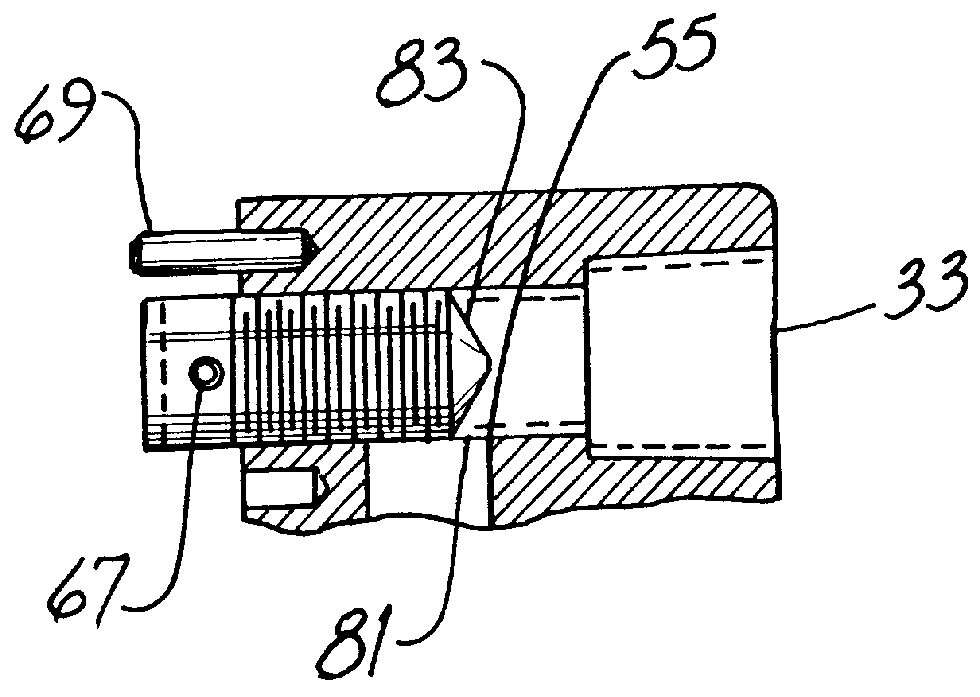

Dual-fuel valve

InactiveUS6068017APrevent movementPrevent inadvertent movementInternal combustion piston enginesFuel supply apparatusInlet channelEmission standard

A valve for flowing gaseous fuel, i.e., natural gas or propane gas, to an internal combustion engine includes a valve body having an inlet passage and first and second outlet paths in parallel with one another and in flow communication with the inlet passage. A plug-type adjustment member is threaded into the body and an annular seat in the body coacts with the adjustment member to form an orifice in the first outlet path. A stop mechanism limits movement of the adjustment member between a first position at which the orifice area is smaller and a second position at which the orifice area is larger. The valve permits adjustment of fuel flow to small engines so that such engines provide maximum power without exceeding applicable emission standards. And the valve is tamper-resistant.

Owner:GENERAC POWER SYSTEMS

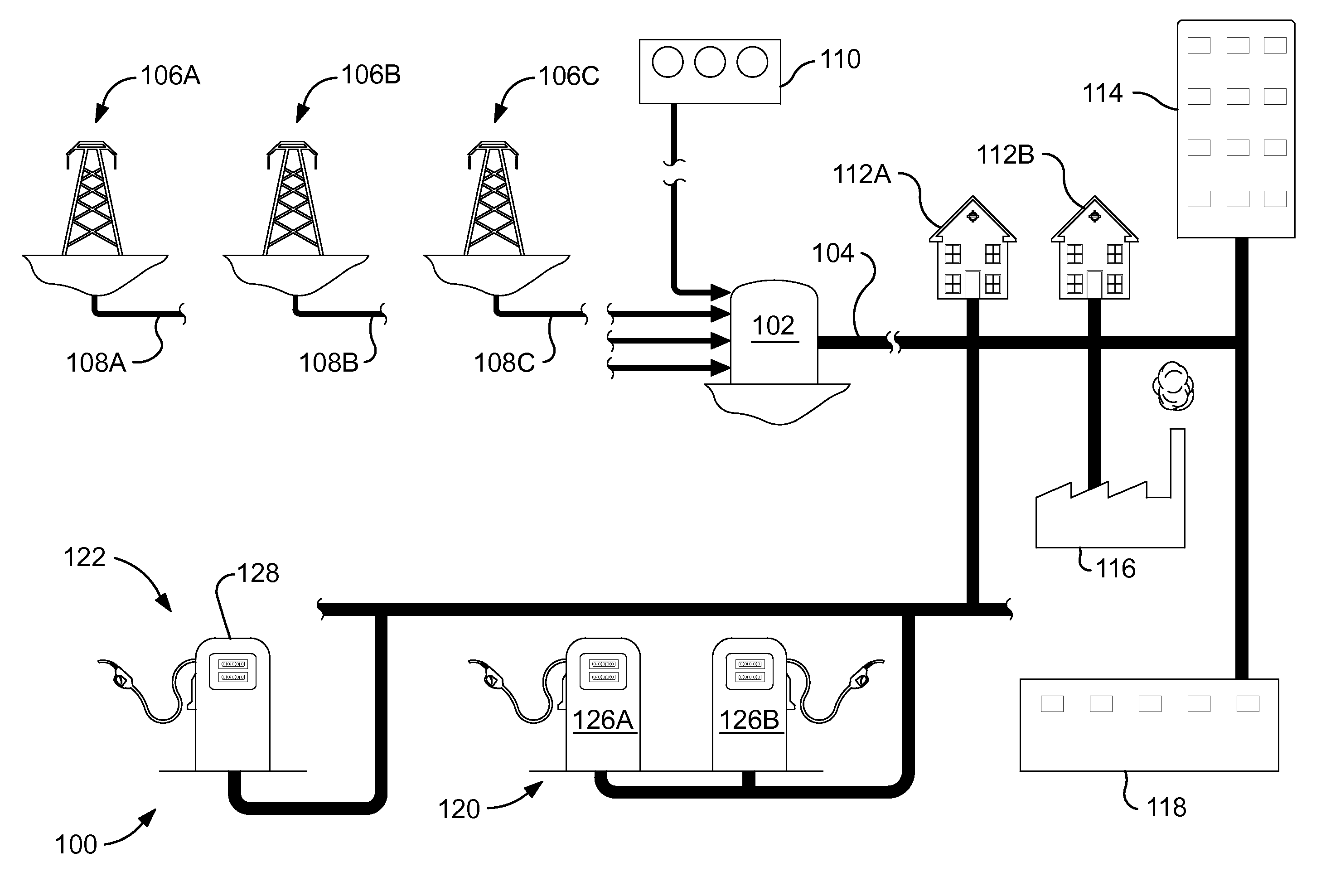

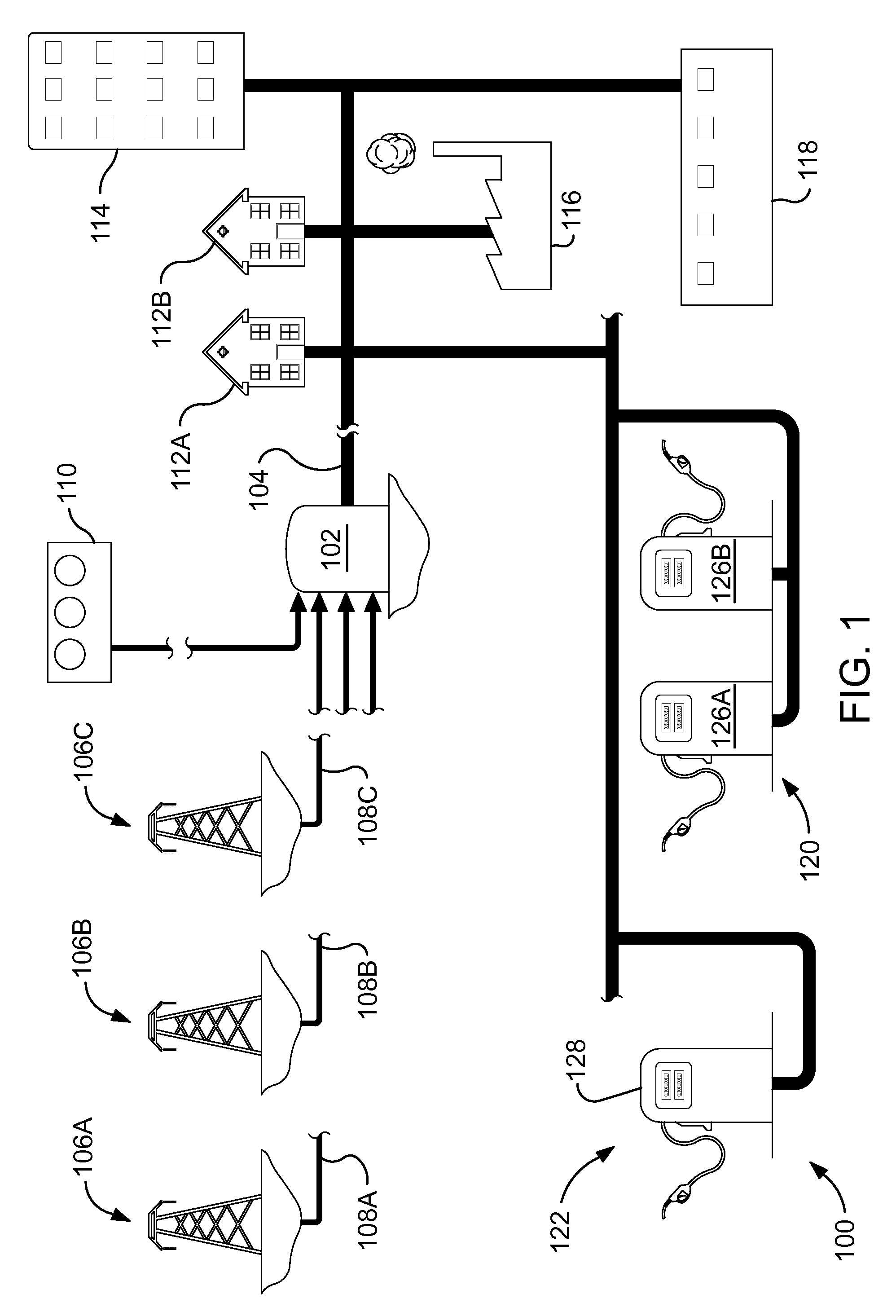

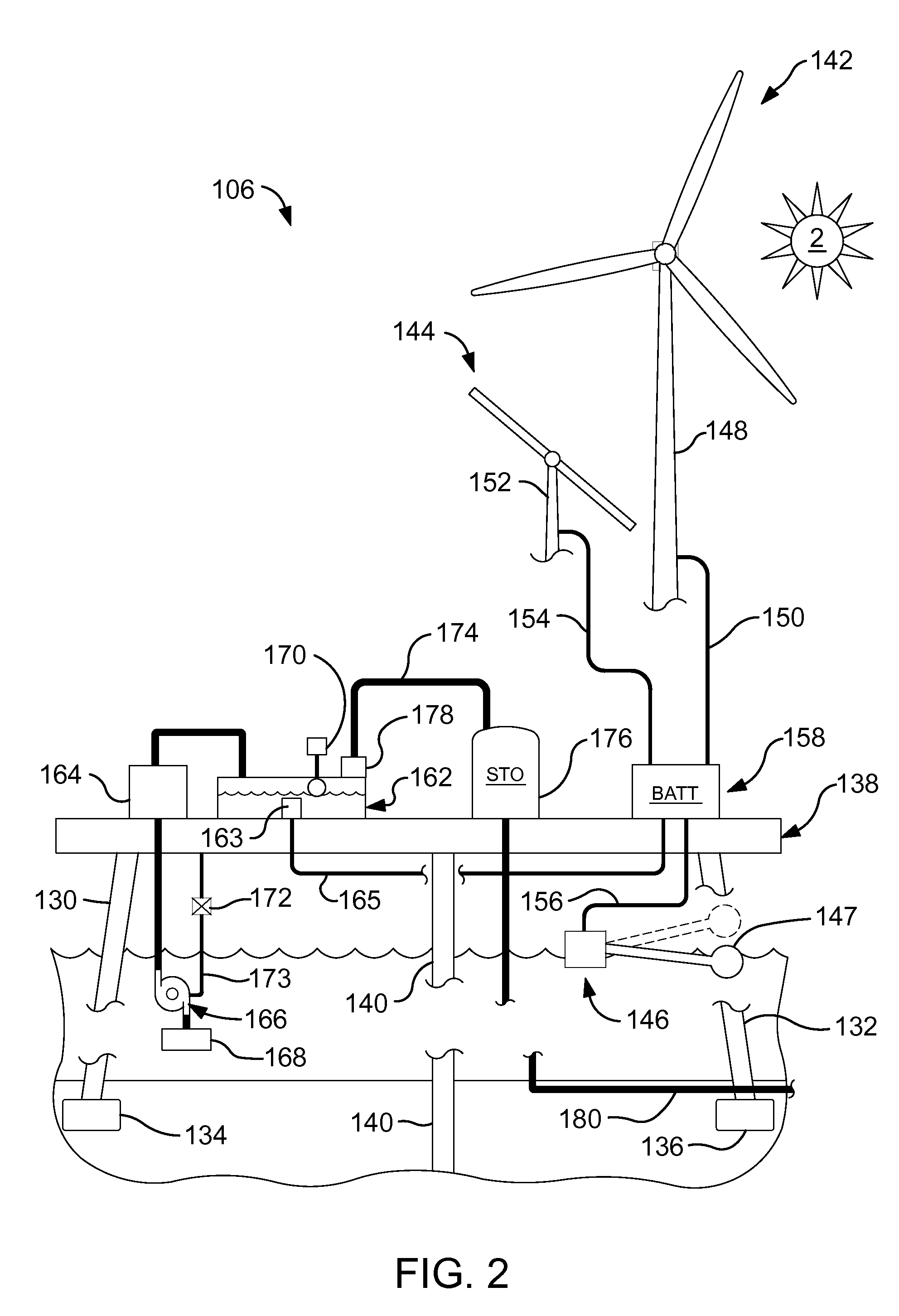

Hydrogen generation and distribution system

InactiveUS20090313896A1Quantity minimizationBatteries circuit arrangementsElectrolysis componentsEnergy infrastructureElectrolysis

A hydrogen production and distribution system which may exploit pre-existing energy infrastructure such as offshore hydrocarbon production facilities, sewage treatment plants, and natural gas pipelines. The offshore facilities and sewage treatment plants may have wind turbines, photovoltaic elements, and wave powered generators to generate electricity, which is then stored in batteries. Electrical power is drawn from the batteries to electrolyze water. Hydrogen collected from electrolysis is conducted to consumers through a system using the natural gas pipelines and optionally, tank trucks formerly used to deliver propane gas. A master computerized control system controls the hydrogen production and distribution system, and is isolated from public communications channels.

