Patents

Literature

170results about How to "Change friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

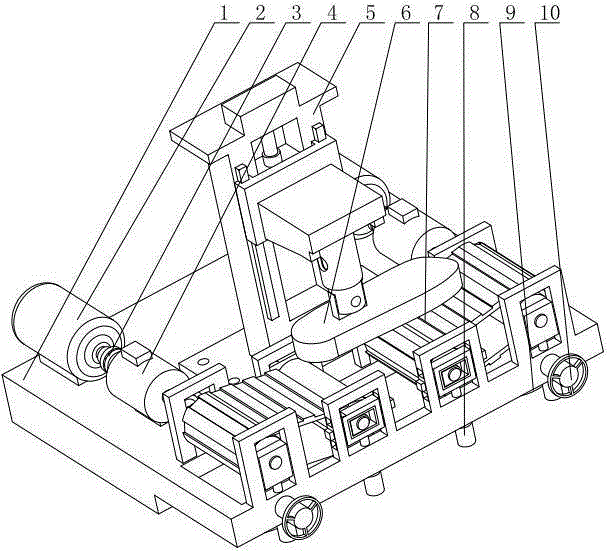

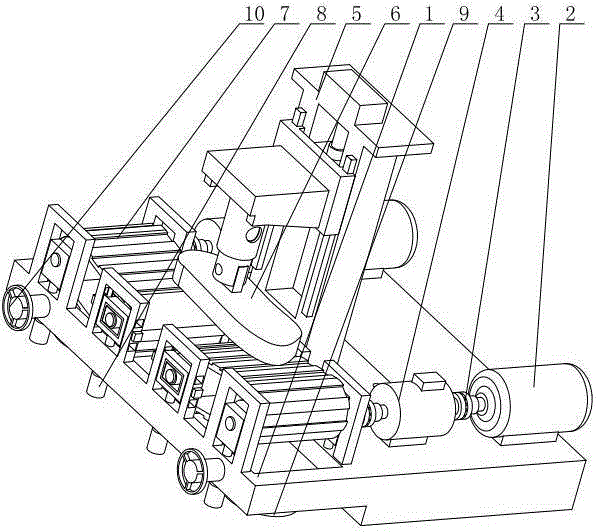

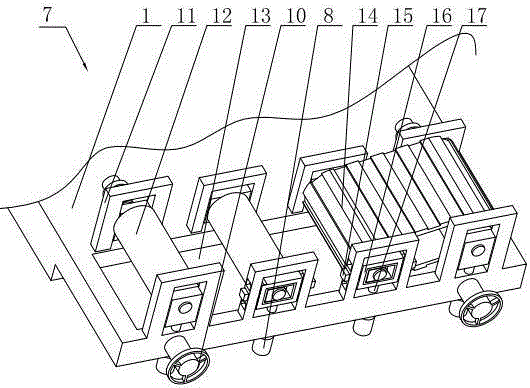

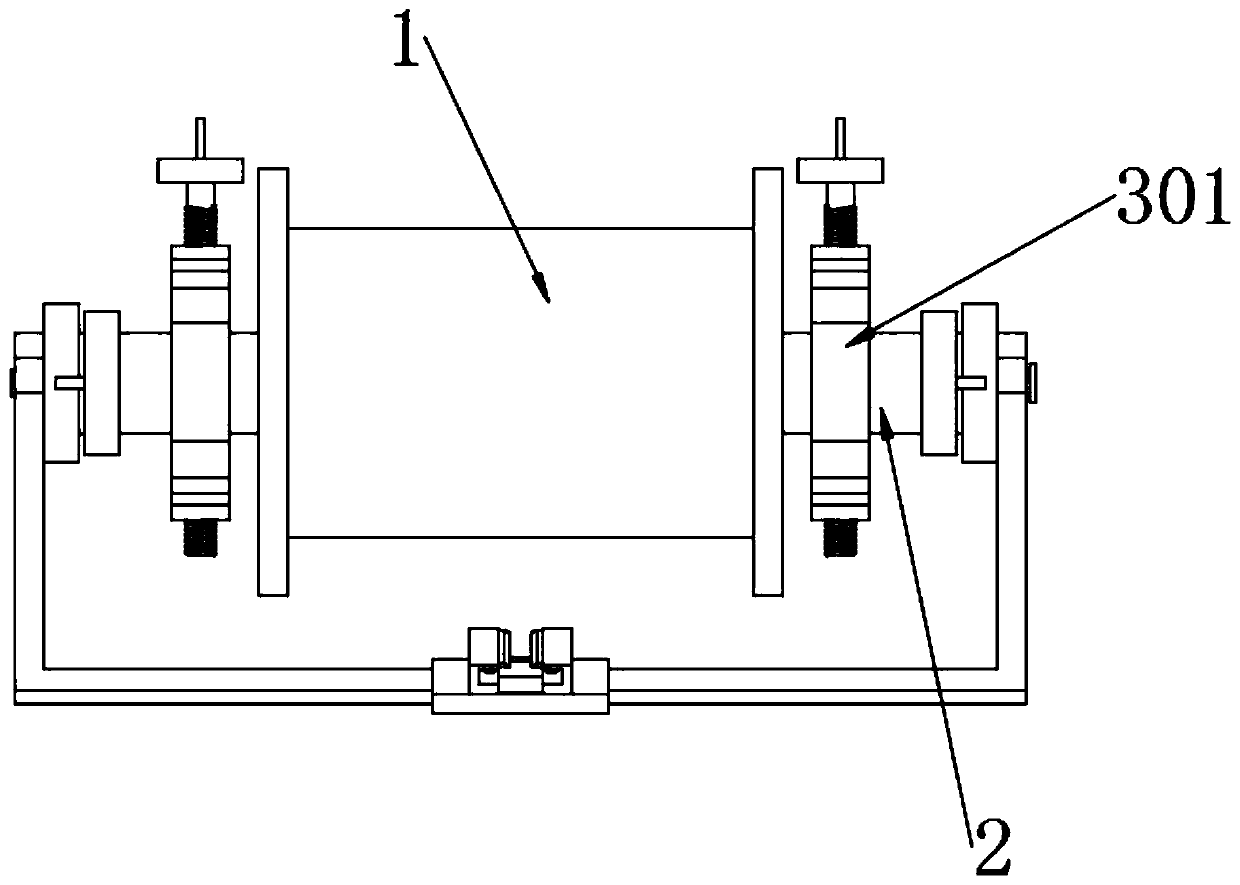

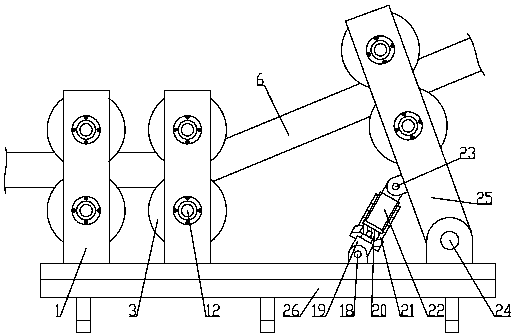

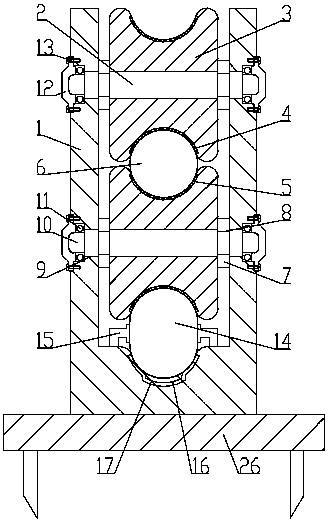

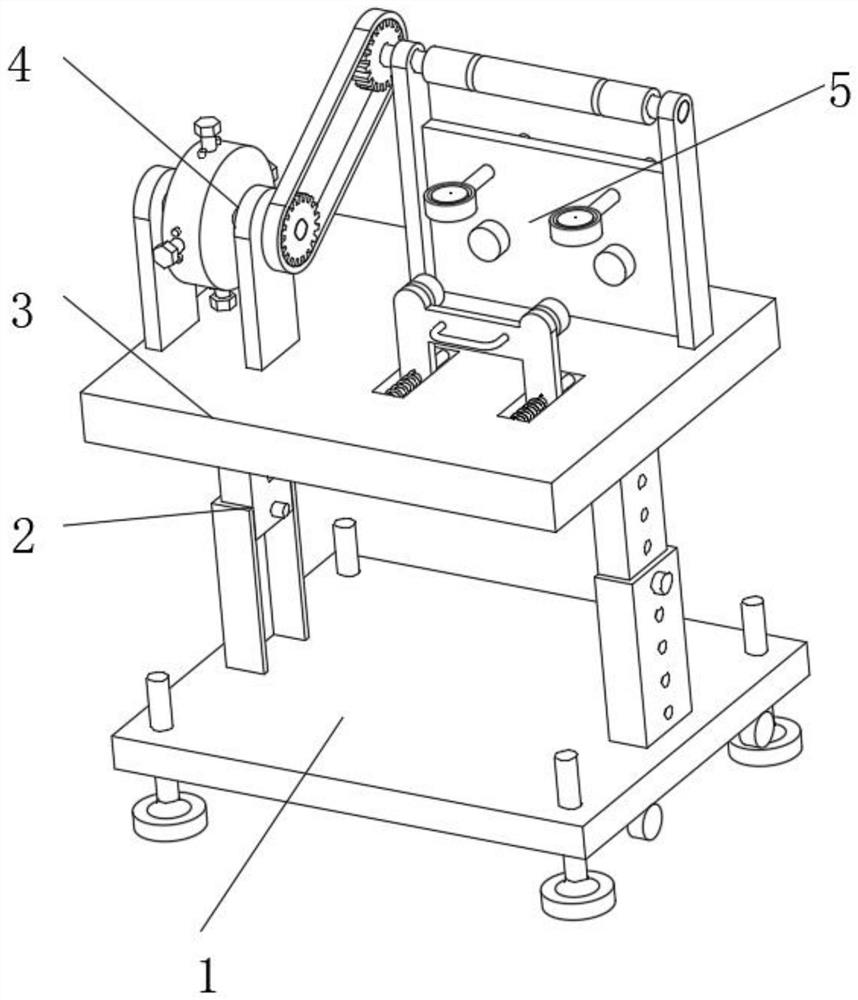

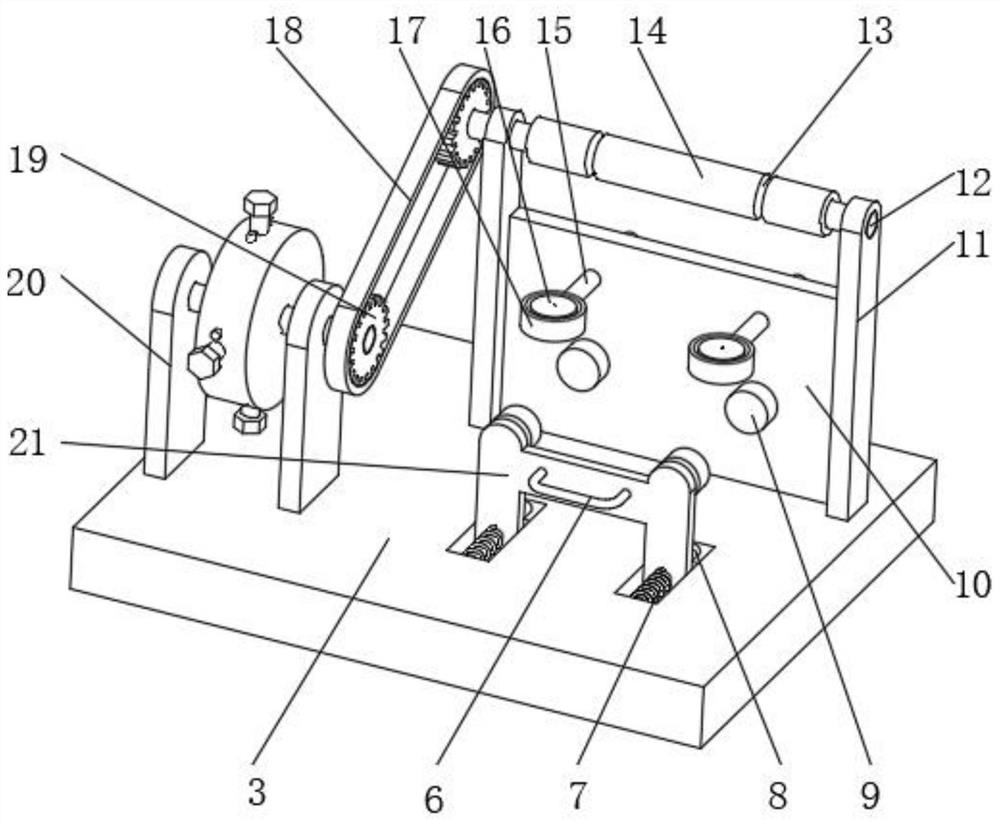

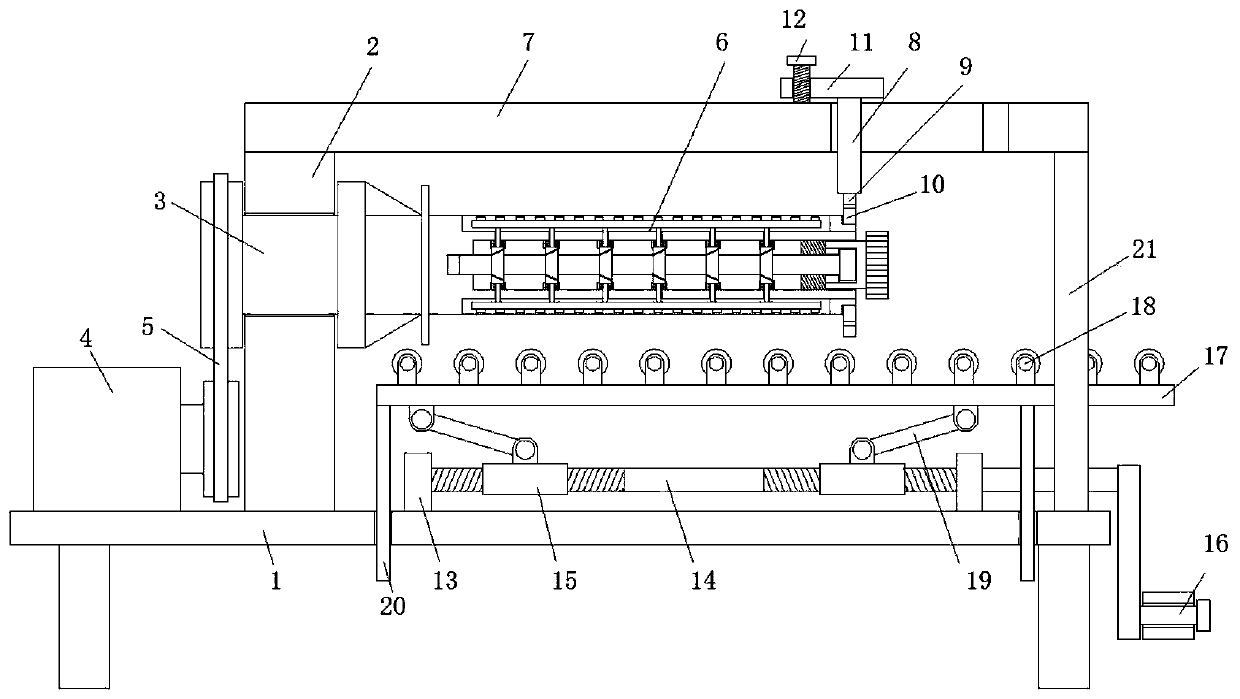

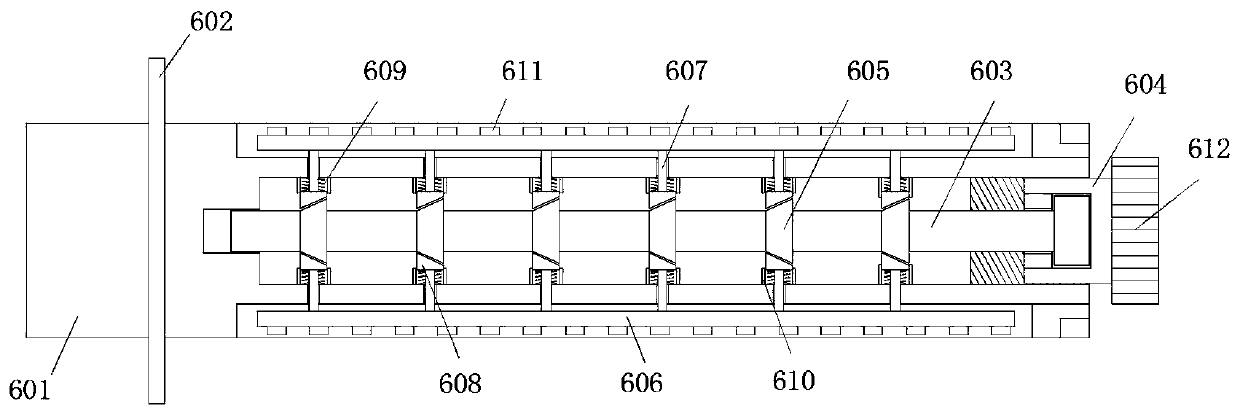

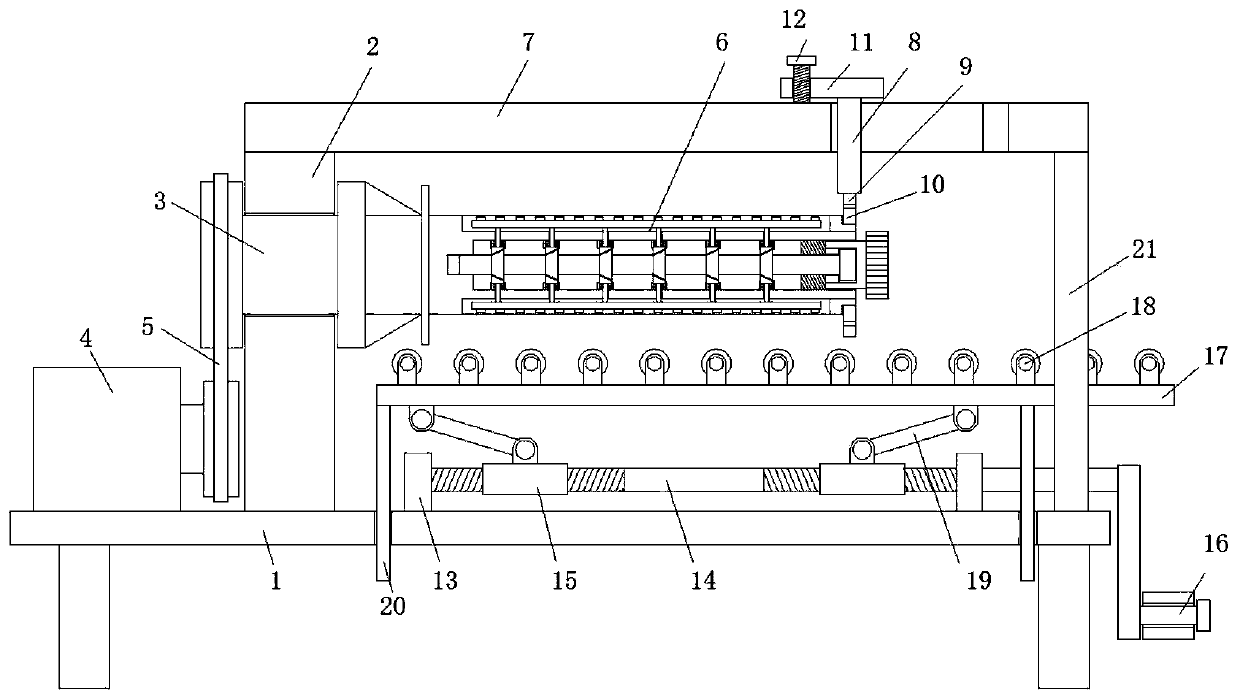

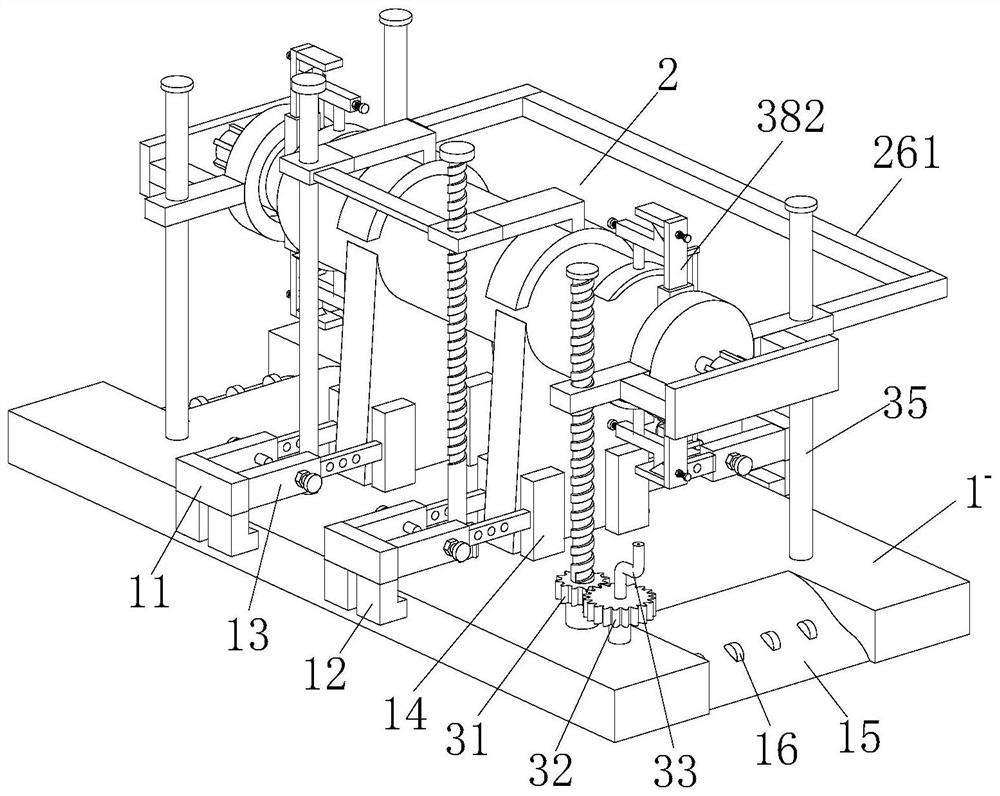

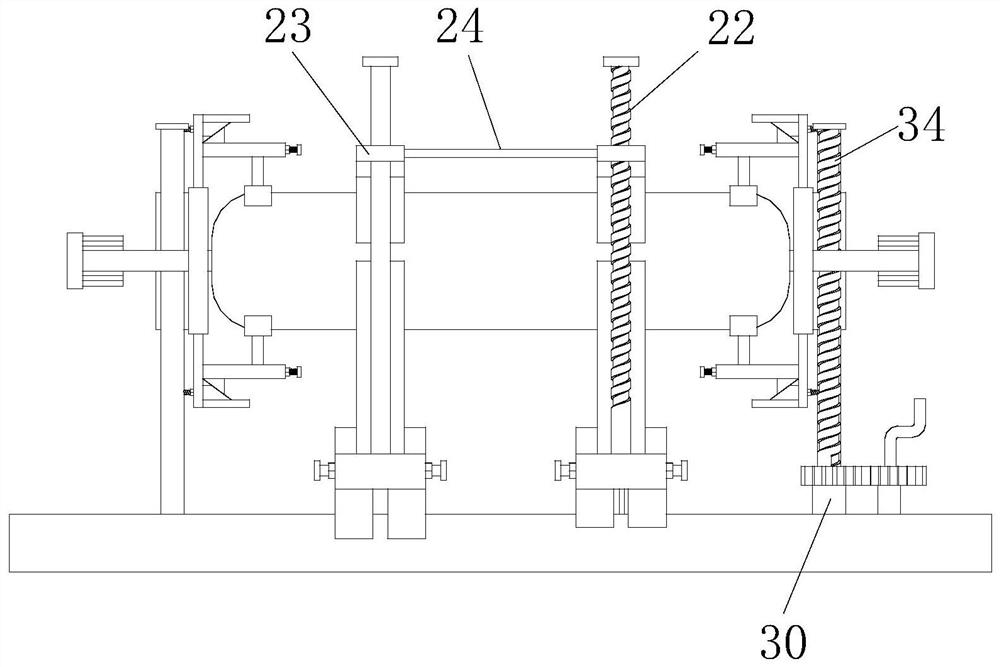

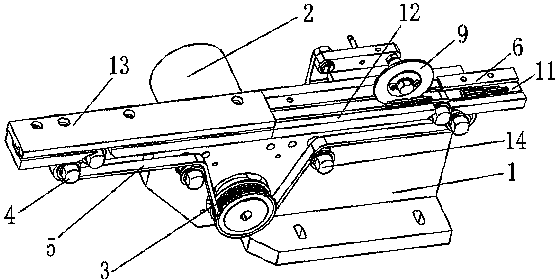

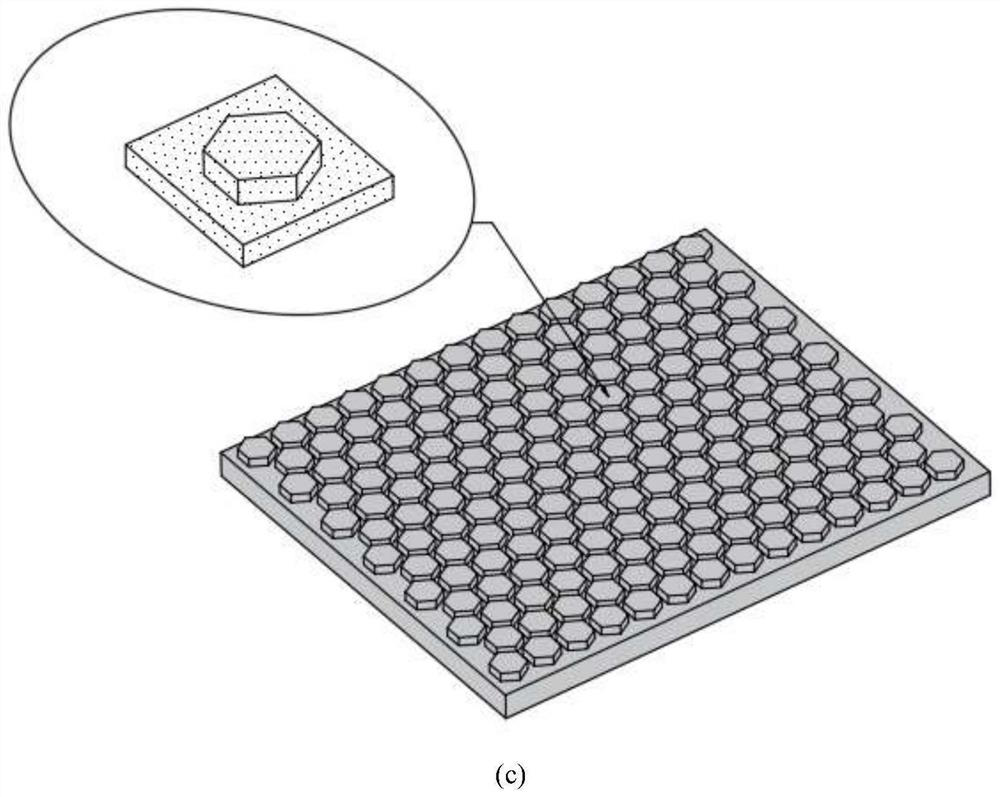

Sole abrasion resistance testing device capable of simulating various environments

ActiveCN105193003ACompact structureReasonable structureFoot measurement devicesEngineeringDrive motor

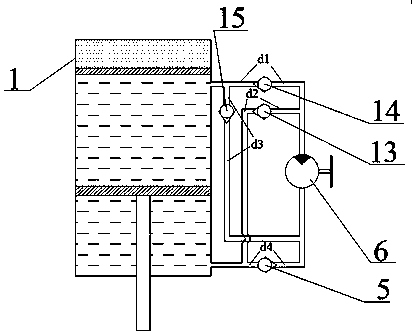

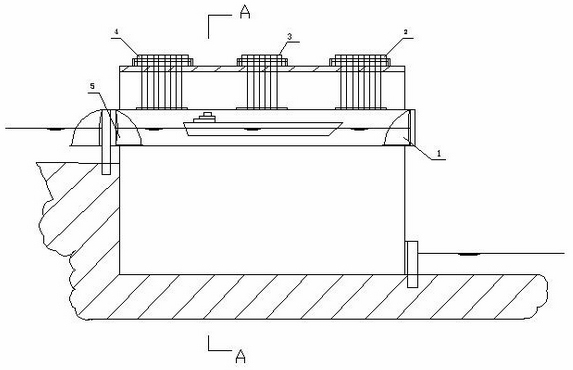

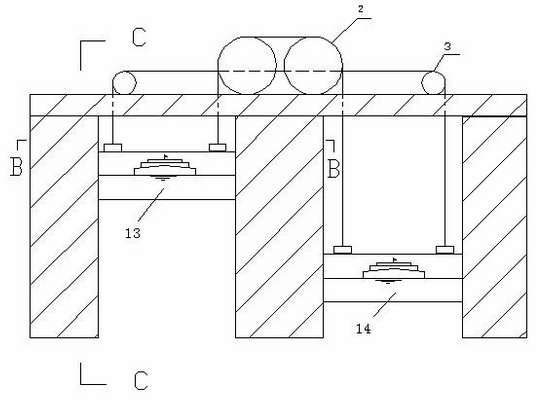

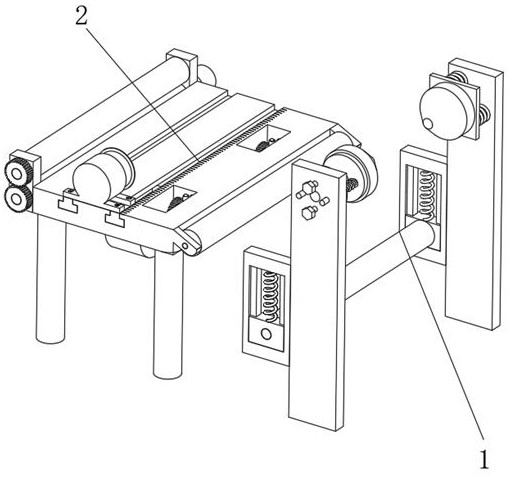

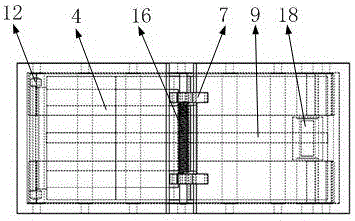

A sole abrasion resistance testing device capable of simulating various environments comprises an experiment table base; two friction experiment devices are arranged at the front end of the experiment table base and mounted at an interval; driving motors used for controlling the movement of the experiment table base, couplers and torque sensors are mounted at two ends of the experiment table base respectively; a hydraulic pressurizing device is mounted in the middle of the experiment table base; a foot model device is connected to the output end of the hydraulic pressurizing device and arranged at the tops of the friction experiment devices. Due to up-down movement of transmission rollers in the friction experiment devices, discontinuous friction of two friction tapes on a shoe, gap between the friction tapes, and replaceability of the friction tapes, the front and back soles of the shoe are abraded by the two friction experiment devices respectively; due to the pressure control of the hydraulic stress application device, and replaceability of a foot model, the walking rules of people can be well simulated; due to torque change measurement of the torque sensors, change of friction coefficient can be obtained indirectly to reflect abrasion degree, so that the obtained data are more direct and accurate.

