Patents

Literature

52results about How to "Adjustable force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

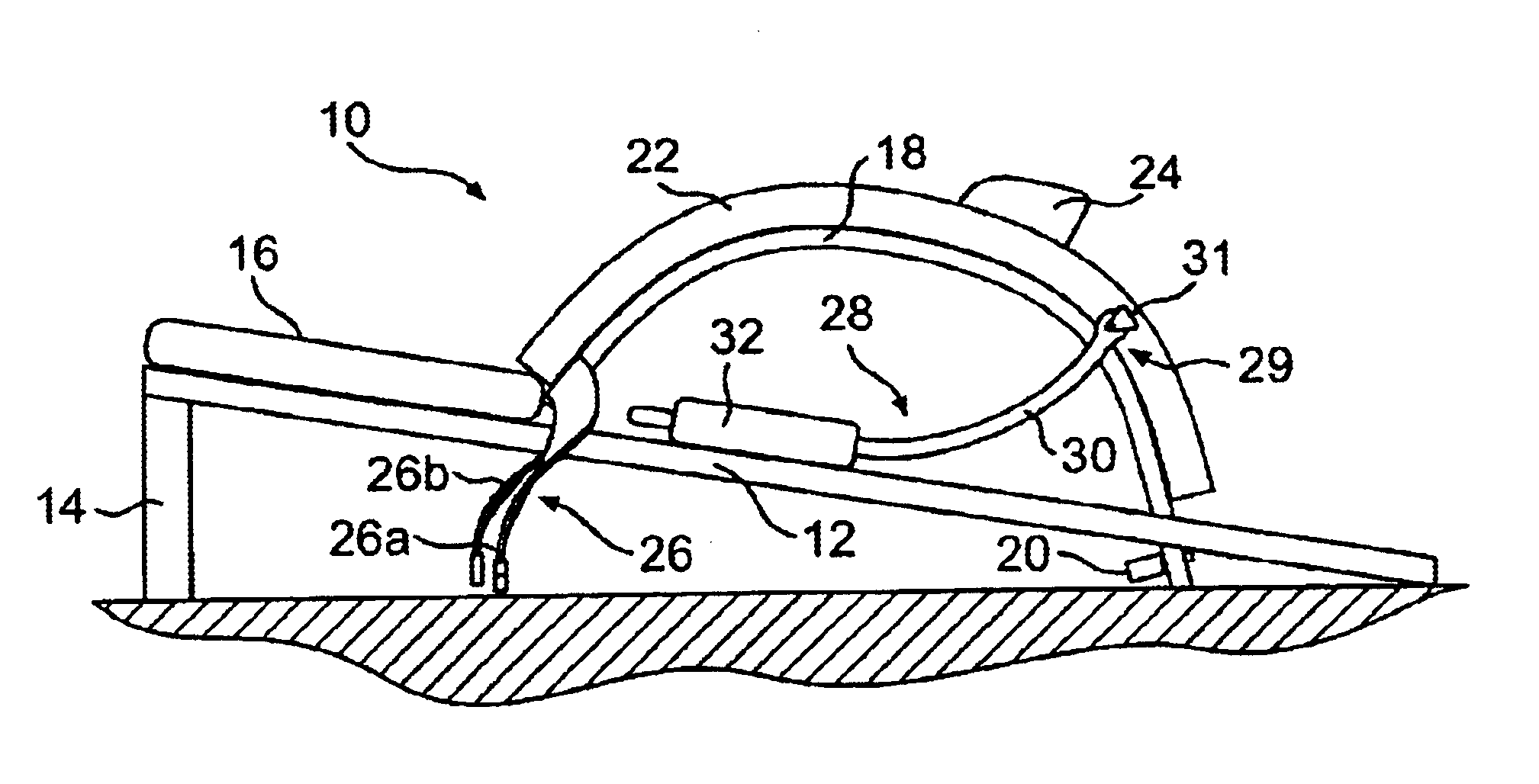

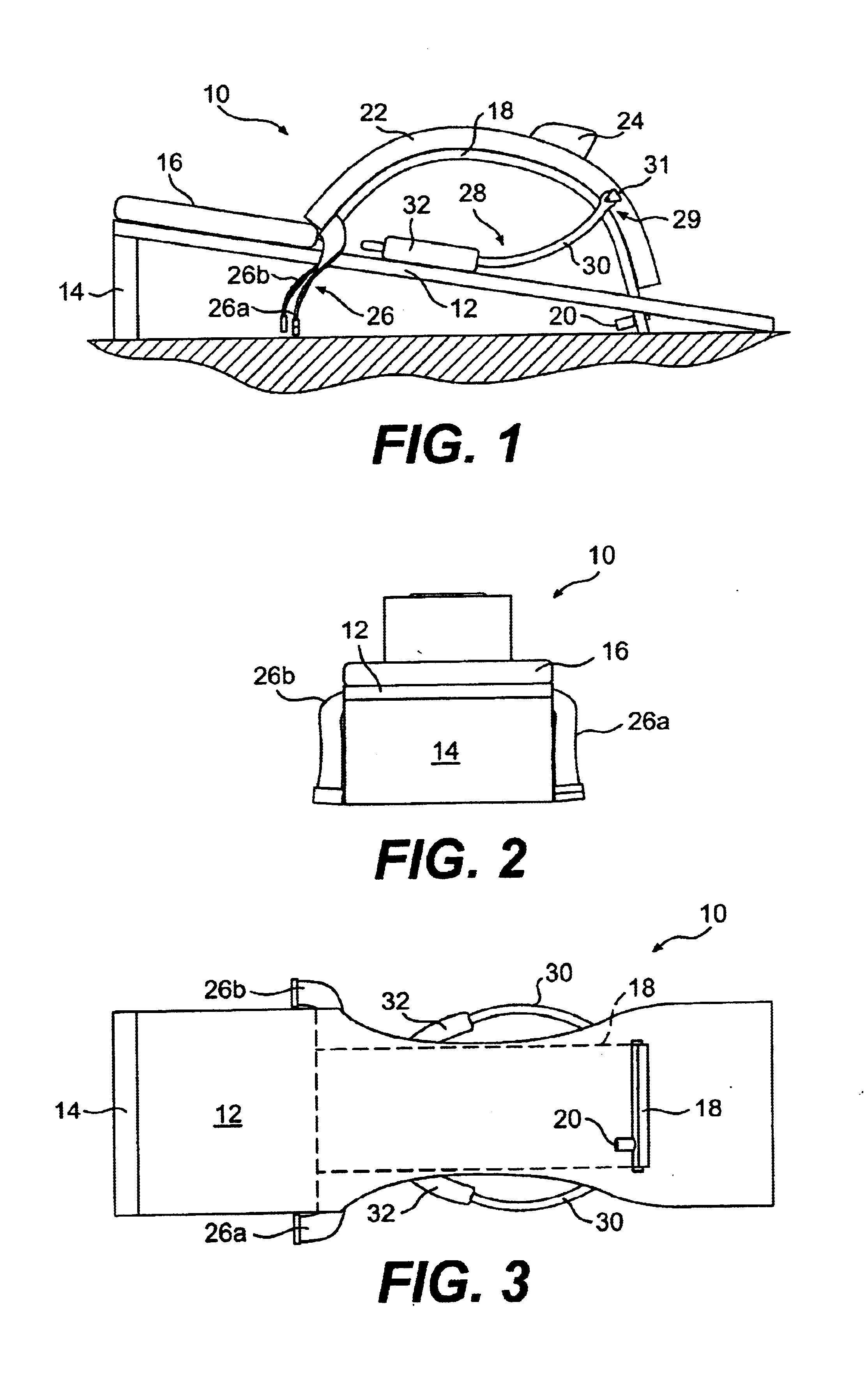

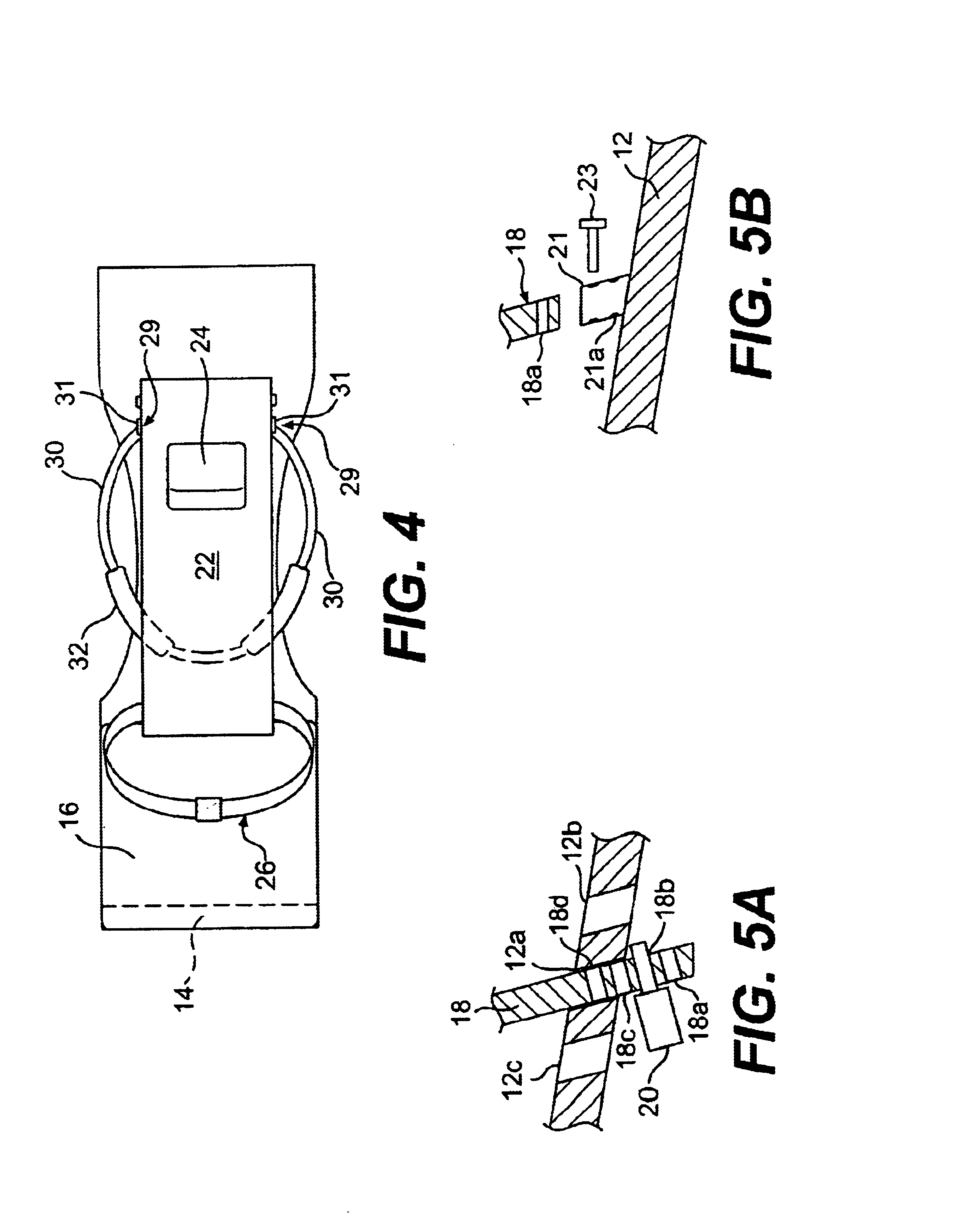

Exercise device for exercising of the abdominal muscles

InactiveUS6843759B2Simple and lightweight in constructionEasy to carryResilient force resistorsChiropractic devicesEngineeringBack support

An exercise device is provided which is used in exercising of the abdominal muscles as well as in exercising the muscles of the upper torso, shoulders and arms while the back of the user is supported, elongated and stretched. The device includes a platform which is elevated at one end from a supporting surface for the device. A seat is located at the one end of the platform and a bowed back support member is disposed on the platform adjacent to the seat. The support member presents a convex curved surface of a longitudinal extent such that the back and head of the user can rest thereon with the user in a backwardly reclining posture. A resilient belt fits around the waist of the user while a restraining arrangement preferably in the form of flexible restraining members is adapted to engage the arms of the user during movement of the user from the backwardly reclining posture wherein the back of the user rests against the convex curved surface to a sitting position. The restraining arrangement thus increases the force that must be exerted by the abdominal muscles of the user in carrying out this movement.

Owner:WALLERSTEIN ROBERT S

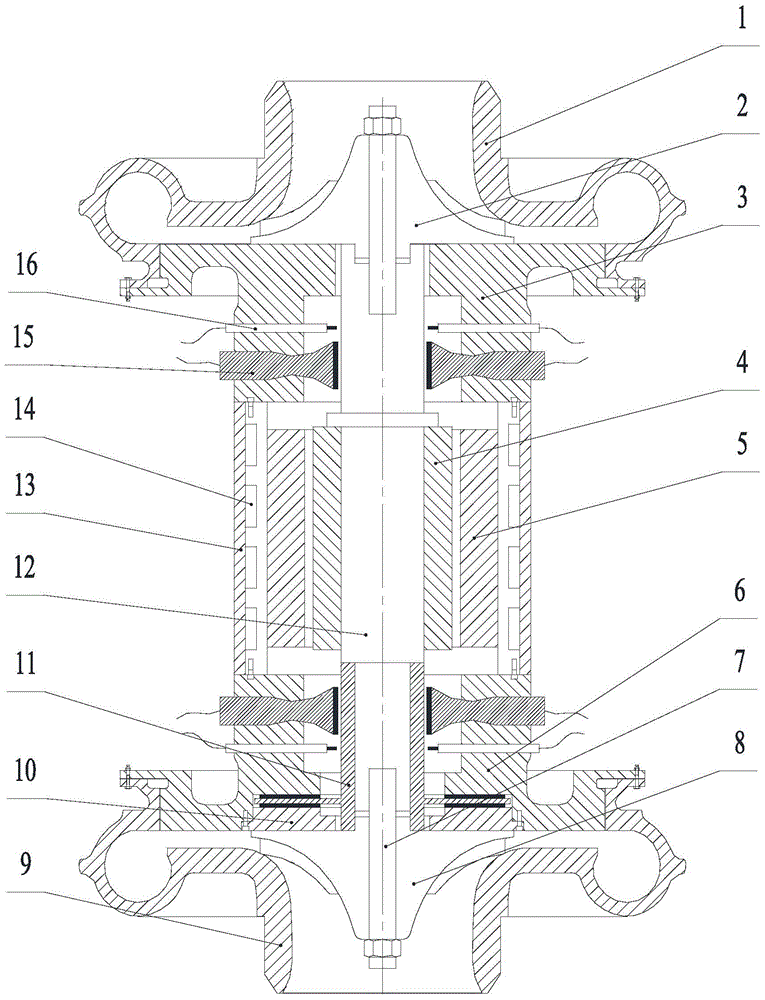

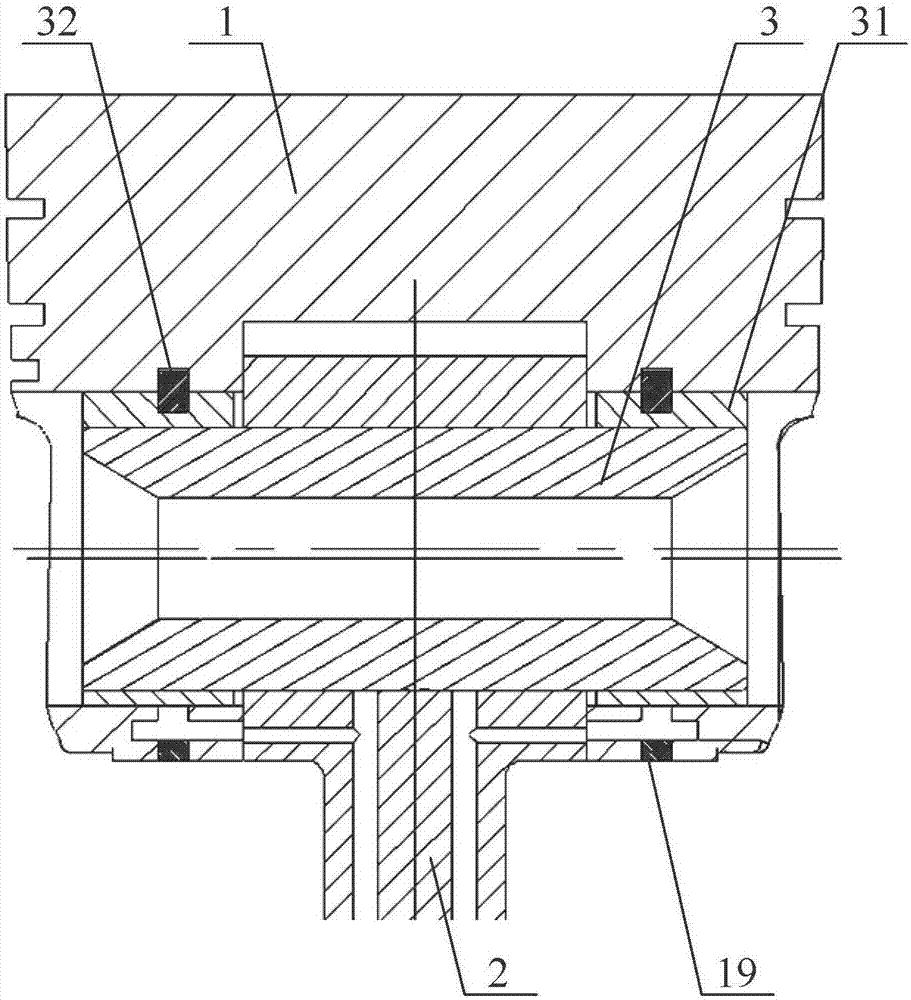

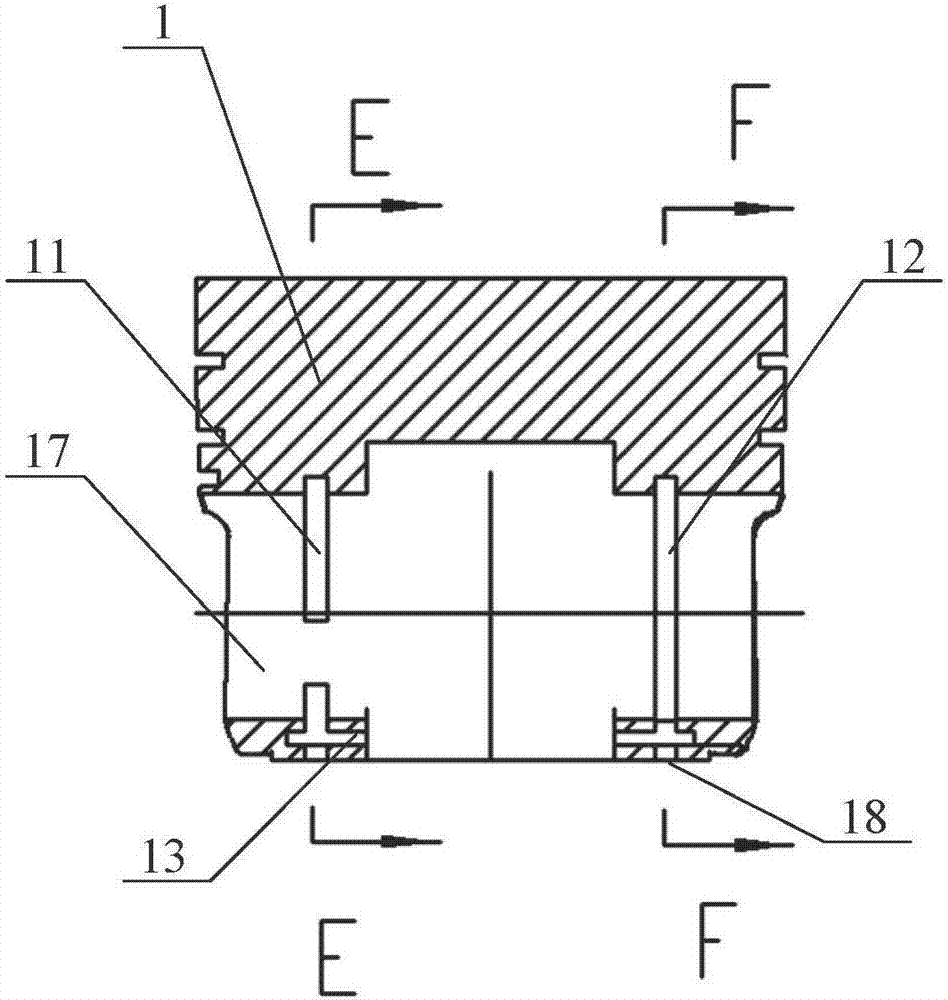

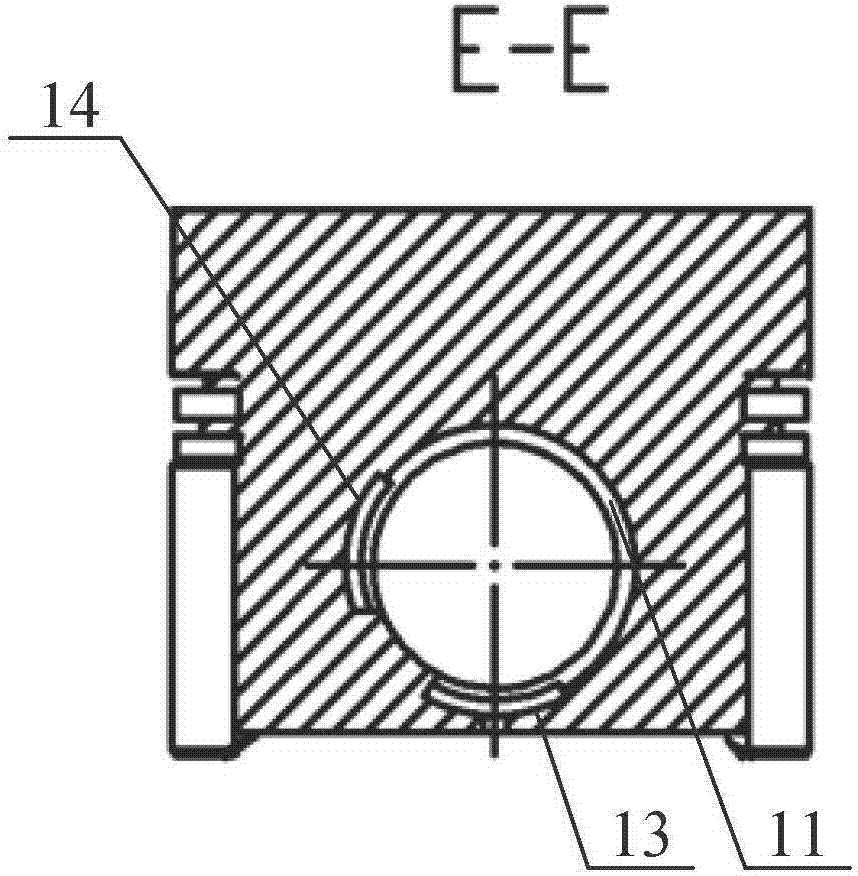

Air compressor with ultrasonic bearings

InactiveCN104895827AAvoid influenceApplicable intake pressurePump componentsPumpsImpellerAxial compressor

The invention relates to an air compressor with ultrasonic bearings. The air compressor with ultrasonic bearings comprises a shell, a motor stator, a motor rotor and a rotor shaft from outside to inside, and further comprises the ultrasonic bearings and a spiral groove type thrust bearing, wherein bearing bushes are arranged at the two ends of the shell, impellers are arranged at the two ends of the rotor shaft respectively, the impellers are sleeved with impeller shells, the impeller shells are in sealing connection with the bearing bushes and are provided with air inlets and air outlets, the air outlet of the impeller shell at one end is connected with the air inlet of the impeller shell at the other end, the ultrasonic bearings are arranged on the bearing bushes at the two ends and are in noncontact connection with the rotor shaft, the spiral groove type thrust bearing is arranged on the part, between the bearing bush at one end and the impeller at the same end, of the rotor shaft, and a thrust bearing cap is arranged between the spiral groove type thrust bearing and the corresponding impeller. Compared with the prior art, the air compressor with ultrasonic bearings has the advantages of being high in rotation speed and efficiency, long in service life, free of lubricating oil and the like.

