Fireproof test device and fireproof test method

A technology of test equipment and main combustion chamber, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that cannot be carried out and restrict the development of special high-pressure fire-resistant and flame-retardant rubber hose assembly technology, and achieve reasonable layout and compact structure , Easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

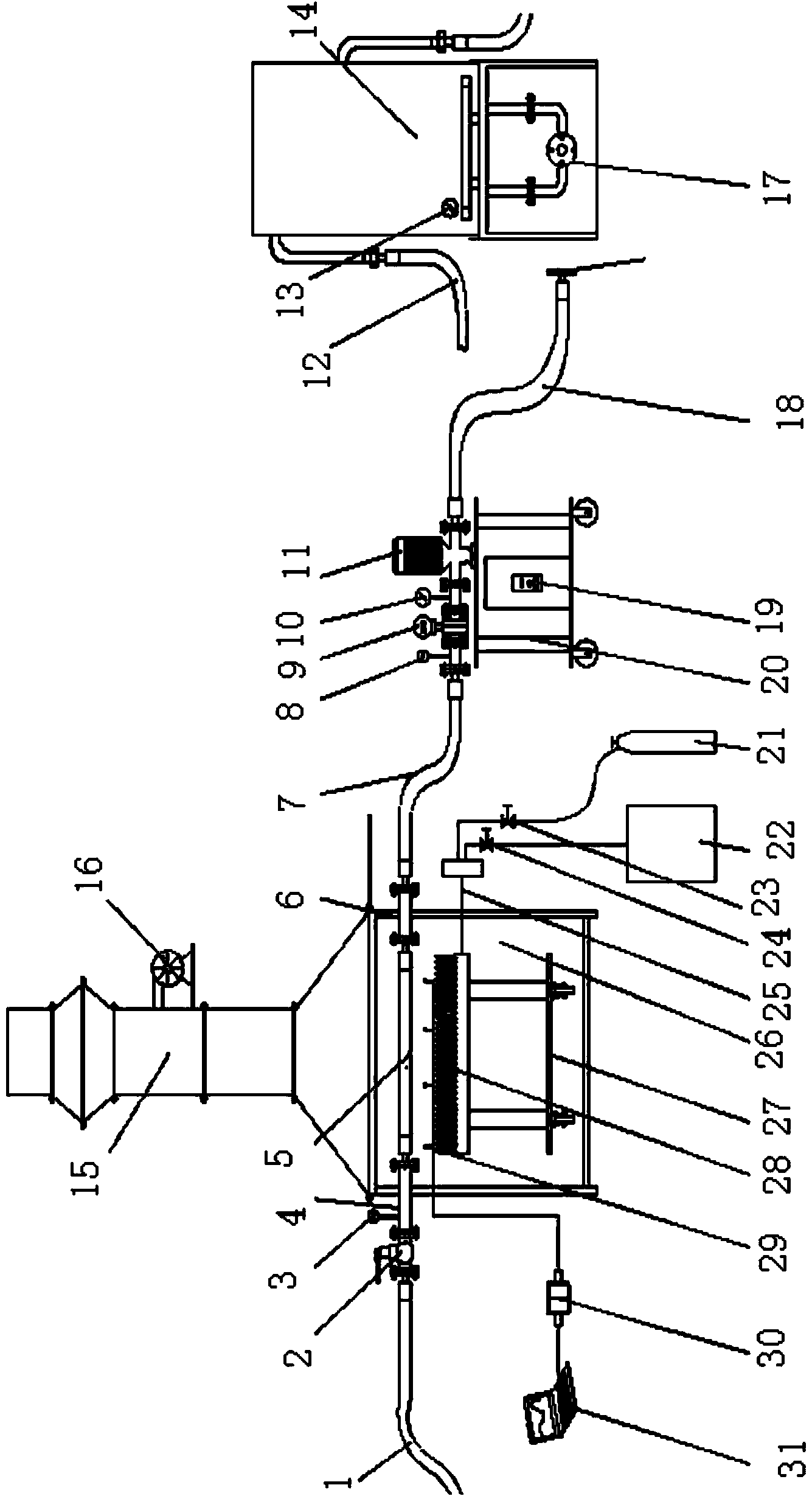

[0018] Describe the present invention in detail below in conjunction with accompanying drawing by specific example:

[0019] A fire test equipment, including the following components:

[0020] 1. Heating device

[0021] The heating device includes a hot water tank 14 , a thermometer 13 , a steam heating coil, a water inlet pipeline, a water outlet pipeline 17 and a water return pipeline 12 .

[0022] The hot water tank 14 is welded by stainless steel plates to prevent the corrosion of the water tank from affecting the conveying equipment. The outside of the water tank is treated with insulation boards, and the structure is a fully sealed structure, which has excellent insulation effects and can keep the temperature of hot water constant.

[0023] The steam heating coil is welded by stainless steel pipes and elbows. It is placed at the bottom of the hot water tank 14. It can be fed with saturated steam to heat the heated tap water for a second time, and the amount of steam ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com