Patents

Literature

68results about How to "Change the amount of compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

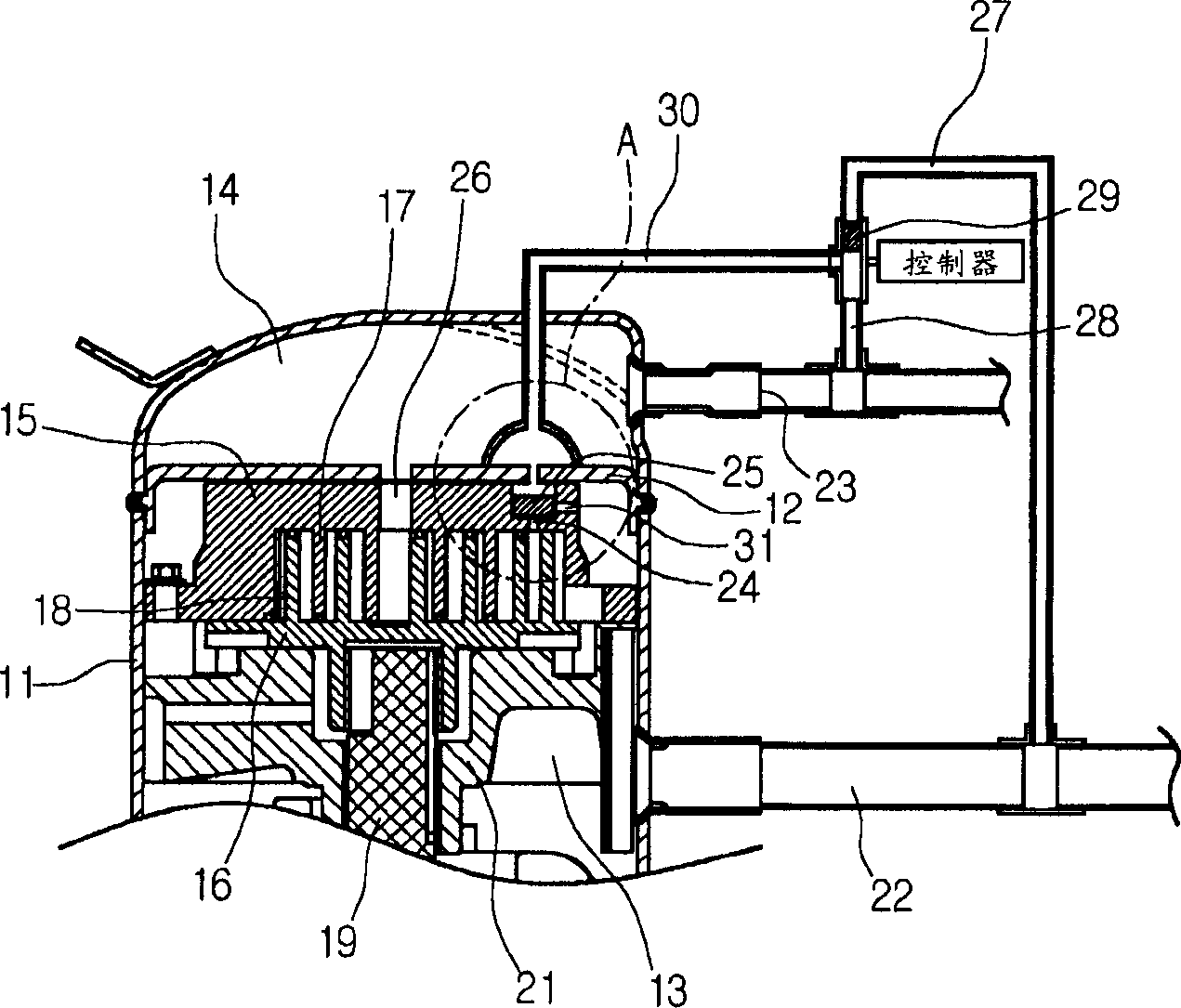

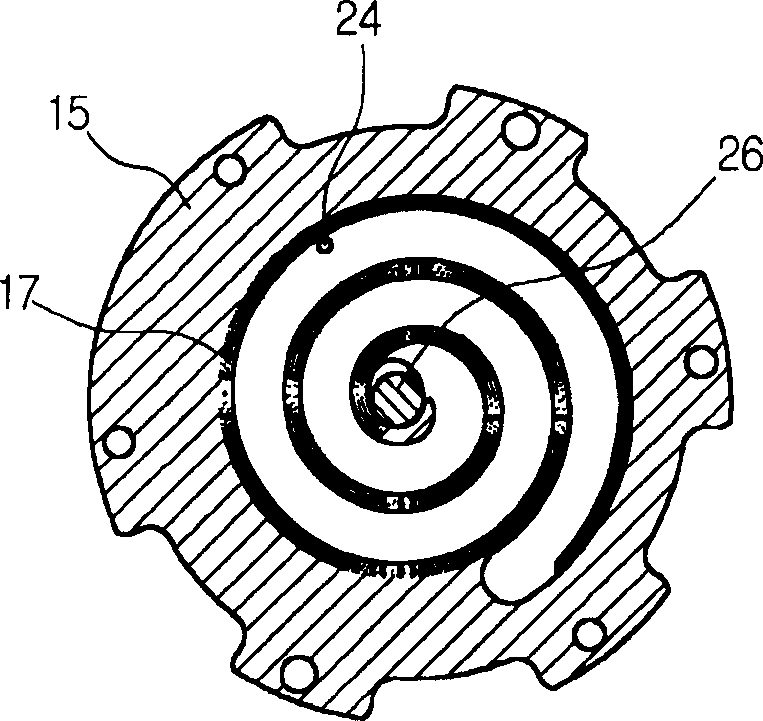

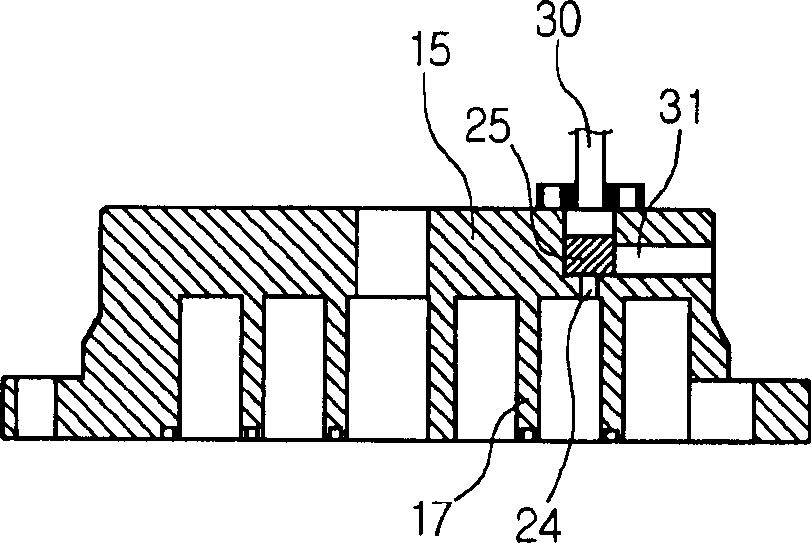

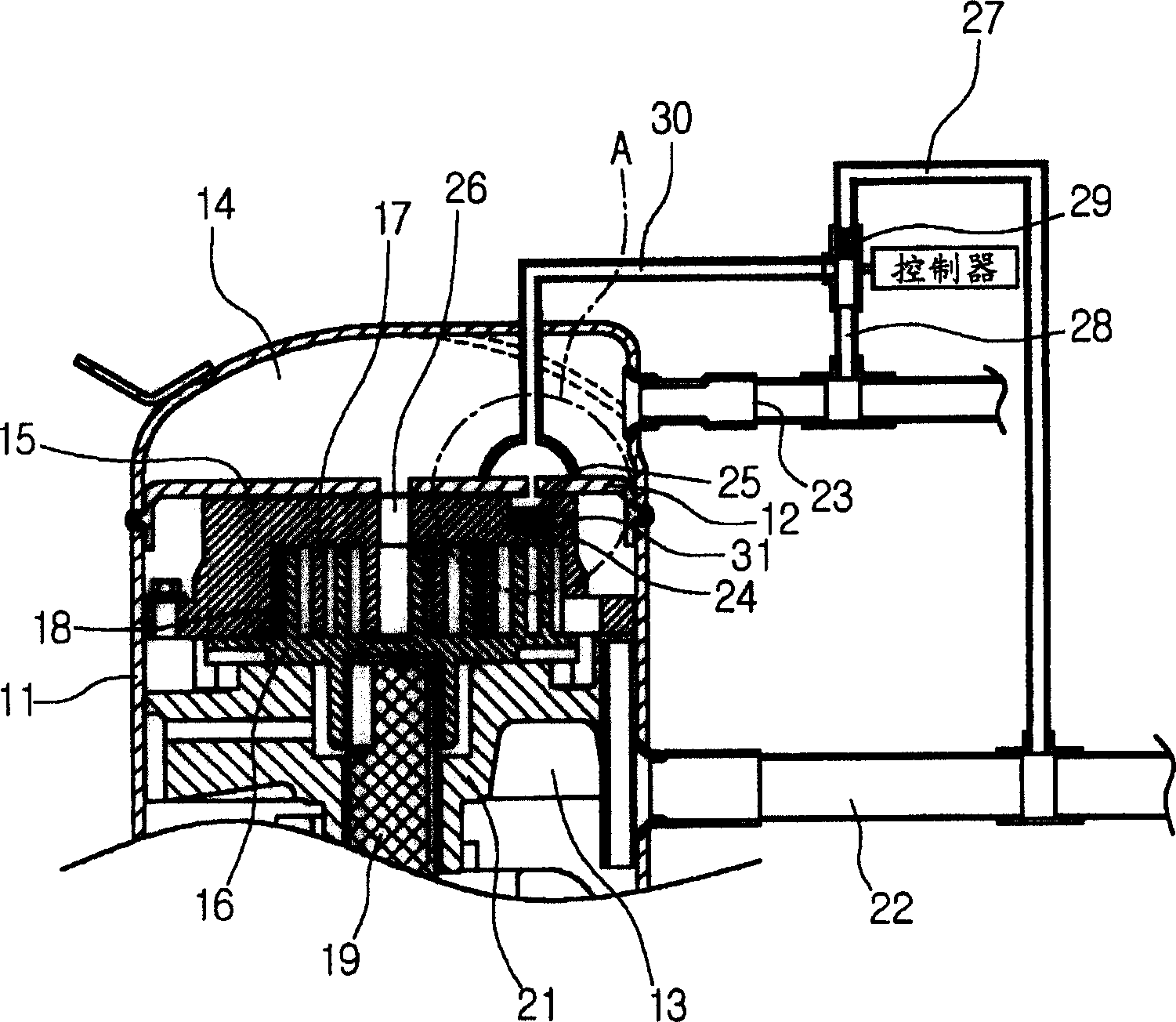

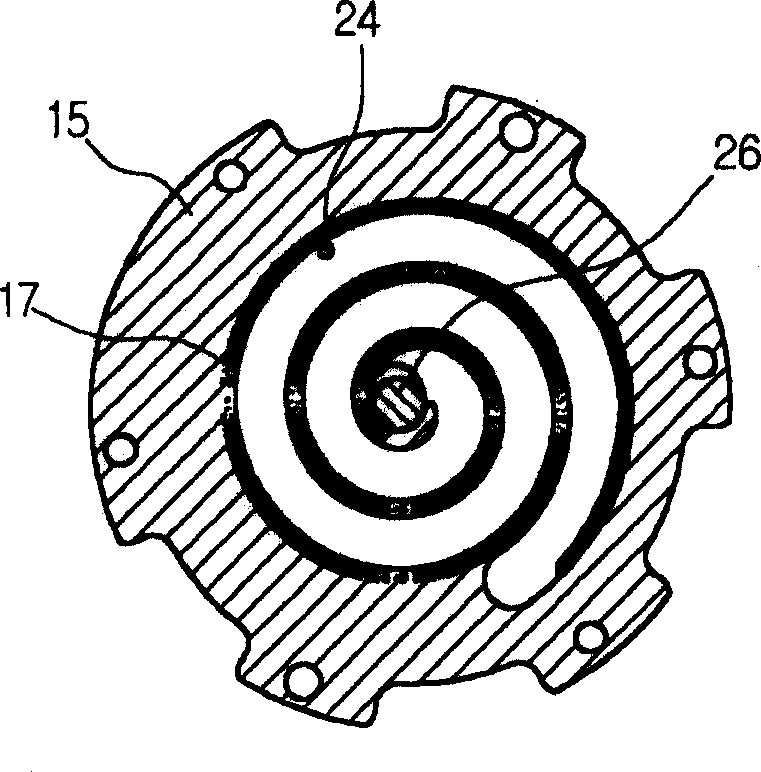

Variable capacity scroll compressor

InactiveCN1576603AControl action stateChange the amount of compressionRotary piston pumpsRotary piston liquid enginesDischarge pressureMechanical engineering