Owner:HUNAN UNIV +1

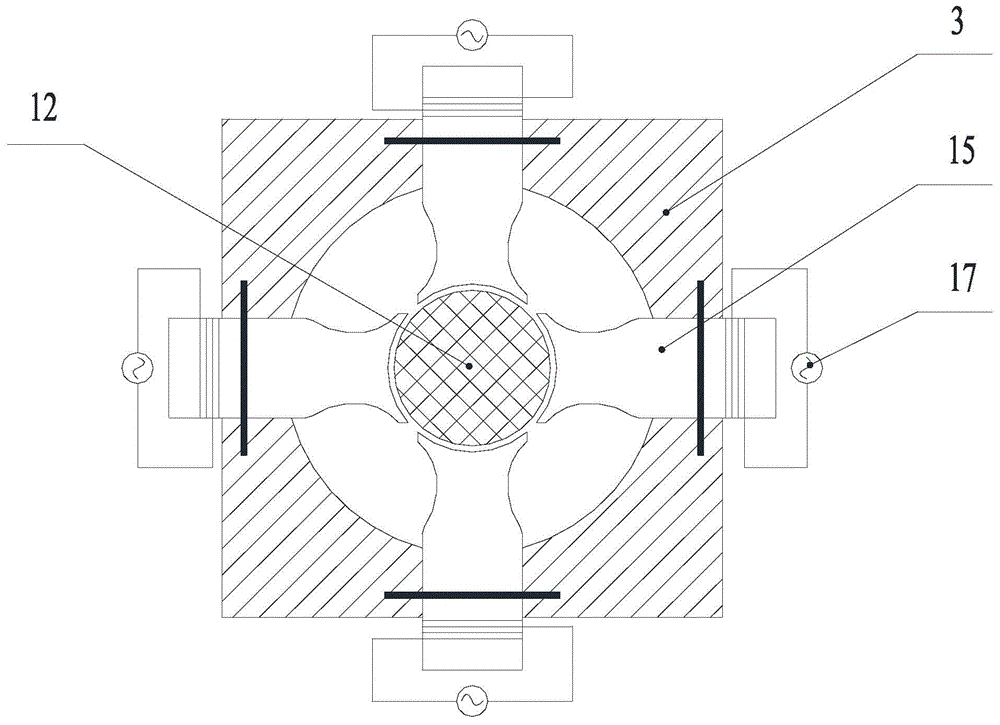

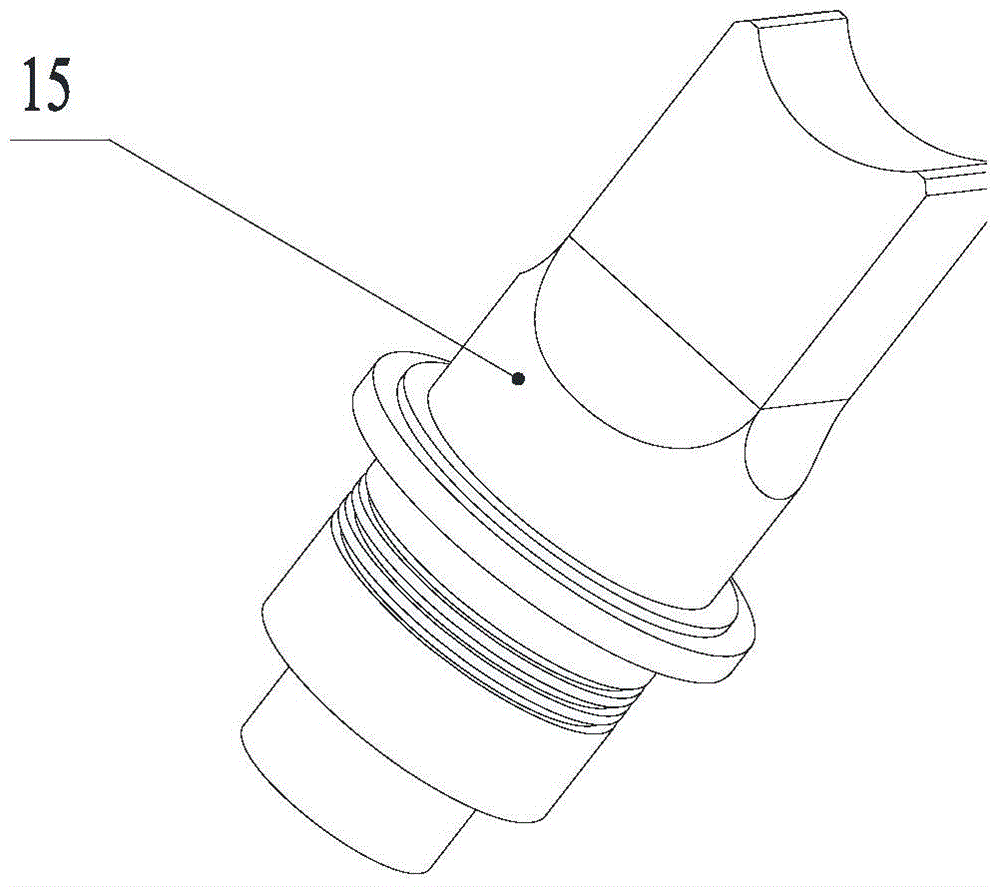

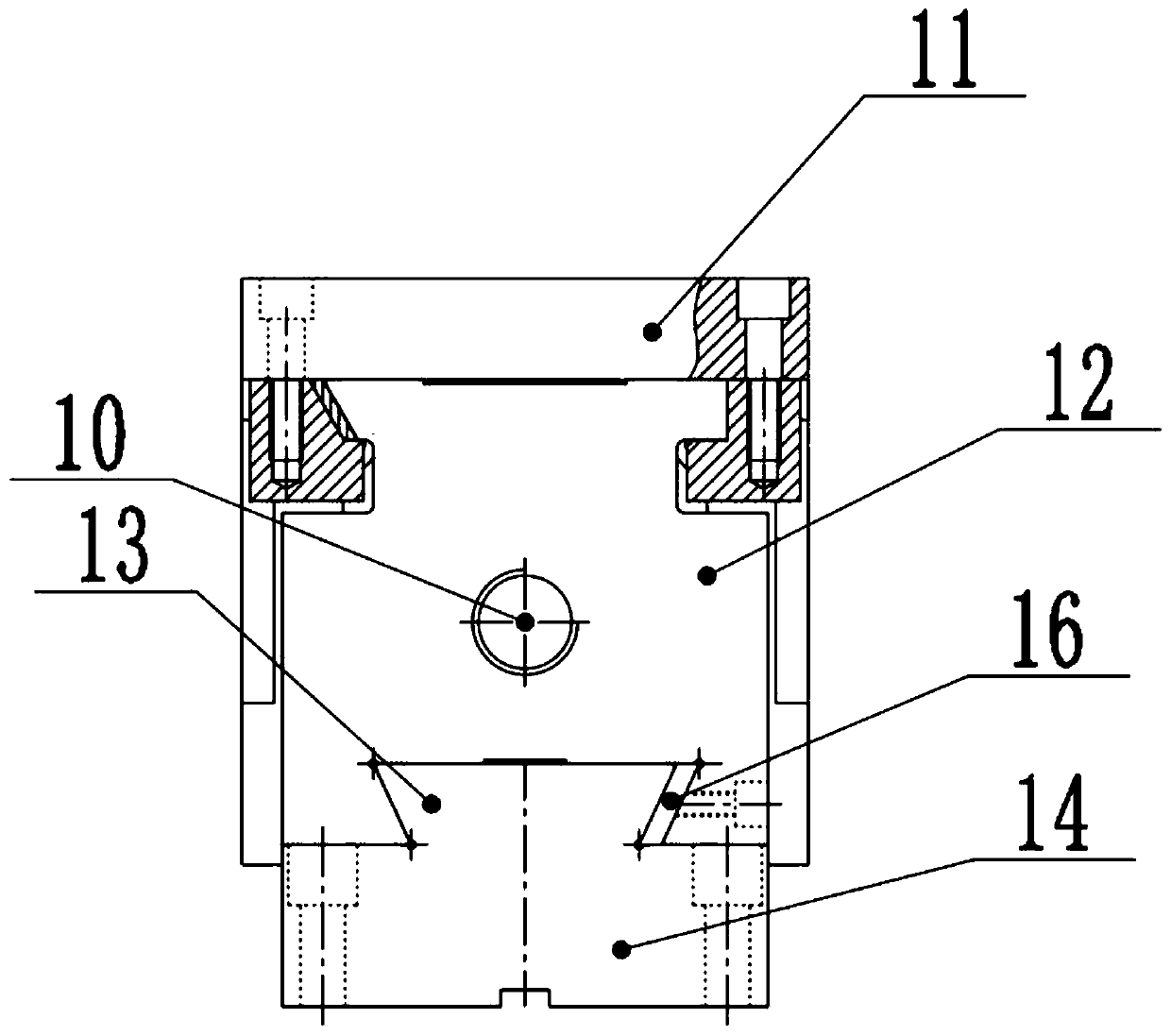

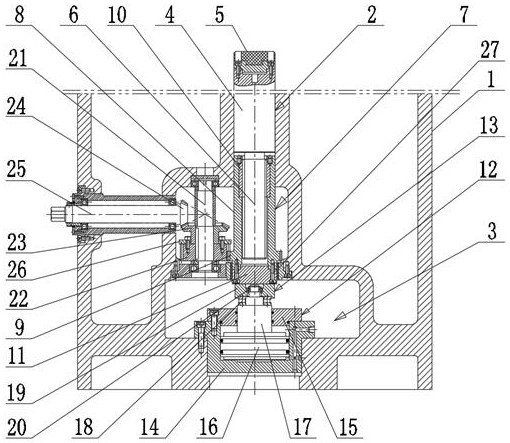

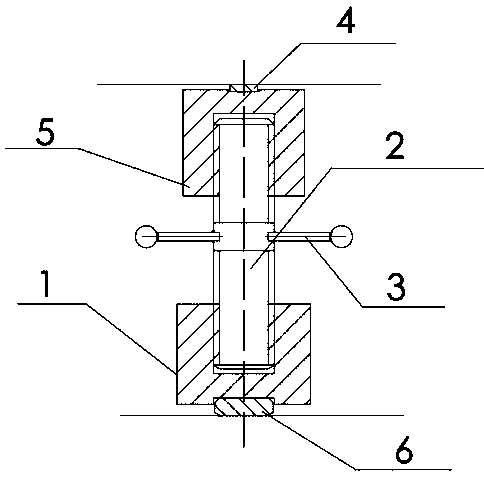

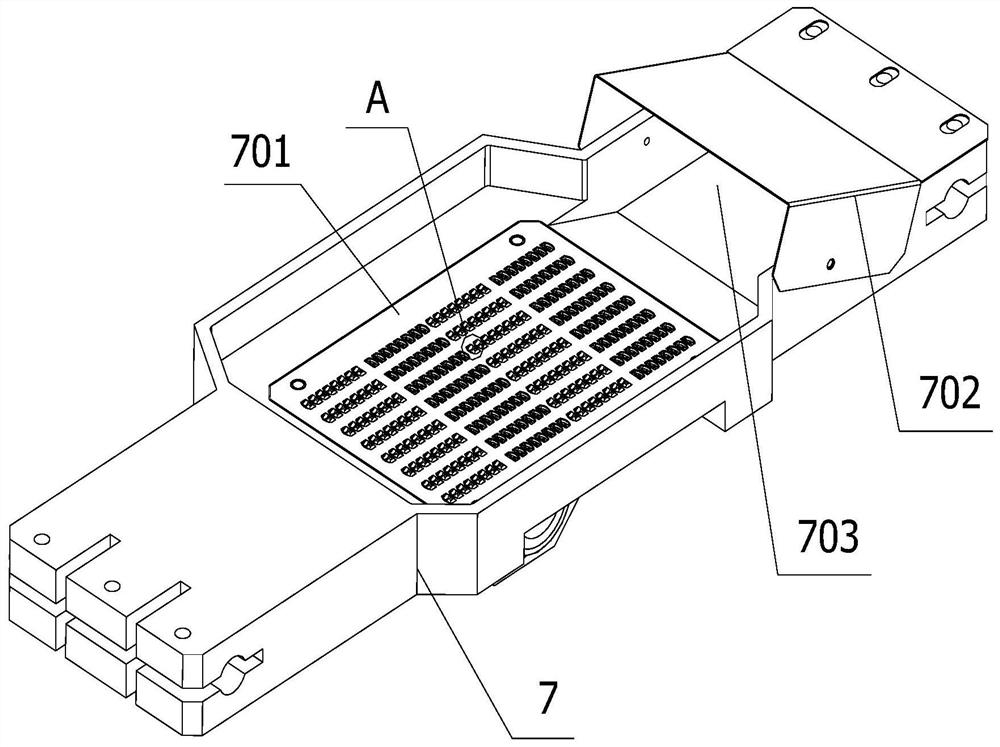

Tactile stimulating device with measurable tactile stimulating force and adjustable force frequency

ActiveCN106249904ASimple structural designHighly integratedInput/output for user-computer interactionGraph readingBiological bodyForce frequency

The invention relates to a tactile stimulating device with measurable tactile stimulating force and adjustable force frequency. The tactile stimulating device comprises an alternating current motor mechanism which is used for sending a pulse and driving an eccentric wheel to rotate, an elastic steel ruler mechanism for generating elastic deformation, an eccentric wheel mechanism for generating force data, and a probe mechanism which is used for generating a displacement in the vertical direction to change to stimulate the epidermis of a living organism, wherein the alternating current motor mechanism is fixedly connected with the eccentric wheel mechanism; the eccentric wheel of the eccentric wheel mechanism is closely attached to an elastic steel ruler of the elastic steel ruler mechanism; and the probe mechanism is fixedly arranged on the lower end surface of the elastic steel ruler mechanism. The tactile stimulating device is simple in structural design, high in integration degree and safe to work; an electromagnetic material covers the outer surface of an alternating current motor to form an electromagnetic shielding device, so that interference is basically eliminated, and the signal stability is high; by the adoption of a noninvasive mechanical stimulation mode, no wound can be caused in the use process; and as the frequency can be adjusted and the stimulating strength can be adjusted, the force action is stable, and the tactile stimulation within a relatively wide frequency range can be flexibly modulated.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

