Movable centre mechanism of numerical control worm grinding wheel gear grinding machine

A technology of worm grinding wheel and gear grinding machine, which is applied in the direction of gear teeth, worms, gear cutting machines, etc. It can solve the problems of affecting the machining accuracy, poor contact between the tip and the tip hole of the workpiece, etc., to improve the grinding accuracy, avoid deformation, and install and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

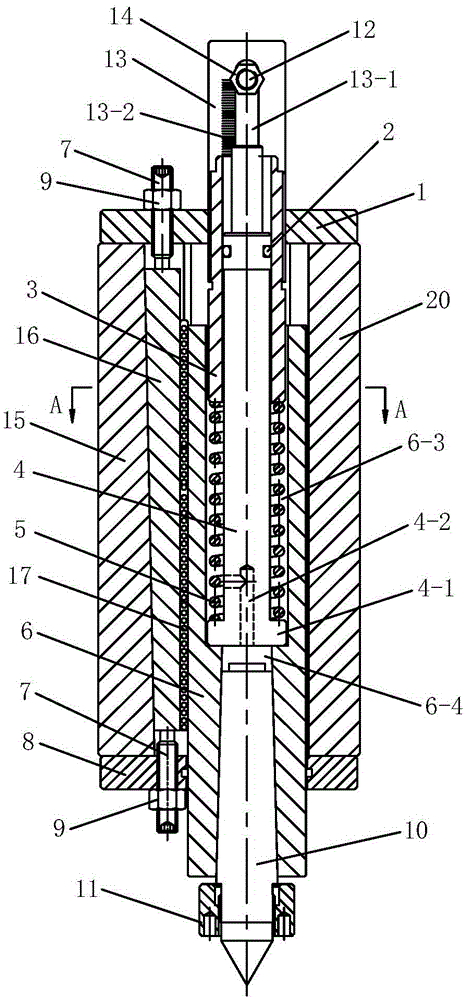

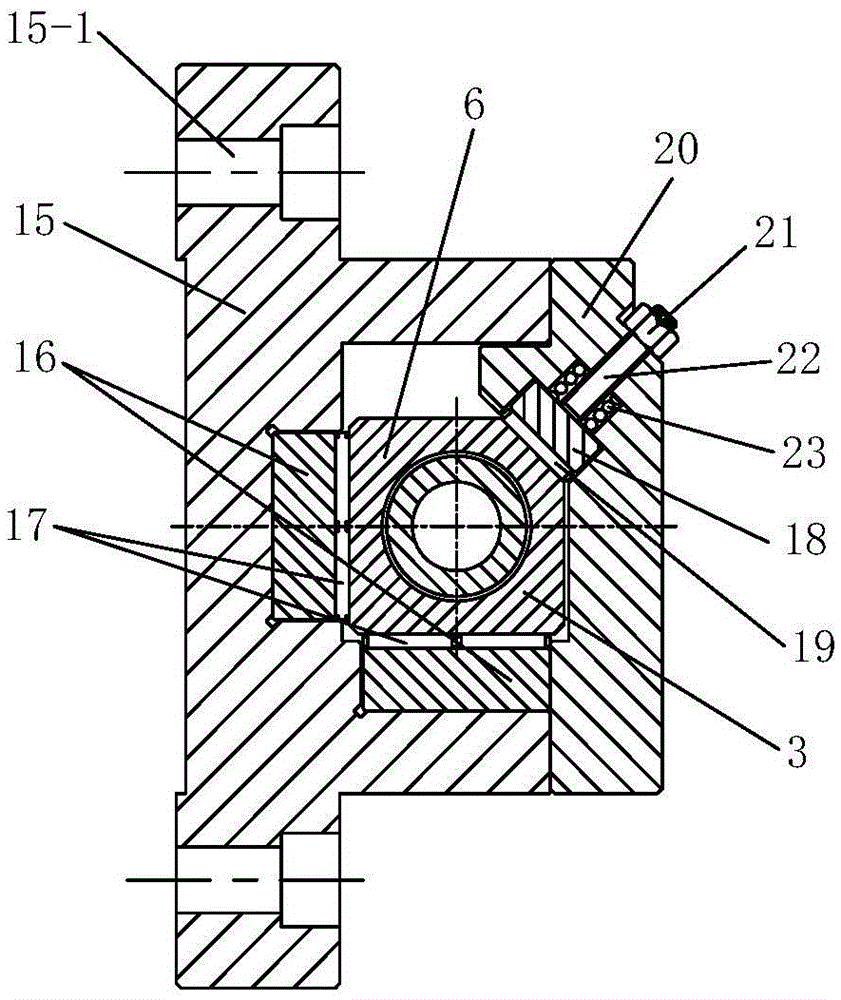

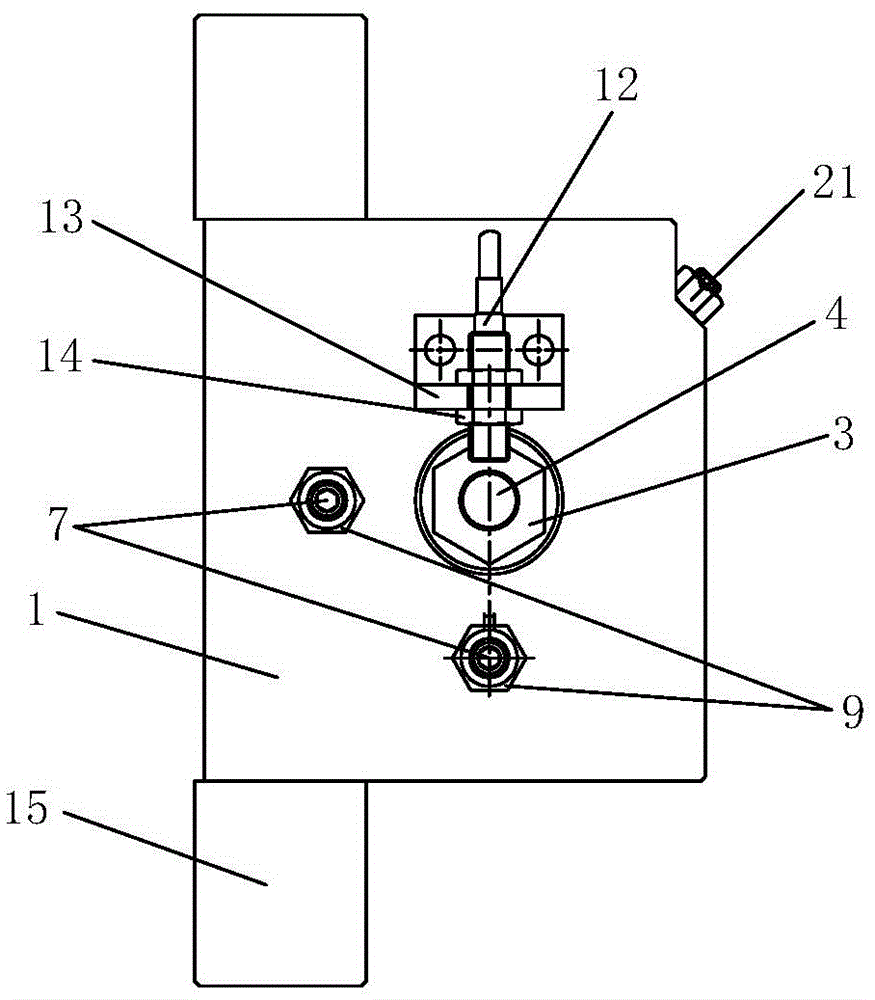

[0040] Such as figure 1 , figure 2 , image 3 , Figure 5 and Figure 6As shown, the present invention includes a top body and a top shaft 6, the top body includes a top seat 15, a cover plate 20, an upper end cover 1 and a lower end cover 8, and the cover plate 20 is arranged on one side of the top seat 15, the The upper end cover 1 is arranged on the top of the top seat 15, the lower end cover 8 is arranged on the bottom of the top seat 15, the top seat 15, the cover plate 20, the upper end cover 1 and the lower end cover 8 are fixed together and the four are fixed together. A cavity is formed between them, the upper part of the tip shaft 6 is arranged in the cavity, the lower part of the tip shaft 6 passes through the lower end cover 8 and is located outside the cavity, and the Morse tip 10 is installed on the tip shaft 6 , the upper part of the tip shaft 6 is provided with a right-angled surface 6-1, and a first plate roller chain 17 and a beveled strip 16 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com