Owner:GLIDEWELL CAMERON

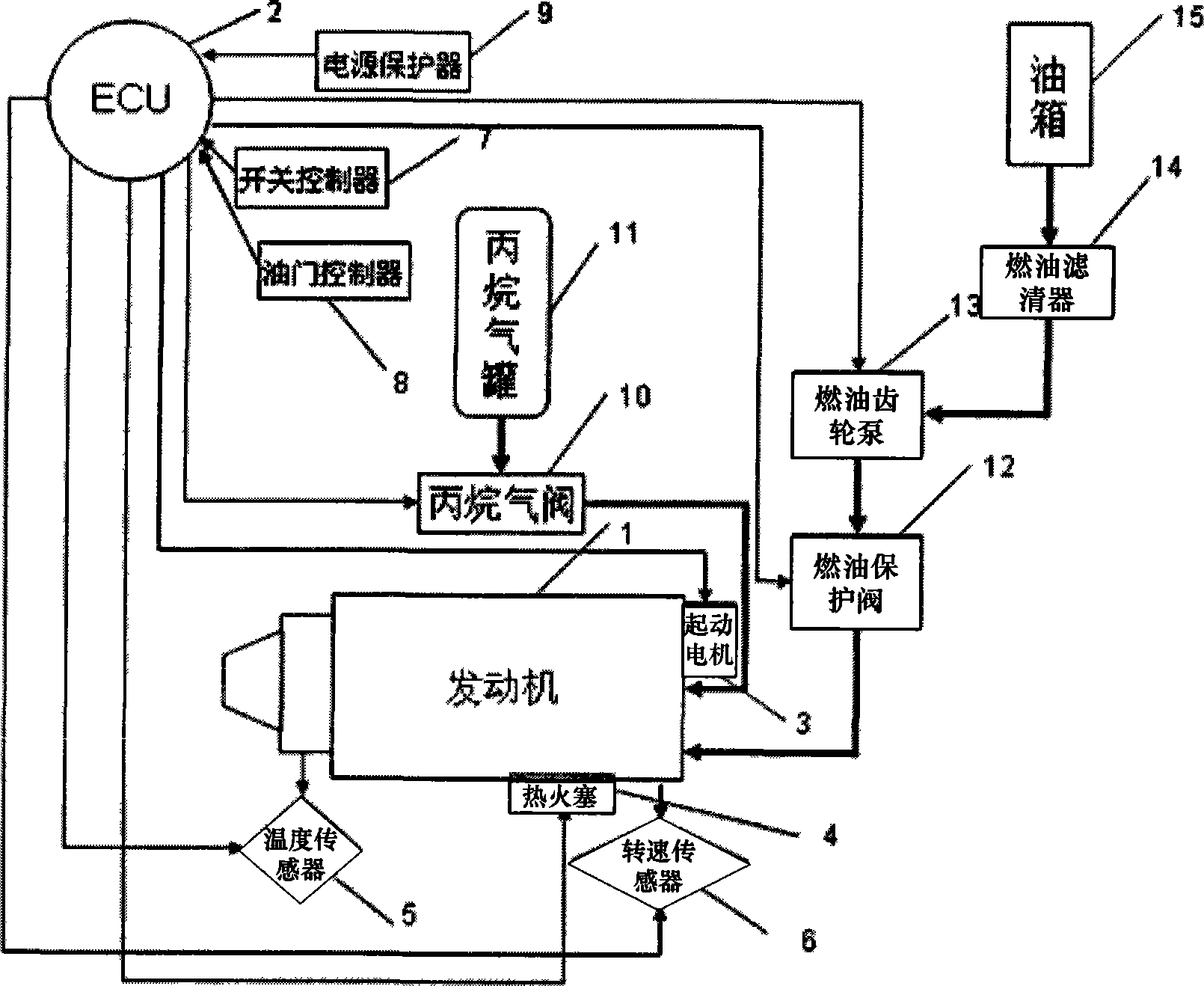

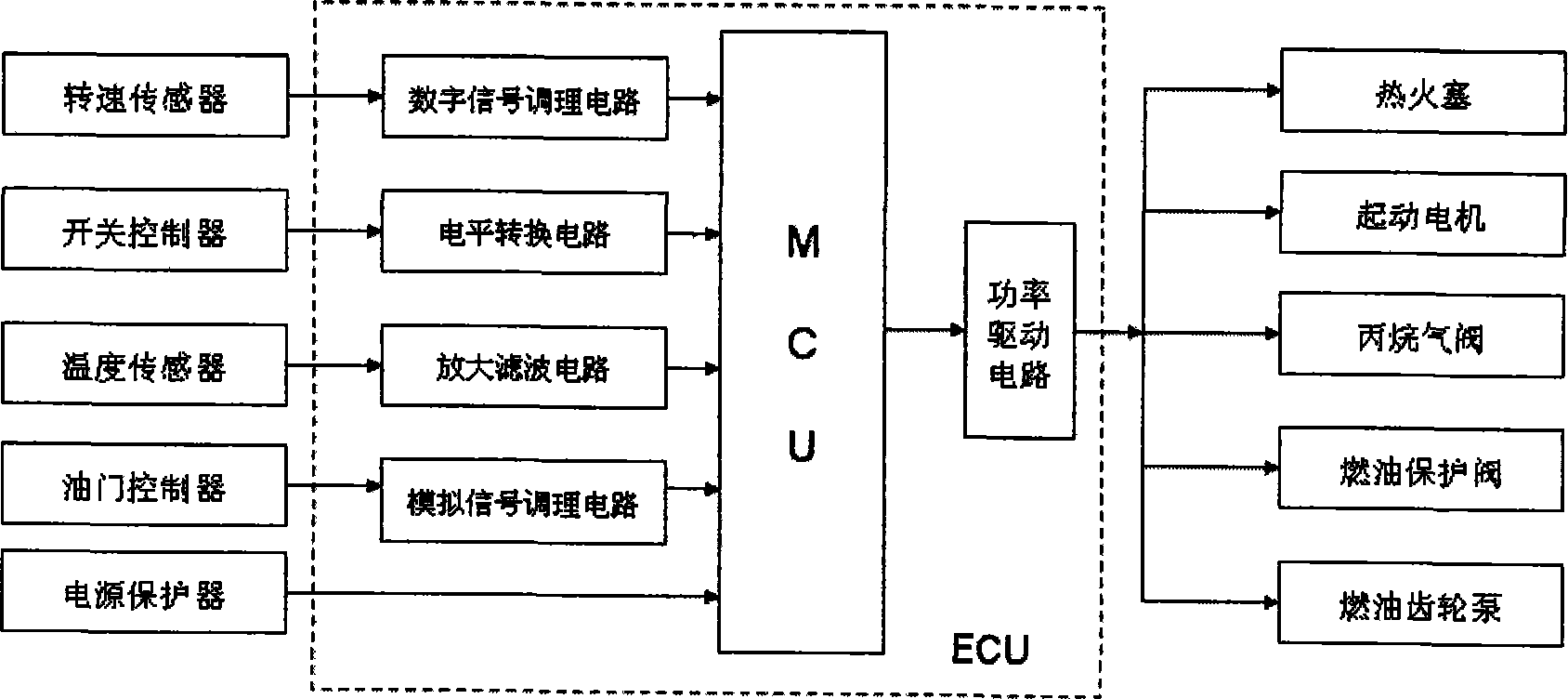

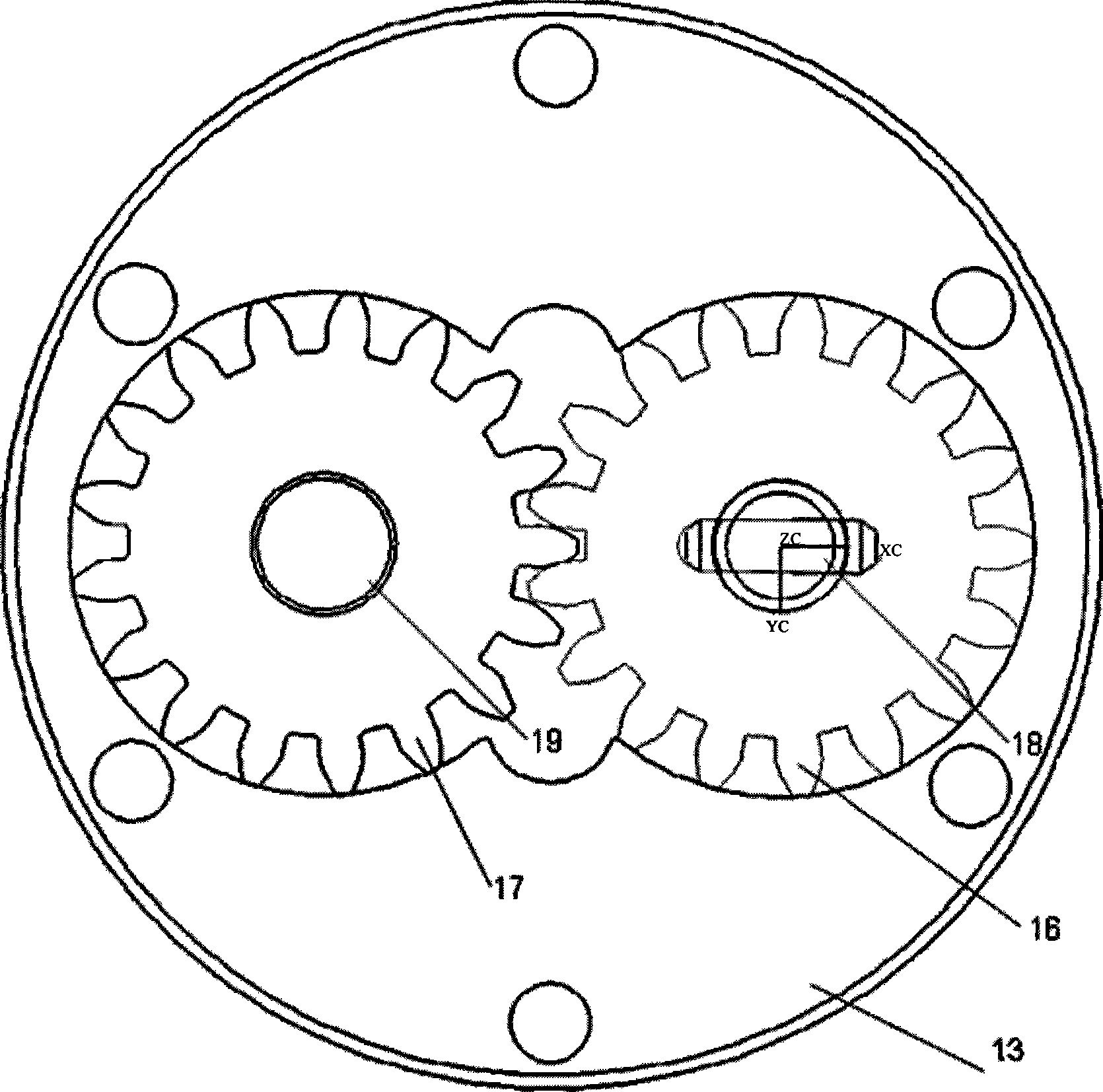

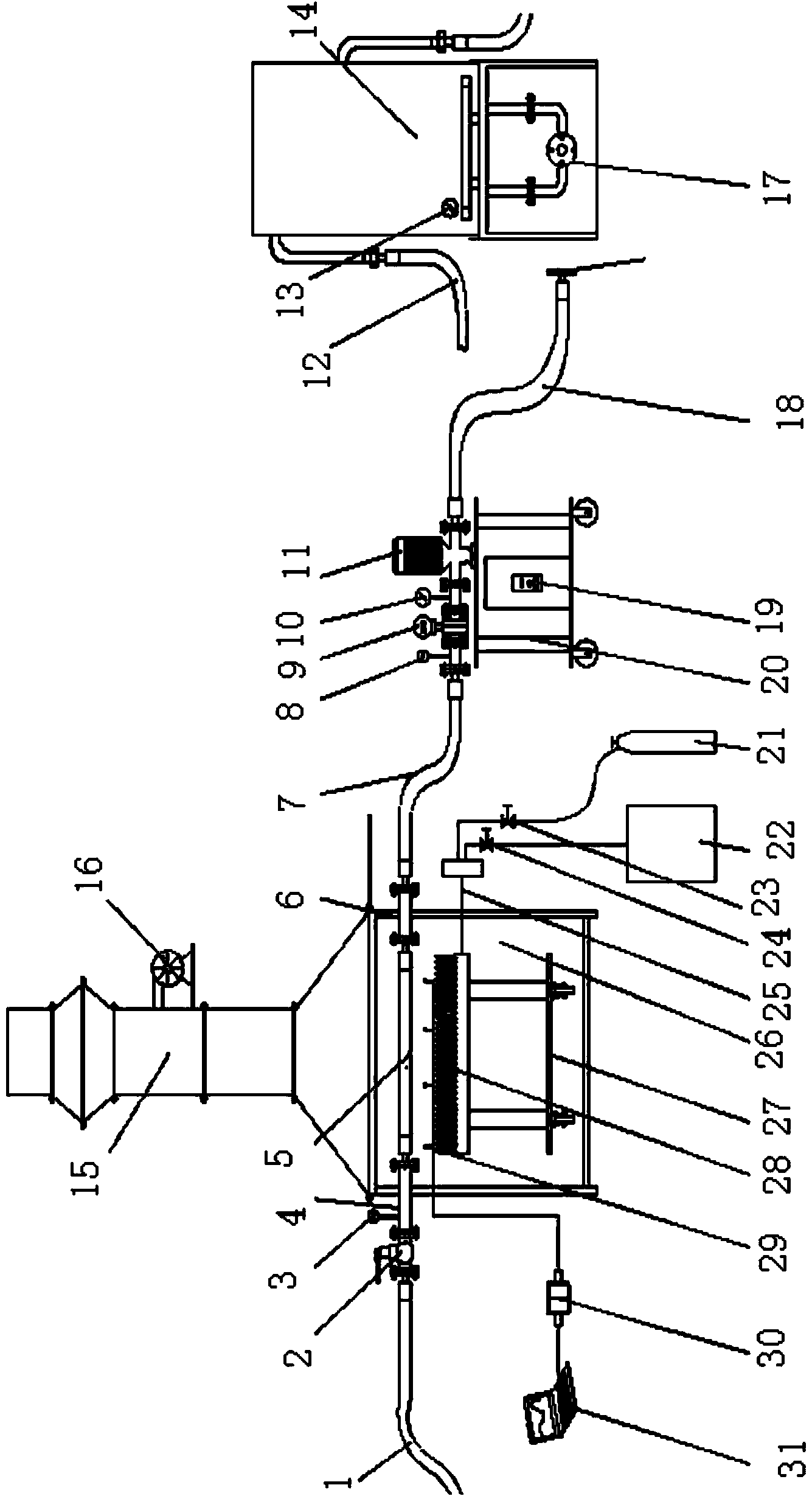

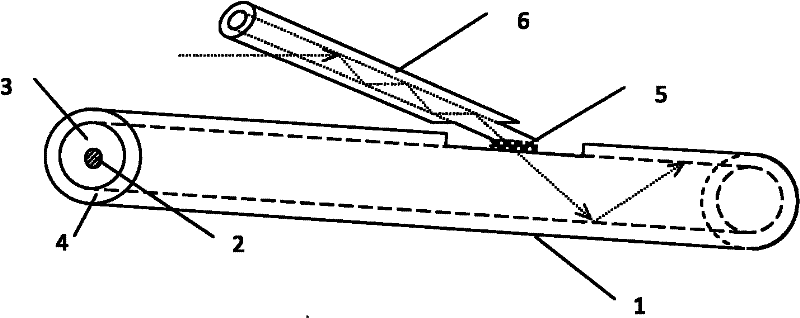

Control device of microminiature turbojet and starting control method thereof

The invention discloses a control device for a microminiature turbojet engine and a starting control method thereof. The device comprises a rotating speed sensor for collecting the rotating speed of an engine, a temperature sensor for collecting exhaust temperature, a switch controller, a throttle controller, an electronic control unit (ECU) and an executing mechanism, wherein the executing mechanism comprises a starting motor, a hot piston, a propane gas valve, a fuel protective valve and a fuel gear pump. The control method comprises the following steps: the ECU monitors the working state of the engine through the sensor, and outputs a pulse-width modulation signal to a power drive circuit to control the starting motor, the hot piston, the propane gas valve, the fuel protective valve and the fuel gear pump so as to complete starting control to the engine; functions of establishing fuel pressure and adjusting fuel quantity can be realized by the fuel gear pump after starting of the engine is completed; and fuel can be accurately supplied to ensure that the engine operates in an expected working state. The device can be used for a microminiature delivery vehicle, and the executing mechanism of the device has the advantages of simple structure, small volume and light weight, and easily realization of reliable and efficient control to the engine.

Owner:北京领动国创科技有限公司

High-efficiency industrial gas

InactiveCN101892102ARaise the combustion temperatureImprove combustion efficiencyGaseous fuelsGas flame welding apparatusIndustrial gasPropane gas

The invention discloses a high-efficiency industrial gas which comprises the raw materials: industrial propane gas with the purity higher than 95% (weight percent), and liquid-phase synergistic additive accounting for 0.3-1.0% (weight percent) of the industrial propane gas. By adding a little liquid-phase synergistic additive into the propane gas, the high-efficiency industrial gas remarkably improves the burning temperature and efficiency; meanwhile, the liquid-phase synergistic additive of the high-efficiency industrial gas has low corrosivity for a container and good volatility.

Owner:BEIJING DATONG HONGYE TECH DEV

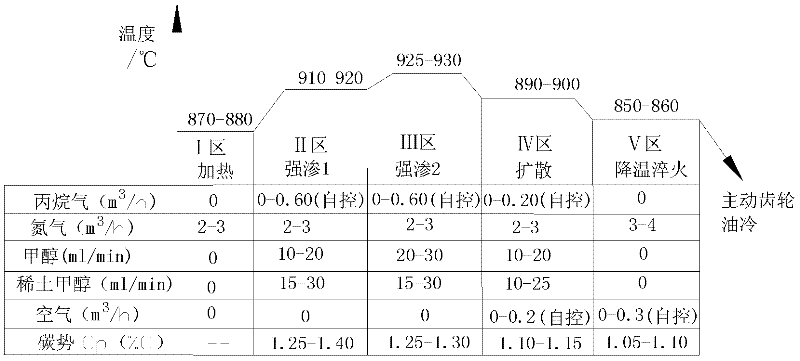

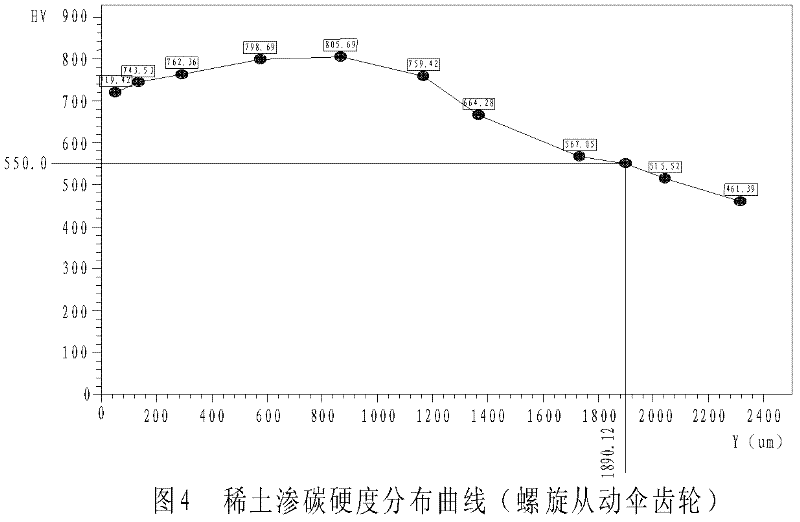

Heat treatment method of spiral bevel gear of cargo truck on double-row rare earth carburization equipment

ActiveCN102373400AEmission reductionIncrease carburizing speedSolid state diffusion coatingCarbon potentialRare earth

The invention provides a heat treatment method of a spiral bevel gear of a cargo truck on double-row rare earth carburization equipment, and relates to a carburization heat treatment technological process of the spiral bevel gear of the cargo truck. The invention solves the problems that energy consumption of carburization heat treatment is high, production cost of a product is high and carburization quenching and gear thermal distortion still exist in a carburization process. The method provided by the invention comprises the following steps of: taking a preheating zone as a strong leakage region 1 and taking a carburizing region as a strong leakage region 2, namely taking a region II and a region III as a carburizing speed main control region and taking a region IV and a region V as a metallographic structure main control region, carrying out temperature control in the regions I, II, III, IV and V, carrying out carbon potential control in the regions II, III, IV and V, and inputtingcarburizing medium propane gas, rare earth methanol penetrating agent, nitrogen, methanol and air into a furnace, thus the heat treatment method is realized. The metallographic structure and surface hardness of the spiral bevel gear subjected to the heat treatment method provided by the invention are all optimized, and heat treatment quality of the spiral bevel gear is improved; meanwhile, capacity is improved by 23%, heat treatment production cost is reduced by 18.9%, and pollution of exhaust emission to the environment is reduced.

Owner:哈尔滨汇隆汽车箱桥有限公司 +3

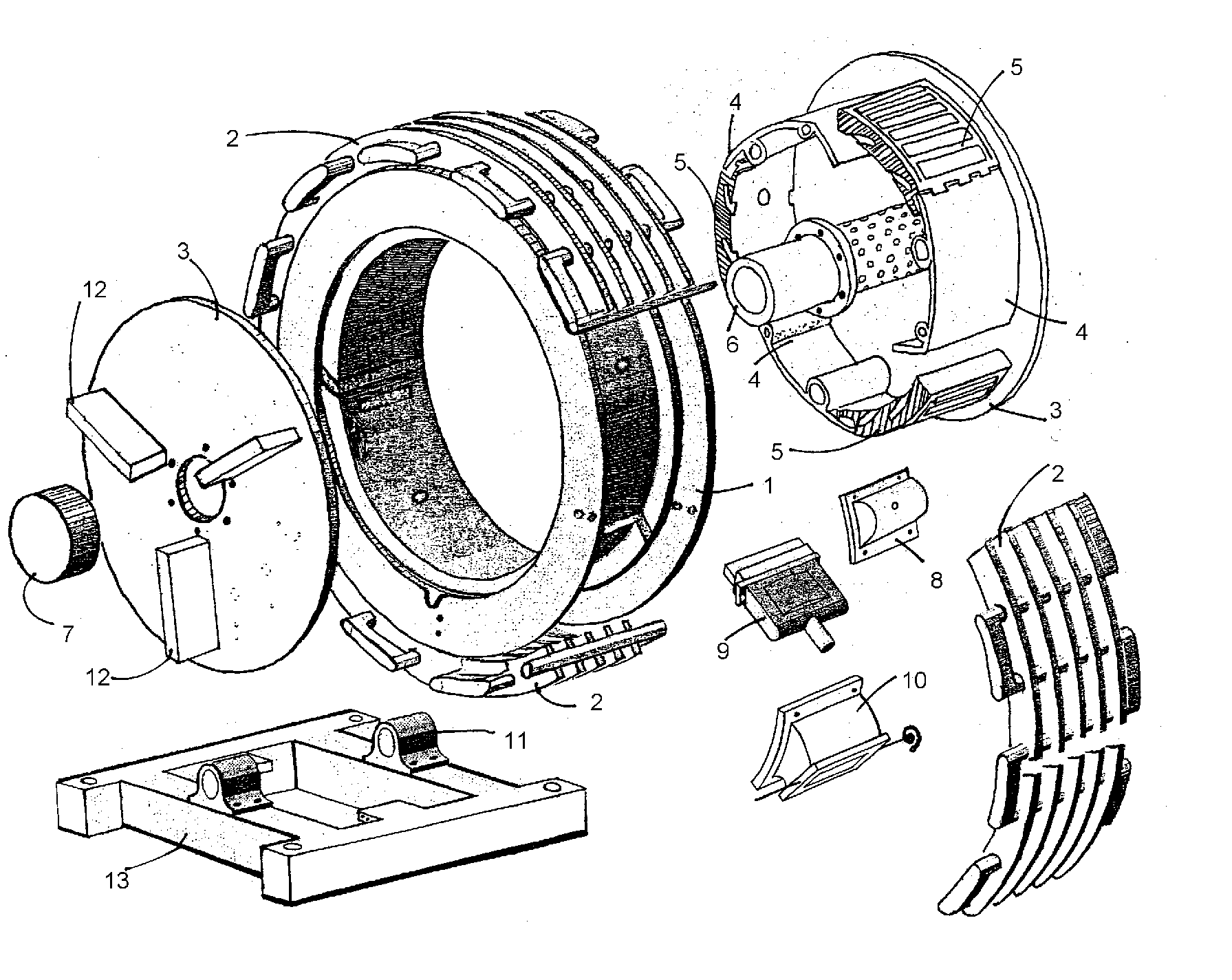

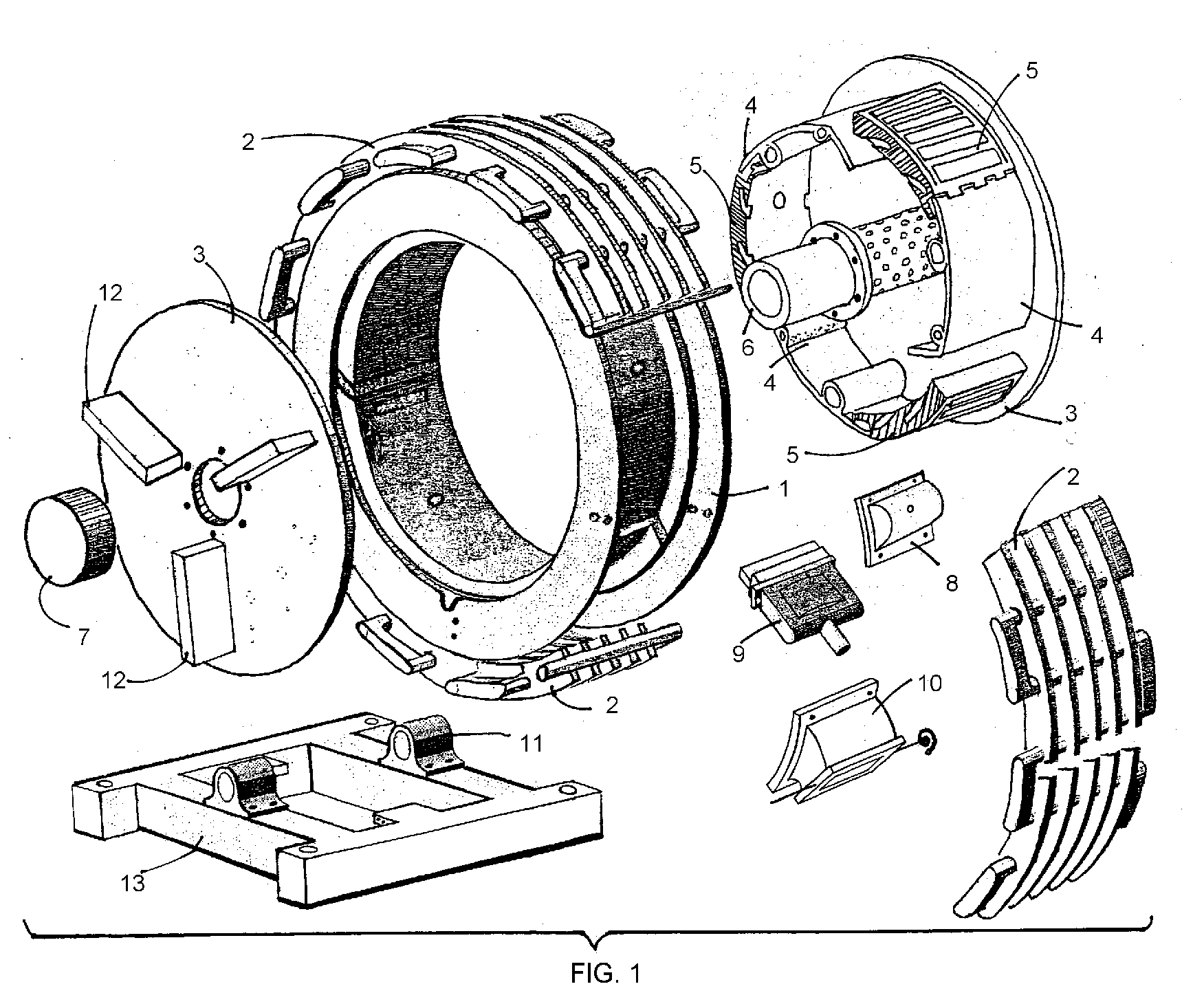

Modular Rotary Engine

InactiveUS20070084434A1Low reciprocating massReduce distanceInternal combustion piston enginesOscillating piston enginesExternal energyEngineering

An internal combustion rotary engine, self cooled, totally concentric and symmetric, dynamically variable compression ratio, capable of developing multiple Otto cycles in each rotation, by means using modules, composed mainly by a solenoid gate valve and three chambers operating at the rotor periphery, producing at low RPM, torsion of value near close at theoretical limit. High power / weight ratio, which increases substantially when number of modules increase, without drive shaft length increase; plus reduced internal friction, is a truly saver fuel machine; with volumetric asymmetry ratio between expansion and compression chambers, and that compression chambers working at beginning of the cycle at normal atmospheric pressure, it gives a fast rise pressure peak, because of the almost wedged form of that chambers. Proper for many types of combustion and class of fuels, including hydrogen, liquefied propane gas and efficient use of air compressed as external energy supply. Excels in aircraft use.

Owner:LEON ENRIQUE HALUY

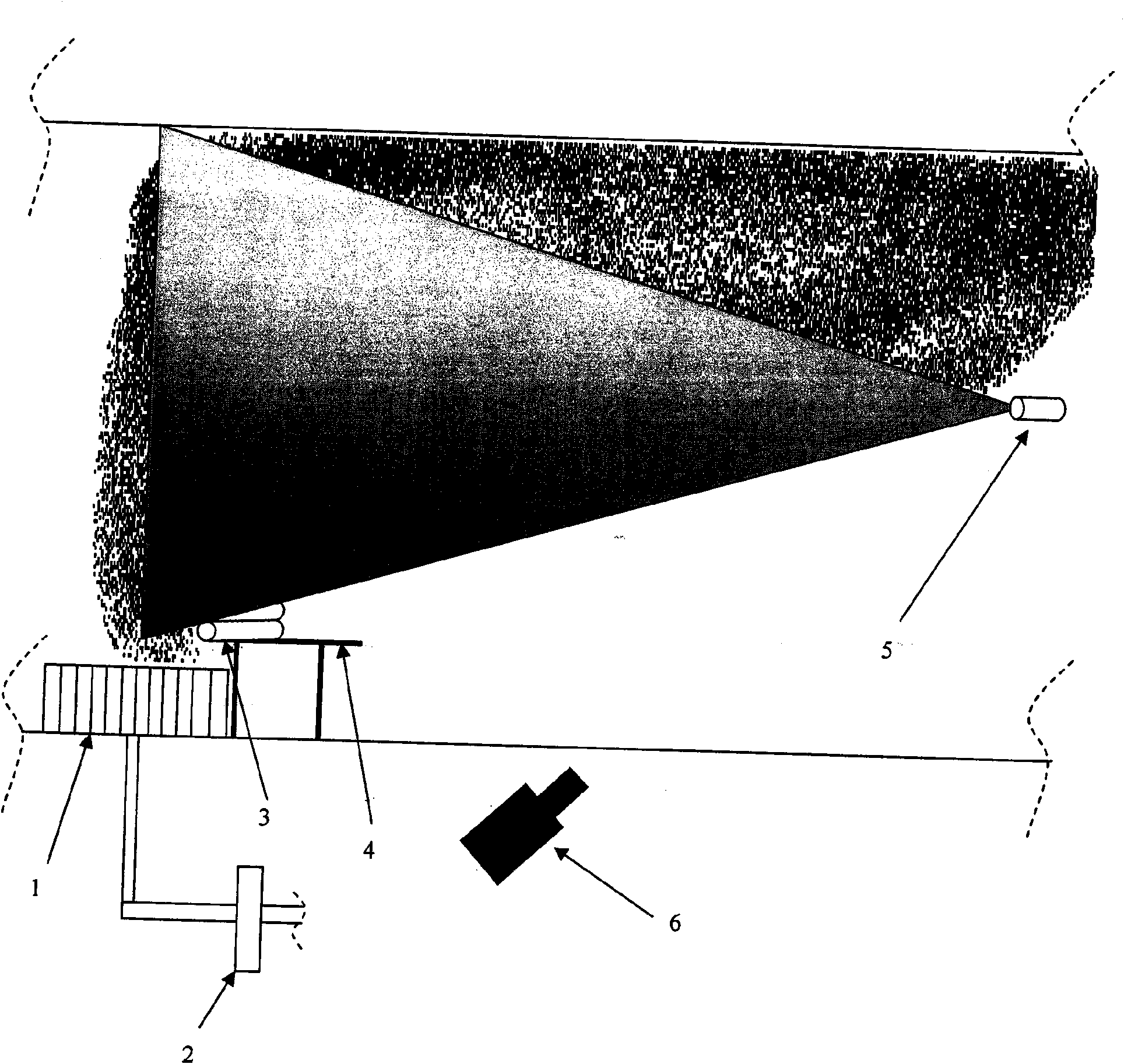

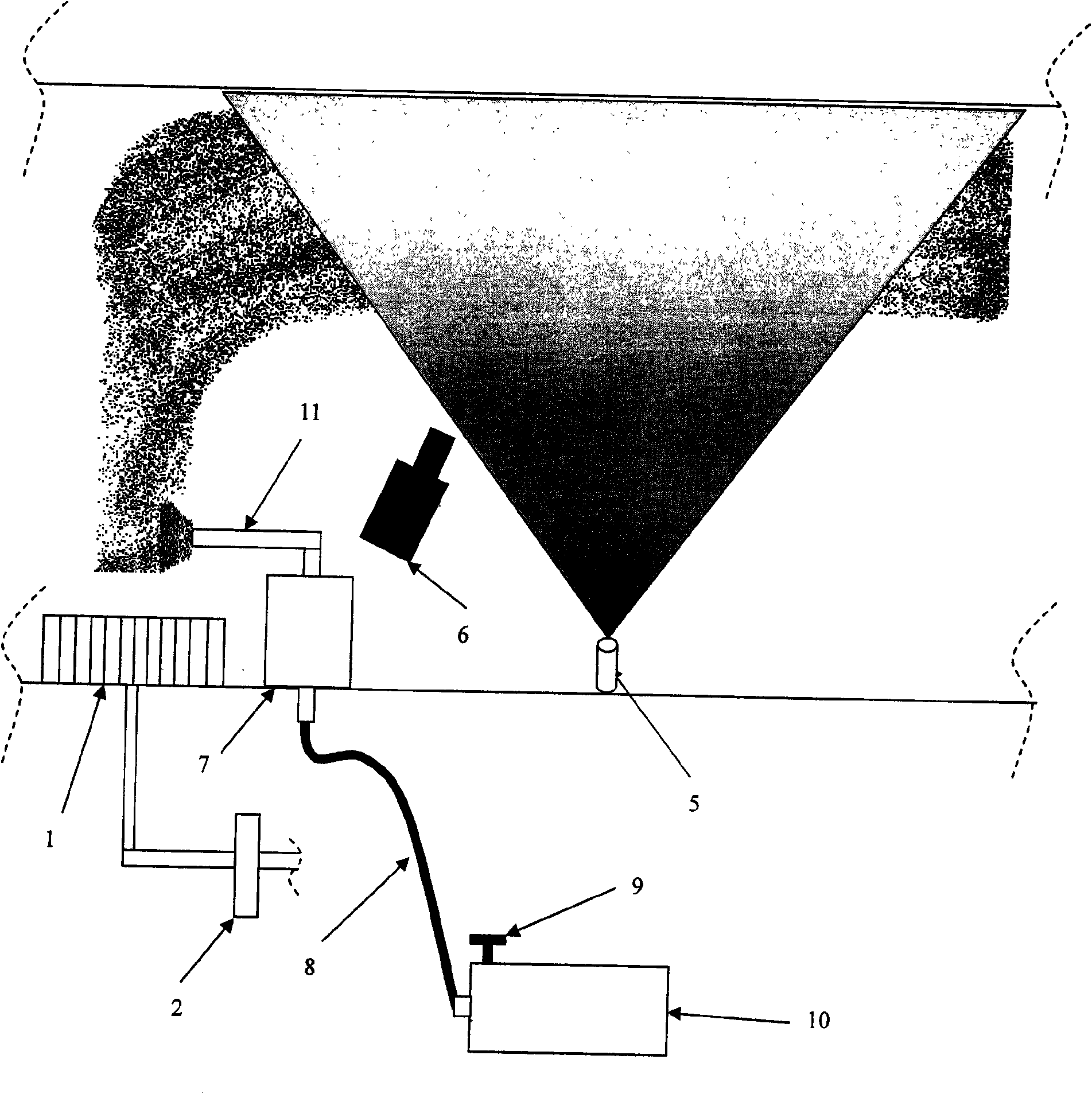

Fire smoke flow field tracer method

InactiveCN101639398ANo pollution in the processPower controllableHydrodynamic testingMaterial analysis by optical meansFire testFlue gas

The invention provides a fire smoke flow field tracer method which comprises a fire source analog system, a laser sheet optical system, an image pickup system, a smoke particle analog method and a tracer grain adding method; wherein the fire source analog system adopts a propane gas burner with controllable gas flow rate; smoke particles generated by burning sandalwood are adopted to simulate firesmoke particles; the grain diameter of the tracer grain is 1-5mu m of boron nitride grain; the boron nitride grains are evenly and stably transmitted into a flue gas layer by an air compressor; the method can be widely applied to small-scale and full-scale tests of fire, so as to lead the process of fire test to be safe, controllable and environment-friendly; by adopting the method, the key parameters such as the thickness, the form, the flow field structure and the like of the fire flue gas layer can be obtained, thus having important significance for guiding fire smoke control.