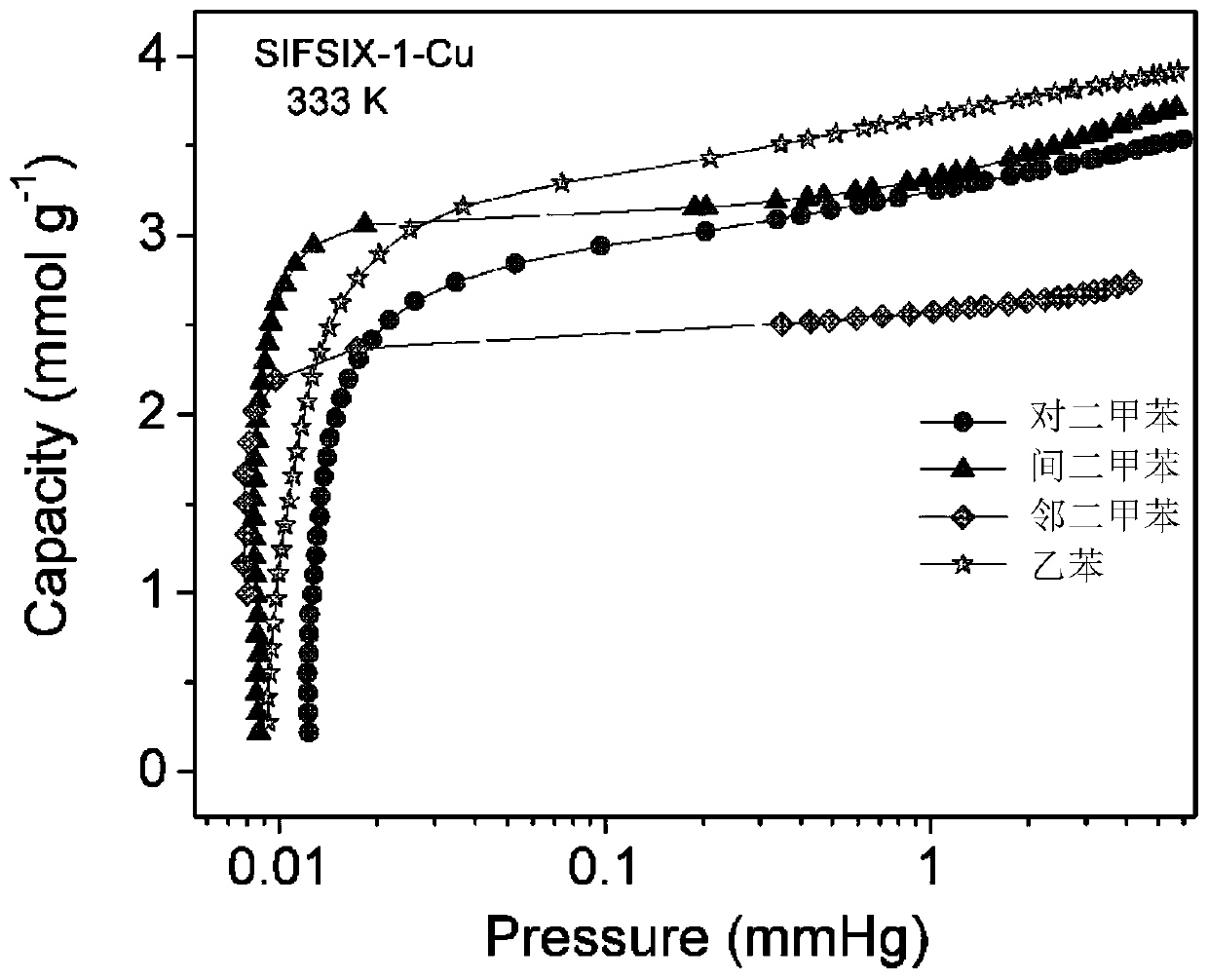

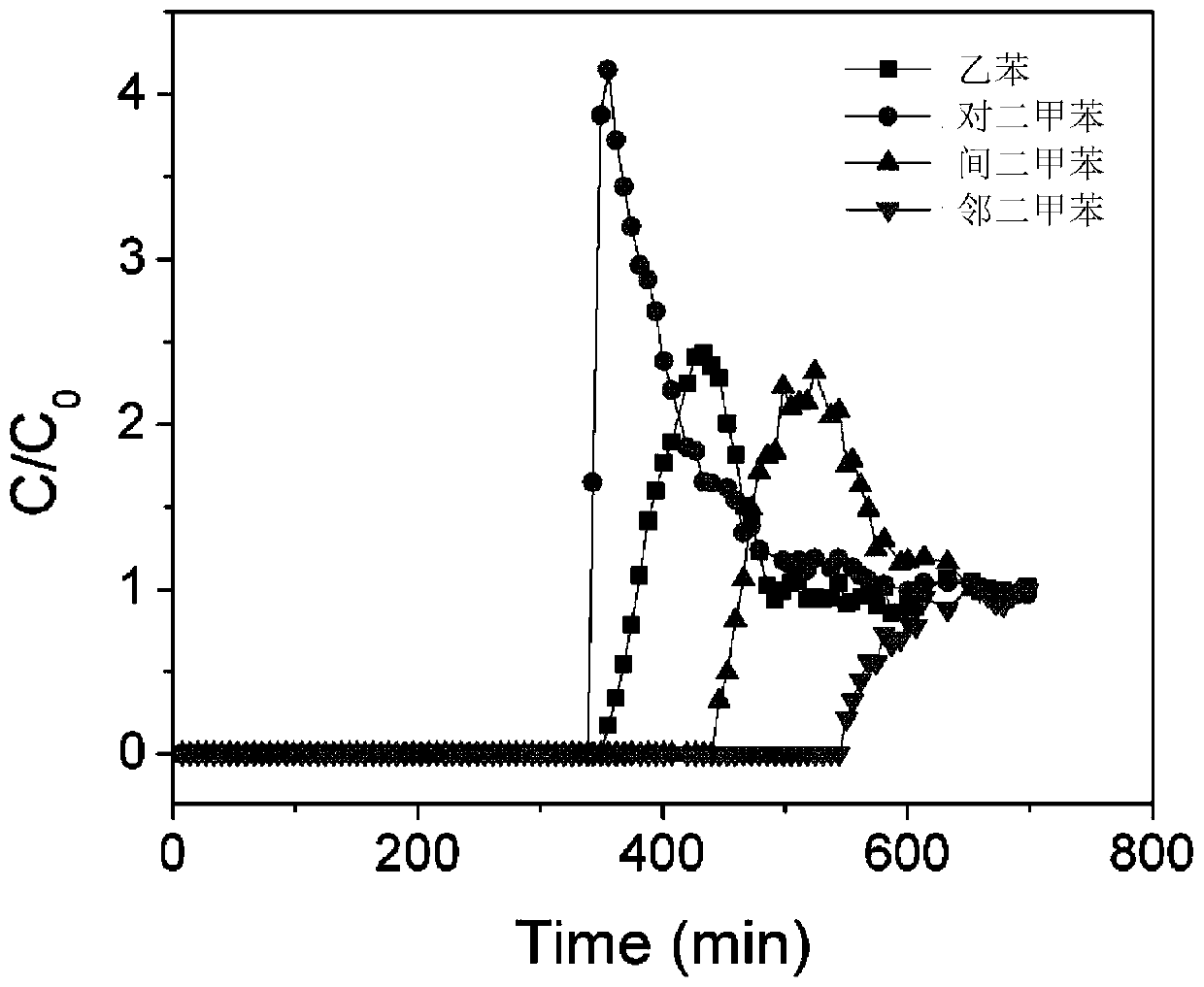

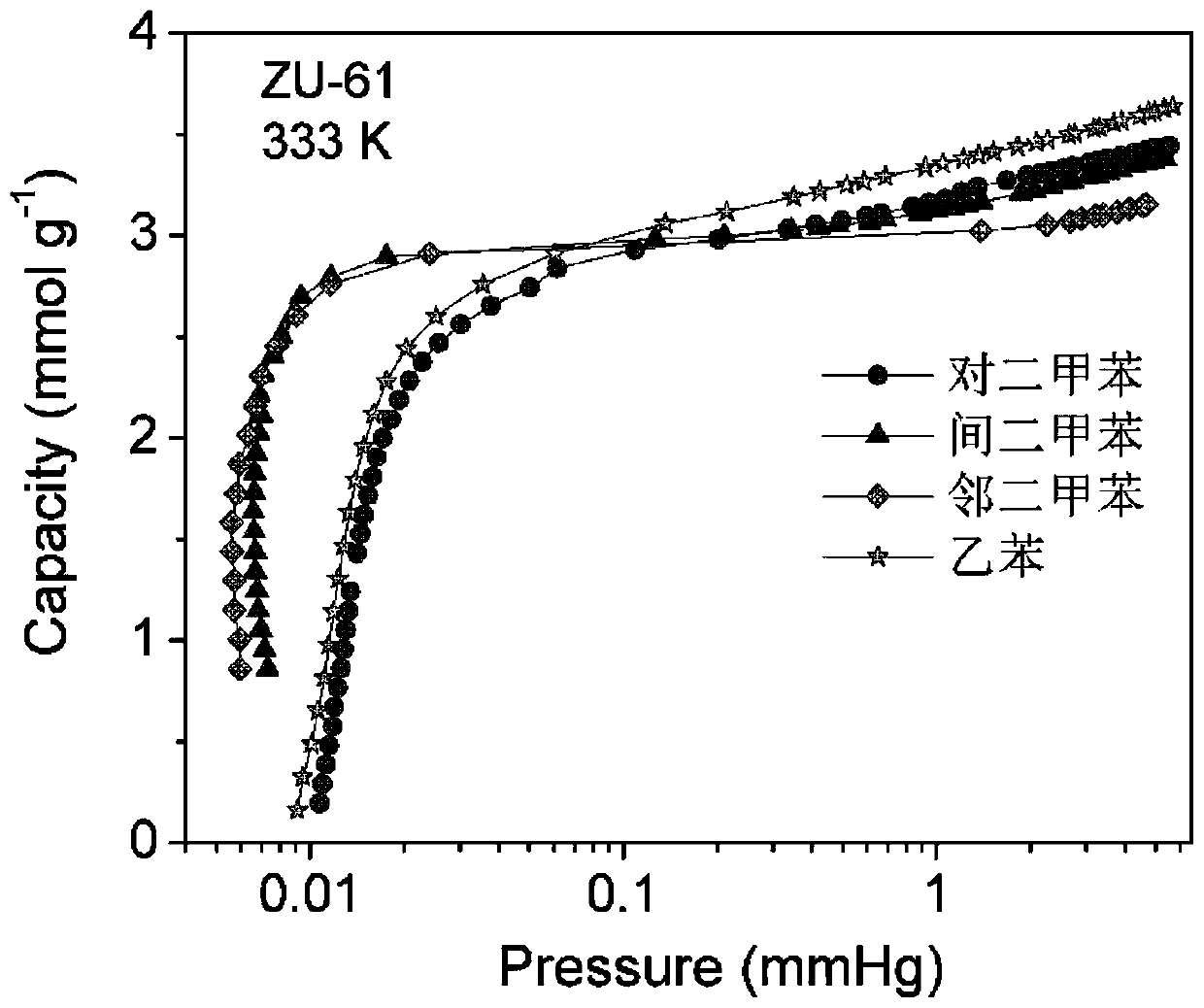

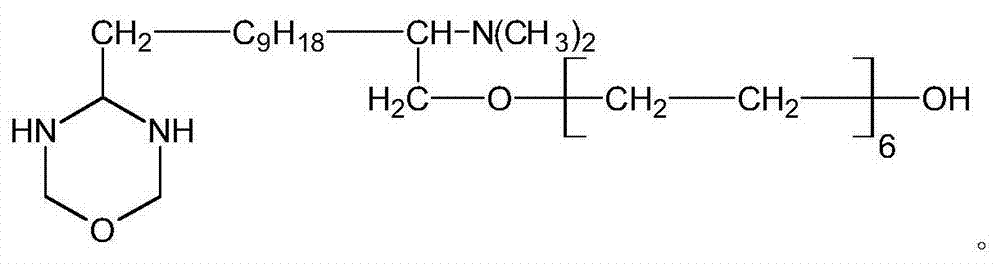

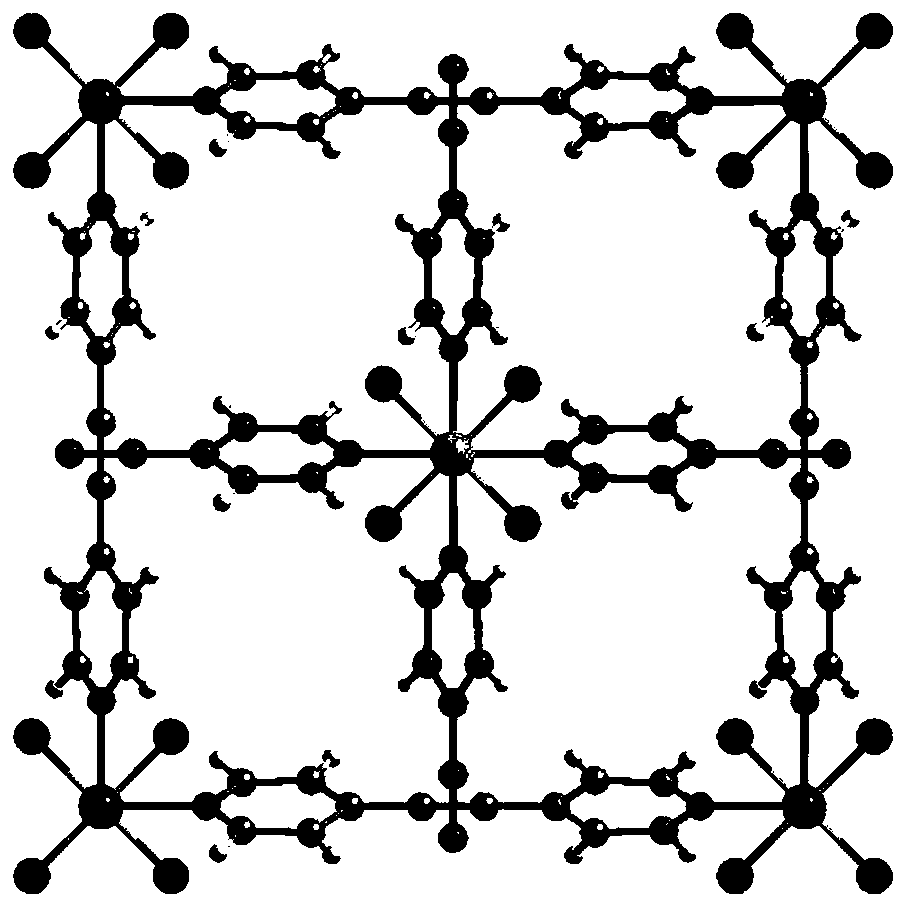

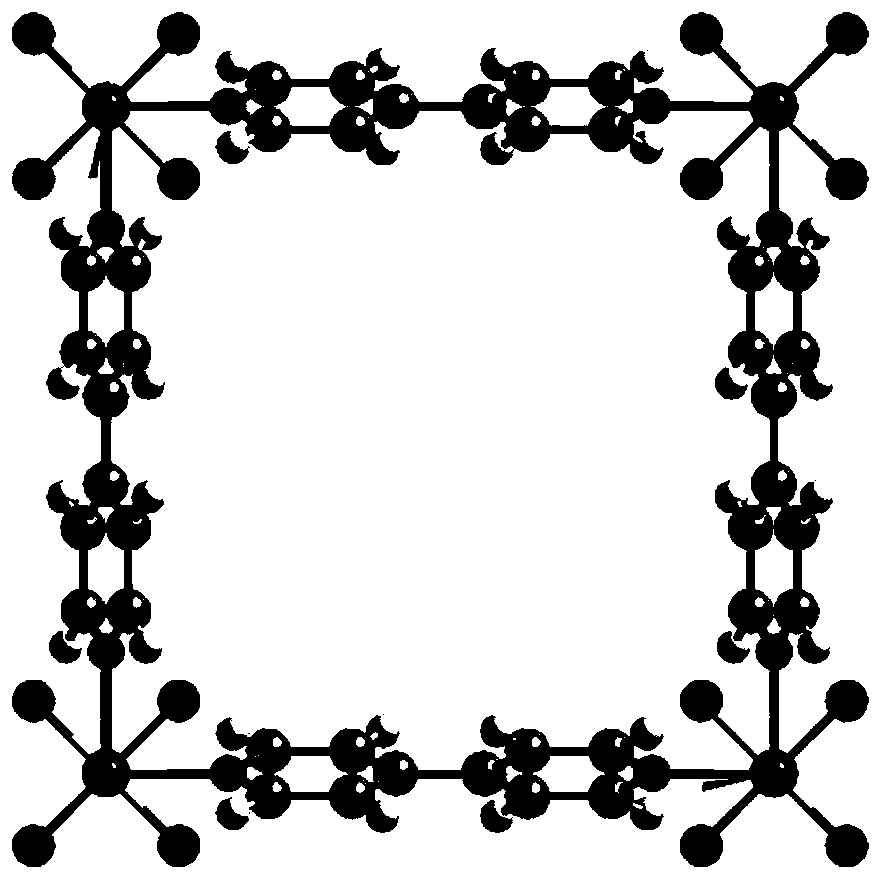

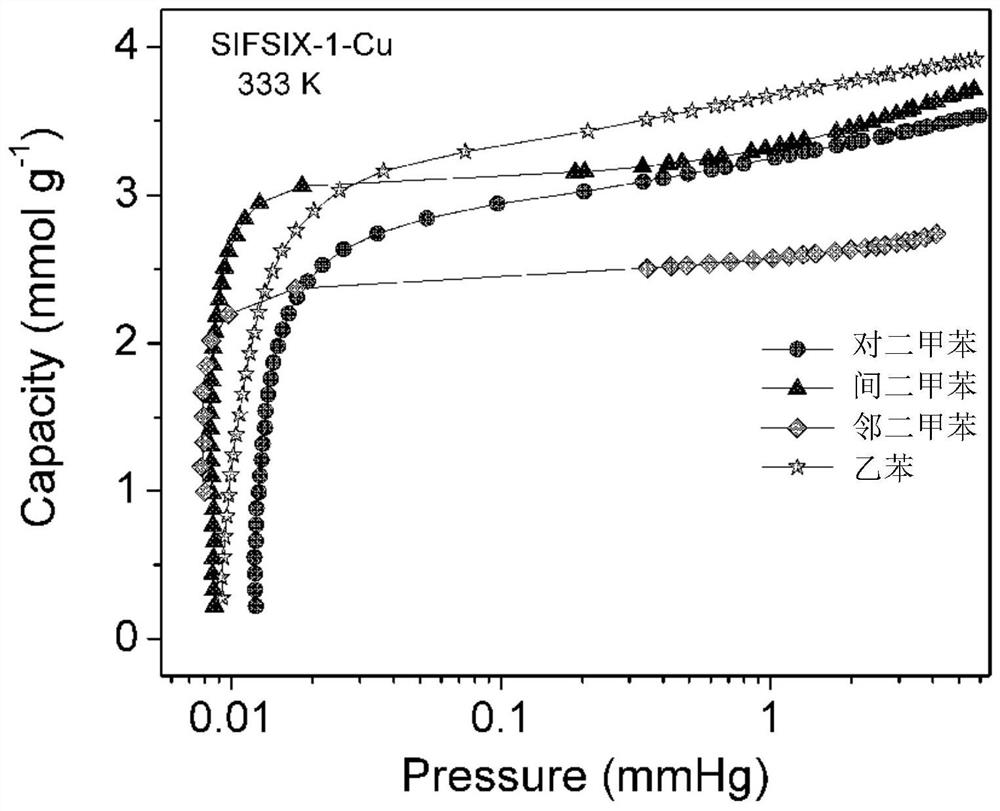

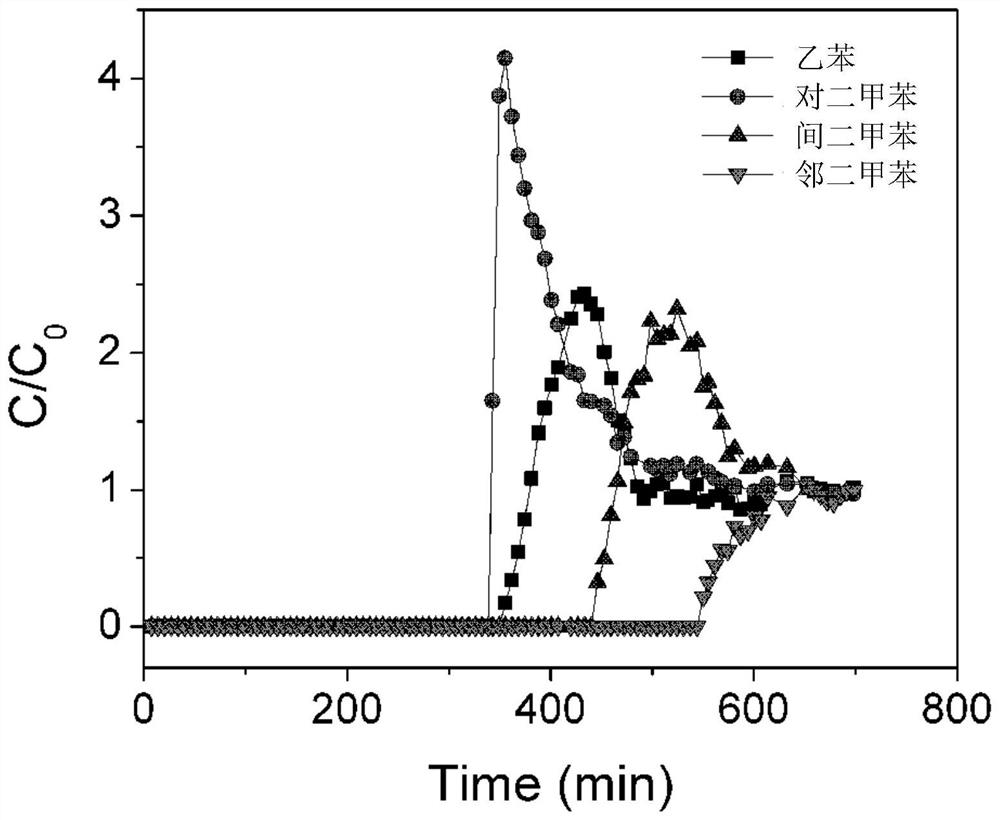

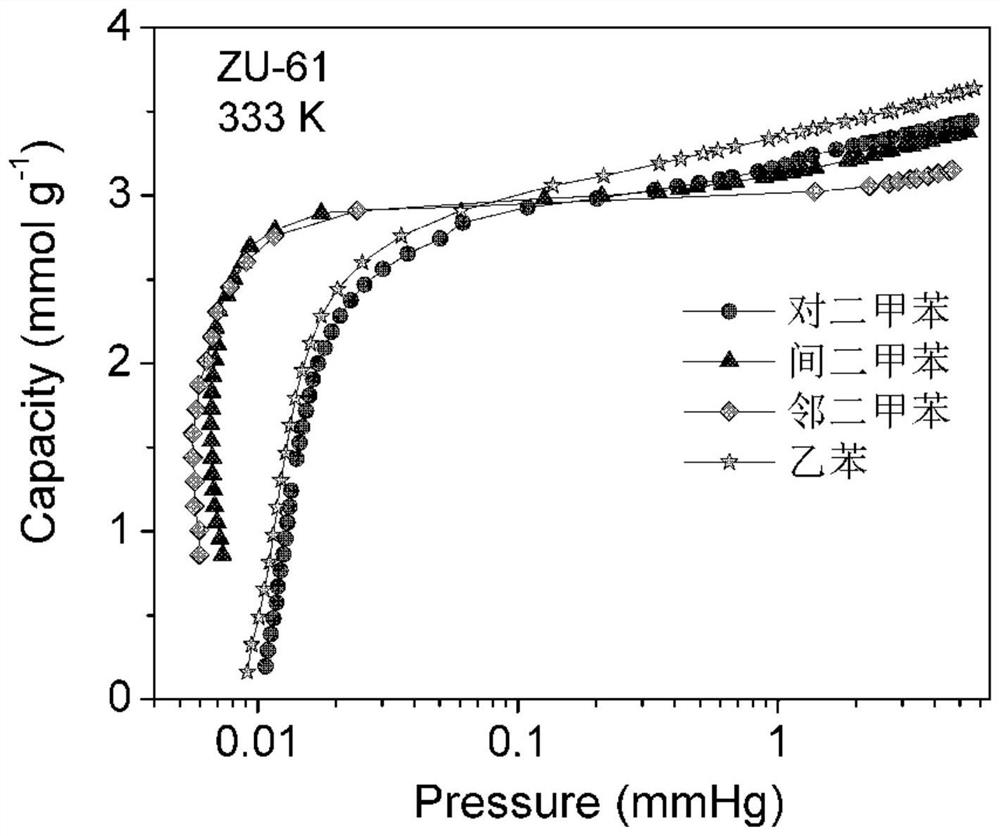

Method for separating C8 aromatic hydrocarbon isomeride mixture

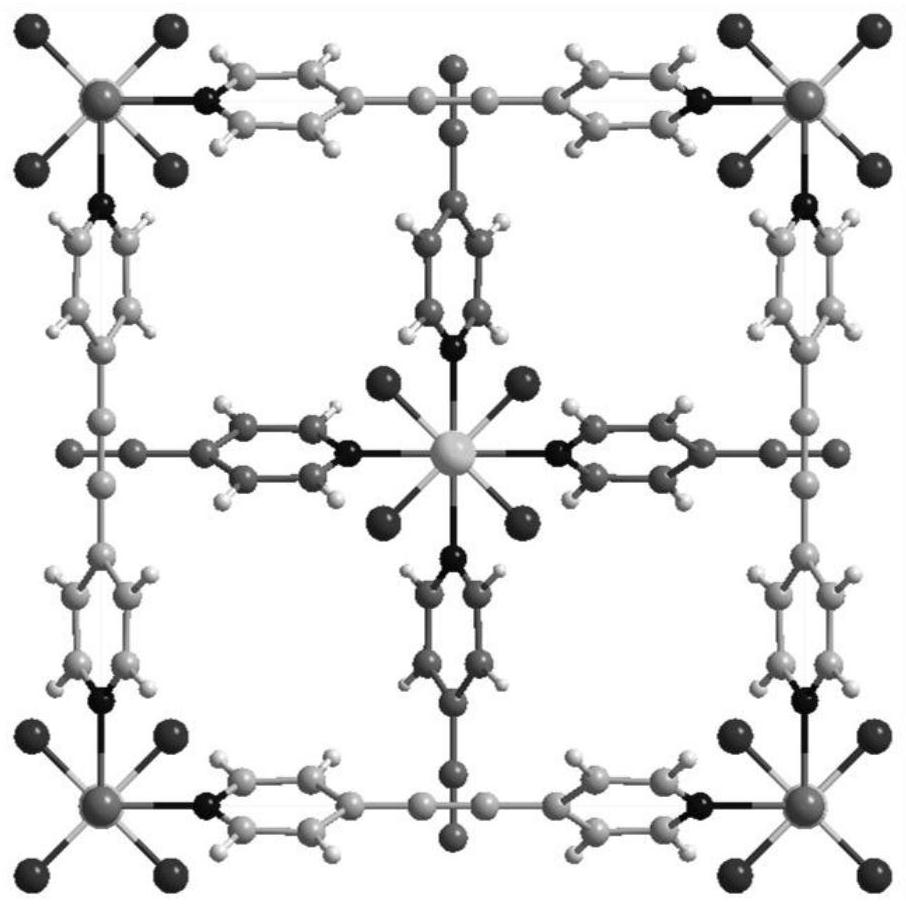

ActiveCN111410596AAdjustable forceHigh separation selectivityGas treatmentChemical industryPhysical chemistryAromatic hydrocarbon

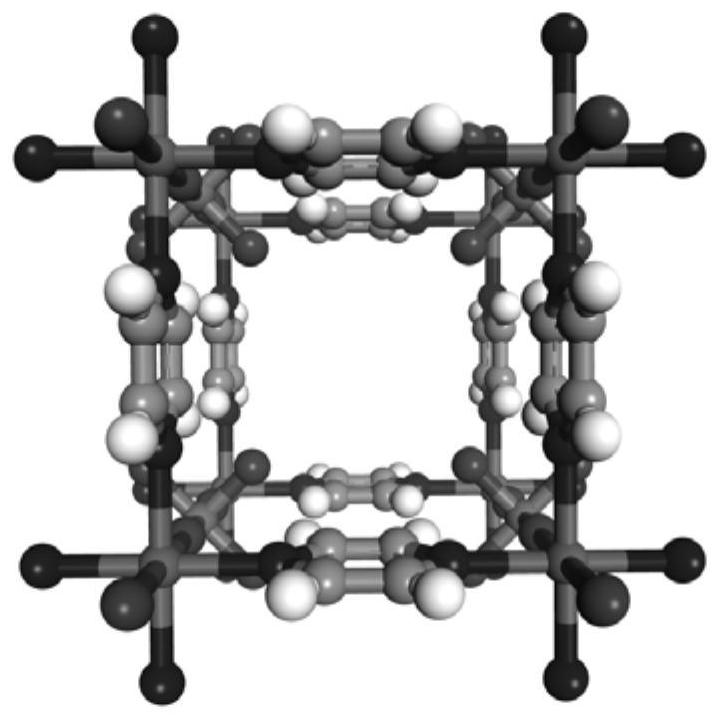

The invention discloses a method for separating a C8 aromatic hydrocarbon isomeride mixture, which comprises the following steps of: contacting the C8 aromatic hydrocarbon isomeride mixture with an adsorbent which is an anionic pillared microporous material of which the pore diameter is in the range of 5-10 microns to realize selective adsorption separation of the C8 aromatic hydrocarbon isomeridemixture, wherein the anionic pillared microporous material is a porous material formed by metal ions M, inorganic anions A and organic ligands L through coordination bonds, the general formula of theanionic pillared microporous material is [MAL2]n, and n is larger than 4 and is an integer, the metal ion M is Fe<2+>, Co<2+>, Ni<2+> or Cu<2+>, the inorganic anion A is SiF6<2->, NbOF5<2->, TaF7<2->, ZrF6<2->, TiF6<2->, GeF6<2->, SO3CF3<-> or NbF6<->, and the organic ligand L is selected from the following structure shown in the specification as shown in the description.

Owner:ZHEJIANG UNIV

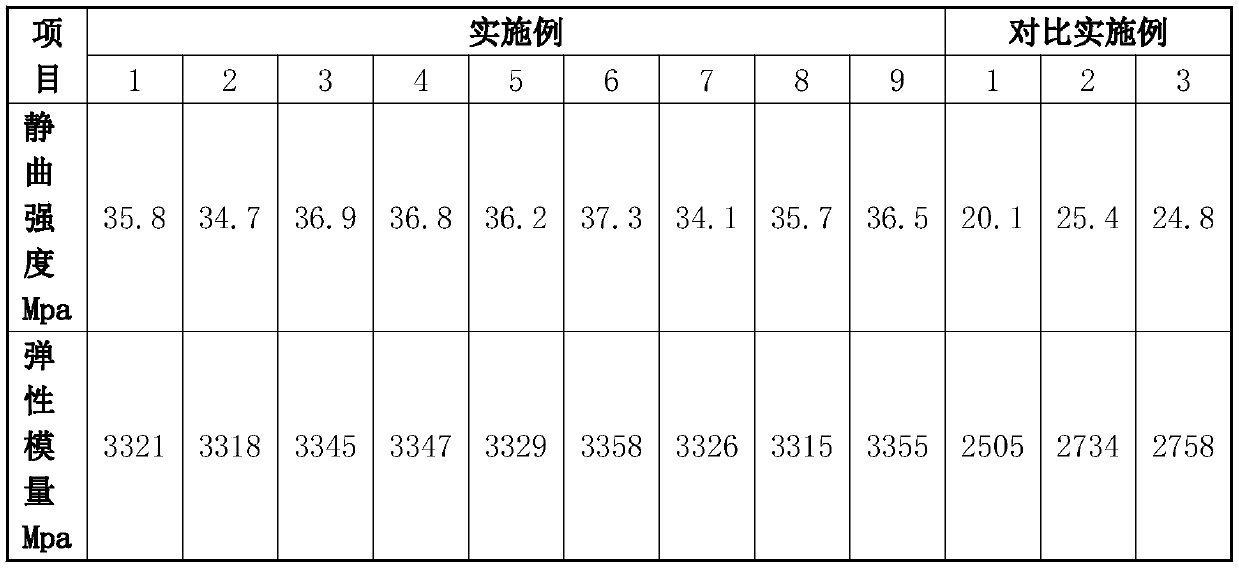

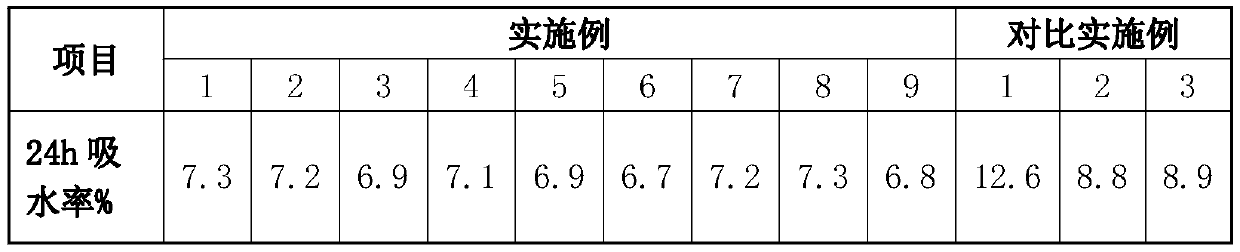

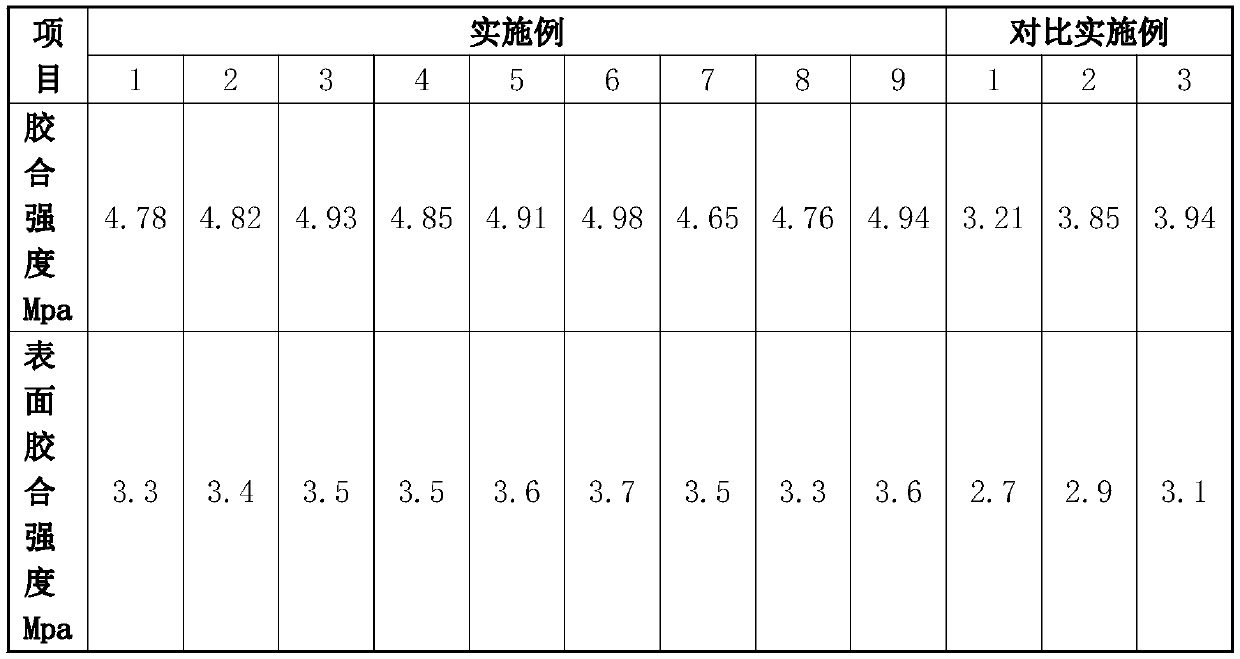

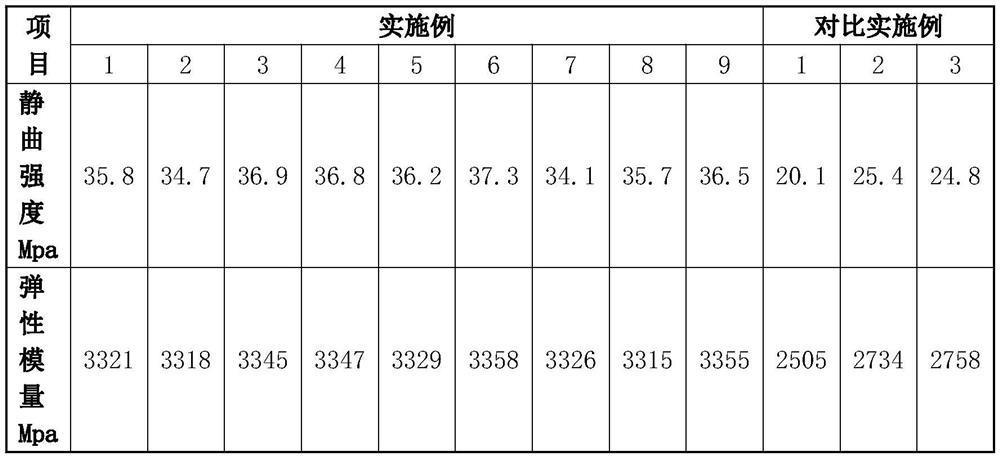

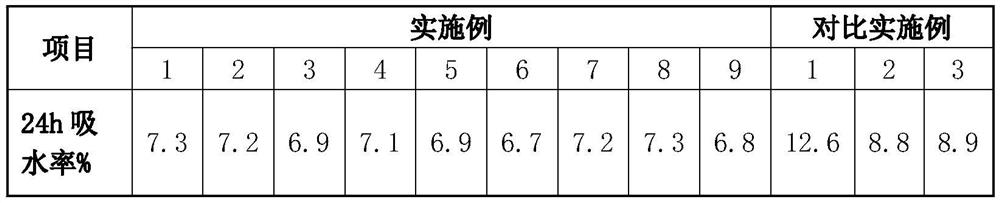

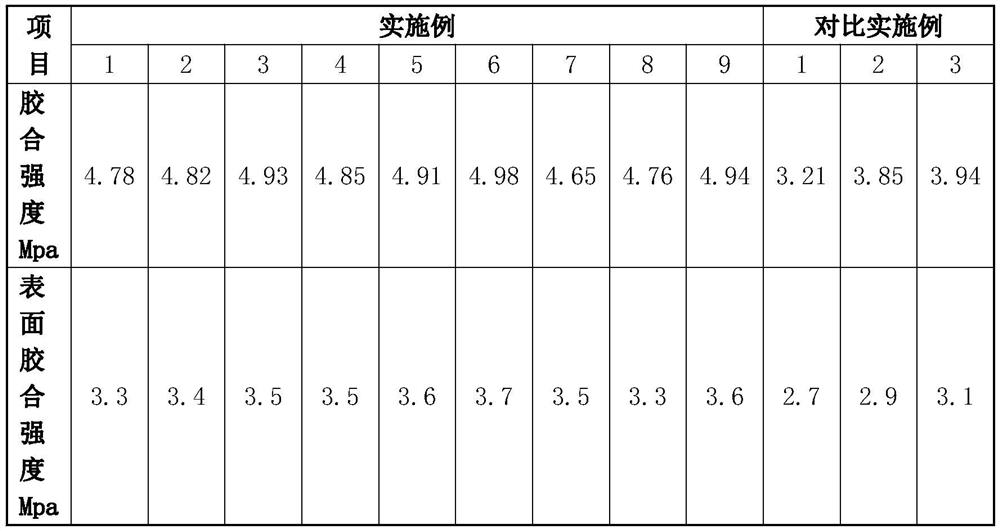

Aluminum-wood heterogeneous composite engineered wood

ActiveCN110861372AWith glossy decorative effectImprove rigidity and toughnessNon-macromolecular adhesive additivesDomestic upholsteryAdhesive cementSingle plate