Owner:JIANGNAN UNIV

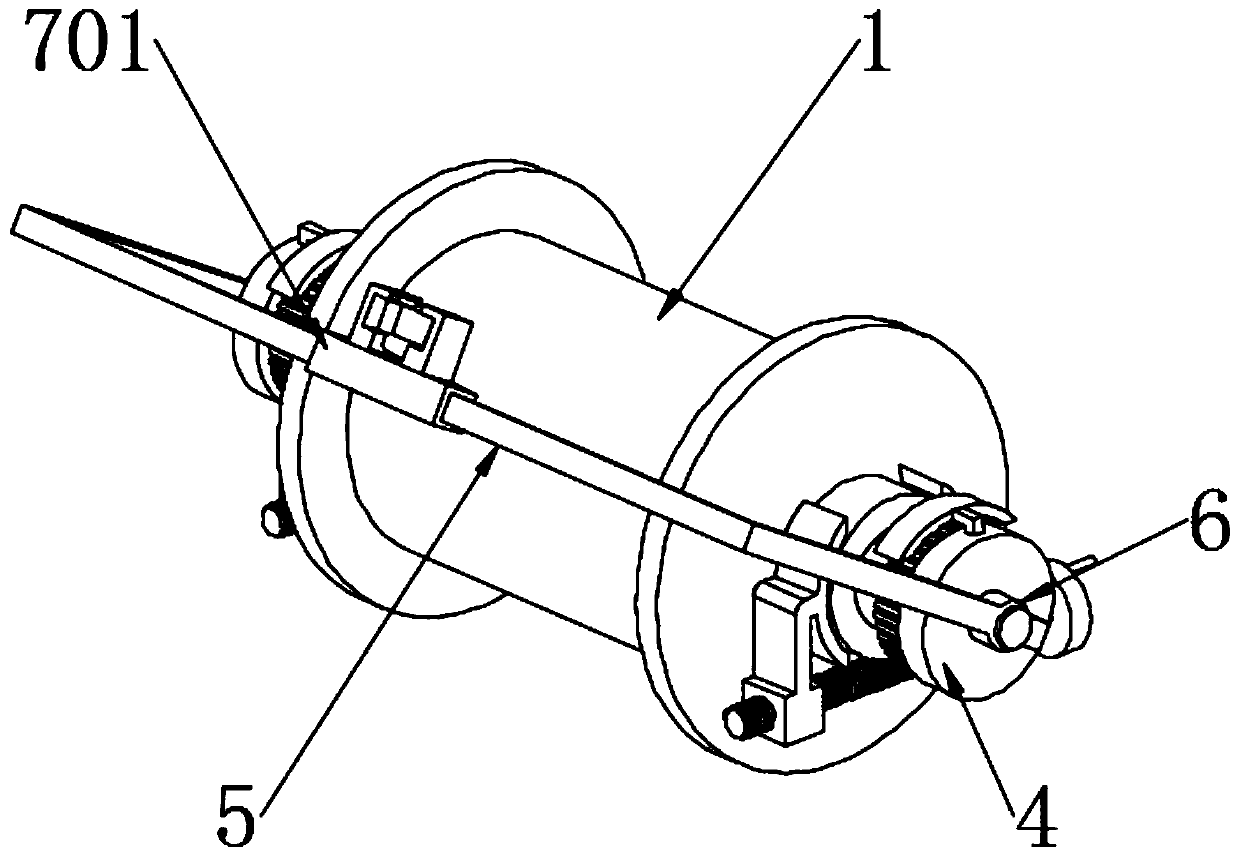

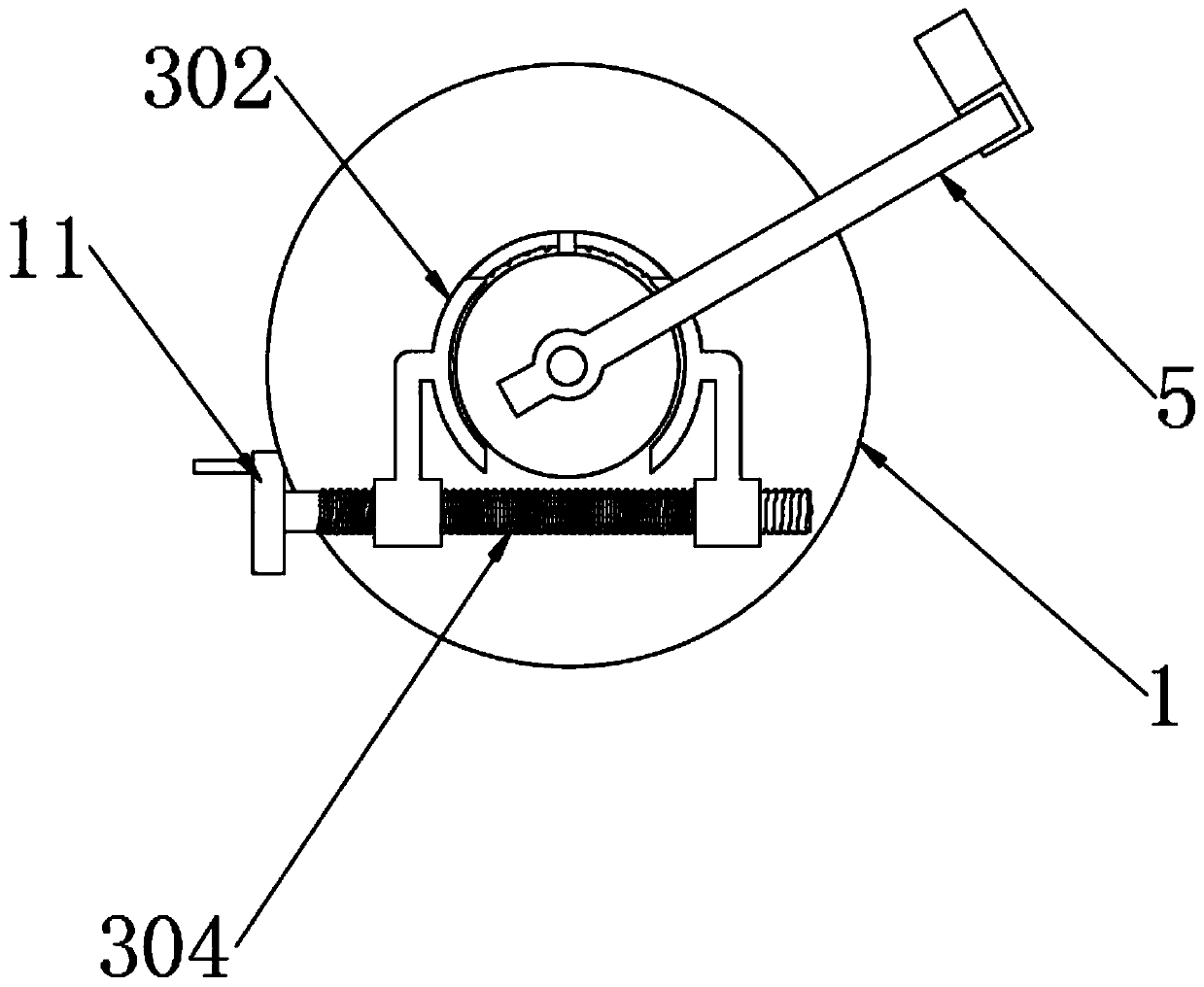

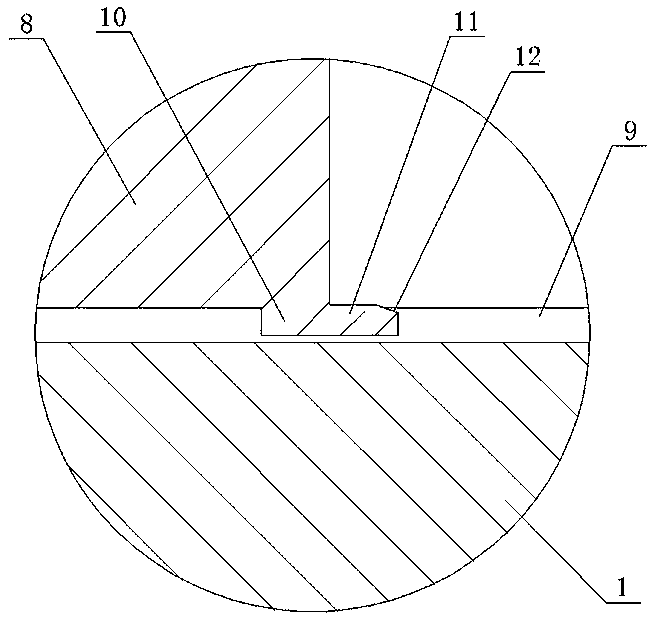

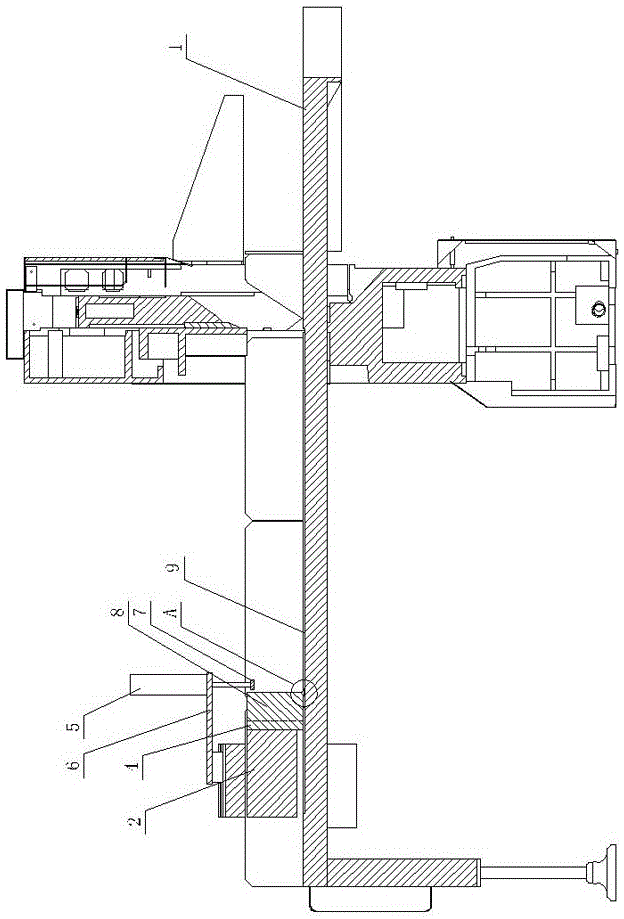

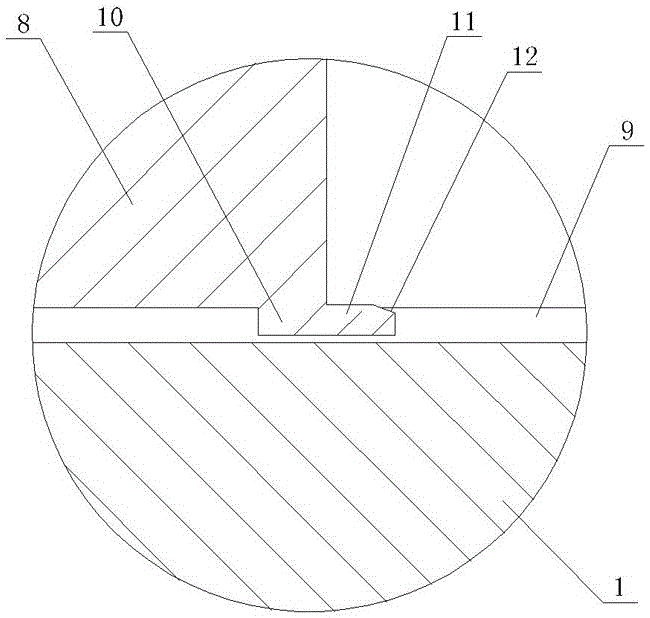

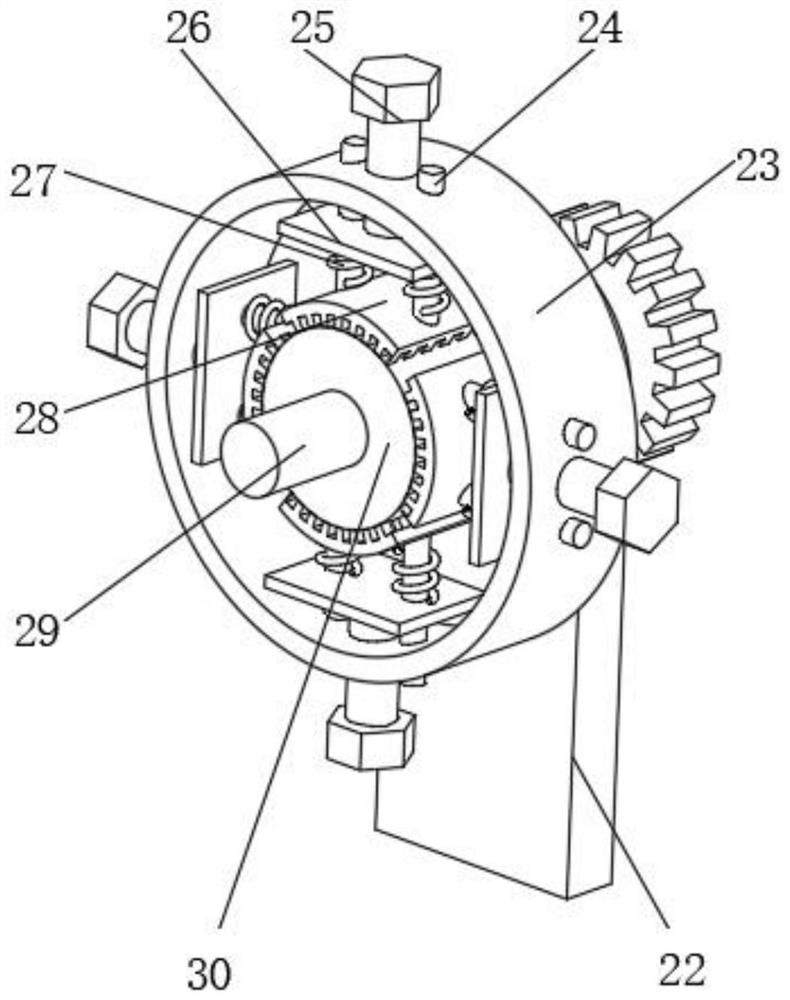

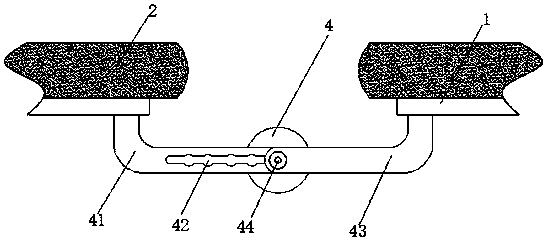

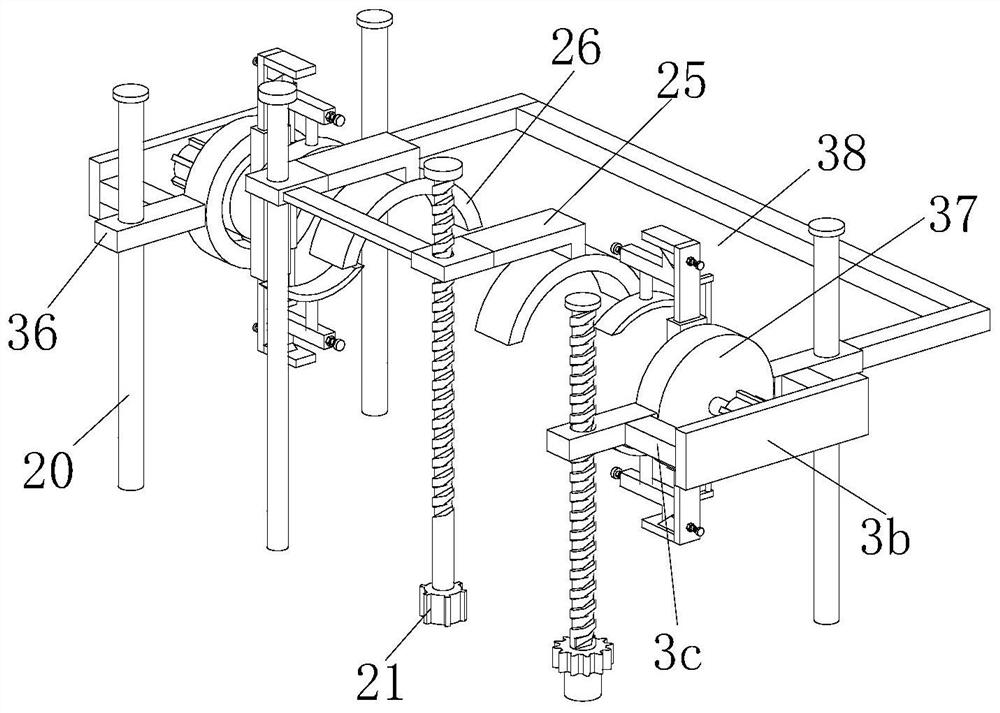

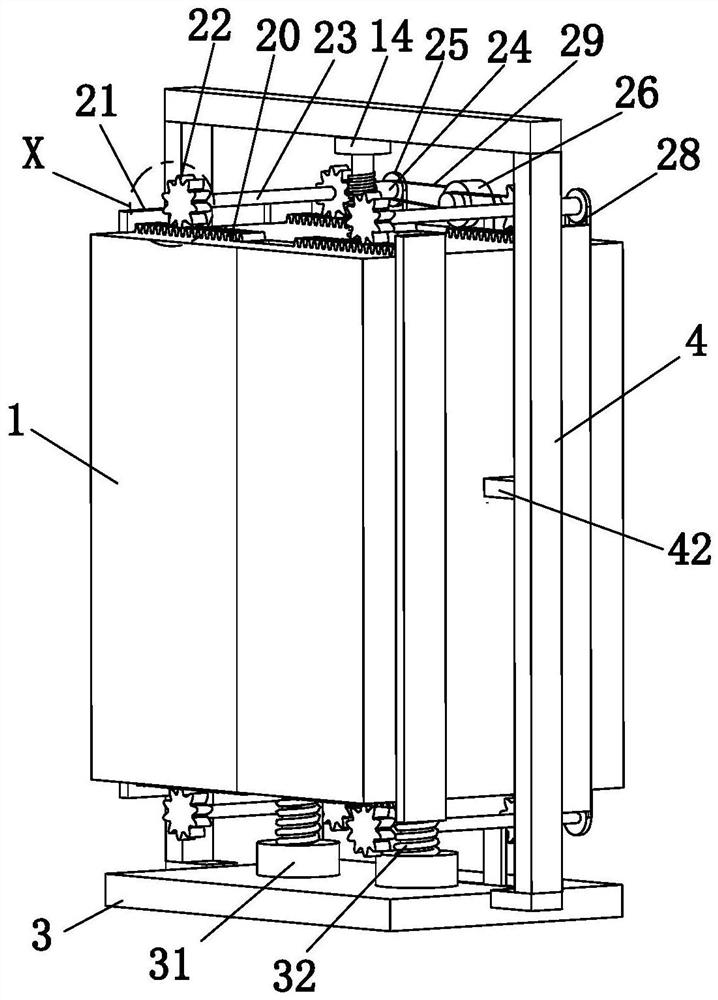

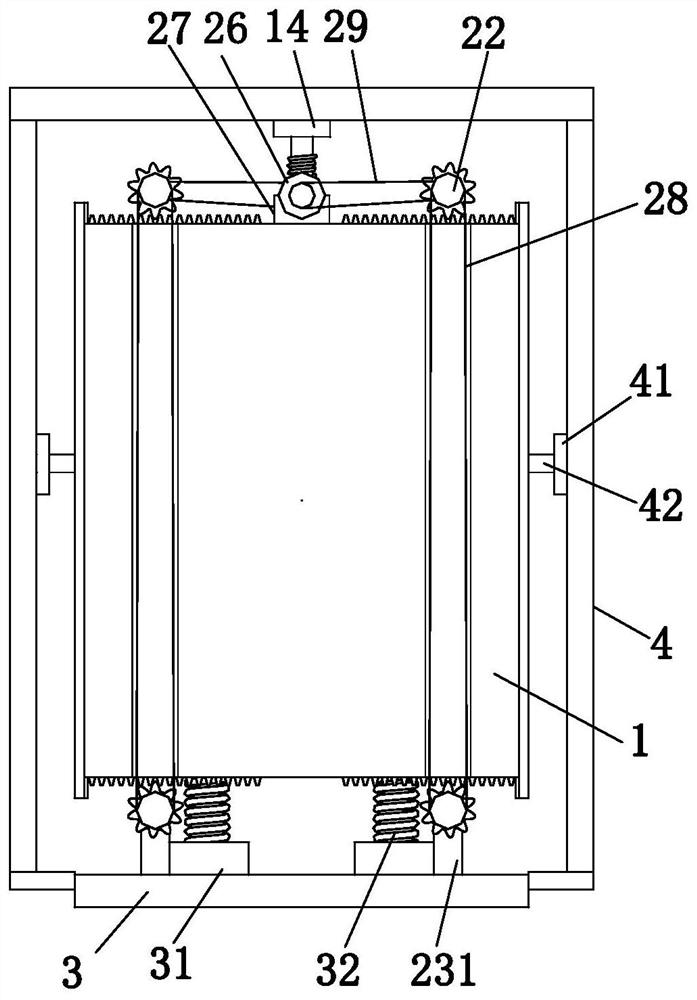

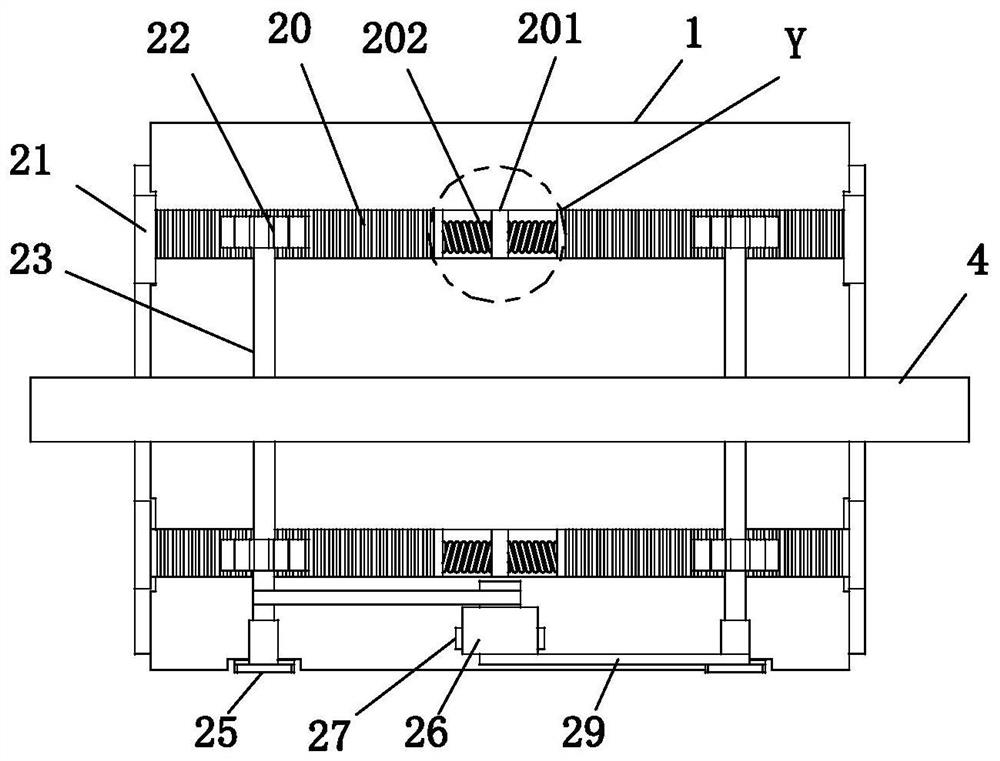

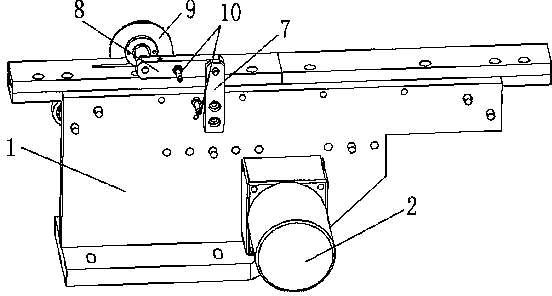

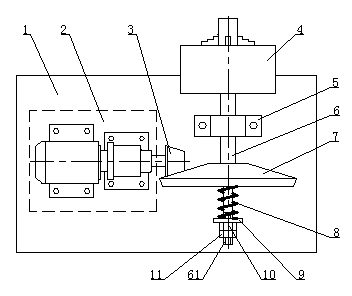

Mechanical damping passive pay-off unit

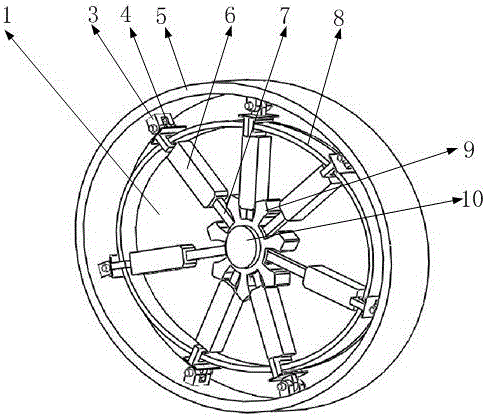

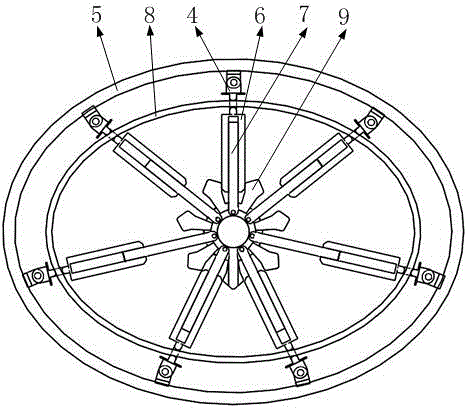

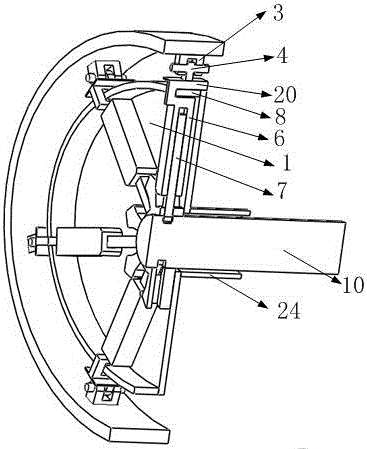

ActiveCN110642092AScientific and reasonable structureEasy to useFilament handlingGear wheelThreaded rod

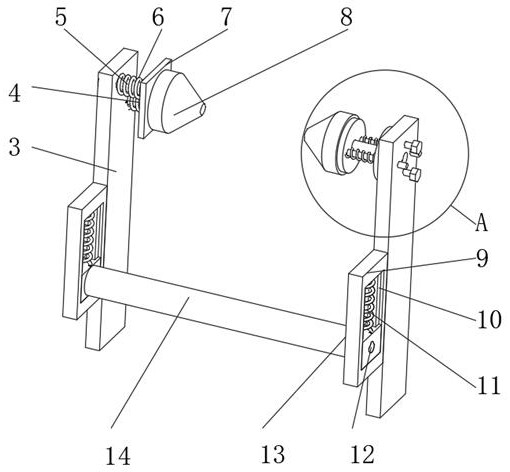

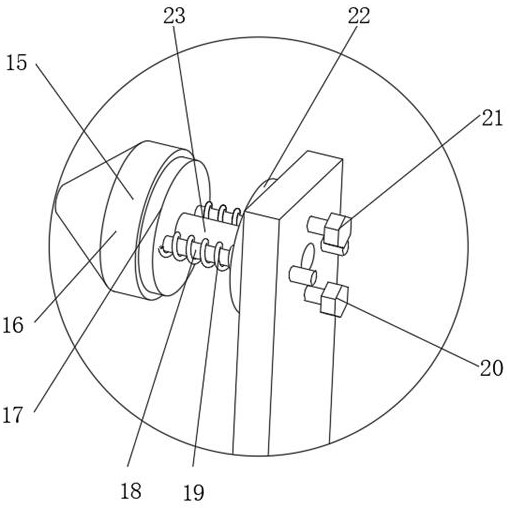

The invention discloses a mechanical damping passive pay-off unit. The mechanical damping passive pay-off unit comprises a pay-off wheel and a center shaft, wherein the center shaft is located in thecenter of the pay-off wheel and penetrates through the pay-off wheel. Damping mechanisms are arranged on the two sides of the center shaft respectively. The mechanical damping passive pay-off unit isscientific and reasonable in structure, and safe and convenient to use; because of the damping mechanisms, friction is generated through contact between each damping fin and the corresponding rotary plate, the pay-off speed of the pay-off wheel can be controlled, and the pay-off wheel can carry out pay-off work stably; because of connecting rods, lead screws, threaded rods and nuts, the separationdistance between each threaded rod and the corresponding nut is adjusted by turning the corresponding lead screw to adjust the gluing force between the corresponding damping fin and the correspondingrotary plate, then friction is changed to achieve the effect of having control over the rotating speed of the pay-off wheel, pay-off is smooth and steady, and the tension of cables is kept as well; and because adjusting gears are driven by rotary shafts to rotate, then racks are driven to move upwards or downwards to enable each positioning toothed plate and the corresponding gear to be separatedor be in engagement connection, the gears can rotate freely when each positioning toothed plate and the corresponding gear are separated, and when each positioning toothed plate and the correspondinggear are separated, the gears are locked, the pay-off wheel is locked as well, and the mechanical damping passive pay-off unit is more convenient to use.

Owner:NANJING INST OF RAILWAY TECH

Hydraulic damper with actively-adjustable damping

The invention provides a hydraulic damper with actively-adjustable damping. A hydraulic motor which is fixedly connected with a flywheel is arranged on a hydraulic loop outside a cylinder body. An upper pipeline of the hydraulic motor is connected with a left cylinder of double-effect hydraulic cylinders, and a lower pipeline of the hydraulic motor is connected with a right cylinder of the double-effect hydraulic cylinders. Pistons are arranged in cylinder bodies of the double-effect hydraulic cylinders. A pushing rod which extends out of the right cylinder is connected with a variable resistance rod. One end of a variable resistor is connected with a positive electrode of a power supply, and the other end of the variable resistor is connected with a coil wound on a second electromagnet. A negative electrode of the power supply is connected with a coil wound on a first