Arc gate big assembly method

A technology of arc doors and door leaves, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of reducing operation difficulty and operation difficulty, and achieves reducing operation difficulty, overcoming operation difficulty, and building requirements simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

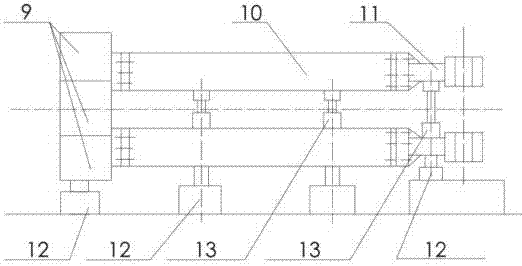

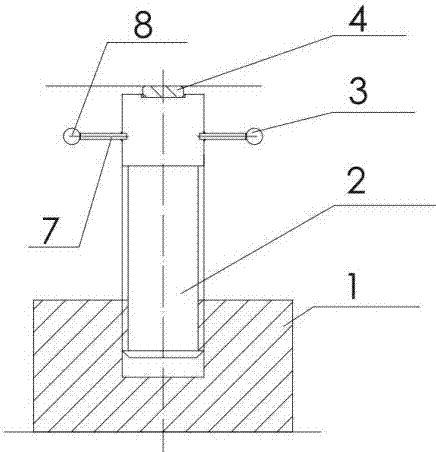

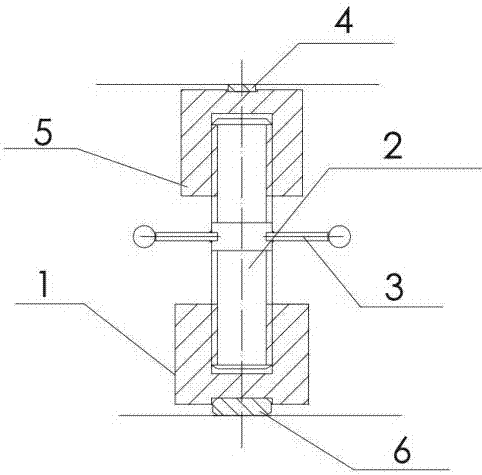

[0045] As a preferred embodiment of the present invention, with reference to the attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 , the present embodiment discloses a method for fighting arc doors, and the present embodiment includes the following steps:

[0046] In the first step, the support arm mechanism composed of the hinge base 11 and the support arm 10 is placed parallel to the ground;

[0047] In the second step, a plurality of support tooling I12 is set under the support arm mechanism and adjusted to the level;

[0048] The third step is to set the arc door leaf 9 so that the two straight sides are perpendicular to the ground, and set a plurality of support tooling I12 between the processing surface of the water seal seat on the side of the arc door leaf 9 and the ground, and adjust it to the level;

[0049] The fourth step is to calibrate the position of the arc door leaf (9) and the support arm mechanism;

...

Embodiment 2

[0071] As a preferred embodiment of the present invention, with reference to the attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 , the present embodiment discloses a method for fighting arc doors, and the present embodiment includes the following steps:

[0072] In the first step, the support arm mechanism composed of the hinge base 11 and the support arm 10 is placed parallel to the ground;

[0073] In the second step, a plurality of support tooling I12 is set under the support arm mechanism and adjusted to the level;

[0074] The third step is to set the arc door leaf 9 so that the two straight sides are perpendicular to the ground, and set a plurality of support tooling I12 between the arc edge of the arc door leaf 9 and the ground, and adjust it to the level;

[0075] The fourth step is to adjust the position of the arc door leaf 9 and the support arm mechanism;

[0076] The fifth step is to weld the connecting e...

Embodiment 3

[0078] As a preferred embodiment of the present invention, with reference to the attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , the present embodiment discloses a method for fighting arc doors, and the present embodiment includes the following steps:

[0079] In the first step, the support arm mechanism composed of the hinge base 11 and the support arm 10 is placed parallel to the ground;

[0080] In the second step, a plurality of support tooling I12 is set under the support arm mechanism and adjusted to the level;

[0081] The third step is to set the arc door leaf 9 so that the two straight sides are perpendicular to the ground, and set a plurality of support tooling I12 between the arc edge of the arc door leaf 9 and the ground, and adjust it to the level;

[0082] The fourth step is to adjust the position of the arc door leaf 9 and the support arm mechanism;

[0083] The fifth step is to weld the connecting end plate of the arc do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com