Hydraulic buffer device for center frame of heavy machine tool

A technology for hydraulic buffering and heavy-duty machine tools, applied in mechanical equipment, liquid shock absorbers, metal processing machinery parts, etc., can solve problems such as deformation of the screw and nut, heavy workpiece weight, affecting use, etc., and achieve adjustable buffering force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

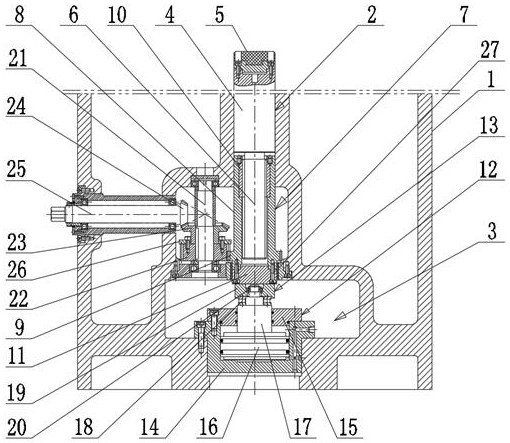

[0025] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described:

[0026] like figure 1 As shown, a hydraulic buffer device for a center frame of a heavy machine tool mainly includes a center frame base 1, a hydraulic buffer holding mechanism and an adjusting mechanism. The center frame usually includes an upper body of the center frame and a center frame base 1. The supporting member on the center frame base 1 is the main bearing part of the workpiece, and the supporting member here is also the most vulnerable to damage. The improvement of the present invention is mainly aimed at It is the holding part at this place, so that the holding part at this place can be buffered after being loaded instantaneously, so as to protect the holding part.

[0027] The center frame base 1 provides support for the hydraulic buffer jacking mechanism. The center frame base 1 is provided with a slide for the hydraulic buffer jacking mechanism to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com