The invention relates to engineered wood, and in particular, relates to aluminum-wood heterogeneous composite engineered wood. The aluminum-wood heterogeneous composite engineered wood sequentially comprises an Ayous veneer layer, more than one group of second blank plate layers and an Ayous veneer layer; the second blank plate layers are each formed by compounding, pressurizing and gluing a firstblank plate layer, an aluminum plate and a second blank plate layer, and the first blank plate layer is formed by recombining more than one Ayous veneer. A preparation method comprises the followingsteps: (1) recombining more than one Ayous veneer by coating a first adhesive to prepare the first blank plate layer; (2) coating the single surface of each of two blank plates A with a second adhesive, and compounding, pressurizing and gluing with a pretreated aluminum plate to obtain the second blank plate layer; (3) compounding, recombining, pressurizing and curing the second blank plate layersand the Ayous veneer coated with a third adhesive, and thus obtaining the aluminum-wood heterogeneous composite engineered wood batten; and (4) slicing. The aluminum-wood heterogeneous composite engineered wood is not prone to cracking and good in stability and has the metallic luster decoration effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

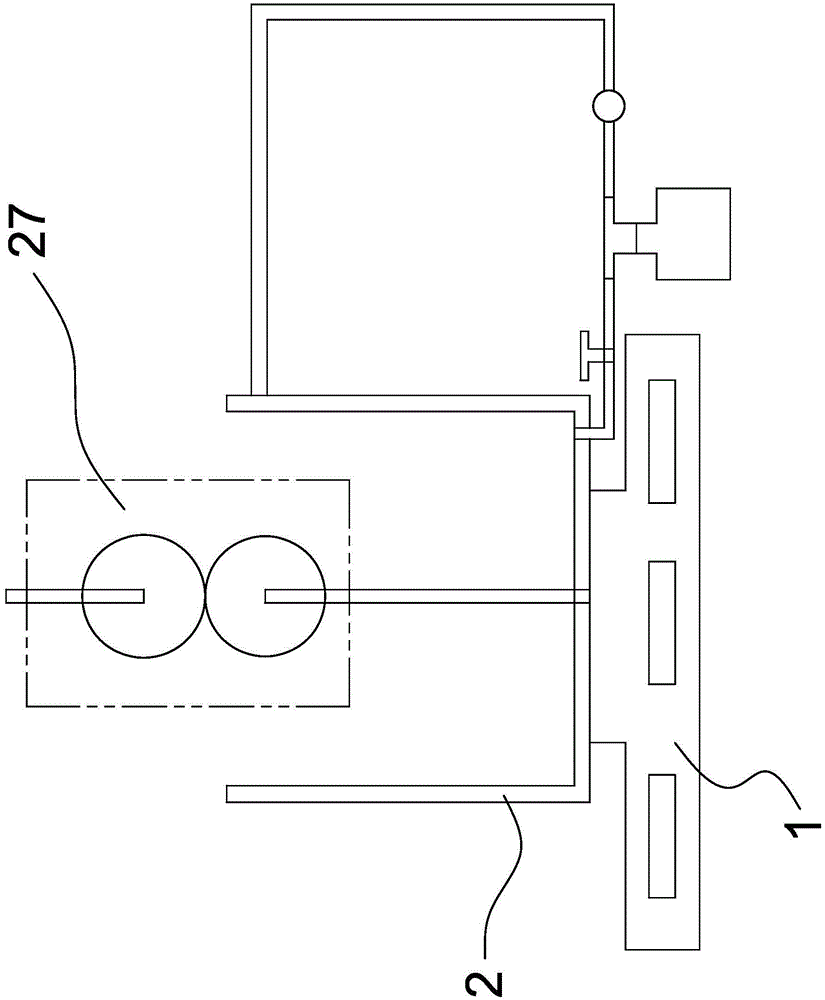

Coating roll assembly of coating machine

InactiveCN104607353AStable clampingUniform coatingLiquid surface applicatorsCoatingsMechanical engineeringDyeing

The invention provides a coating roll assembly of a coating machine, belongs to the technical field of printing and dyeing, and solves the technical problems that the existing coating device is non-uniform in coating, poor in coating effect, poor in adaptability and the like. The coating roll assembly of the coating machine is characterized by comprising an upper roller and a lower roller, the lower roller is axially fixed on a stander in a circumferential rotating manner, the lower roller is arranged in a coating solution trough, the upper roller is axially fixedly arranged right above the lower roller and is against the lower roller in a circumferential rotating manner, the upper roller and the lower roller are parallel to each other, the upper roller is connected with a force application mechanism which is used for enabling the upper roller to contact the lower roller and generating given pressure, and the lower roller is connected with a rotating mechanism capable of driving the lower roller to rotate. The coating roll assembly of the coating machine has advantages of good coating effect, wide application range and the like.

Owner:中山市通成包装设备有限公司

Pesticide sustained release granule containing thiamethoxam and preparation method thereof

ActiveCN104839195APrevent curingHydrophilicBiocideAnimal repellantsAnhydrous Calcium SulfateThiamethoxam

The invention discloses a pesticide sustained release granule containing thiamethoxam and a preparation method thereof, wherein the pesticide sustained release granule is prepared from the following raw materials in parts by weight: thiamethoxam, anhydrous calcium sulfate, kaolin, other carriers, membrane material and white carbon black, and the membrane material is calculated in parts by mass and comprises the following components: 0.1-15 percent of displacer, 5-60 percent of curing agent, 0.01-5 percent of membrane filter agent, 0.2-5 percent of passivation material, and the balance of cross-linking agent, wherein the structure of displacer is similar with that of the thiamethoxam, and the pesticide sustained release granule is sequentially prepared according to the following steps of mixing, prilling, spraying membrane firstly, spraying membrane secondly, protecting granule, toning, checking and packaging, and the effective constituent of the pesticide sustained release granule is similar with that of the displacer, gradually penetrates outward, and the sustained release period is long, the pesticide effect is stable, the preparation method is simple and the cost is low.

Owner:青岛海纳生物科技有限公司

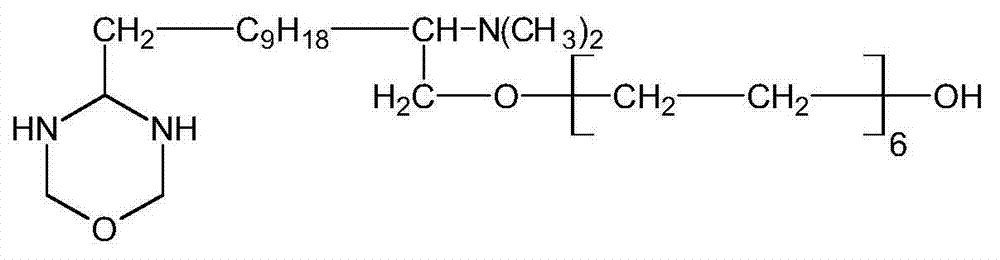

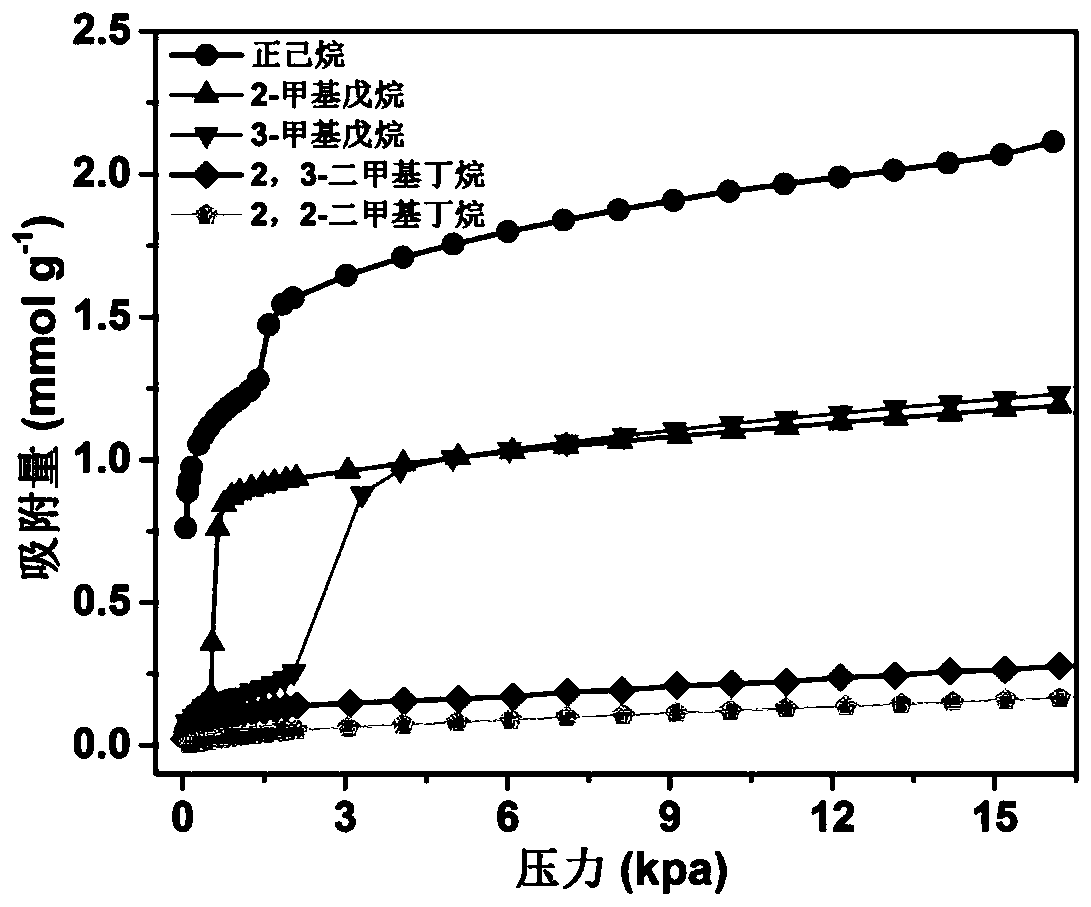

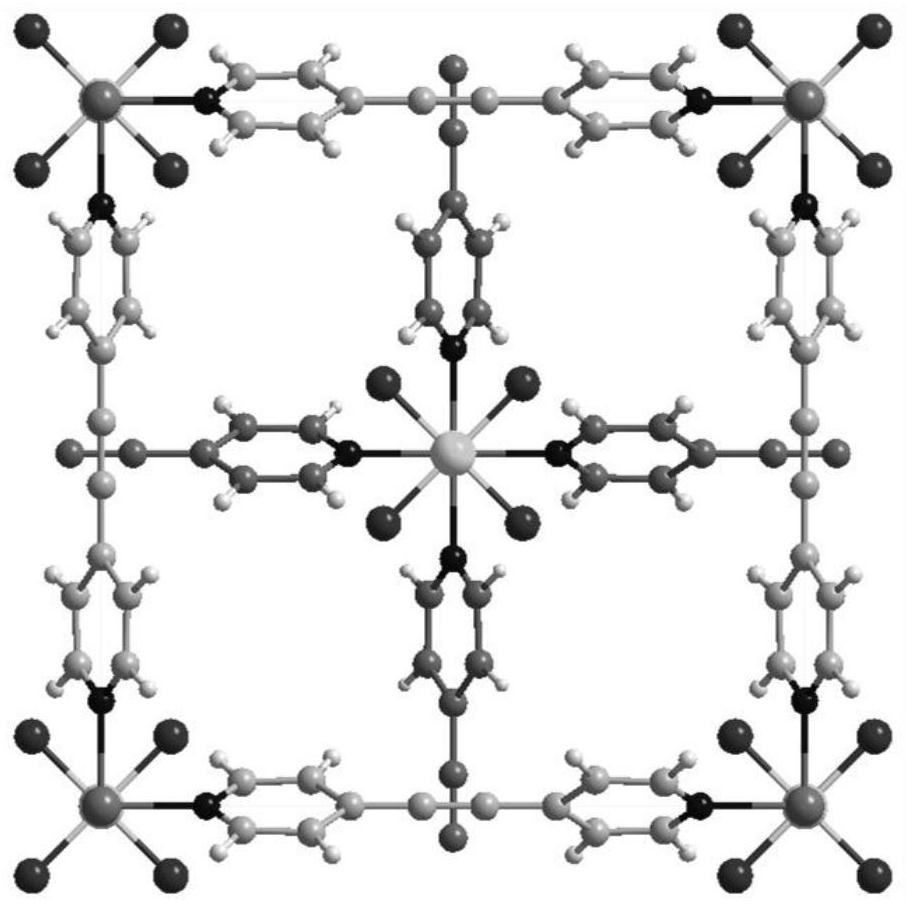

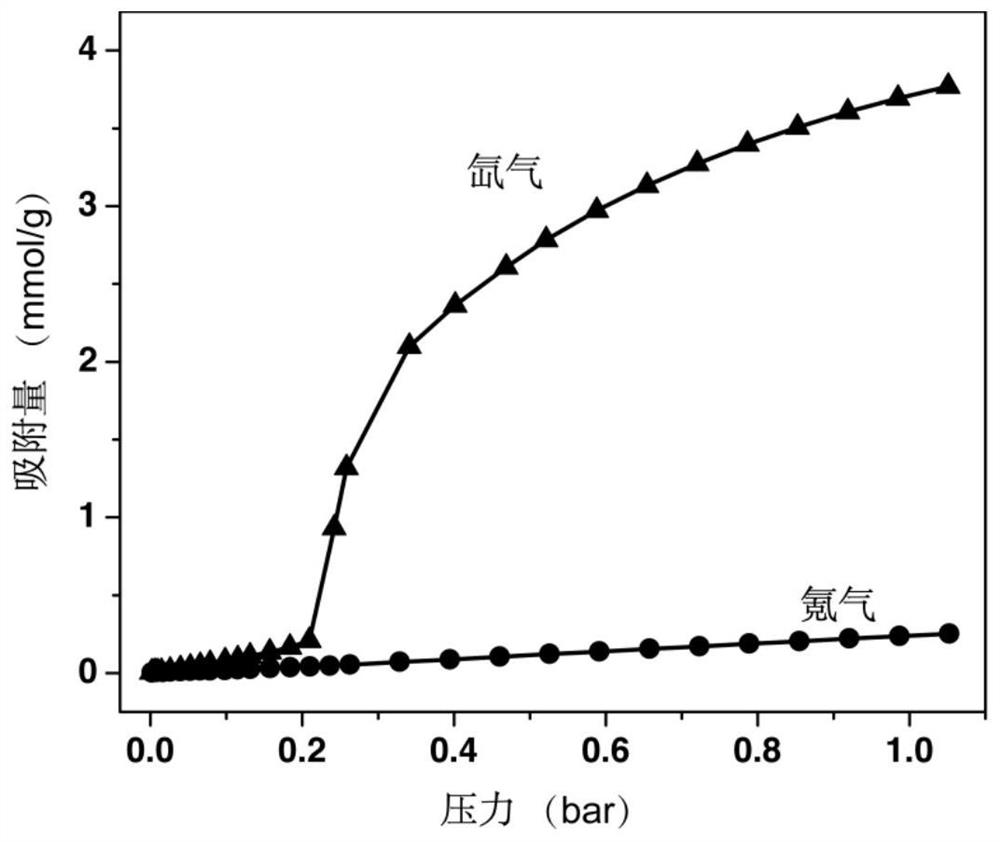

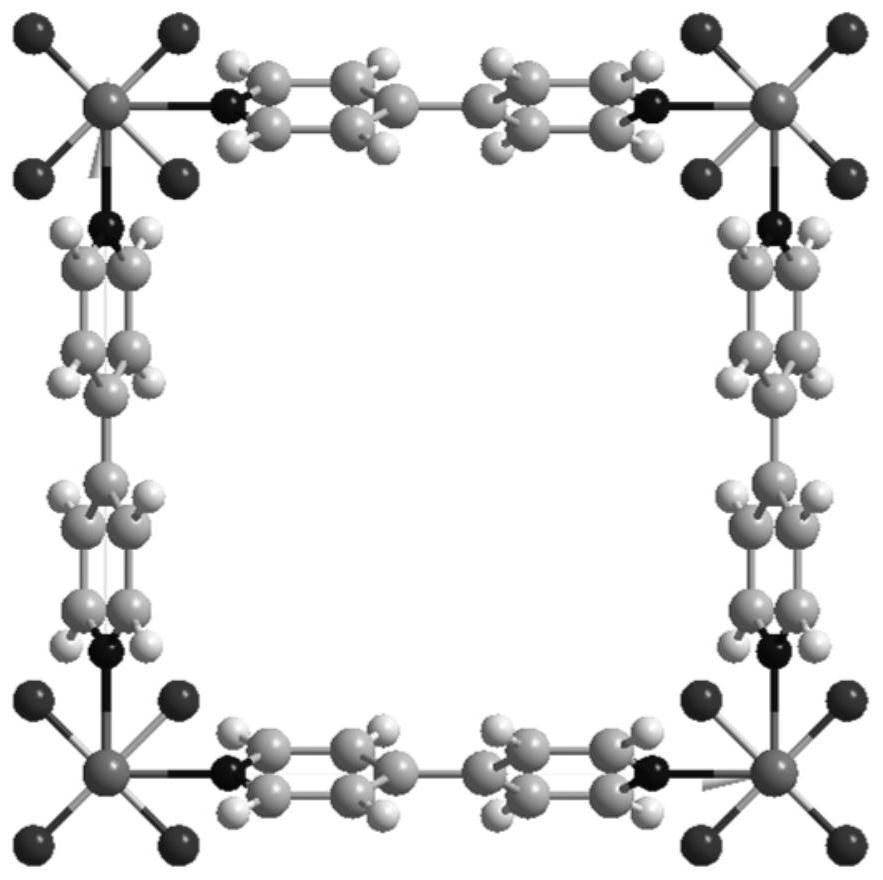

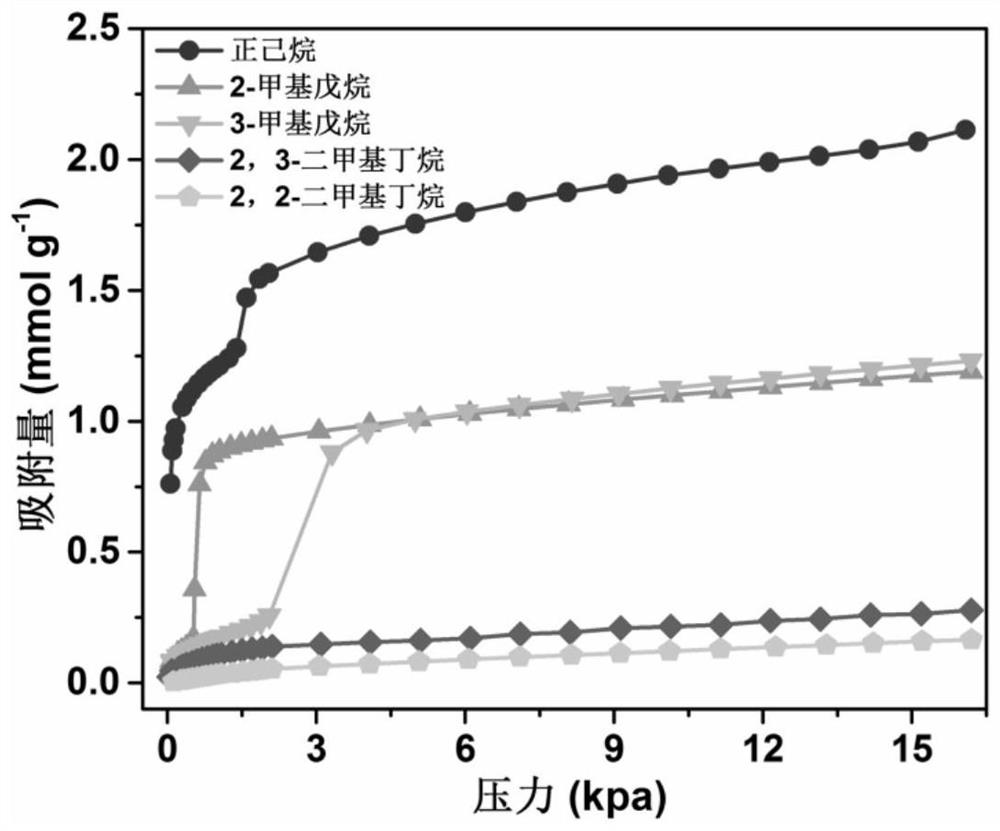

Separation method of isomerized oil

ActiveCN111575047ABoost octaneWith flexible functionAdsorption purification/separationHydrocarbon oils refiningIsomerizationPhysical chemistry

The invention discloses a separation method of isomerized oil. The isomerized oil contains C5-C8 low-octane-number alkane and high-octane-number alkane. The low-octane-number alkane comprises at leastone of n-alkane and single-branched-chain alkane, and the high-octane-number alkane comprises multi-branched-chain alkane; according to the separation method, a fluorine-containing anionic hybrid porous material with a flexible function is used as a separation adsorbent, and the separation adsorbent is in contact with the isomerized oil to realize selective adsorption separation of the low-octanealkane and the high-octane alkane; the structural general formula of the fluorine-containing anion hybrid porous material is M-L1-A or M-L2-A, and M is a metal ion and is selected from Cu < 2 + >, Zn< 2 + >, Co < 2 + > or Ni < 2 + >, wherein A is an inorganic fluorine-containing anion and is selected from SnF6 < 2->, ZrF6 < 2->, GeF6 < 2->, SiF6 < 2-> or TiF6 < 2->; L1 is an organic ligand 1, 2-dipyridyl acetylene; and L2 is an organic ligand 4, 4 '-dipyridyl.

