Propylene and propane separation method

A technology of propylene propane and separation method, which is applied in separation methods, dispersed particle separation, adsorption purification/separation, etc. problem, to achieve the effect of significant industrial application prospects, low cost and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1mmol Co(BF 4 ) 2 , 1mmol (NH 4 ) 2 GeF 6 and 5 mmol of pyrazine were placed in a strain bottle, 2 ml of water and 1 ml of methanol were added, and stirred at room temperature for 48 h. After suction filtration, the obtained slurry was activated for 24 h under vacuum at 140° C. to obtain GeFSIX-3-Co material.

[0041] Fill the obtained GeFSIX-3-Co material into a 5cm adsorption column, and pass 0.2Mpa of propylene: propane (50:50) mixed gas at 0.5mL / min into the adsorption column at 35°C, and high purity can be obtained in the effluent gas Propane (greater than 99.9%) gas, when propylene breaks through, stops adsorption. The adsorption column adopts vacuum desorption at 100°C to obtain propylene (purity greater than 95%), and the adsorption column can be recycled.

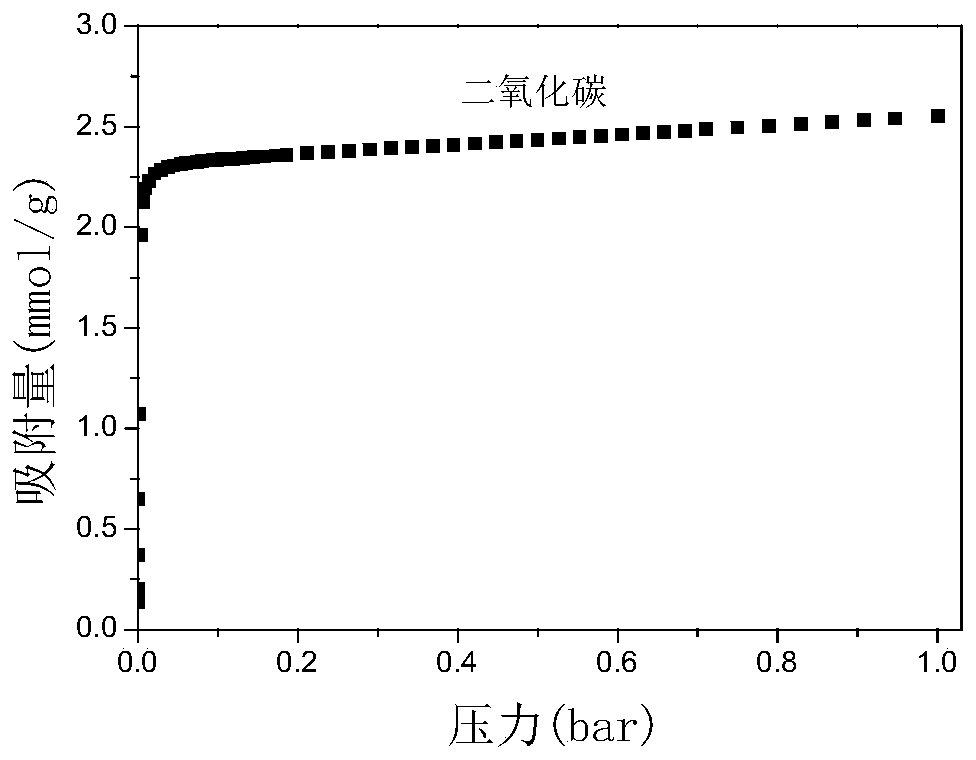

[0042] GeFSIX-3-Co material to CO at 298K 2 Adsorption isotherms such as figure 1 As shown, CO 2 The adsorption isotherm can show that the pore size of the material is about.

[0043] The adsorpt...

Embodiment 2

[0045] 1mmol Ni(BF 4 ) 2 , 1mmol (NH 4 ) 2 SiF 6 and 3 mmol of pyrazine were placed in a strain bottle, 1 ml of water and 2 ml of methanol were added, and stirred at room temperature for 48 h. After suction filtration, the obtained slurry was activated for 24 h under vacuum at 130° C. to obtain SIFSIX-3-Ni material.