Owner:LG ELECTRONICS INC

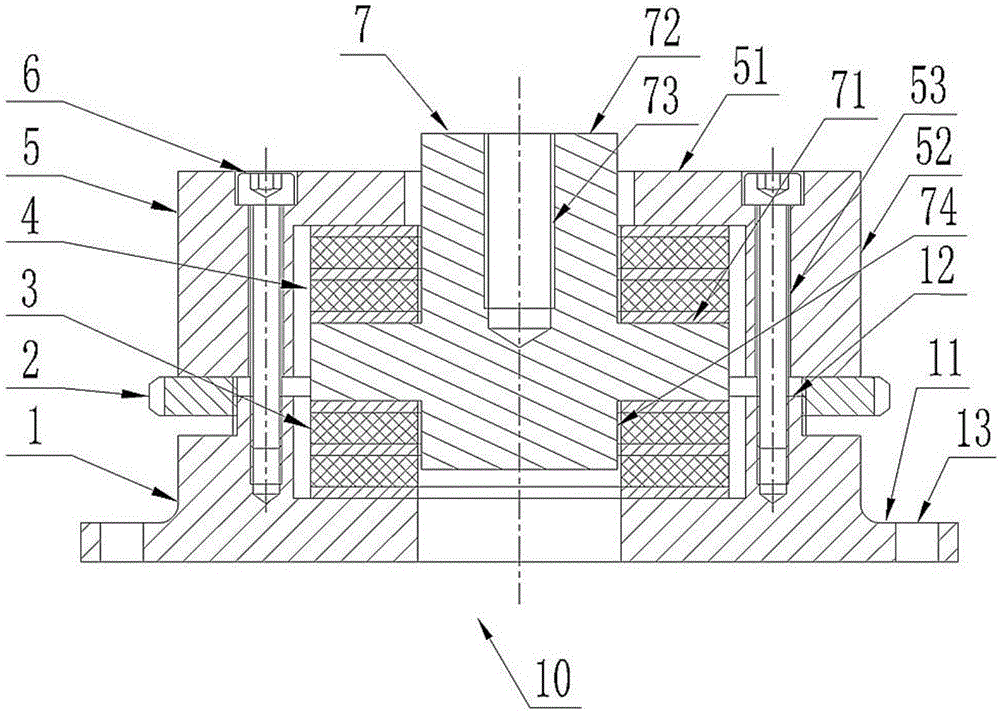

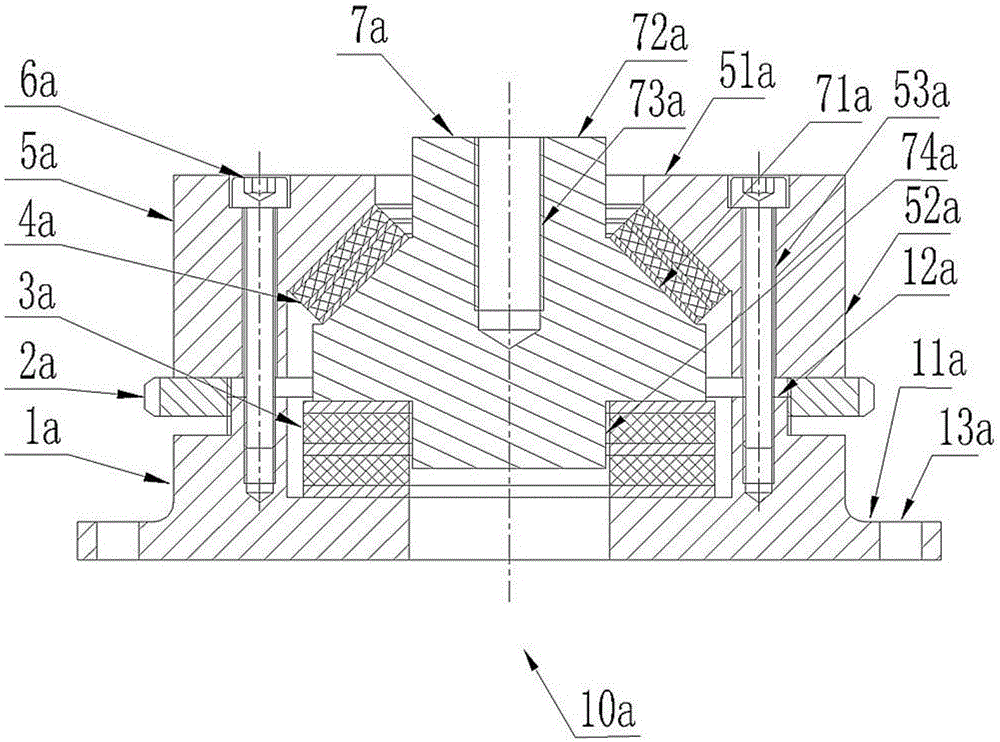

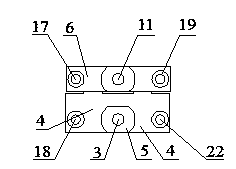

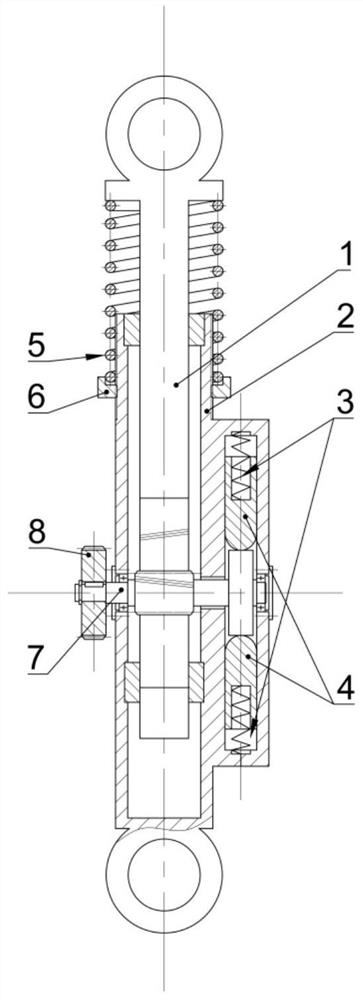

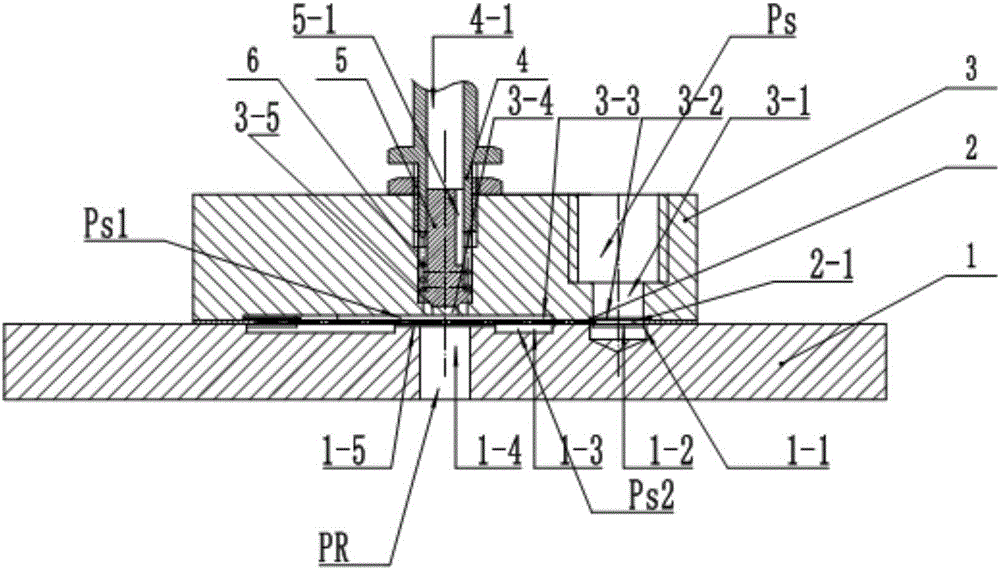

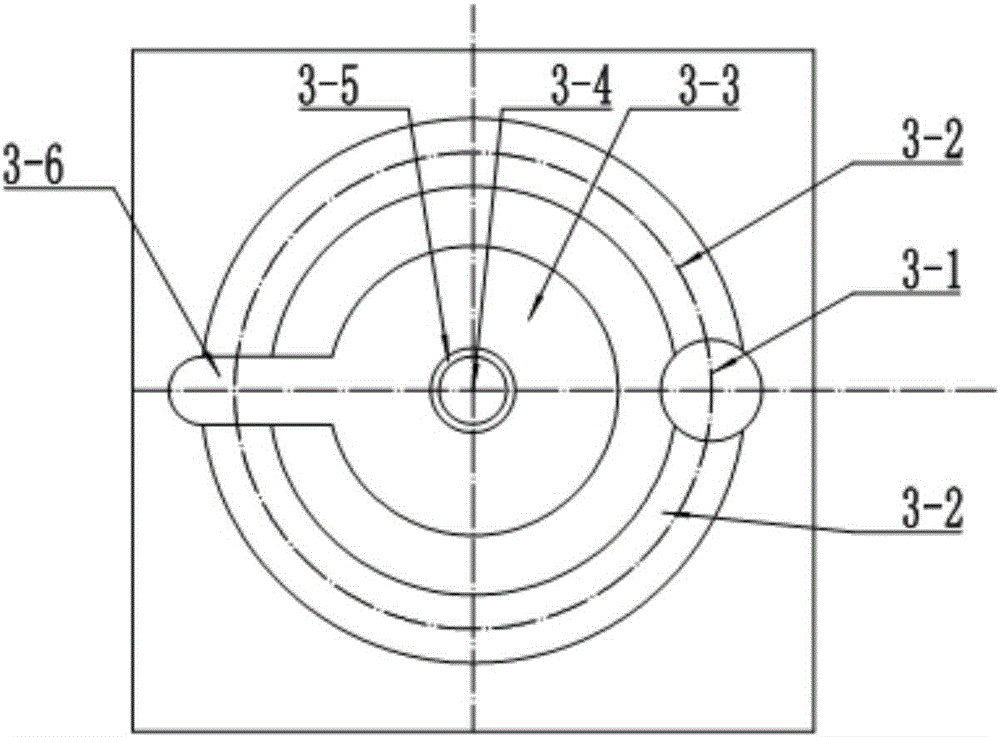

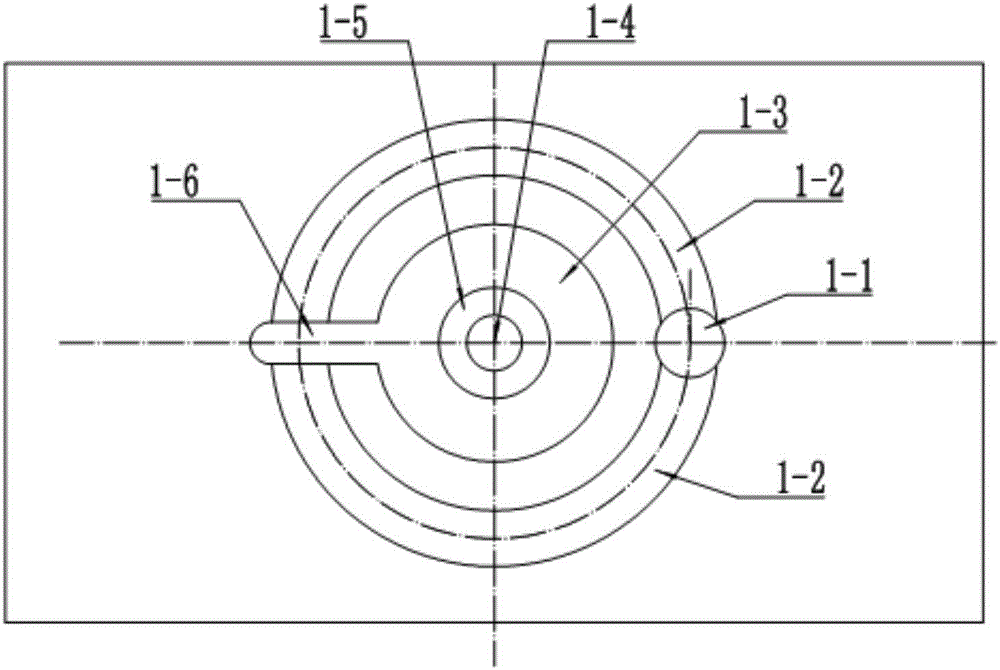

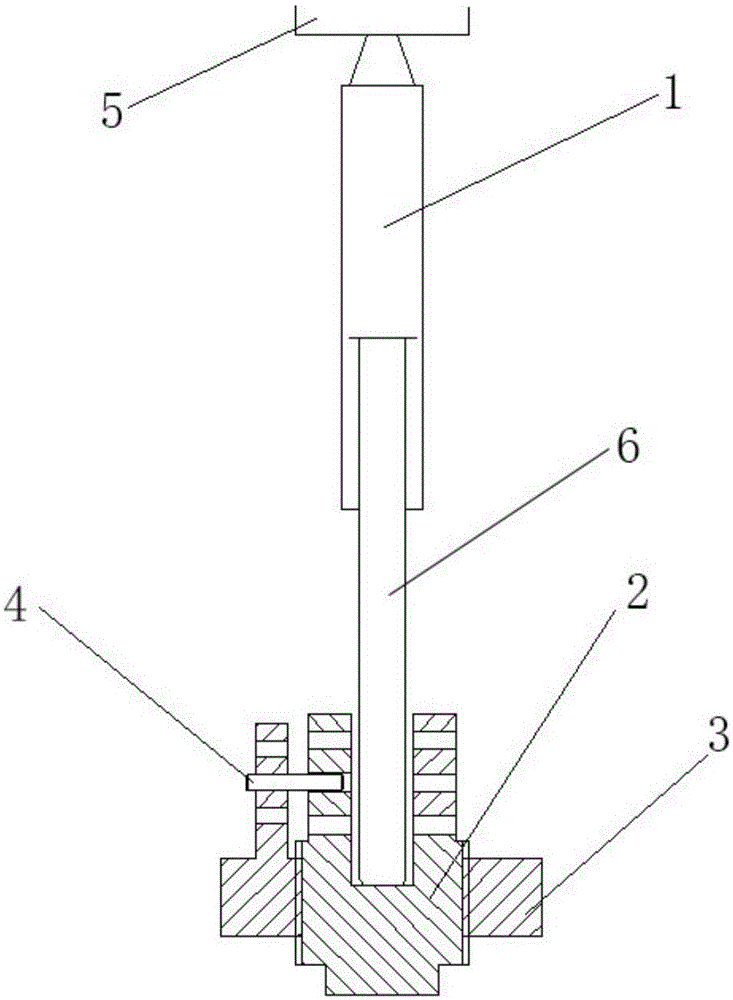

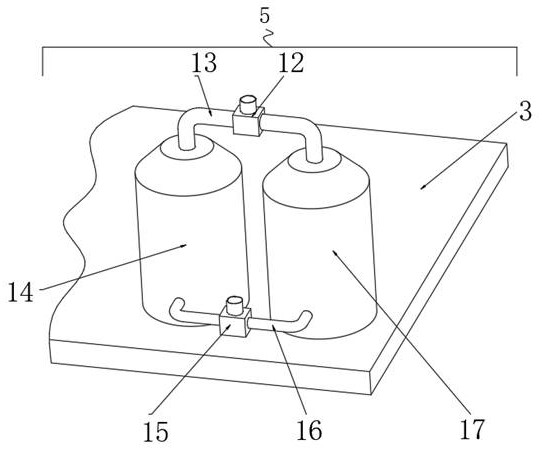

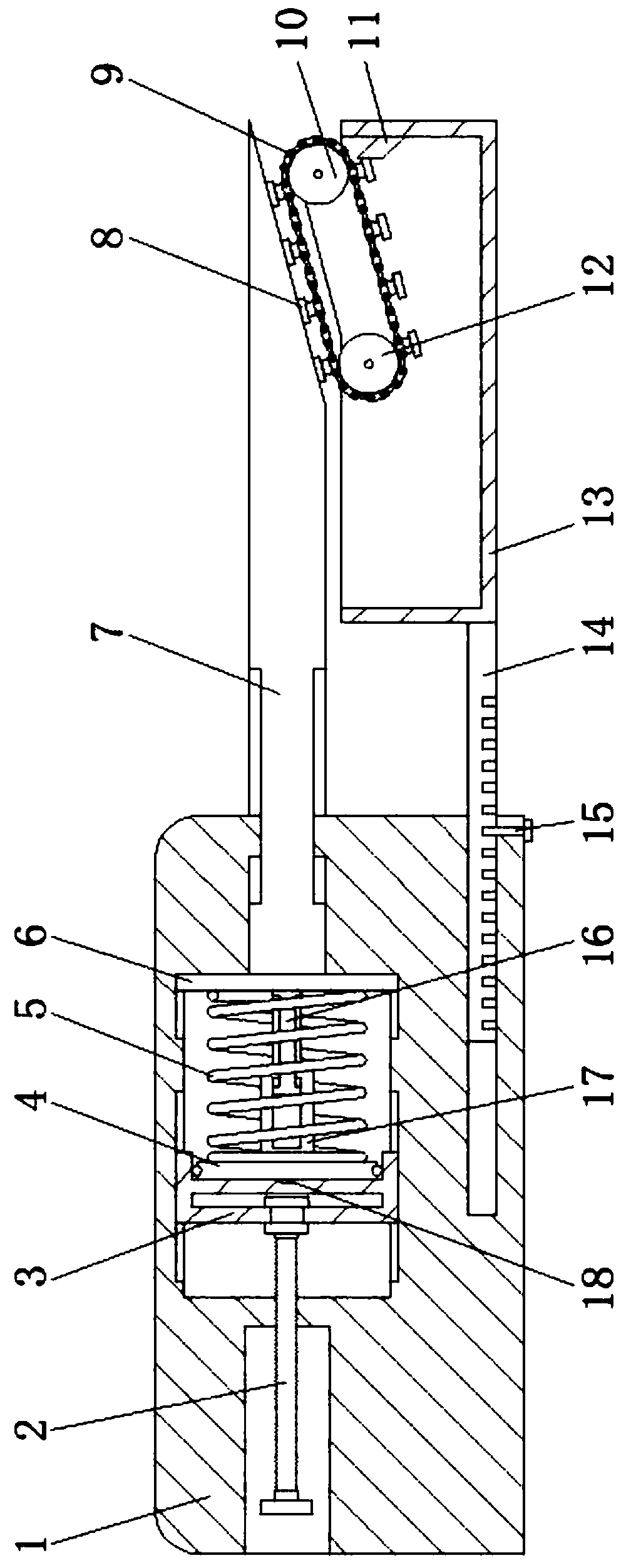

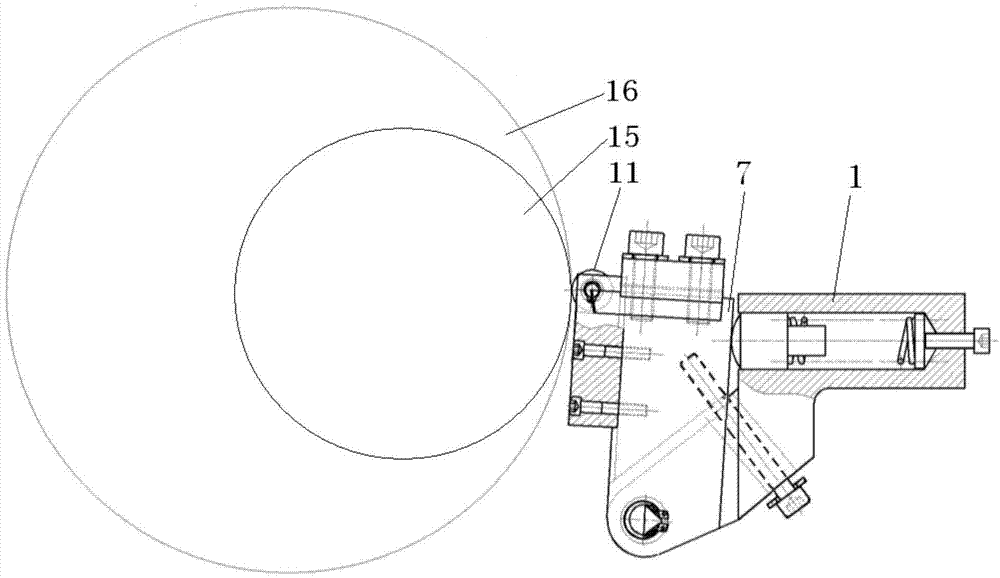

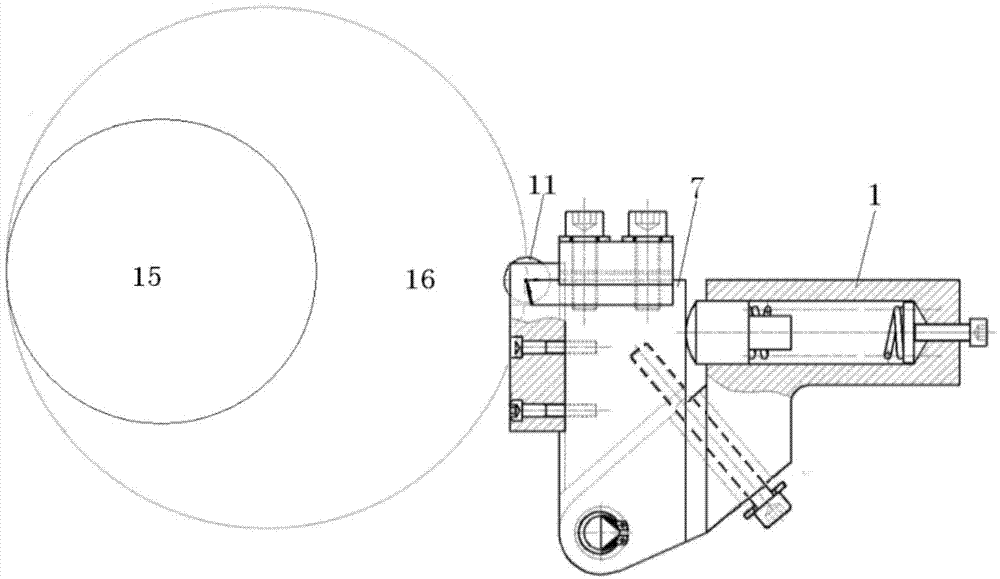

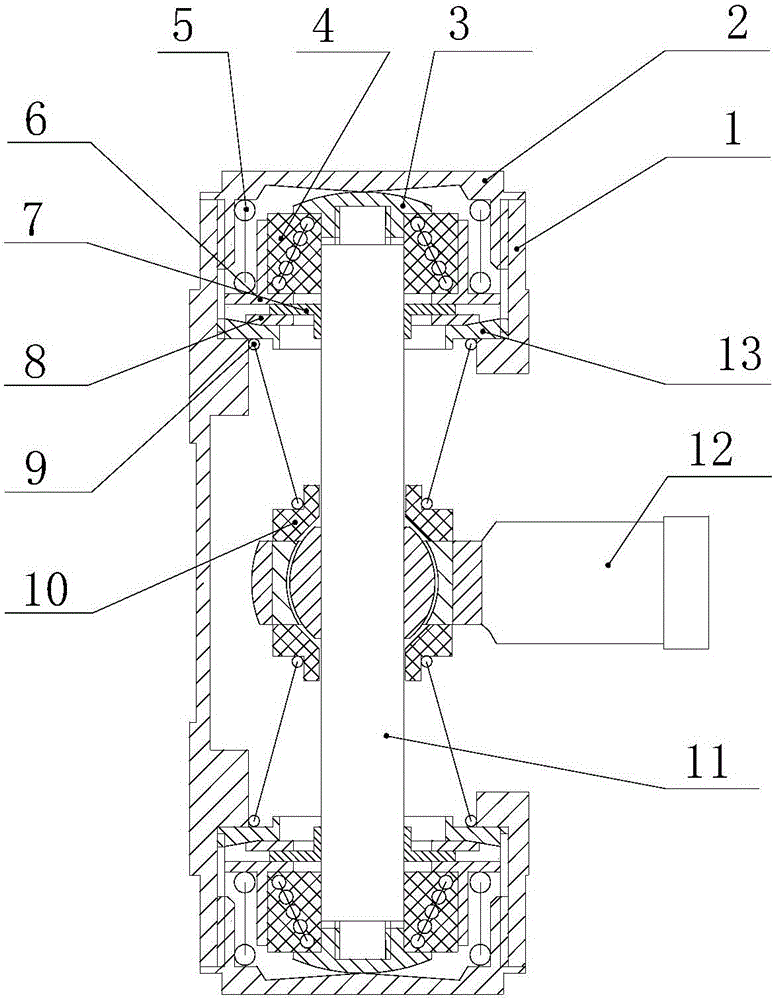

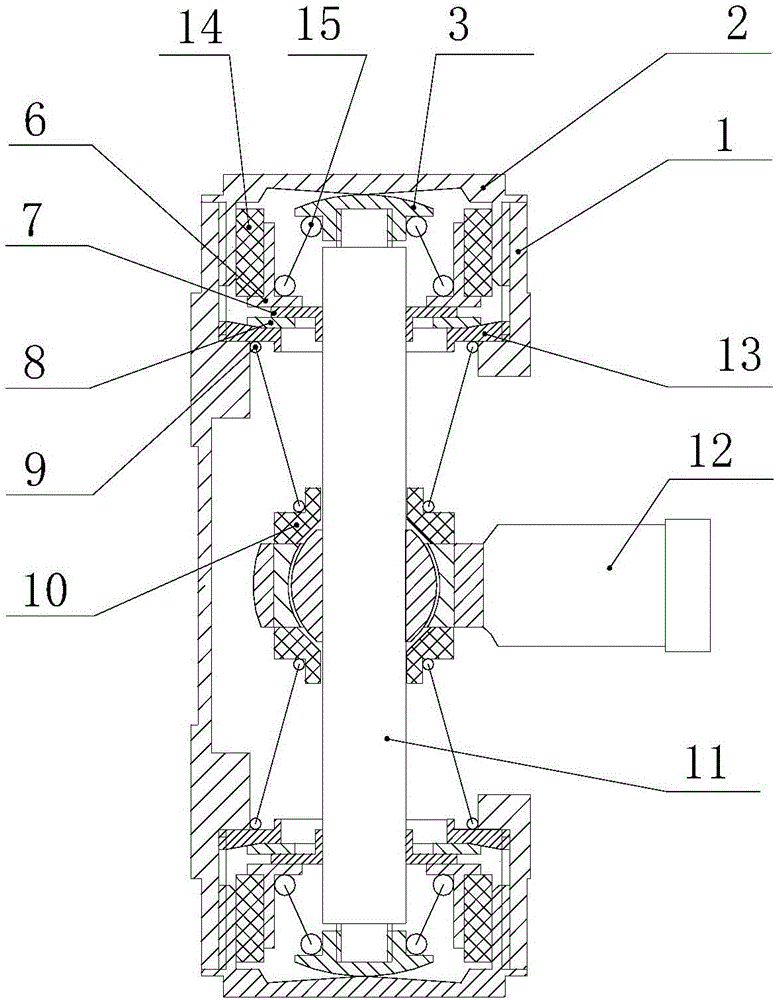

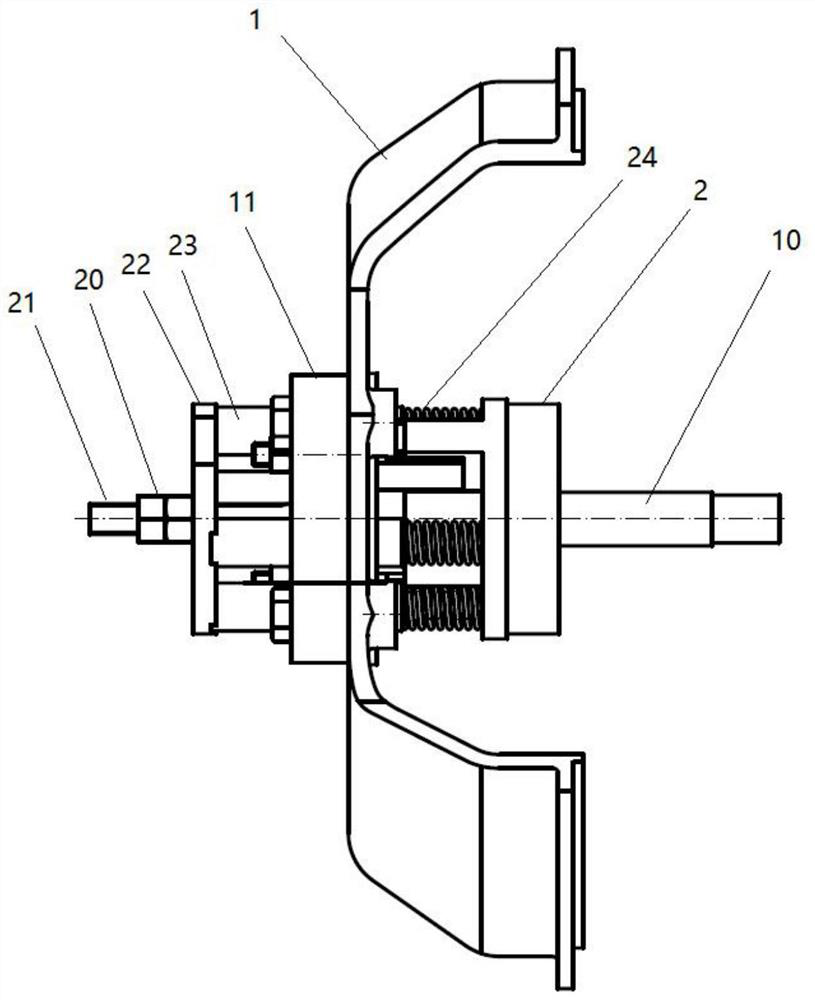

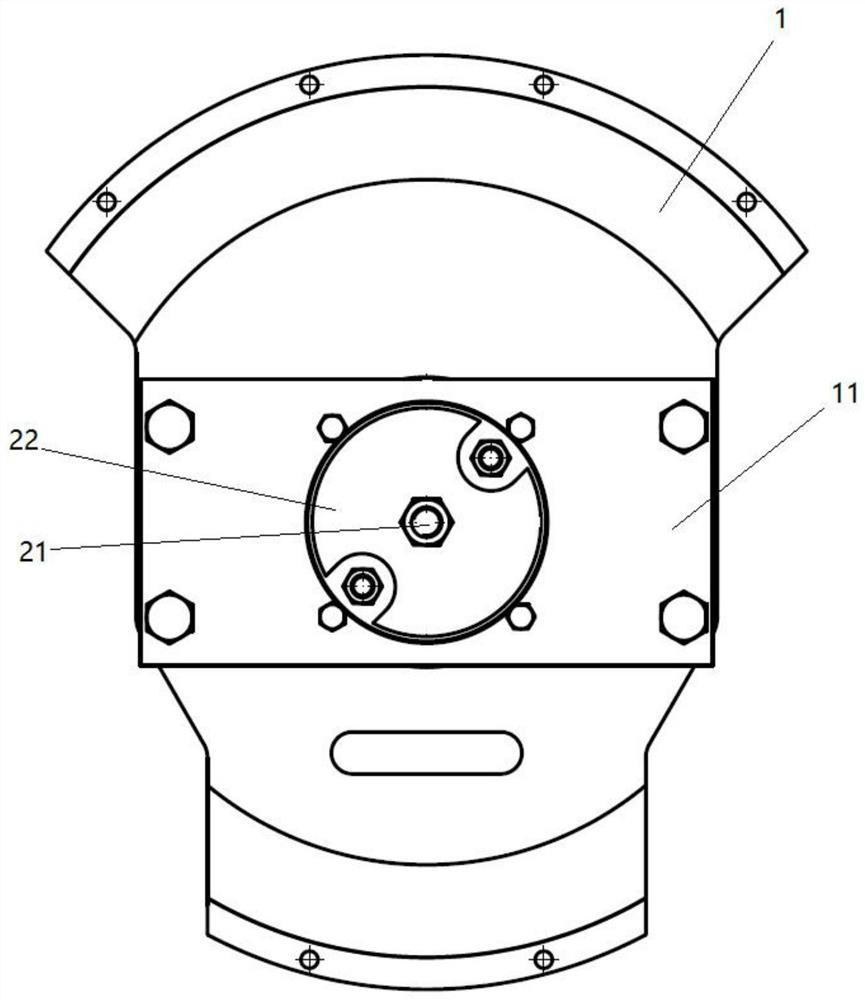

Shock absorber

ActiveCN105065566AChange the amount of precompressionChange the amount of compressionNon-rotating vibration suppressionEngineeringShock absorber

The invention relates to a shock absorber which comprises a lower supporting seat, an upper supporting seat, a joint, a lower elastic piece and an adjusting piece, wherein the upper supporting seat is tightly pressed towards the lower supporting seat; the joint comprises a core block and a supporting rod, the core block is arranged between the upper supporting seat and the lower supporting seat, and the supporting rod extends out of the core block and penetrates through the upper supporting seat; the lower elastic piece is arranged between the core block and the lower supporting seat, and the adjusting piece is used for adjusting the distance between the upper supporting seat and the lower supporting seat. The stiffness valve of the shock absorber can be adjusted on an installation site so that the demand for different shock absorbing stiffness is met, and the adaptability of the shock absorber is stronger than that of a common shock absorber. Meanwhile, after the shock absorber is used for a long time, the stiffness variation of the shock absorber caused by the aging and creep deformation of the lower elastic piece can be corrected by readjusting the distance between the upper supporting seat and the lower supporting seat, and therefore the service life of the shock absorber is relatively prolonged.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

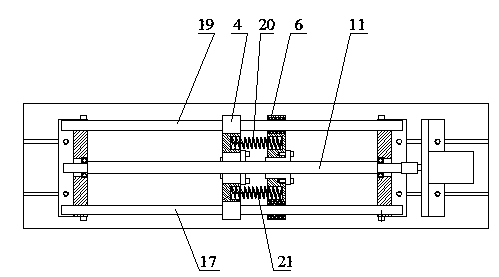

Transmission shaft vibration absorber

ActiveCN103821874AVibration frequency controlFlexible adjustment of screw-in amountRotating vibration suppressionDrive shaftEngineering