Owner:ZHEJIANG UNIV

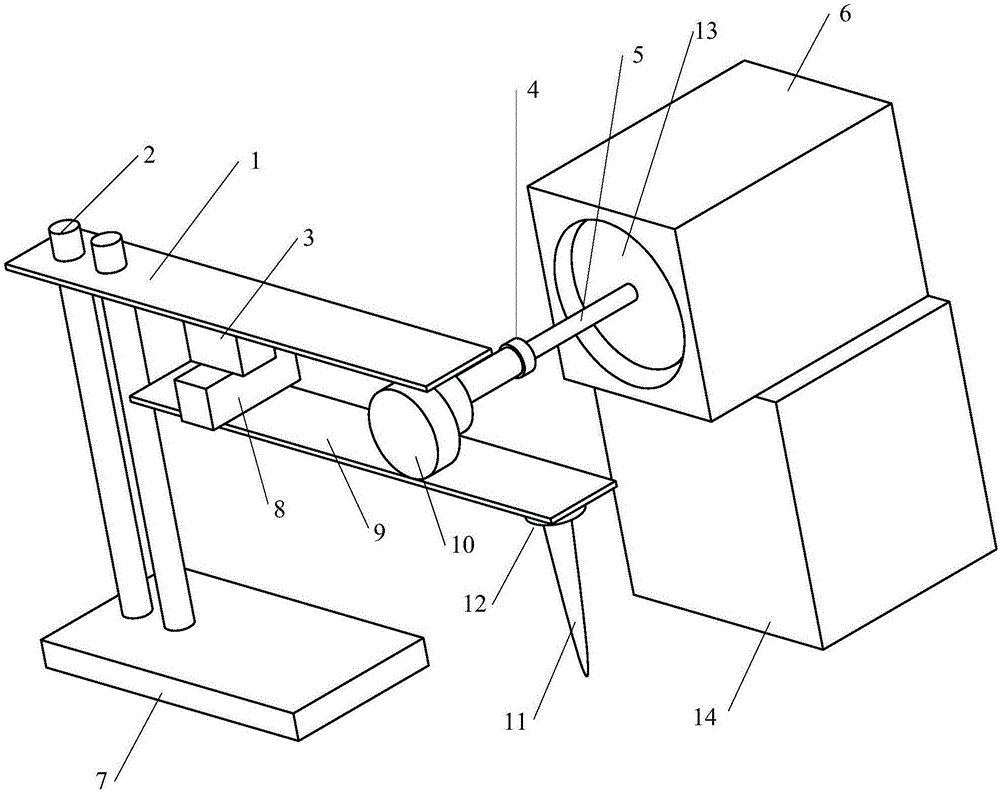

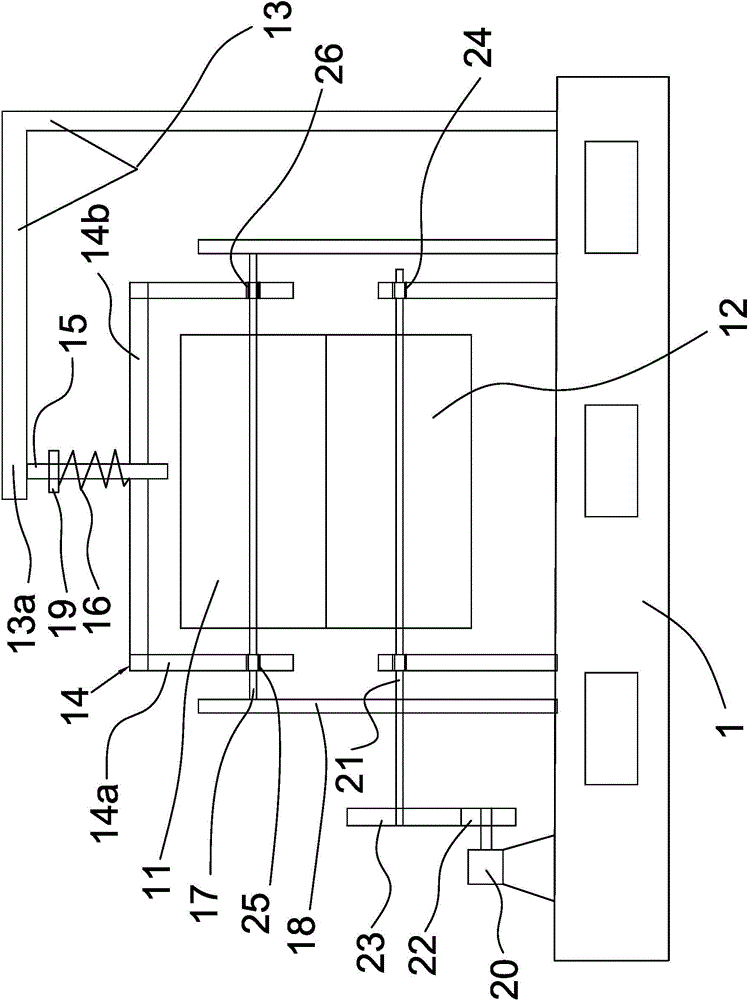

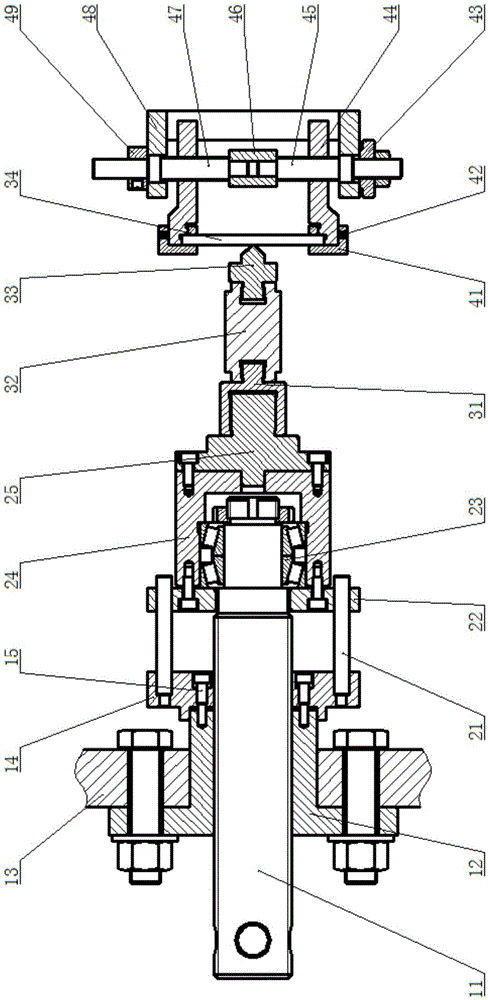

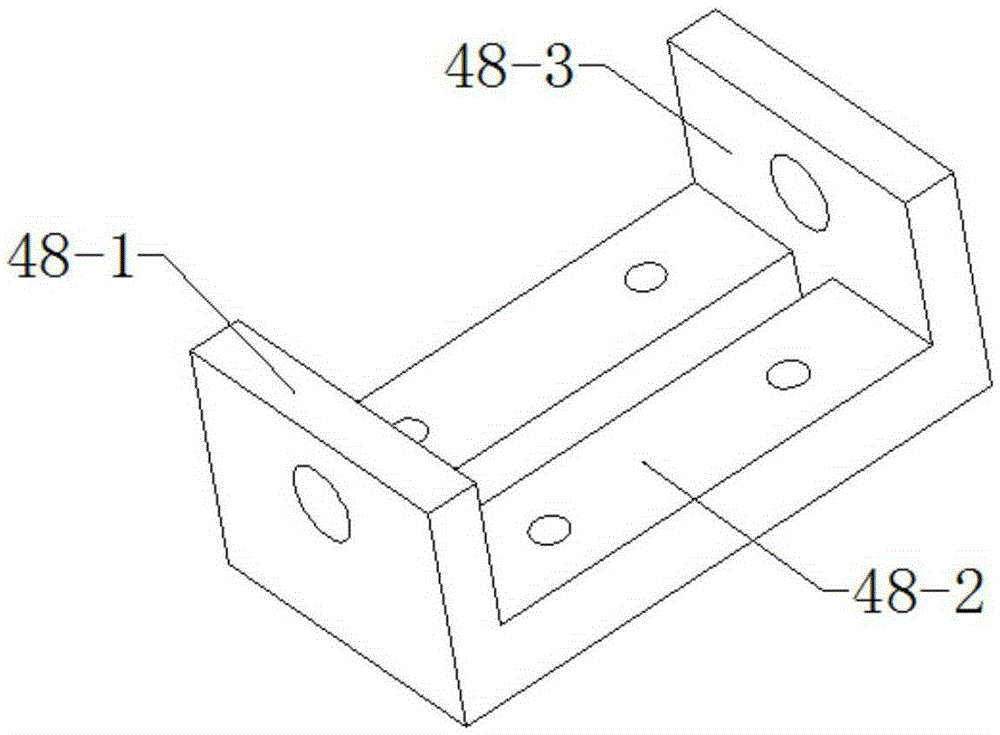

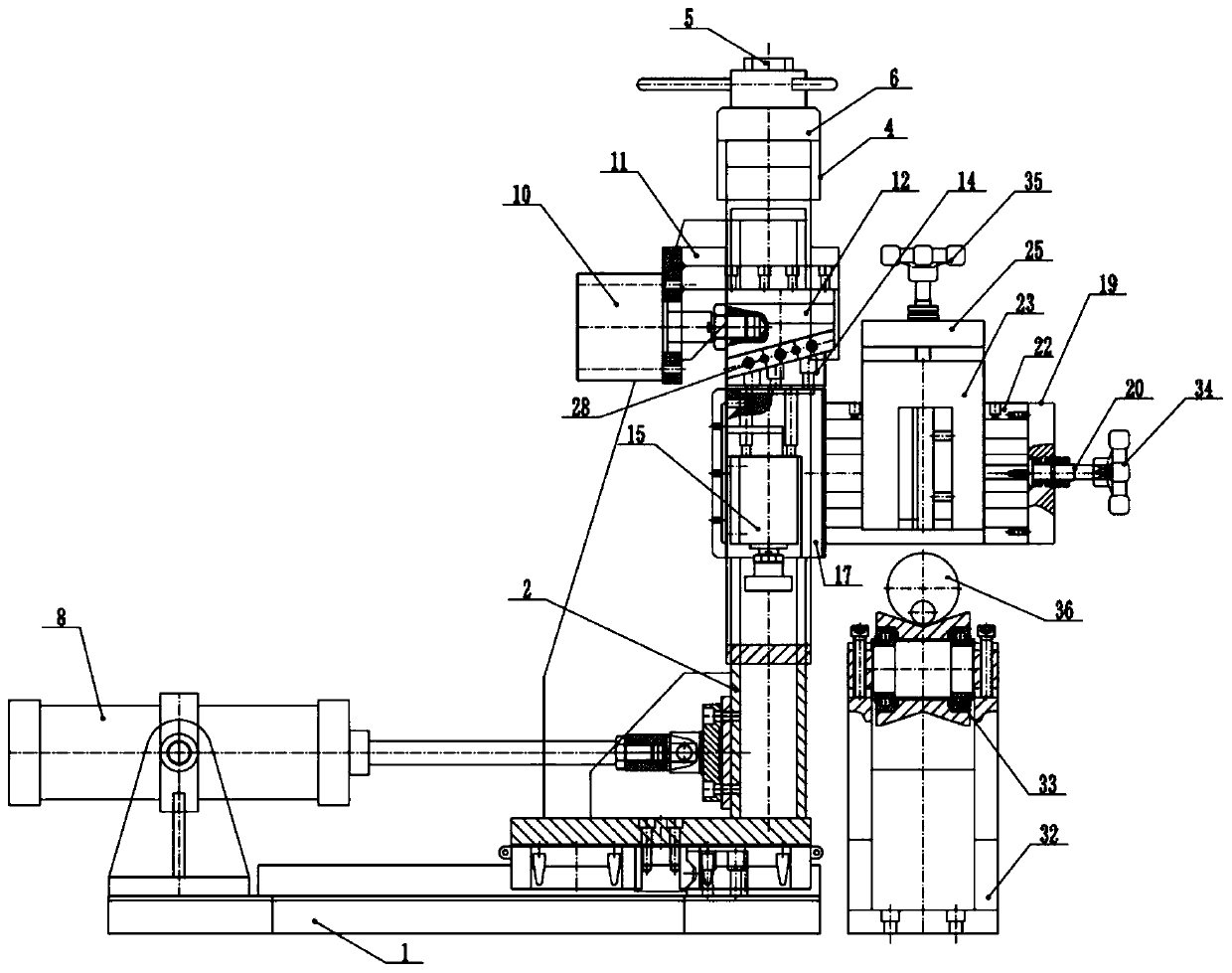

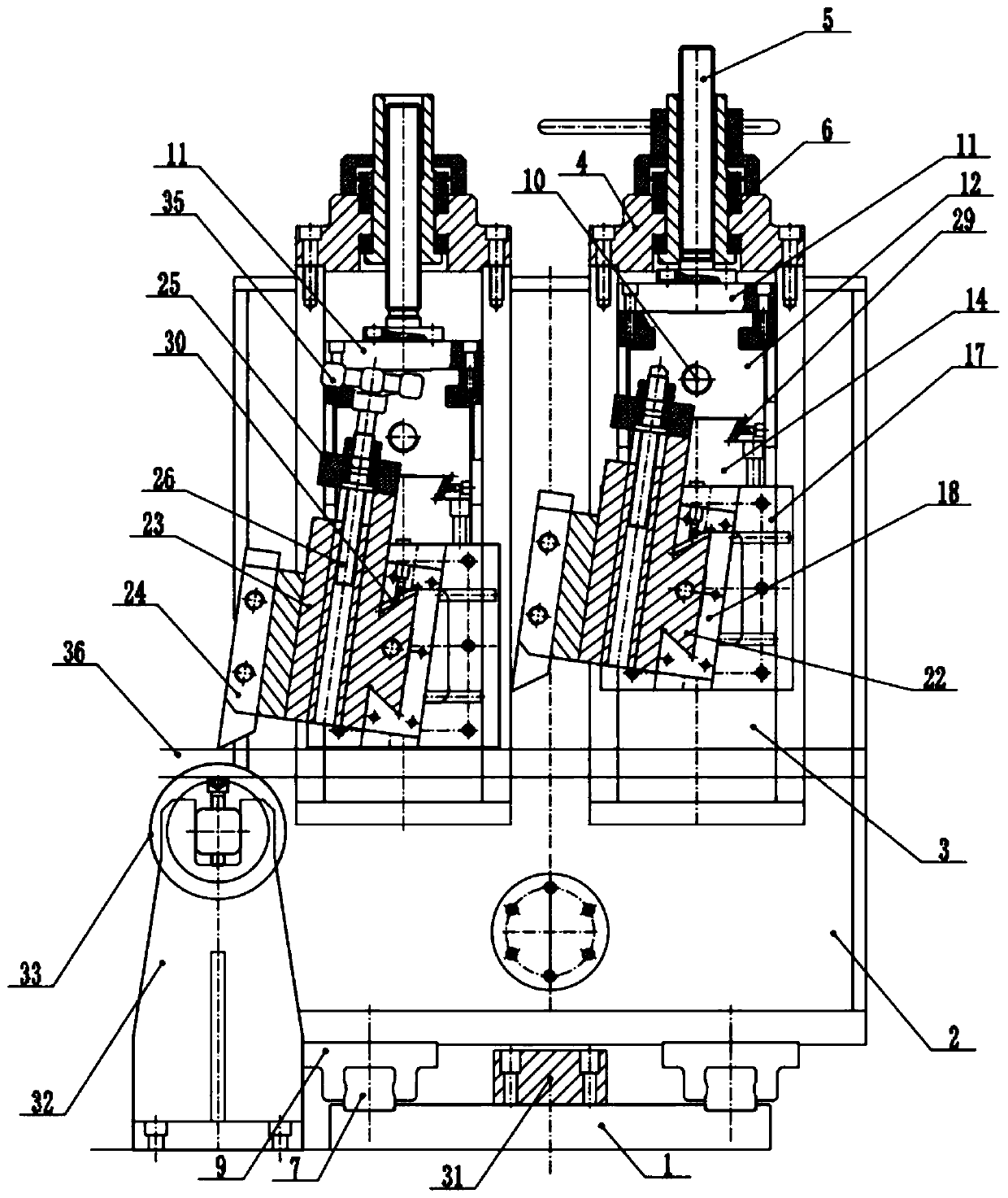

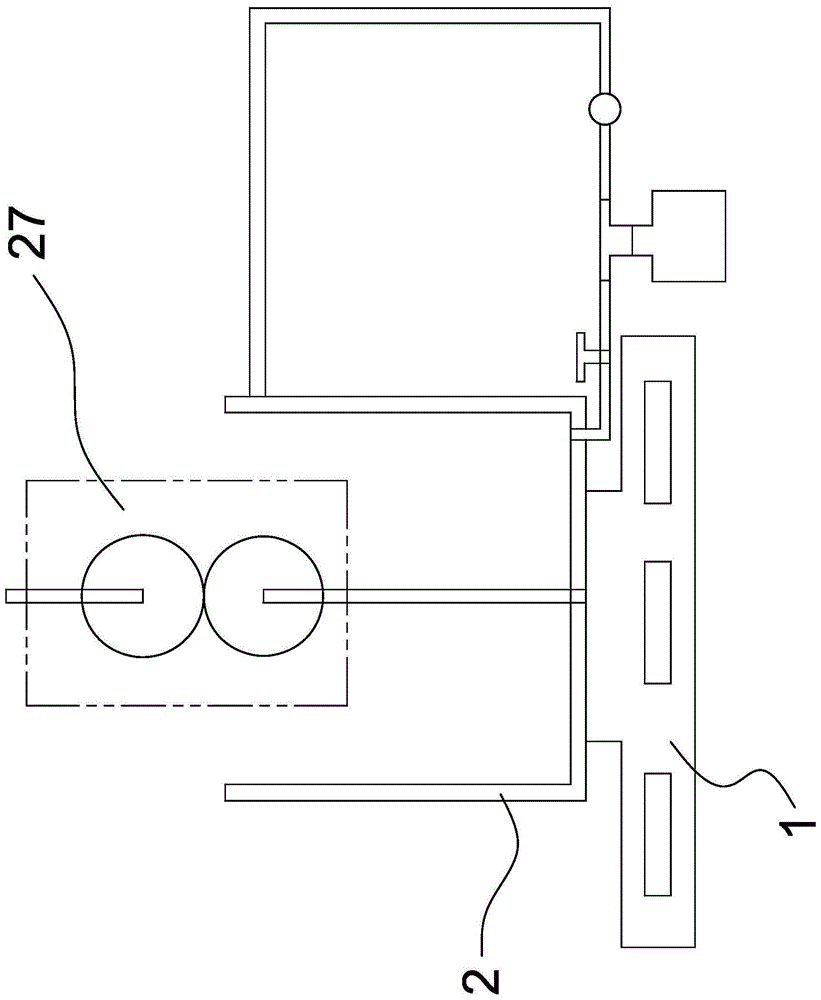

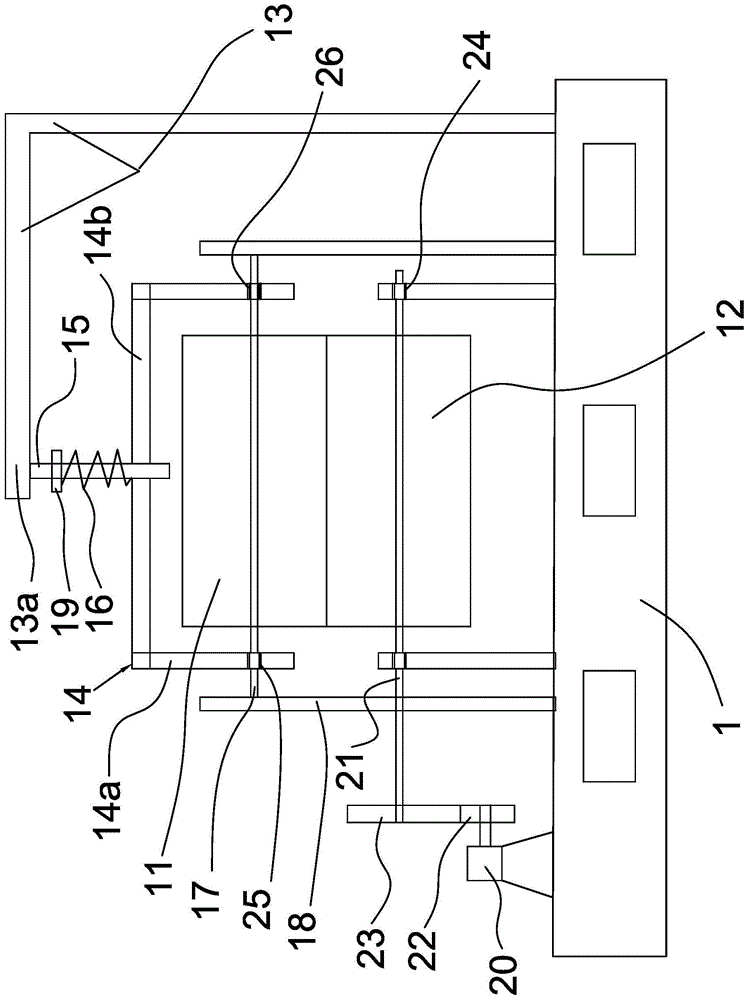

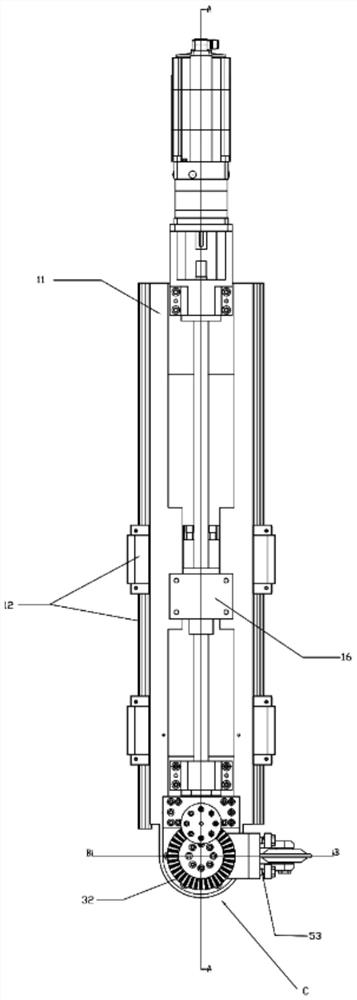

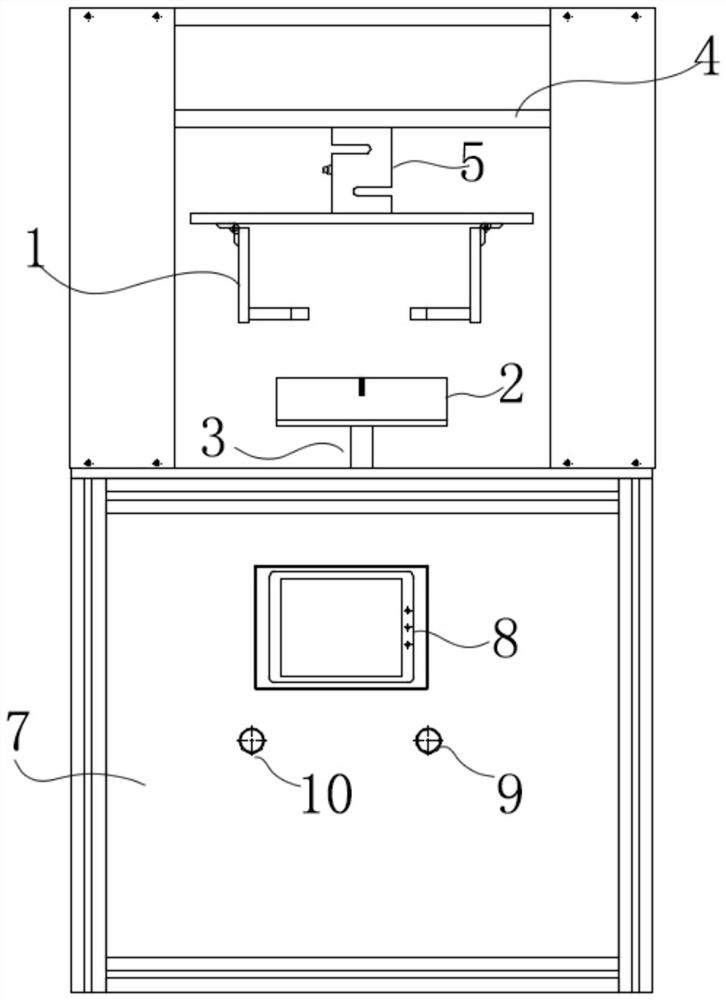

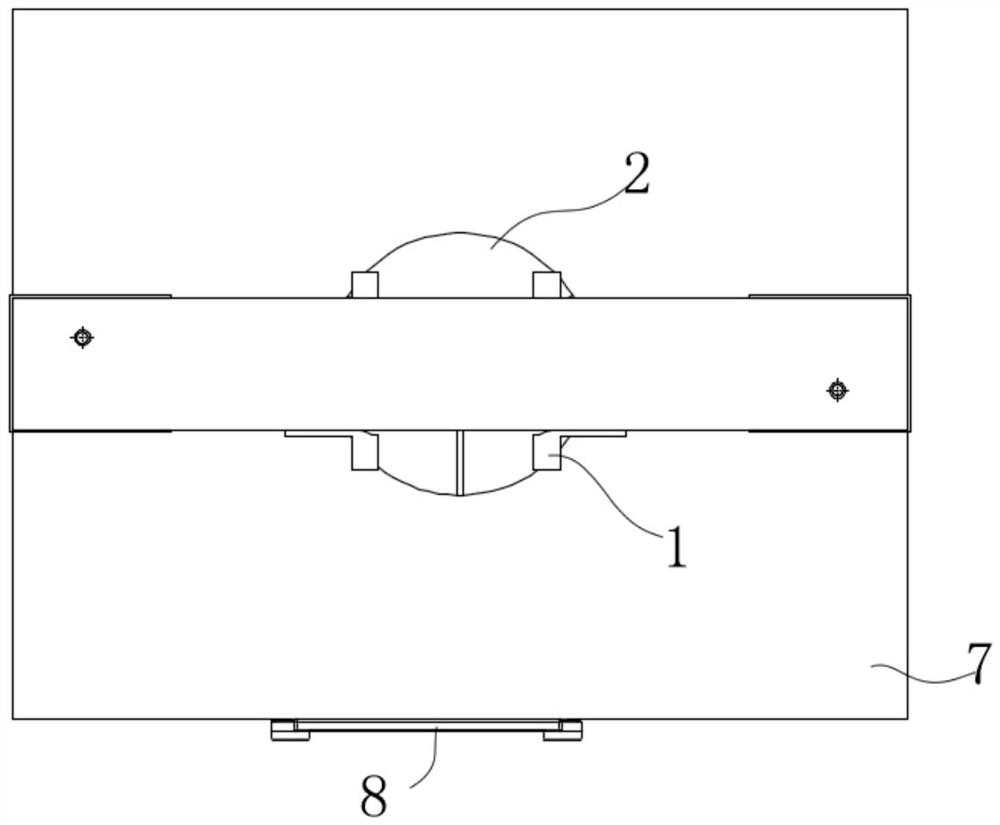

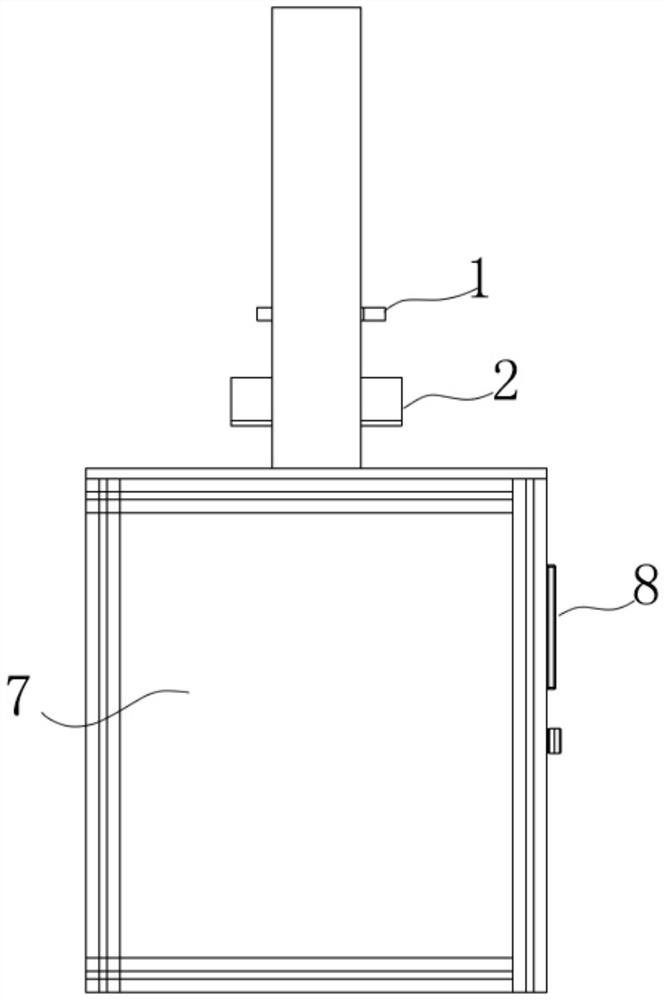

Integrated device for in-situ static and dynamic force calibration

ActiveCN106546379AAchieving static force in situRealize dynamic force calibrationForce/torque/work measurement apparatus calibration/testingEngineeringDirectivity

The present invention discloses an integrated device for in-situ static and dynamic force calibration. The integrated device comprises a loading mechanism, a direction control mechanism, a force source control mechanism and an alignment and clamping mechanism; one end of the direction control mechanism is connected with the loading mechanism, and the other end of the direction control mechanism is fixed to one end of the force source control mechanism; and the alignment and clamping mechanism is connected with the other end of the force source control mechanism. With the integrated device adopted, the actual working condition of a system can be simulated in situ, and static force calibration or dynamic force calibration can be performed on the system under a condition that the working sensor of the system is not disassembled. According to the integrated device, the directivity of the excitation force of the integrated device is excellent, and the positions of the acting points of the excitation force of the integrated device are consistent; excitation of different force values can be applied, the magnitude of the excitation can be adjusted, and an exciting frequency range is wide; and a pressed component can be automatically aligned and clamped, and accurate alignment and limiting can be realized through using a vernier. The integrated device can be flexibly installed and used in a horizontal or vertical direction. The integrated device is compact in structure and is easy to operate.