electromagnet through a protective resistor. Electrifying directions on the coils on the two electromagnets are opposite. One end of the second electromagnet is connected with a friction shoe which is attached with the flywheel. Pressure difference between the two ends of the hydraulic motor is used for pushing the pistons, the pushing rod changes the magnitude of variable damping connected into a circuit, so that currents are changed, repulsive force between the two electromagnets is changed along with the currents, and accordingly friction force between the friction shoe and the flywheel is changed, and finally resistance of the hydraulic motor on pipeline oil liquid is changed.

Owner:JIANGSU UNIV

Gear rack vertical ship lifting device

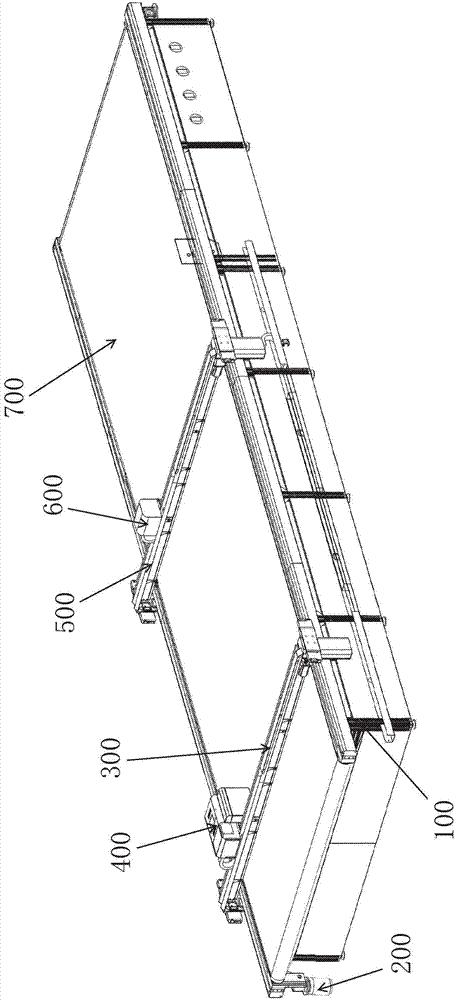

InactiveCN102146670AIngenious structural designFree to change the direction of transportationVertical ship-liftingTransportation capacityWhole body

The invention discloses a gear rack vertical ship lifting device, which consists of two ship lifting device ship chamber rooms, two ship chambers, a gear rack mechanism and a safety mechanism. The gear rack vertical ship lifting device is characterized in that the ship lifting device ship chamber rooms are symmetric double ship chamber rooms, the symmetric ship chambers in the two ship chamber rooms are completely as the same as each other, the two ship chamber rooms which are completely as the same as each other are connected with each other into a whole body by a steel wire rope and a rope wheel, the movement directions of the two ship chambers are inverse, and the weights of the two ship chambers are countered with each other. The novel gear rack vertical ship lifting device is power-saving, is low in manufacture cost, can change the transportation capacity according to the specific circumstance of a sea channel, can lead the ship chambers not to be blocked in a ship device, and can be used for timely evacuating the passengers.

Owner:陈光耀

Edge cutting device capable of effectively preventing cloth from wrinkling

InactiveCN111826931ANo creases appearGuaranteed dimensional accuracySevering textilesStructural engineeringMechanical engineering

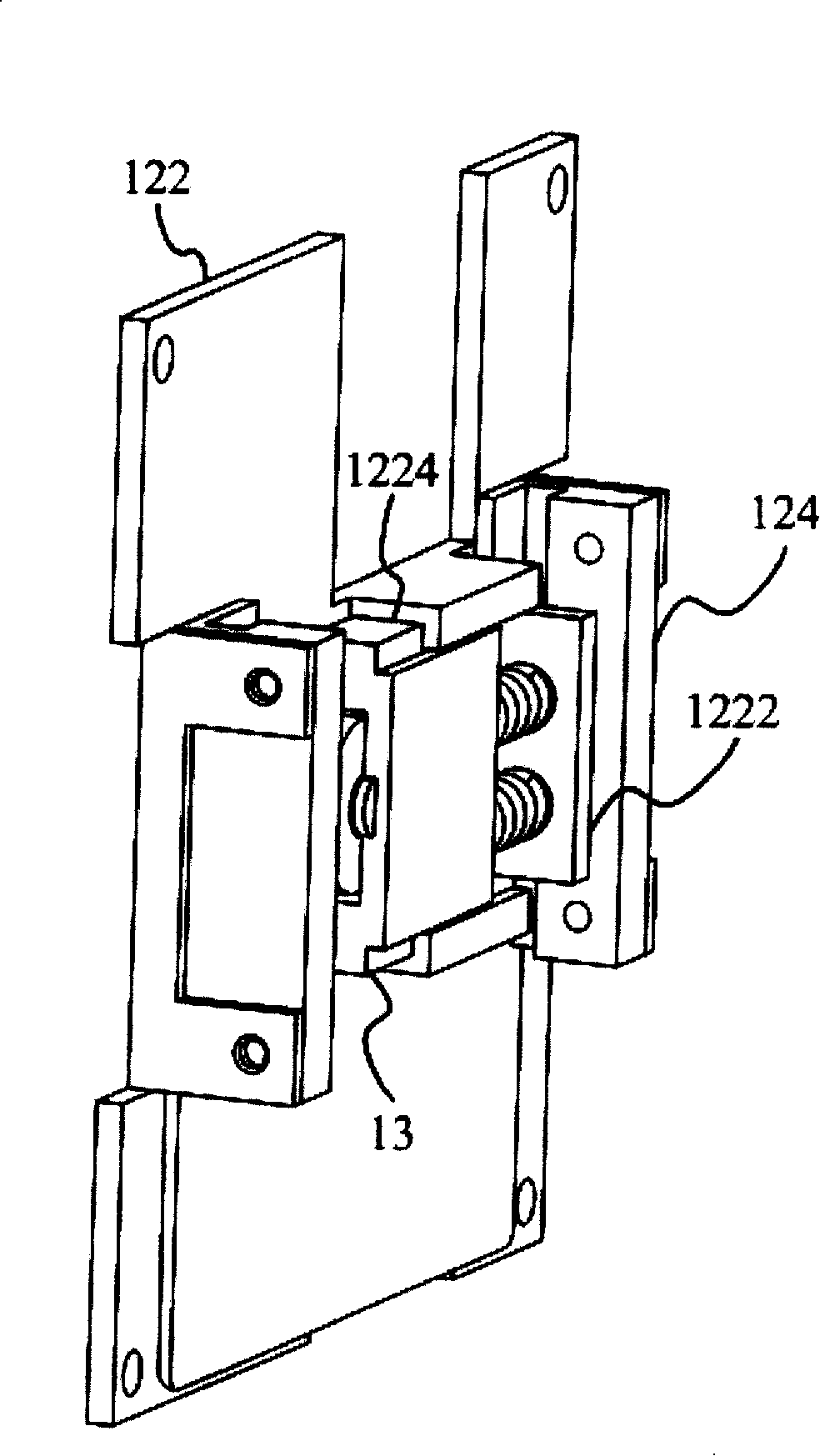

The invention discloses an edge cutting device capable of effectively preventing cloth from wrinkling, and relates to the technical field of cloth processing. To solve the wrinkle problem, specifically, the edge cutting device comprises a material guide mechanism and a cutting mechanism, wherein the material guide mechanism comprises two vertical plates fixed to the ground, as well as an adjustable clamping assembly, a damping clamping assembly and a tensioning assembly which are arranged on the outer walls of the vertical plates, the adjustable clamping assembly comprises pressing springs andfirst ejector pins, the tensioning assembly comprises tensioning springs and a tensioning roll, a tensioning frame is fixedly installed on the outer wall of each vertical plate, and a first sliding groove is formed in the inner wall of each tensioning frame. According to the edge cutting device, the damping clamping assembly and the tensioning assembly are arranged, when a conveying assembly is used for conveying, the damping clamping assembly can provide moving damping force for rotation of a cloth roll, due to the damping force, the two tensioning springs are pressed, thus downward tensionforce is generated for the cloth, so that the whole cloth is in a tension state, then wrinkles are avoided, and further, the size accuracy of a cutting assembly during cutting is guaranteed.