Owner:GREAT WALL MOTOR CO LTD

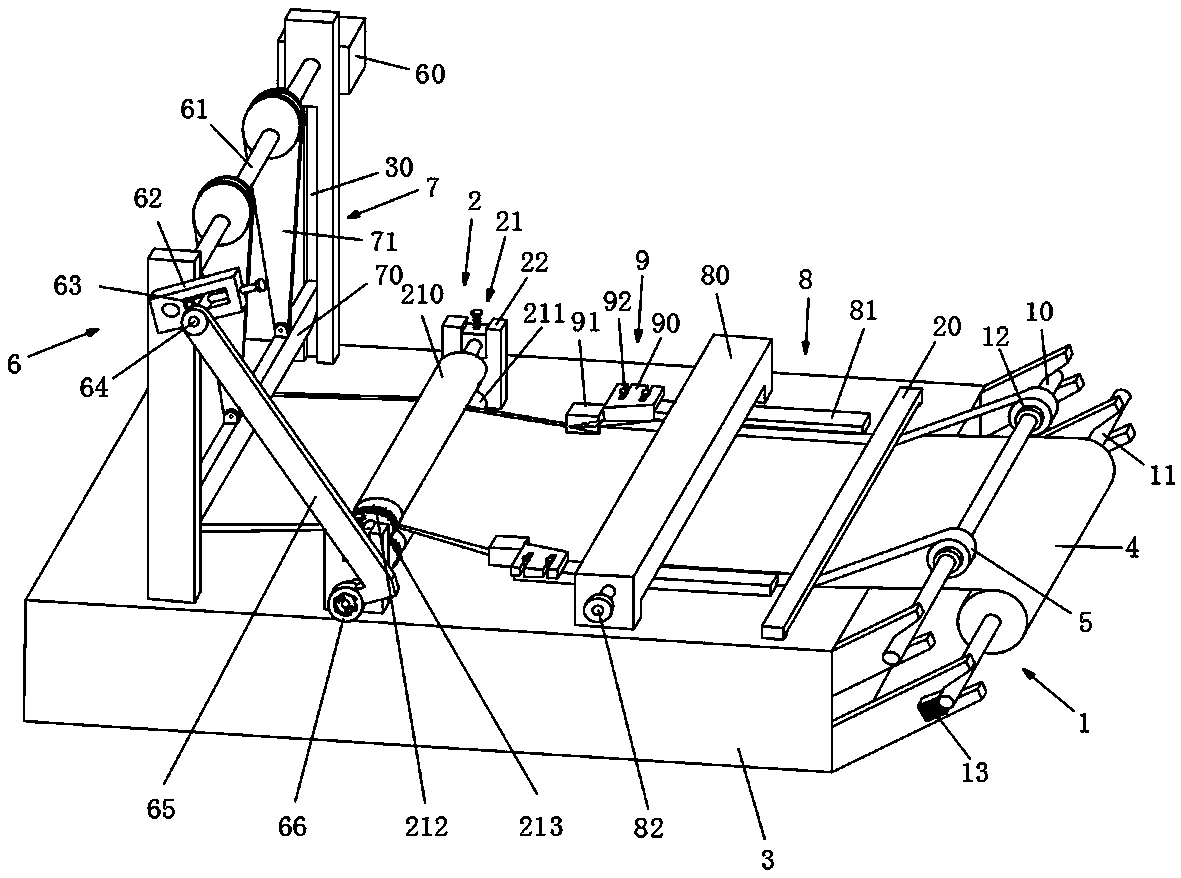

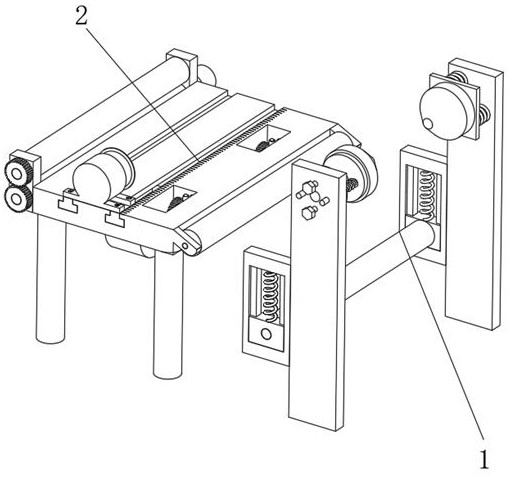

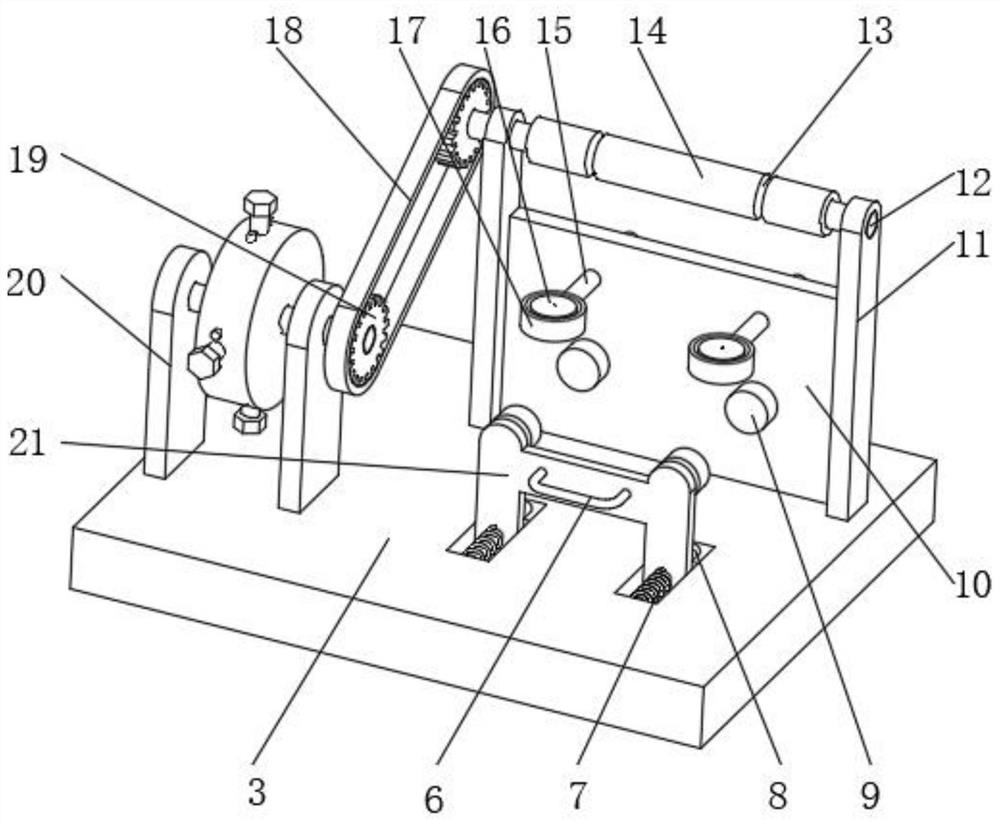

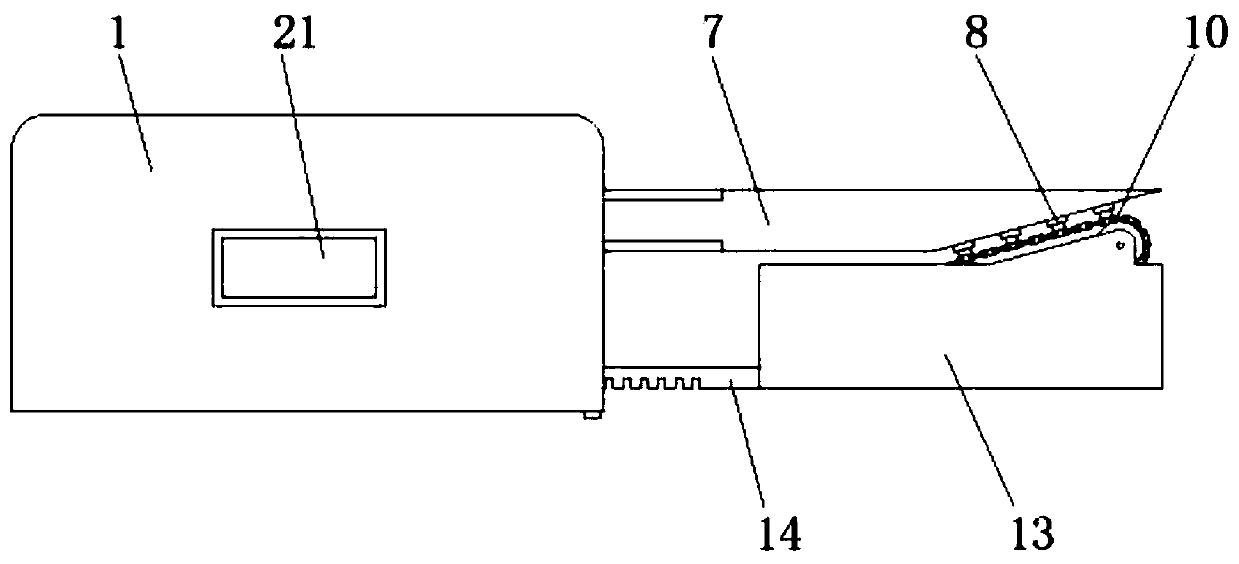

Adhesive tape pasting and folding device for insulation paper and pasting and folding method thereof

ActiveCN110015587AReduce slipImprove insulation performancePaper/cardboard articlesFolding thin materialsPulp and paper industryPaper sheet

The invention relates to an adhesive tape pasting and folding device for insulation paper. The device comprises a discharging mechanism, a pasting main body and a machine frame, wherein the discharging mechanism comprises an upper rotating shaft and a lower rotating shaft, the lower rotating shaft is sleeved with insulation paper, the upper rotating shaft is sleeved with two adhesive tapes, the two adhesive tapes are positioned above the two side edges of the insulation paper; the pasting main body comprises a pre-pressing rod and a counter-pressing roller, the lower ends of the two sides of the pre-pressing rod are fixed on the machine frame, the adhesive tapes and the insulation paper penetrate through the lower portion of the pre-pressing rod, so that the adhesive tapes are adhered to the insulation paper, the counter-pressing roller comprises an upper counter-pressing roller and a lower counter-pressing roller, the upper counter-pressing roller and the lower counter-pressing rollerare rotationally fixed on the machine frame through a mounting seat with adjustable pressure, the upper counter-pressing roller and the lower counter-pressing roller are driven by a driving device torotate and roll the insulation paper, then the insulation paper is discharged, a folding mechanism is arranged between the pre-pressing rod and the counter-pressing roller; a cutting mechanism used for cutting folded insulation paper is fixed on the machine frame.

Owner:福州鼎之诚机电设备有限公司

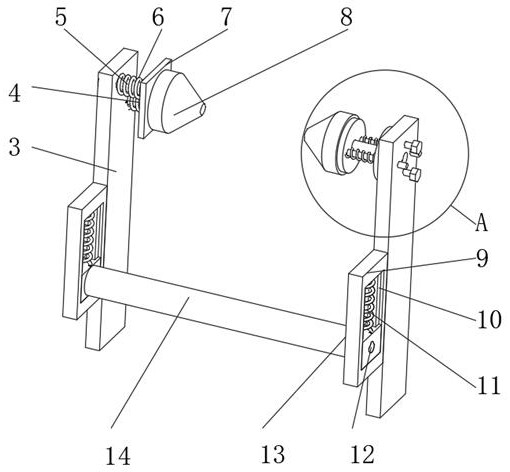

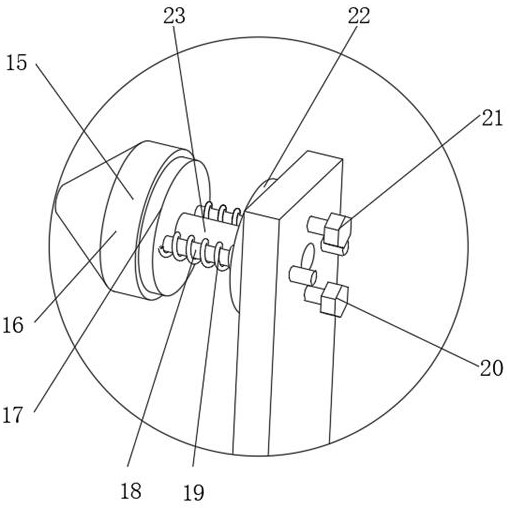

Edge cutting device capable of effectively preventing cloth from wrinkling

InactiveCN111826931ANo creases appearGuaranteed dimensional accuracySevering textilesStructural engineeringMechanical engineering

The invention discloses an edge cutting device capable of effectively preventing cloth from wrinkling, and relates to the technical field of cloth processing. To solve the wrinkle problem, specifically, the edge cutting device comprises a material guide mechanism and a cutting mechanism, wherein the material guide mechanism comprises two vertical plates fixed to the ground, as well as an adjustable clamping assembly, a damping clamping assembly and a tensioning assembly which are arranged on the outer walls of the vertical plates, the adjustable clamping assembly comprises pressing springs andfirst ejector pins, the tensioning assembly comprises tensioning springs and a tensioning roll, a tensioning frame is fixedly installed on the outer wall of each vertical plate, and a first sliding groove is formed in the inner wall of each tensioning frame. According to the edge cutting device, the damping clamping assembly and the tensioning assembly are arranged, when a conveying assembly is used for conveying, the damping clamping assembly can provide moving damping force for rotation of a cloth roll, due to the damping force, the two tensioning springs are pressed, thus downward tensionforce is generated for the cloth, so that the whole cloth is in a tension state, then wrinkles are avoided, and further, the size accuracy of a cutting assembly during cutting is guaranteed.

Owner:安徽工美服装有限公司

Variable capacity scroll compressor

InactiveCN1576604AChange the amount of compressionRotary piston pumpsRotary piston liquid enginesPhysicsThermodynamic cycle

Disclosed is a variable capacity scroll compressor in which a high-pressure fluid within a thermodynamic cycle is introduced into the inside of the compressor to increase the compression volume and also the fluid inhaled / exhausted from the compressor allows the fluid being compressed to be bypassed in multi-stages, thereby varying the capacity of the compression fluid.

Owner:LG ELECTRONICS INC

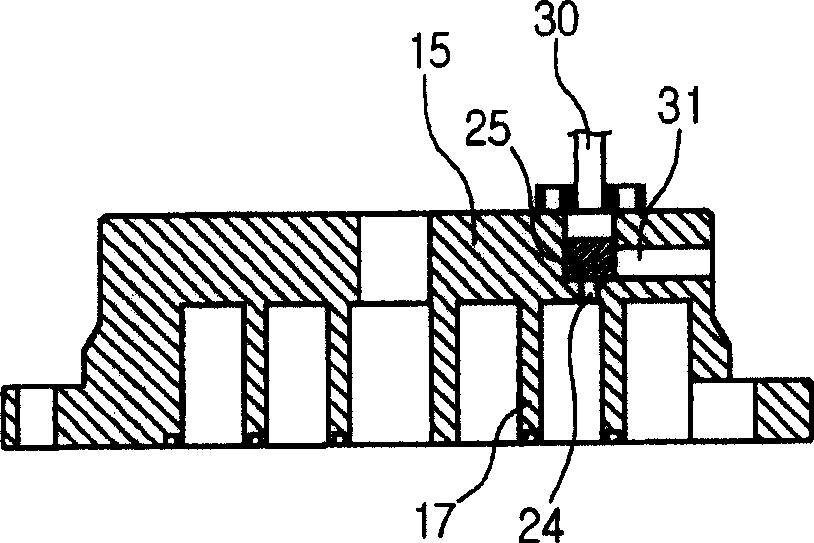

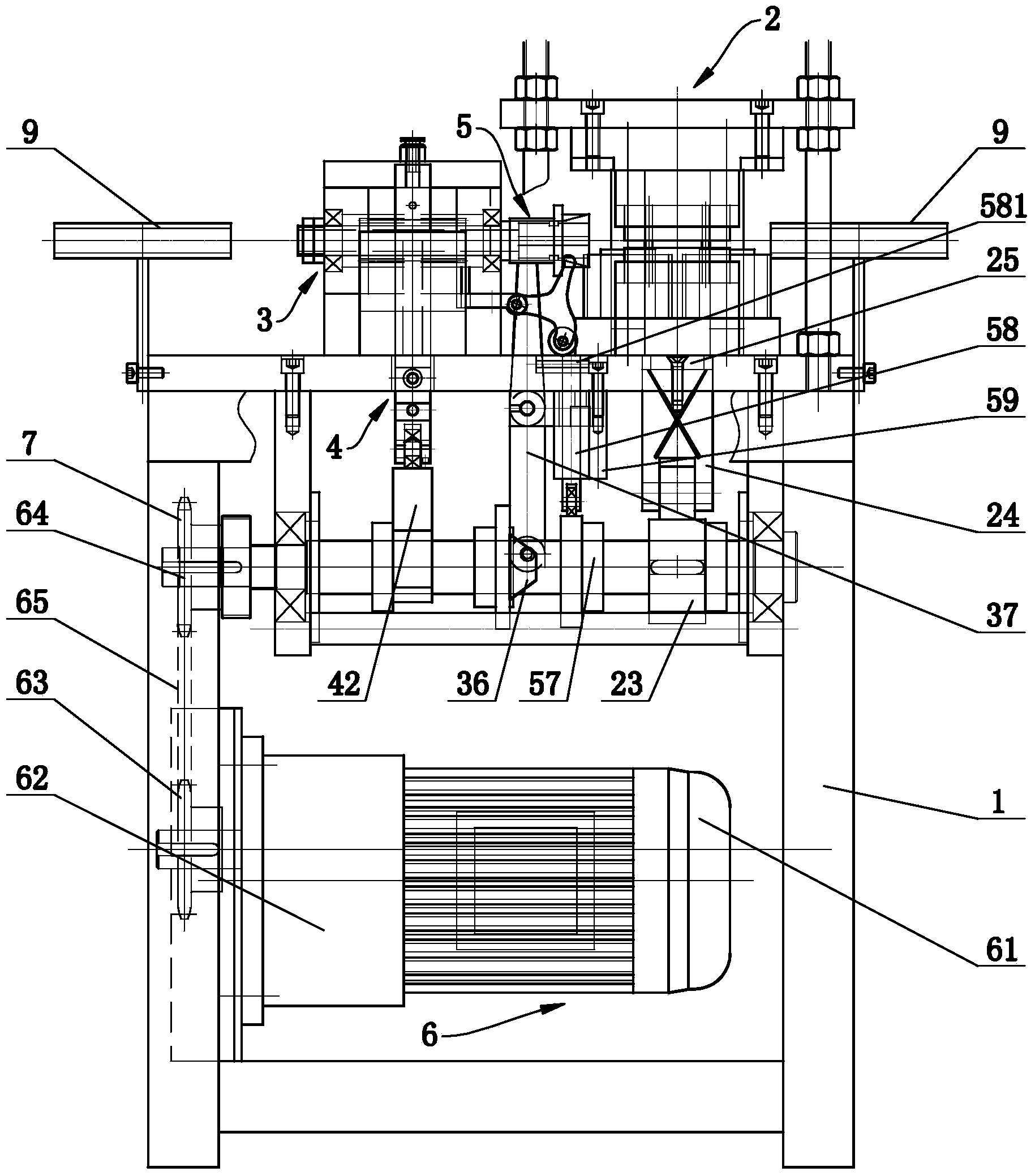

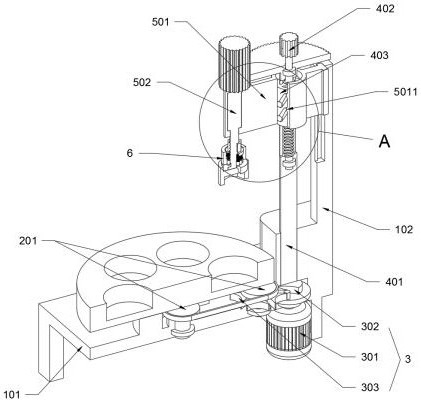

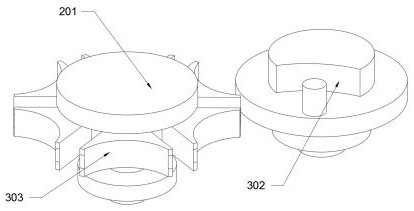

Automatic thin wall gold tube necking machine

ActiveCN103861963AQuality improvementPrecise feeding positionShaping toolsMetal-working feeding devicesEngineeringMachining process

The invention discloses an automatic thin wall gold tube necking machine, belonging to the technical field of jewelry processing equipment. The automatic thin wall gold tube necking machine comprises a rack, wherein the rack is provided with a feed system; the downstream of the feed system is provided with a mould system used for stamping a tube billet of a thin wall gold tube into bead strings; the feed system comprises an axial feeding device used for conveying the tube billet of the thin wall gold tube, a rotation feeding device used for rotating the tube billet of the thin wall gold tube in an intermittent way and a clamp device used for clamping or loosening the tube billet of the thin wall gold tube. According to the automatic thin wall gold tube necking machine, feeding, rotating clamping and stamping of the tube billet of the thin wall gold tube are automatic, so automatic feeding and stamping of the processing of the tube billet of the thin wall gold tube are realized. When the stamping is performed, the tube billet of the thin wall gold tube is clamped, so the quality of the produced bead strings is stable. In the machining process, stock lifting for the tube billet of the thin wall gold tube is not needed, so the working efficiency is significantly improved.