Owner:NANJING UNIV OF SCI & TECH

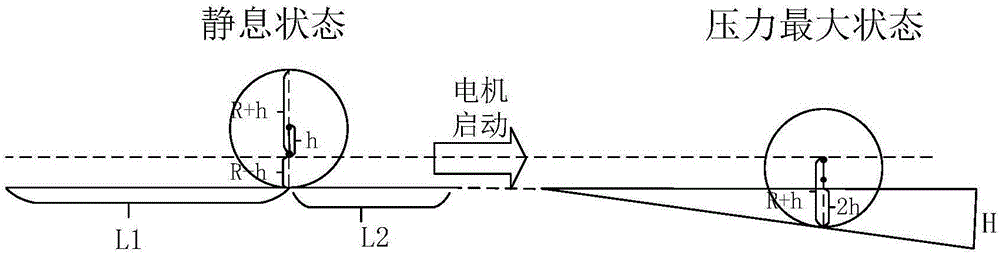

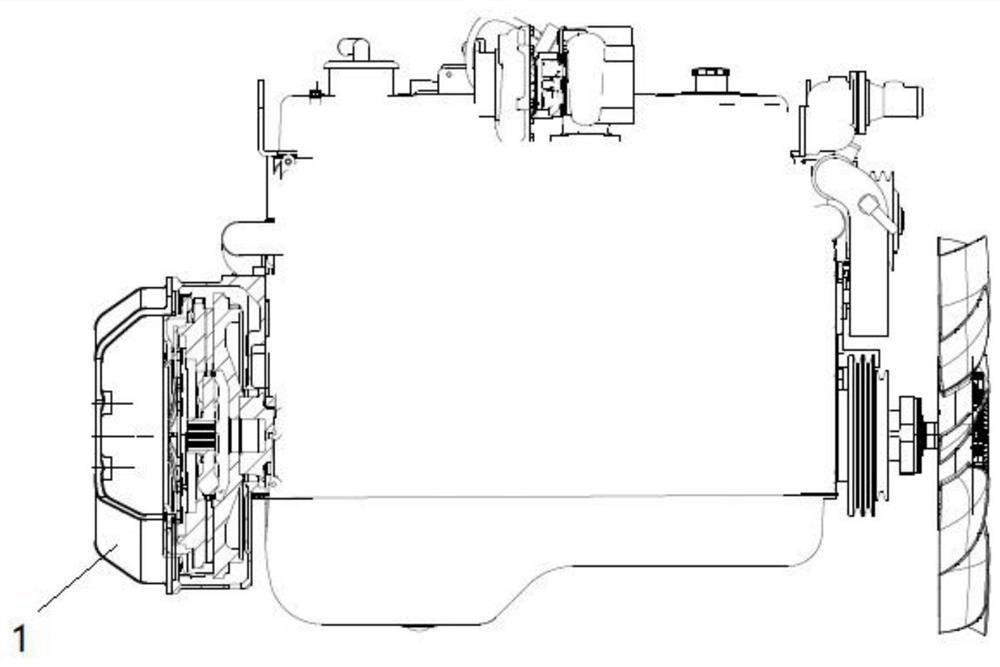

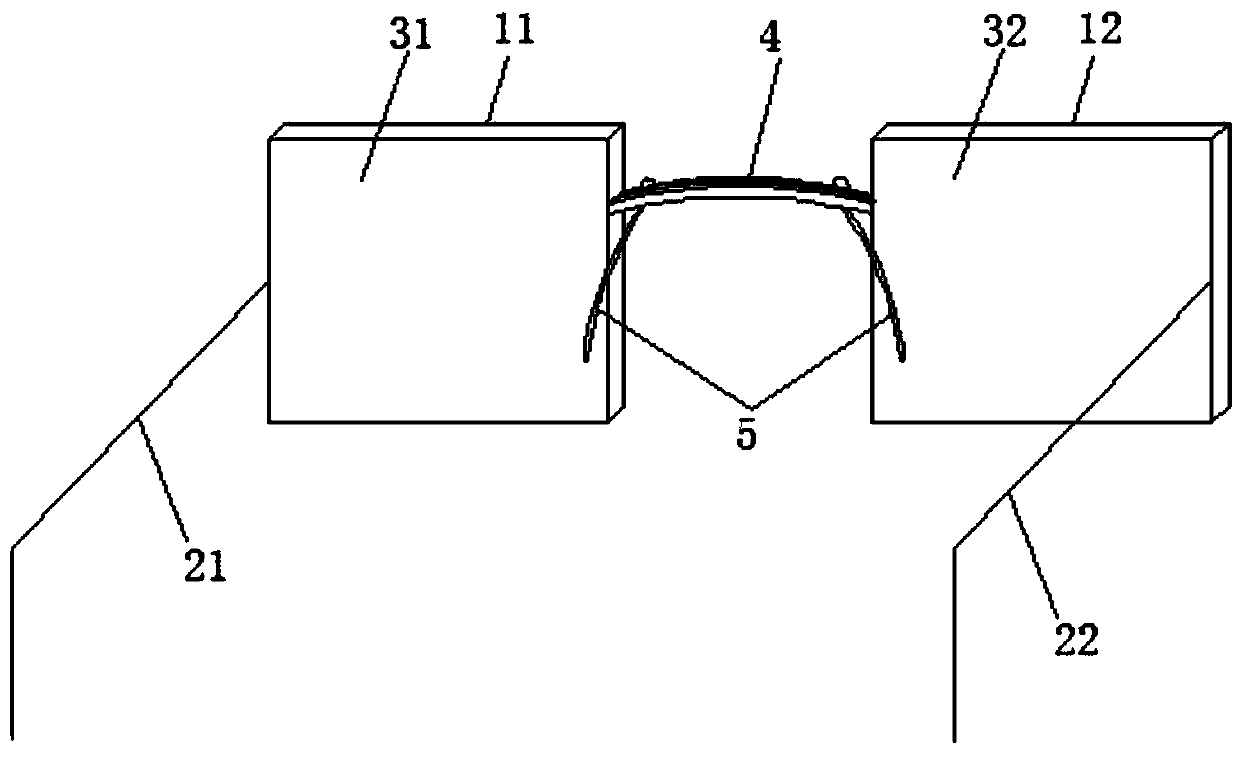

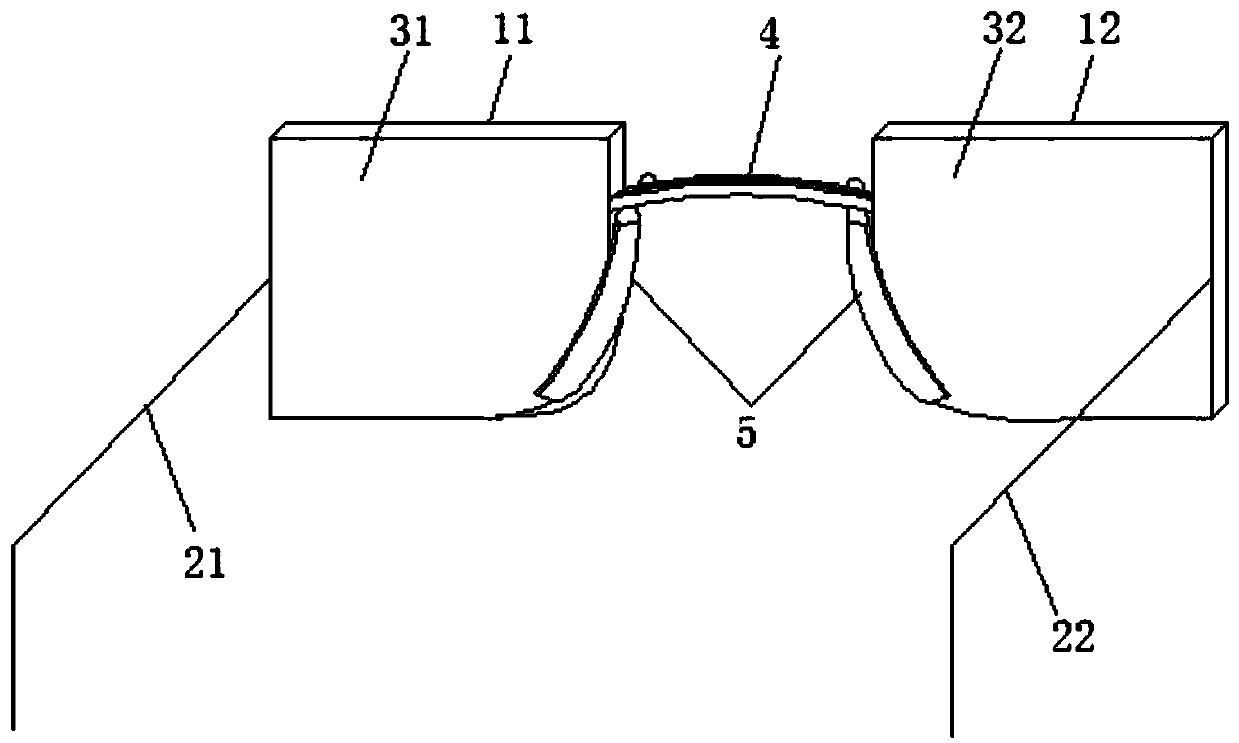

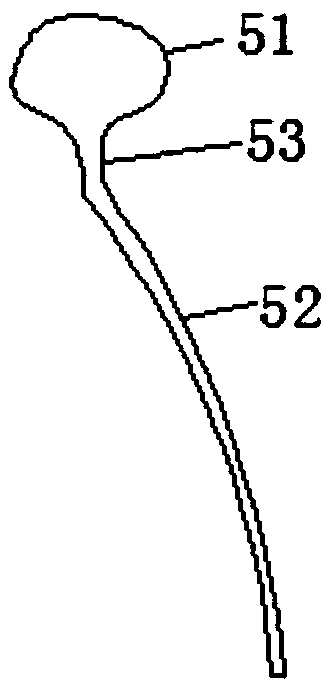

Vehicle and engine thereof

ActiveCN107489524AChange exercise positionAdjustable compression ratioEngine controllersMachines/enginesEngineeringMechanical engineering

The invention discloses an engine. The engine comprises a piston, a connecting rod and a piston pin used for connecting the piston with the connecting rod. The piston pin and the piston are tightly matched through a pin sleeve. The inner circle and the outer circle of the pin sleeve are provided with eccentric structures in order to adjust the relative positions of the piston pin and the piston through rotating of the pin sleeve. According to the engine, by arranging the pin sleeve to be of an eccentric structure, when the pin sleeve is at different angles, an inner hole of the pin sleeve is changed relative to the distance of the top surface of the piston, the total length of the piston and the connecting rod is changed, the movement position of the piston in a cylinder is changed, the combustion chamber volume is adjusted, because the engine displacement is unchanged, the compression ratio of the engine is adjusted along with rotation of the pin sleeve; and according to the engine, the fact that the compression ratio can be adjusted is achieved, meanwhile, the fact that eccentricity of the piston is adjustable is realized, according to different operating conditions, piston stress is adjusted, and the reliability of the piston is improved. The invention further discloses a vehicle comprising the engine.

Owner:BEIQI FOTON MOTOR CO LTD

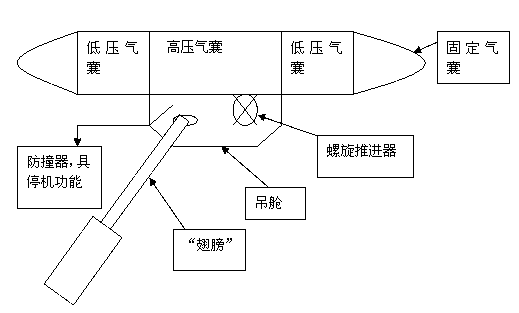

Bionic manned airship

The invention discloses a bionic manned airship which comprises air bags, a pod for accommodating humans and weights, and spiral propelling devices. The bionic manned airship is characterized in that the pod is fixed behind a high-pressure air bag, and two ends of the high-pressure air bag are connected with foldable low-pressure air bags; outer ends of the low-pressure air bags are connected with fixed air bags; the high-pressure air bag and the low-pressure air bag are connected through air pipes, switches and air bag type compressors; wings which can flap are arranged on two sides of the pod, and the spiral propelling devices which can rotate in 360 degrees are further arranged on two side surfaces of the pod; and a solar cell panel is further fixed on a body of the airship. The airship doesn't require for fuel, cannot pollute the air, is energy-saving, environment-friendly, safe and reliable, and can finish various activities of a human in a near space.

Owner:蒲福祥

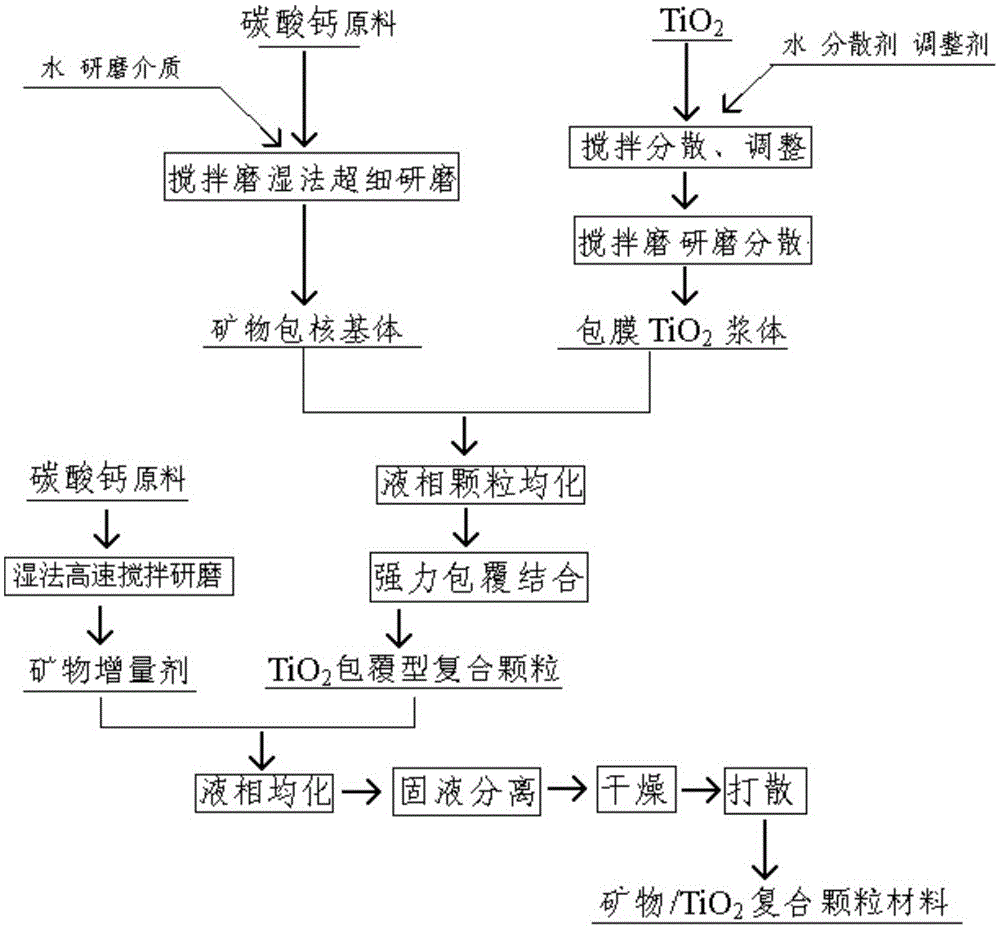

Production technique of mineral/TiO2 composite granular material

The invention discloses a production technique of a mineral / TiO2 composite granular material. The production technique comprises the following steps: preparing a mineral core base, preparing a coating TiO2 slurry, preparing TiO2-coated composite granules, preparing a mineral extending agent, mixing the TiO2-coated composite granules with the mineral extending agent, and carrying out liquid-phase homogenization, solid-liquid separation, drying and dispersion to obtain the mineral / TiO2 composite granular material. The production technique has the advantages of low production cost and excellent product performance, and is suitable for large-scale production.

Owner:安徽牛山矿业股份有限公司

Preparation of silicone oil-containing lubricating anti-corrosion composite coating with low friction coefficient

PendingCN112266717AEvenly dispersedImprove anti-friction and anti-wear propertiesAnti-corrosive paintsPolyurea/polyurethane coatingsLiquid stateSilicone oil

The invention provides a preparation method of a silicone oil-containing lubricating anti-corrosion composite coating with a low friction coefficient. Silicone oil is used as a corrosion inhibitor anda lubricant, and solid-liquid separation in the coating is realized by utilizing the characteristic that low-molecular silicone oil still keeps a liquid state at the curing temperature of polyurethane. Controllable surface migration of organic silicon is achieved by adjusting the type or content of silicone oil, and the wear-resisting service life is prolonged while the friction coefficient of the coating is reduced. The preparation method is simple in preparation and convenient to use, the acting force between the polyurethane matrix and silicone oil molecules is adjustable, and uniform dispersion and controllable release of silicone oil are realized. A composite coating can realize controllable release of the silicone oil filler under stimulation of friction motion, and can simultaneously realize lubrication and corrosion resistance effects through a solid-liquid composite lubrication action mechanism and hydrophobicity of silicone oil, so that the coating has excellent antifrictionand anti-wear properties and corrosion resistance, and the composite coating has huge application potential and market value in the fields of friction and corrosion.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

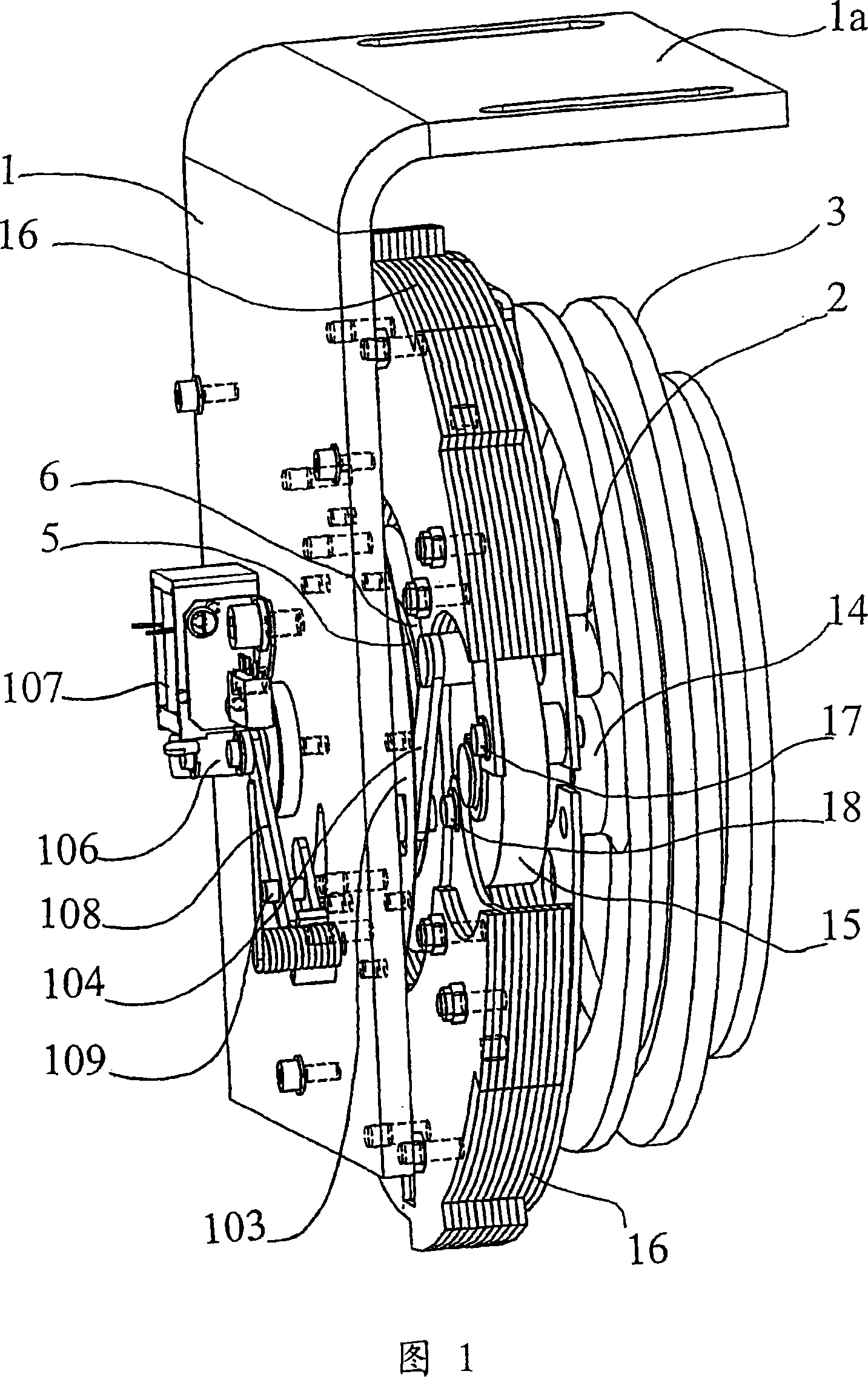

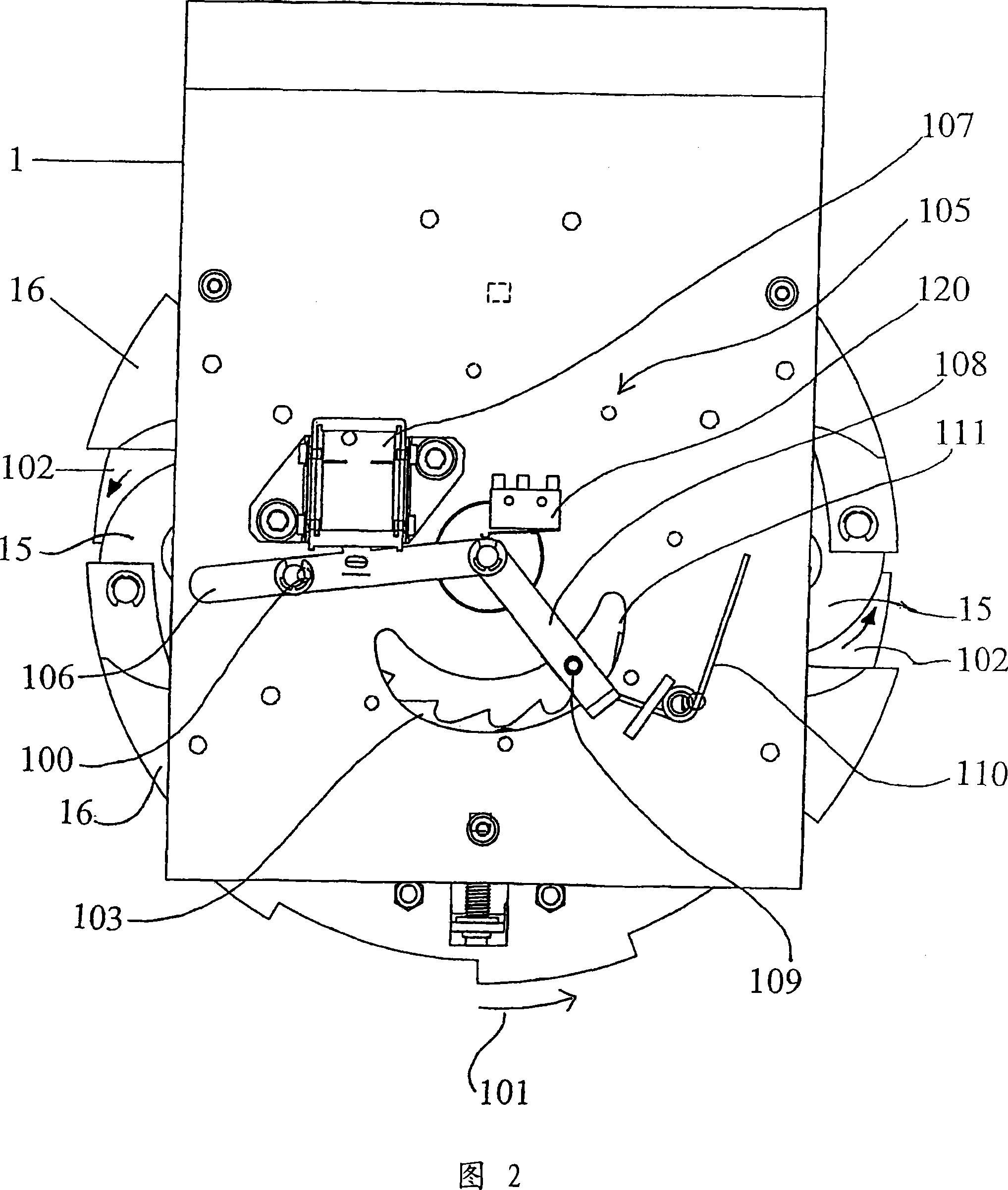

Method and appliance for tripping the safety gear of an elevator

InactiveCN101198537AAchieve disconnectionAvoid skiddingElevatorsHoisting equipmentsEngineeringActuator

A method for tripping safety gear of an elevator, at a speed lower than a gripping speed of the elevator may include: slowing a rope sheave of an overspeed governor of the elevator using a device adapted to slow the rope sheave; disconnecting an actuator connected to the overspeed governor from movement of the rope sheave when the device slows the rope sheave; and tripping the safety gear in an overspeed situation using a rope driving the overspeed governor via the rope sheave. An appliance for tripping safety gear of an elevator may include: an overspeed governor; a rope sheave of the overspeed governor; a device adapted to slow the rope sheave; and an actuator connected to the overspeed governor that is arranged to disconnect from movement of the rope sheave when the device adapted to slow the rope sheave acts to slow the movement of the rope sheave.