Owner:安徽工美服装有限公司

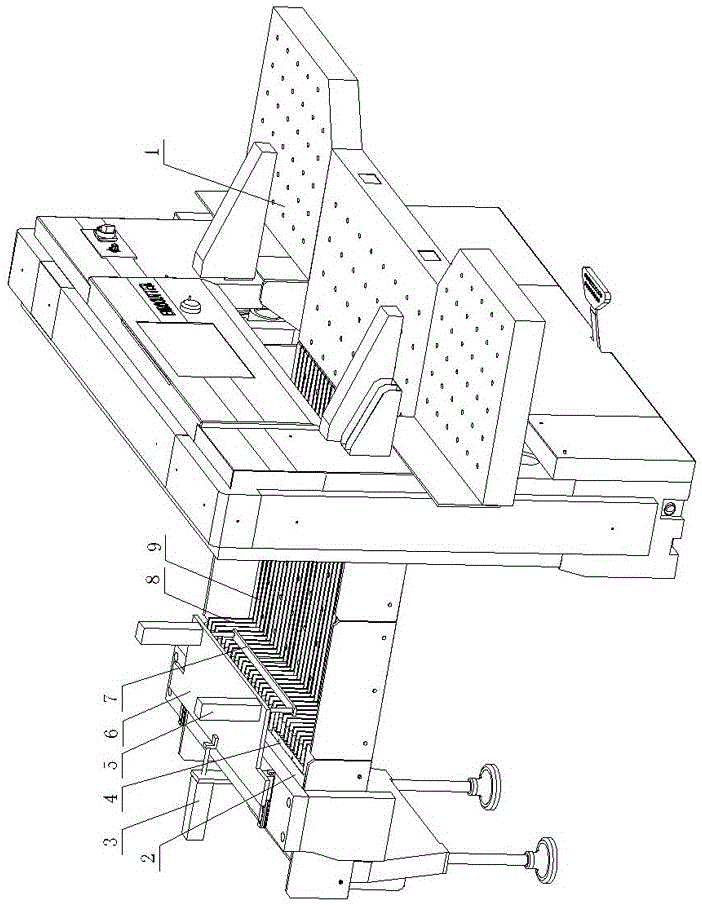

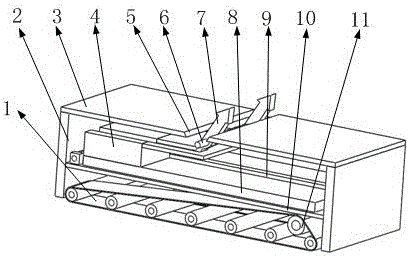

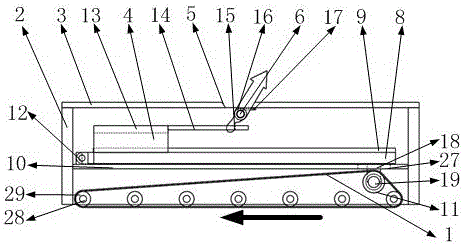

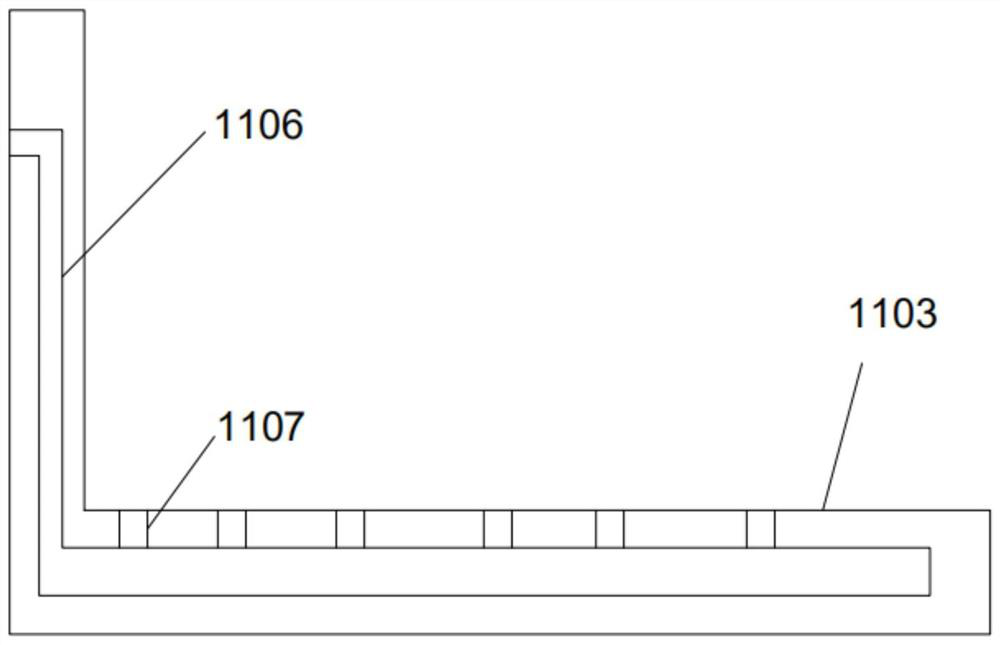

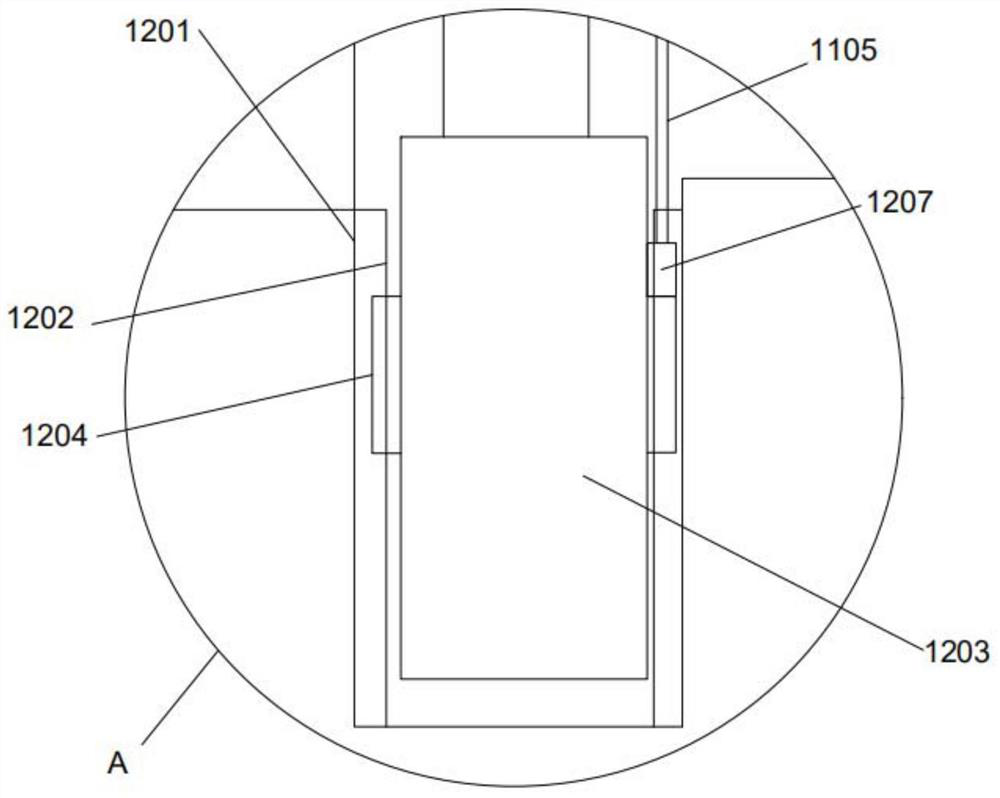

Cutting bed and belt conveying method thereof

ActiveCN104260138AIncrease usageImprove processing efficiencyMetal working apparatusThree-phaseEngineering

The invention discloses a cutting bed. By the use of a structure of multiple stations, a scanning head and a cutting head, pipeline automatic continuous operation of scanning, composing, cutting and collecting for irregular-outlined fabrics such as leather being cut with the cutting bed is achieved, and utilization rate of machines and processing efficiency are greatly improved. Further disclosed is a belt conveying method of the cutting bed. The cutting bed comprises a main conveying portion and an assisted conveying portion; in the main conveying portion, a conveyor belt is clamped through a clamping device arranged on a cross beam; a beam power motor of the cutting bed is used to drive the conveyor belt to convey materials; the structure is simple, and the cost is lowered. The assisted portion employs a three-phase motor to provide power, the conveyor belt is in a critical state of not moving while being able to move, the conveyor belt is controlled to move back and forth through the cross beam and experiences very low motion resistance, the conveyor belt hardly deforms, the fabrics never move when being conveyed, and conveying precision is improved.

Owner:HANGZHOU ECHO SCI TECH

a paper cutter

The invention discloses a paper cutting machine which comprises a paper cutting platform and a paper pushing frame. The paper pushing frame is moved front and back on the surface of the rear half part of the paper cutting platform. A paper pushing block is fixedly installed at the front end of the paper pushing frame. The paper pushing face of the paper pushing block is provided with gate teeth. The paper cutting machine is characterized in that the surface of the rear half part of the paper cutting platform is transversely provided with multiple narrow-strip-shaped shallow slots in the front-back direction, the narrow-strip-shaped slots correspond to the gate teeth, the bottoms of the gate teeth are provided with inserting plates extending downwards, and the inserting plates are inserted into the narrow-strip-shaped shallow slots; and a movable plate is arranged on the top of the paper pushing frame., the movable plate is pushed by a longitudinal air cylinder to move in the front-back direction, a paper pressing plate is arranged in front of the paper pushing block, the paper pressing plate is pushed by a vertical air cylinder to move in the vertical direction, and the vertical air cylinder is fixedly installed at the front end of the movable plate. According to the paper cutting machine, the technical problems of paper clamping and inertia forward movement of paper piles in the paper pushing process can be solved, paper cutting precision is ensured, the high-speed paper cutting requirement for the paper cutting machine can be better met, and the production speed of the paper cutting machine is increased.

Owner:ZHEJIANG HUAYUE PACKING MACHINERY

Wind generator cable laying guide device

InactiveCN110535070AImprove smooth performanceImprove certaintyApparatus for laying cablesFlangeWind power generator

The invention provides a wind generator cable laying guide device which comprises guide frames, mounting shafts, guide wheels, rubber sleeves, a cable, a positioning arc plate, a positioning flange, support wheels, support wheel mounting frames, non-slip pads, a mounting rod, an adjustment sleeve, an adjustment rod and a mounting base. A number of guide frames are connected with the upper side ofthe mounting base. Mounting rod grooves are formed in both sides of the guide frames. The mounting rod grooves match the mounting shafts. Two ends of the mounting shafts are connected with the mounting rod grooves. The middle part of each mounting shaft is connected with a guide wheel, and the mounting shaft is clamped in the guide wheel and rotates in a guide frame. The outer side of each guide wheel is connected with a rubber sleeve which sleeves the guide wheel. Each rubber sleeve comprises a cable guide groove which matches the cable. The cable is connected with the cable guide grooves. The cable slides in the cable guide grooves. The lower side of each lower guide wheel is connected with a support wheel.

Owner:天津市盛佳怡电子有限公司

Paper cutting machine

ActiveCN105965584ANormal push paper workIncrease production speedMetal working apparatusPaper cutPaper sheet

The invention discloses a paper cutting machine which comprises a paper cutting platform and a paper pushing frame. The paper pushing frame is moved front and back on the surface of the rear half part of the paper cutting platform. A paper pushing block is fixedly installed at the front end of the paper pushing frame. The paper pushing face of the paper pushing block is provided with gate teeth. The paper cutting machine is characterized in that the surface of the rear half part of the paper cutting platform is transversely provided with multiple narrow-strip-shaped shallow slots in the front-back direction, the narrow-strip-shaped slots correspond to the gate teeth, the bottoms of the gate teeth are provided with inserting plates extending downwards, and the inserting plates are inserted into the narrow-strip-shaped shallow slots; and a movable plate is arranged on the top of the paper pushing frame., the movable plate is pushed by a longitudinal air cylinder to move in the front-back direction, a paper pressing plate is arranged in front of the paper pushing block, the paper pressing plate is pushed by a vertical air cylinder to move in the vertical direction, and the vertical air cylinder is fixedly installed at the front end of the movable plate. According to the paper cutting machine, the technical problems of paper clamping and inertia forward movement of paper piles in the paper pushing process can be solved, paper cutting precision is ensured, the high-speed paper cutting requirement for the paper cutting machine can be better met, and the production speed of the paper cutting machine is increased.

Owner:ZHEJIANG HUAYUE PACKING MACHINERY

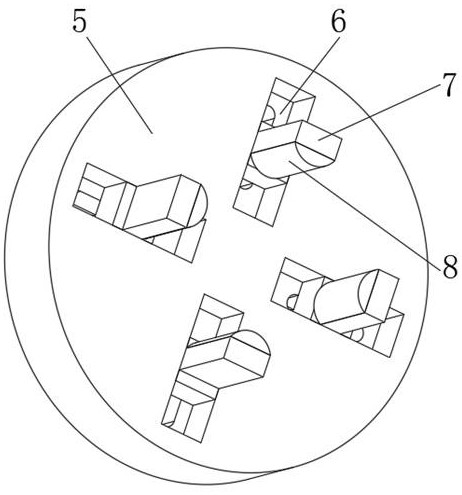

Self-adjusting static friction type vehicle stopping mechanism

ActiveCN106758964APrevent forward rollStabbed smoothlyTraffic restrictionsStatic frictionFriction tape

The invention belongs to the technical field of vehicle stopping and particularly relates to a self-adjusting static friction type vehicle stopping mechanism. The self-adjusting static friction type vehicle stopping mechanism comprises a plurality of wheel constraint mechanisms, wherein each wheel constraint mechanism comprises a friction belt, a balance block, spiked nails, a force applying board, resistance wheels and a friction wheel and can constrain the wheel of a running vehicle. After the wheels are constrained by the wheel constraint mechanisms, the car drags the wheel constraint mechanisms to move forwards along with the vehicle, static friction force between the ground each friction belt is generated to drive the friction belt to rotate due to the fact that the friction belt is arranged on the bottom surface of the wheel constraint mechanism, and the resistance wheels on the friction belt generate appropriate resistance to allow the resistance of the resistant wheels to constantly keep the static friction state between the ground the friction belt. In addition, the balance block is added into each wheel constraint mechanism, the positions of the balance body in the wheel constraint mechanism are adjusted according to vehicle speed, the faster the vehicle is, the more rear the balance block is, forward turning, driven by the vehicle, of the wheel constraint mechanism is prevented, fast vehicle braking is achieved, and a good use effect is achieved.

Owner:HEBEI ZONGSHEN GEMEILI AGRI MACHINERY MFG CO LTD

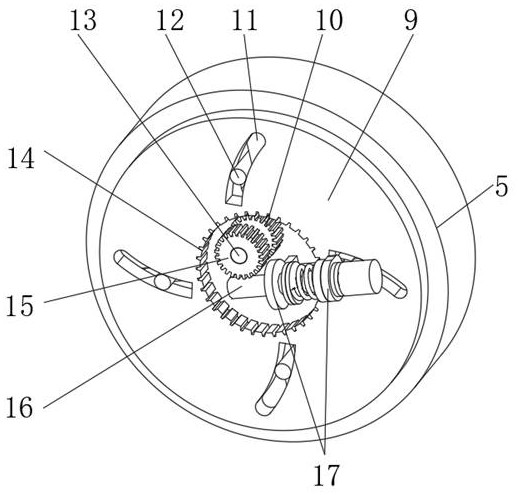

Elliptical wheel based vehicle stopping mechanism

ActiveCN106677096AIncrease resistanceChange frictionTraffic restrictionsGround contactForward sliding

The invention belongs to the technical field of vehicle stopping and particularly relates to an elliptical wheel based vehicle stopping mechanism. The mechanism comprises a top cover, a shell, elliptical wheels, penetration thorns, a swing rod, elliptical cavities, driving shafts and stable shaft sleeves. Wheel constraint mechanisms are capable of tightly pulling wheels through barbs of the penetration thorns, and the wheels are static under the pulling action of the penetration thorns and the limiting action of the top cover. After the wheels are fixed by the wheel constraint mechanisms, the wheel constraint mechanisms are driven to continue sliding forwards due to inertia of a vehicle body, and the wheel constraint mechanisms generates a static friction force to the ground through the four elliptical wheels so as to stop the constrained vehicle body to the greatest extent. In addition, under the condition that the wheel constraint mechanisms are limited in height, the elliptical wheels are larger in ground contact friction as compared with common round wheels, and accordingly vehicle stopping is facilitated. By adoption of the wheel constraint mechanisms for wheel constraint, vehicle braking is quickly realized without vehicle damages, public security bureaus can be assisted in stopping of illegal vehicles, and great utilization effects are achieved.

Owner:南通卓效自动化有限公司

Fixed strength training apparatus

ActiveCN108499032ASmall footprintEasy to operateSpace saving gamesFrictional force resistorsStrength trainingEngineering

The invention discloses a fixed strength training apparatus, which comprises two groups of training mechanisms which are cooperated in use, wherein each group of training mechanism comprises an upperfixed plate and a lower fixed plate which are fixed to a wall surface, and a base plate which is vertically arranged, wherein the upper sides of the base plates are connected to the upper fixed platesin a hinged mode; the lower sides of the base plates are detachably connected to the lower fixed plates; a sliding rail is arranged on each base plate; sliding blocks, which can slide, are arranged on the sliding rails; operating handles are arranged on the sliding blocks; and magnetic adsorption mechanisms are additionally arranged on the sliding blocks. The training apparatus is applicable to use in a mode of being fixed indoors; and the training apparatus is small in occupied space, and weight can undergo linear adjusting in accordance with actual demands.

Owner:岳贤玉

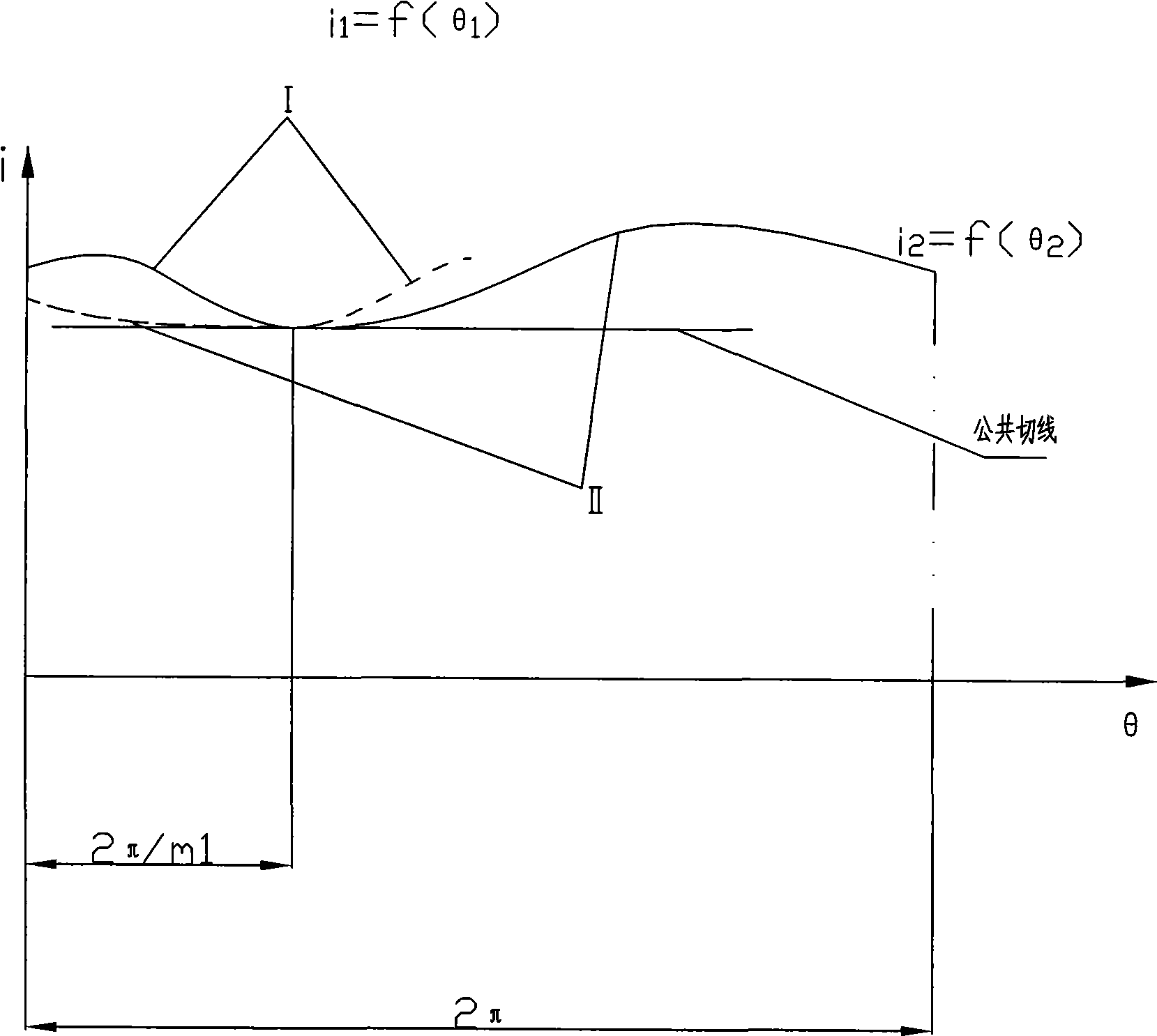

Deformed elliptic gear speed change mechanism for paper transport transmission

A deformed oval gear speed-change mechanism for paper feeding transmission relates to a speed-change mechanism of a paper feeder. The speed-change mechanism of a prior paper feeder adopts an oval gear and can cause instability for paper feeding. The deformed oval gear speed-change mechanism comprises a box body, an input shaft and a transmission shaft supported to the box body, a vibration absorber arranged in the middle of the transmission shaft, and a gear cluster arranged between the transmission shaft and the input shaft. The deformed oval gear speed-change mechanism is characterized in that the gear cluster comprises an external gear pair, two engaged gears of the external gear pair are deformed oval gears which are respectively a first deformed oval gear connected to the input shaft and a second deformed oval gear connected to the external end of the transmission shaft, the vibration absorber comprises a power vibration absorber arranged in the box body with a clearance existing between the power vibration absorber and the box body, wherein the power vibration absorber comprises a power damping disc rotating along with the transmission shaft and a damping flywheel sleeved outside the power damping disc, and a damping friction plate is arranged between the damping flywheel and damping disc. The invention ensures accurate paper feeding and stable paper transmission.