Owner:SHANDONG MOKINGRAN JEWELRY

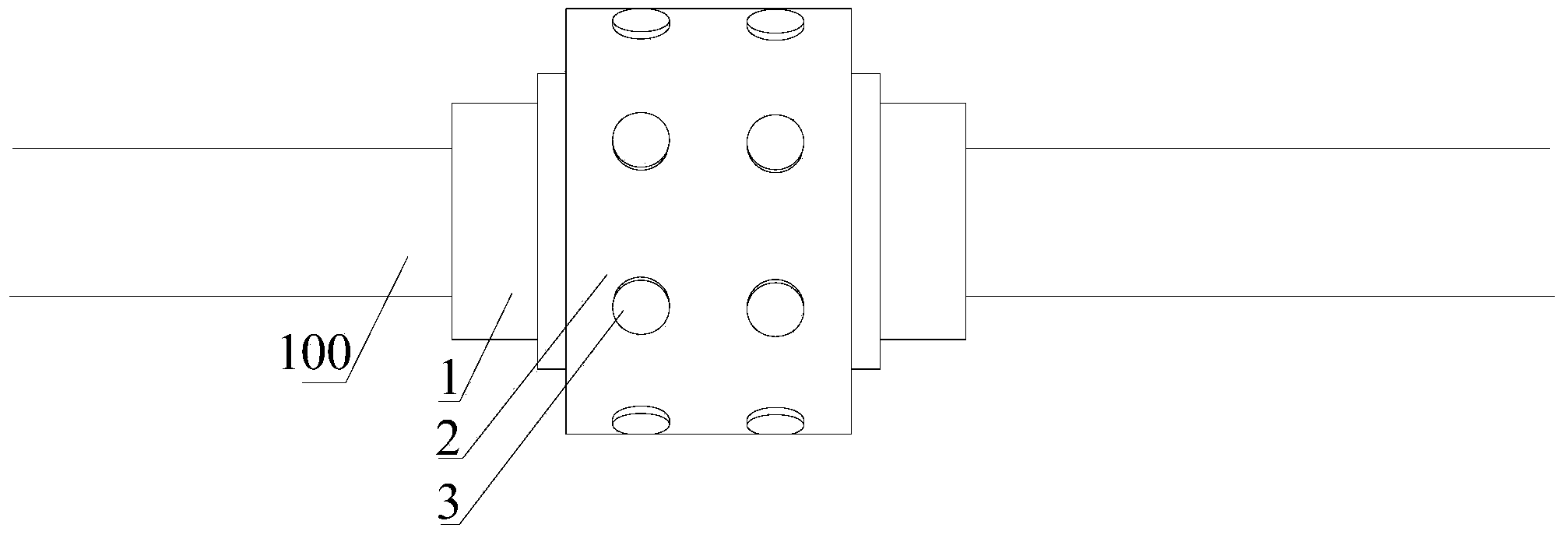

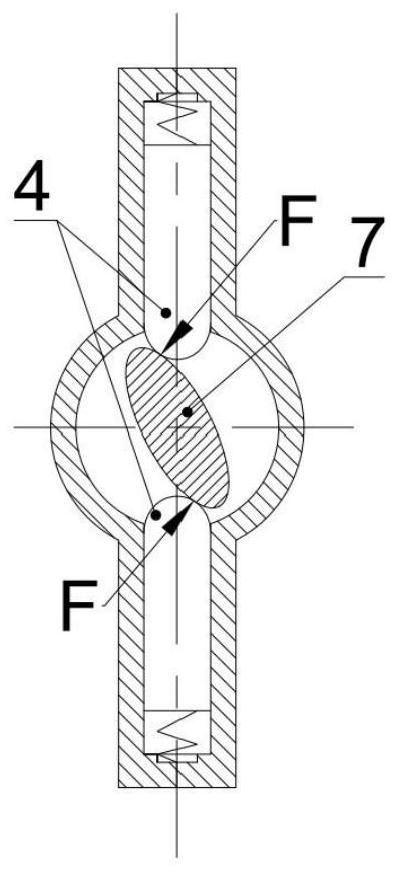

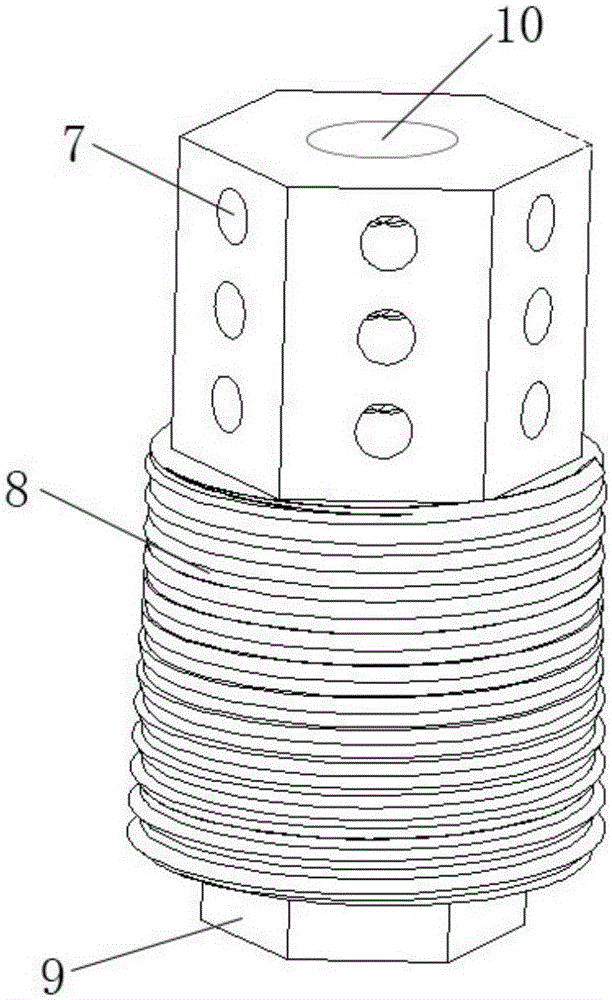

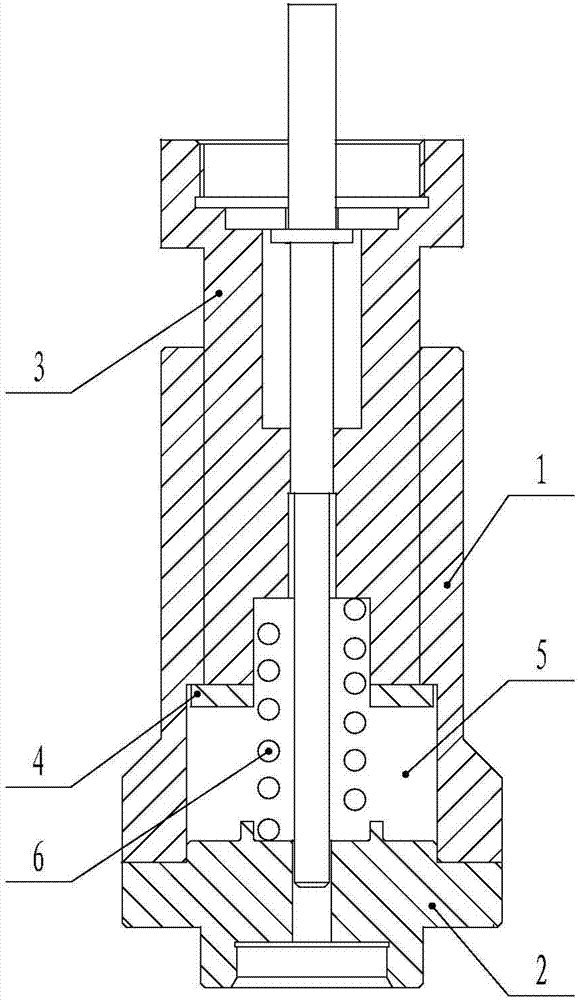

Check valve with spring pre-tightening force adjustable

InactiveCN103104724AChange the size of the pressure lossAdjustable preloadCheck valvesEngineeringScrew thread

The invention provides a check valve with spring pre-tightening force adjustable. The check valve comprises a valve body, a valve seat, a valve plate, a valve rod and a spring. The valve seat is clamped on an opening of the valve body; one side of the valve plate is connected with the valve seat; the valve rod penetrates through the valve seat, and the valve plate is fixed through a nut; the spring penetrates through the valve rod, one end of the spring is fixed on the valve seat, and one end of the spring is connected with an adjusting shim placed on an adjustment nut; and the adjusting nut is connected with outer threads corresponding to the valve rod through inner threads. The check valve with the spring pre-tightening force adjustable has the advantages that because the pre pre-tightening force of the spring of the check valve is adjustable, the adjusting nut rotates to drive the adjusting shim to move left and right along the valve rod, and therefore compression amount of the spring is changed, the pre-tightening force of the spring is adjusted, and accordingly pressure loss of the check valve is changed to satisfy requirements of different users.

Owner:TIANJIN GUOWEI FEEDING & DRAINAGE EQUIP MENT MFG

Yarn guiding device with dust removing function

ActiveCN112320476AGuaranteed reliabilityAdjustable tensionFilament handlingTextile disintegration and recoveryYarnTextile technology

The invention discloses a yarn guiding device with a dust removing function, and relates to the technical field of textile. The problem of self-adaptive tension adjustment is solved. The yarn guidingdevice with the dust removing function specifically comprises a base, a workbench is connected to the outer wall of the top of the base through a lifting mechanism, and a self-adaptive adjustable damping mechanism and a yarn guiding mechanism are arranged on the outer wall of the top of the workbench; and the self-adaptive adjustable damping mechanism comprises an outer cover, a friction wheel andfour friction assemblies, the outer cover is rotationally connected with a third supporting plate through a rotating shaft, and the third supporting plate is fixed to the outer wall of the top of theworkbench through bolts. According to the yarn guiding device with the dust removing function, a friction plate is in sliding connection with the outer cover through a third sliding rod, the outer cover is in transmission fit with the yarn guiding mechanism, when the yarn feeding speed is increased, the rotating speed of the outer cover is increased, a transition plate is relatively fixed, the friction plate is subjected to outward centrifugal force to balance the elastic force of second springs at the moment, therefore, tension is reduced, and the purpose of self-adaptively adjusting the tension according to the yarn feeding speed is achieved.

Owner:衡阳新新纺织机械有限公司

Gas pressure reduction valve

InactiveCN105650315AChange the size of the compressive stressSimple structureEqualizing valvesSafety valvesInlet channelEngineering

The invention discloses a gas pressure reduction valve which comprises a valve body. The valve body is provided with an inlet channel and an outlet channel. A pressure reduction part is arranged in the valve body and comprises a valve core and a valve seat, the valve body is further in threaded connection with a pressure base, and a first spring is arranged between the pressure base and the valve core. The gas pressure reduction valve further comprises a regulating valve and a piston cavity, a piston is further arranged in the piston cavity, one side of the piston close to the valve core is provided with a connecting rod, and an outlet connecting pipe is further provided with a discharge valve. One side of the valve core close to the inlet channel is further fixedly connected with a guide rod, the pressure base or the valve body is provided with a hole in clearance fit with the guide rod, a gap between the hole and the guide rod is not larger than 0.5 mm, and the gap is axially sealed through at least one O-shaped ring. A second spring with the two ends in contact with the valve seat and the piston respectively are further arranged between the valve seat and the piston. The gas pressure reduction valve is simple in structure, long in service life and high in air outlet pressure regulation precision.

Owner:CHENGDU KESHENG PETROLEUM TECH

Air valve structure

InactiveCN105715841AChange the amount of compressionSimple structureEqualizing valvesSafety valvesInlet channelEngineering

The invention discloses a gas valve structure, which comprises a valve body, an inlet channel and an outlet channel are arranged on the valve body, a decompression part is arranged in the valve body, the decompression part includes a valve core and a valve seat, and the valve body also has a A pressure seat is threadedly connected, a first spring is arranged between the pressure seat and the valve core, and a regulating valve and a piston chamber are also included. A piston is also arranged in the piston chamber, and a connecting rod is provided on the side of the piston close to the valve core. A discharge valve is also arranged on the outlet connecting pipe; a second spring with two ends in contact with the valve seat and the piston is also arranged between the valve seat and the piston. The invention has simple structure and high accuracy of regulating the outlet pressure.