Owner:KONE CORP

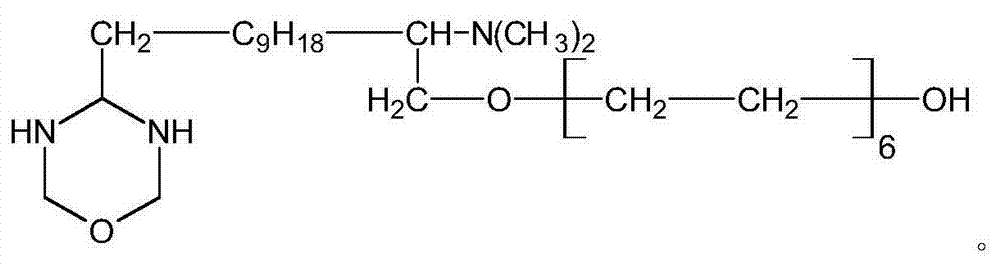

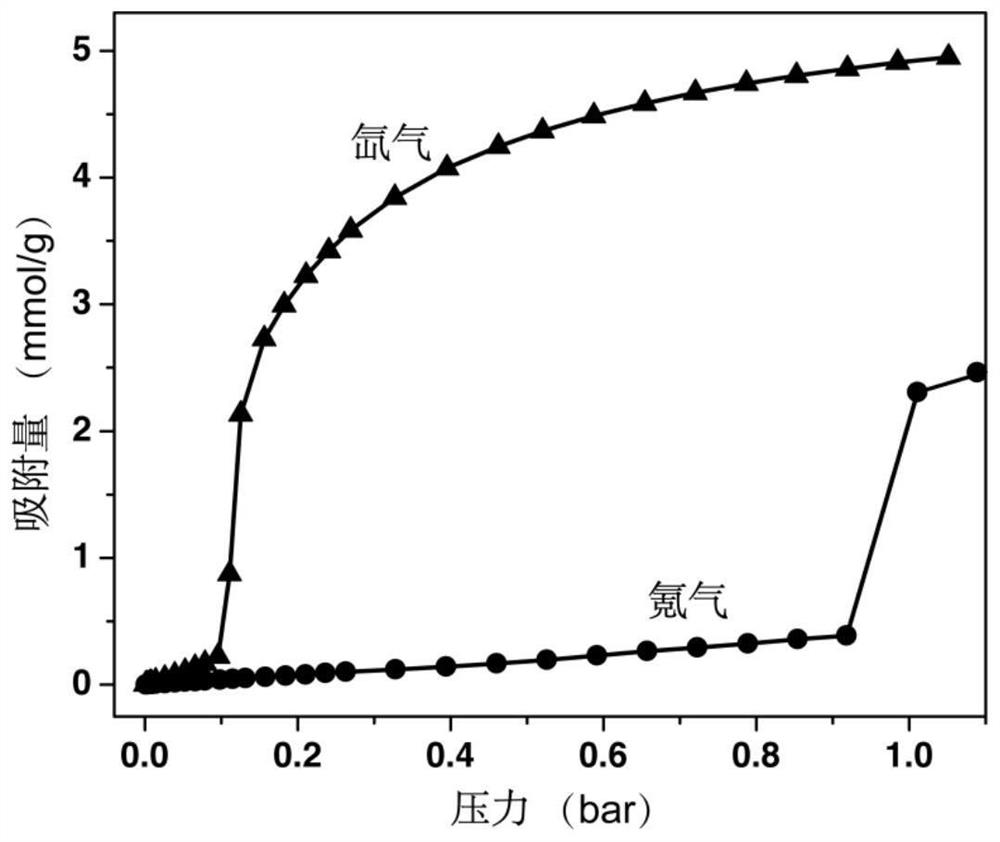

A kind of xenon gas krypton separation method

ActiveCN110451466BAchieve separationStrong forceOther chemical processesNoble gas compoundsKryptonStructural formula

The invention discloses a xenon-krypton separation method. A fluorine-containing anion hybridized ultramicropore material with a flexible function is adopted to selectively adsorb xenon in a mixed xenon-krypton gas, and then separation of xenon from krypton is achieved; and the fluorine-containing anion hybridized ultramicropore material with the flexible function has a structural formula of M-(C12H8N2)-AF6 or M-(C10H8N2S2)-AF6, in the formula, C12H8N2 is an organic ligand 1,2-bipyridine acetylene, C10H8N2S2 is an organic ligand 4,4'-dipyridinyl disulfide, M is a metal ion, and AF6 is inorganic fluorine-containing anion. Compared with a common adsorbent, the fluorine-containing anion hybridized ultramicropore material with the flexible function, which is disclosed by the invention, has theadvantages of being adjustable in pore structure, adjustable in action with adsorbate molecules, and meanwhile has a high adsorption capacity and high selectivity.

Owner:ZHEJIANG UNIV

Device for scrapping welding slag outside welding pipe

The invention discloses a device for scrapping welding slag outside welding pipes. The device comprises a mounting base, a supporting frame and plane cutter assemblies. The device is characterized inthat the supporting frame and the mounting base are in sliding connection; mounting grooves are formed in the supporting frame, a plane cutter adjusting mechanism is arranged in each mounting groove and comprises a horizontal drive assembly, a lifting assembly and a cantilever assembly, and each lifting assembly is connected with the corresponding drive assembly and the corresponding cantilever assembly; the cantilever assemblies are connected with the plane cutter assemblies; and the lifting assemblies corresponding to the plane cutter adjusting mechanisms are arranged on the supporting frame. The device has the beneficial effects that the overall moving structure is adopted, dual plane cutters are arranged, one plane cutter is used while the other plane cutter is used for standby application, the structure is simple, the device is suitable for production of welding pipes of multiple specifications, the work state is stable, the plane cutter replacement time is saved, production can be carried out continuously, and the work efficiency is improved.

Owner:张家港市中悦冶金设备科技有限公司

Coating roller assembly of a coating machine

InactiveCN104607353BStable clampingUniform coatingLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides a coating roll assembly of a coating machine, belongs to the technical field of printing and dyeing, and solves the technical problems that the existing coating device is non-uniform in coating, poor in coating effect, poor in adaptability and the like. The coating roll assembly of the coating machine is characterized by comprising an upper roller and a lower roller, the lower roller is axially fixed on a stander in a circumferential rotating manner, the lower roller is arranged in a coating solution trough, the upper roller is axially fixedly arranged right above the lower roller and is against the lower roller in a circumferential rotating manner, the upper roller and the lower roller are parallel to each other, the upper roller is connected with a force application mechanism which is used for enabling the upper roller to contact the lower roller and generating given pressure, and the lower roller is connected with a rotating mechanism capable of driving the lower roller to rotate. The coating roll assembly of the coating machine has advantages of good coating effect, wide application range and the like.

Owner:中山市通成包装设备有限公司

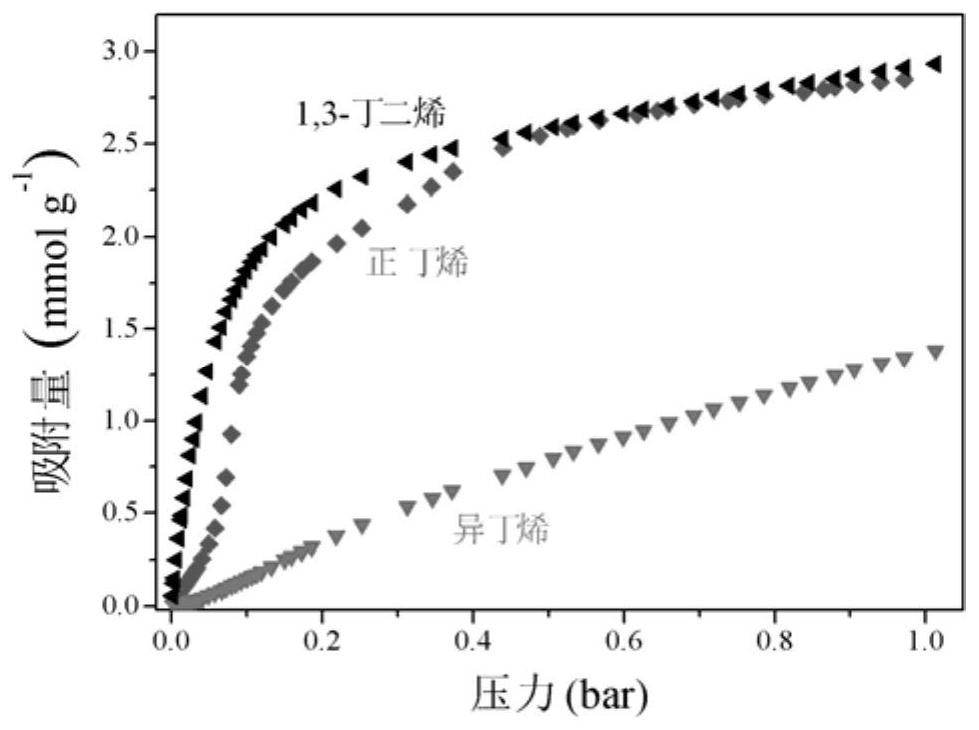

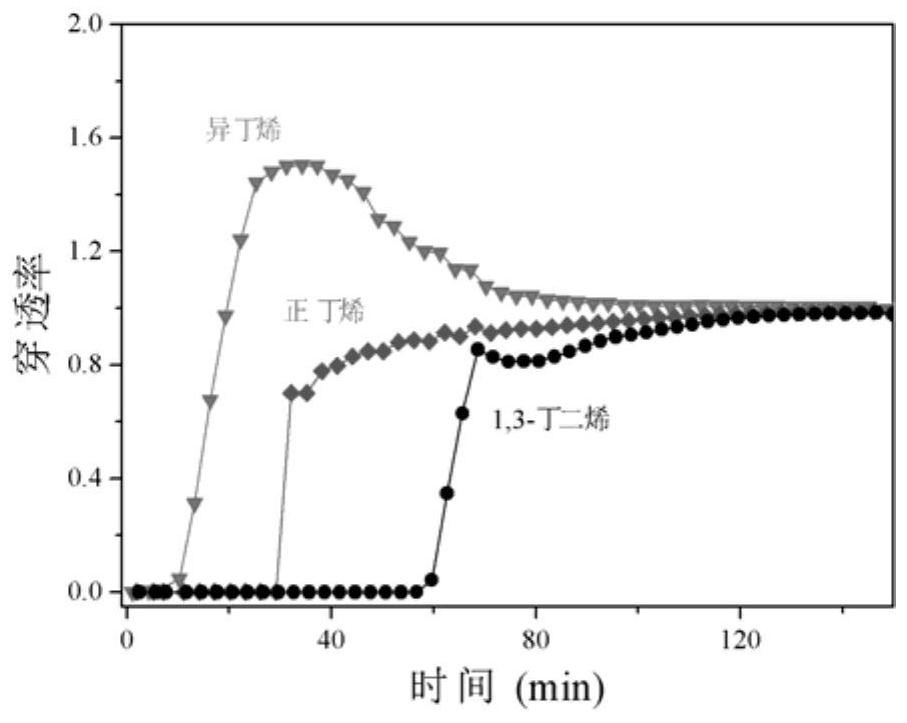

A method for separating C4 olefins from ultramicroporous ion-hybrid porous materials

ActiveCN109422616BAchieving selective recognitionRaw materials are easy to getOther chemical processesChemical industryPyrazinePhysical chemistry

The invention discloses a method of using an ultra-micropore ion-hybridized porous material to separate C4 alkenes. The ultra-micropore ion-hybridized porous material is taken as an adsorbent and is contacted with a C4 alkene mixture so as to separate C4 alkenes from the mixture. The ultra-micropore ion-hybridized porous material is prepared from inorganic fluorine containing negative ions, metalions, and a pyrazine derivative organic ligand through coordination bonds; and is contacted with the C4 alkene mixture to separate C4 alkenes from the mixture. The pore diameter of the ultra-microporeion-hybridized porous material can be precisely controlled to selectively identify C4 alkene molecules, and selective separation of C4 alkenes can be realized.

Owner:ZHEJIANG UNIV

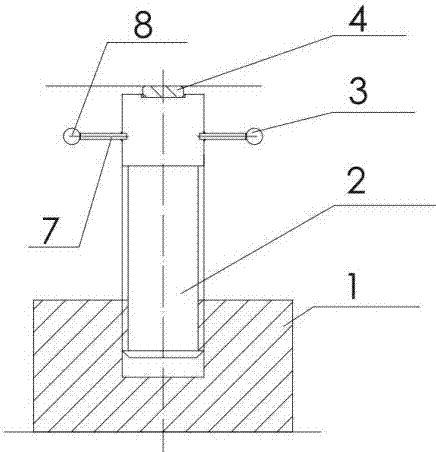

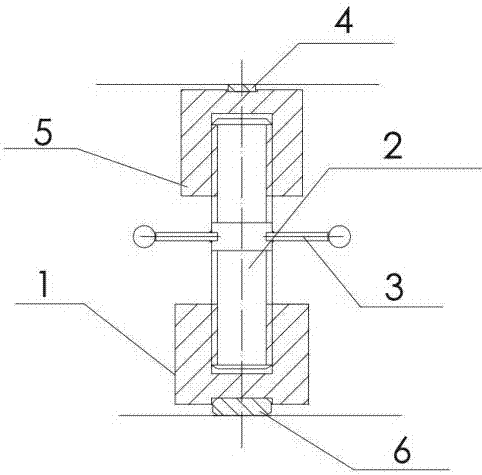

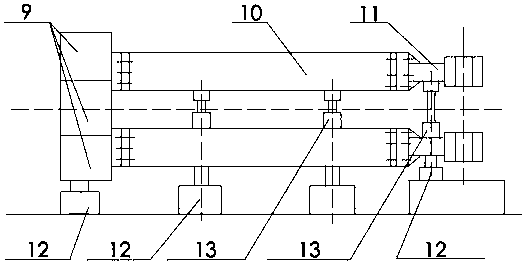

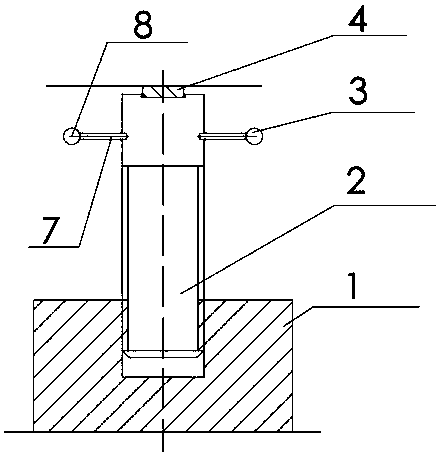

Hydraulic buffer device for center frame of heavy machine tool

PendingCN112324850ARealize the correction operationAvoid deformationSpringsLiquid based dampersEngineeringStructural engineering

The invention discloses a hydraulic buffer device for a center frame of a heavy machine tool. The buffer device comprises a center frame base, a hydraulic buffer jacking mechanism and an adjusting mechanism, wherein the hydraulic buffer jacking mechanism is arranged on the center frame base and comprises an adjustable jacking piece and a hydraulic buffer seat; the adjustable jacking piece is columnar and is in sliding fit with the center frame base; the hydraulic buffer seat is fixed to the center frame base and abuts against the end of the adjustable jacking piece; and the adjusting mechanismis arranged on the center frame base and acts on the adjustable jacking piece. Acting force brought by a workpiece can be buffered after instantaneous bearing of the adjustable jacking piece, abrasion of a lead screw and a nut is effectively avoided, and the service life of the center frame is prolonged.

Owner:TIANSHUI SPARK MACHINE TOOL

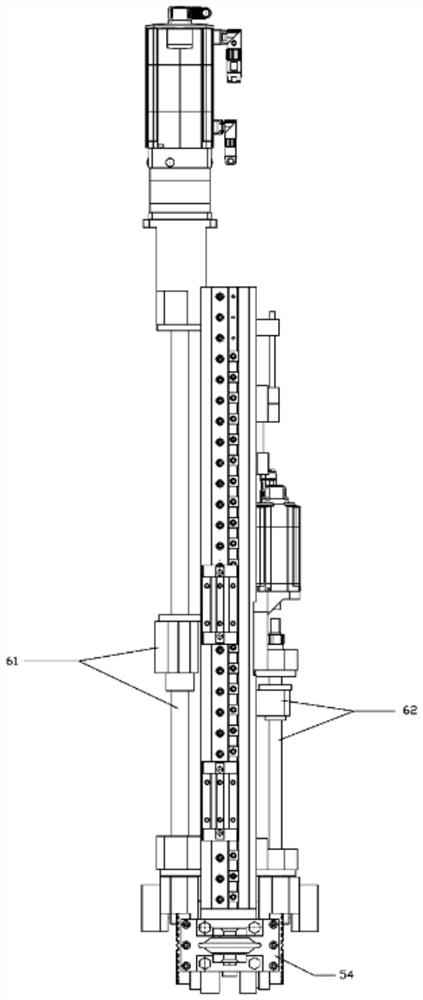

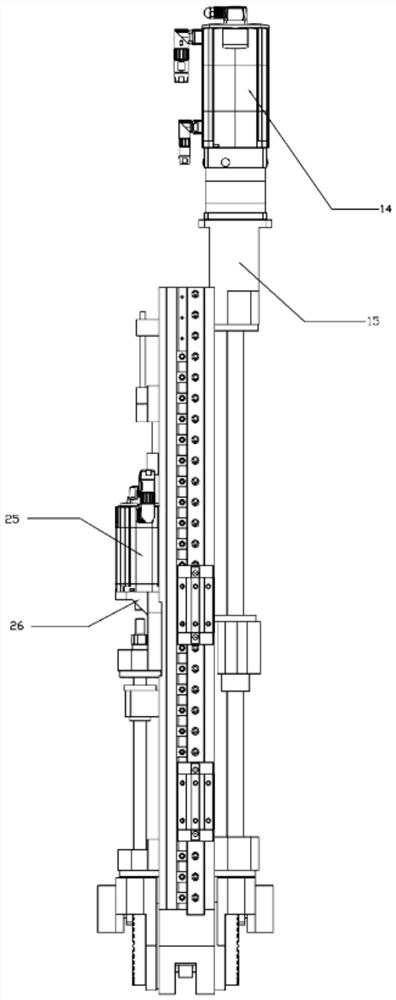

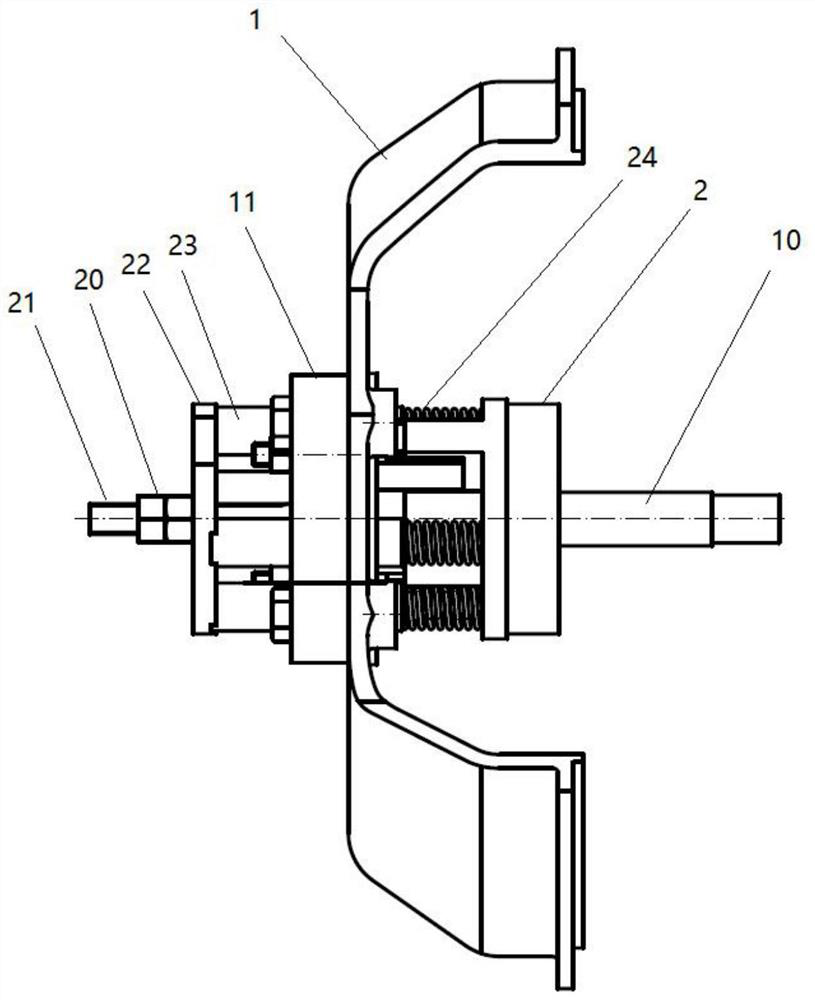

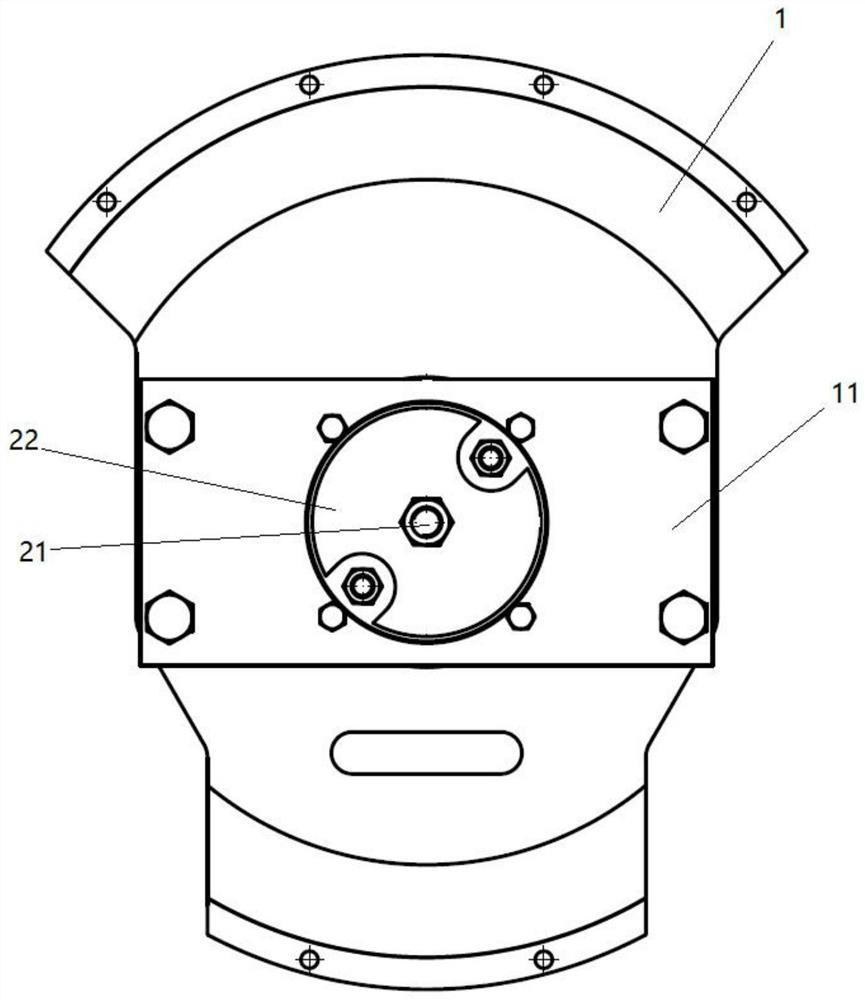

Telescopic arm structure of hub roller press

PendingCN112719014AAdjustable angleAdjust the Angle RelationshipMetal-working apparatusRotational axisMachine parts

The invention relates to the technical field of spinning machines, in particular to a telescopic arm structure of a hub roller press. The telescopic arm structure of the hub roller press comprises a Z-axis main body, a positioning mechanism, a rolling wheel assembly, a roller disc rotating mechanism and a tensioning mechanism. A B-axis servo motor drives a second lead screw to rotate, so that a second nut is driven to move up and down, then a chain connecting block is driven to move up and down, the chain connecting block moves up and down to pull a chain, then a rotary main chain wheel rotates, a rotary main chain wheel on the lower portion rotates to drive a rotary shaft to rotate, then a positioning fluted disc rotates to drive the rolling wheel assembly on the positioning fluted disc to rotate by a certain angle, then the angle relation between a rolling wheel and the to-be-machined part is adjusted, the purpose of adjusting the rolling angle is achieved, and the outer surface and the inner surface of a hub are rolled at a time and rolled comprehensively.

