Edge cutting device capable of effectively preventing cloth from wrinkling

A cutting device and fabric technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of easy wrinkling, inability to guarantee the cutting size accuracy, and inability to ensure that the fabric does not appear wrinkled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

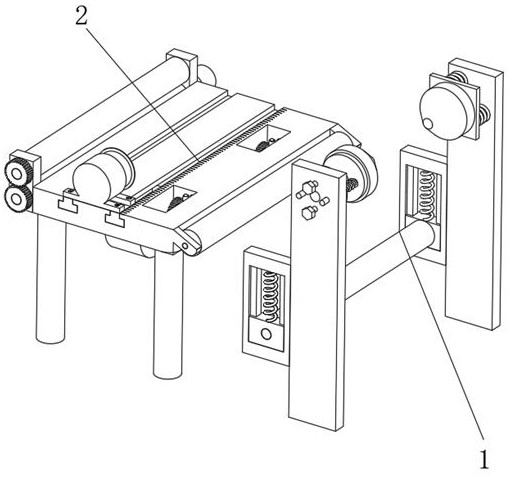

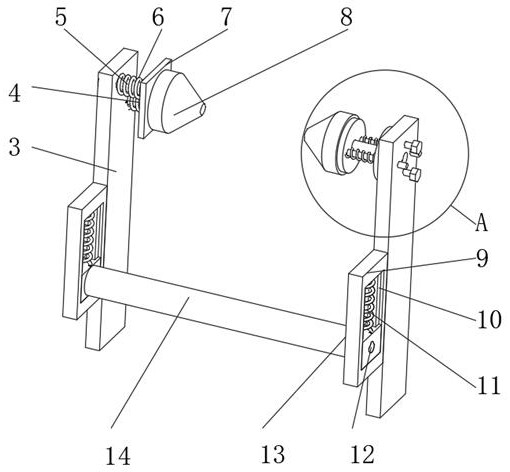

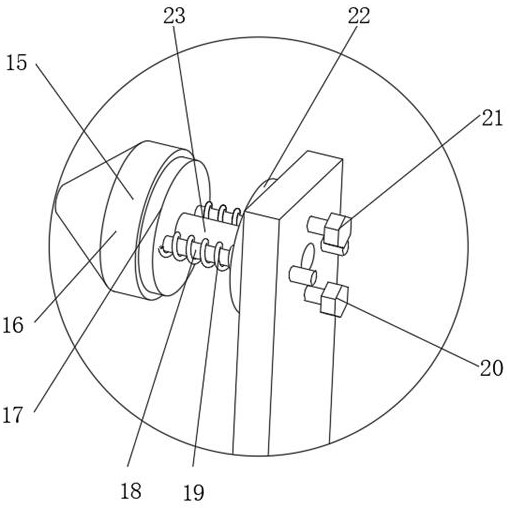

[0036] An edge cutting device that effectively prevents fabric wrinkles, such as figure 1 , 2 , 3 and 4, including a material guide mechanism 1 and a cutting mechanism 2, the material guide mechanism 1 includes two vertical plates 3 fixed on the ground and an adjustable clamping assembly 4 and a damping clamp arranged on the outer wall of the vertical plate 3 Hold assembly 15 and tension assembly 9, described adjustable clamp assembly 4 comprises compression spring 6 and first thimble 8, and described tension assembly 9 comprises tension spring 11 and tension roller 14, and described vertical plate 3 The outer wall of the tension frame 13 is fixedly installed with a tension frame 13, and the inner wall of the tension frame 13 is provided with a first chute 10, the outer wall of the first chute 10 is slidably connected with a slider 12, and the inner walls of the two sliders 12 are rotatably connected with a On the same tensioning shaft, the tensioning roller 14 is sleeved on ...

Embodiment 2

[0043] An edge cutting device that effectively prevents fabric wrinkles, such as Figure 4 , 5 , 6, in order to solve the anti-wrinkle problem perpendicular to the conveying direction; this embodiment makes the following improvements on the basis of embodiment 1: it also includes two sets of transverse tensioning mechanisms, and the transverse tensioning mechanisms include transverse tensioning Wheel 26 and tensioning motor 40, described tensioning motor 40 is fixedly installed on the bottom outer wall of workbench 24, the output shaft of tensioning motor 40 is connected with the 3rd gear 41 by key, and described transverse tensioning wheel 26 is connected in rotation On the inner wall of the workbench 24, one side of the outer wall of the transverse tension wheel 26 meshes with the third gear 41 through the teeth provided on it, and the outer wall of the transverse tension wheel 26 is fixedly equipped with a dial in a circular array. Rod 42, the rotational speeds of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com