Owner:CHENGDU KESHENG PETROLEUM TECH

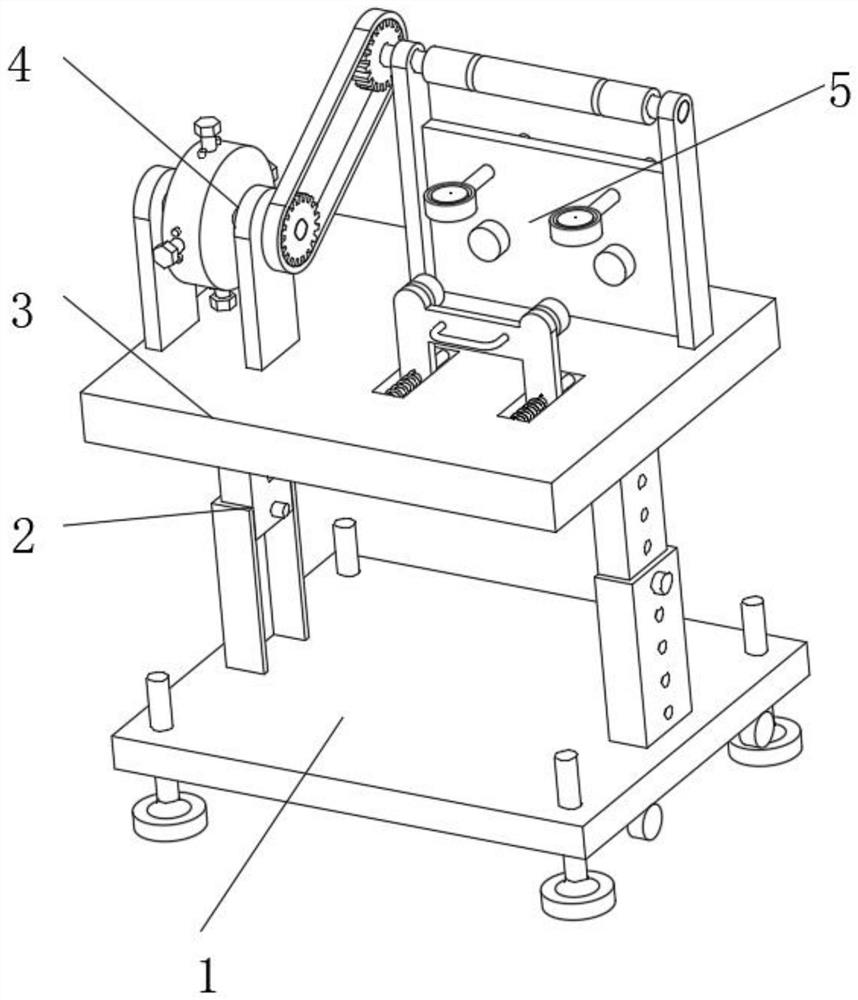

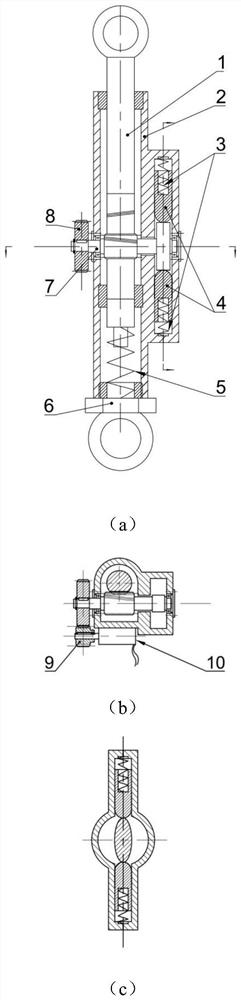

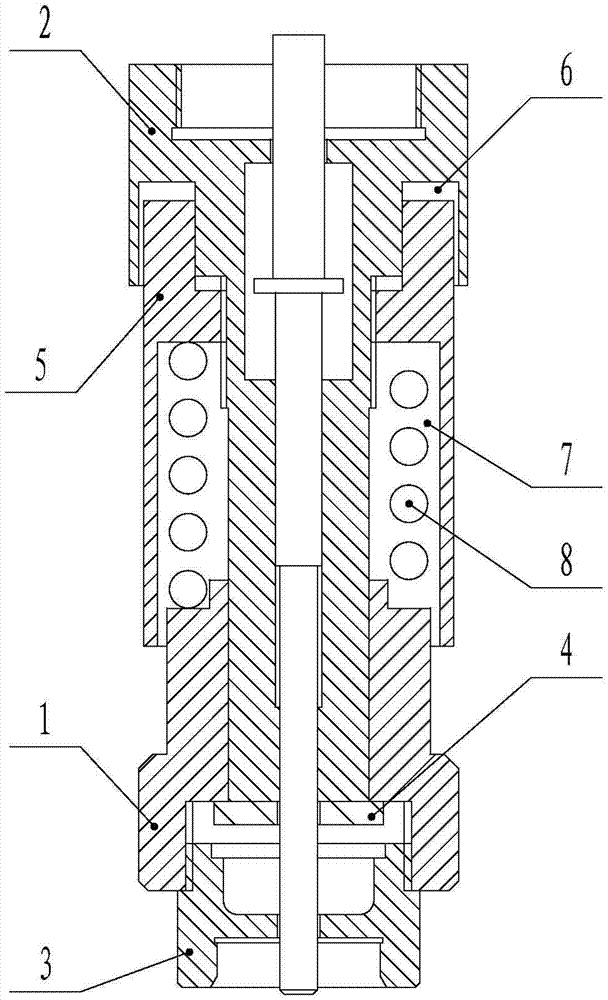

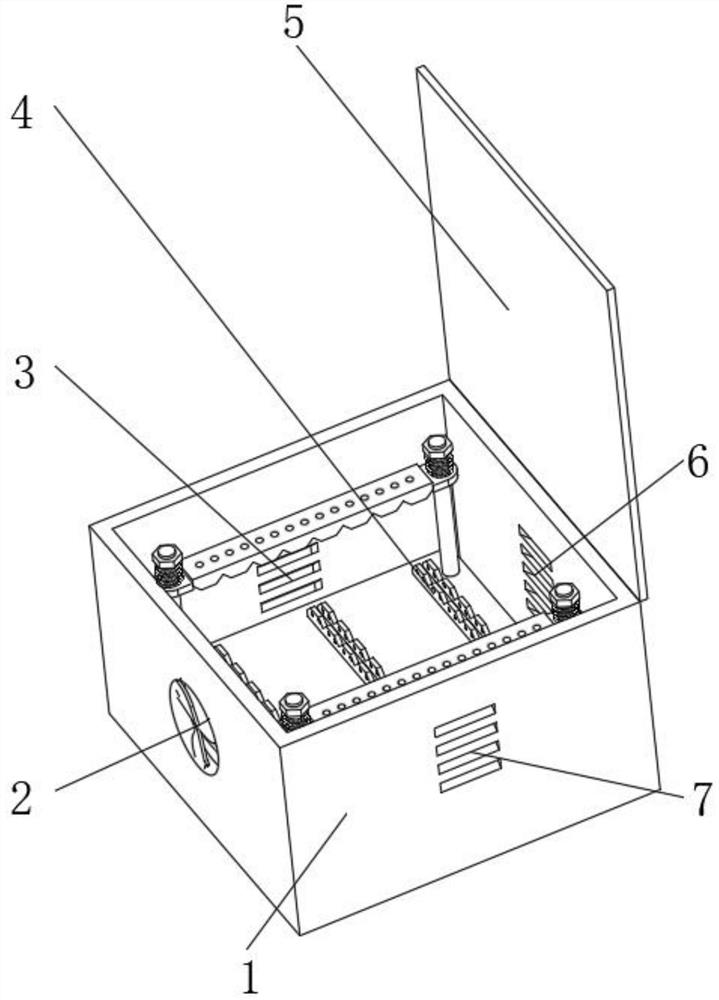

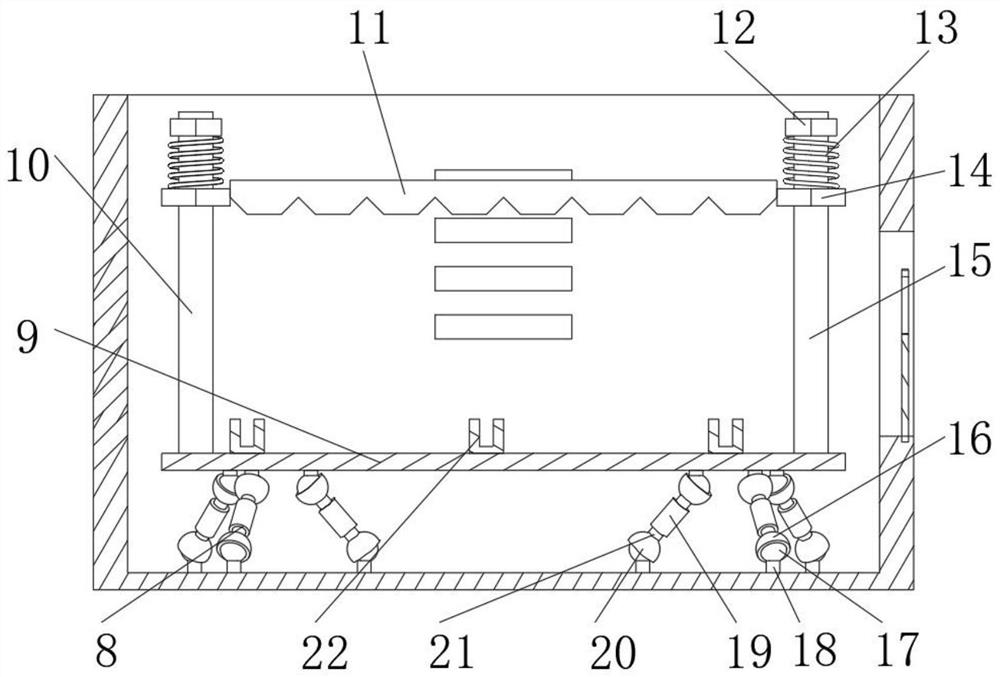

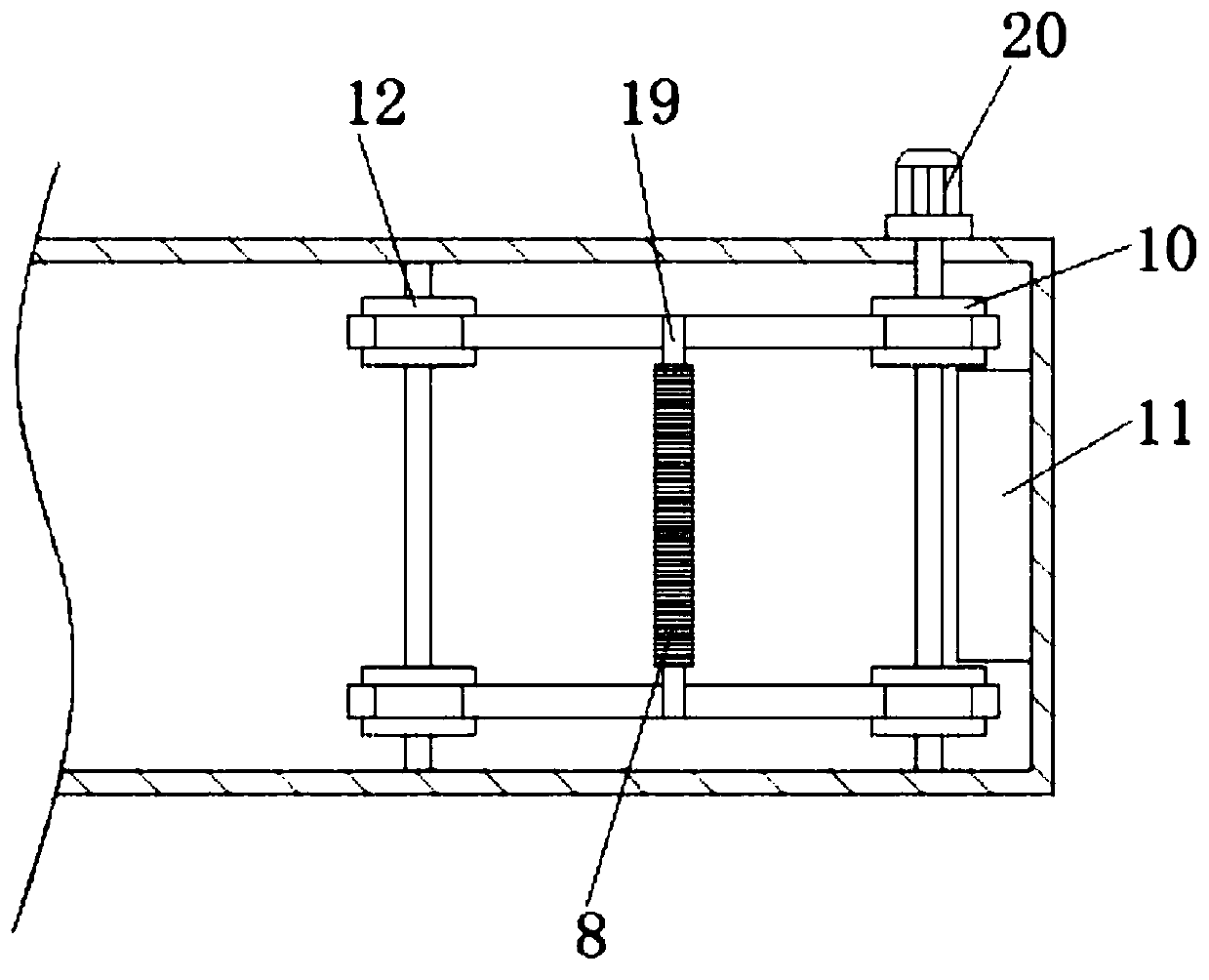

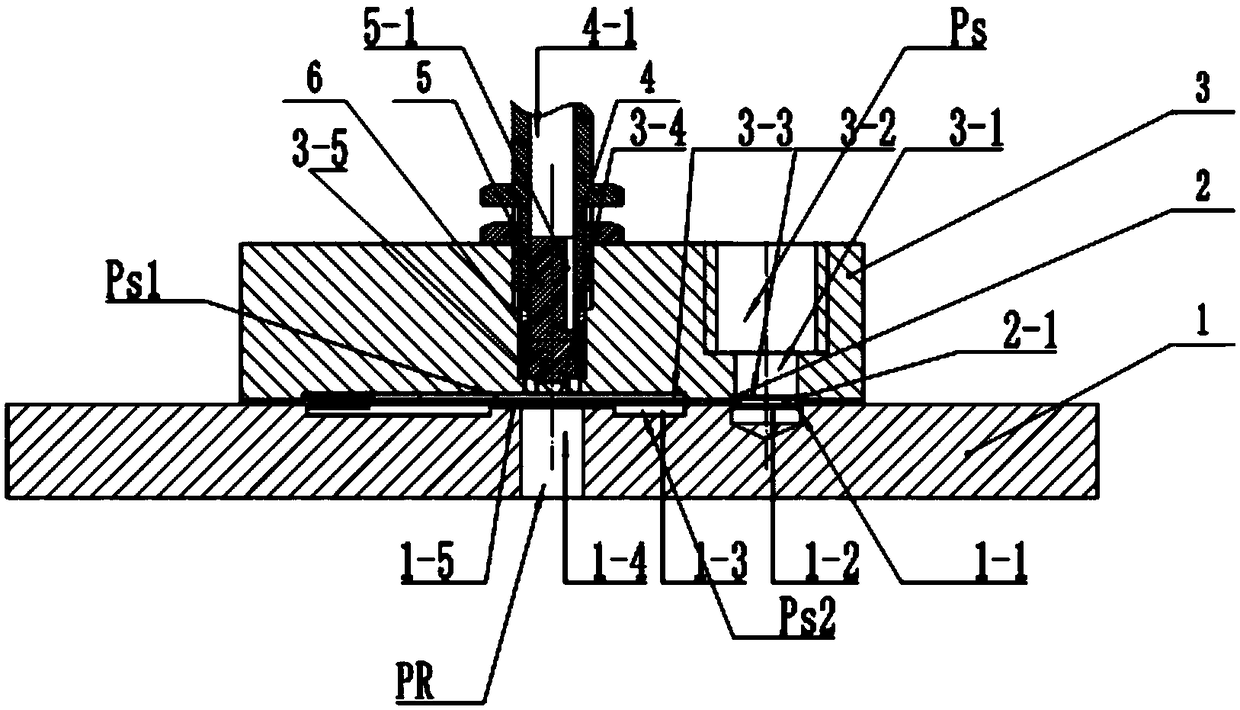

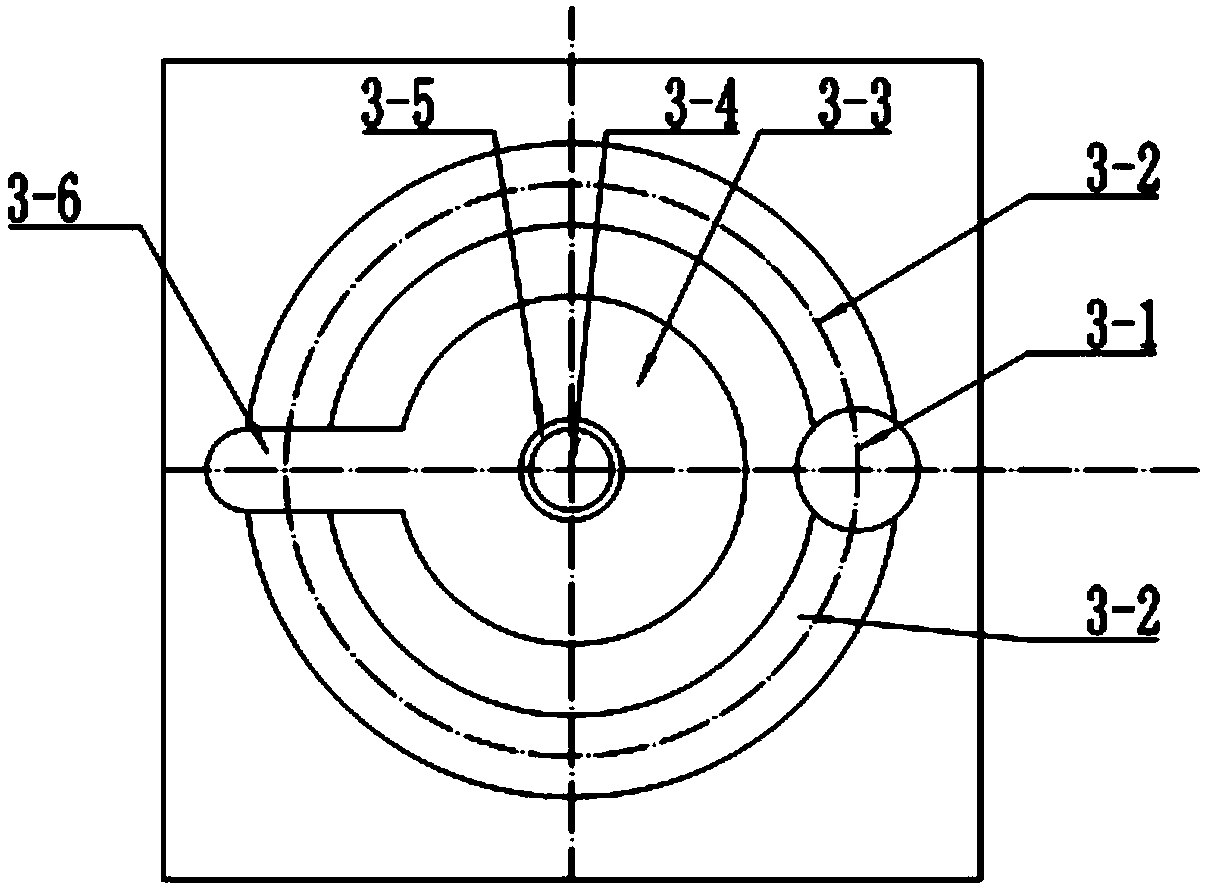

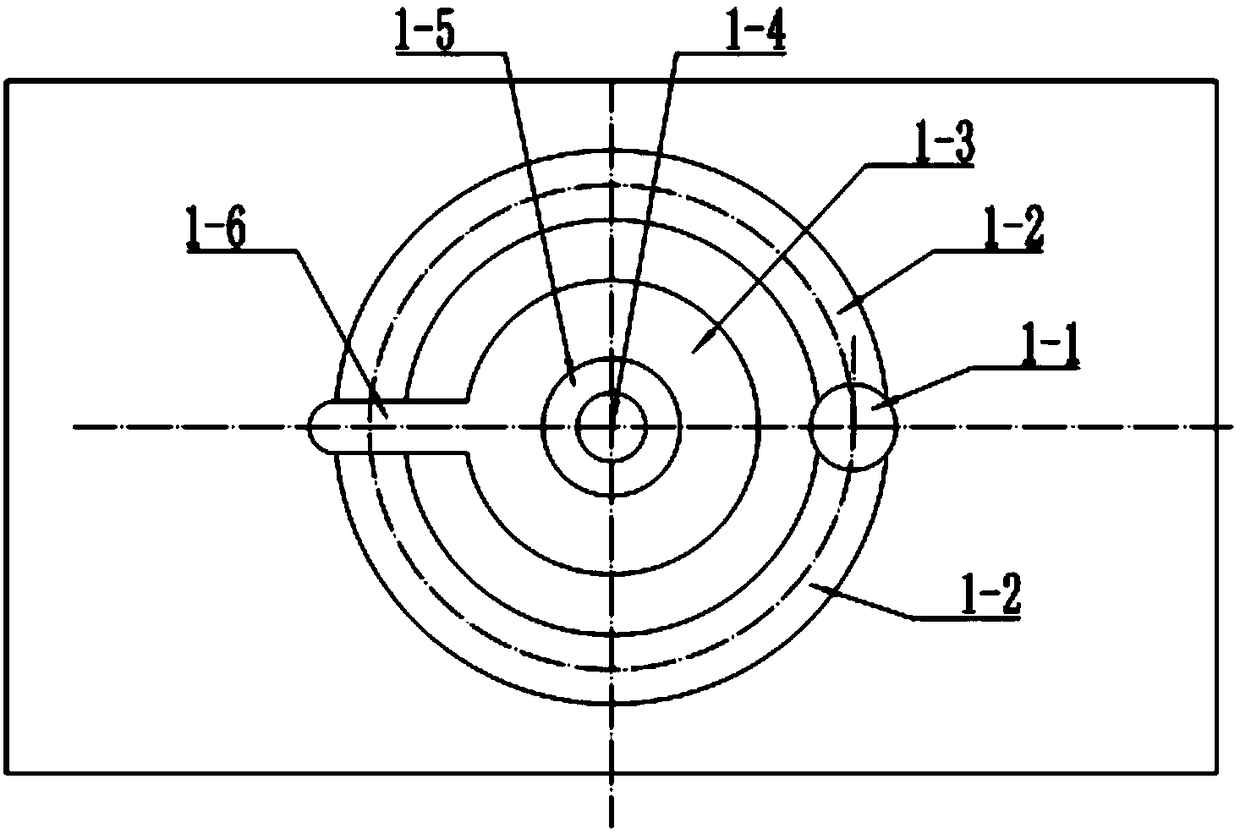

Ball screw pair failure testing experiment table

InactiveCN103868687AChange the amount of compressionReduce decreaseMachine part testingEngineeringBall screw

A ball screw pair failure testing experiment table comprises an experiment table machine base, two supporting bases are arranged on the machine base, a standard ball nut supporting base and a to-be-tested ball nut supporting base are arranged between the two supporting bases, the ball nut supporting bases are respectively provided with two guide rail sliding holes and a ball nut mounting hole, guide rails are arranged in the guide rail sliding holes respectively, two ends of the guide rails are connected with the two supporting bases respectively, a standard ball nut is arranged in the standard ball nut mounting hole, two protrusions are arranged on the standard ball nut supporting base, the to-be-tested ball nut mounting hole is used for allowing a to-be-tested ball nut to be mounted, the two ball nuts are respectively in threaded connection with a ball screw, two springs are arranged between the two ball nut supporting bases, two ends of the two springs are connected with the standard ball nut supporting base and the to-be-tested ball nut supporting base respectively, two motors are arranged on the machine base and drive the two ball screws to rotate, and the two nut supporting bases move linearly.

Owner:SOUTHEAST UNIV

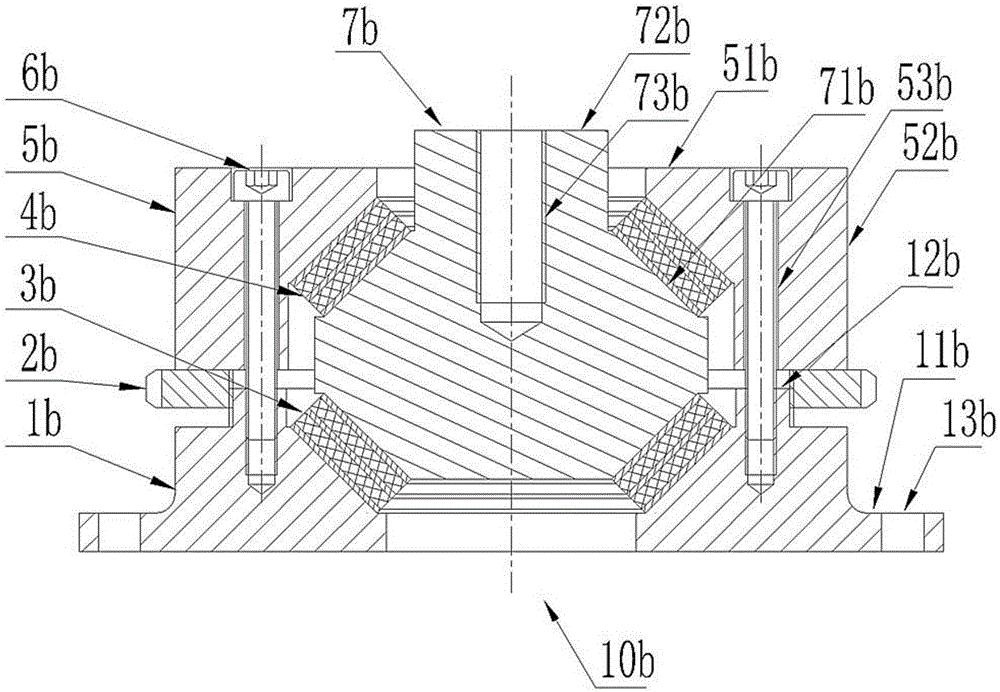

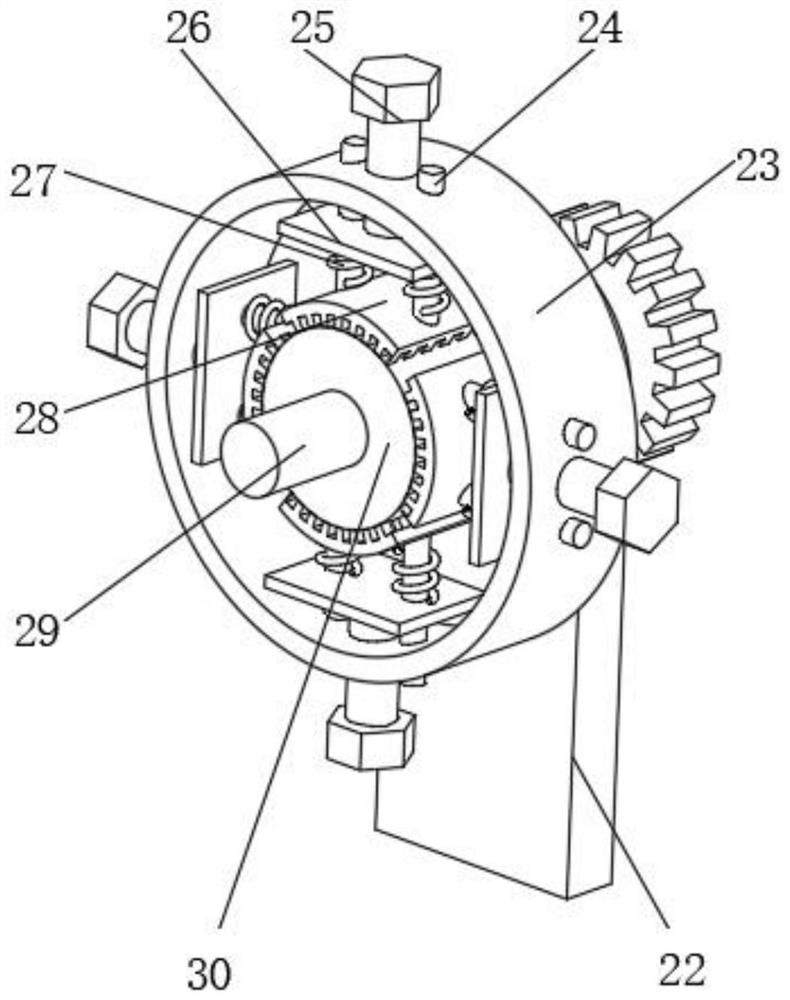

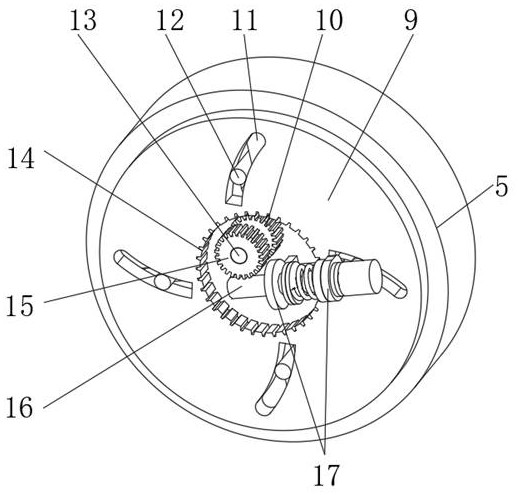

Quasi-zero stiffness vibration isolator with energy recovery function

ActiveCN112152387AReduce horizontal sizePlay the role of recyclingMechanical energy handlingShock absorbersGear driveGear wheel

The invention provides a quasi-zero stiffness vibration isolator with an energy recovery function, and belongs to the technical field of vibration isolation. The quasi-zero stiffness vibration isolator comprises a shell, a gear cam shaft and a rack shaft are connected into the shell, the axes of the gear cam shaft and the rack shaft are perpendicular, and the gear cam shaft is matched with the rack shaft. A slideway symmetrical about the axis of the gear cam shaft is arranged on the outer side of the shell, and a sliding column is embedded into the slideway, makes contact with an auxiliary spring and further makes contact with the cam end of the gear cam shaft; the adjusting mechanism is arranged at one end of the shell and makes contact with the rack shaft through a main spring. A gear pair is connected to the end, away from the cam, of the gear cam shaft and fixedly connected with an electric generator. The elastic direction of the auxiliary spring providing the negative stiffness isparallel to the elastic direction of a positive spring providing the positive stiffness, so that the transverse size of the vibration isolator is greatly reduced, and the vibration isolator can be applied to places with high space requirements; movement can be transmitted to the electric generator through gear transmission to achieve power generation, and energy recovery is achieved.

Owner:JIANGSU UNIV

Self-stabilization single-face thin film restrictor with prepressure adjusting function

InactiveCN106641353AAdjust the amount of compressionAdjust the gapEqualizing valvesSafety valvesSelf-stabilizationEngineering