Owner:UNIV OF SCI & TECH OF CHINA

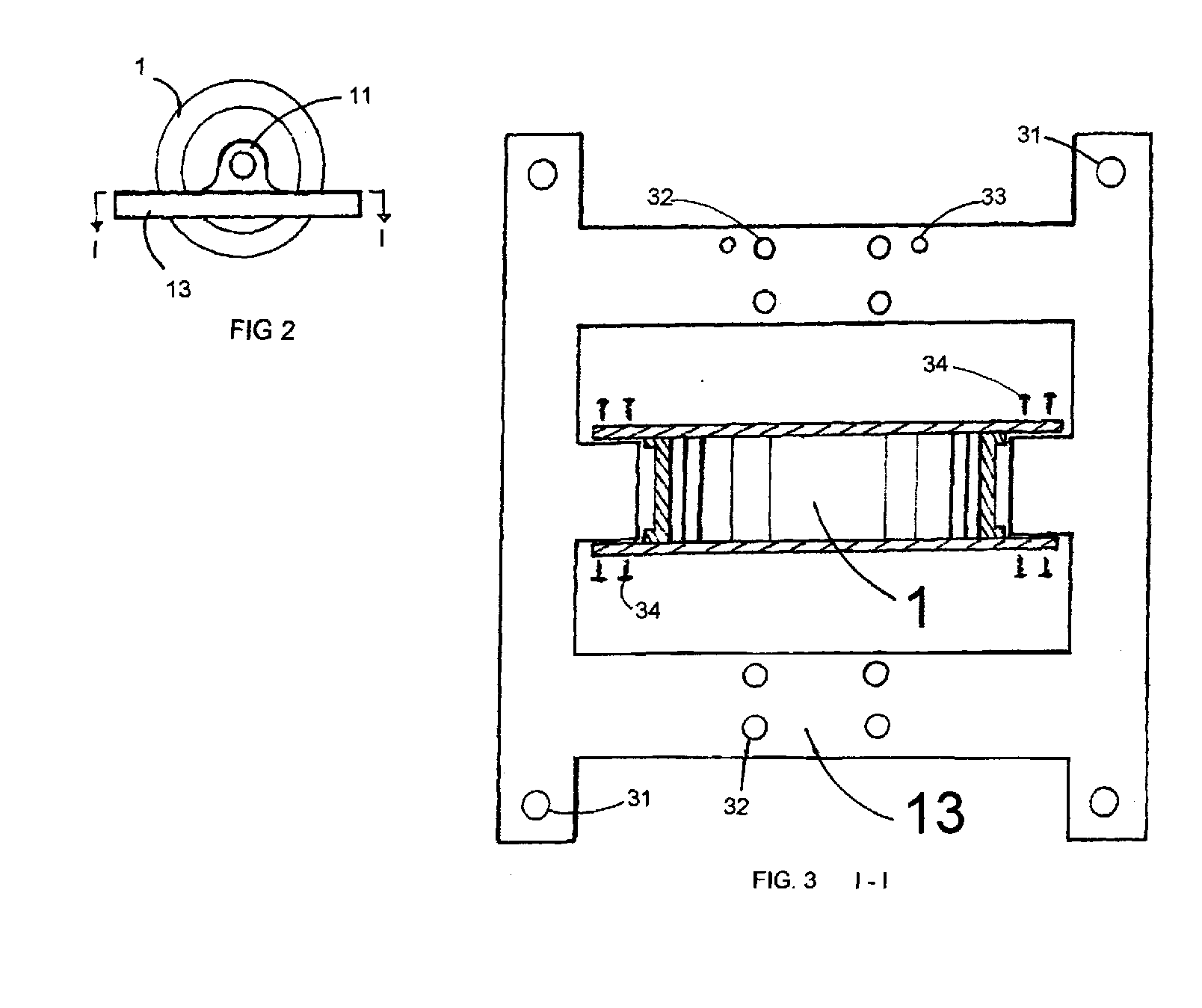

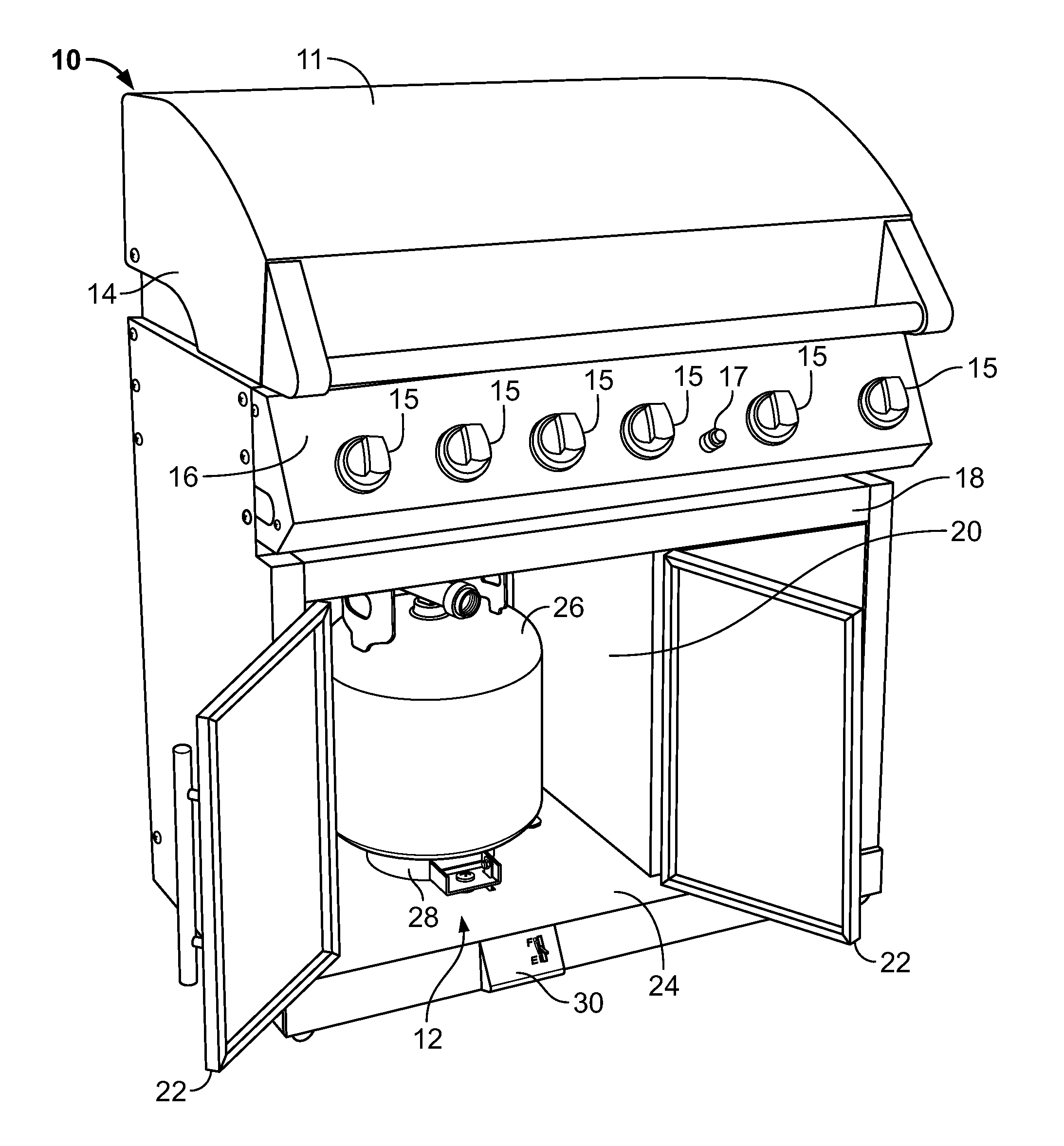

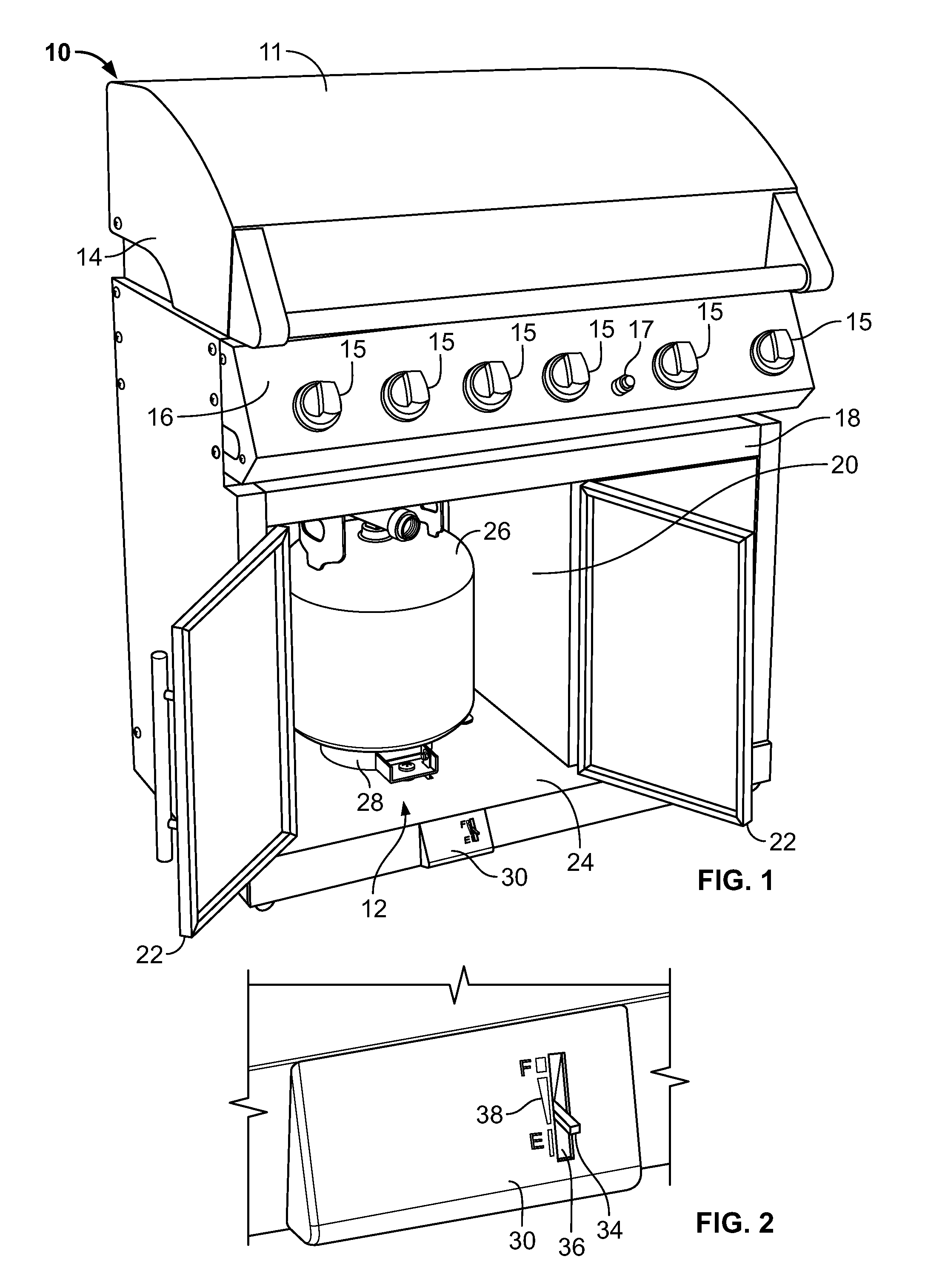

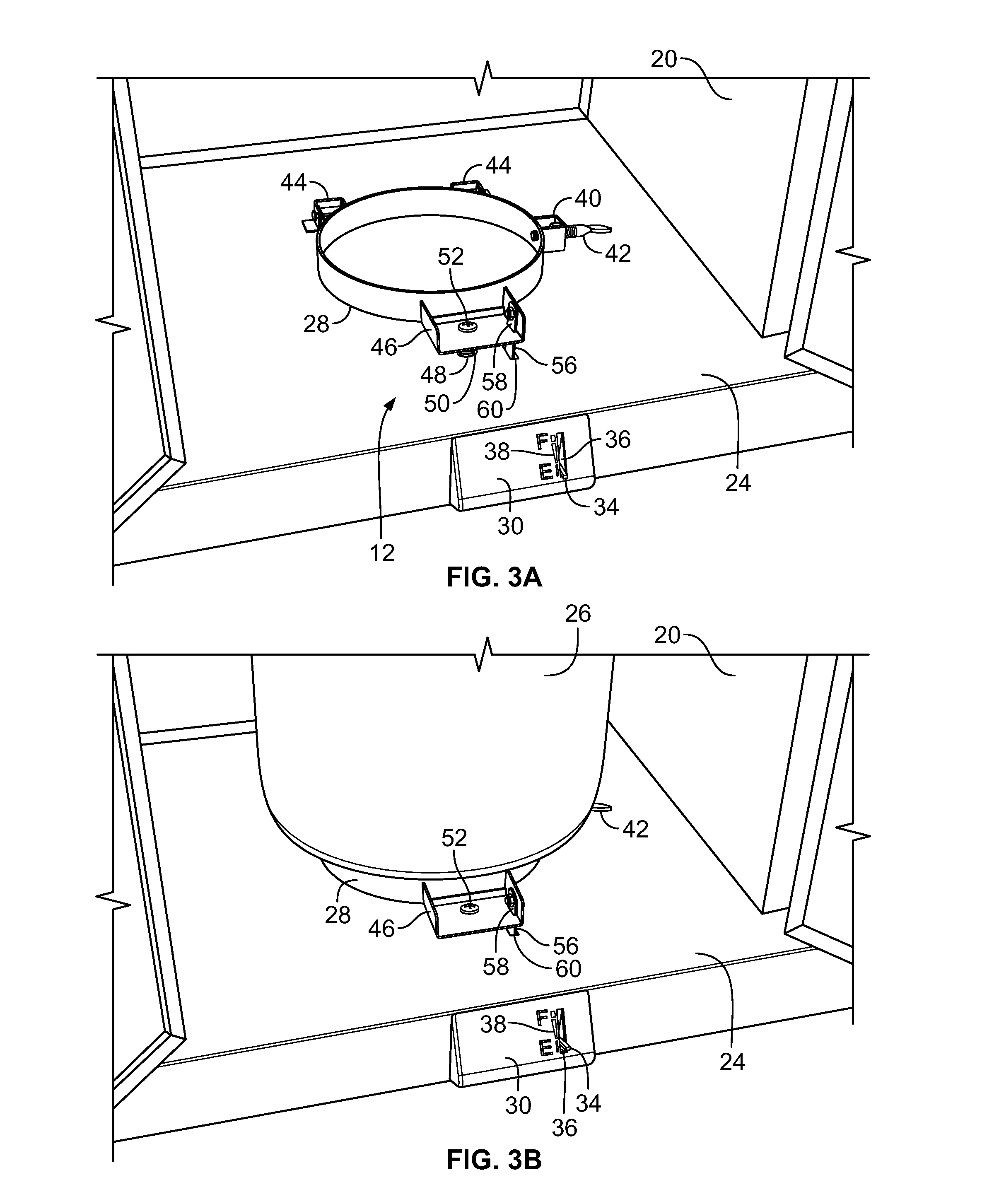

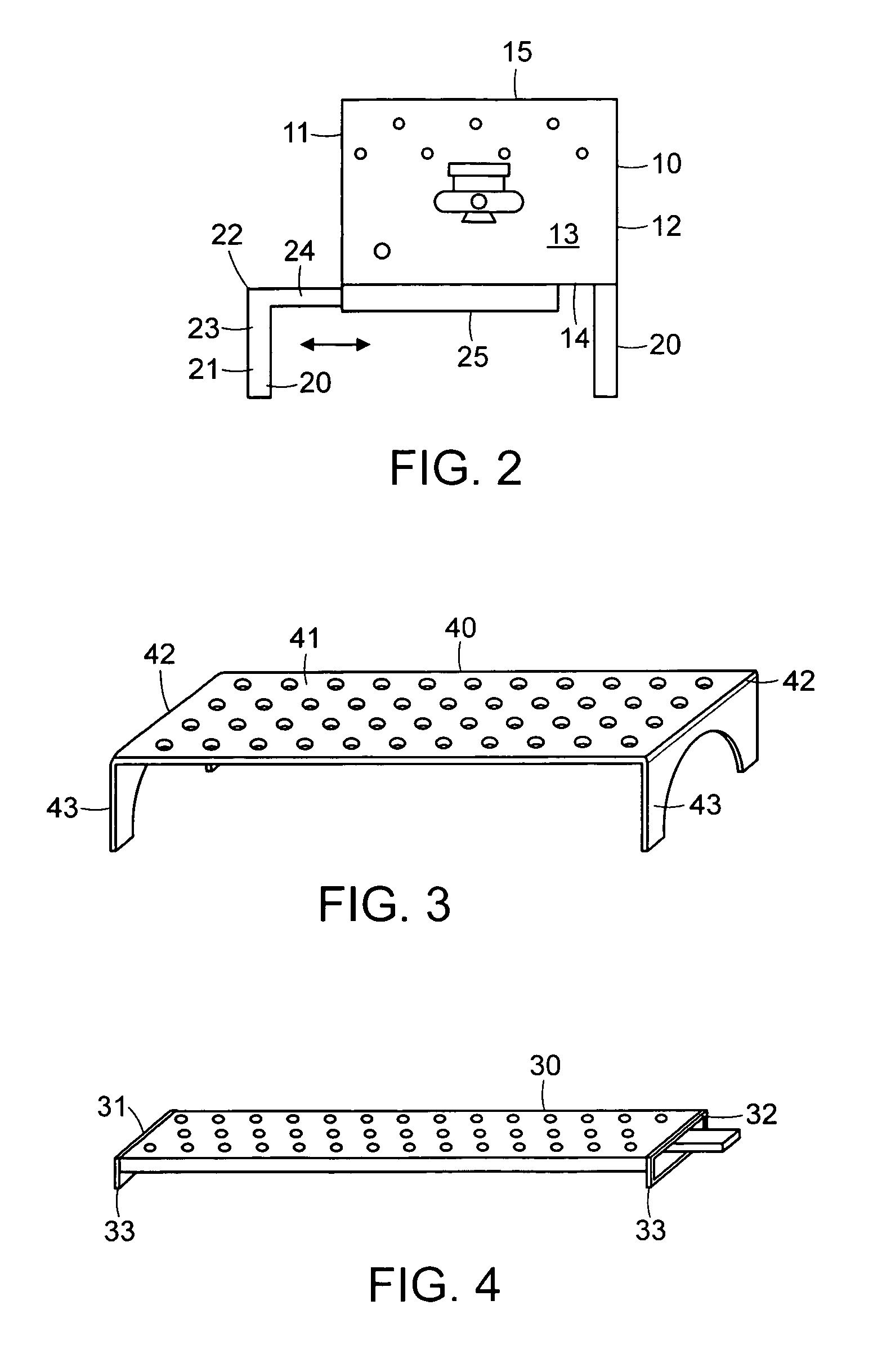

Propane tank fuel gauge for barbecue grill

InactiveUS20140090635A1Less fuelReduce pushDomestic stoves or rangesLighting and heating apparatusEngineeringPropane gas

A propane tank fuel gauge for use with a barbecue grill that measures the weight of the tank and thereby provides a readily perceived indication of the amount of propane gas remaining therein. The fuel gauge comprises a base, a tank mount adapted for mounting a propane tank, a spring-loaded support mechanism for supporting the tank mount relative to the base, and a fuel level indicator connected to the support mechanism for providing an indication of the total weight of the tank including the propane gas remaining therein.

Owner:LIGHTSTAR CORP

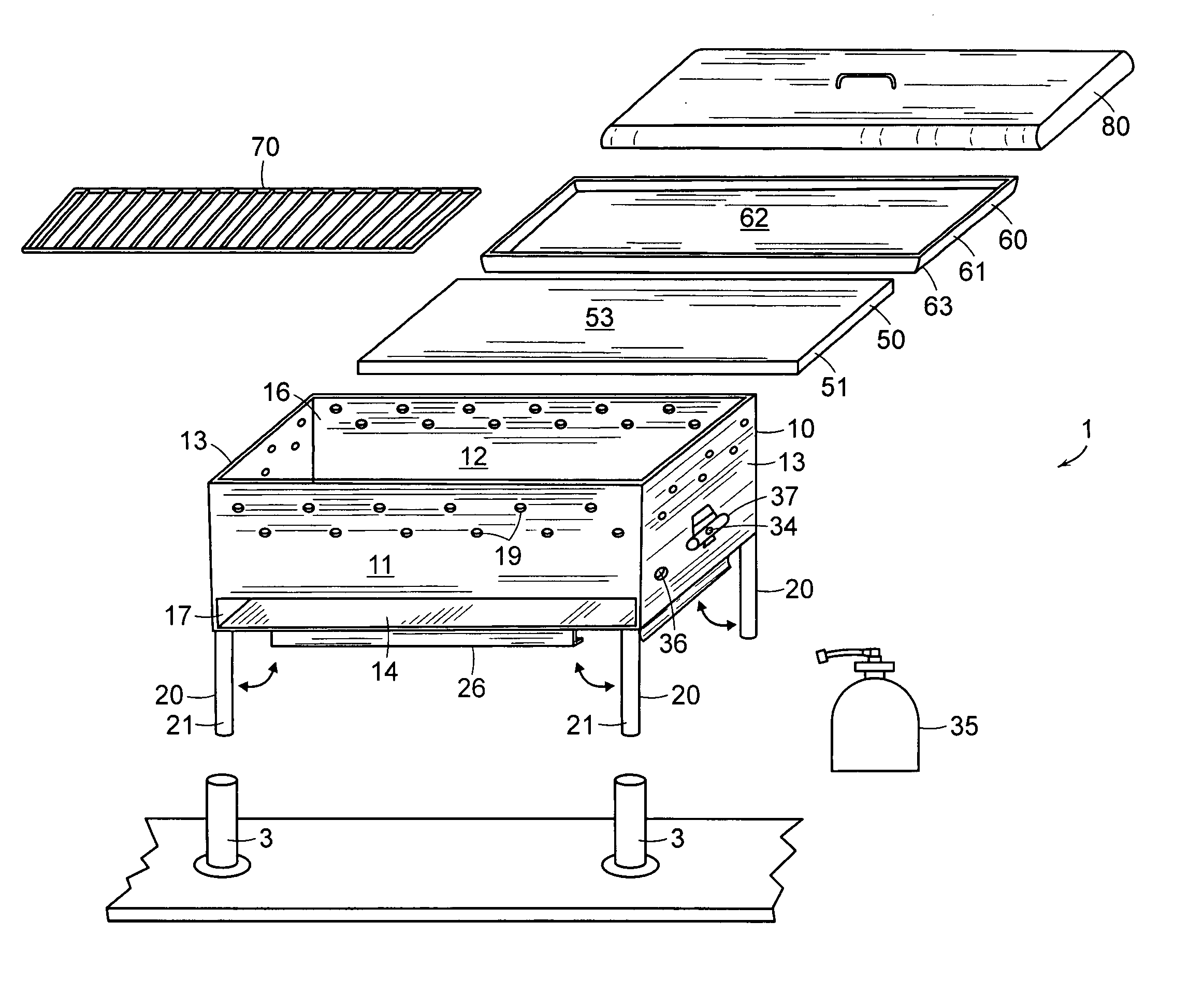

Convertible portable cooker

A portable outdoor cooker particularly adapted for boats and convertible for grill, griddle, steam and roast cooking. A cooker unit having an open top and a propane gas log interiorly positioned and attached to a propane supply is provided. Various racks and pans and covers are mounted on the cooker providing the ability to grill, griddle, steam or roast. The cooker has removable or retractable legs for mounting on boat rails.

Owner:UMBRIANNA PETER JR MR

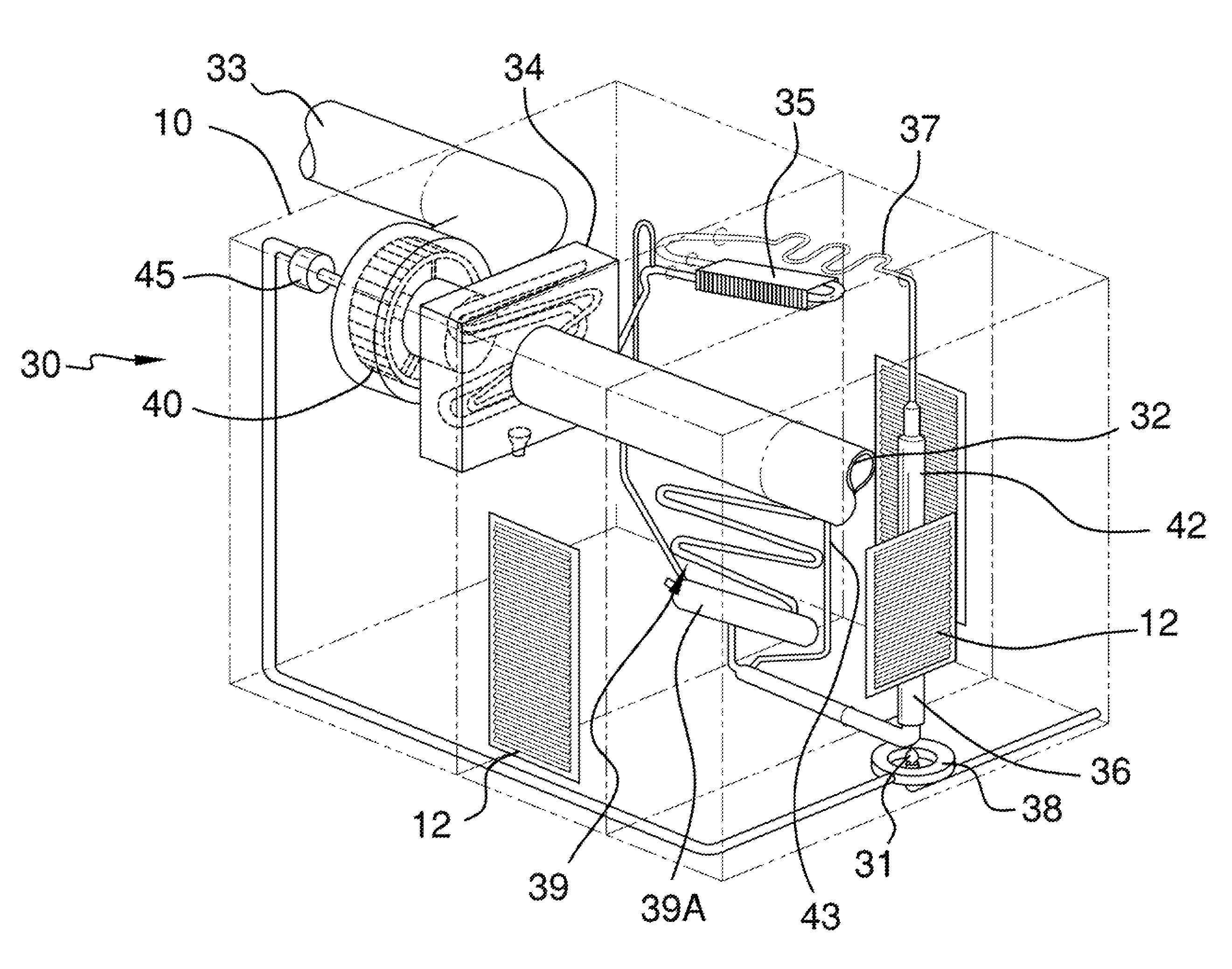

Portable powered air conditioner

InactiveUS7814764B1Climate change adaptationEnergy efficient heating/coolingElectricityElectrical battery

The present invention relates to an outdoor portable cooling system for patios, campsites, and other related areas. The invention is primarily to be used as a portable cooling system, but may be adapted as a permanently affixed cooling system. The invention includes a housing that contains an absorption system that would be powered by a propane burner. Heat generated by the burning propane gas can be used to operate the fan motor via a module that produces electricity from heat or whereby the motor is powered by a battery supply. The battery supply may be recharged by a solar panel or by a standard electrical line.