Owner:江西鼎力旋压装备有限公司

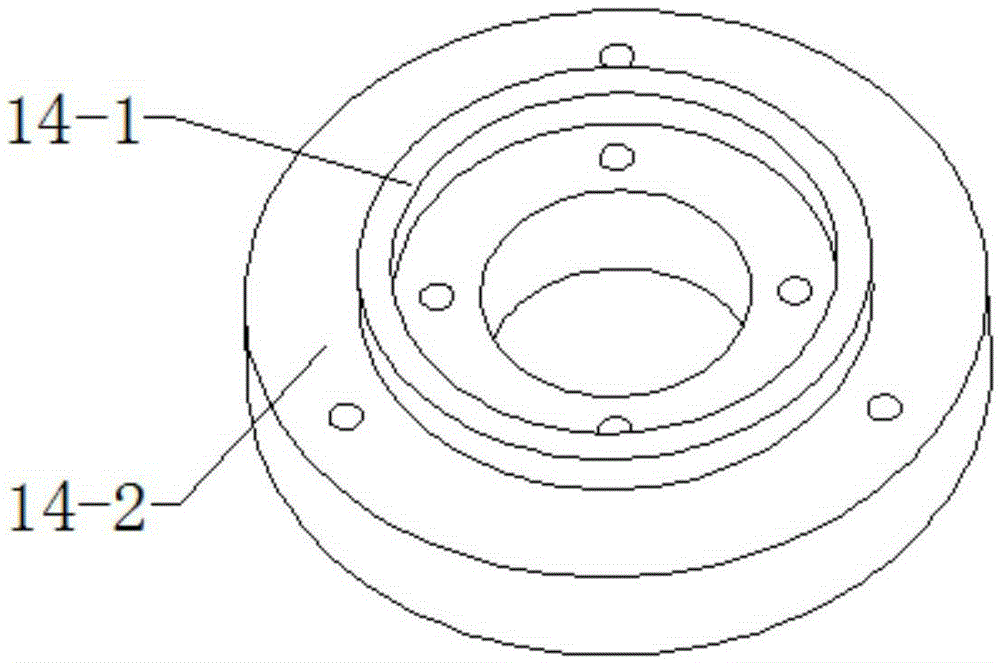

Thrust plate reliability test device

PendingCN113237783AAdjustable forceChange the amount of compressionMechanical actuated clutchesInvestigating abrasion/wear resistanceControl engineeringStructural engineering

The invention discloses a thrust plate reliability test device, which is characterized in that the thrust plate reliability test device comprises a tool clutch cover, a release bearing assembly, a positioning assembly and a thrust adjusting assembly, a positioning hole is formed in the middle of the tool clutch cover, a round hole is formed in the center of the release bearing assembly, one end of the release bearing assembly is provided with two symmetrical limiting ends and four symmetrical spring circular grooves, the positioning assembly is installed in the middle of the tool clutch cover, the thrust adjusting assembly is distributed on the left portion of the positioning assembly, the release bearing assembly is installed on the right portion of the positioning assembly, and the thrust adjusting assembly is matched with the release bearing assembly. The thrust plate reliability test device has the advantages of being compact in structure, easy to install, adjustable in stress, capable of being connected with an engine for real operation test and accurate in test result.

Owner:GUANGXI YUCHAI MASCH CO LTD

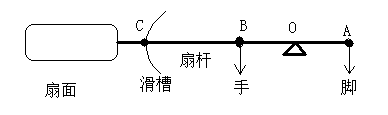

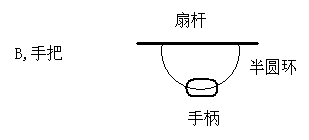

Rhinoplasty glasses

The invention discloses rhinoplasty glasses, and belongs to the field of cosmetic instruments. The rhinoplasty glasses comprise a left glasses frame, a right glasses frame, a left glasses leg, a rightglasses leg and a glasses bridge; the left end of the glasses bridge is connected with the left glasses frame, the right end of the glasses bridge is connected with the right glasses frame, the glasses bridge is provided with a sliding groove, two rhinoplasty devices are slidably connected to the sliding groove and slide in the left-right direction of the glasses bridge, each rhinoplasty device comprises a framework body, and each framework body comprises an anti-shedding protrusion, a connecting part and a nose contact part which are sequentially connected; the size of each anti-shedding protrusion in the front-rear direction is larger than that of the sliding groove in the front-rear direction, and each connecting part is matched with the sliding groove; the glasses bridge and / or each rhinoplasty device is provided with a locking structure for locking the corresponding framework body. By means of the rhinoplasty glasses, a person can simultaneously wear the rhinoplasty devices and the glasses, and the rhinoplasty devices can conveniently adjust the position and pressure at the same time.

Owner:上海回初科技有限公司

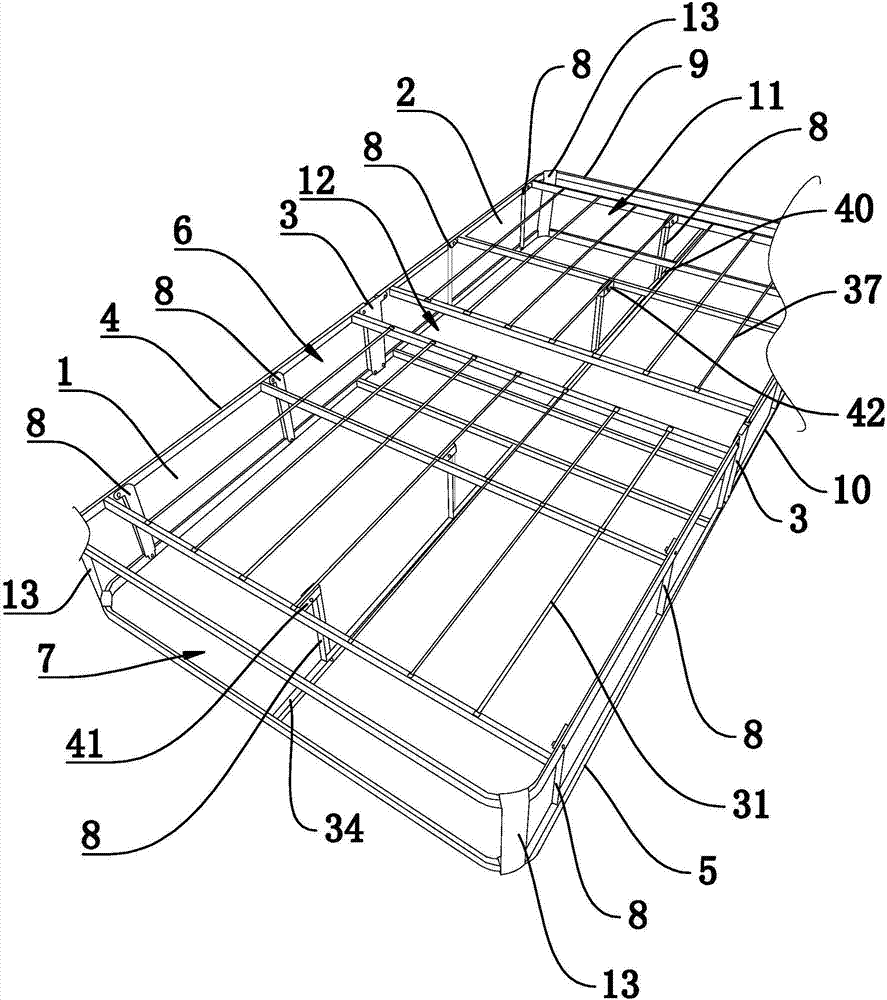

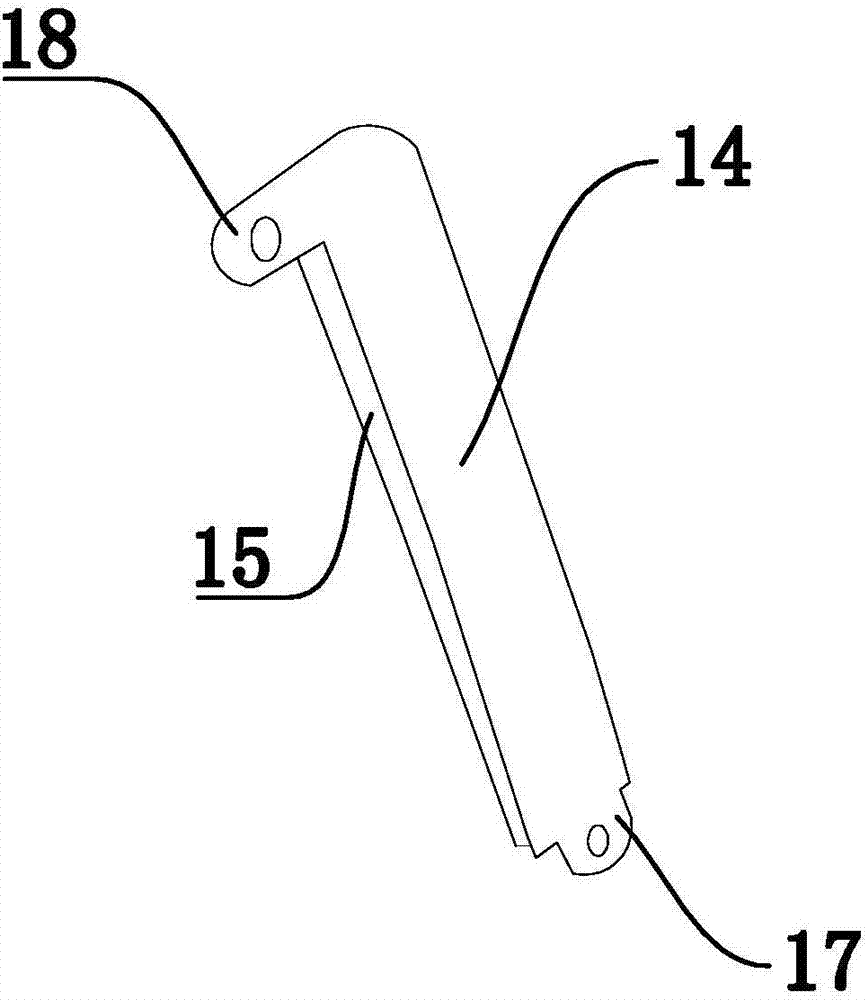

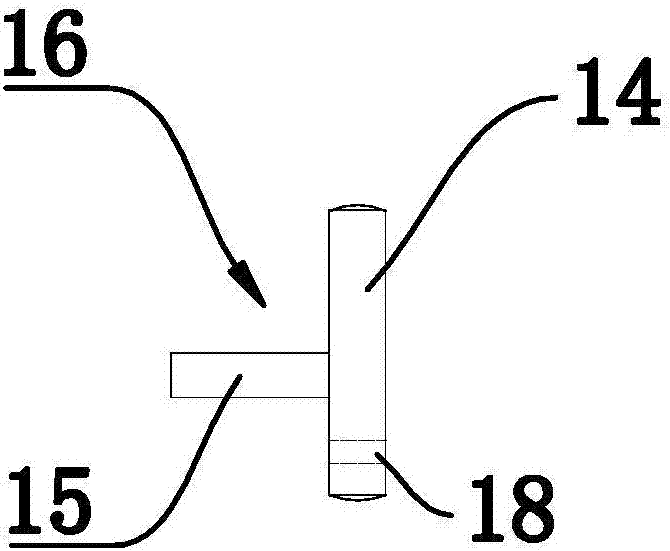

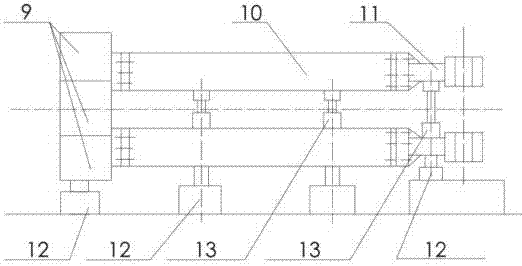

Easily-carried bedstead

PendingCN107981606AExcellent elasticityThe folding operation is stable and does not pinch your handsBedstandsFurniture joiningEngineering

Owner:海宁市正凯纺织品经营部

Arc gate big assembly method

ActiveCN107052671AOvercome operational difficultiesPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesHinge angleComputer engineering

The invention relates to the technical field of machine assembly, in particular to an arc gate big assembly method. The arc gate big assembly method includes the following steps that (1) a support arm mechanism composed of a support hinge base and a support arm is placed in parallel to the ground; (2) a plurality of support tools I are arranged below the support arm mechanism and are adjusted to be level; (3) an arc gate blade is arranged to be in the state that two straight edges are vertical to the ground, and a plurality of support tools II are arranged between the position below the arc edge of the arc gate blade and the ground and are adjusted to be level; (4) the positions of the arc gate blade and the support arm mechanism are adjusted; and (5) welding is carried out to complete assembly. By means of the arc gate big assembly method, some inconvenience in traditional assembly can be overcome, gate blade stacking and assembling and support arm assembly, adjustment and alignment are very convenience, overall assembly becomes adjustment and alignment in different horizontal faces, the problem that operation is difficult when adjustment and alignment can carried out within a space scope, an adjustable positioning tool device enables the support arm, the support hinge base and the like to be accurate in positioning, and the operation difficulty is reduced.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

A kind of arc door big fight method

ActiveCN107052671BEasy to assembleEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesComputer engineeringWelding

The invention relates to the technical field of machine assembly, in particular to an arc gate big assembly method. The arc gate big assembly method includes the following steps that (1) a support arm mechanism composed of a support hinge base and a support arm is placed in parallel to the ground; (2) a plurality of support tools I are arranged below the support arm mechanism and are adjusted to be level; (3) an arc gate blade is arranged to be in the state that two straight edges are vertical to the ground, and a plurality of support tools II are arranged between the position below the arc edge of the arc gate blade and the ground and are adjusted to be level; (4) the positions of the arc gate blade and the support arm mechanism are adjusted; and (5) welding is carried out to complete assembly. By means of the arc gate big assembly method, some inconvenience in traditional assembly can be overcome, gate blade stacking and assembling and support arm assembly, adjustment and alignment are very convenience, overall assembly becomes adjustment and alignment in different horizontal faces, the problem that operation is difficult when adjustment and alignment can carried out within a space scope, an adjustable positioning tool device enables the support arm, the support hinge base and the like to be accurate in positioning, and the operation difficulty is reduced.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

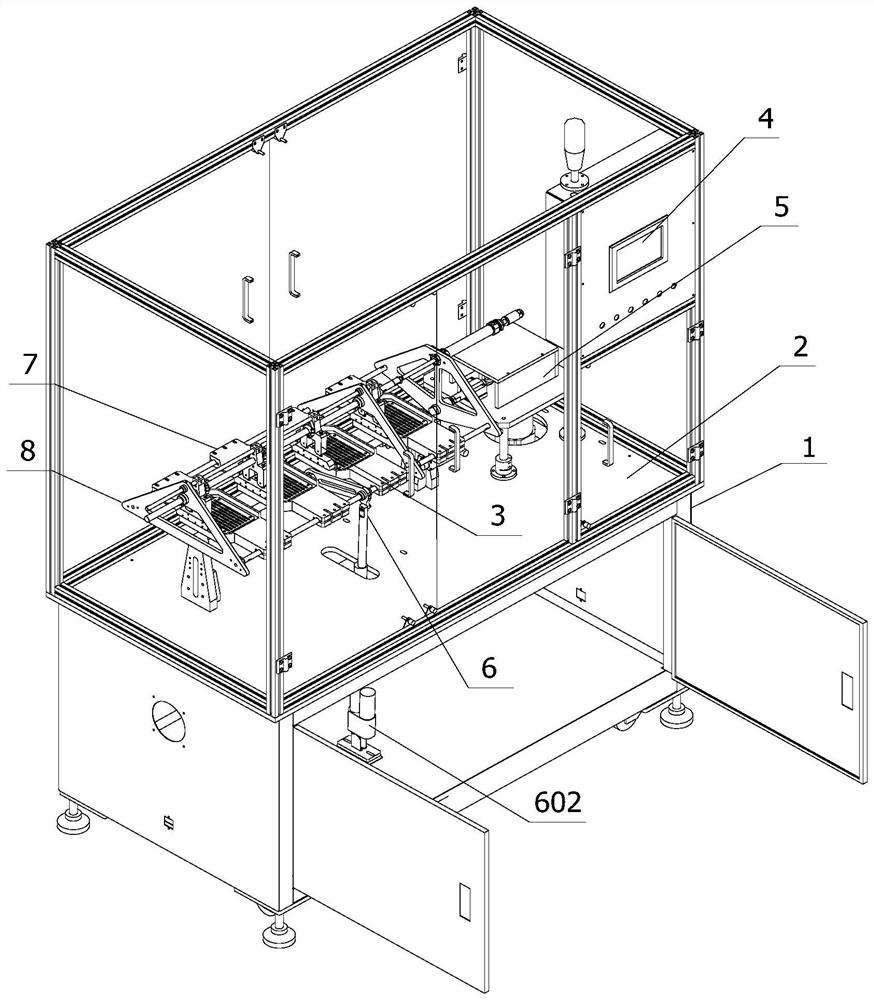

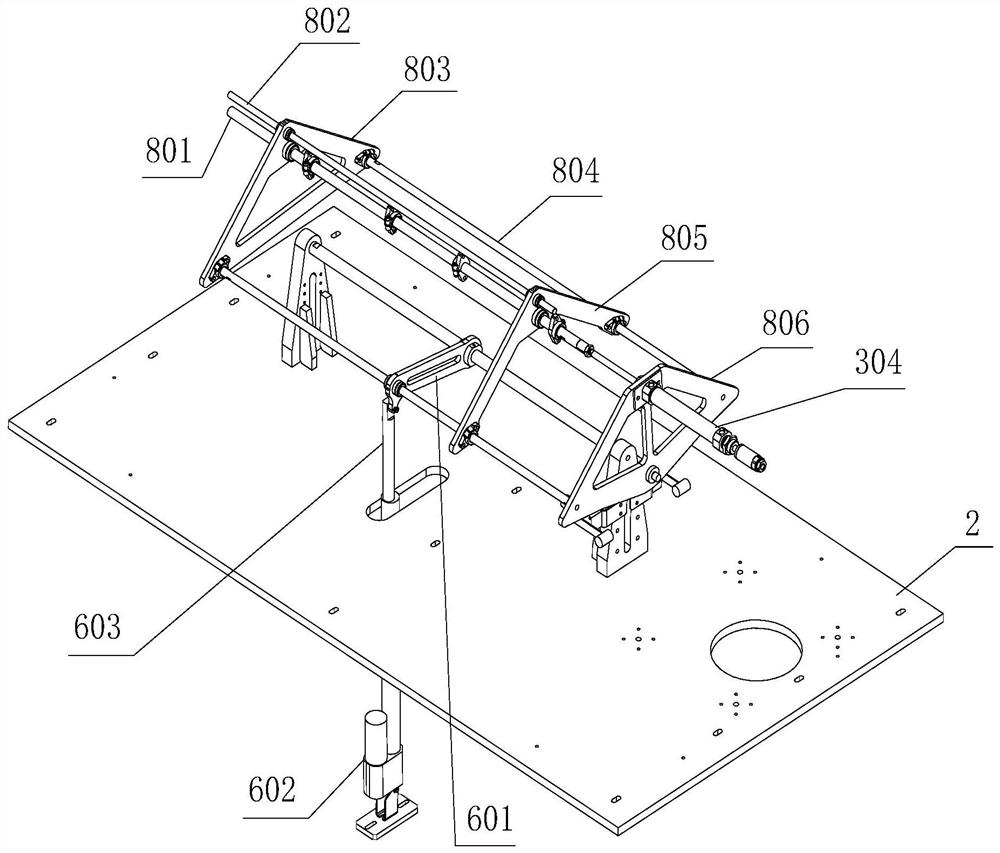

Method for testing folding life of folding electric kettle

PendingCN112326216ANo manual operationReduce labor intensityMachine part testingReciprocating motionElectric machine

The invention discloses a method for testing the folding life of a folding electric kettle. A testing device comprises a kettle top clamp seat which is used for the installation of a detachable kettletop clamp and is connected to a mechanical arm which can carry out the periodic reciprocating motion; and a kettle bottom clamp seat which is used for mounting a detachable kettle bottom clamp, is connected to an output shaft of a motor and can periodically rotate in a reciprocating manner. The kettle top clamp and the kettle bottom clamp are oppositely arranged along the same straight line. Themethod is wide in application range, and full-automatic operation can be achieved in the testing process.

Owner:VKAN CERTIFICATION & TESTING

A kind of aluminum-wood heterogeneous composite technology wood

ActiveCN110861372BWith glossy decorative effectImprove rigidity and toughnessNon-macromolecular adhesive additivesDomestic upholsteryAdhesive cementSingle plate

The invention relates to a technical wood, in particular to an aluminum-wood heterogeneous composite technical wood. It includes Ayousi veneer layer, more than one set of second blank ply and Ayousi veneer layer in turn; the second blank ply is composed of the first blank ply, aluminum plate and first blank ply by composite pressure gluing into; the first slab layer is recombined from more than one layer of Ayous veneer. The preparation method includes the following steps: (1) recombining more than one layer of Ayousi veneer by coating the first adhesive to obtain the first blank layer; (2) coating the second adhesive on one side of the two-layer blank A, Composite pressure gluing with the pretreated aluminum plate to obtain the second blank layer; (3) Composite and reorganizing the second blank layer with the Ayousi veneer coated with the third adhesive, pressurizing, and curing to obtain aluminum Wooden heterogeneous composite technology wood square; (4) Slicing. The aluminum-wood heterogeneous composite technical wood of the invention is not easy to crack, has good stability and has a metallic luster decoration effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

A kind of separation method of C8 aromatic hydrocarbon isomer mixture

ActiveCN111410596BAdjustable forceHigh separation selectivityGas treatmentChemical industryPhysical chemistryAromatic hydrocarbon

The invention discloses a method for separating isomer mixtures of C8 aromatic hydrocarbons. An anionic pillared microporous material with a large pore size is used as an adsorbent, and the mixture of C8 aromatic hydrocarbon isomers is contacted with the adsorbent to realize carbon Selective adsorption and separation of octaaromatic isomer mixtures; the anionic pillared microporous material is a porous material formed by a metal ion M, an inorganic anion A and an organic ligand L through a coordination bond, and the general formula is [MAL 2 ] n , wherein n>4 and is an integer; the metal ion M is Fe 2+ 、Co 2+ 、Ni 2+ or Cu 2+ ; The inorganic anion A is SiF 6 2‑ , NbOF 5 2‑ , TaF 7 2‑ , ZrF 6 2‑ 、TiF 6 2‑ 、GeF 6 2‑ , SO 3 CF 3 ‑ or NbF 6 ‑ ; The organic ligand L is selected from the following structures:

Owner:ZHEJIANG UNIV

Flat vibrator discharge equipment

ActiveCN111776676BRealize automatic nestingIncrease the discharge speedConveyorsConveyor partsReciprocating motionEngineering

The invention relates to flat vibrator discharge equipment, which belongs to the technical field of mechanical equipment, and includes a frame and a material box assembly arranged on it. The material box assembly includes a material box body, the upper side of the material box body has a groove, and one end of the groove is A material tray is provided, and the material tray has several troughs matching the vibrator; the other end of the groove is provided with a cover plate, and the cover plate and one end of the corresponding groove form a material bin; the lower side of the material box body is provided with a rotating shaft, and the material box The body is rotationally connected with the frame through a rotating shaft; one side of the tray is provided with a material brush that can reciprocate along the upper side of the tray, and the brush is connected with a brush driving device; it also includes a swing mechanism that enables the box body to rotate around the shaft. And a material screening mechanism that enables the material box assembly to reciprocate axially along the rotating shaft. The invention realizes the automatic discharge of the flat vibrator and improves the discharge speed of the flat vibrator.

Owner:重庆市灵龙电子有限公司

A kind of separation method of isomerized oil

ActiveCN111575047BBoost octaneWith flexible functionAdsorption purification/separationHydrocarbon oils refiningIsomerizationStructural formula

The invention discloses a method for separating isomerized oil. The isomerized oil contains C5-C8 low-octane alkanes and high-octane alkanes. The low-octane alkanes include normal alkanes, At least one of branched alkanes, the high-octane alkanes include multi-branched alkanes; the separation method is to use the fluorine-containing anion hybrid porous material with flexible function as the separation adsorbent, and the separation adsorbent Contact with the isomerized oil to realize the selective adsorption and separation of the low-octane alkanes and high-octane alkanes; the general structural formula of the fluorine-containing anion hybrid porous material is M‑L1‑A or M ‑L2‑A, wherein: M is a metal ion selected from Cu 2+ , Zn 2+ 、Co 2+ or Ni 2+ ; A is an inorganic fluorine-containing anion selected from SnF 6 2‑ , ZrF 6 2‑ 、GeF 6 2‑ 、SiF 6 2‑ or TiF 6 2‑ ; L1 is an organic ligand 1,2-dipyridylacetylene; L2 is an organic ligand 4,4'-bipyridine.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com