Owner:QILU UNIV OF TECH +1

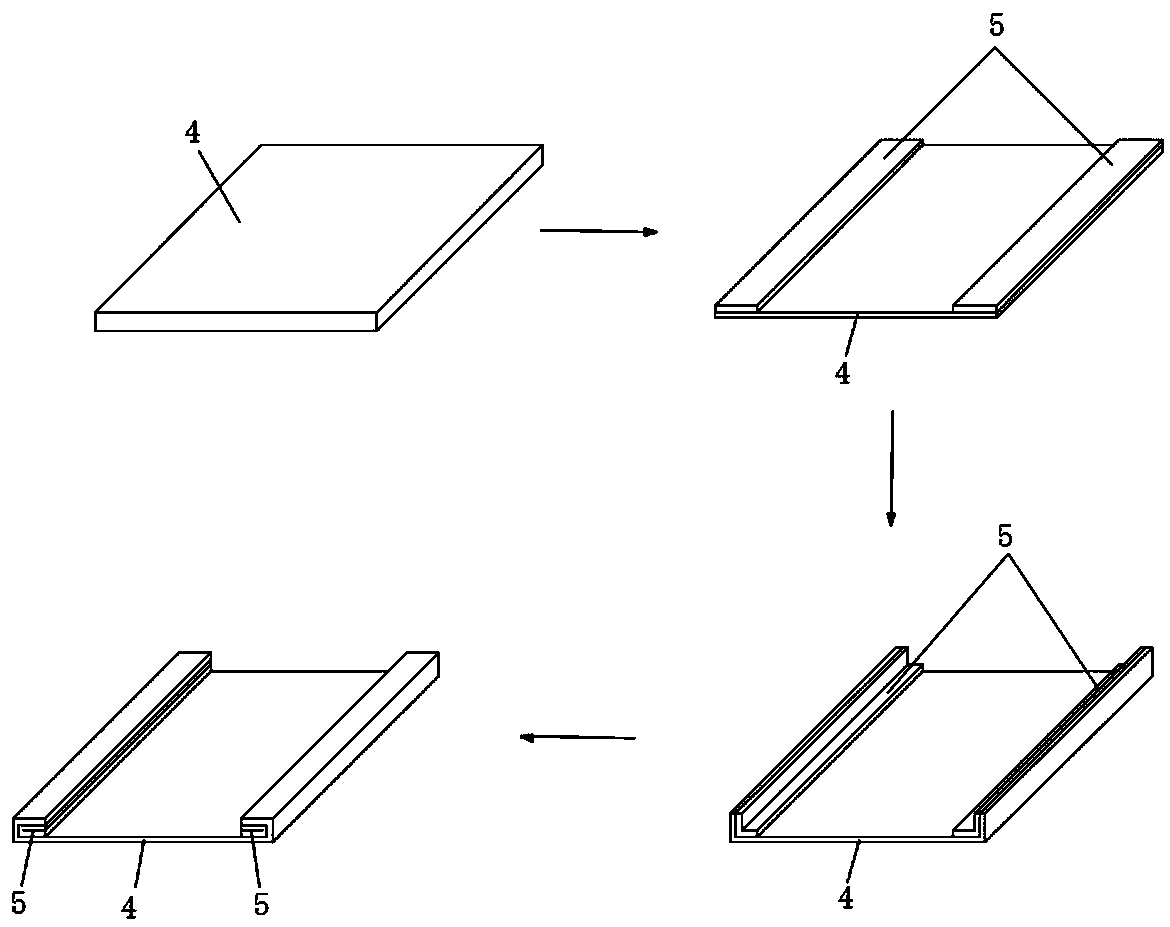

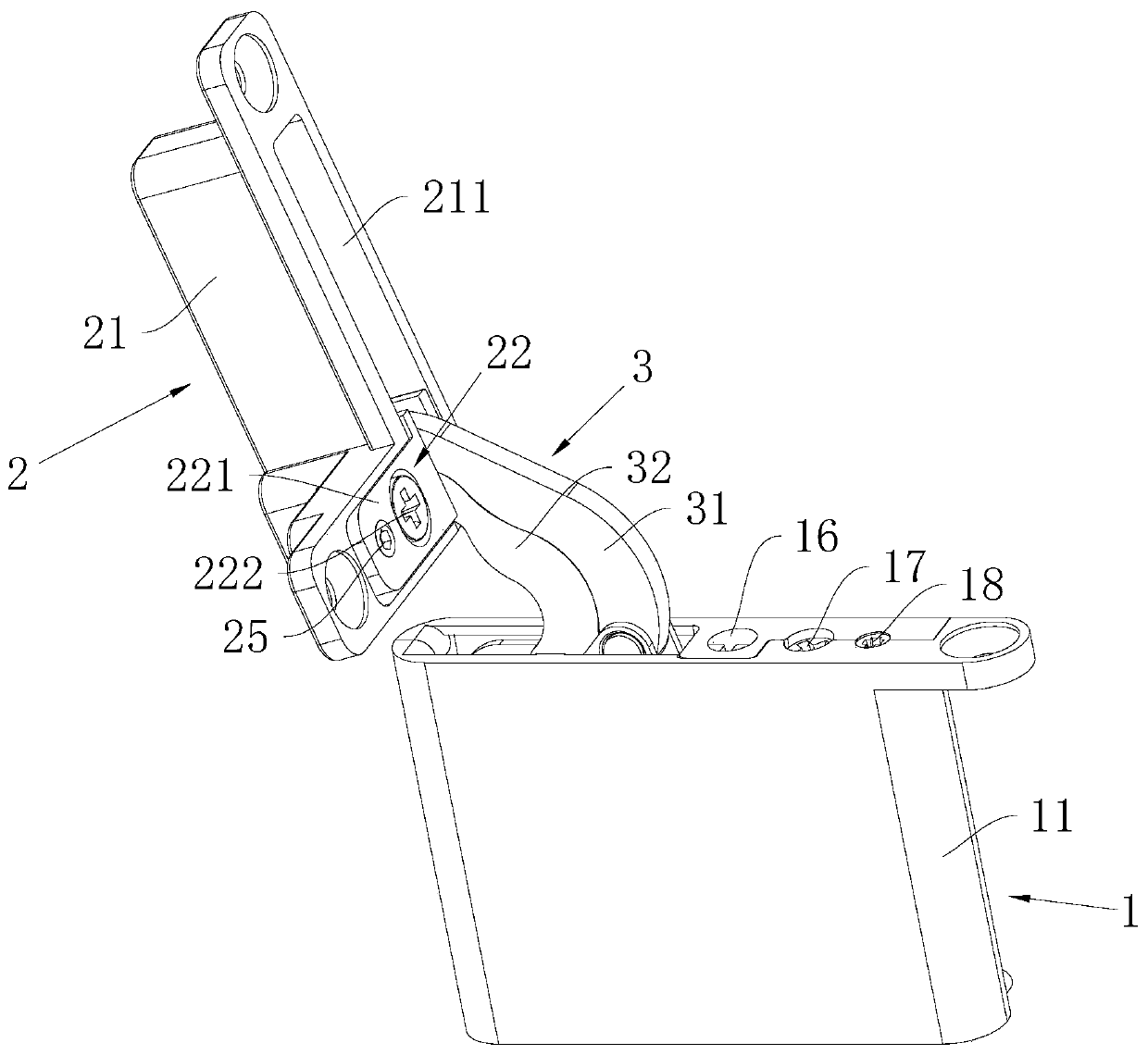

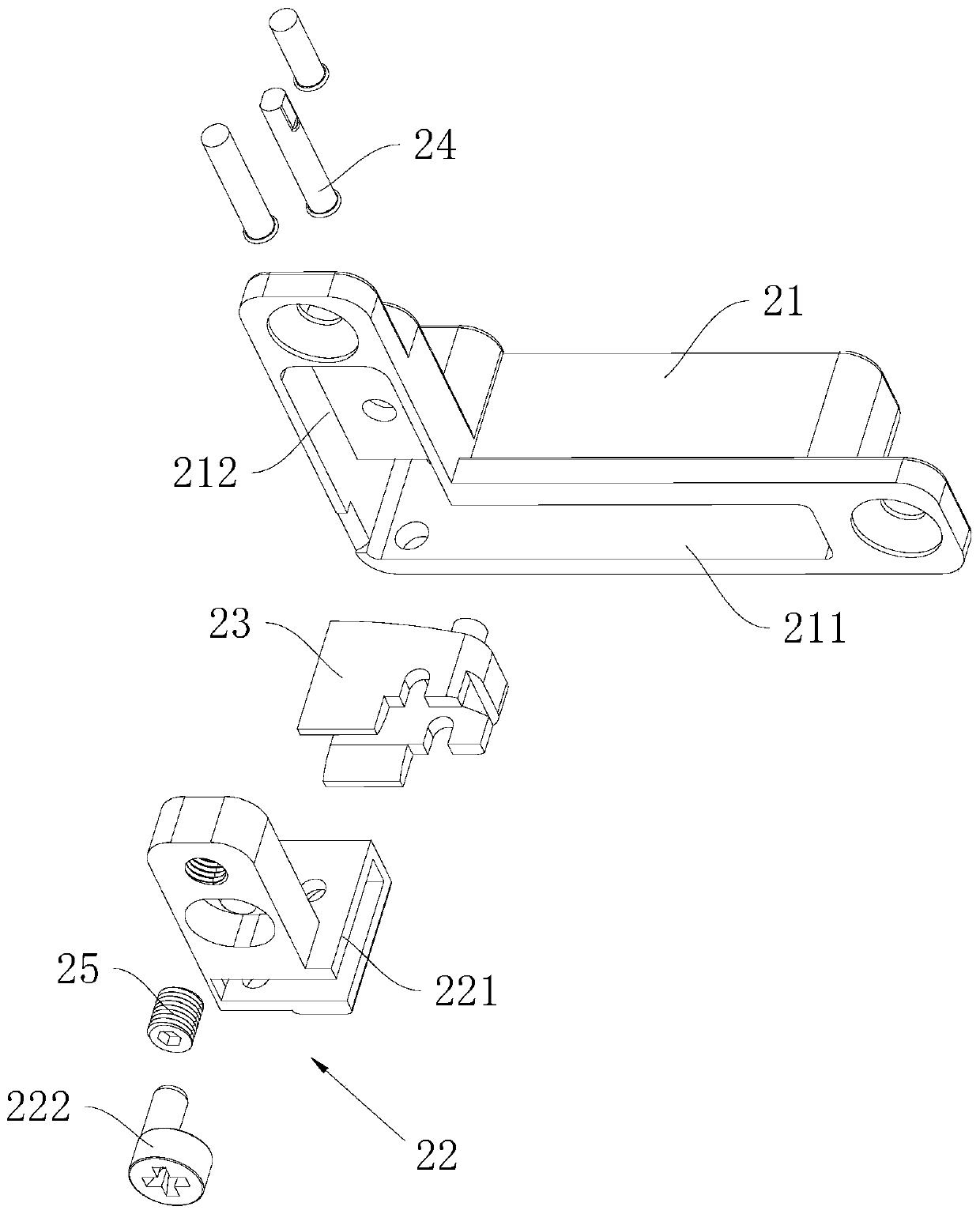

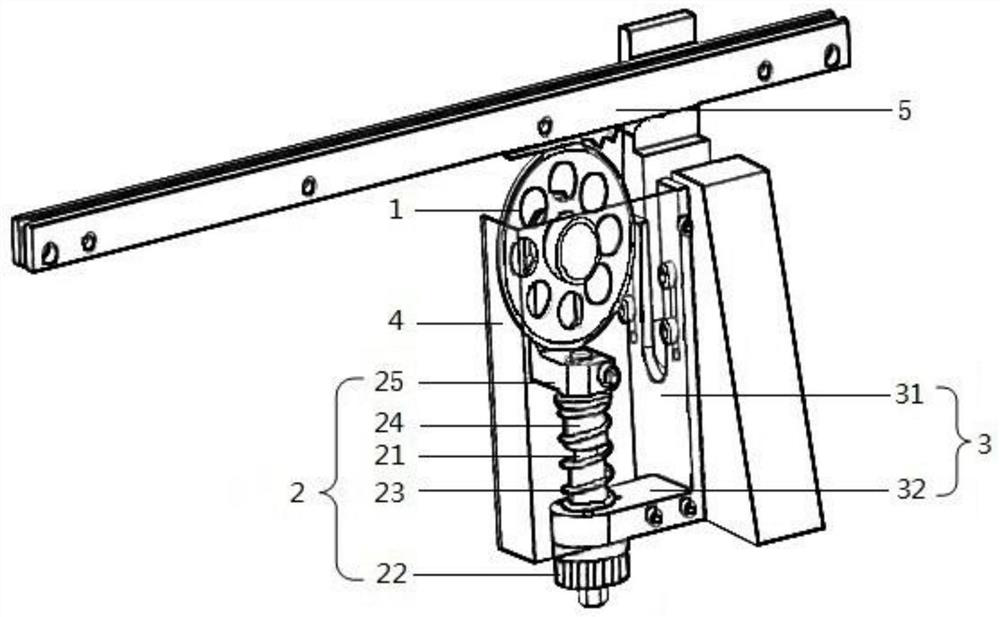

Adjustment device for air spring of aircraft seat

ActiveCN105108713AChange the amount of compressionSimple structureMetal-working hand toolsAir springGas spring

The invention relates to an adjustment device for an air spring of an aircraft seat. The adjustment device comprises an air spring telescopic rod (6), an adjustment block (2) and an adjustment underframe (3). A blind hole (10) is formed in the adjustment block (2). The end of the air spring telescopic rod (6) is abutted against the bottom of the blind hole (10). The adjustment block (2) is connected with the adjustment underframe (3) in a threaded mode. According to the adjustment device for the air spring of the aircraft seat, the height of the adjustment device can be adjusted by rotating the adjustment block, the position of the end of the air spring telescopic rod is changed accordingly, so that the compression amount of the air spring is changed, and the stroke for adjusting the air spring and the stroke for adjusting the seat up and down are completed. The adjustment device for the air spring of the aircraft seat is simple in structure, reliable in performance ad low in cost, can be widely applied to aircraft seats and has great use value.

Owner:CHINA AVIATION LIFESAVING INST

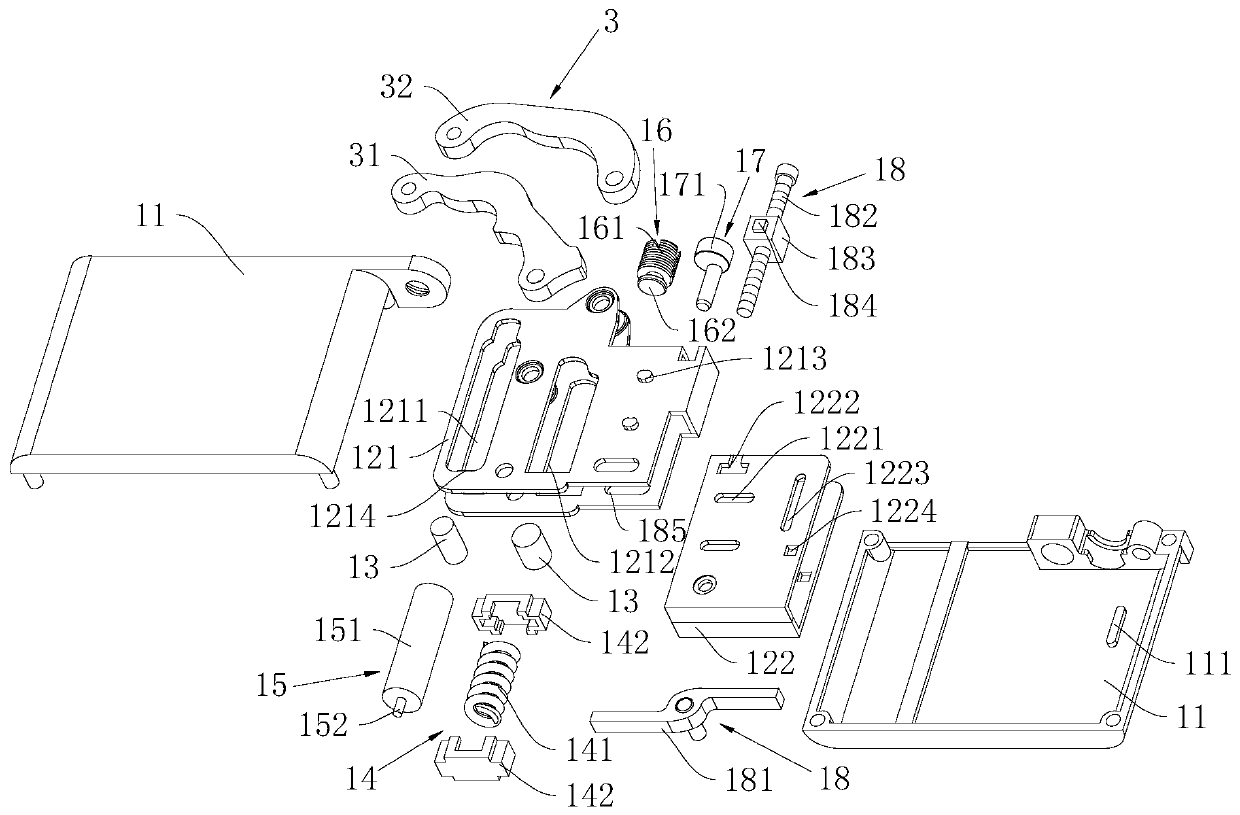

Hidden type top-bottom hinge

PendingCN111550143AModerate closing speedSmooth closing speedHingesWing openersDrive shaftRestoring force

The invention provides a hidden type top-bottom hinge. The hidden type top-bottom hinge comprises a first component, a second component and a connecting force arm, wherein the two ends of the connecting force arm are hinged to the first component and the second component correspondingly; the connecting force arm comprises a first force arm body and a second force arm body; the first component comprises a hinge box, an installation frame, a transmission shaft, a damping assembly and a spring assembly; the installation frame is arranged in the hinge box; the transmission shaft, the damping assembly and the spring assembly are all positioned on the installation frame; the first force arm body abuts against the damping assembly through the transmission shaft so as to be used for providing buffering force for closed rotation of the connecting force arm when the first component and the second component are closed; and the second force arm body abuts against the spring assembly through the transmission shaft so as to be used for providing restoring force for closed rotation of the connecting force arm when the included angle between the first component and the second component is within apreset range, and therefore the closing speed of a door leaf or a window is moderate and stable.

Owner:广东顶固集创家居股份有限公司

Tobacco tow density adjusting device

ActiveCN112021645AImprove uniformityChange the amount of compressionCigarette manufactureEngineeringStructural engineering

The invention discloses a cigarette tow density adjusting device, and belongs to the field of cigarette equipment in the cigarette industry. The device comprises a compaction wheel, an adjusting assembly and a fixing support, the adjusting assembly comprises a connecting frame, an adjusting shaft, a spring and an adjusting wheel, the compaction wheel is rotatably mounted at the upper end of the connecting frame, the fixing support comprises a mounting end face and a fixing end face, the fixing end face is fixedly connected with a filament suction beam fixing seat, and a mounting hole is formedin the mounting end face. The adjusting shaft penetrates through the mounting hole, the upper end of the adjusting shaft is fixedly connected to the lower end of the connecting frame, the lower end of the adjusting shaft is connected with the adjusting wheel, and the spring sleeves the adjusting shaft and is supported between the lower end of the connecting frame and the mounting end face. According to the device, the gram weight deviation of a single cigarette is reduced, the empty end rejection rate of the cigarette is reduced, meanwhile, the residual cigarette amount is reduced, the cigarette index stability is improved, and the factory production and manufacturing level is continuously improved.