Owner:HEATER TIM +5

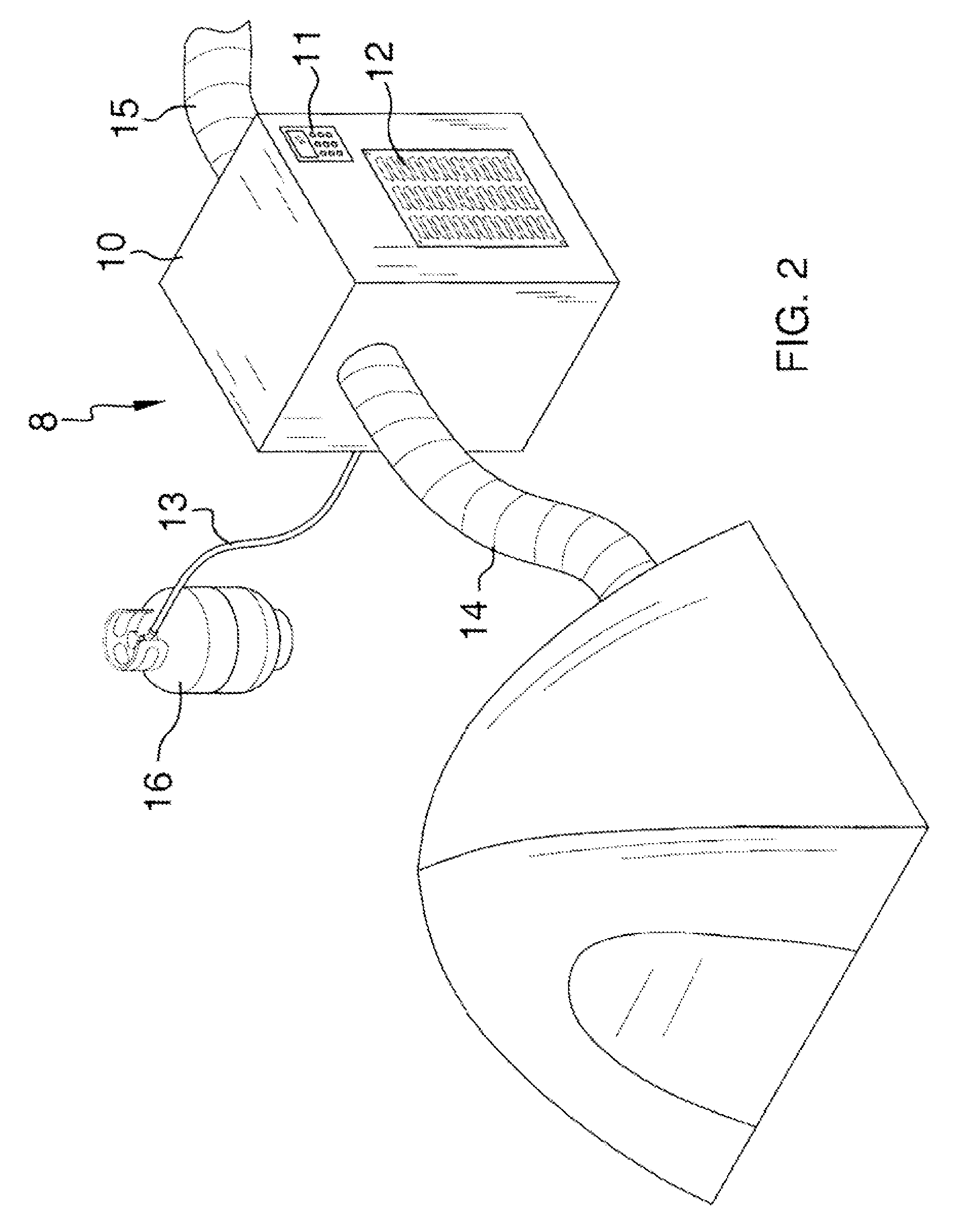

All around radiation heating apparatus

InactiveUS9328927B2Improve installation securityPortable HandlingDomestic stoves or rangesLiquid heating fuelLiquid propaneEngineering

Owner:CHANGZHOU GARDENSUN FURNACE

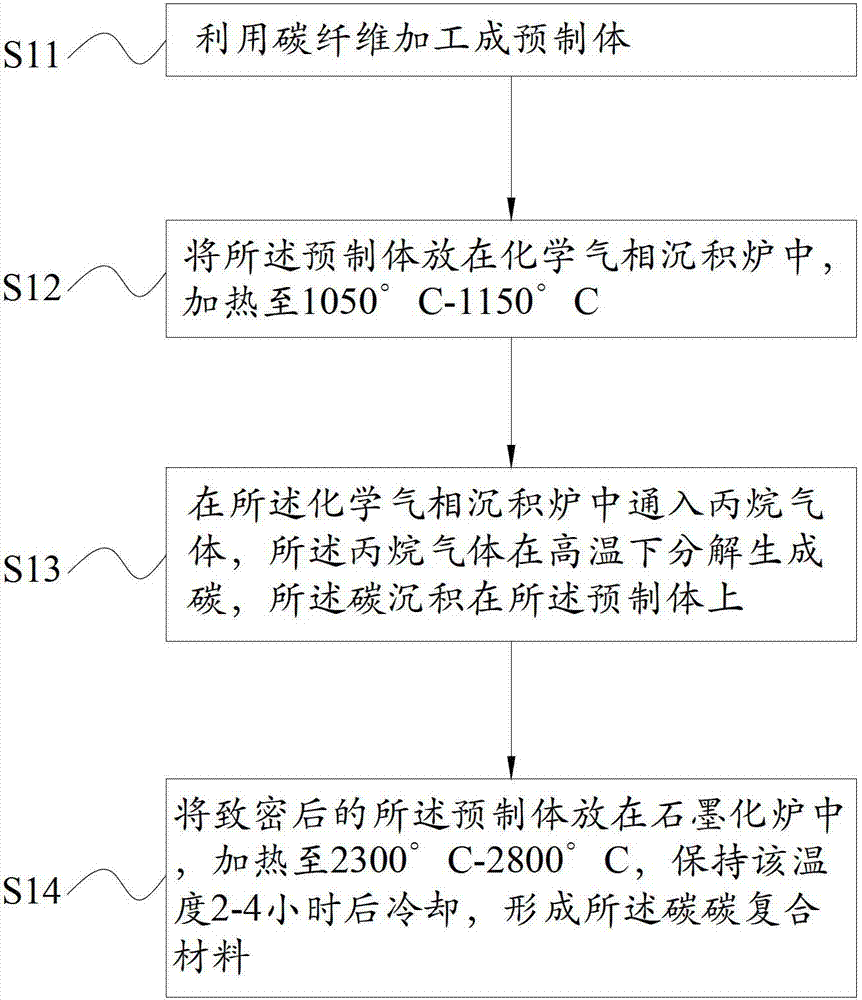

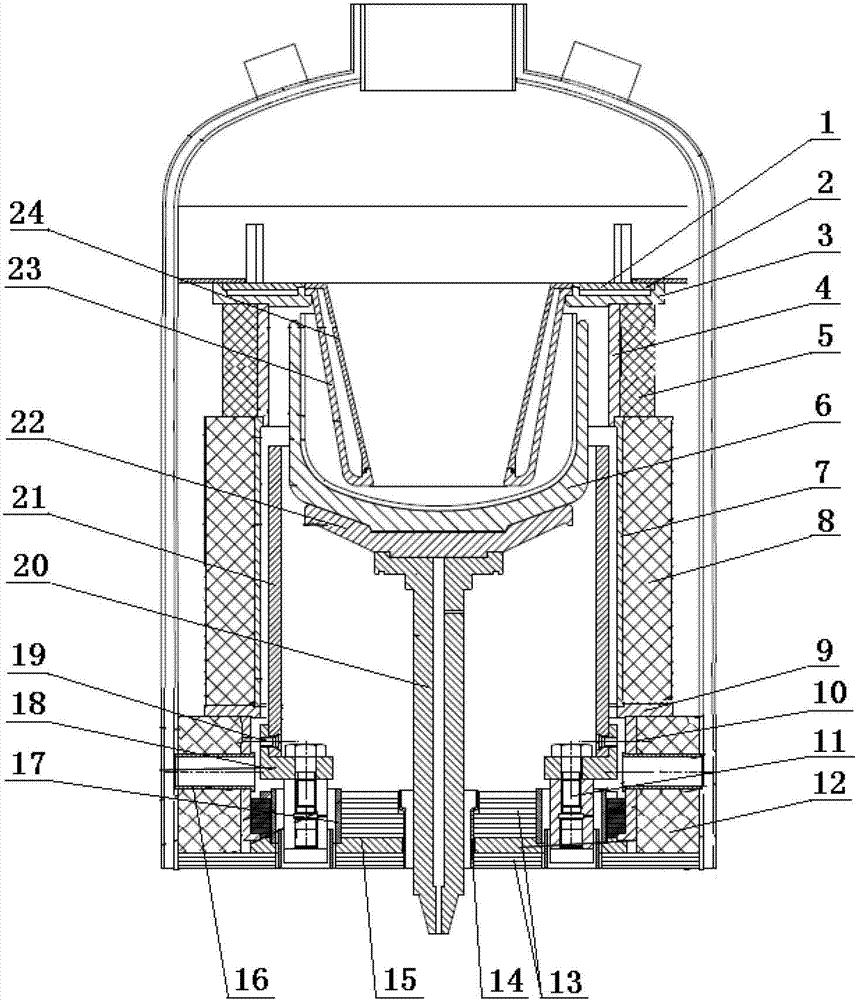

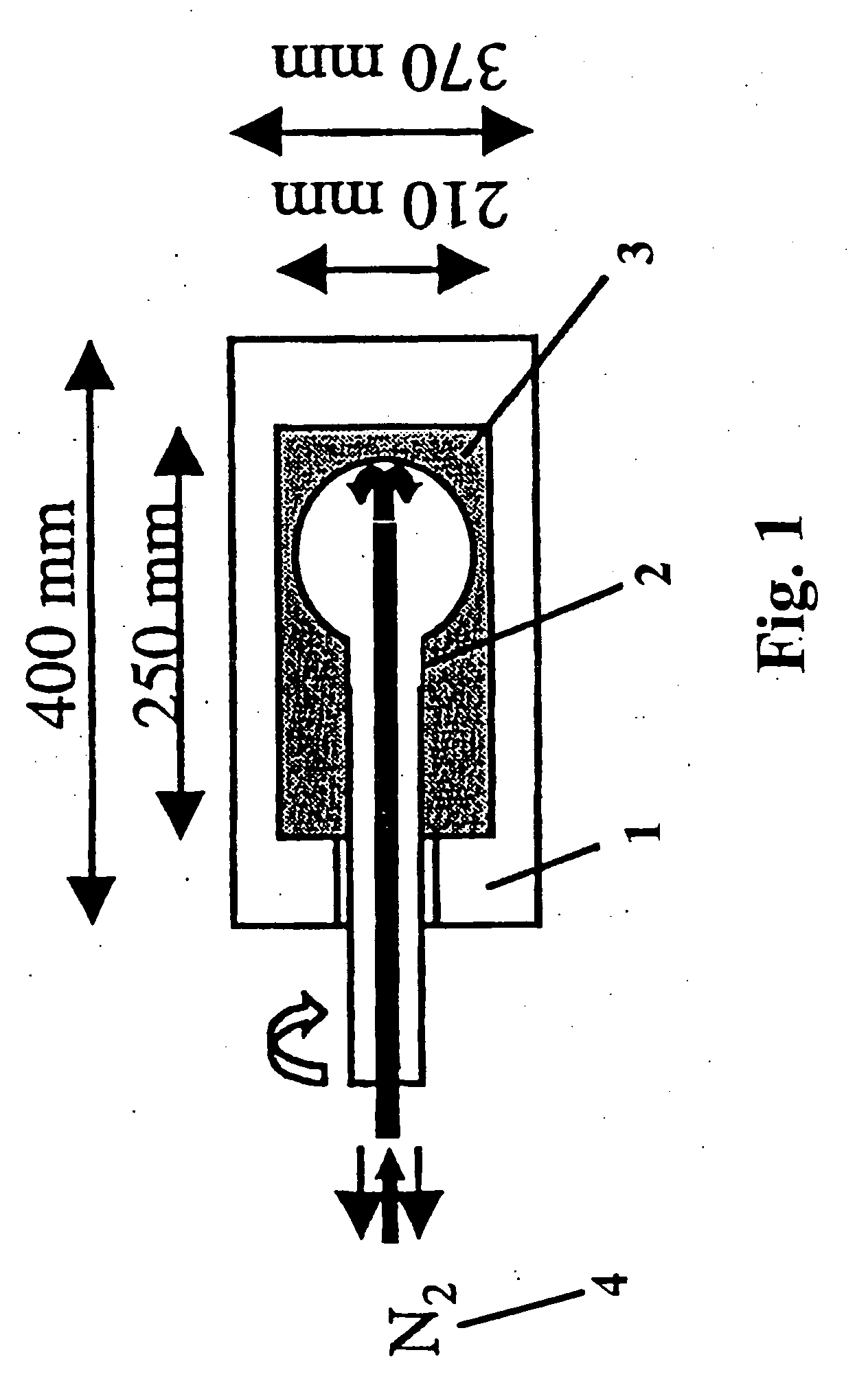

Straight pulling single crystal furnace and processing method of carbon-carbon composite material for straight pulling single crystal furnace

InactiveCN102731134ASimple processing methodContains less impuritiesBy pulling from meltFiberCarbon composites

The invention discloses a processing method of carbon-carbon composite material for a straight pulling single crystal furnace. The method comprises the steps of processing carbon fiber into a prefabricated body, then heating the prefabricated body in a chemical deposition furnace to 1050-1150 DEG C, and introducing propane gas, wherein the propane gas is decomposed at high temperature to generate carbon and the carbon is deposited in the prefabricated body; placing the compacted prefabricated body in a graphitization furnace; heating to 2300-2800 DEG C, and maintaining the temperature for 2-4 hours and cooling to form the carbon-carbon composite material. The invention further discloses the straight pulling single crystal furnace which comprises a heater processed by the carbon-carbon composite material. Density of the heater is greater than or equal to 1.8g / cm<3>. The processing method of the carbon-carbon composite material provided by the invention replaces a method of repeated impregnation by carrying out compacting treatment to the prefabricated body by using the chemical vapor deposition furnace, so that not only is the process simple, but also more impurities do not be doped in the compacting treatment process, and high temperature purification is not needed, thereby greatly simplifying the processing method.

Owner:BEIJING JINGYI CENTURY ELECTRONICS

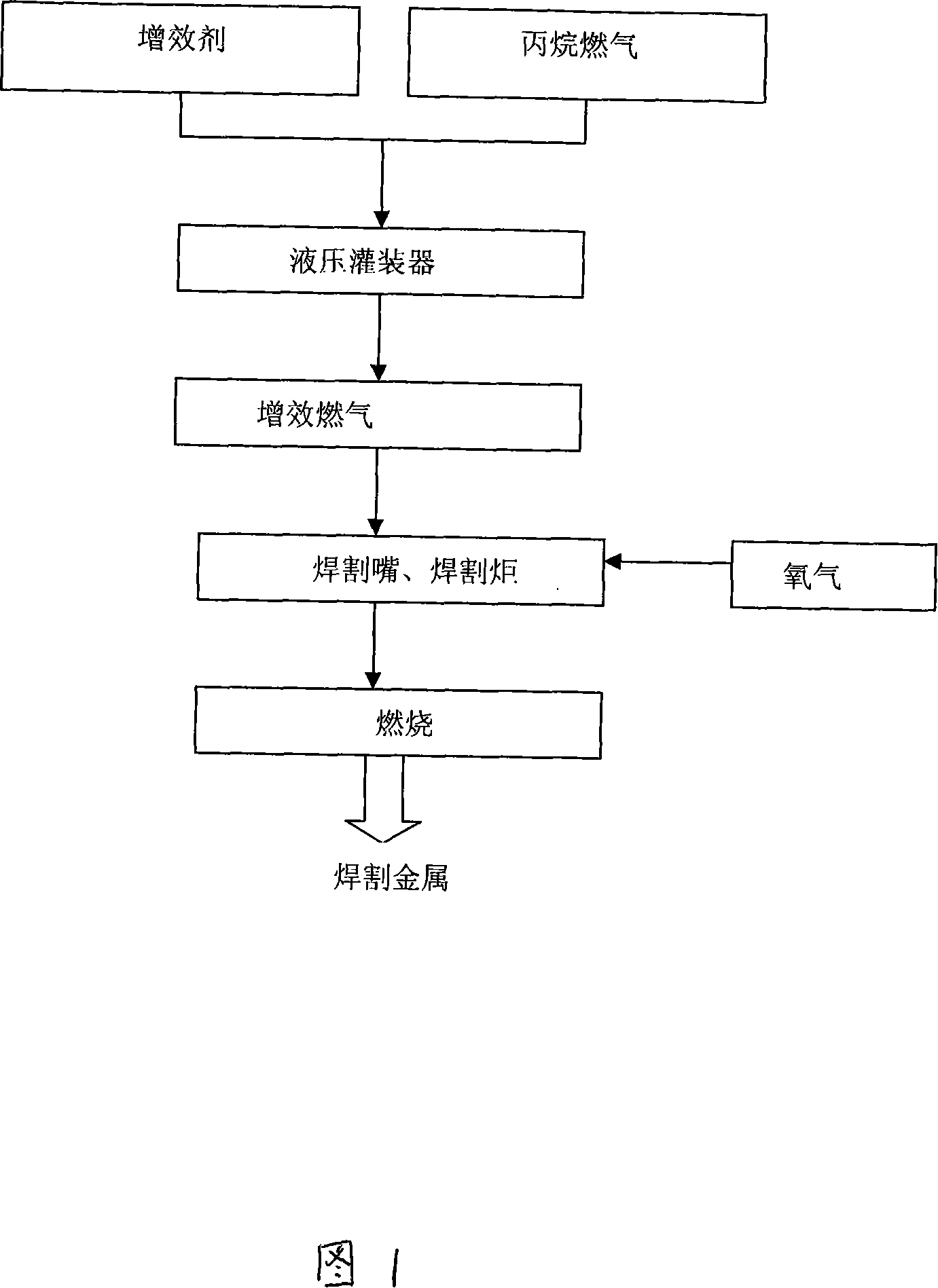

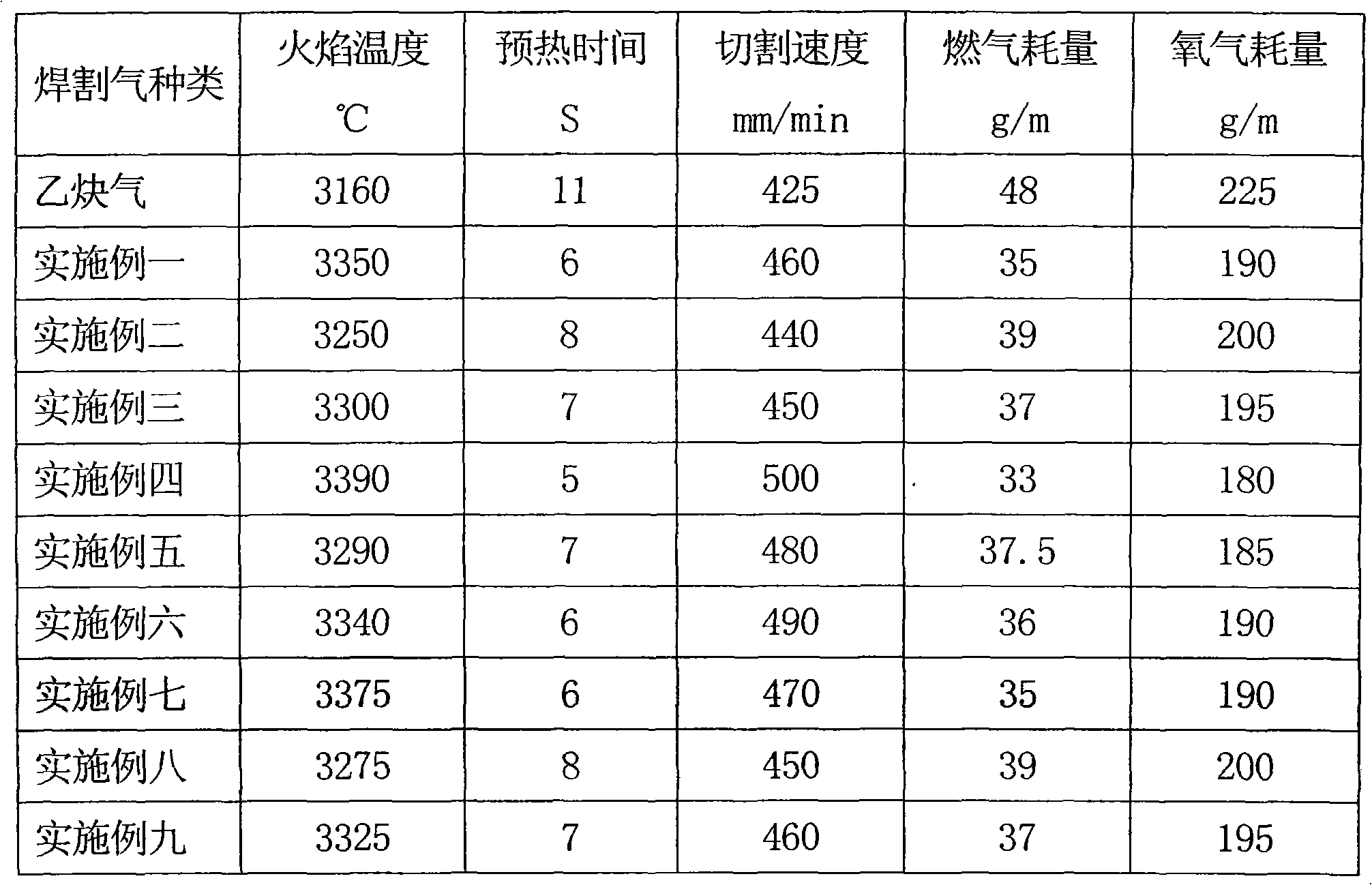

Environment-protection energy-saving gas for welding and cutting

InactiveCN101139535ARaise the combustion temperatureBurn fasterGaseous fuelsForeign matterEngineering

The invention relates to a fuel gas for welding cut that is environmental friendly and energy saving, in particular to a fuel gas that can substitute acetylene gas. The fuel gas comprises a propane gas, which is characterized in that synergist is added in certain proportion in the propane gas; the content of the propane gas is 97-99%; the content of the synergist is 5 per mill-1%, the content of the liquefiable foreign matter of gas is less than 2.5% by weight; the synergist is a mixed solution comprising combustion catalyst, smoke-removing agent, polymer degrading agent, solvent, solution assistant, and combustion assistant, etc.; the fuel gas is used as combustion gas in place of acetylene gas to weld and cut metals. The flame of the fuel gas is of high temperature, is free from reverse (return) combustion; the fuel gas is of very low explosion limit and low toxicity, free from harm to human bodies, of low comprehensive cost, high efficiency, is safe, environmental friendly and energy saving.

Owner:周尧

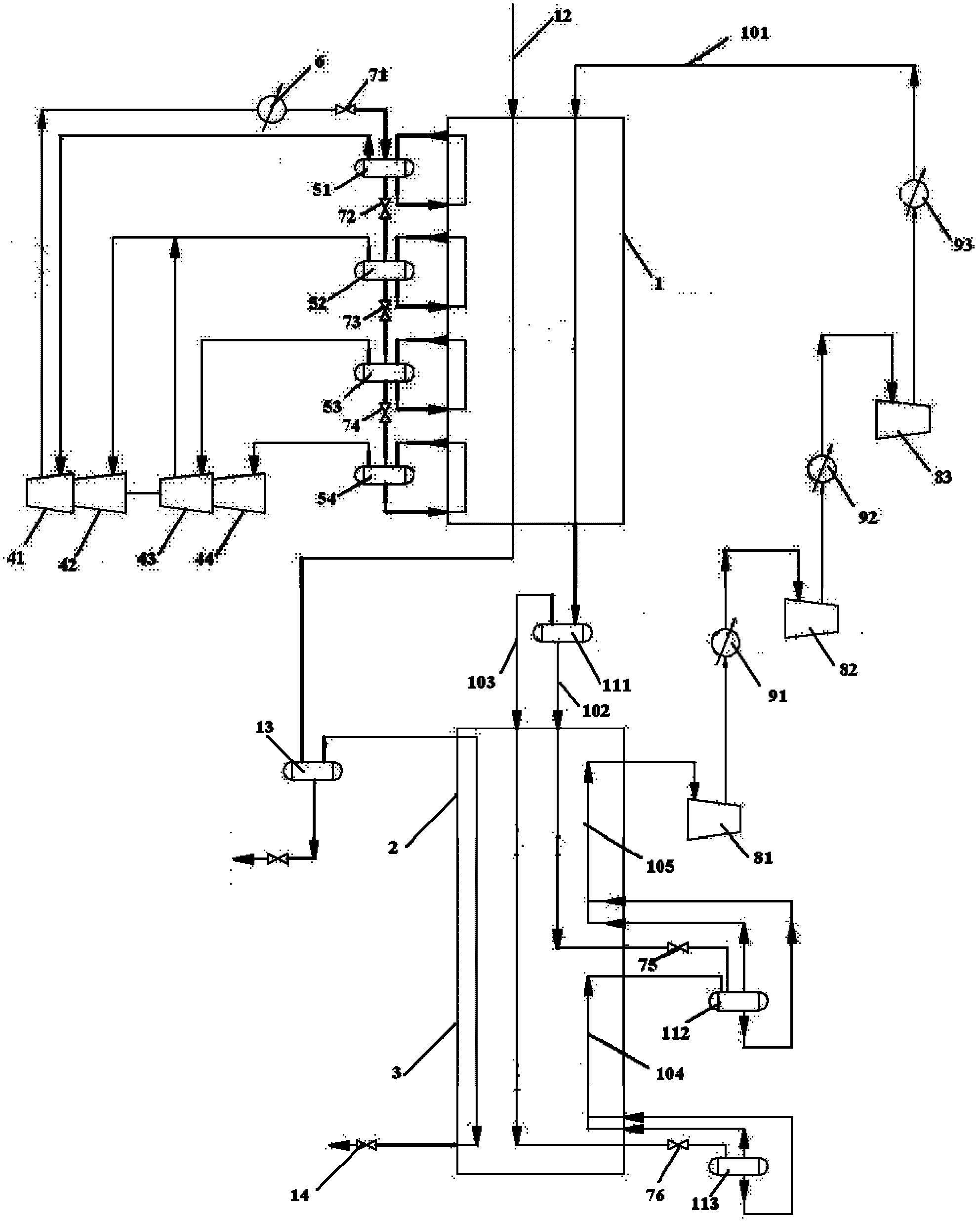

Propane pre-cooling mixed refrigerant liquefaction system applied to base-load type natural gas liquefaction factory

The invention discloses a propane pre-cooling mixed refrigerant liquefaction system applied to a base-load type natural gas liquefaction factory. The system comprises a pre-cooling cold box, a liquefaction cold box, a copious cooling cold box, a propane pre-cooling circulation mechanism and a mixed refrigerant liquefaction copious cooling circulation mechanism. Due to the adoption of the propane pre-cooling mixed refrigerant liquefaction system, natural gas which is qualified after pretreatment can be introduced into the mixed refrigerant liquefaction copious cooling circulation mechanism to be further cooled by a mixed refrigerant after being precooled by the propane pre-cooling circulation mechanism and is finally introduced into a liquefied natural gas (LNG) storage tank through throttling; the propane pre-cooling circulation mechanism and a flow channel of the pre-cooling cold box are subjected to heat transfer through liquid propane in a propane gas-liquid separation tank by a thermal siphon principle, and propane which is subjected to heat transfer and is gasified in the pre-cooling cold box is returned to a corresponding inlet of a propane compressor for gradual compression until a final-stage outlet is reached so as to finish a circulation process; and when used for liquefying natural gas, the system provided by the invention is convenient to operate, is safe and reliable and has high efficiency and high adaptability, equipment investment is reduced, flow control automation is improved, and driving time is shortened.