Owner:ZHEJIANG TONGYE PRINTING MACHINERY

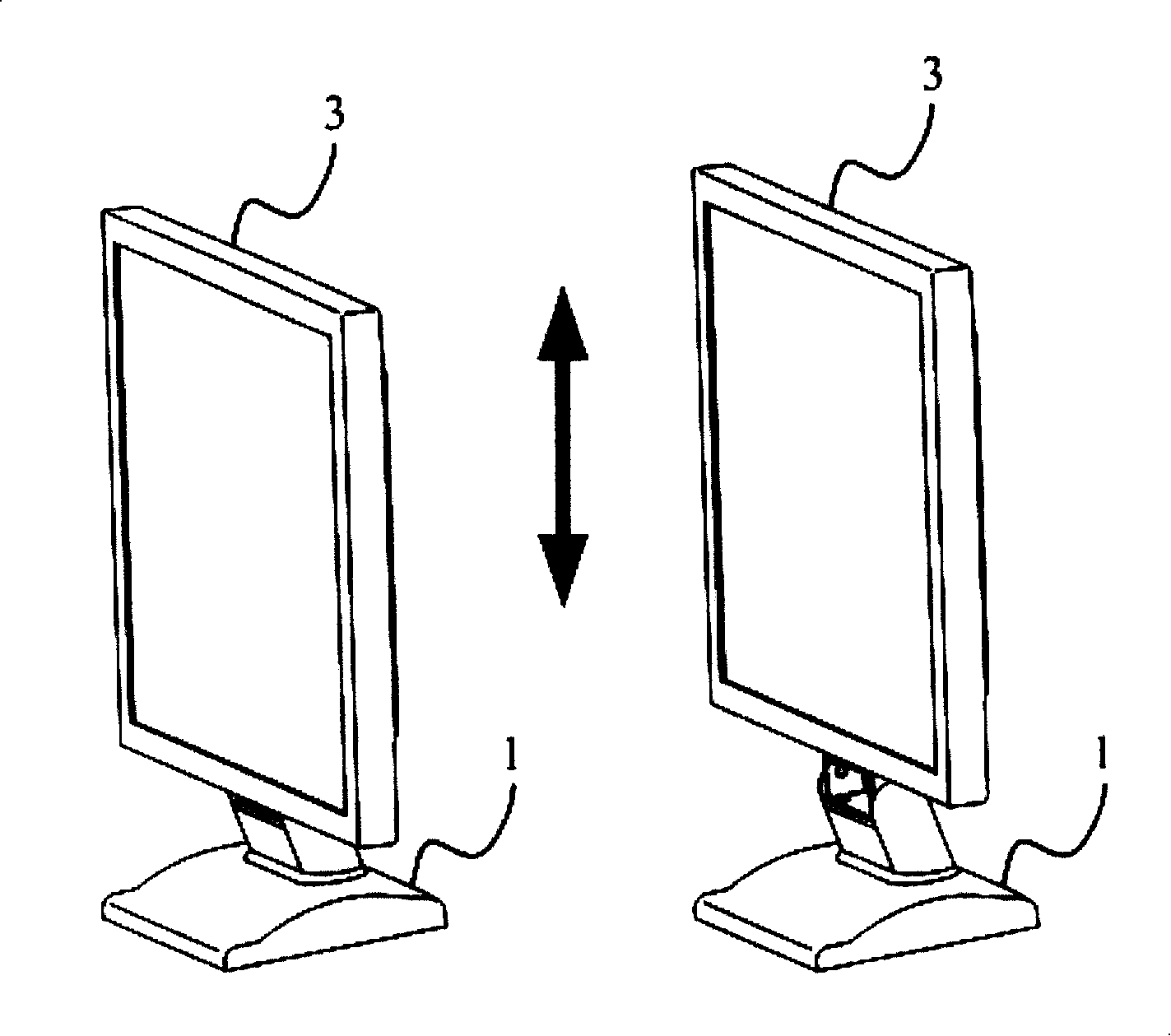

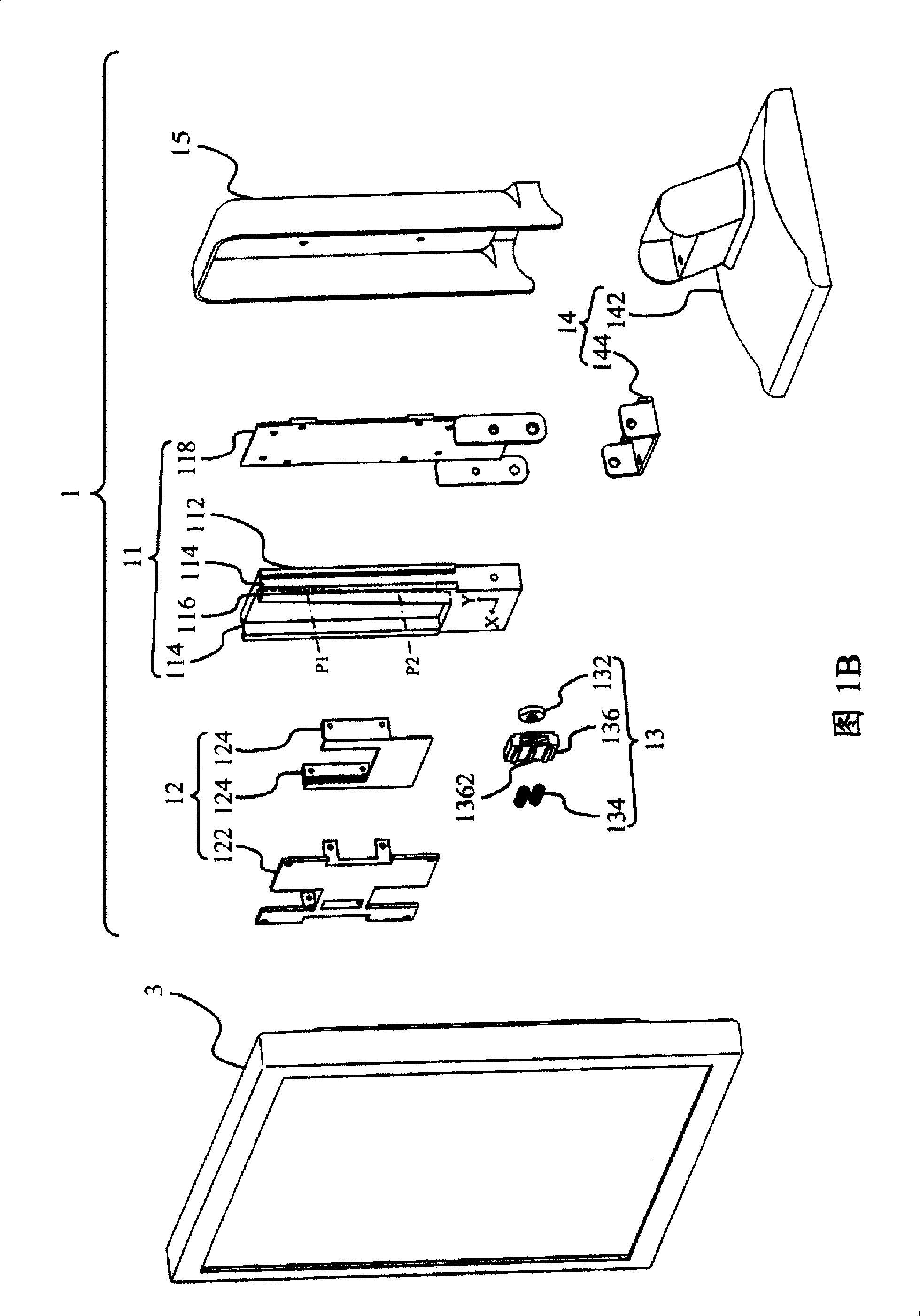

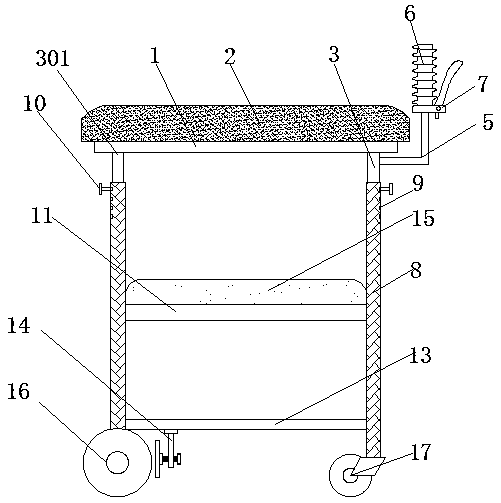

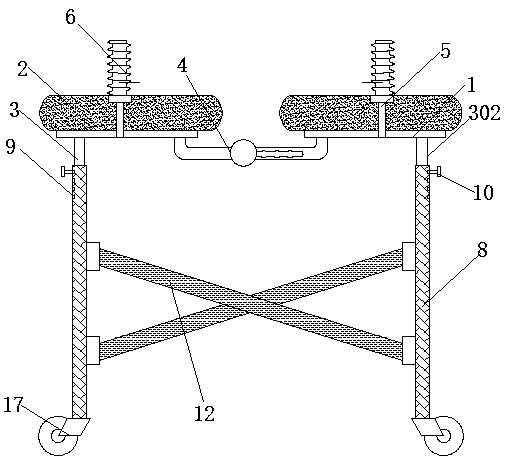

Supporting device with adjustable high

InactiveCN101178944AIncreased length changeAdd a reaction forceInstrument housingStands/trestlesEngineering

Owner:QUISDA CORP

Yarn guiding device with dust removing function

ActiveCN112320476AGuaranteed reliabilityAdjustable tensionFilament handlingTextile disintegration and recoveryYarnTextile technology

The invention discloses a yarn guiding device with a dust removing function, and relates to the technical field of textile. The problem of self-adaptive tension adjustment is solved. The yarn guidingdevice with the dust removing function specifically comprises a base, a workbench is connected to the outer wall of the top of the base through a lifting mechanism, and a self-adaptive adjustable damping mechanism and a yarn guiding mechanism are arranged on the outer wall of the top of the workbench; and the self-adaptive adjustable damping mechanism comprises an outer cover, a friction wheel andfour friction assemblies, the outer cover is rotationally connected with a third supporting plate through a rotating shaft, and the third supporting plate is fixed to the outer wall of the top of theworkbench through bolts. According to the yarn guiding device with the dust removing function, a friction plate is in sliding connection with the outer cover through a third sliding rod, the outer cover is in transmission fit with the yarn guiding mechanism, when the yarn feeding speed is increased, the rotating speed of the outer cover is increased, a transition plate is relatively fixed, the friction plate is subjected to outward centrifugal force to balance the elastic force of second springs at the moment, therefore, tension is reduced, and the purpose of self-adaptively adjusting the tension according to the yarn feeding speed is achieved.

Owner:衡阳新新纺织机械有限公司

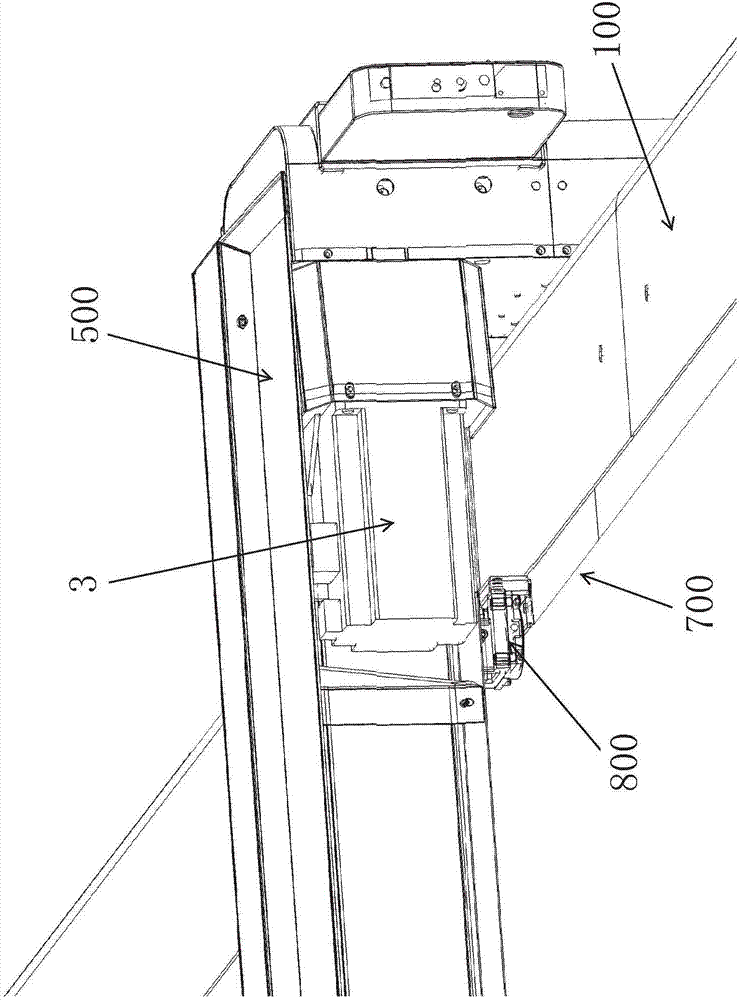

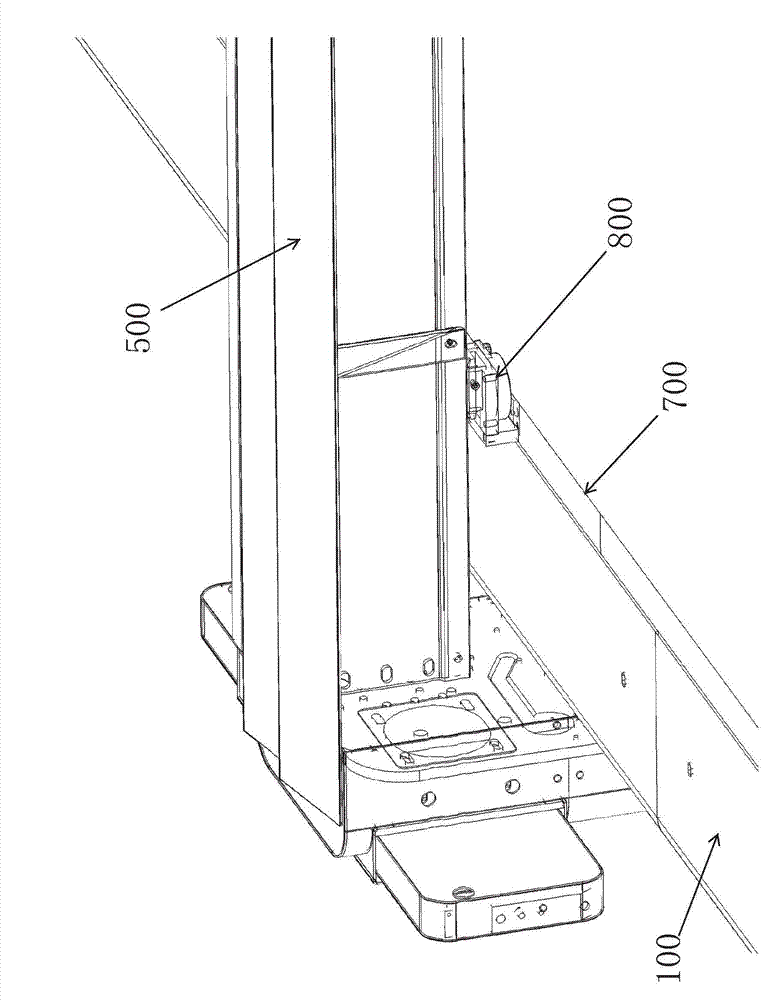

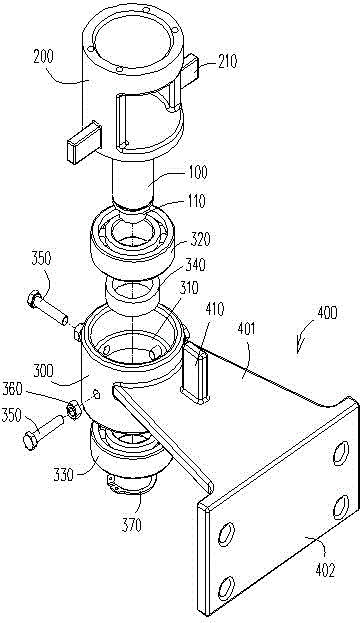

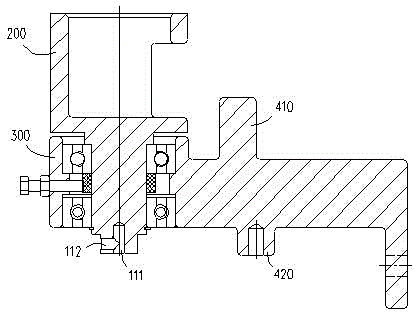

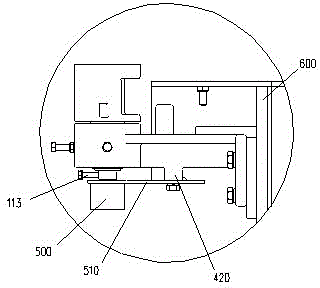

Electric steering power-driven traction trolley steering support assembly

ActiveCN104787112AChange the turning torqueChange frictionSteering linkagesSteering columnsElectricitySteering column

The invention provides an electric steering power-driven traction trolley steering support assembly. The electric steering power-driven traction trolley steering support assembly comprises a steering column, a bearing base and a support installation plate fixedly connected to the bearing base; a steering arm installation base is coaxially connected to the upper end of the steering column, a pair of corner stopping blocks are symmetrically arranged on the circumferential lateral wall of the steering arm installation base, and a step cylinder used for fixing the output end of a corner potentiometer is arranged at the lower end of the steering column; a protruding ring is arranged in the bearing base in the circumferential direction, an upper bearing and a lower bearing are arranged at the upper end and the lower end of the protruding ring respectively, a damping ring is arranged between the upper bearing and the lower bearing, and the steering column is sequentially sleeved with the upper bearing, the damping ring and the lower bearing; a corner limiting block is arranged on the top face of the support installation plate, and a connecting piece for fixing a support of the corner potentiometer is arranged on the bottom face of the support installation plate. According to the electric steering power-driven traction trolley steering support assembly, the force of friction of the damping ring and the steering column is changed by adjusting the compression force of a fastening bolt on the damping ring, the gyroscopic moment of the steering column is accordingly changed, operation is convenient, and the abrasion strength is lower.