Owner:ZHANGJIAKOU CIGARETTE FACTORY

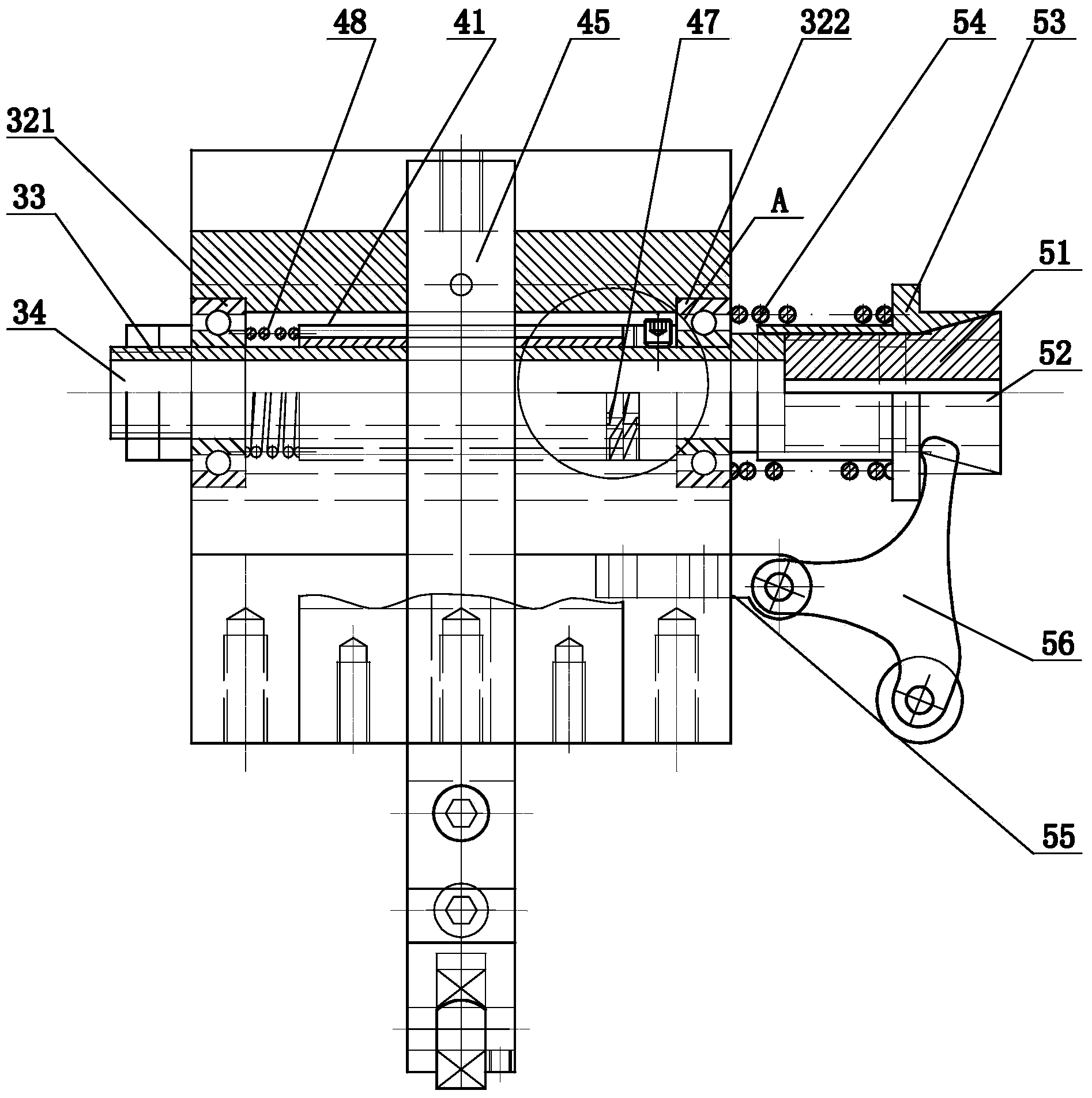

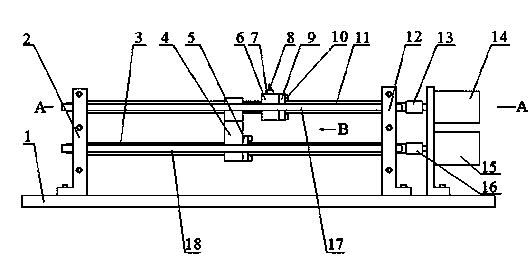

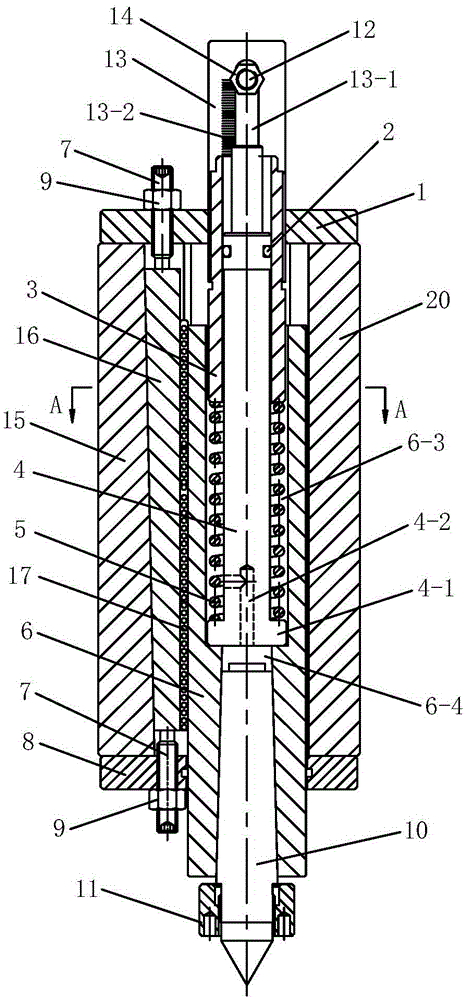

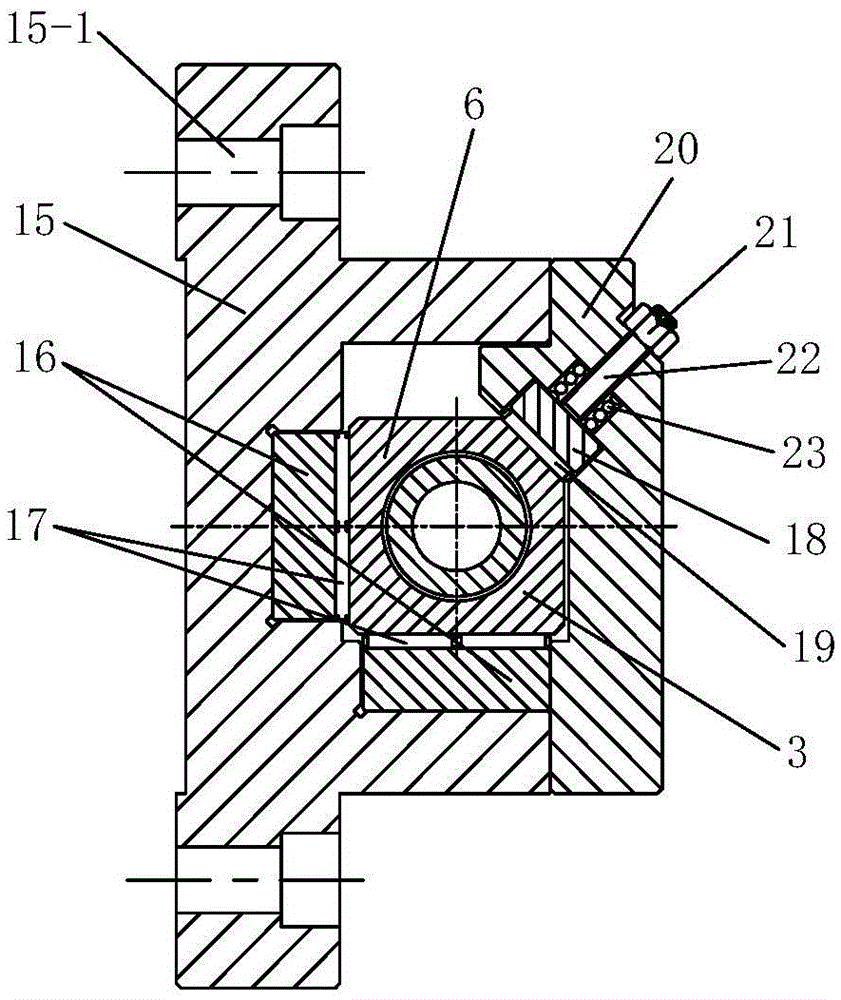

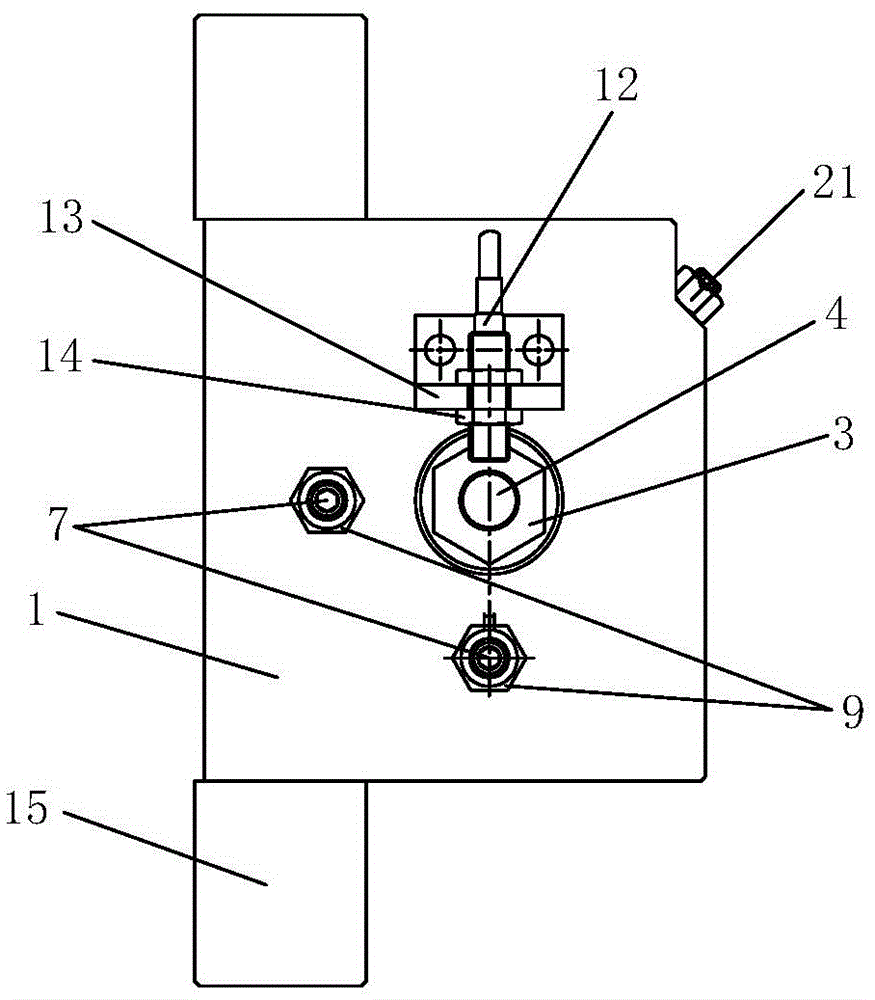

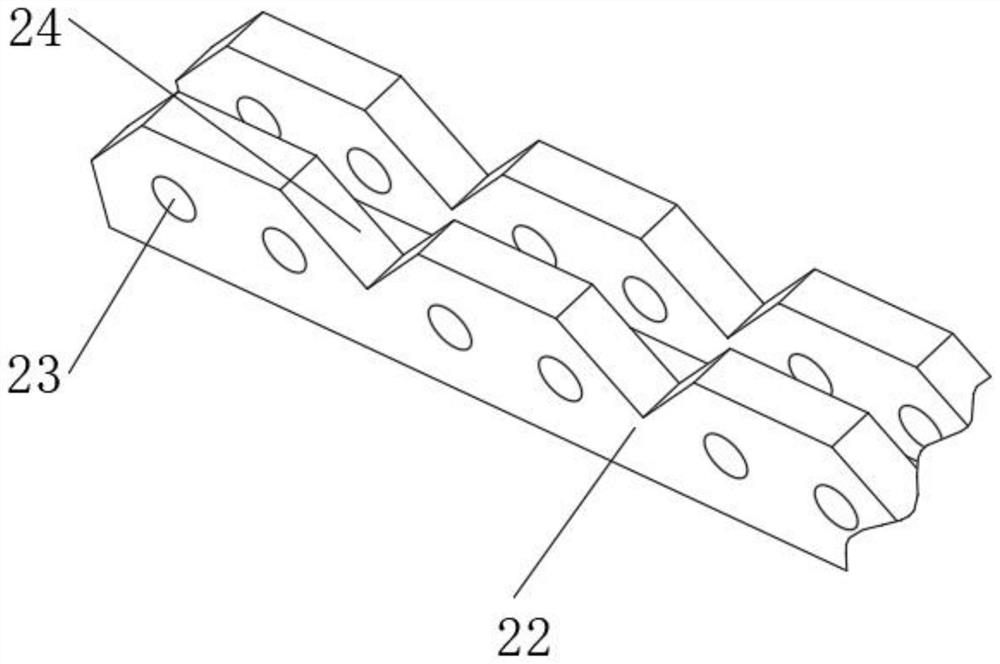

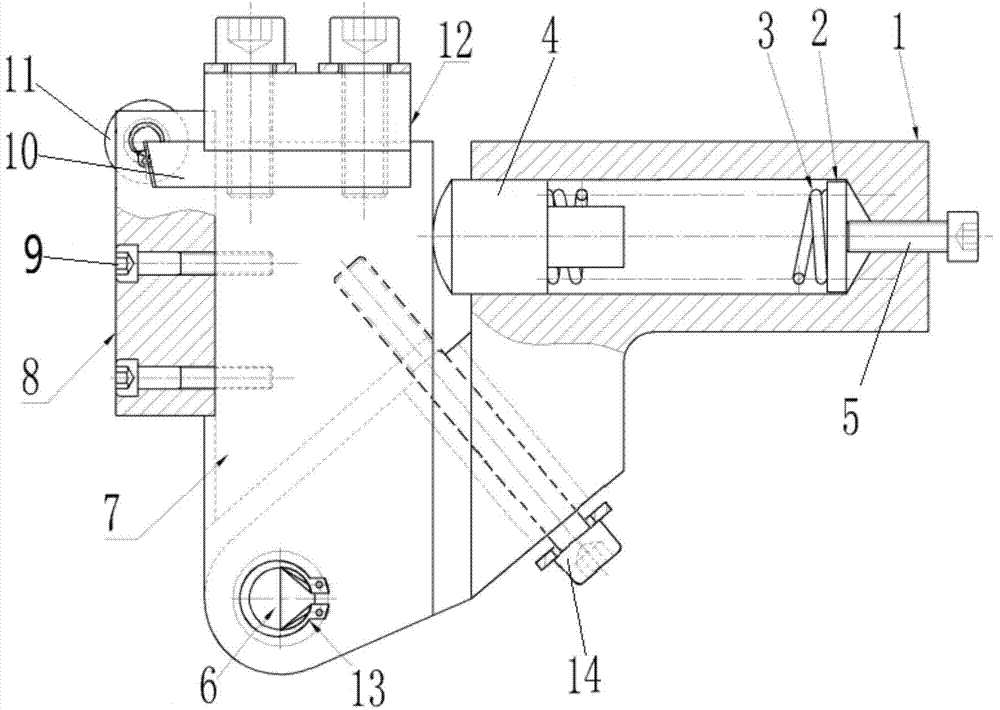

Movable centre mechanism of numerical control worm grinding wheel gear grinding machine

ActiveCN105537693ASolve the problems of poor contact and low grinding precisionSimple structureGear-cutting machinesWormsGear grindingNumerical control

The invention discloses a movable centre mechanism of a numerical control worm grinding wheel gear grinding machine. The movable centre mechanism of the numerical control worm grinding wheel gear grinding machine comprises a centre body and a centre shaft. The centre body comprises a centre base, a cover plate, an upper end cover and a lower end cover. The centre base, the cover plate, the upper end cover and the lower end cover are fixed together, and a cavity is formed among the centre base, the cover plate, the upper end cover and the lower end cover. The upper portion of the centre shaft is arranged in the cavity. The lower portion of the centre shaft penetrates out of the lower end cover. A Morse centre is installed on the centre shaft. A right-angle face is arranged on the upper portion of the center shaft. A first plate type rolling column chain and an inclined inlaid strip are arranged between each of the two straight faces of the right-angle face and the inner wall of the centre base. The bevels of the inclined inlaid strips are matched with the bevel of the inner wall of the centre base. The upper end cover and the lower end cover are both in a threaded connection with a first jackscrew. First locking nuts are arranged on the first jackscrews. The length of the inclined inlaid strips is smaller than the height of the cavity. The first plate type rolling column chains are shorter than the inclined inlaid strips. A tight ejecting mechanism is arranged on the cover plate. By means of the movable centre mechanism, the radial position of a centre and the pressing force of the centre on a workpiece can be precisely adjusted, adjustment is convenient, and adjusting precision is high.

Owner:西安贝吉姆机床股份有限公司

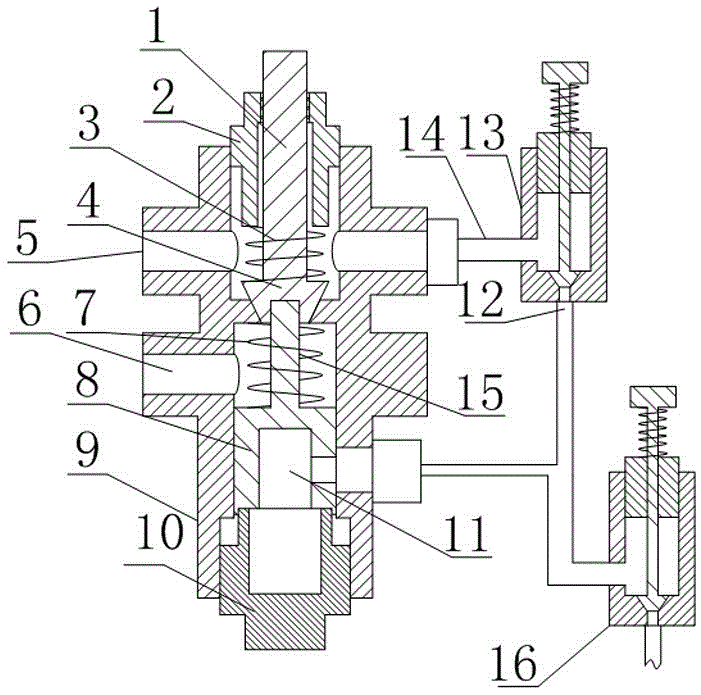

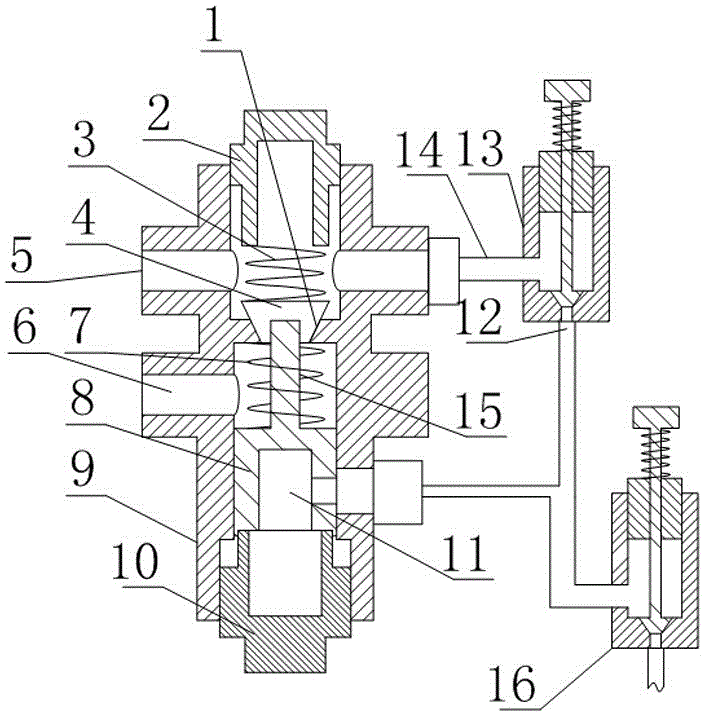

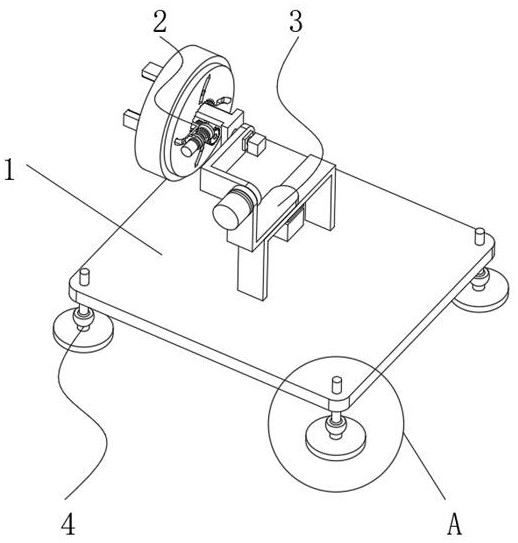

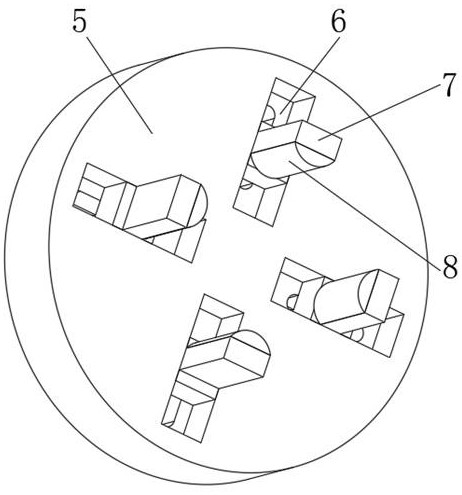

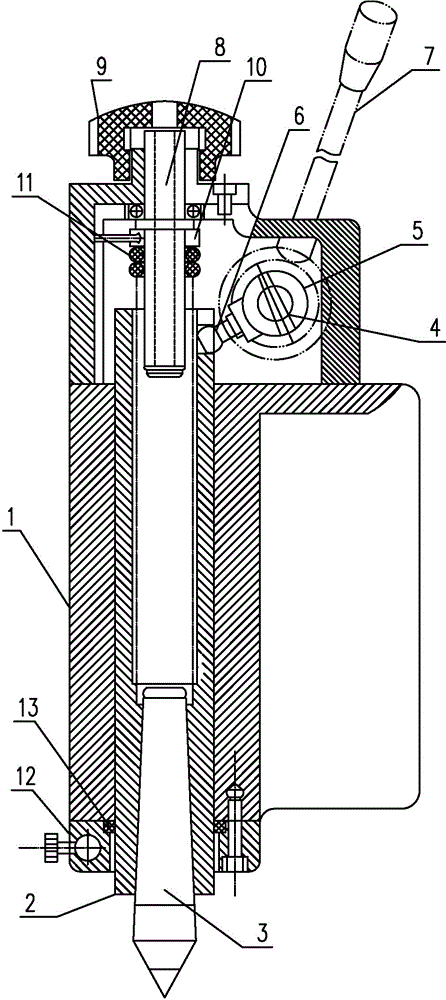

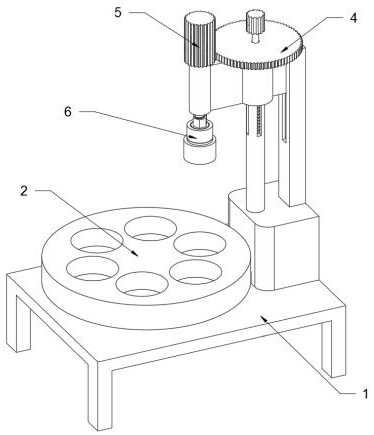

Calibration device of fiber-optic gyroscope inclinometer

The invention discloses a calibration device of a fiber-optic gyroscope inclinometer, relates to the technical field of fiber-optic gyroscope inclinometers, and aims to solve the problem of coaxiality during fixing. The device specifically comprises a base, wherein the top of the base is connected with a clamping assembly through a rotating assembly, the clamping assembly comprises a main body and a clamping ring, four sliding grooves in a 90-degree circular array are formed in the inner wall of the main body, clamping jaws are slidably connected to the inner walls of the sliding grooves, arc-shaped pads are fixed to the outer walls of the clamping jaws through bolts, the clamping ring is rotationally connected with the main body, a limiting sliding column penetrating through the main body is fixed to the outer wall of the other side of the clamping jaw through a bolt, an arc-shaped groove matched with the limiting sliding column is formed in the inner wall of the clamping ring, teeth are arranged on the inner wall of the clamping ring and engaged with a planet wheel, and the planet wheel is fixedly connected with a worm wheel through a transmission shaft. According to the invention, the contact ratio of the axis of the clamped fiber-optic gyroscope inclinometer and the axis of the main body is relatively high, so that the accuracy of subsequent calibration is ensured.

Owner:刘铭

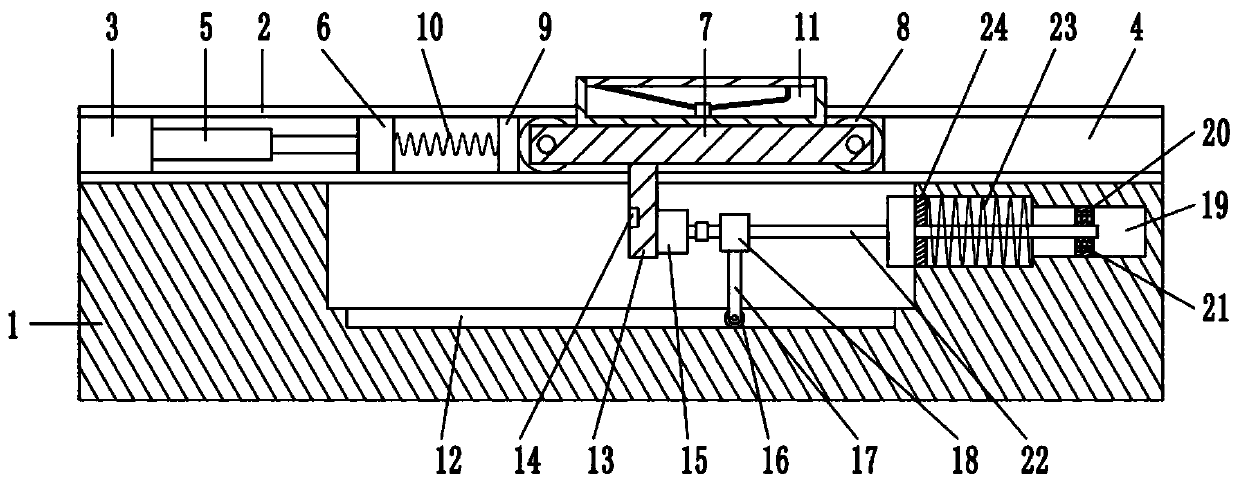

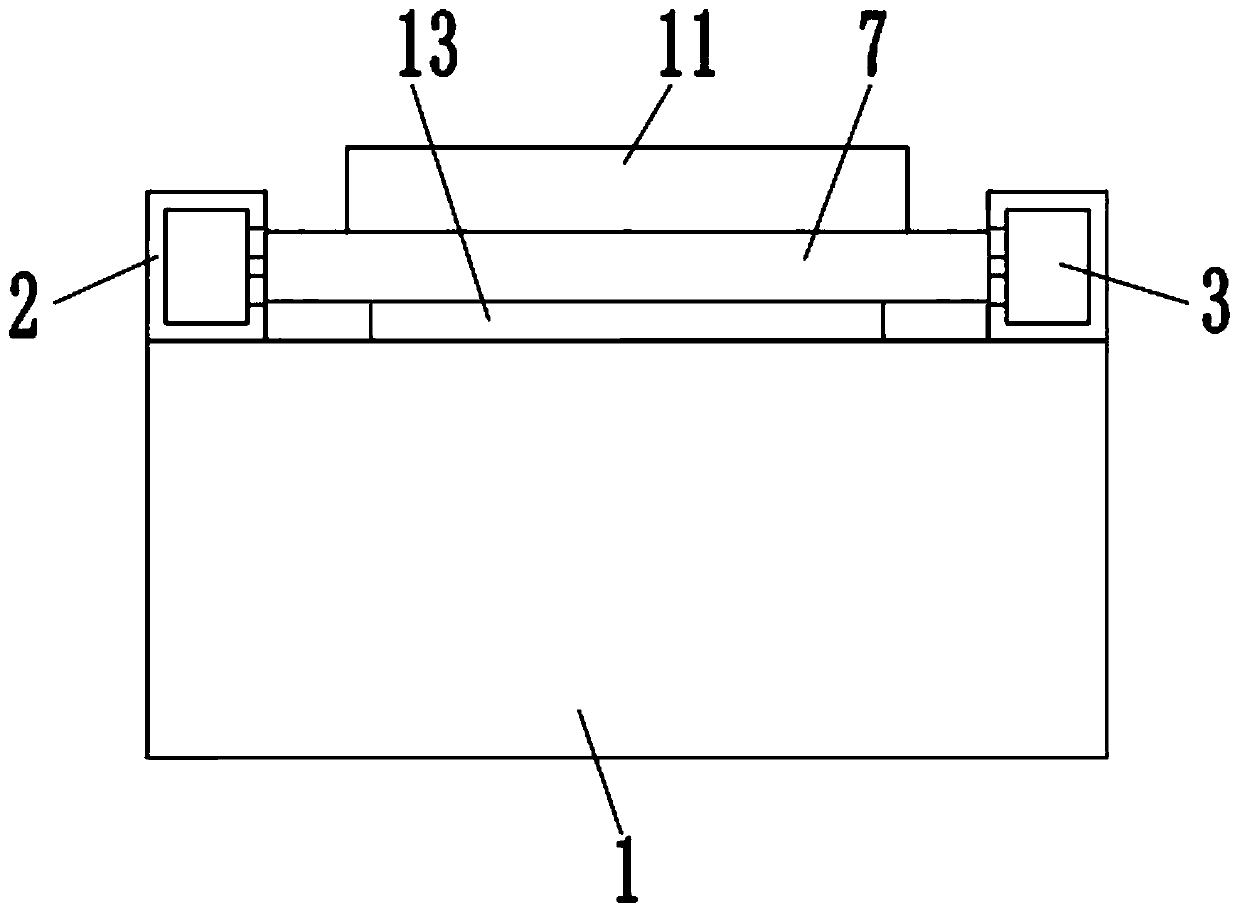

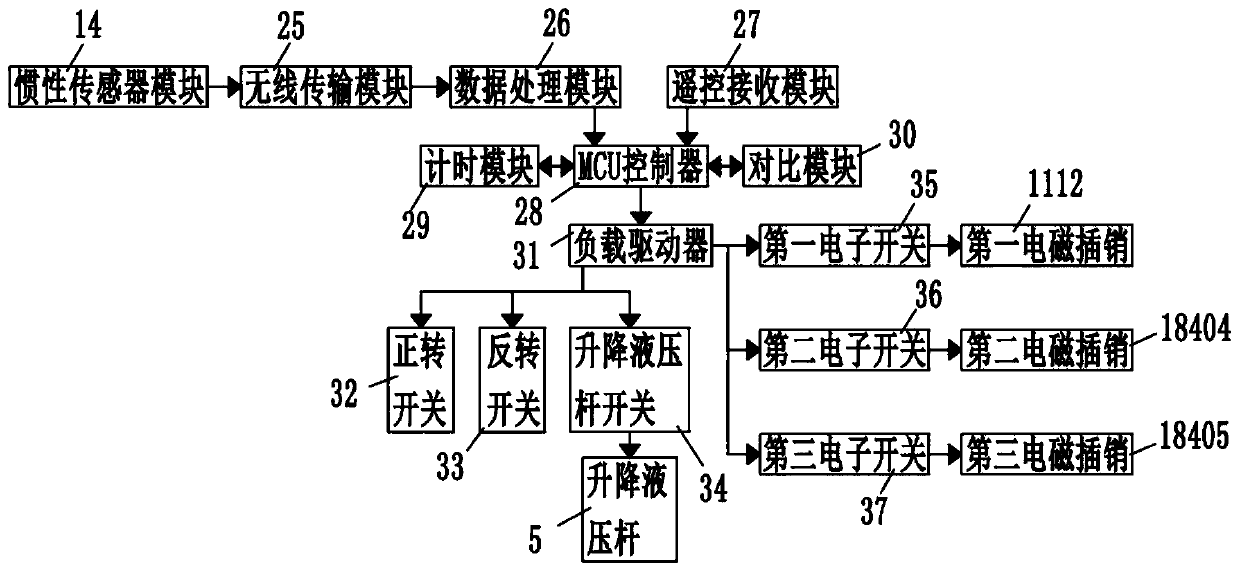

Protection device for driver during emergency braking of automobile

InactiveCN111152697AChange the amount of compressionReverse force increases rapidlyVehicle seatsDriver/operatorBall screw

The invention discloses a protection device for a driver during emergency braking of an automobile, and belongs to the technical field of automobile safety. The protection device comprises a half-frame base, two sets of C-shaped steel, two sets of left welding blocks, two sets of right welding blocks and two sets of lifting hydraulic rods. Openings of the two sets of C-shaped steel are oppositelyand horizontally fixed to the front side and the rear side of a top opening of the semi-frame base; the two sets of left welding blocks are welded to the left ends of inner cavities of the two sets ofC-shaped steel correspondingly. A forward and reverse motor rotates backwards such that a nut of a ball screw moves leftwards; meanwhile, when the inertia force is small, a first telescopic spring isused for buffering the seat; a speed increasing device can provide three ball screw rotating speeds; within the same time, the nut moving distances of the ball screws are different, then the compression amount of a second telescopic spring is changed, the reverse acting force is rapidly increased, speed reduction is facilitated. The device is automatically and manually combined, operation is convenient, a driver and passengers are protected in the speed reduction process, and safety is high.