Owner:CHINA NAT OFFSHORE OIL CORP +1

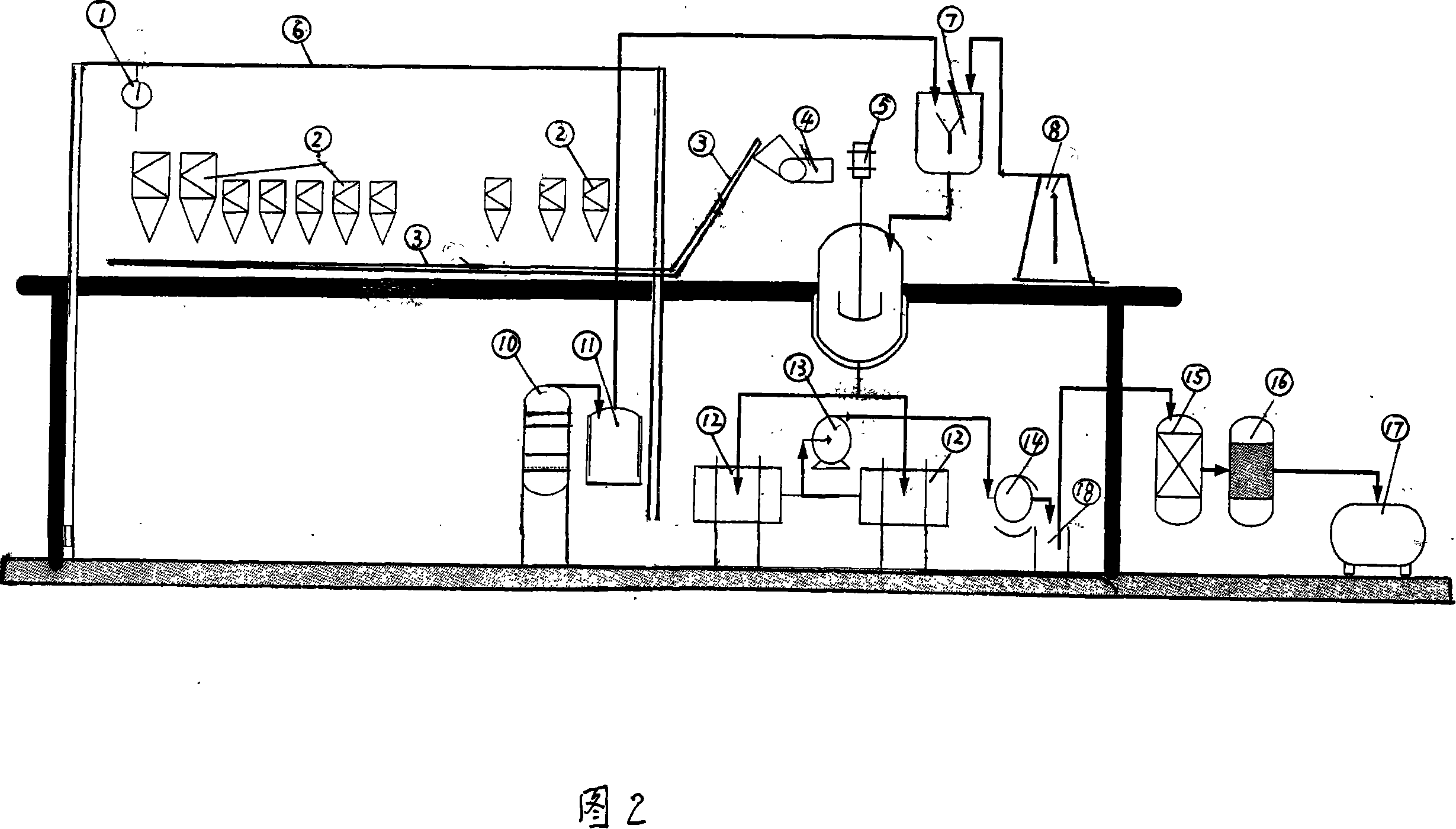

Process for preparing liquefied propane gas and gasoline with high octane value from plant fibres

InactiveCN1360007AHigh calorific valueLow costLiquid hydrocarbon mixture productionCracking reactionMixed gas

A process for preparing liquefied propane gas and gasoline with high octane value includes vacuum dry distilling-cracking reaction of plant fibres (corn stalk, rice straw, reed, etc) to generate the gas mixture of CO and propane, pressure-swing adsorption to separate CO from said gas mixture, generating and purifying hydrogen gas, recovering CO2, preparing liquefied propane gas, synthesizing methanol from resultant CO, CO2 and H2, and preparing gasoline. Its advantages are high purity and low cost.

Owner:丛大拥

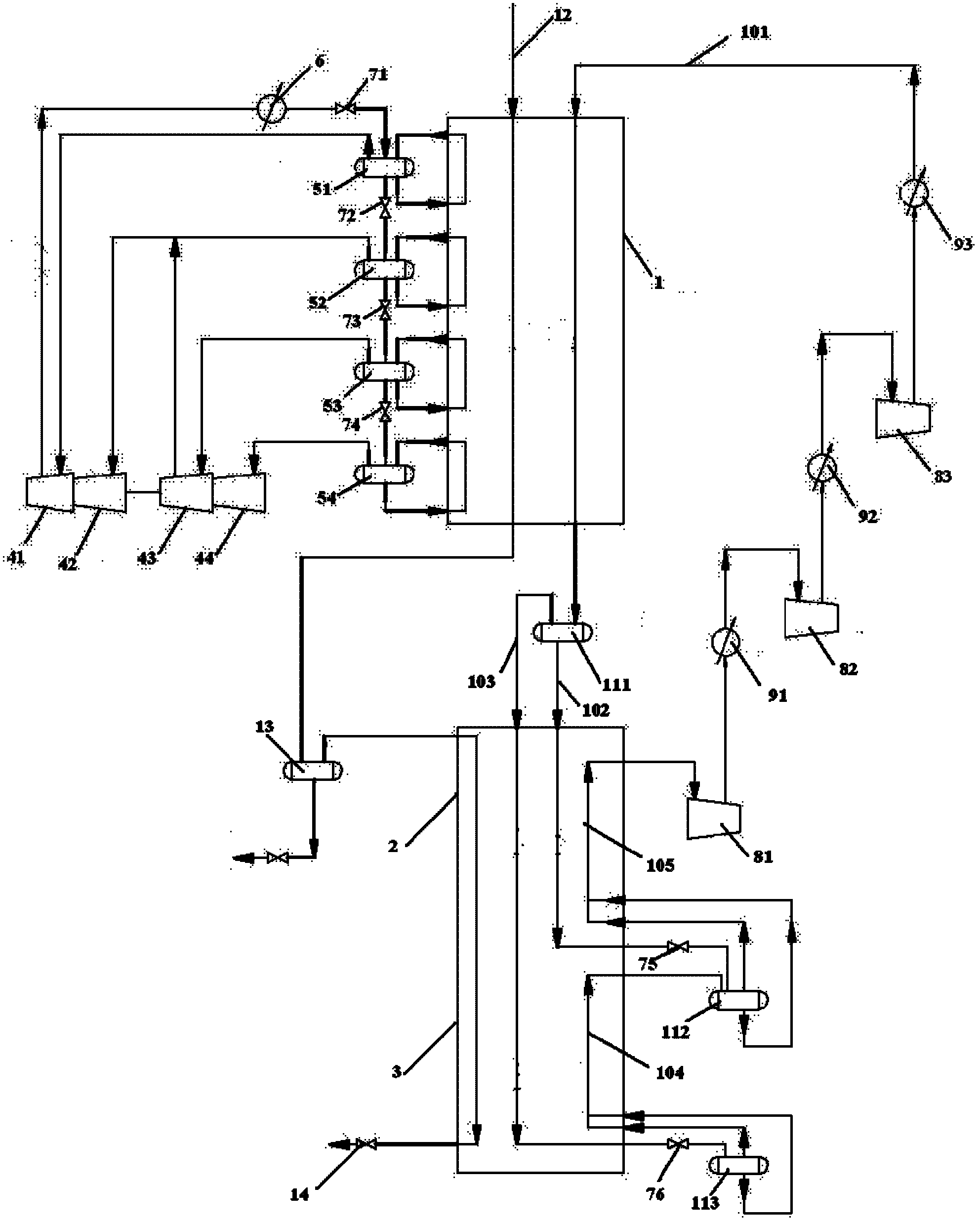

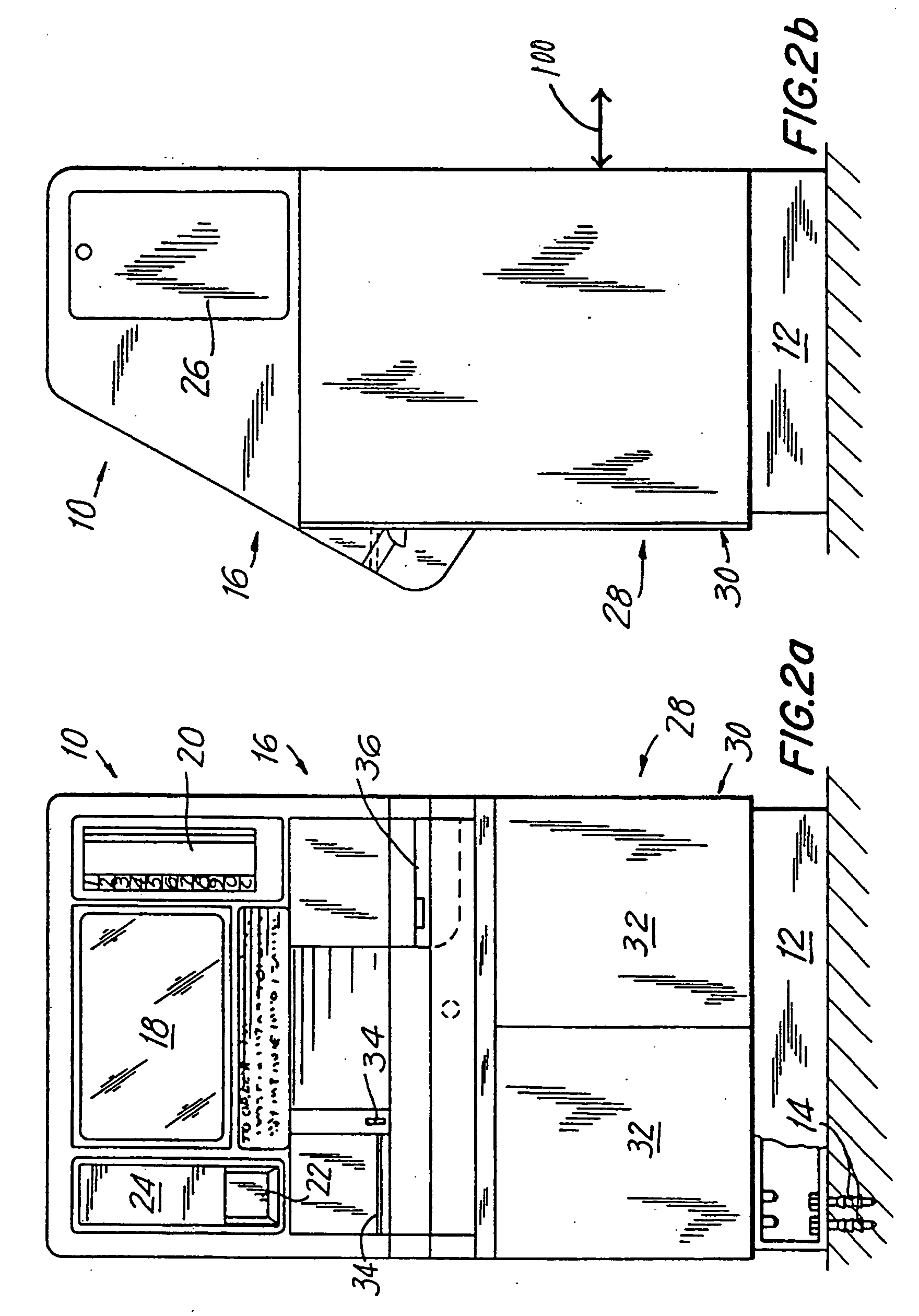

System for automatic check-in and check-out for space occupancy

An automated check-in and check-out for a user needing rental space. Specifically, there is an electronic device configured to: provide information regarding the rental space available for rental; provide the user with a way to select desired information; and provide for entry of data needed to use the rental space. Provide automated reservation check in / out management without interaction of business personnel. The device works for rental space that is selected from the group selected from: RV Park, hotel, motel, resort cabins, property storage units, camp sites, harbor boat slips, cruise ship cabins. Additionally, the electronic device gives a list of services provided to a user at the rental space. Wherein the list of services provided to a user at the rental space is selected from the group consisting of: laundry pick-up and delivery, propane gas delivery, grocery delivery, pharmaceutical delivery, pizza delivery, and a mobile mechanic repair service.

Owner:CHASE DOUGLAS G

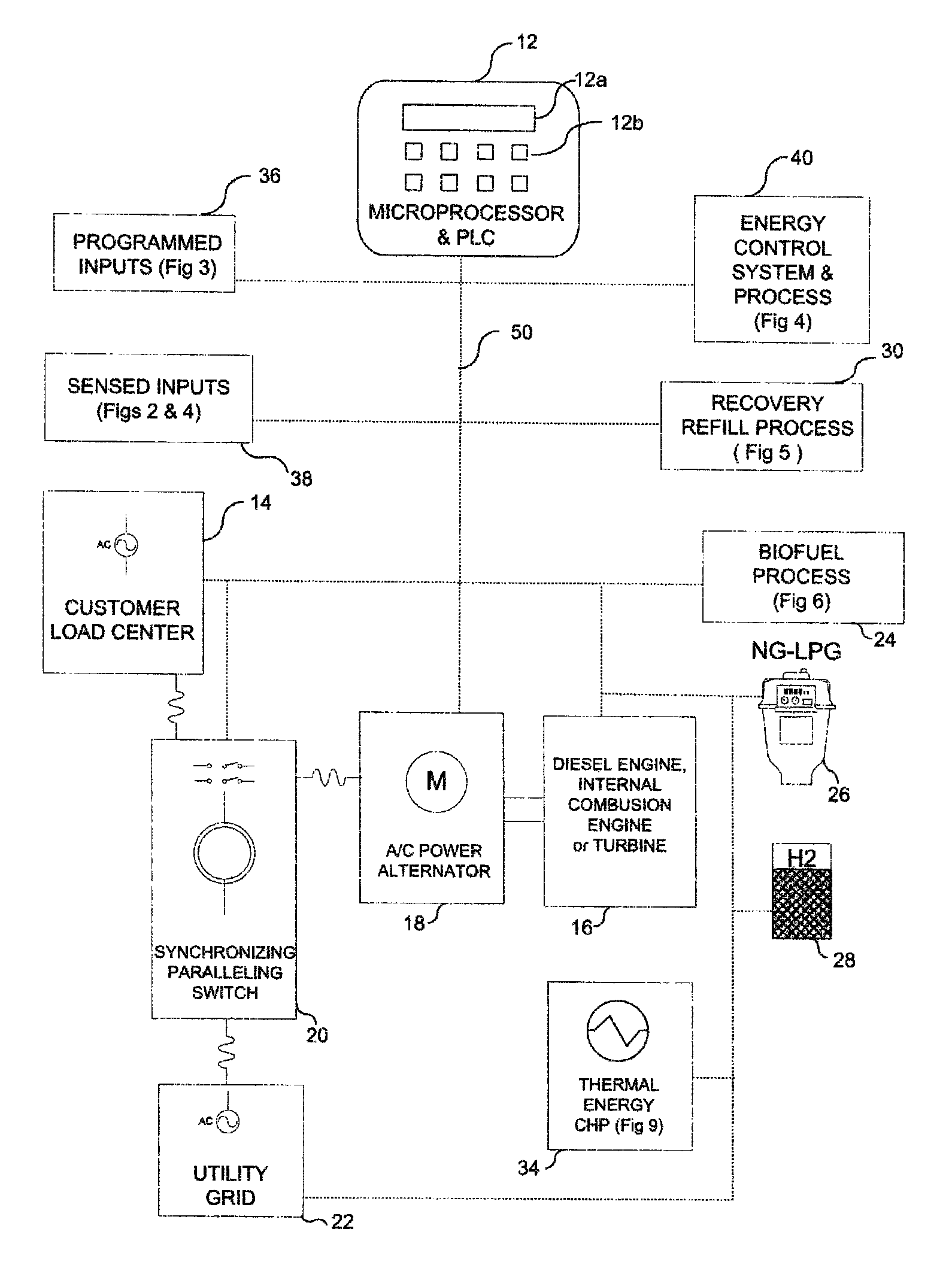

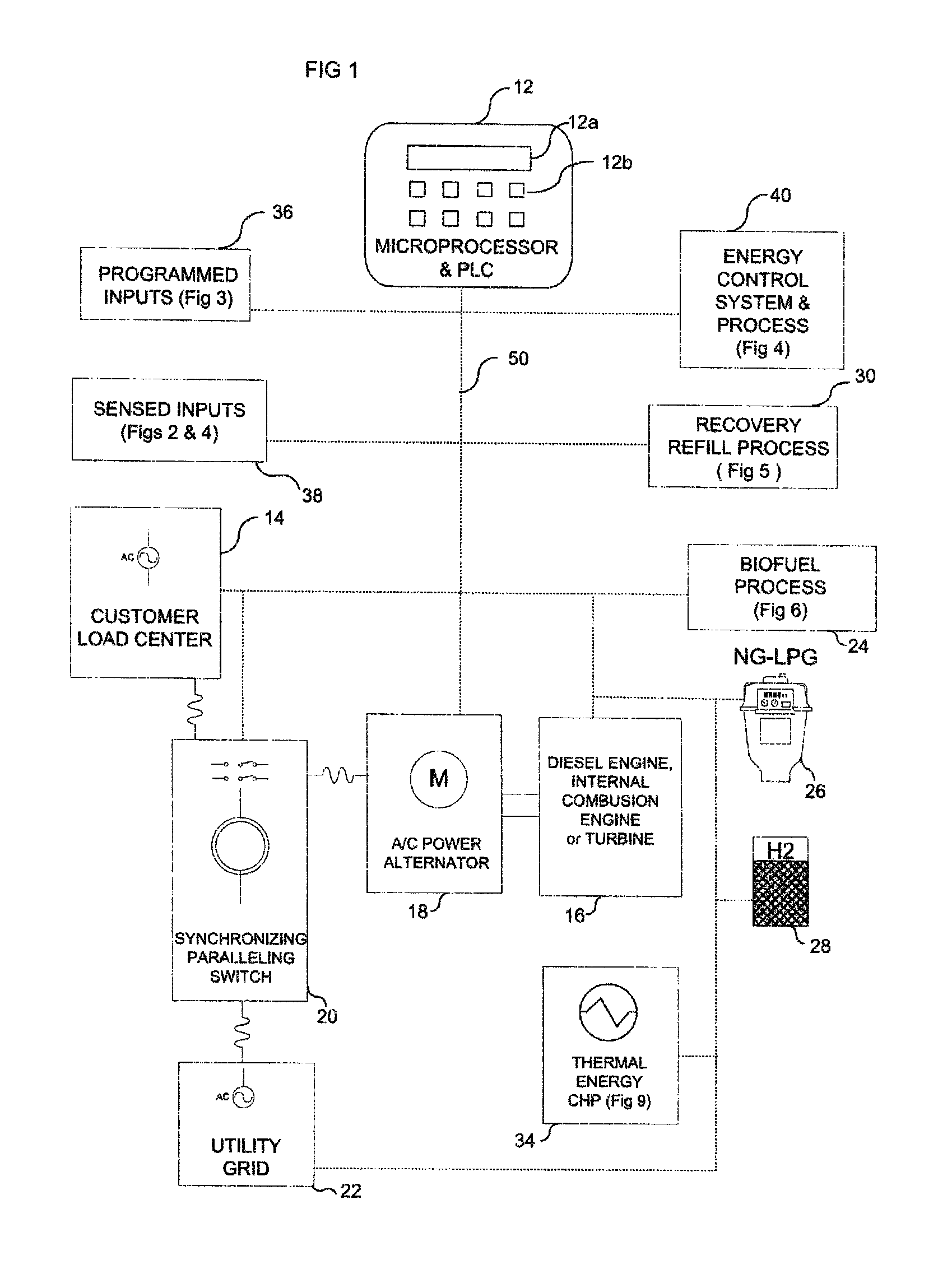

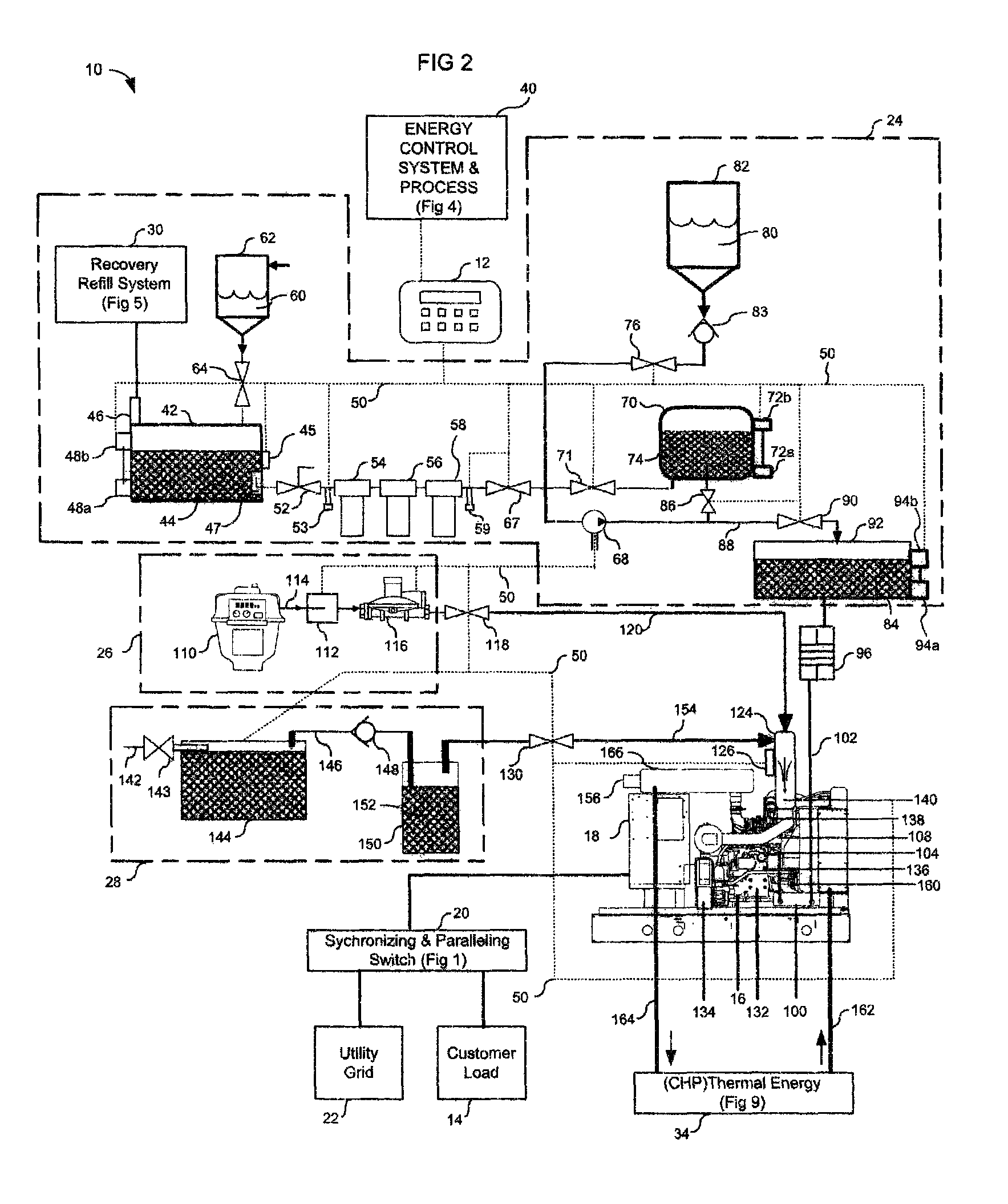

Microprocessor controlled automated mixing system, cogeneration system and adaptive/predictive control for use therewith

InactiveUS8583350B1Easy to useReduce dependenceLevel controlDigital data processing detailsOn boardCogeneration

A microprocessor controlled automated, multi-fuel apparatus to blend hydrogen, bio-fuel and / or natural or propane gases. This novel multi-stage apparatus first converts cooking oils into bio-fuel. The system automatically blends the bio-fuel with at least one of or both hydrogen gas, generated by a self-contained on-board hydrogen electrolyzer, and / or natural or propane gases. This blended “Hyenrich” gaseous fuel drives various processes including, but not limited to, cogeneration systems and electrical generators to produce “green” electricity by utilizing an adaptive and predictive learning algorithms to significantly reduce cost per kilowatt and lessen dependency on the over taxed utility grid, while simultaneously reducing emissions of CO, CO2 and NOx, making the method and apparatus an environmentally-friendly energy device.

