A remote control high-altitude wiring pliers

A wiring pliers and remote control technology, applied in the field of high-altitude power testing equipment, can solve the problems of large overall weight, complex structure, time-consuming and labor-intensive wiring process, etc., and achieve the effect of simple operation method, simple mechanical transmission, and simplified overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

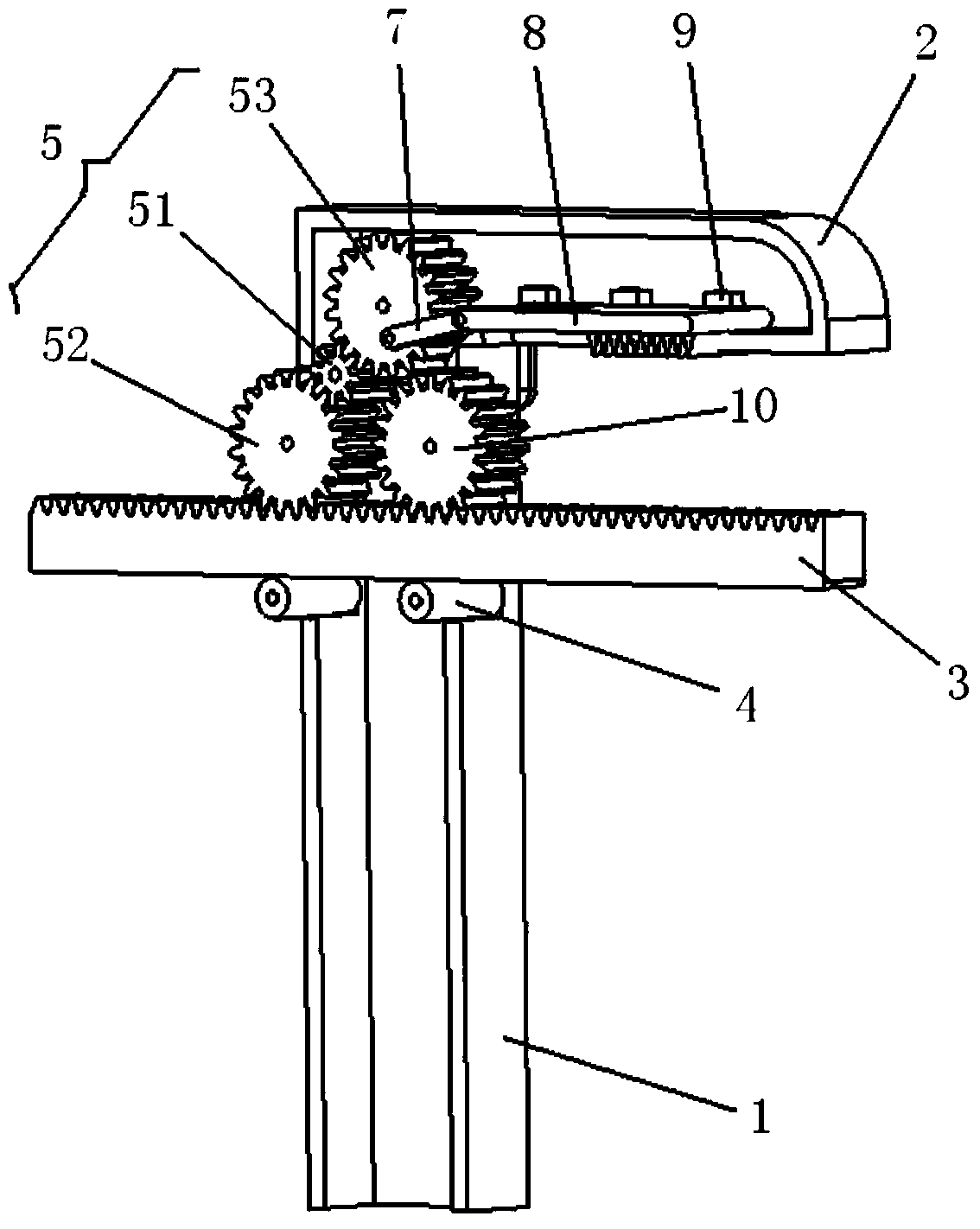

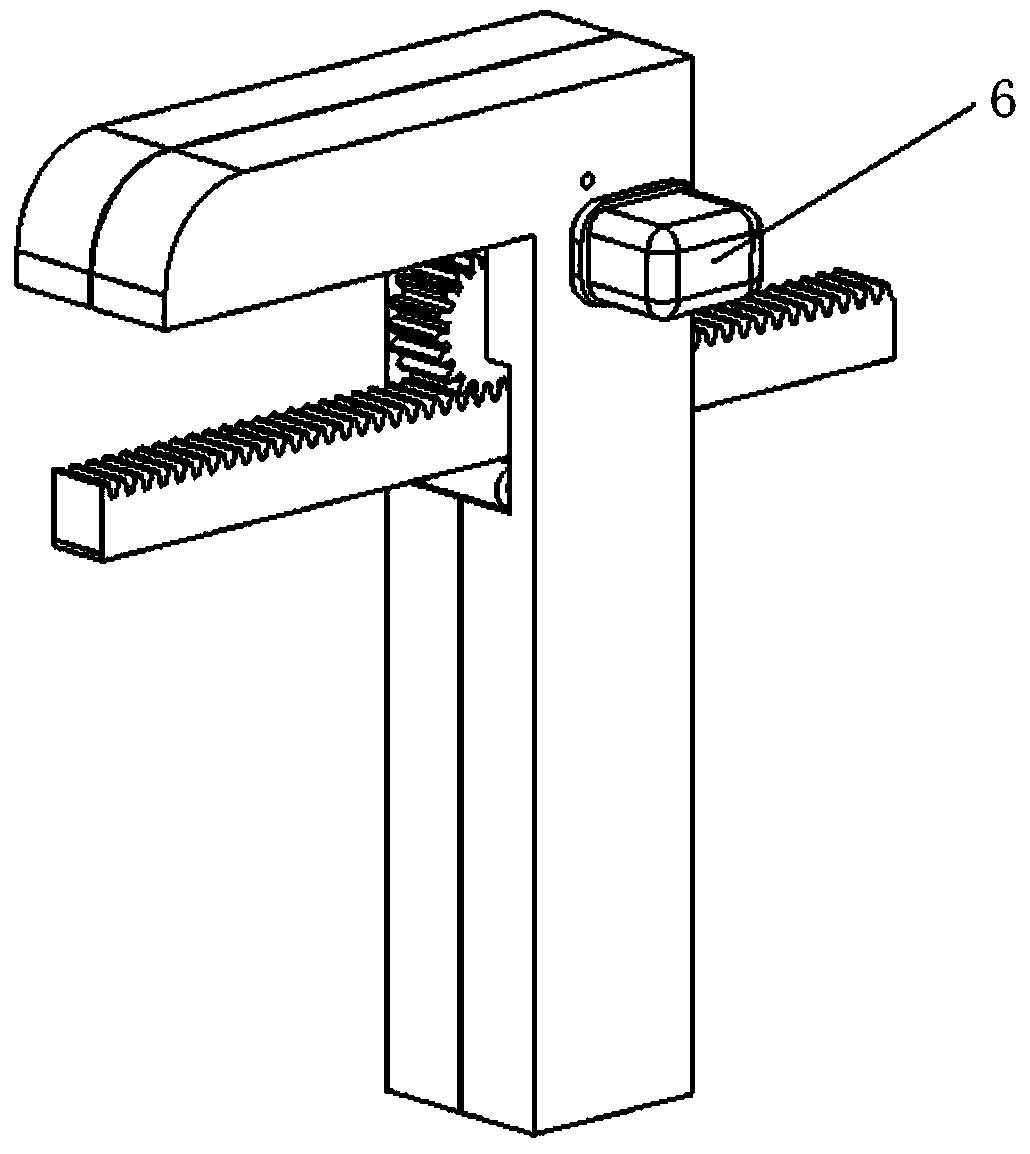

[0029] see Figure 1 to Figure 2 , in a preferred embodiment of the present invention, a remote-controlled high-altitude wiring pliers includes a pliers body 1, an upper jaw 2, a lower jaw 3, a gear set 5 and a motor are installed on the pliers body 1 6. The lower jaw 3 is arranged below the upper jaw 2, and is engaged with the gear set 5, and is driven by the gear set 5 to move laterally. The motor 6 is connected with the gear set 5 to drive the lower jaw 3 to move laterally through the gear set 5; preferably, the motor 6 is a servo motor to realize forward rotation and reverse rotation of the output shaft of the motor 6, and then drive the lower jaw 3 Move back and forth to realize the hiding and stretching out of the lower jaw 3.

[0030] Further, see figure 1 , the upper jaw 2 is located on one side of the pliers body 1, and the lower jaw 3 is arranged on the corresponding lower side of the upper jaw 2; preferably, the upper jaw 2 and the lower jaw 3 are vertically arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com