Owner:安徽江淮重型工程机械有限公司

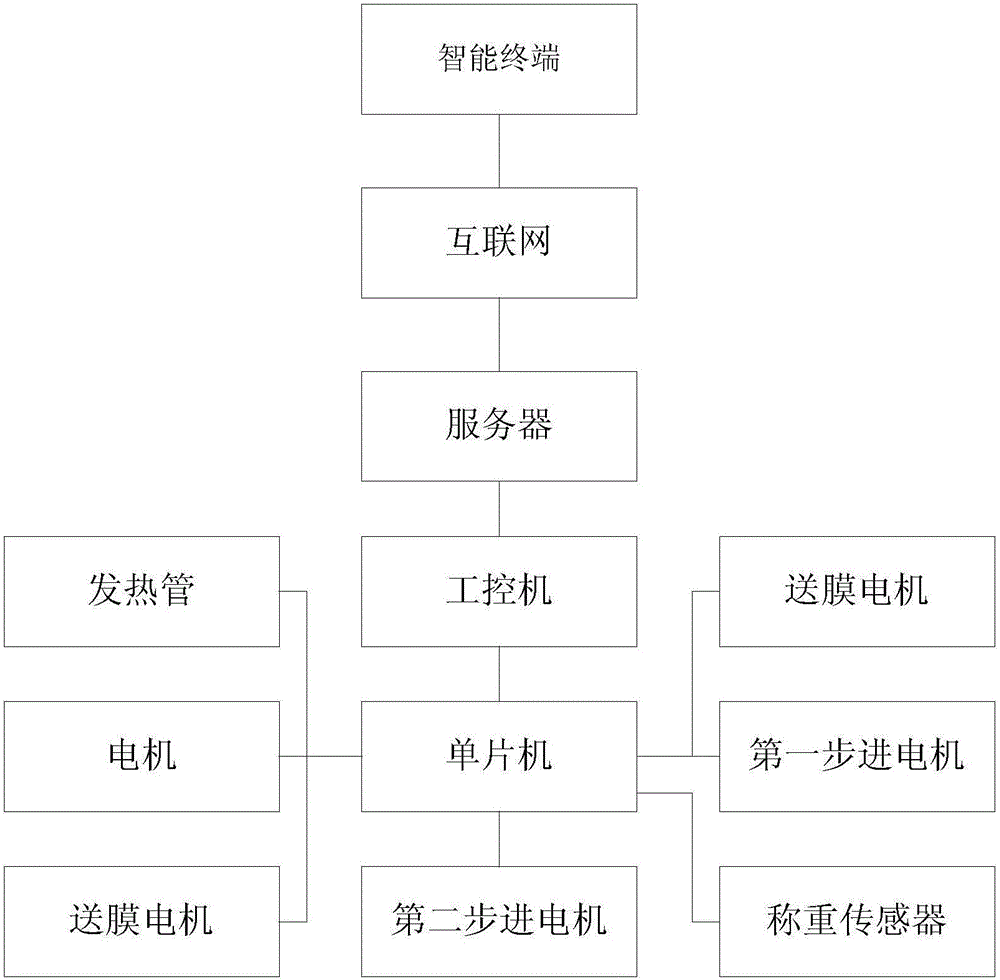

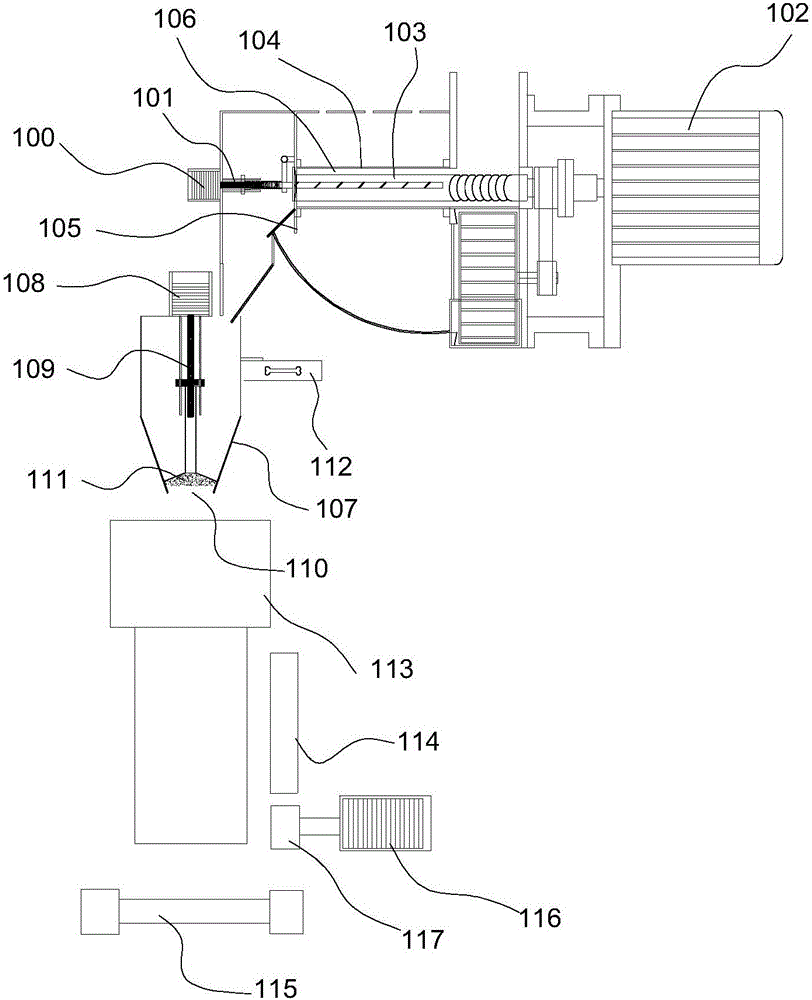

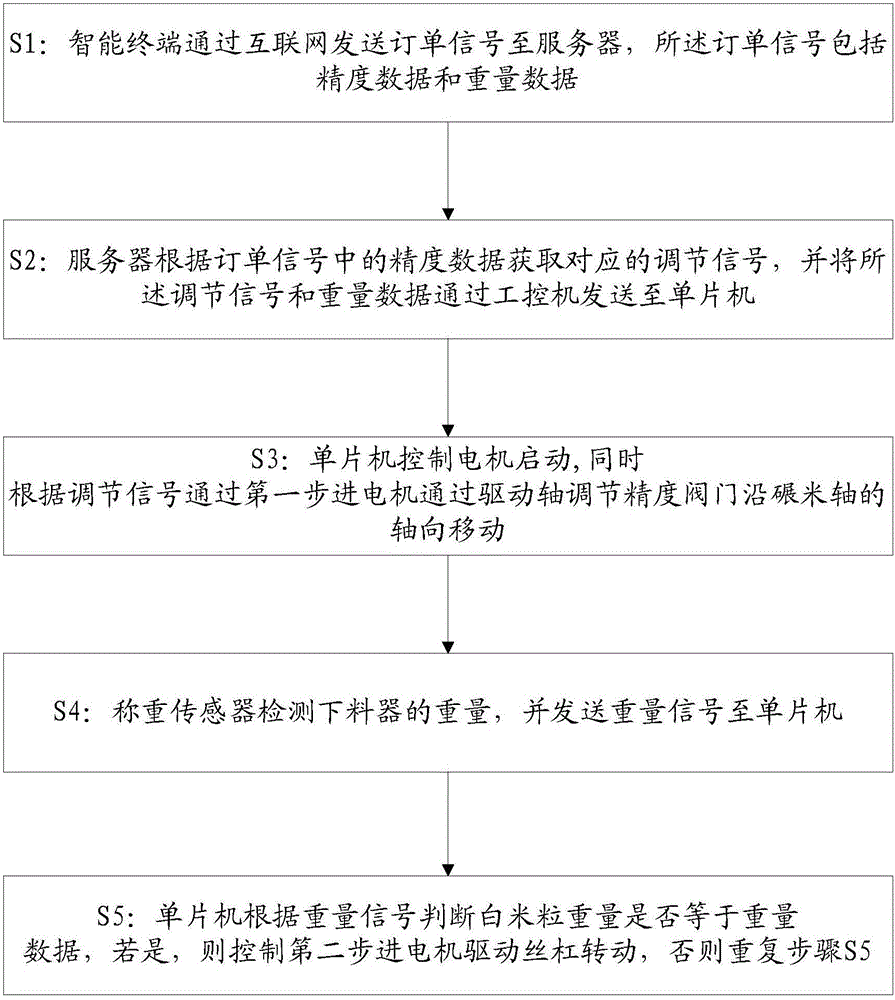

Control system and control method of intelligent rice milling machine

ActiveCN105689043AChange frictionAccuracy automatic adjustmentGrain huskingGrain polishingMicrocontrollerMicrocomputer

The invention relates to a control system and a control method of an intelligent rice milling machine. The system comprises an intelligent terminal, an intelligent rice milling machine, a server and internet, wherein the intelligent terminal is used for sending an order signal to the server through the internet; the server is used for obtaining a corresponding regulating signal according to precision data in the order signal, and sending the regulating signal and weight data to a single chip microcomputer through an industrial controller; the single chip microcomputer is used for controlling a motor to start, so that the motor drives rice and a rice milling sieve to generate friction by rotating a rice milling shaft to obtain hulled rice; according to the regulating signal, the single chip microcomputer is further used for regulating a precision valve via a drive shaft to axially move along the rice milling shaft through a first step motor; and a weighing sensor is used for detecting weight of an unloader, and is used for sending a weight signal to the single chip microcomputer. A second step motor controls the precision valve to move, so that the precision of rice milling is automatically regulated while manual treatment is not needed any more; and rice of the corresponding weight can be automatically packed according to the order demand, so that the control system is convenient and quick.

Owner:日照先农氏物联网科技有限公司

Walking aid having high practicability

InactiveCN107822839AChange difficulty levelImprove practicalityWalking aidsFriction effectEngineering

The invention relates to the technical field of medical care, and discloses a highly practical walking aid, comprising a support body, an elastic pad is fixedly installed on the upper surface of the support body, and one end of the bottom of the support body is fixedly connected with a width adjusting device , the width adjusting device includes a first adjusting frame, the first adjusting frame is provided with a first adjusting hole, the other end of the bottom of the support body is fixedly connected with the second adjusting frame, and one end of the second adjusting frame is connected to the first adjusting frame through the first bolt. The adjustment frame is threadedly connected, the outer wall of the first supporting leg is fixedly connected with the first connecting rod, and a handle is fixedly connected with one end of the first connecting rod. This practical walker, by setting the friction adjustment device, uses the third bolt to change the contact area between the brake pad and the driving wheel, and achieves the effect of changing the friction force between the drive wheel and the brake pad, thereby changing the walking aid. The ease of operation is suitable for patients in different health processes, which improves the practicability of the device.

Owner:常盛杰

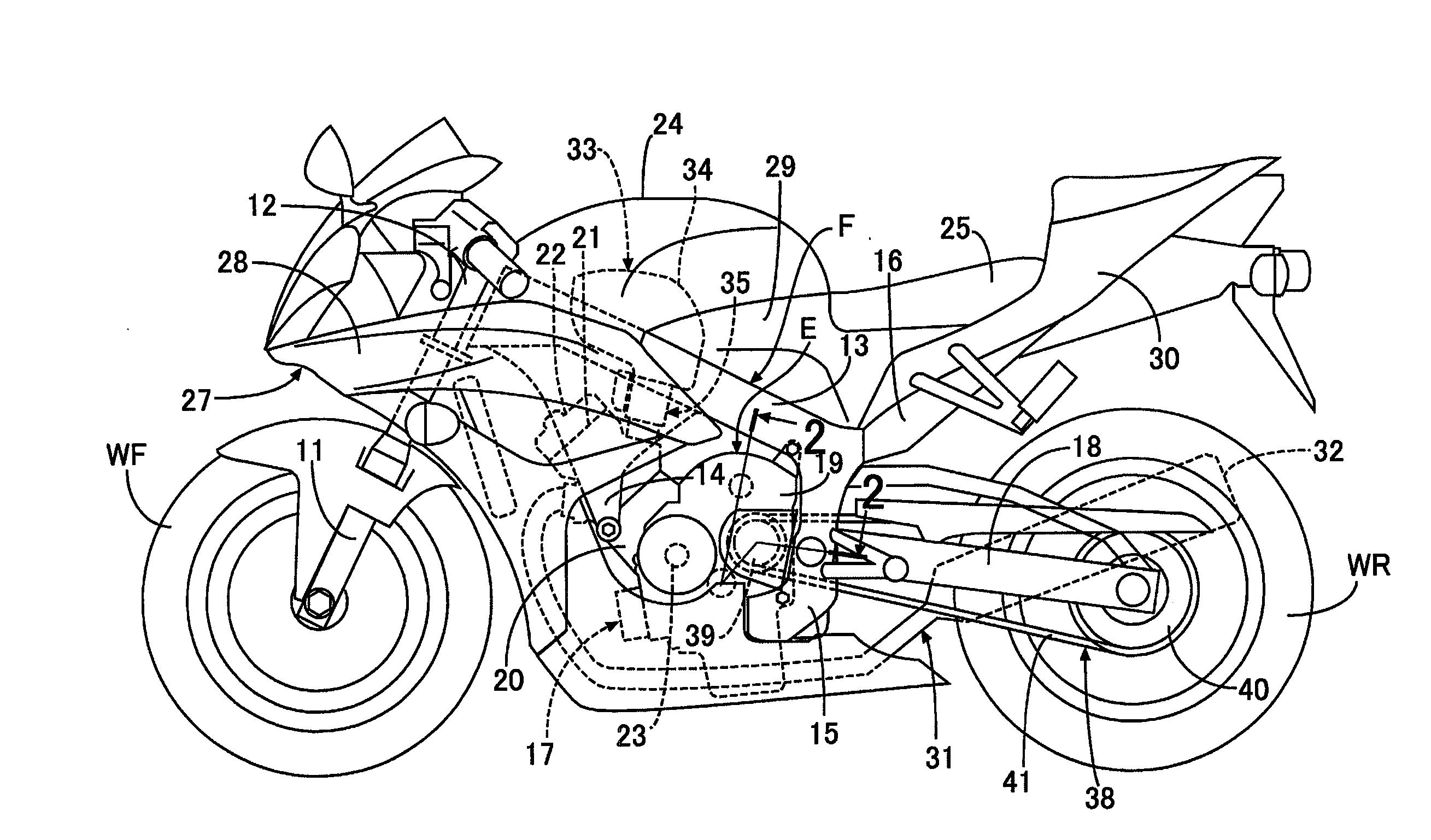

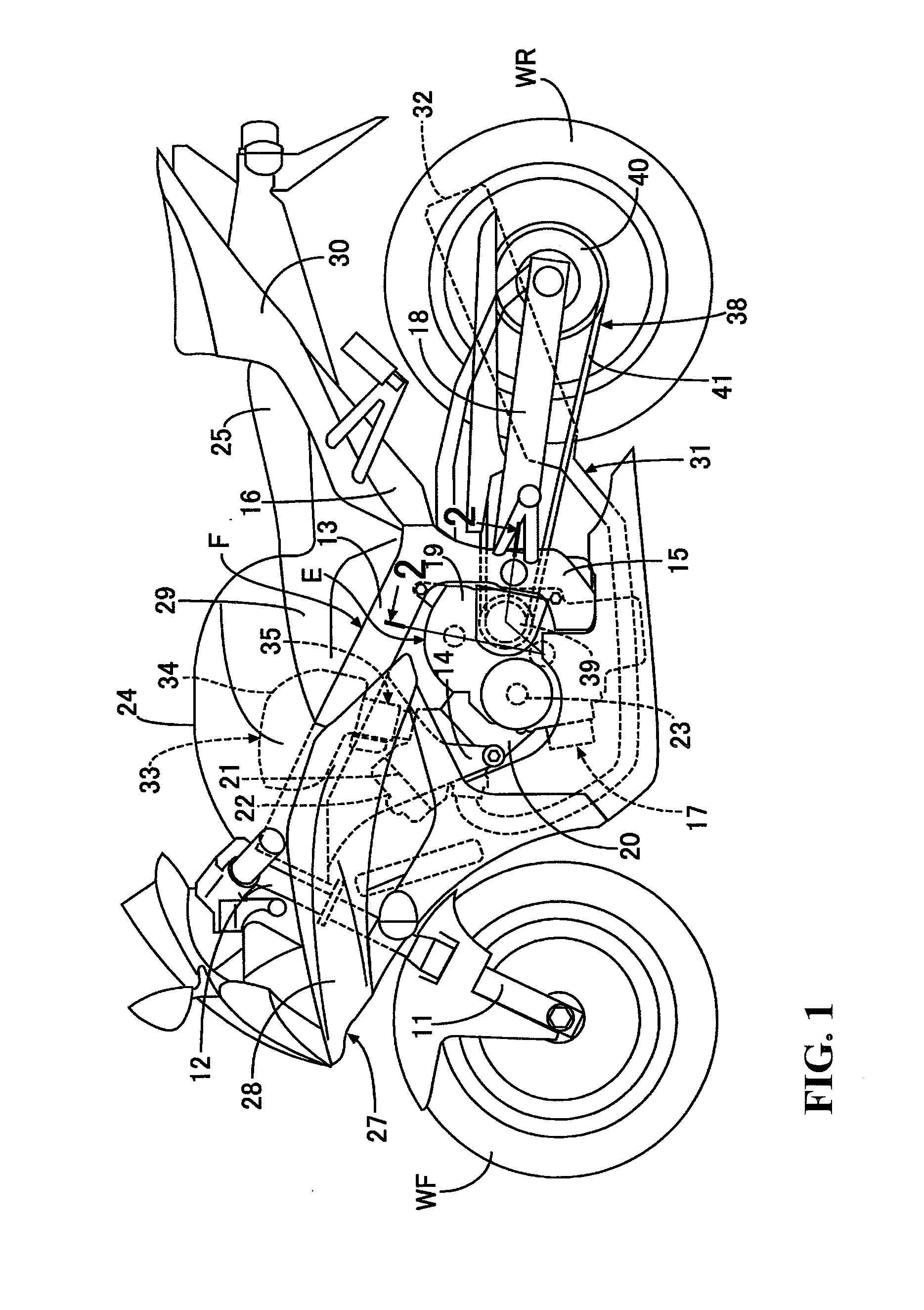

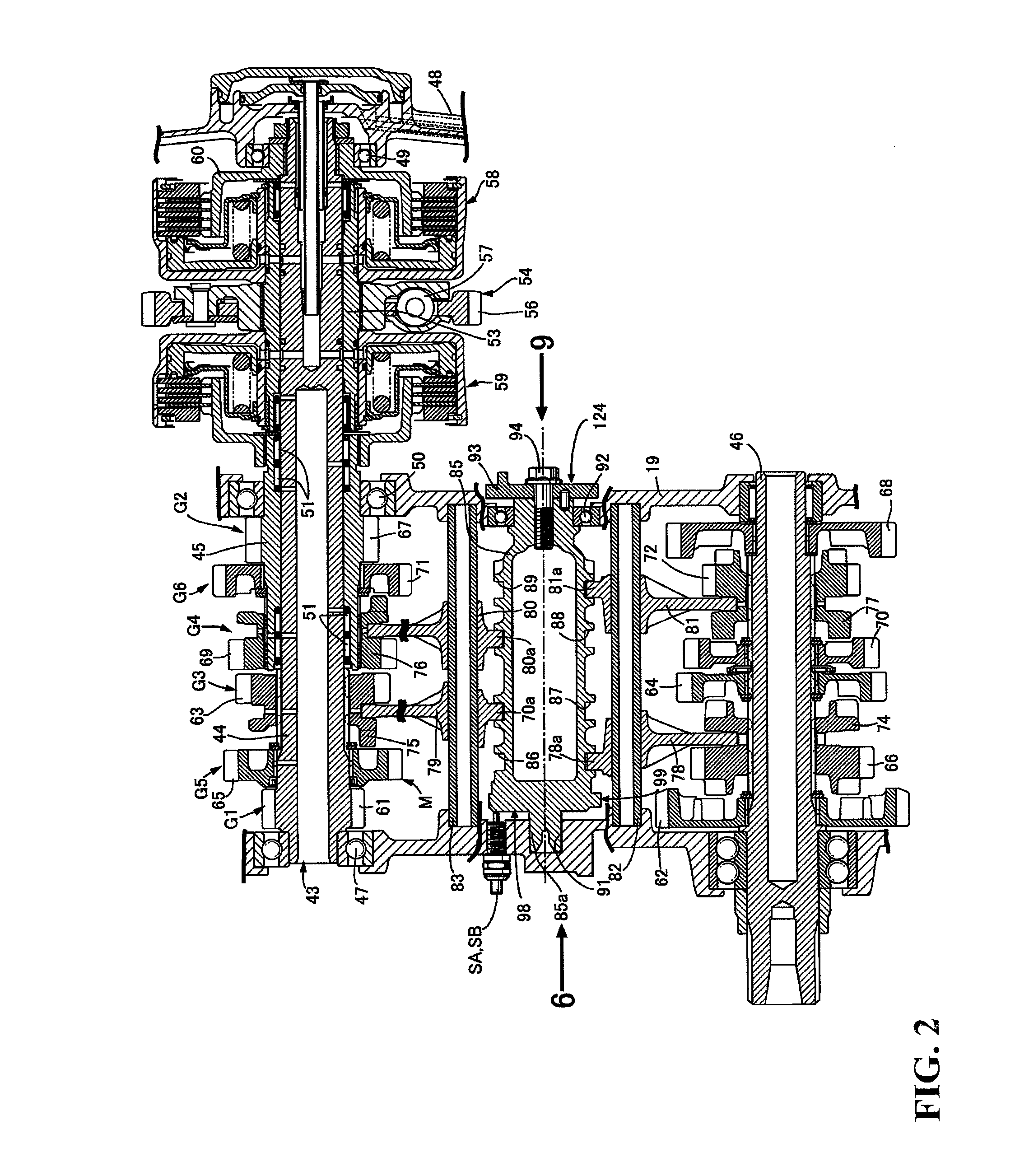

Shift position detecting device

ActiveUS20150006042A1Change frictionNo discomfortDigital data processing detailsGearing controlEngineeringShift time

A shift position detecting device where a shift position determining member is provided for determining a shift position based on a combination of switching modes of three switches corresponding to at least one of a plurality of projection rows each having a plurality of projection portions in a one-by-one basis, and “1, 1, 1” indicative of an ON state of each switch is allocated as a detection logic at a neutral position arranged between a first speed position and a second speed position, wherein a change in friction at the time of a shift operational to the neutral position is alleviated thus giving an operational feeling with no discomfort to a rider. Two projection rows that are objects to be detected by two specified switches among the three switches are formed so as to change switching modes of the specified switches from an OFF state to an ON state.

Owner:HONDA MOTOR CO LTD

Unwinding device for raincoat production

The invention discloses an unwinding device for raincoat production. The unwinding device for the raincoat production comprises a workbench, and a rotating seat and a servo motor are arranged on one side of the top of the workbench; a I-shaped rotating disc is rotatably connected into the rotating seat through a bearing, and a transmission chain is connected between an output shaft of the servo motor and the I-shaped rotating disc in a transmission mode; a load-bearing rotating shaft is fixedly and coaxially connected to one side of the I-shaped rotating disc, and the load-bearing rotating shaft comprises a main shaft; one end of the main shaft is fixedly welded to one side of the I-shaped rotating disc, and a second limiting side ring is fixedly welded to the outer wall of one end of themain shaft; a side cavity is formed in the other end of the main shaft, and an inner shaft is arranged in the side cavity; and a sliding groove is formed in the inner wall of the side, near the I-shaped rotating disc, of the side cavity, one end of the inner shaft is slidably connected into the sliding groove, and the other end of the inner shaft is of a T-shaped structure and a threaded sleeve ring is rotatably arranged at the other end of the inner shaft in a sleeving mode. According to the unwinding device for the raincoat production, unwinding of fabric rolls can be more accurate, the labor is saved, the production efficiency is improved, and the use requirements of people in production and living are met.

Owner:ANHUI YOOAN RAINGEAR

Intelligent energy-saving refrigerator and cold conduction equipment thereof

InactiveCN112179008AEasy accessReduce cooling spaceLighting and heating apparatusDomestic refrigeratorsCold airEngineering

The invention discloses an intelligent energy-saving refrigerator and cold conduction equipment thereof. The intelligent energy-saving refrigerator comprises a refrigerator body, wherein a sliding door is fixedly arranged on the left side of the top of the refrigerator body; a telescopic air cylinder is fixedly arranged at the bottom of the refrigerator body, and a placement plate is fixedly connected to the top of the telescopic air cylinder; and a separation box is fixedly arranged at the bottom of the refrigerator body, a controller is fixedly arranged on the left side inside the separationbox, and a compressor is fixedly arranged on the right side inside the separation box. Cold air is extracted from the interior of the refrigerator body through the cold conduction device, and an aircurtain wall is formed through an air curtain device, so that the cold air emission amount is reduced; gravity conduction can be carried out through a gravity conduction device according to the numberof placed objects, and the gravity presses a cold quantity control device along with a conduction rod, so that an air outlet of the cold quantity control device is enlarged; and regulation and control can be carried out according to the number and the weight of the cargos, and then after the cargos are taken out, the cooling capacity control device is shut down, so that the effects of saving energy and reducing consumption are achieved.

Owner:绍兴市华获智能装备有限公司

Petrochemical engineering steel pressure vessel forming processing equipment and processing technology

ActiveCN113231939AIncrease pressureIncrease frictionGrinding machinesGrinding work supportsElectric machineryEngineering

The invention relates to petrochemical engineering steel pressure vessel forming machining equipment and a processing technology. The petrochemical engineering steel pressure vessel forming machining equipment comprises a base, a fixing device and grinding devices, wherein the lower end of the base is connected with the existing ground, the fixing device is installed at the upper end of the base, and the grinding devices are symmetrically arranged on the left side and the right side of the fixing device. According to the device, through mutual cooperation of a first motor, a threaded rod, a guide rod and rectangular sliding blocks, an L-shaped plate is matched to drive circular-arc blocks to do descending motion, a connecting rod can make the two rectangular sliding blocks distributed left and right descend synchronously, and the two circular-arc blocks descend synchronously and extrude the upper end of the pressure container, so that the function of easily fixing the pressure can be achieved, and the phenomenon that the grinding block and the weld joint deviate due to the fact that a foot stool of a pressure container deviates and shakes is avoided.

Owner:烟台兴隆压力容器制造有限公司

Anti-falling elevator car

ActiveCN111960212AReduce shockReduce the level of psychological panicElevatorsBuilding liftsControl theoryFriction force

The invention relates to an anti-falling elevator car which comprises a car body, an anti-falling device, a base and concentric-square-shaped racks. The anti-falling devices are symmetrically mountedat the upper and lower ends of the car body, the anti-falling devices are symmetrically arranged front and back, a base is arranged below the car body, the concentric-square-shaped racks are mounted at the left and right ends of the base, and the car body is located in the middle of the concentric-square-shaped racks. By changing design philosophy of size of a friction force between the car and awall for effective anti-falling arrangement, the anti-falling device can change the friction force between the elevator car and the wall in a quick falling process of the elevator car as a result of faults to improve the friction between the elevator car and the wall and decrease the falling speed of the elevator car to further achieve a good car anti-falling effect.