Owner:HYCOGEN POWER

Complex heavy oil reservoir oil solubility foaming agent intensified mixed gas huff-puff experimental equipment and application method thereof

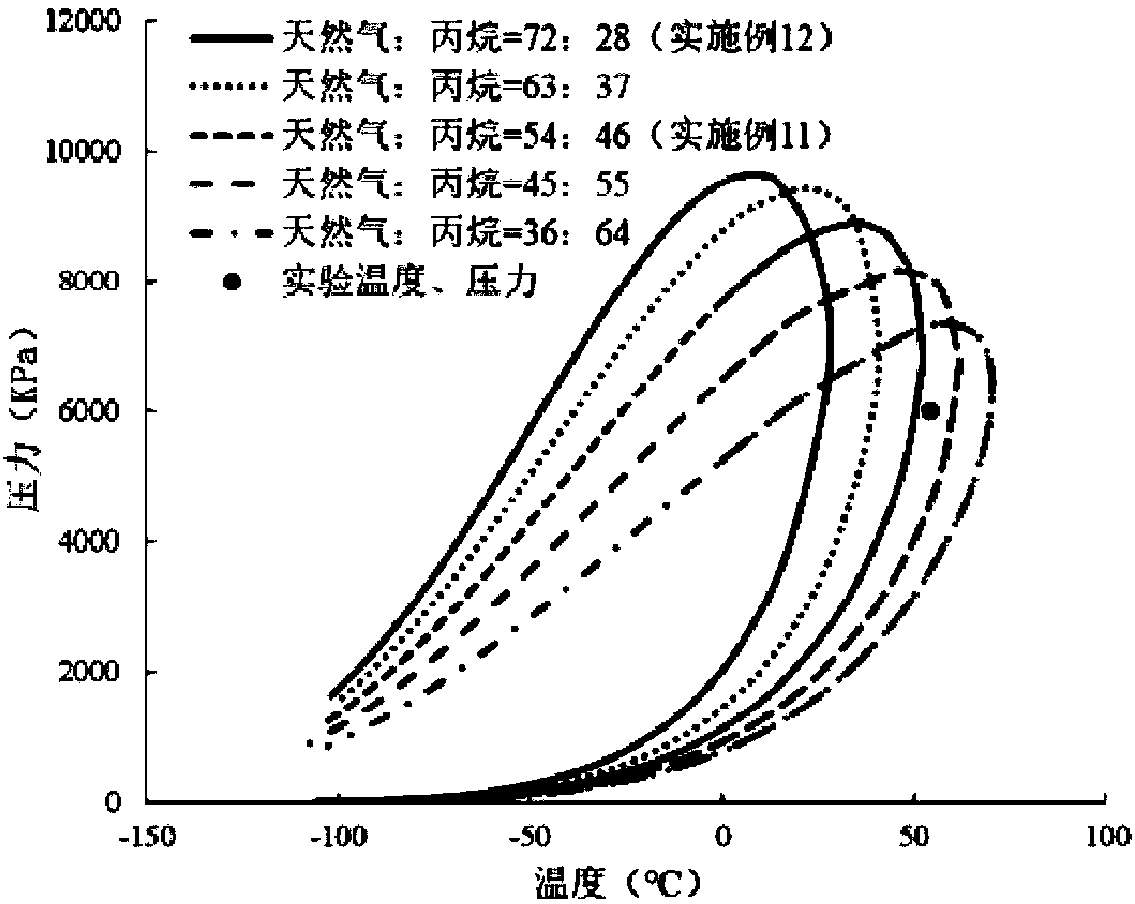

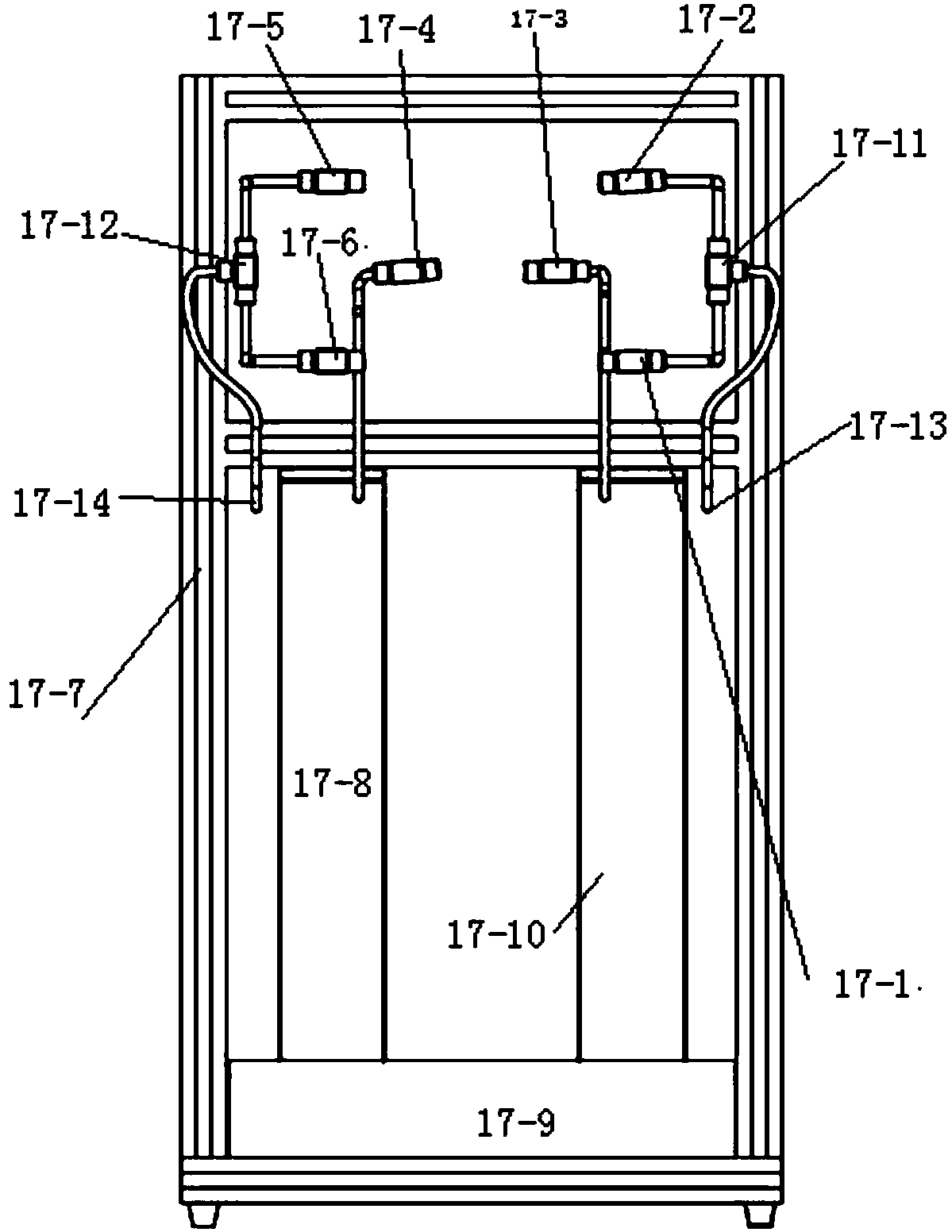

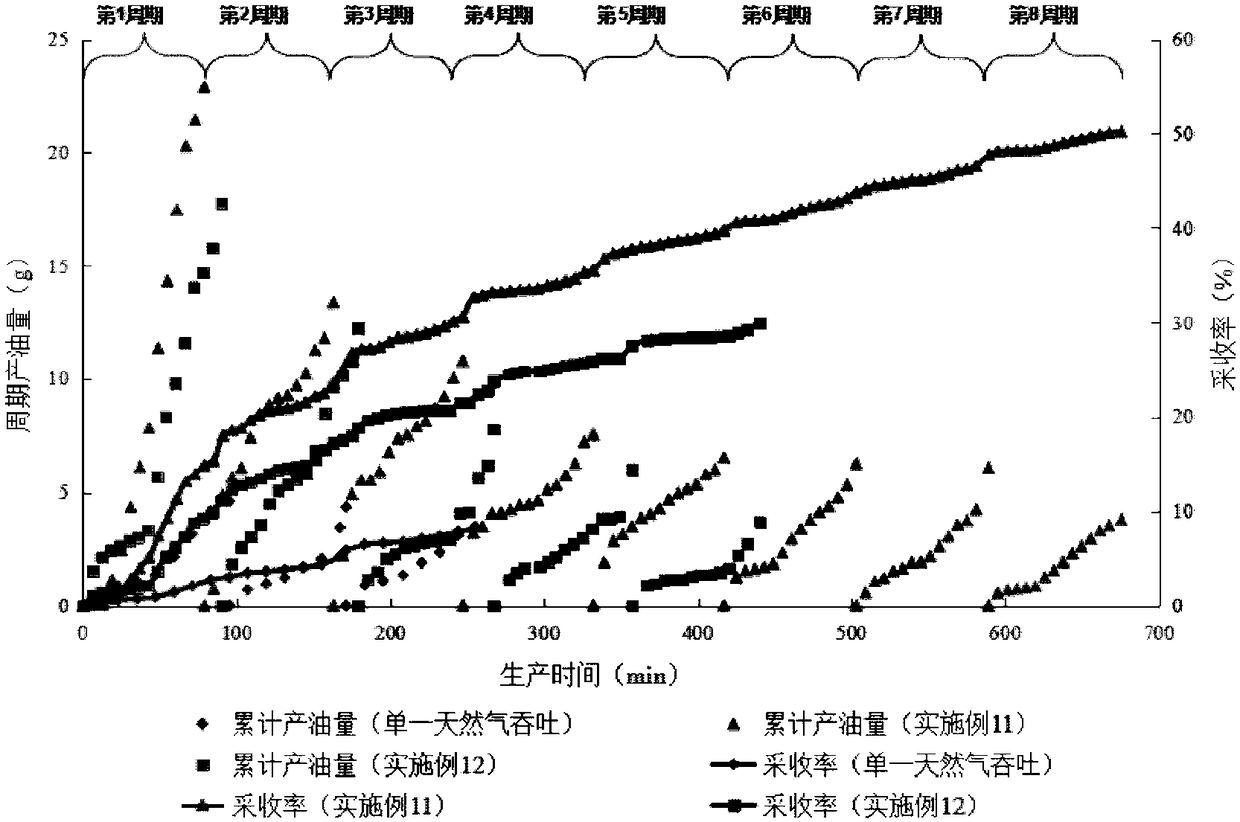

ActiveCN108071390AEnhanced Oil RecoveryEnhanced overall recoverySurveyFluid removalSolubilityFoaming agent

The invention discloses complex heavy oil reservoir oil solubility foaming agent intensified mixed gas huff-puff experimental equipment. The mixed gas is natural gas and propane which have better dissolution and viscosity-breaking effects compared with the natural gas, CO2 or CH4 and other single light component gas, the propane gas can be effectively prevented from liquefaction, so that the propane gas consumption can be reduced, and the propane gas use cost is reduced. In addition, an oil solubility foaming agent is matched with the mixed gas to generate artificial foam oil to reduce the speed of gas output during the huff-puff period, and the heavy oil viscosity can be reduced, so that the problem that the recovery efficiency of existing complex heavy oil reservoir is not high can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

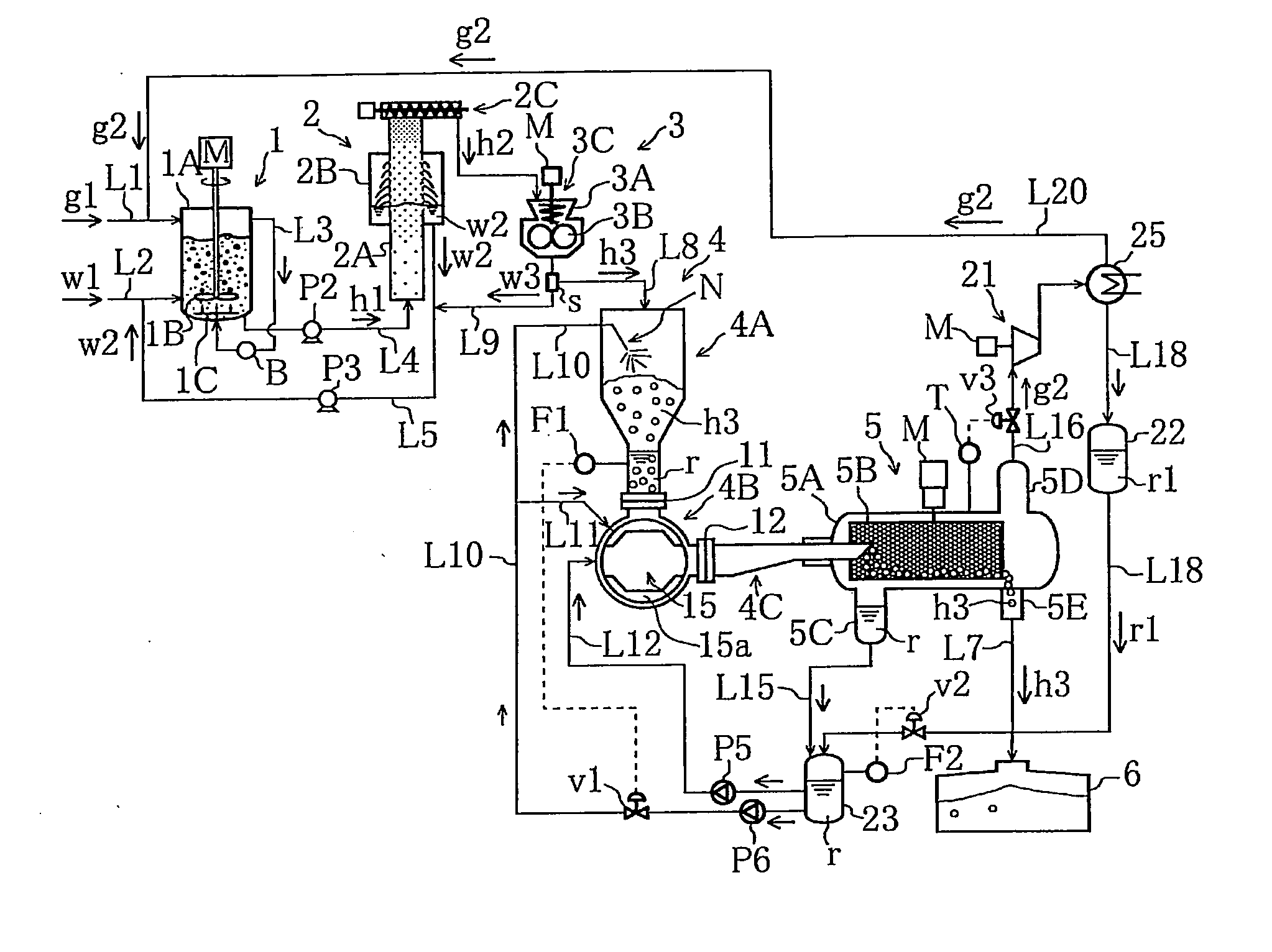

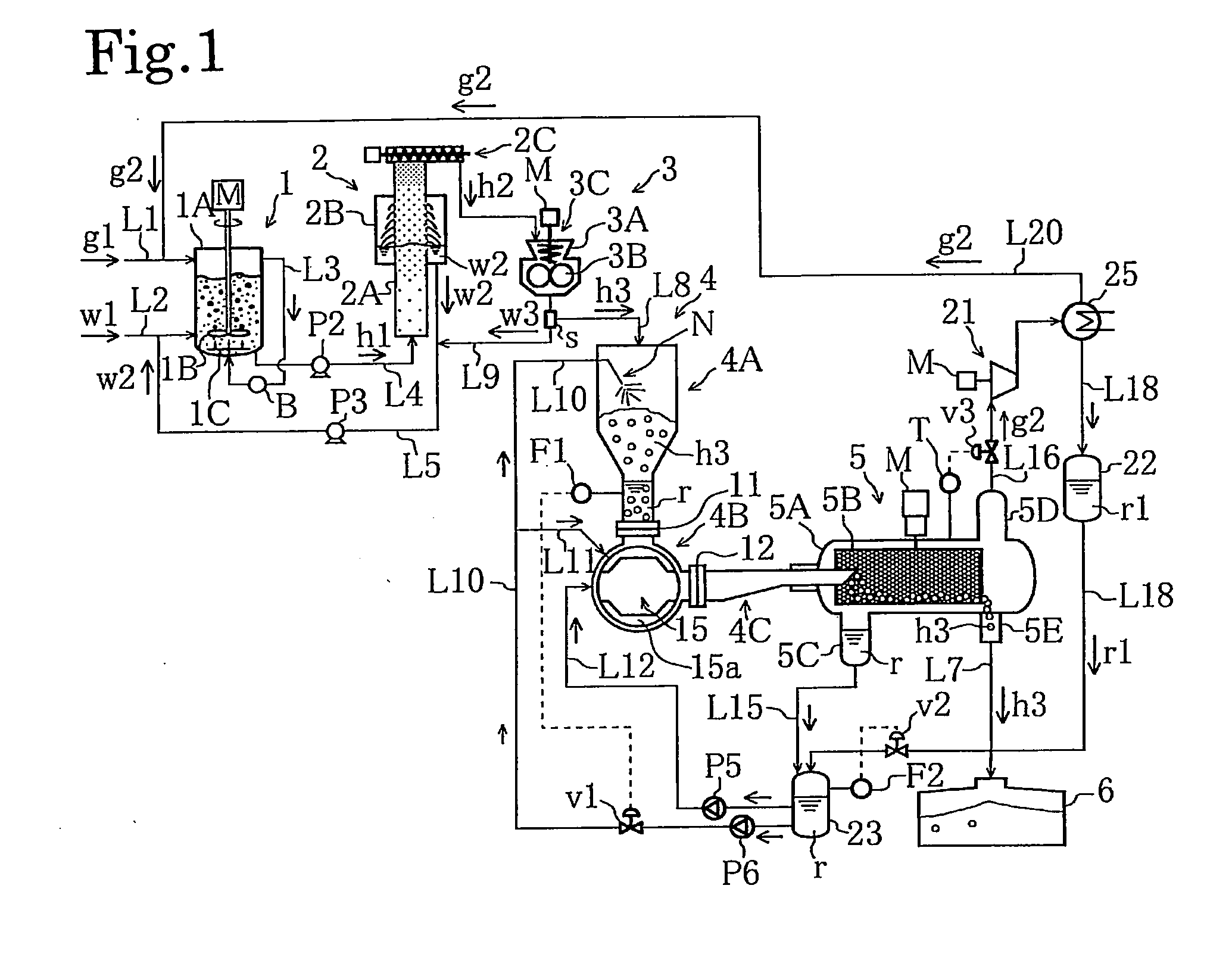

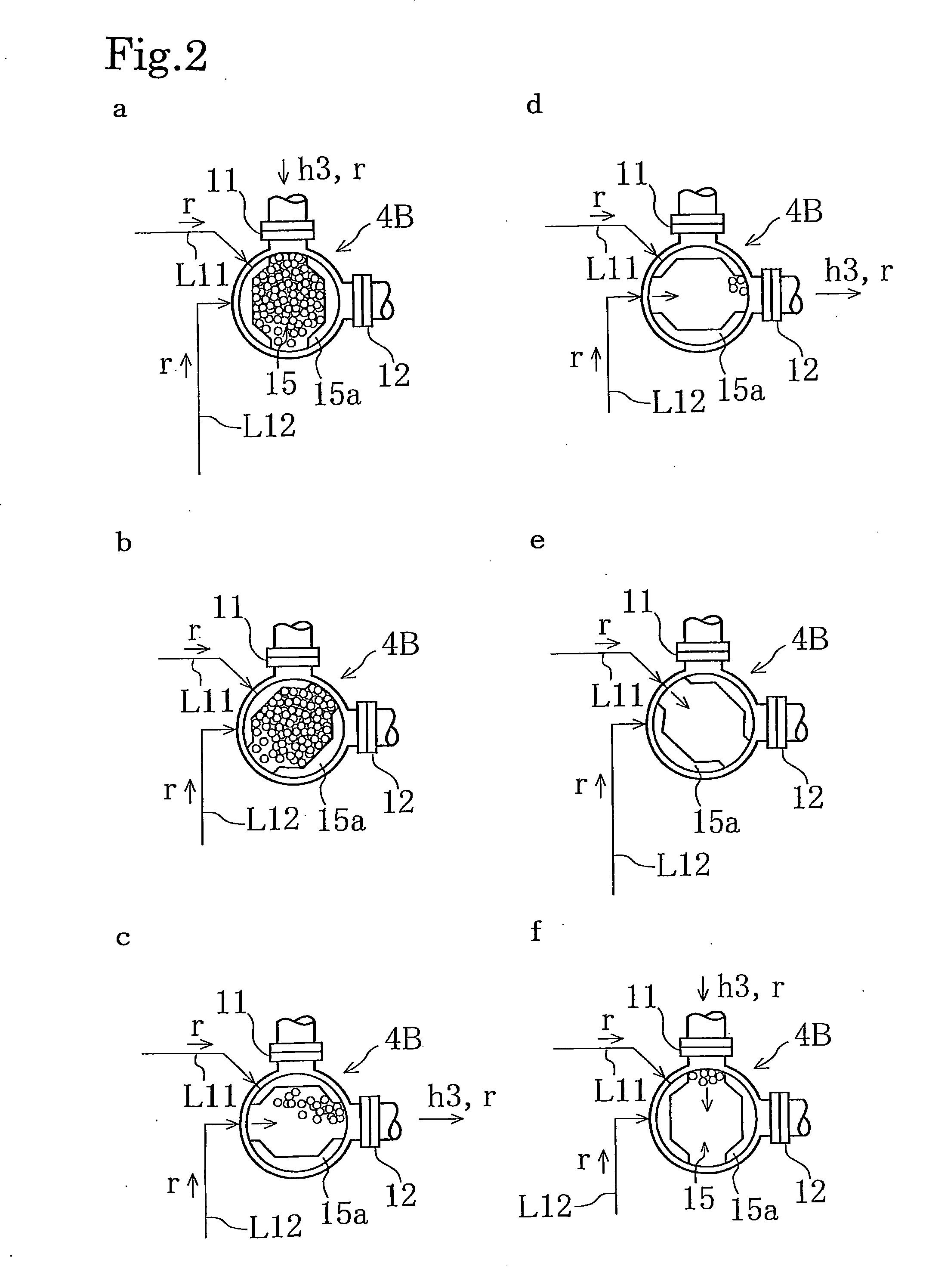

Process and appratus for producing gas hydrate

InactiveUS20100326132A1Increase heatIncrease heating capacitySolidificationLiquefactionCompression moldingProduct gas

A process is provided which includes: bringing a natural gas, e.g., methane gas or propane gas, or a mixture of these gases into gas-liquid contact with raw-material water to form a gas hydrate; compression-molding the gas hydrate into pellets; and cooling / depressurizing the pellets. Also provided is an apparatus for use in the process. In the cooling / depressurizing step 4, molded gas hydrate masses h3 in a pressurized state are cooled and depressurized to a downstream-side pressure. In the cooling / depressurizing step 4, a receiving chamber 15 which accommodates the gas hydrate masses h3 obtained in the molding step 3 is provided, and the masses h3 are depressurized to the downstream-side pressure while passing through the receiving chamber 15. The masses h3 are introduced into and immersed in a liquid refrigerant r packed in the receiving chamber 15 so that the masses h3 are cooled by solid / liquid contacting with the liquid refrigerant r.

Owner:MITSUI ENG & SHIPBUILD CO LTD

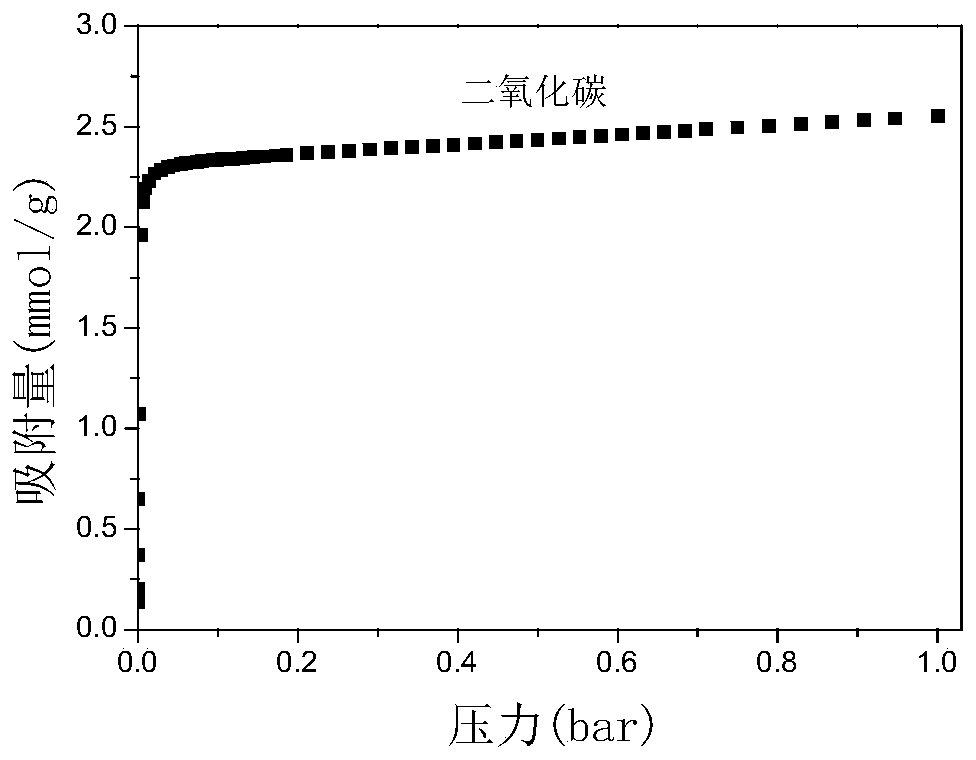

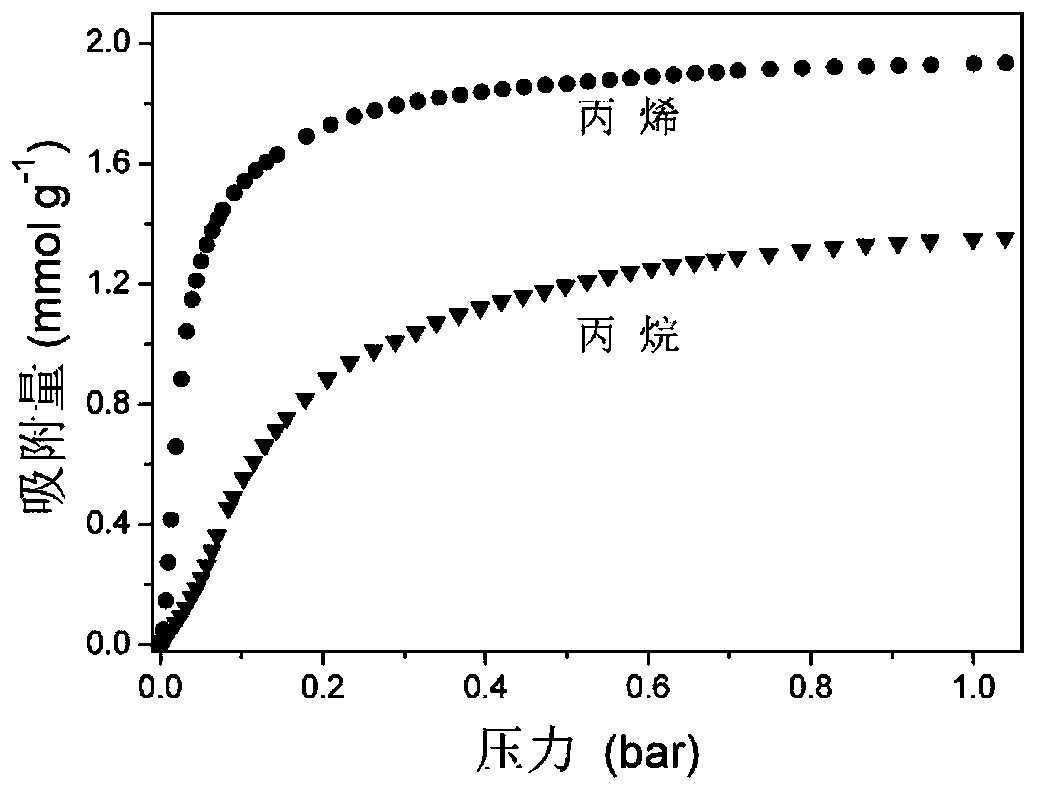

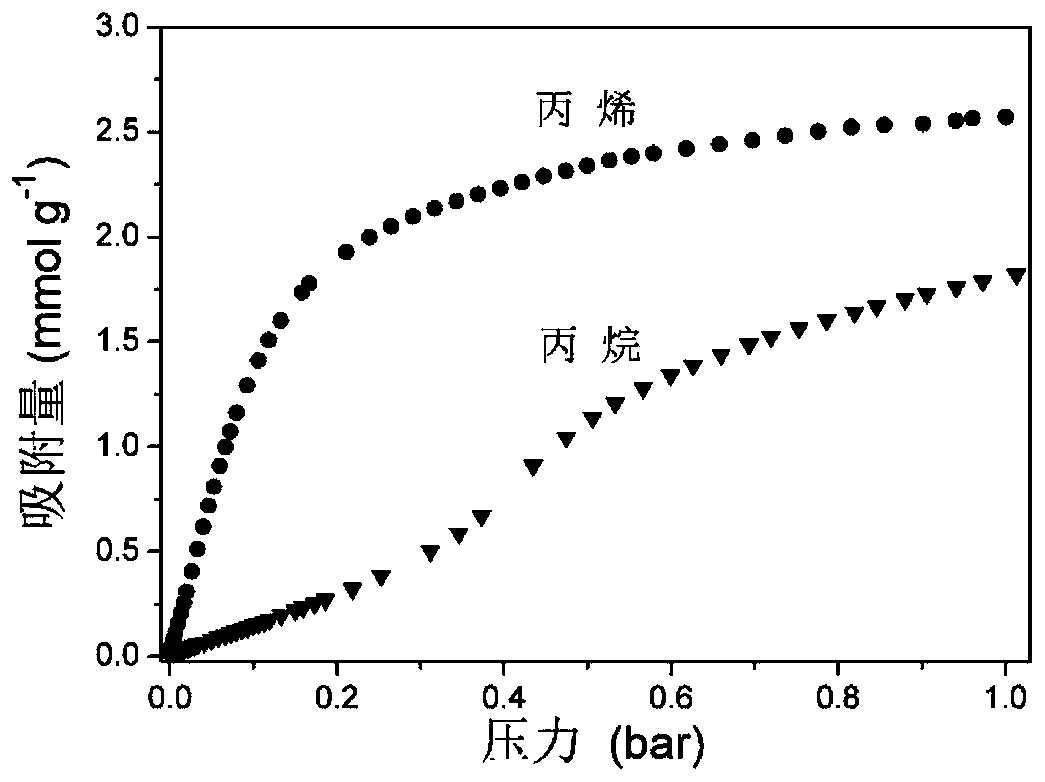

Propylene and propane separation method

ActiveCN109776252AAchieve separationPrecise control of apertureProductsOther chemical processesPyrazineAbsorbent material

The invention discloses a propylene and propane separation method, which comprises the following step: an anion-containing hybrid supermicroporous material is used as an absorbent material to contactwith a propylene-propane gas mixture for identification and capture of propylene so as to realize separation of propylene and propane. The anion-containing hybrid supermicroporous material is formed by an inorganic fluorine-containing anion A, a metal ion M and an organic ligand L through a coordination bond, and the general formula is L-M-A. The organic ligand L is pyrazine and its derivative; the inorganic fluorine-containing anion A is any one of NbF7<2->, ZrF6<2->, GeF6<2->, SiF6<2-> and TiF6<2->; and the metal ion M is any one of Co<2+>, Ni<2+>, Fe<2+> and Mn<2+>. The pore diameter of theanion hybrid supermicroporous material is accurately regulated, which exhibits strong action force on propylene; and by controlling rotation degree of F atoms in the pores, propylene is allowed to enter the pore structure and the action force on propane is weak and the propane adsorbing capacity is less, thus realizing separation of propylene and propane.