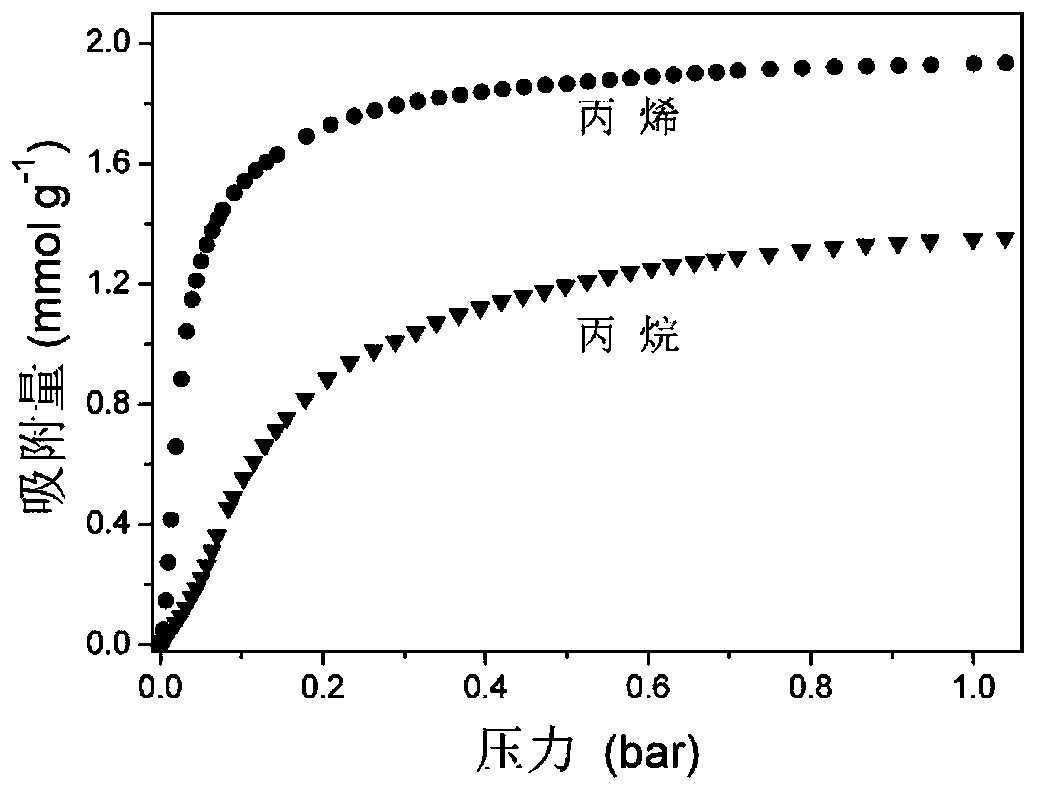

[0046] The adsorption isotherms of SIFSIX-3-Ni material for propylene and propane at 298K are as follows: figure 2 shown.

Embodiment 3

[0048] 1mmol Ni(NO 3 ) 2 , 1mmol (NH 4 ) 2 TiF 6 and 10mmol of pyrazine were placed in a strain bottle, after adding 2ml of methanol and 1ml of water, stirred at room temperature for 48h, and after suction filtration of the obtained slurry, it was vacuum activated at 150°C for 24h to obtain TIFSIX-3-Ni material.

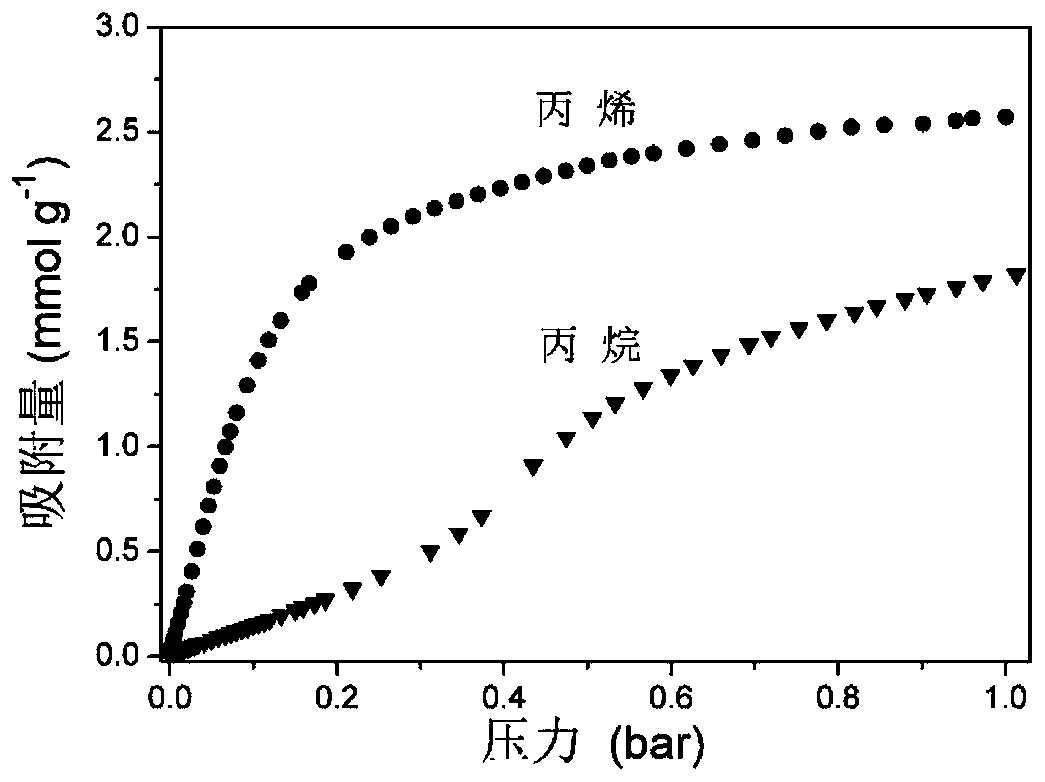

[0049] The adsorption isotherms of TIFSIX-3-Ni material for propylene and propane at 298K are as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com