Owner:GUANGDONG SHENGDA ELEVATOR

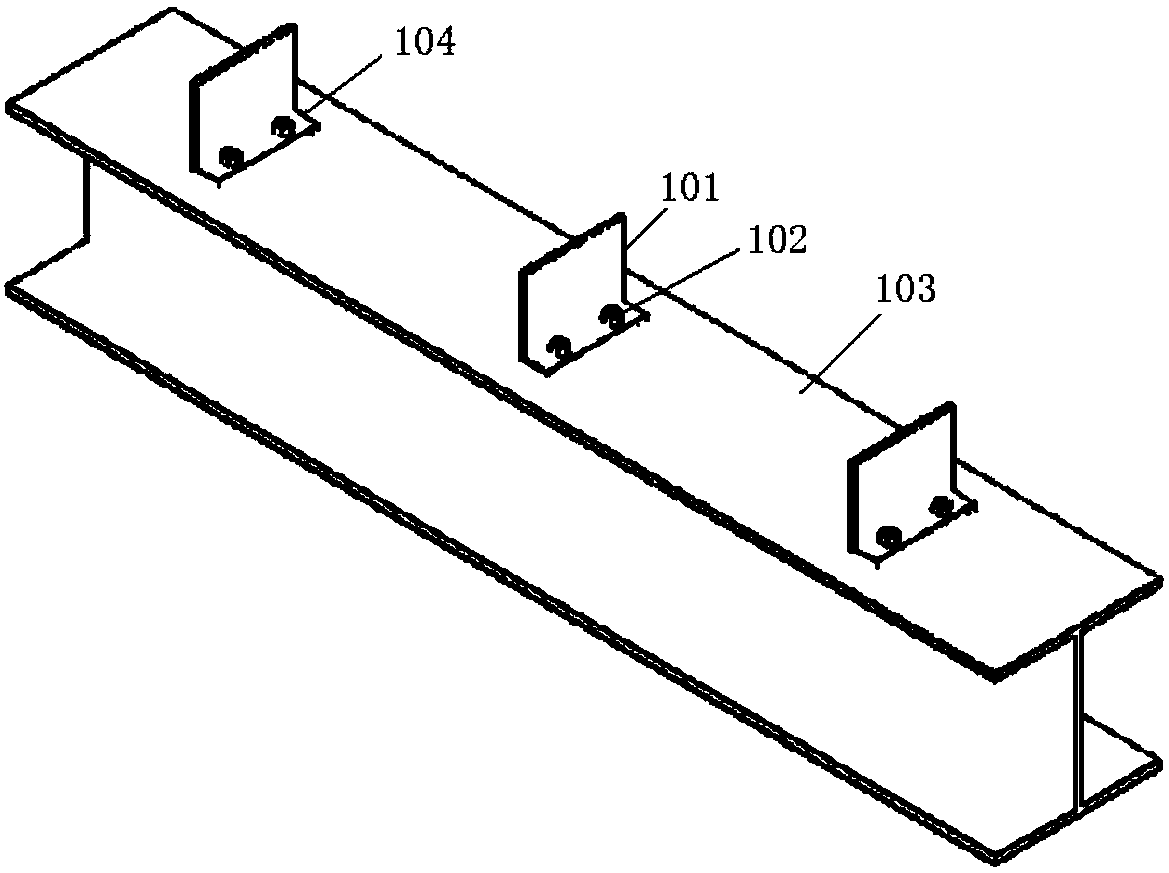

Shearing-resistant and not-pull-resistant friction-type shearing force connection part and construction method thereof

ActiveCN107642170AHigh degree of prefabricationReduce labor costsBuilding constructionsTransfer modeHigh intensity

The invention discloses a shearing-resistant and not-pull-resistant friction-type shearing force connection part and a construction method thereof. The shearing force connection part includes a shearing force connection part main body and a high-strength bolt assembly; the shearing force connection part main body is angle steel, a plurality of bolt holes matched with the high-strength bolt assembly are formed in one flange edge, and the shearing force connection part main body is connected with a main beam through the high-strength bolt assembly. According to the shearing-resistant and not-pull-resistant shearing force connection part, force transferring modes of traditional shearing force connection parts are improved, interface friction between the shearing force connection part main body and a plate is reasonably utilized, bolts are reasonably designed, shearing force of the bolts can be monitored and controlled in real time, the factory prefabrication degree is high, bolt splicingis conducted on the spot, and therefore the labor cost is saved. The shearing-resistant and not-pull-resistant friction-type shearing force connection part is not provided with a fixed end and has theeffects of being resistant to shearing and not resistant to pulling.

Owner:HOHAI UNIV

Automatic feeding mechanism

The invention discloses an automatic feeding mechanism. The automatic feeding mechanism comprises a base, a motor, a synchronous pulley, transition wheels, a belt and a material collecting plate and is characterized by also comprising a vertical connecting plate, a horizontal connecting plate, a friction wheel and an adjusting screw; the motor which is arranged on the rear side of the base penetrates the base to be connected with the synchronous pulley which is arranged on the front side of the base; the transition wheels are arranged at two ends on the front side of the base; the synchronous pulley is connected with the transition wheels which are arranged at the two ends through the belt; the tail end of the belt moving direction is in butt joint with the material collecting plate which is arranged at the top of the base; the vertical connecting plate is fixed on the rear side of the base; the horizontal connecting plate is fixed at the top of the vertical connecting plate; a free end of the horizontal connecting plate is connected with the friction wheel through a rotary shaft; the friction wheel is in contact with the belt which is arranged under the friction wheel; the adjusting screw penetrates the horizontal connecting plate to be connected with a screw hole which is formed in the top of the base. The automatic feeding mechanism has the advantages of being simple in structure and convenient to use, maintaining the normal conveying force of the belt and enabling products to be normally conveyed.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

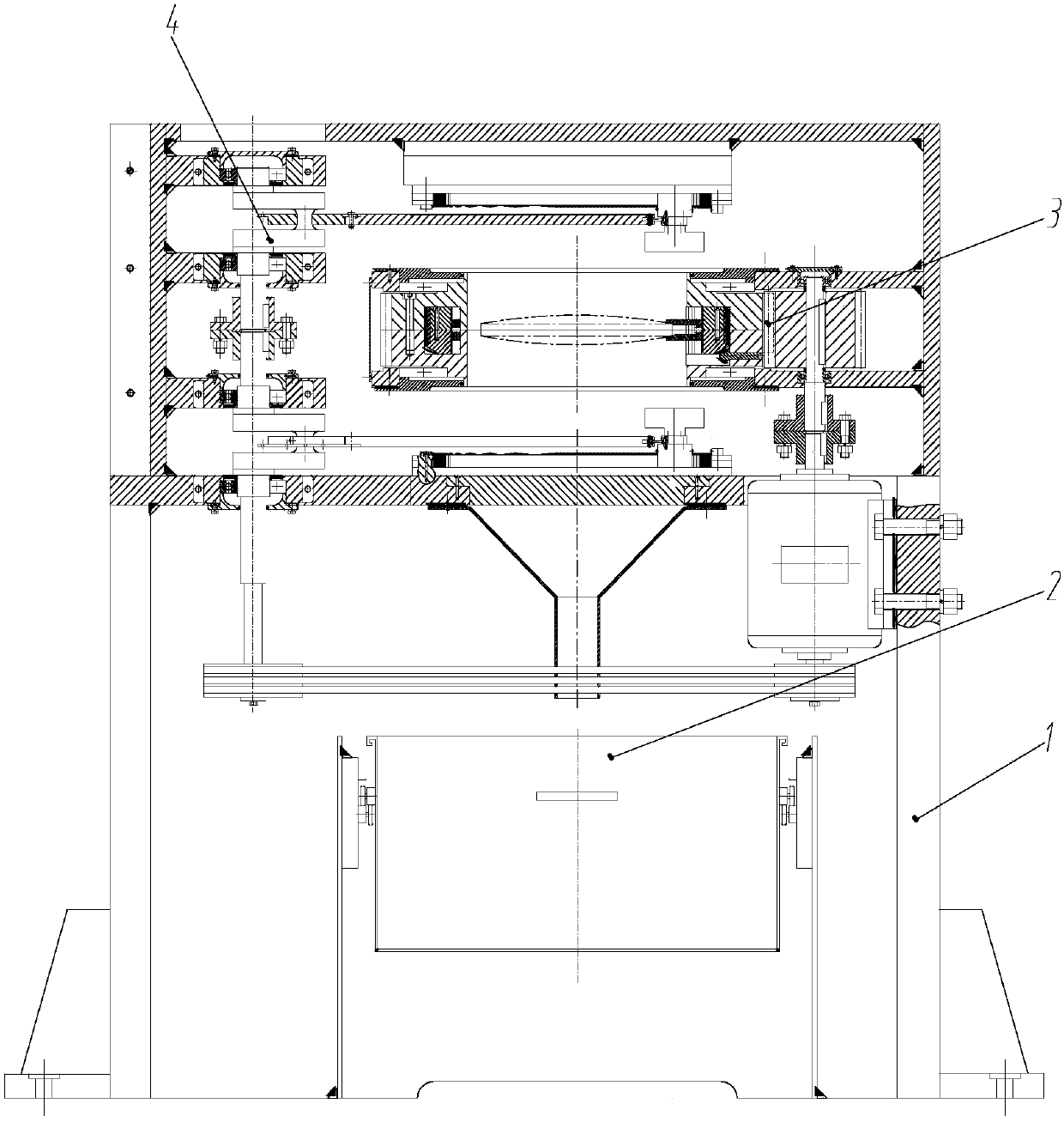

Magnetic grinder for two-sided disc small-curvature-surface component

PendingCN107617932AImprove processing qualityImprove processing efficiencyGrinding work supportsLinear motionEngineering

The invention discloses a magnetic grinder for a two-sided disc small-curvature-surface component. The magnetic grinder comprises a workpiece rotating mechanism, a workpiece clamping mechanism, a magnetic grinding head reciprocating linear motion mechanism and a magnetic grinding material collecting device. When the whole magnetic grinder is driven by a double-shaft output motor, a workpiece can rotate through gear transmission, and double-eccentric-crankshaft sliding blocks can be driven through belt transmission to assist a magnetic grinding head in reciprocating linear motion; the transmission ratio of the gear transmission to the belt transmission is 1:1, that is, the magnetic grinding head performs the reciprocating linear motion once when the workpiece rotates in a circle; under theaction of a magnetic brush, machining tracks on the workpiece can be uniformly distributed on the whole machining surface through the matching between the rotating motion and the reciprocating linearmotion; in the above process, the grinding material is collected by the magnetic grinding material collecting device, thereby improving the workpiece machining quality and efficiency; and accordingly,the magnetic grinder can be utilized for the finishing grinding of a high-precision large-diameter lens, and has an extensive application prospect in the field of high-precision machining.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

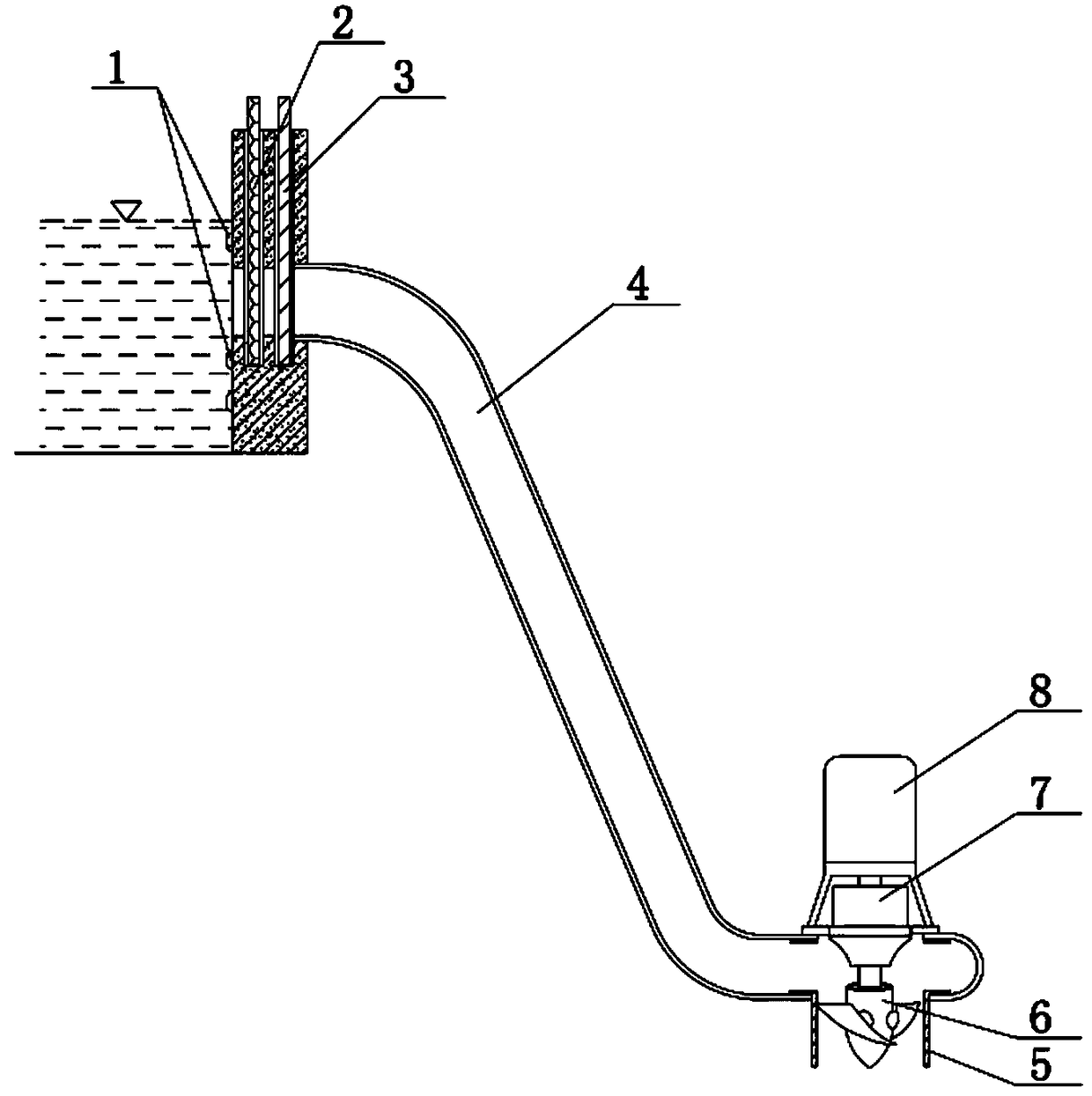

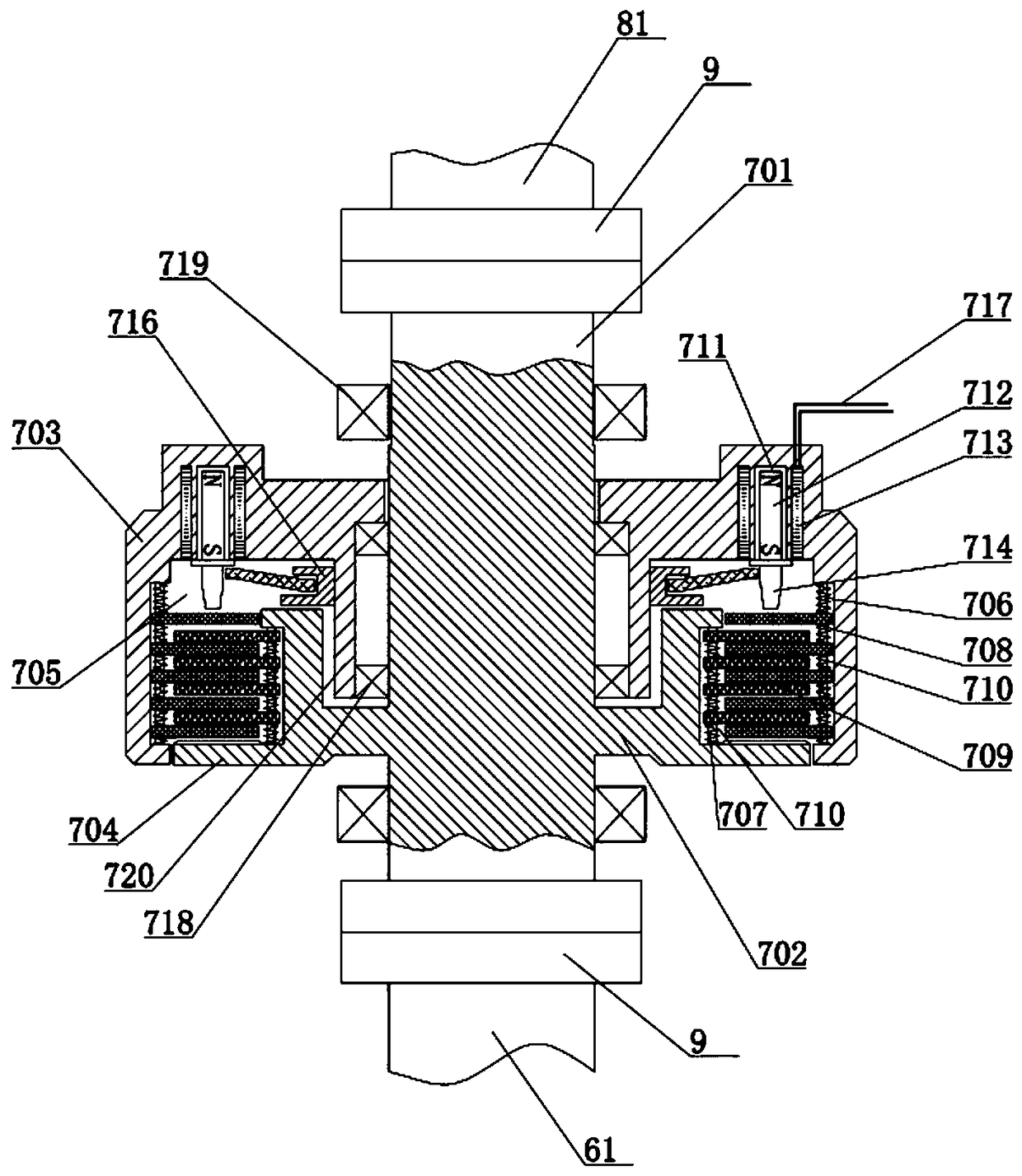

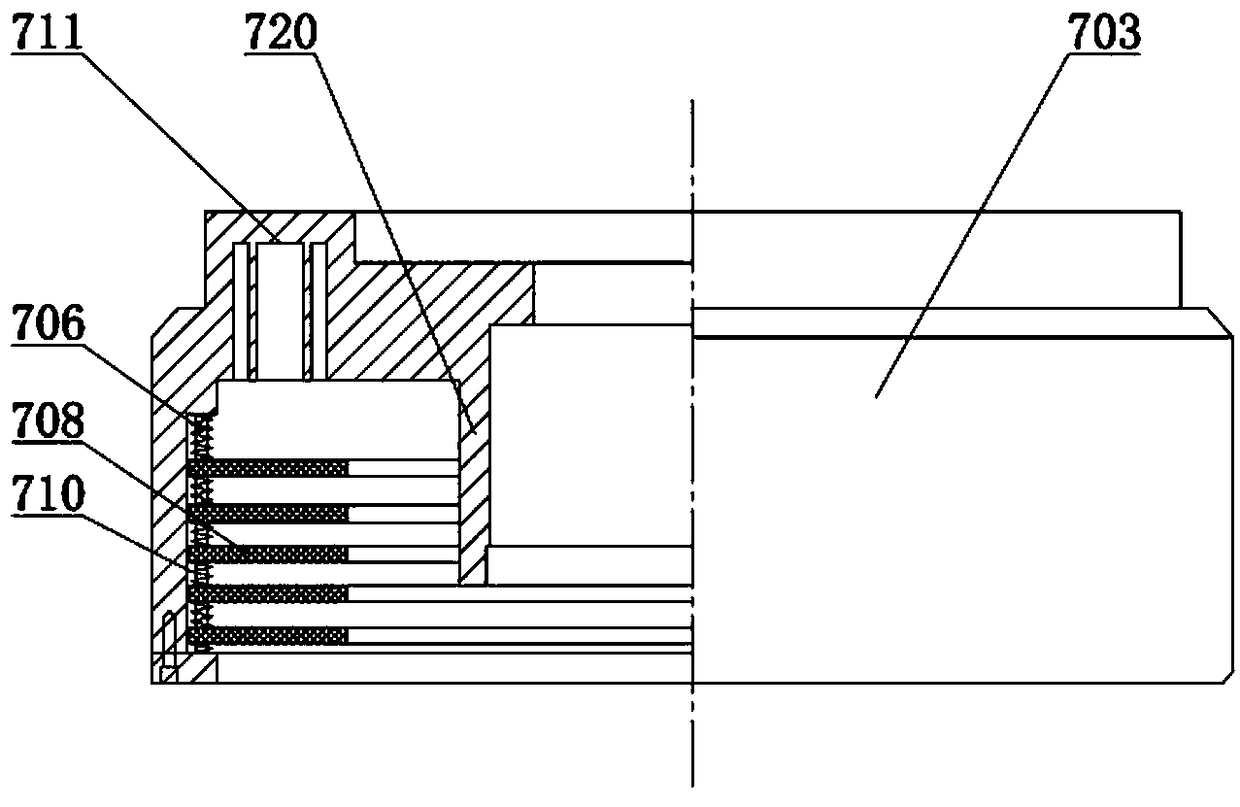

Water turbine transmission mechanism with controllable output

PendingCN108915929AControl the level of distractionRealize timing automatic controlHydro energy generationMachines/enginesStopped workAutomatic control

The invention discloses a water turbine transmission mechanism with controllable output. An annular inner shell is fixedly connected to a mandrel through a connecting ring, meanwhile, the inner shellis sleeved with an outer shell, an annular inner cavity is defined by the outer shell and the inner shell, outer ring axial sliding rods are evenly distributed on the inner wall of the outer shell, inner ring axial sliding rods are evenly distributed on the outer wall of the inner shell, the outer ring axial sliding rods are sleeved with multiple outer ring friction pieces, the inner ring axial sliding rods are sleeved with multiple inner ring friction pieces, and multiple pushing and driving mechanisms parallel to the axial direction are evenly distributed on the inner wall of the outer shell. The rotating speed of a runner can be changed and the runner can stop rotating by controlling the pushing and driving mechanisms, the interference degree of runner blades on an inner bin of a waterturbine is controlled, and therefore a safety passageway can be provided for upstream and downstream fishes. By means of the water turbine transmission mechanism, an upstream fish gate can be controlled to be opened and reduced or the water turbine can stop working in the fish flow period, and a condition is provided for timing automatic control.