Owner:安徽青壹讯网络科技有限公司

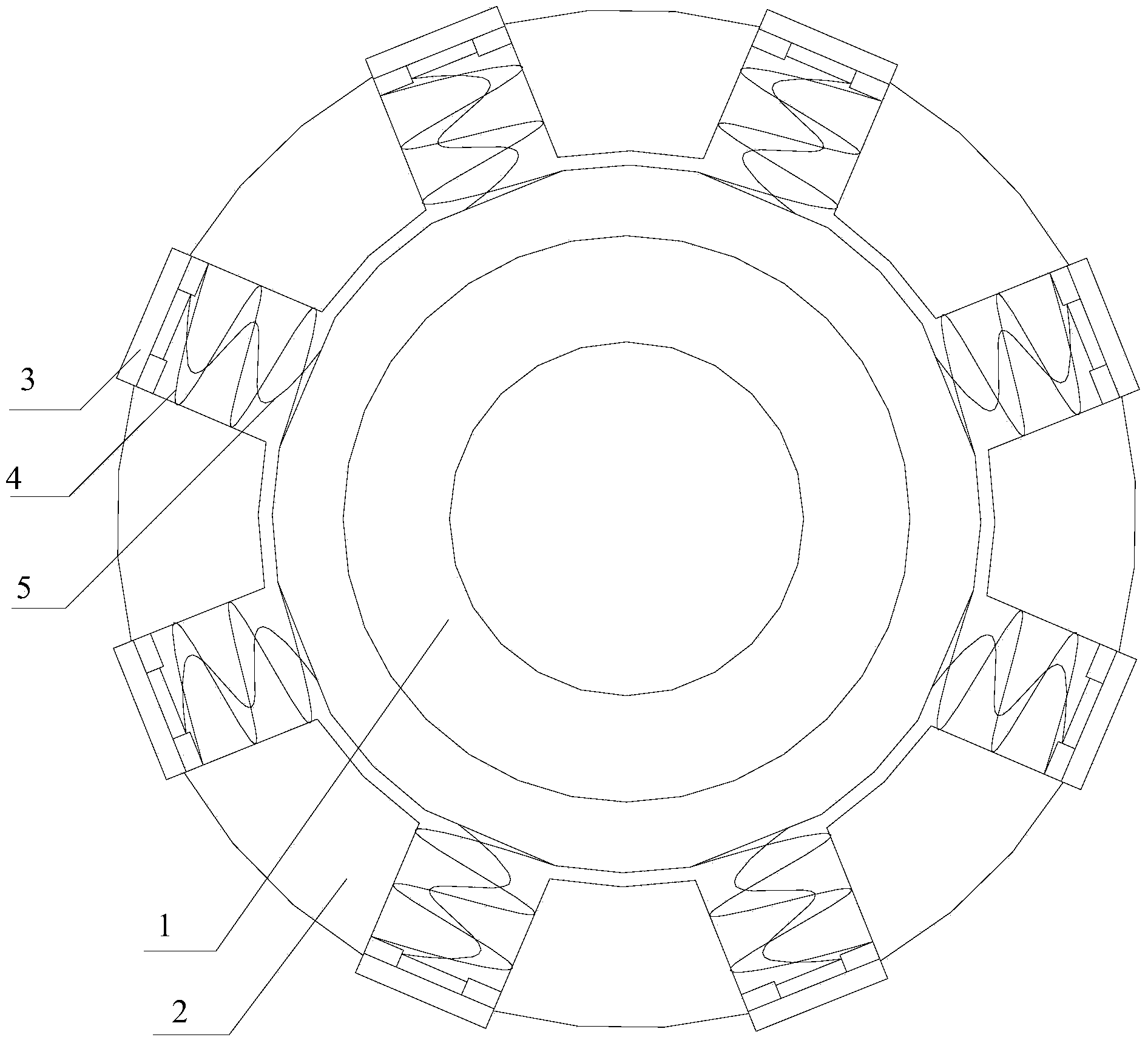

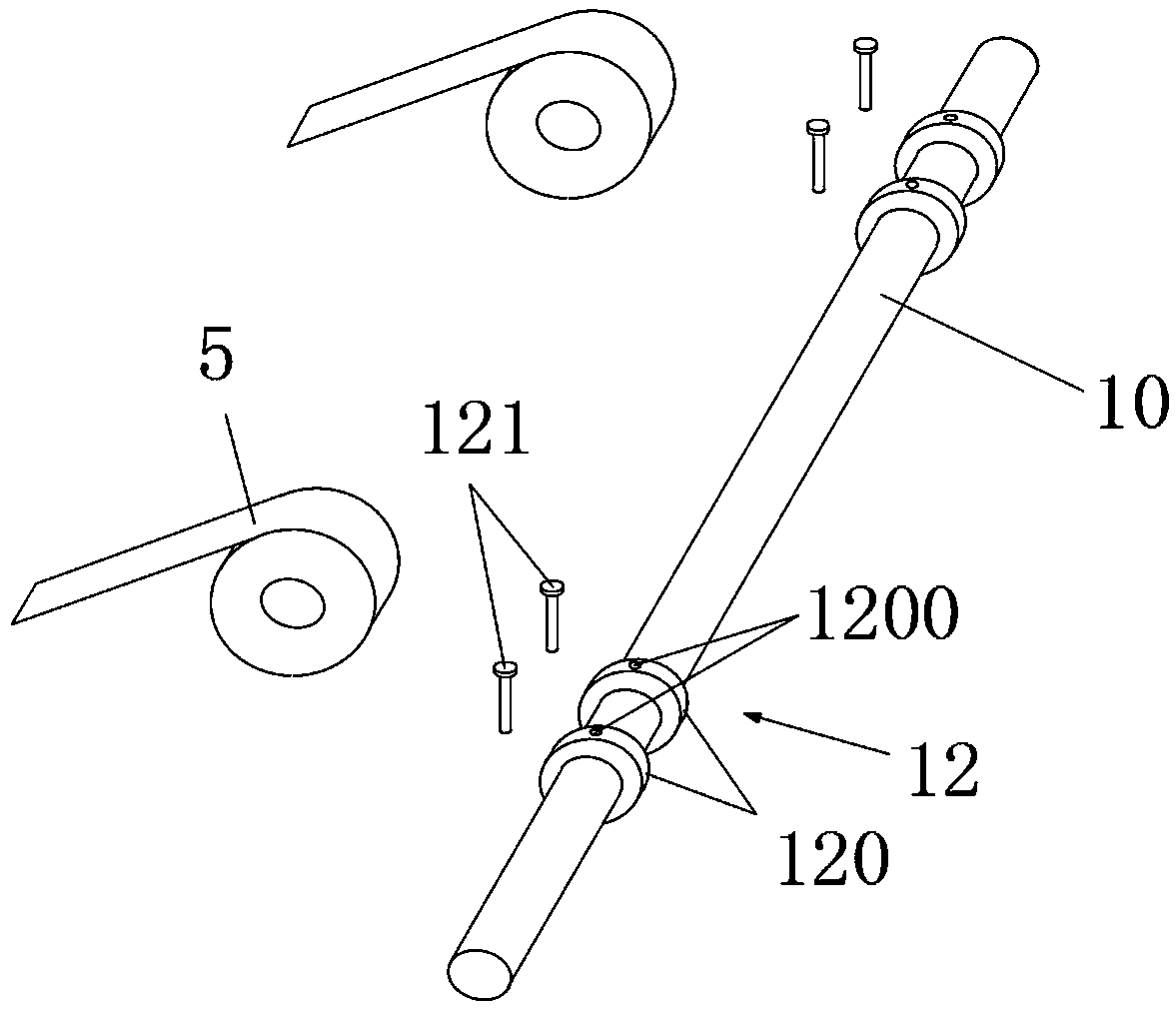

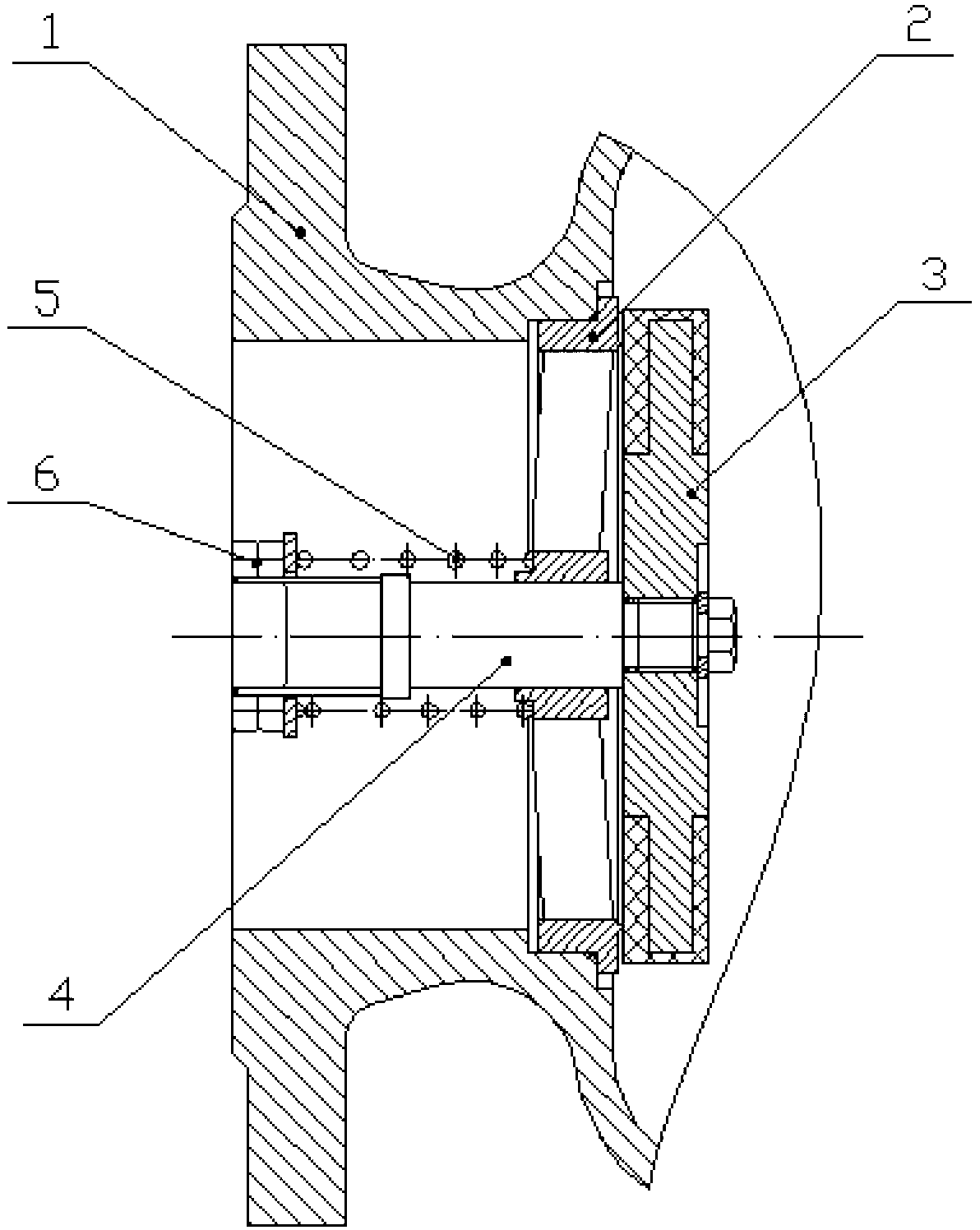

Capping head

ActiveCN103663315AChange pressureChange the amount of compressionFlanged caps applicationEngineeringMechanical engineering

The invention relates to a capping head. The capping head comprises an installation base and a lifting block which is matched with the installation base, the lower half portion of the lifting block is movably arranged in the installation base, a cap obtaining head is arranged on the bottom of the installation base, a positioning step which is matched with the installation base is arranged on the bottom of the lifting block, an adjusting block is arranged on the outer side of the upper half portion of the lifting block in a surrounding mode, the upper end of the adjusting block is connected with the lifting block, the vertical position of the adjusting block can be adjusted, a cavity is defined by the lifting block, the installation base and the adjusting block, a spring is arranged in the cavity, and the two ends of the spring abut against the adjusting block and the installation base respectively. The capping head is applicable to capping machines with pressure needing to be regulated.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Grinding machine tail seat structure

InactiveCN104308731AChange the amount of compressionAvoid enteringGrinding work supportsEngineeringTailstock

Owner:CHONGQING JINLUN IND

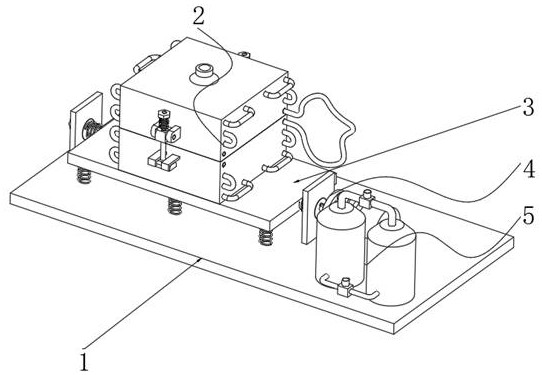

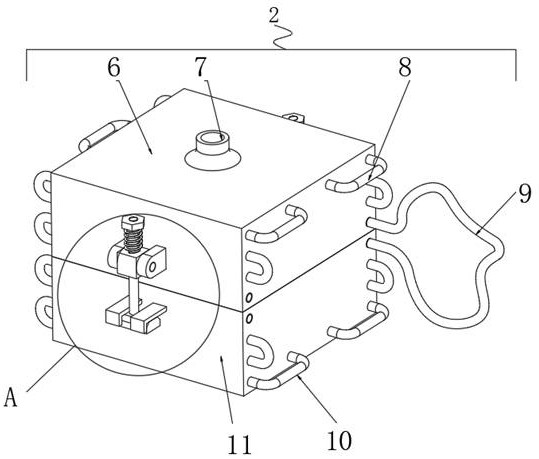

Aluminum alloy gravity casting die with good cooling effect

InactiveCN113351856ASpeed up coolingImprove cooling efficiencyFoundry mouldsFoundry coresHeat transmissionCooling effect

The invention discloses an aluminum alloy gravity casting die with a good cooling effect, and relates to the technical field of gravity casting. The problem of cooling efficiency is solved. The aluminum alloy gravity casting die specifically comprises a base and a supporting seat, an upper and lower die assembly is arranged at the top of the supporting seat, an auxiliary assembly is arranged at the top of the base, the upper and lower die assembly comprises an upper die and a lower die, and a plurality of first U-shaped pipe combination pipes and a plurality of second U-shaped pipe combination pipes are connected to the inner walls of the other three sides of the non-opening side of the upper die and the inner walls of the other three sides of the non-opening side of the lower die in an embedded mode respectively. A pump located in a cooling water barrel is started, cooling water circulates through the first U-shaped pipe combination pipes and the second U-shaped pipe combination pipes, the upper die and the lower die are cooled in a heat transfer mode, and therefore the cooling speed of a casting is increased, the first U-shaped pipe combination pipes and the second U-shaped pipe combination pipes occupy the inner walls of the three sides of the upper die and the lower die, three sides are simultaneously cooled, so that the cooling efficiency is greatly improved.

Owner:潘德强

New energy automobile battery protection device

PendingCN112563644AImprove protectionRestraint torsionCell component detailsAxial displacementAutomotive battery

The invention discloses a new energy automobile battery protection device, and relates to the technical field of new energy batteries. the invention aims to solve the life problem; the device specifically comprises a shell, a battery placement mechanism is arranged in the shell, the battery placement mechanism comprises four sets of damping assemblies, a placement base and a clamping assembly, thefour sets of damping assemblies are arranged at the four corners of the bottom of the placement base correspondingly, and each set of damping assembly comprises three sets of damping rods and six sets of universal ball structures; the top and the bottom of each set of damping rods are movably connected to the inner wall of the bottom of the shell and the outer wall of the bottom of the placementbase through universal ball structures respectively, the three sets of damping rods form a triangular pyramid structure, each damping rod comprises a first sleeve and a second sleeve, and the inner wall of the first sleeve and the inner wall of the second sleeve are movably connected with the same piston rod. According to the device, a spring II can be effectively prevented from being subjected tonon-axial displacement and spiral torque, the spring II can be well protected, and the service life thereof is prolonged.

Owner:李拙

An ink scraper for convenient ink collection

ActiveCN108749318BAdjust thrustAdjust the intensityPrinting press partsStructural engineeringMechanical engineering

Owner:安徽金辉印务有限公司

Crankshaft balance weight fan blade chamfering mechanism

InactiveCN104708112AChange the amount of compressionAdjust the chamfer depthEconomic benefitsThreaded rod

The invention provides a crankshaft balance weight fan blade chamfering mechanism. The crankshaft balance weight fan blade chamfering mechanism comprises a cutting unit and a flexible cutter receding unit located behind the cutting unit. The cutting unit comprises a square-column-shaped cutter body, a positioning block fixed to the front side face of the cutter body, two cutters and a rolling piece, wherein the two cutters are symmetrically fixed to the upper portion of the left side face and the upper portion of the right side face of the cutter body in the horizontal direction, the rolling piece is installed at the front end of the top end of the positioning block through a pin shaft, and the rolling face of the rolling piece protrudes out of the front side face of the positioning block and is located in front of cutter blades. The flexible cutter receding unit comprises a cutter holder, an ejector block installed in the cutter holder, a compressed spring, a baffle and an adjusting threaded rod fixedly connected with the baffle, wherein the bottom end of the cutter holder is hinged to the bottom end of the cutter body. The chamfering mechanism has the advantages of being easy to install, convenient to use, high in machining precision and capable of reducing the loss of the cutters and waste products; the chamfering mechanism is used for conducting chamfering on a crankshaft balance weight fan blade, the machining cost can be greatly reduced, the product quality can be fully guaranteed, and the obvious economic benefits are achieved.

Owner:荆州环球汽车零部件制造有限公司

Anti-vibration impact-resistant rear part vibration isolator

ActiveCN105805213AChange the amount of compressionChange positive pressureShock absorbersClassical mechanicsVibration isolation

The invention relates to an anti-vibration impact-resistant rear part vibration isolator. The anti-vibration impact-resistant rear part vibration isolator comprises a shell and a central shaft, wherein a set of buffer adjustment device is arranged between each of the two ends of the central shaft and the corresponding inner wall of a hollow cavity; each buffer adjustment device comprises a rotary cover which covers the opening part of one end of the hollow cavity of the shell, a locking nut which is fixedly connected with the corresponding end part of the central shaft through threads and an open ring, a conical ring, a damping slide sheet, a spring sleeve, a first main spring and a complex spring which are sequentially in butt joint and pressing fit in a mutual match manner through the rotary cover, the locking nut and the inner wall of the shell; when the vibration isolator vibrates horizontally, the damping force of a damper is linear, so that a better vibration isolation effect is achieved; and during impact, the damping force of the damper is non-linear, so that a better buffering effect is achieved.

Owner:武汉中电华瑞科技发展有限公司

A Preload Adjustable Self-stabilizing Single-sided Thin Film Throttle

InactiveCN106641353BAdjustable pressureChange the amount of compressionEqualizing valvesSafety valvesSelf-stabilizationEngineering

Owner:QILU UNIV OF TECH +1

Intelligent assembling device based on robot assembly line

ActiveCN113501479AWon't wear outTo achieve assembly useCapsThreaded caps applicationRobot handLinkage (mechanical)

The invention discloses an intelligent assembling device based on a robot assembly line, relates to the technical field of intelligent assembling devices, and solves the problem that the quality of assembled products is uneven due to the fact that the assembling torque cannot be adjusted when assembling is carried out on an existing bottle cap and a bottle body. The intelligent assembling device based on the robot assembly line comprises a mounting part, and a supporting stand column is fixedly connected to one side of the top face of a working platform. A material distributing disc can regularly and circularly rotate a mechanical arm under the action of a grooved wheel mechanism of a driving assembly to place bottle body and bottle cap at the bottom of an assembling body, the assembling body achieves assembling of the bottle body and the bottle cap under the cooperation action of a linkage assembling assembly and a driven assembling assembly, the screwing torque of the assembling body can be adjusted, when the screwing torque is larger than the set torque of the assembling body, the assembling body can idle to protect the bottle body and the bottle cap from being abraded, use is stable, and the operation is easy and convenient.

Owner:徐州智云安全技术研究院有限公司

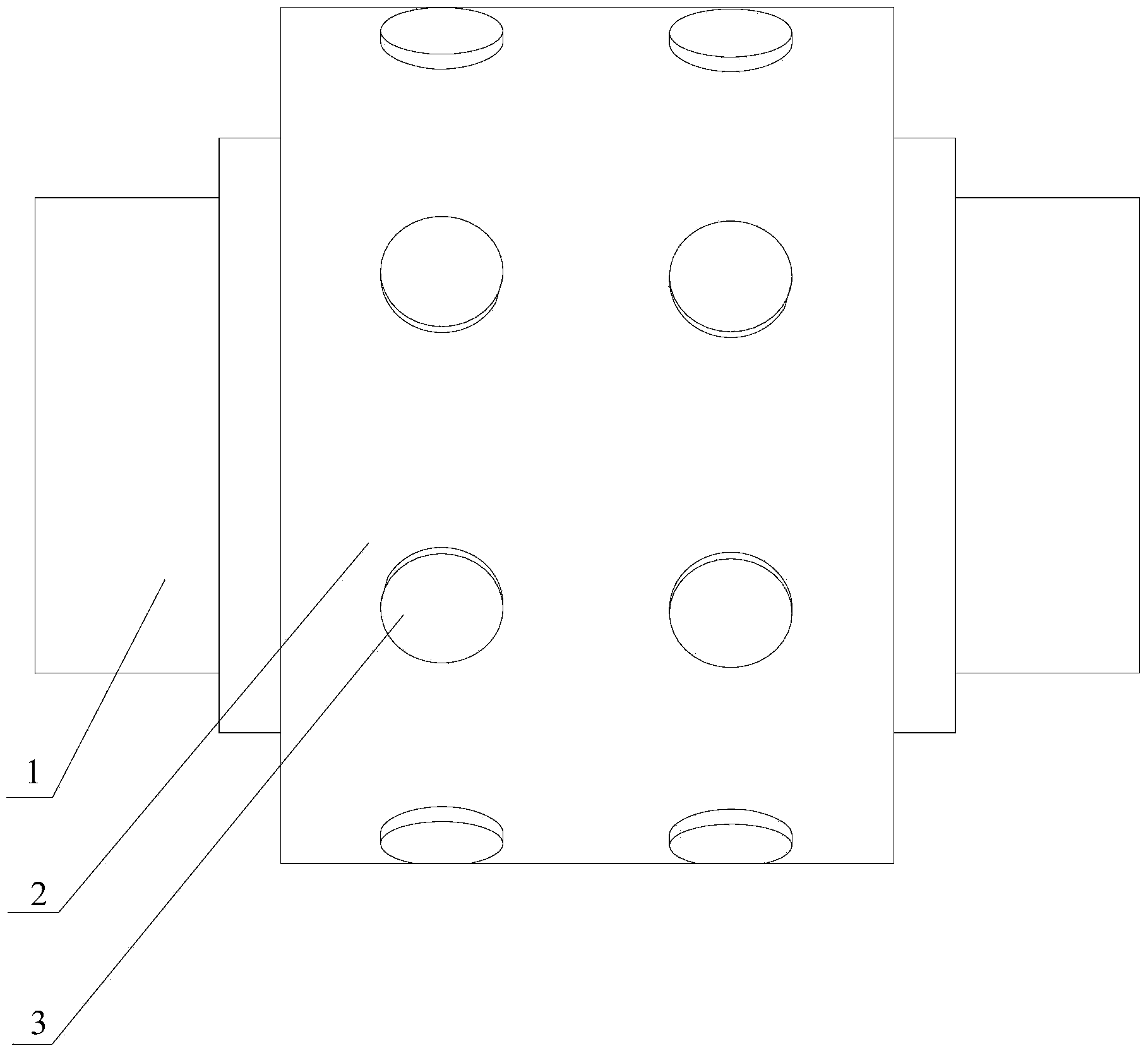

Thrust plate reliability test device

PendingCN113237783AAdjustable forceChange the amount of compressionMechanical actuated clutchesInvestigating abrasion/wear resistanceControl engineeringStructural engineering

The invention discloses a thrust plate reliability test device, which is characterized in that the thrust plate reliability test device comprises a tool clutch cover, a release bearing assembly, a positioning assembly and a thrust adjusting assembly, a positioning hole is formed in the middle of the tool clutch cover, a round hole is formed in the center of the release bearing assembly, one end of the release bearing assembly is provided with two symmetrical limiting ends and four symmetrical spring circular grooves, the positioning assembly is installed in the middle of the tool clutch cover, the thrust adjusting assembly is distributed on the left portion of the positioning assembly, the release bearing assembly is installed on the right portion of the positioning assembly, and the thrust adjusting assembly is matched with the release bearing assembly. The thrust plate reliability test device has the advantages of being compact in structure, easy to install, adjustable in stress, capable of being connected with an engine for real operation test and accurate in test result.

Owner:GUANGXI YUCHAI MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com