Owner:ZHEJIANG UNIV

Mixed welding and cutting gas

InactiveCN102041119AIncrease temperatureHigh combustion valueGaseous fuelsGas flame welding apparatusN-Butyl AlcoholPetroleum ether

The invention discloses a mixed welding and cutting gas, comprising the following ingredients by weight percent: 94%-96% of liquefied petroleum gas or natural gas or propane gas, 0.6%-1.8% of alcohol, 1.6%-2.9% of n-butyl alcohol, 0.09%-0.6% of ferrocene, and 0.4%-2.1% of petroleum ether. The mixed welding and cutting gas takes natural gas or propane gas or liquefied petroleum gas as a basic master batch and a certain amount of a synergist is added to the basic master material, thus the mixed welding and cutting gas has the advantages of high temperature, high combustion value, full combustion, regular flame shape and the like, is easy to control and is an ideal substitute for acetylene gas.

Owner:SHANDONG JUSHIJIE IND

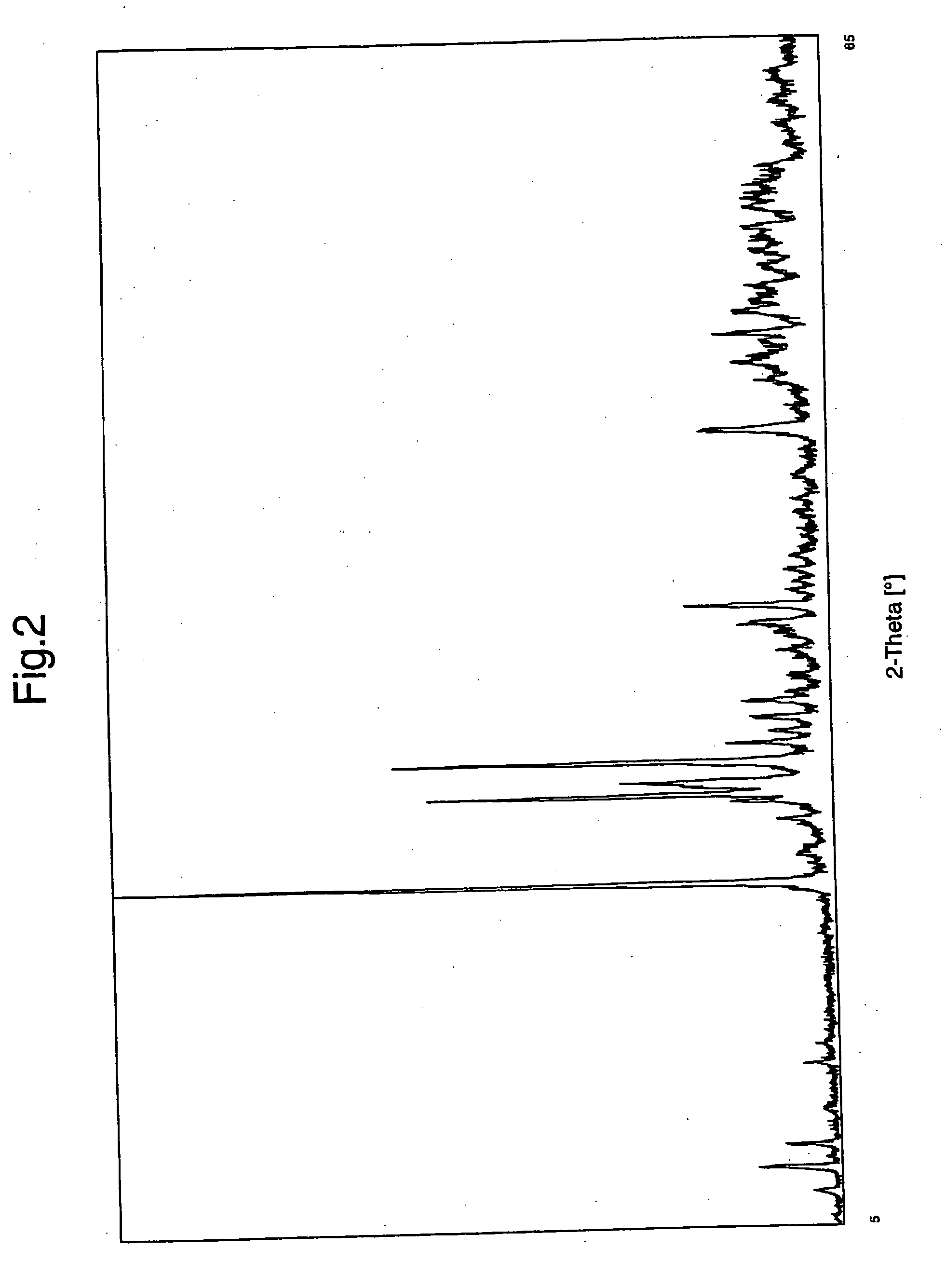

Catalyst comprising a support and a catalytically active oxide material applied to the surface of the substrate

InactiveUS20060074258A1High selectivityInorganic chemistryOrganic compound preparationGas phaseCatalytic oxidation

A coated catalyst whose coating of active composition is a multimetal oxide comprising the elements Mo, V and Te and / or Sb can be used for the gas-phase catalytic oxidation of propane to acrylic acid.

Owner:BASF AG

Odorant for fuel gas

The present invention provides an odorant suitable for use in fuel gases, such as liquefied natural gas (LNG), city gas, and LP gas, or methane gas, propane gas, butane gas and hydrogen gas. Preferably, the present invention provides a novel odorant that can also be used for fuel gases for fuel cells, including hydrogen gas. The odorant for fuel gases of the present invention has a perceptual threshold of 1 ppb or less, and includes a compound that has no sulfur atoms and no nitrogen atoms in its molecules. The odorant for fuel gases of the present invention is suitable for use in fuel cells that use hydrogen gas or other gases as a fuel.

Owner:SODA AROMATIC A CORP OF JAPAN

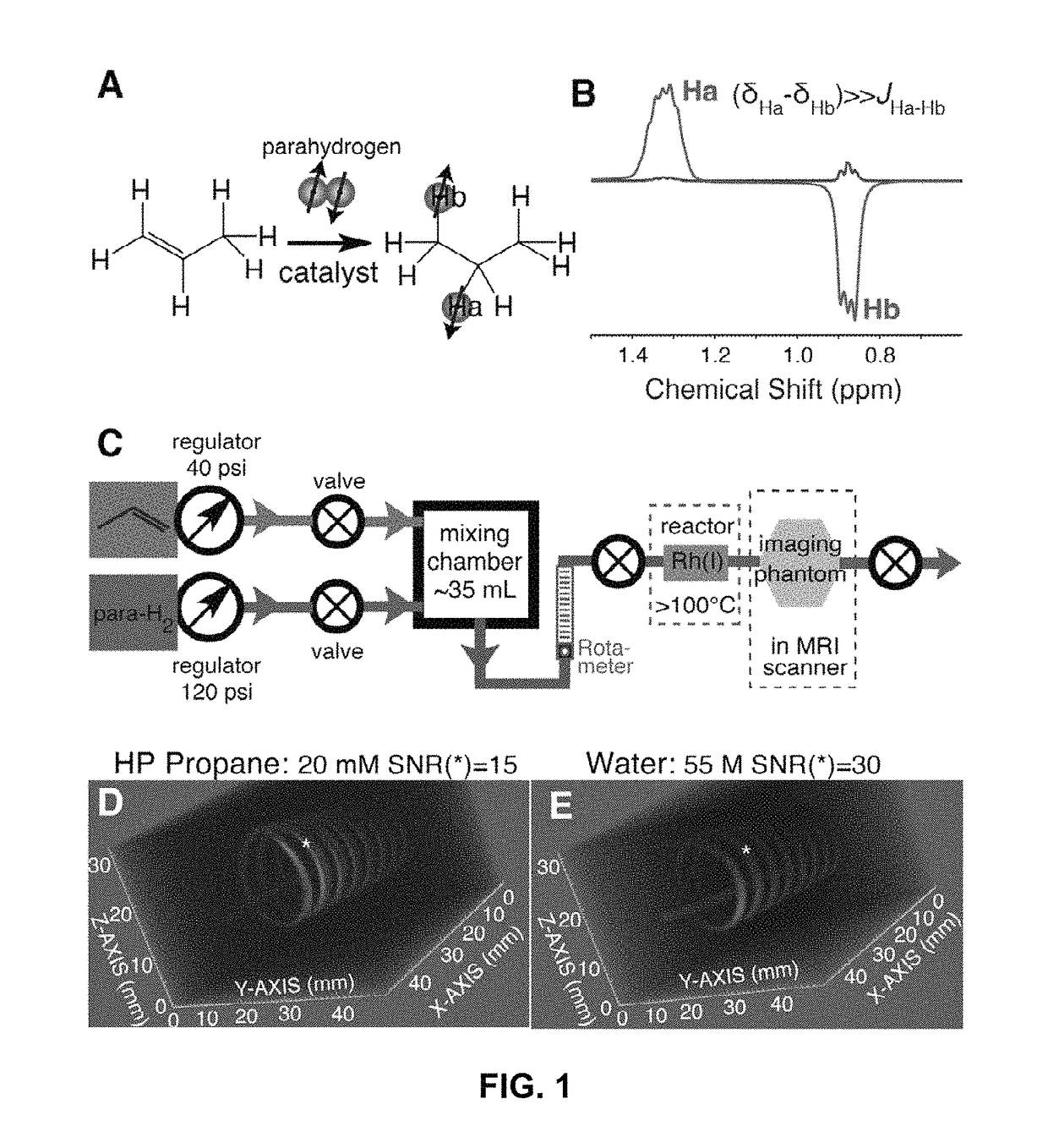

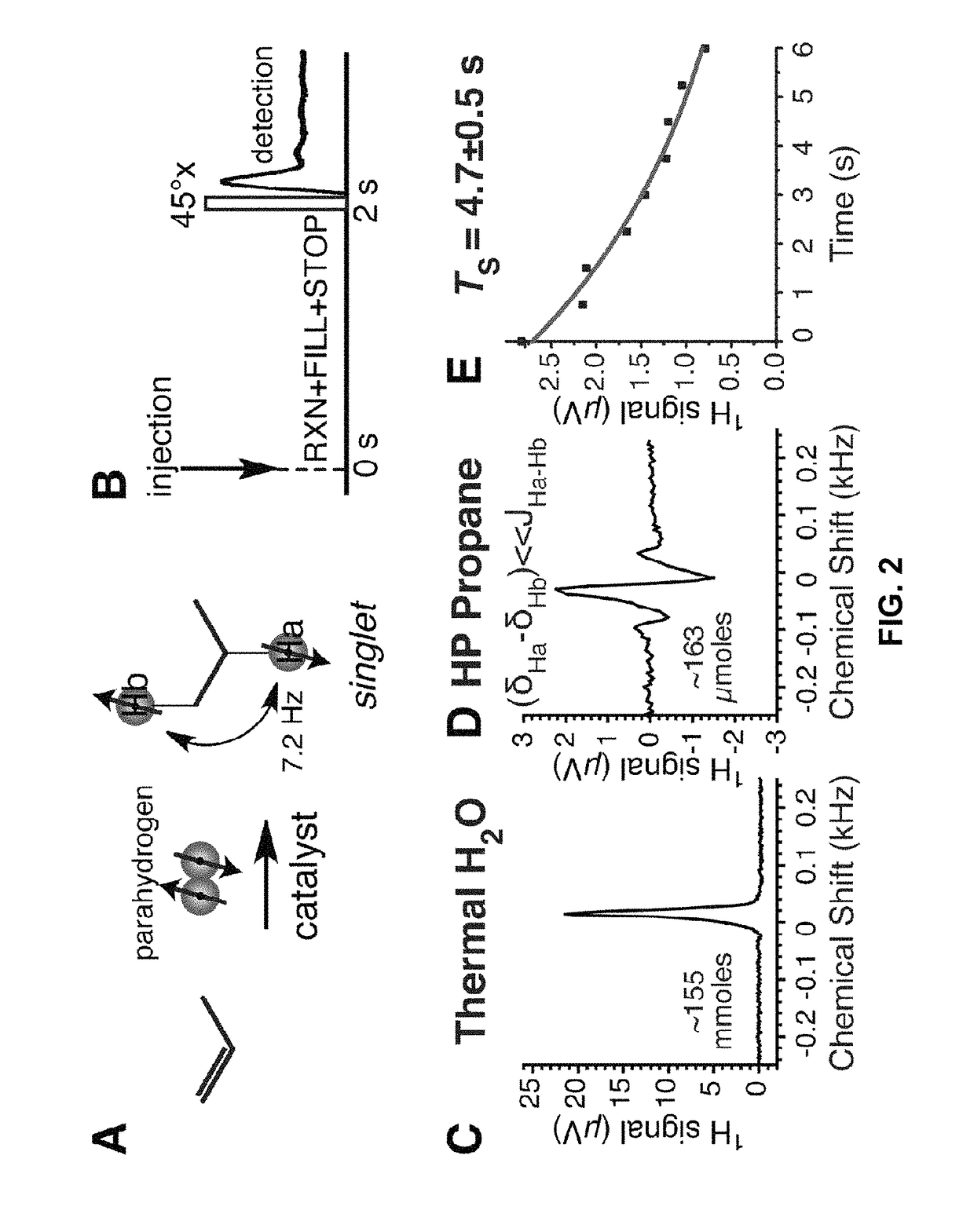

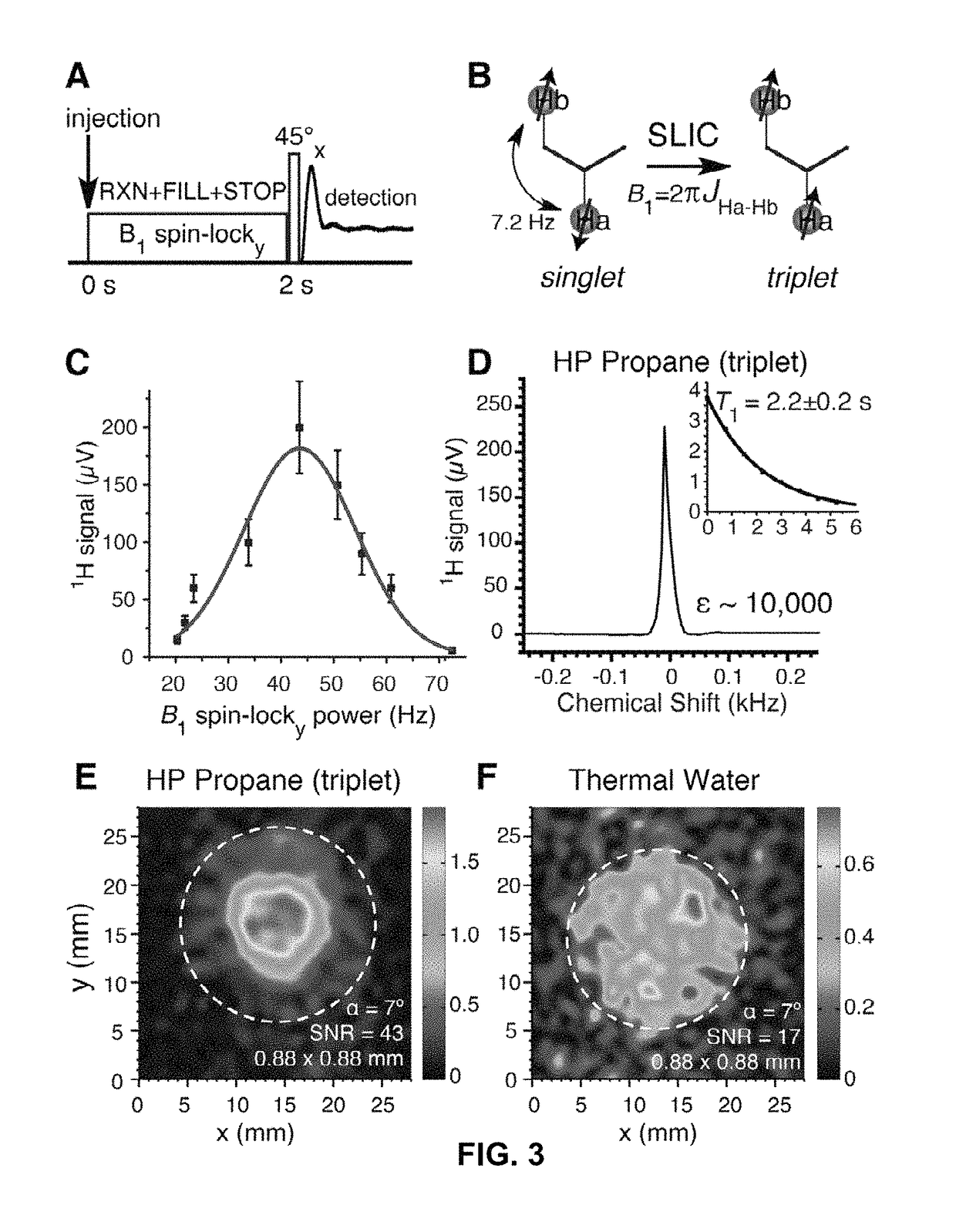

Creation of long-lived singlet states of gases and their use as inhalable MRI contrast agents

InactiveUS9702946B1Dispersion deliveryX-ray constrast preparationsMRI contrast agentTemporal resolution

Parahydrogen Induced Polarization was employed to prepare nuclear singlet state between methylene and methyl protons in propane gas. Low-field MRI preserves this singlet state with much longer TS=4.7±0.5 s. Spin-Lock Induced Crossing (SLIC) transforms singlet state in observable nuclear magnetization suitable for MRI with sub-millimeter and sub-second spatial and temporal resolution respectively with signal enhancement>10,000 times. Long-lived spin states created in hyperpolarized propane-d6 gas can be detected directly at 0.0475 T. This long lifetime and non-toxic nature of propane gas could be useful for bio-imaging applications including potentially pulmonary low-field MRI. The feasibility of high-resolution low-field 2D gradient-echo MRI was demonstrated with 0.88×0.88 mm2 spatial and ˜0.7 s temporal resolution respectively at 0.0475 T. Propane is a non-toxic gas, and therefore, these results enable low-cost high-resolution high-speed MRI of gases for imaging of lungs.

Owner:SAPRYGIN KONSTANTIN

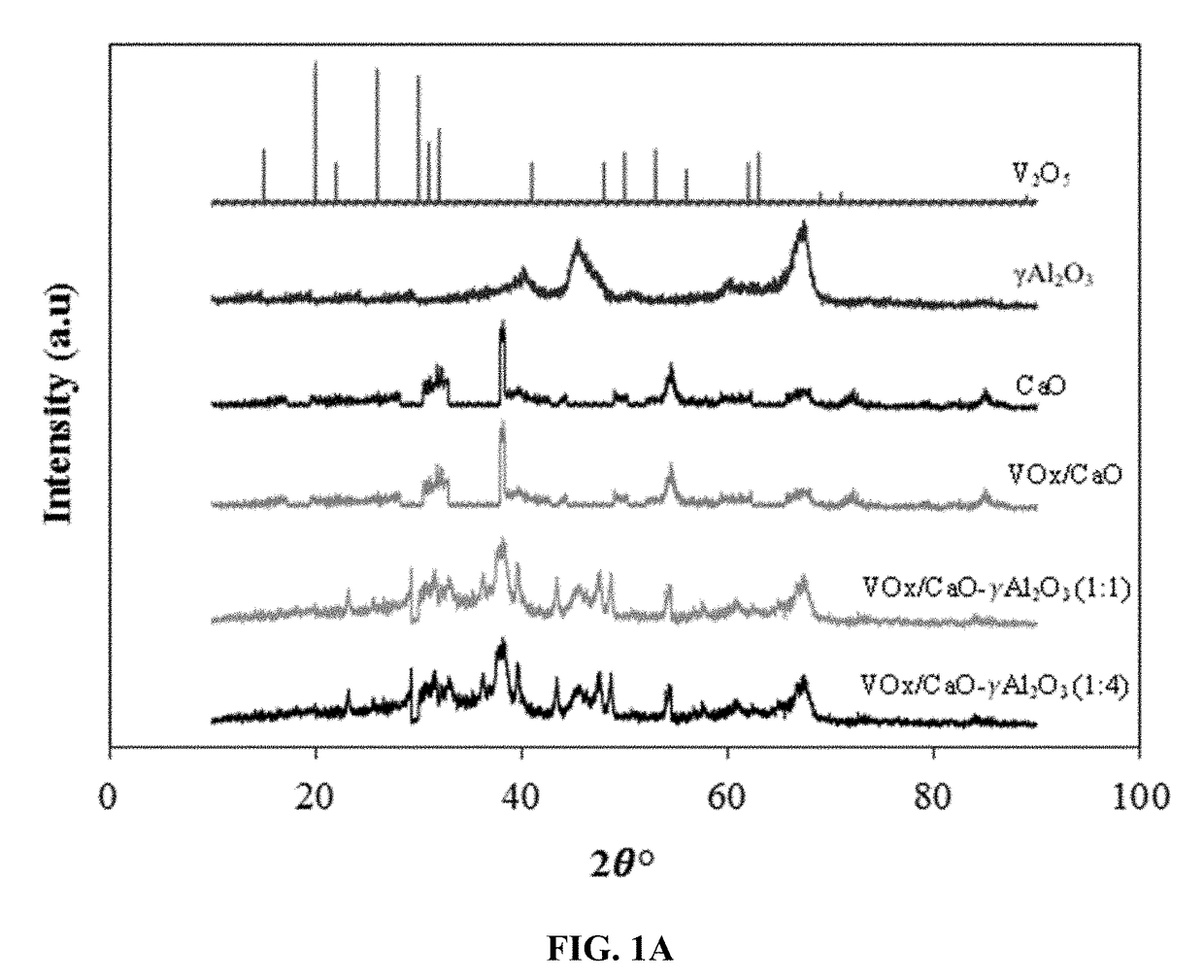

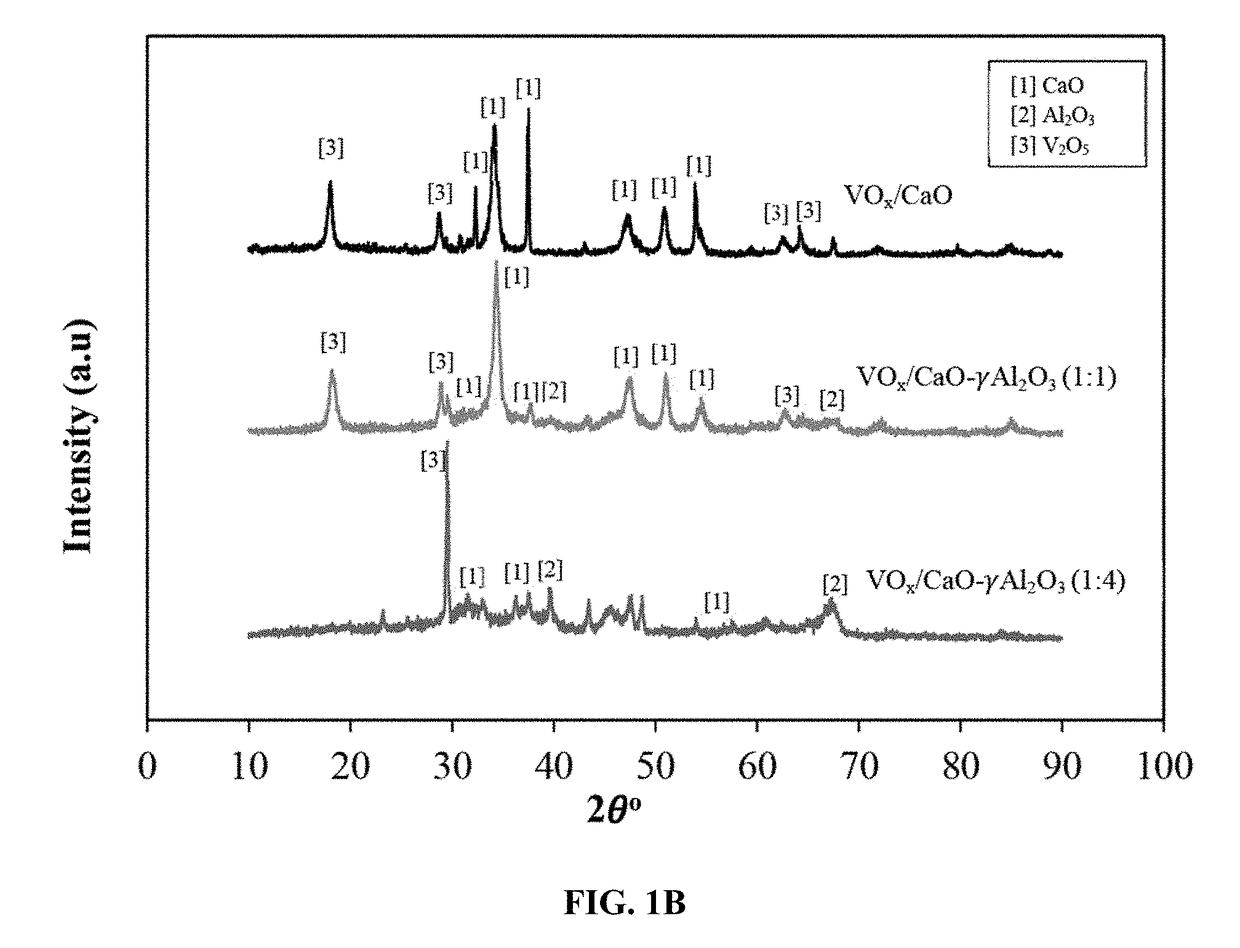

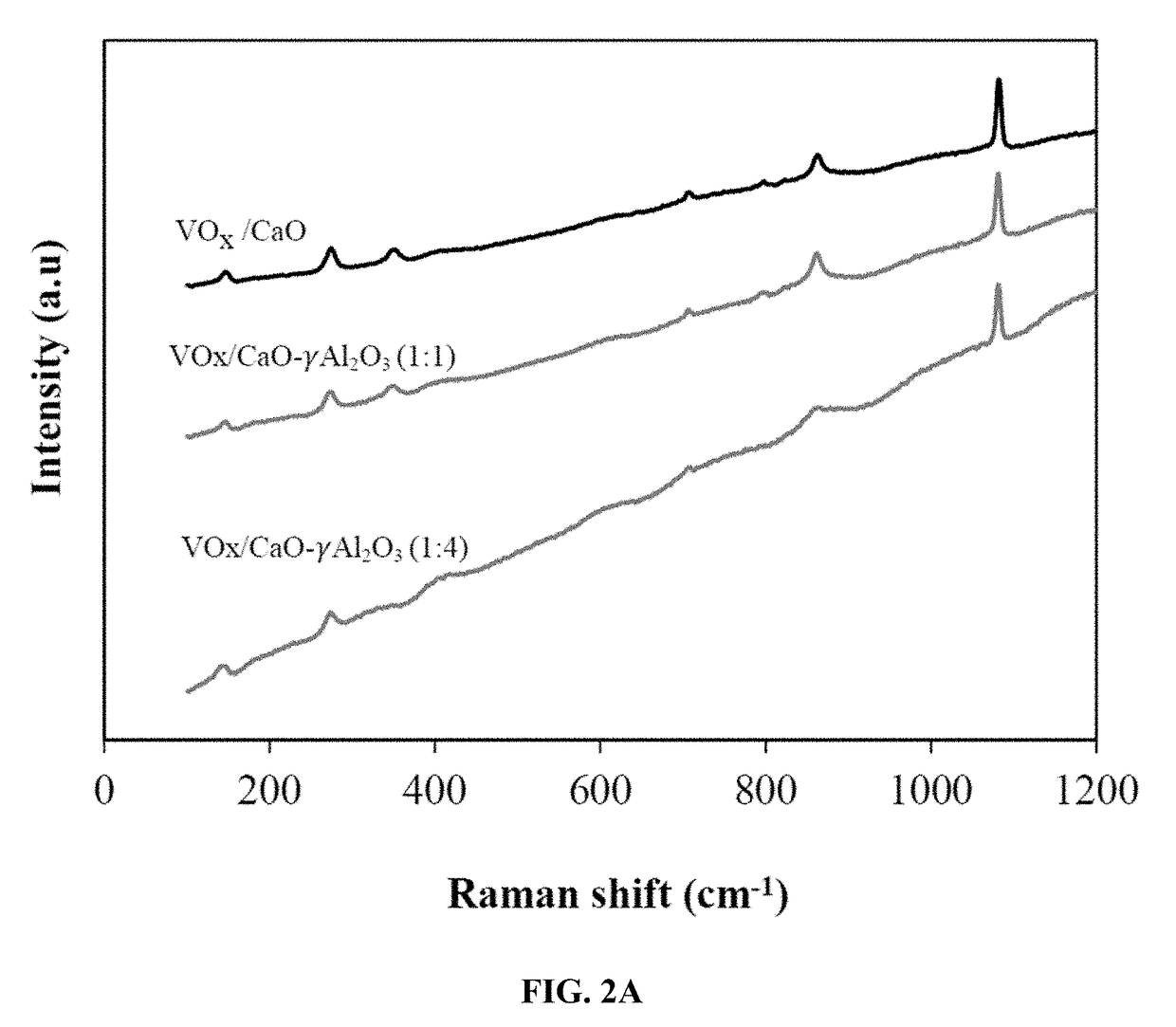

Fluidizable vanadium catalyst for oxidative dehydrogenation of alkanes to olefins in a gas phase oxygen free environment

InactiveUS20170354955A1Organic compound preparationCarboxylic acid esters preparationAlkaneGas phase

Fluidizable catalysts for the gas phase oxygen-free oxidative dehydrogenation of alkanes, such as propane, to corresponding olefins, such as propylene. The catalysts comprise 5-20% by weight per total catalyst weight of one or more vanadium oxides (VOx), such as V2O5. The dehydrogenation catalysts are disposed on an alumina support that is modified with calcium oxide to influence characteristics of lattice oxygen at the catalyst surface. Various methods of preparing and characterizing the catalyst as well as methods for the gas phase oxygen free oxidative dehydrogenation of alkanes, such as propane, to corresponding olefins, such as propylene, with improved alkane conversion and olefin product selectivity are also disclosed.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

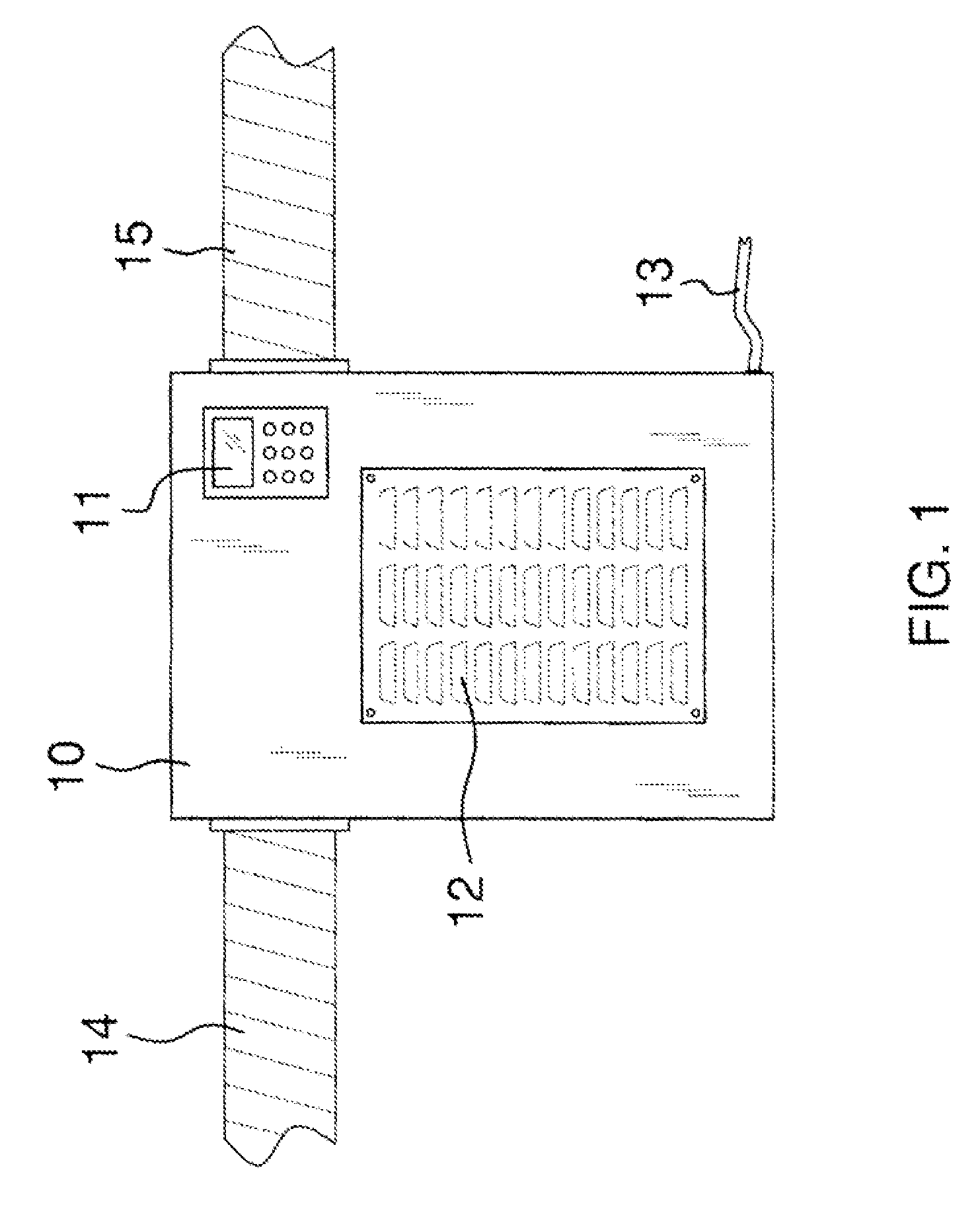

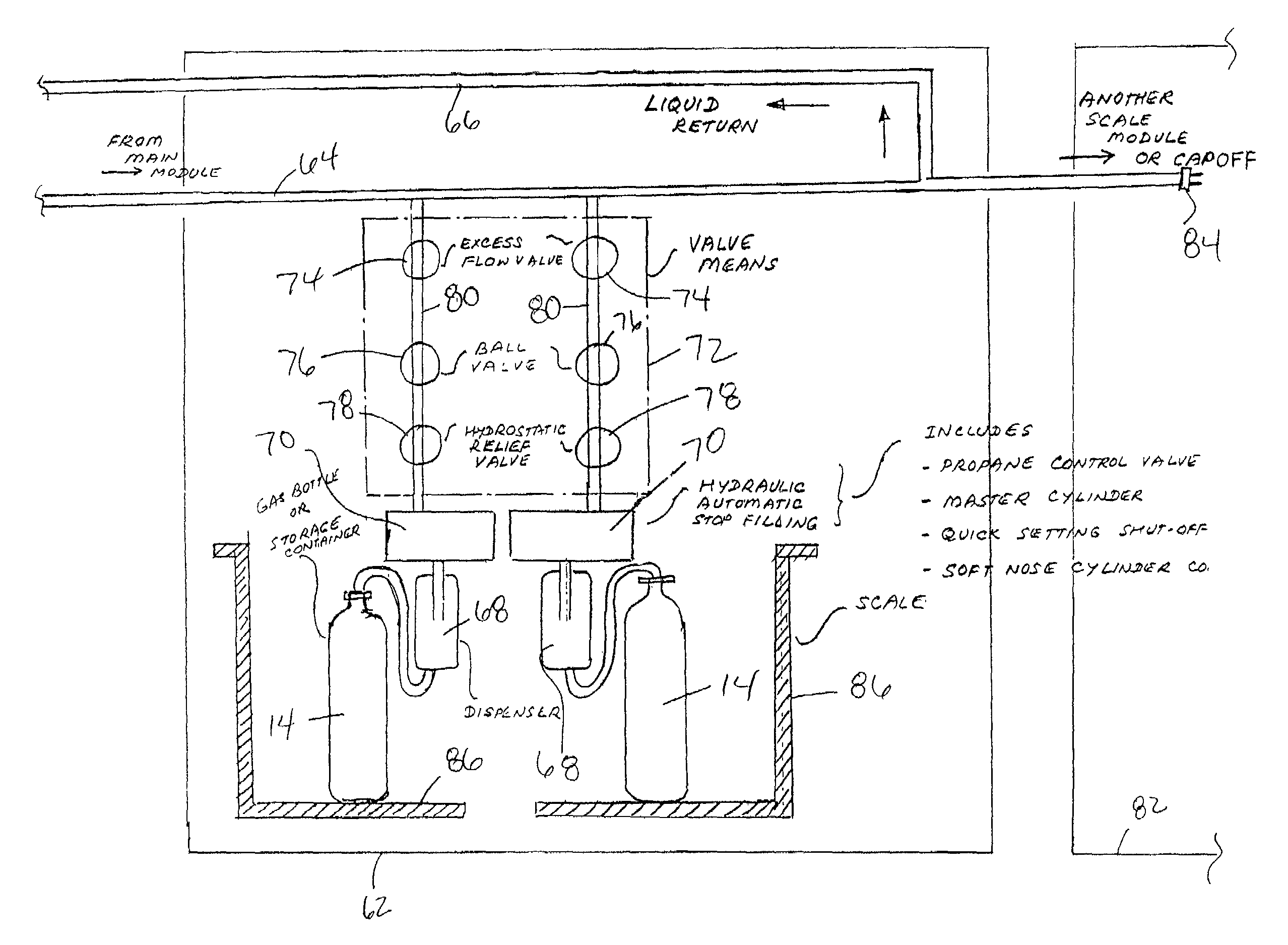

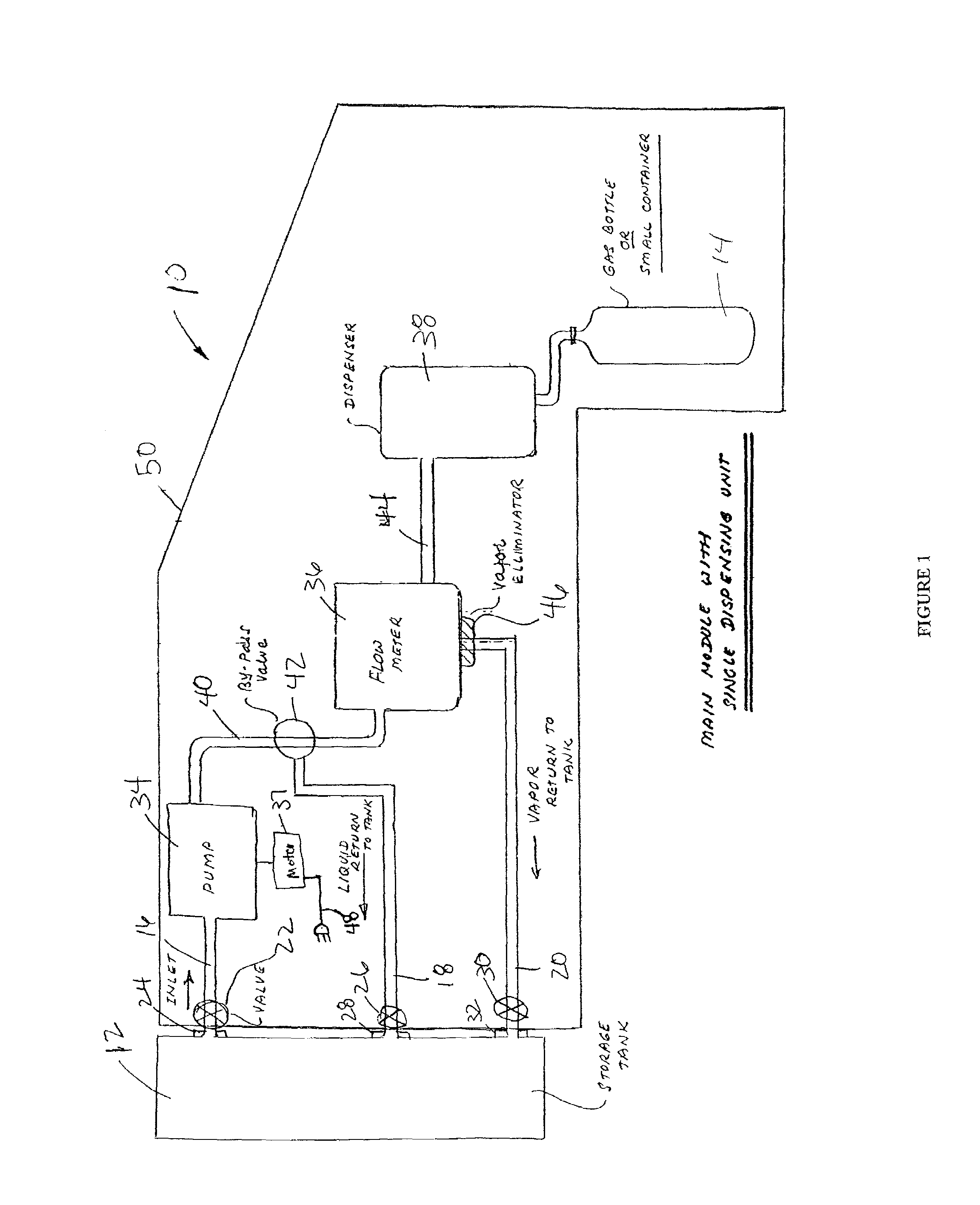

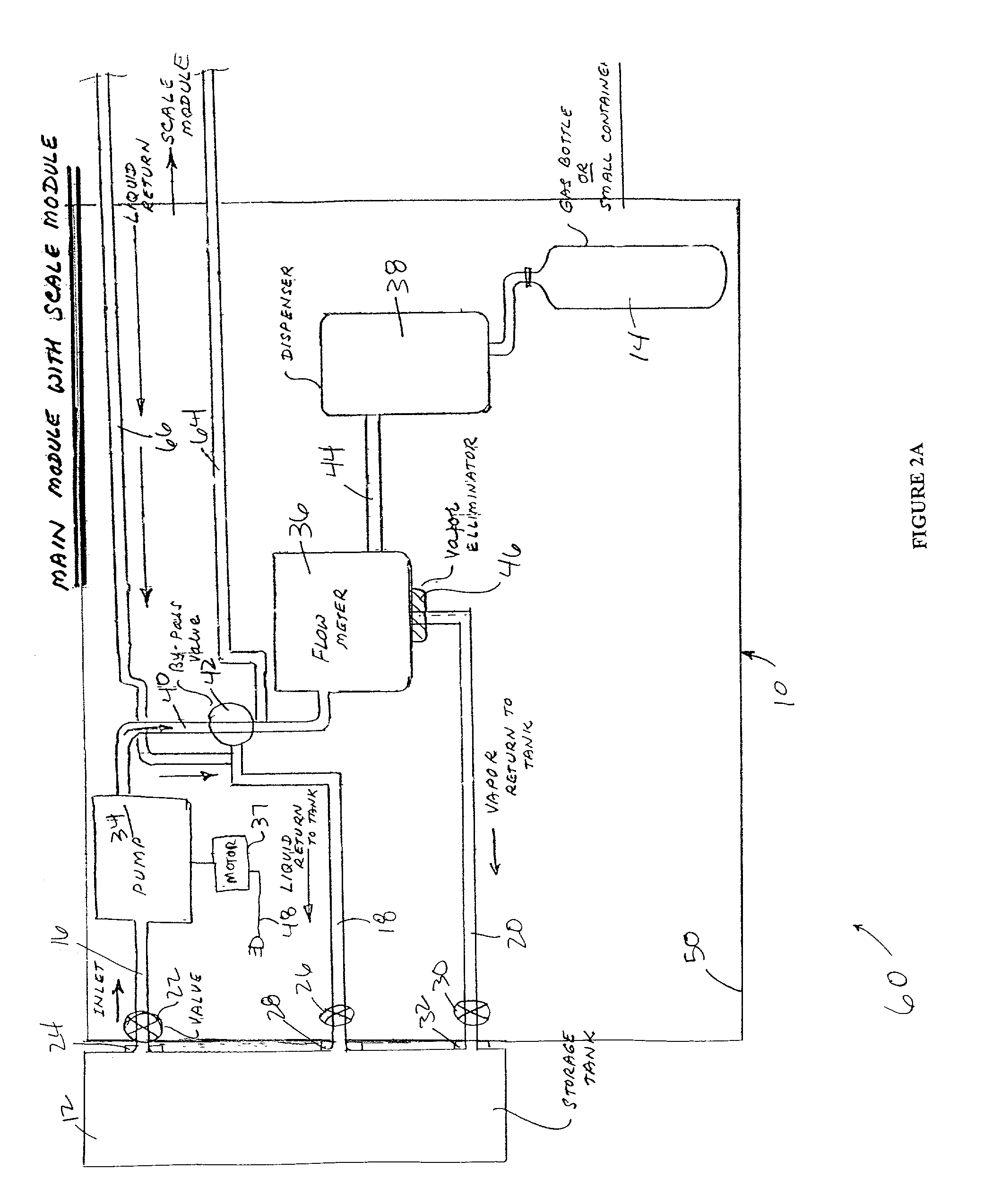

Apparatus for dispensing propane gas

InactiveUS7185684B2Ensure filling safetyVessel mounting detailsVessel geometry/arrangement/sizeGas cylinderStops device

A mobile fill station for filling propane cylinders by weight and volume. There can be up to three cabinets in the system wherein any one of the cabinets can have a beam scale with a hydraulic automatic stop device to stop filling automatically as the total weight of the cylinder reaches a pre-set scale limit. Any one of the cabinets can also include a flow meter to stop filling when an operator monitors an amount on the meter and manually stops propane flow. The cabinets could also include an electronic scale with a digital indicator where filling stops automatically as the total weight of the cylinder reaches a pre-set computer limit.

Owner:NGUYEN VAN H

Odorant for fuel gas

The present invention provides an odorant suitable for use in fuel gases, such as liquefied natural gas (LNG), city gas, and LP gas, or methane gas, propane gas, butane gas and hydrogen gas. Preferably, the present invention provides a novel odorant that can also be used for fuel gases for fuel cells, including hydrogen gas. The odorant for fuel gases of the present invention has a perceptual threshold of 1 ppb or less, and includes a compound that has no sulfur atoms and no nitrogen atoms in its molecules. The odorant for fuel gases of the present invention is suitable for use in fuel cells that use hydrogen gas or other gases as a fuel.

Owner:SODA AROMATIC A CORP OF JAPAN

Fireproof test device and fireproof test method

ActiveCN104034747ACompact structureReasonable layoutMaterial thermal analysisCombustion chamberAutomatic control

The invention provides a test device which sequentially comprises a heating device, a conveying device, a flow control device, a main combustion chamber, a combustion control device and a flow velocity control device,wherein the heating device is capable of automatically controlling the temperature of circulating hot water, and is constant in temperature and low in error; a water pump motor of the conveying device adopts a variable frequency motor and a programmable logic controller (PLC) system, so that the flow speed, the flow and the pressure of the circulating hot water can be controlled to be constant in the test process; the combustion control device can be used for adjusting the mixing ratio of propane gas and air by an adjusting device, and generating the flame with the temperature of 800+ / -50 DEG C; the temperature of the flame is recorded and automatically stored by an automatic temperature measurement recorder; the temperature fluctuation is low, the structure is simple, and the energy is saved. The whole fireproof test device is compact in structure, reasonable in layout, low in manufacturing cost, high in degree of automation as well as convenient to operate and use.

Owner:山东悦龙橡塑科技有限公司

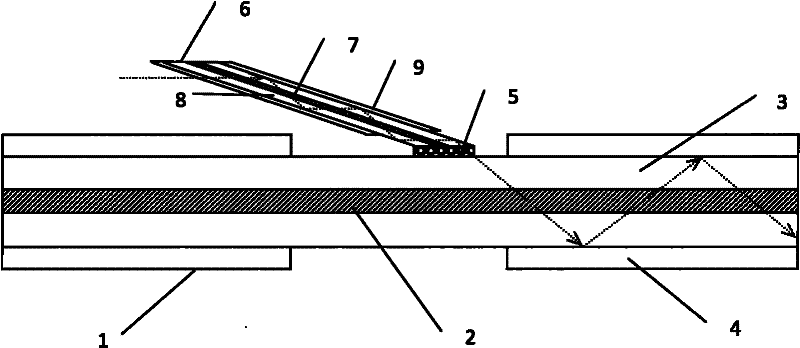

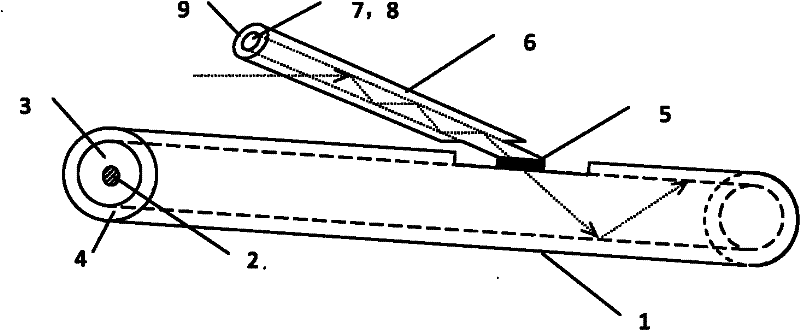

Method utilizing medium with low melting point to realize fusion coupling of side face of optical fiber

InactiveCN101750677AHelp with transmissionImprove coupling efficiencyCoupling light guidesFiberDouble-clad fiber

The invention provides a method utilizing a medium with low melting point to realize fusion coupling of the side face of an optical fiber. In the method, small-angle end face grinding and polishing are carried out on a pumping optical fiber; the medium with low melting point is uniformly adhered on the ground and polished inclined plane, and is then adhered to the side plane of an inner cladding of the dual-cladding optical fiber; and then two optical fibers are fused together by the medium with low melting point in heating fusion zones such as oxyhydrogen flames, a CO2 laser device, propane gas, a fine-particle blow lamp and the like. The medium with low melting point is a fusion medium, the melting point of the fusion medium is lower than that of the optical fiber, and the fusion medium comprises glass with low melting point, quartz with low melting point, a glass optical fiber and the like. By adopting the medium with low melting point as the fusion medium, the method can finish fusion under the condition that the temperature is far lower than the melting point of the optical fiber without causing slight deformation of a fiber core structure of the optical fiber, thereby increasing the coupling efficiency of signal light.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com