Owner:STATE GRID CORP OF CHINA +2

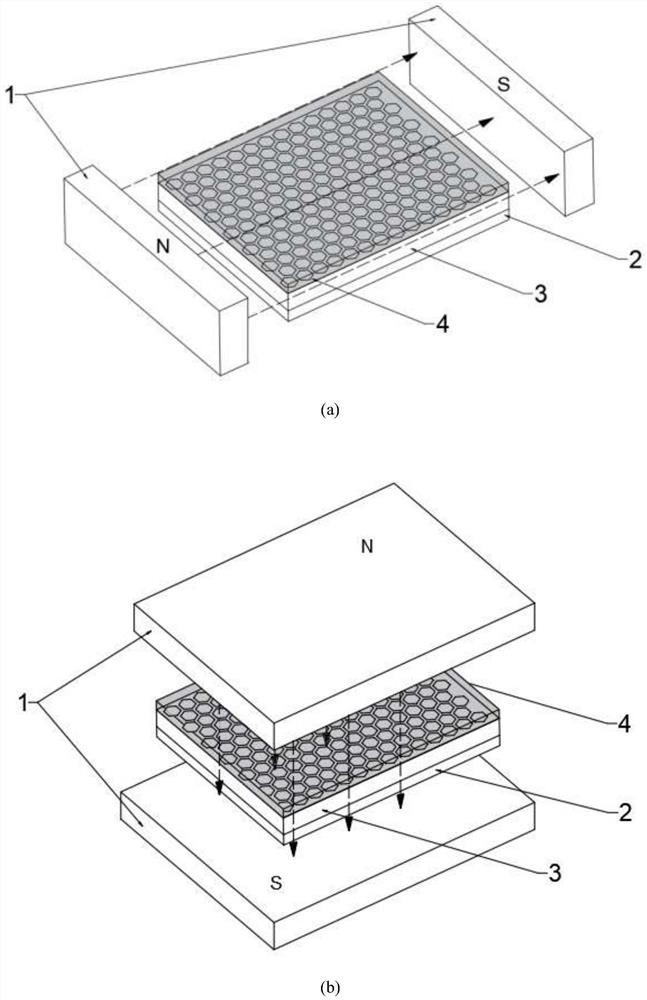

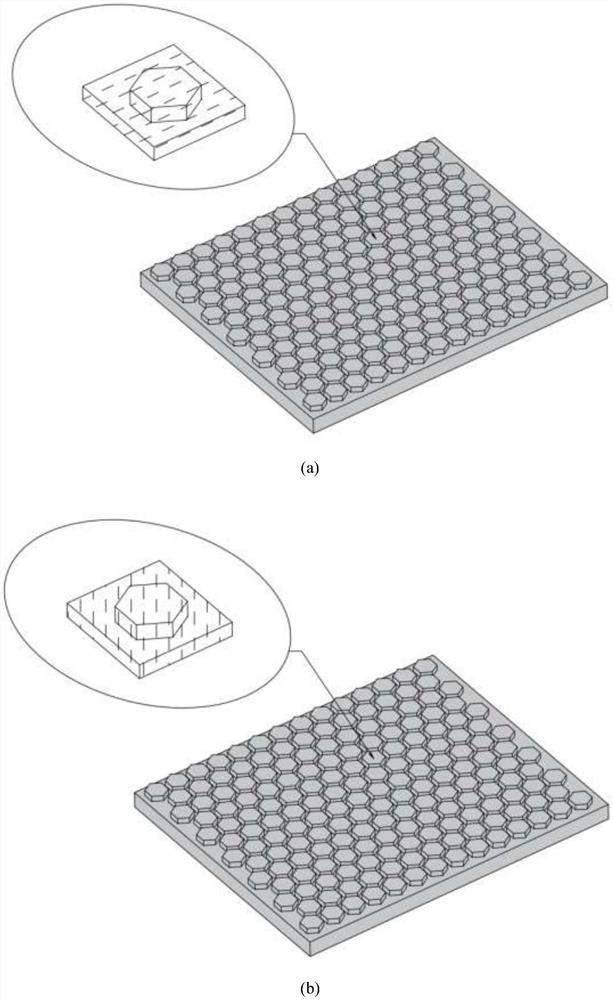

Manufacturing method of magnetic control bionic film microstructure

PendingCN114236967AChange frictionEasy to crawlPhotomechanical coating apparatusPhotomechanical exposure apparatusMagnetite NanoparticlesThin membrane

The invention discloses a manufacturing method of a magnetic control bionic film microstructure, and belongs to the field of intelligent materials and micromachining. By limiting the mixing ratio and mixing mode of the magnetic nanoparticles and the PDMS mixture and combining glass rod stirring, ultrasonic oscillation and vortex mixing, the distribution and form of the magnetic nanoparticles in PDMS are controlled, the obtained thin film microstructure has good magnetic response characteristics, and a fine thin film surface microstructure can be formed. In addition, the microstructure of the thin film and the concentration of the magnetic nanoparticles have obvious influence on the magnetic elasticity modulus, the invention provides three methods for forming the microstructure, the concentration range of the magnetic nanoparticles is limited, and the friction performance and the motion characteristic of the microstructure of the thin film can be effectively controlled through a magnetic field.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

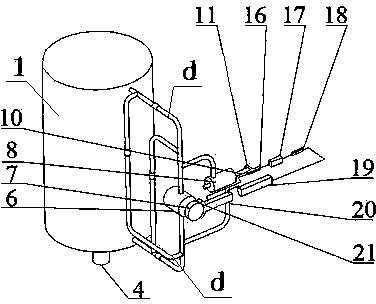

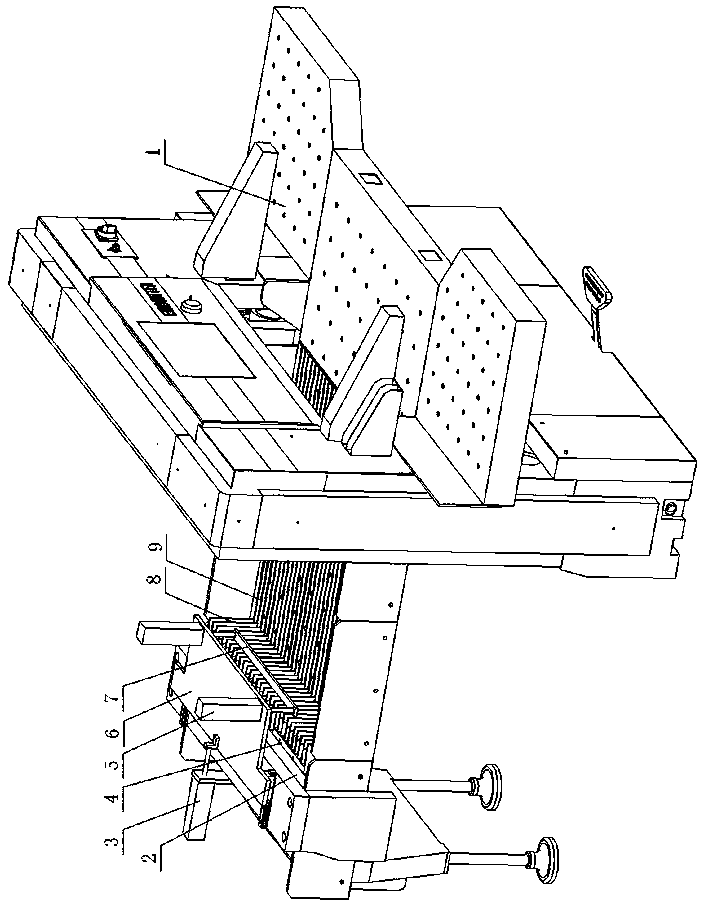

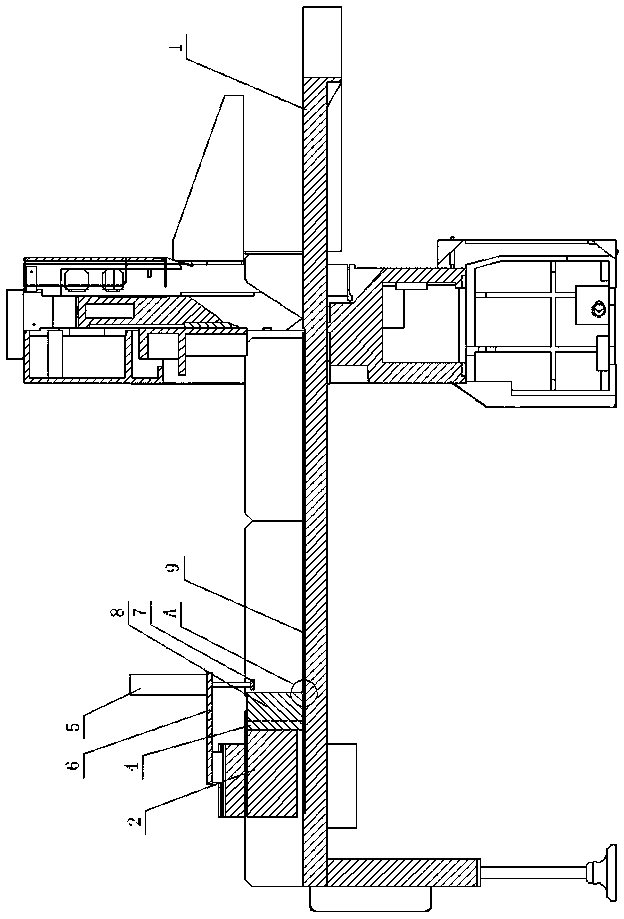

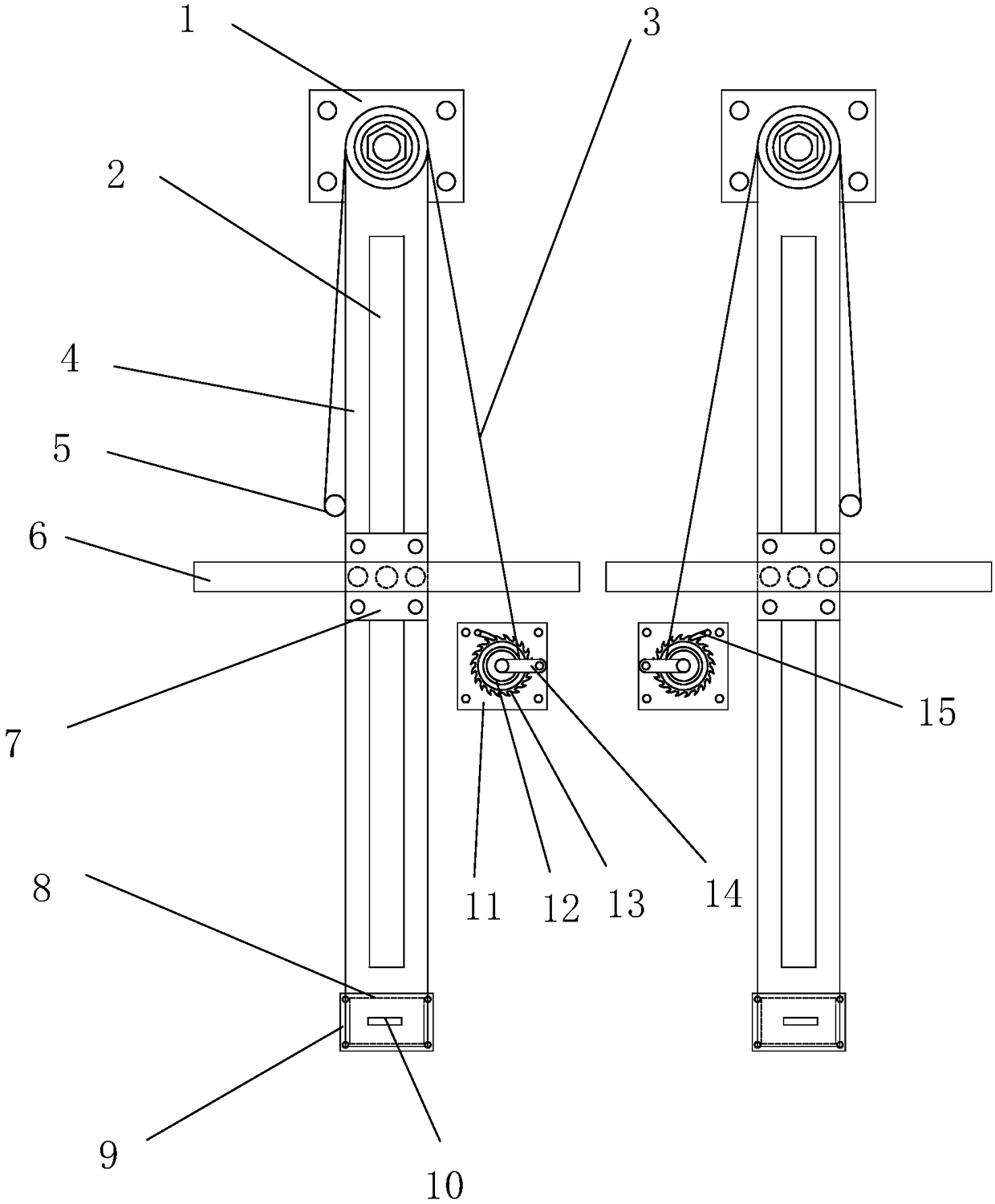

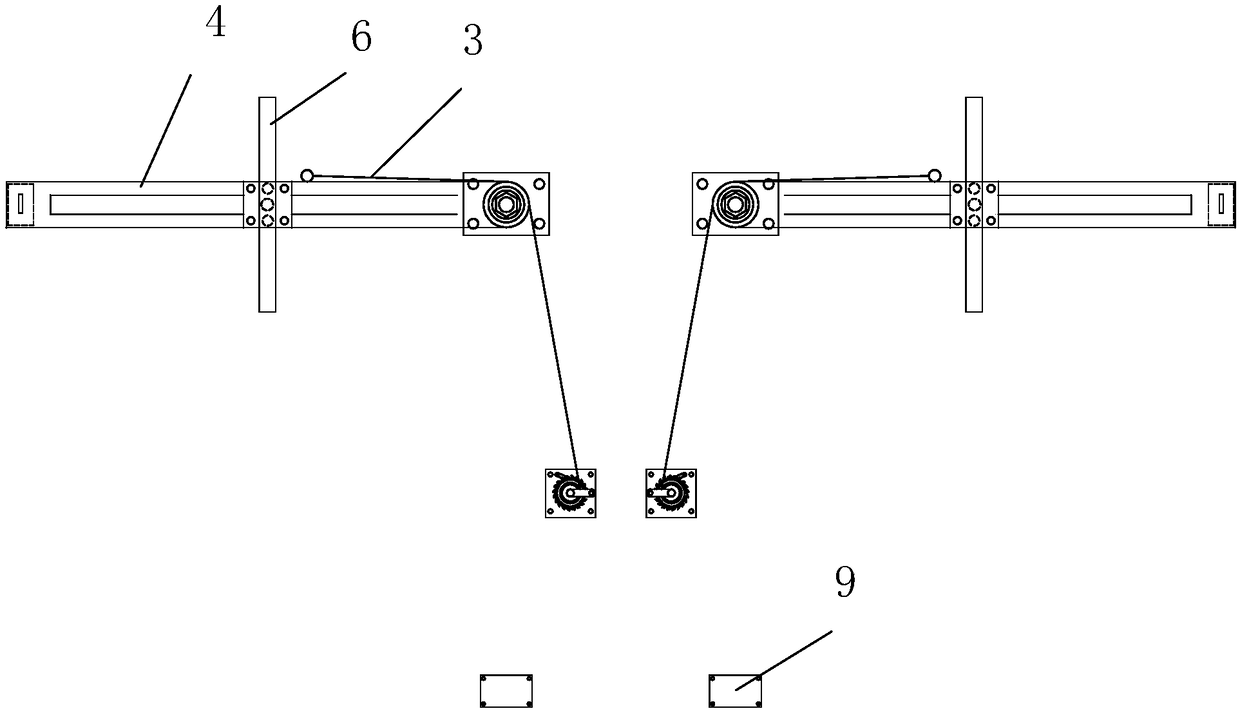

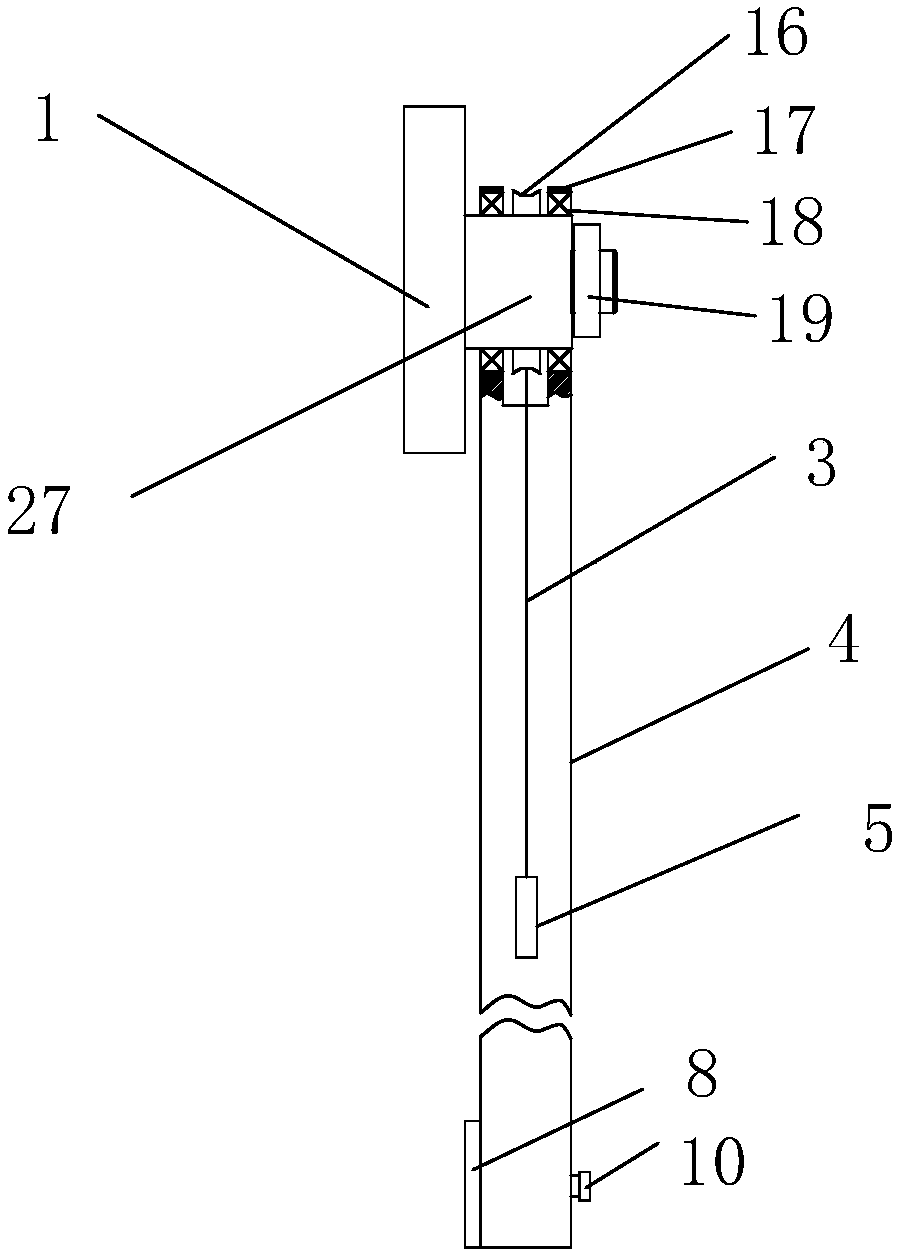

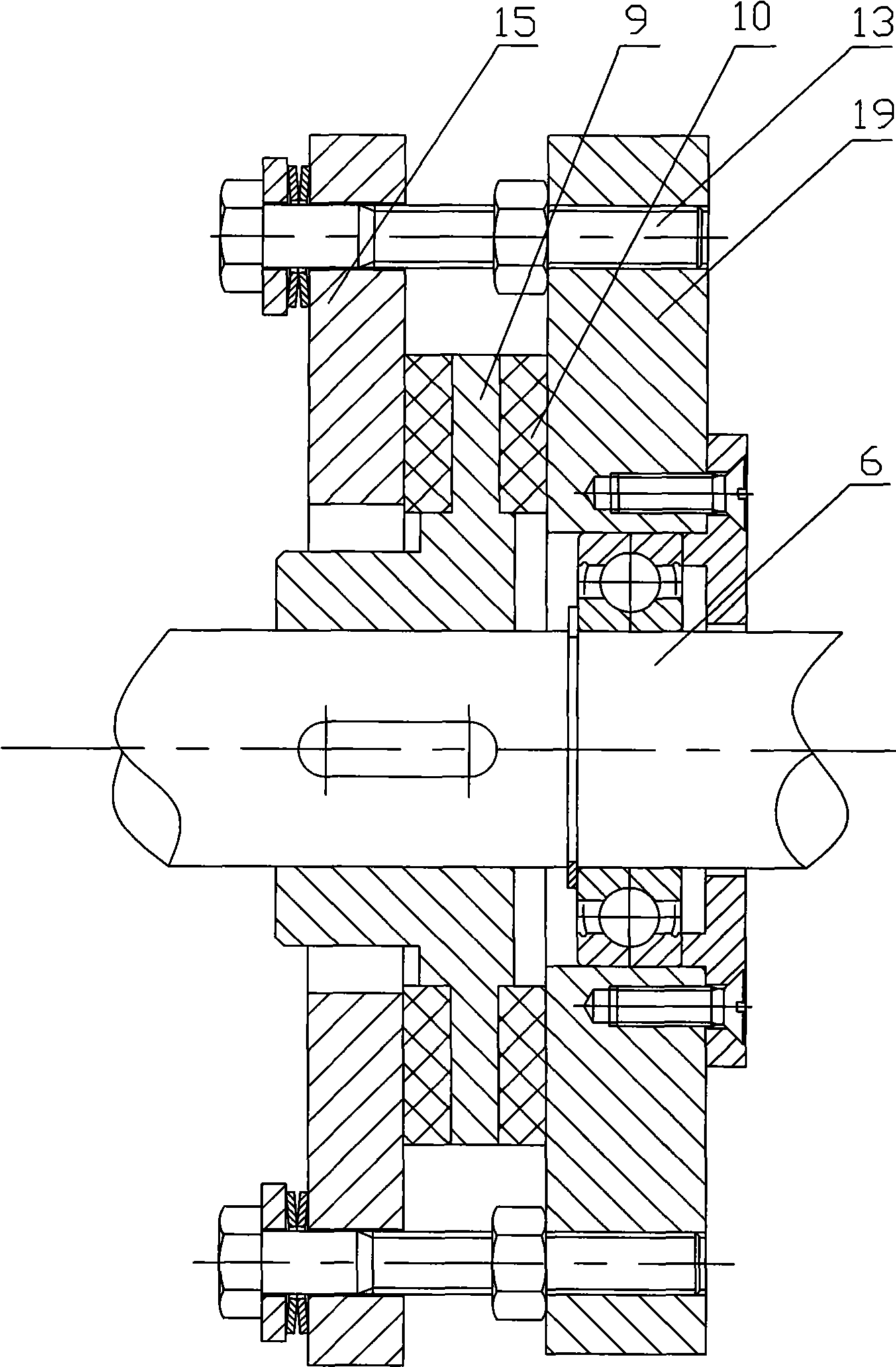

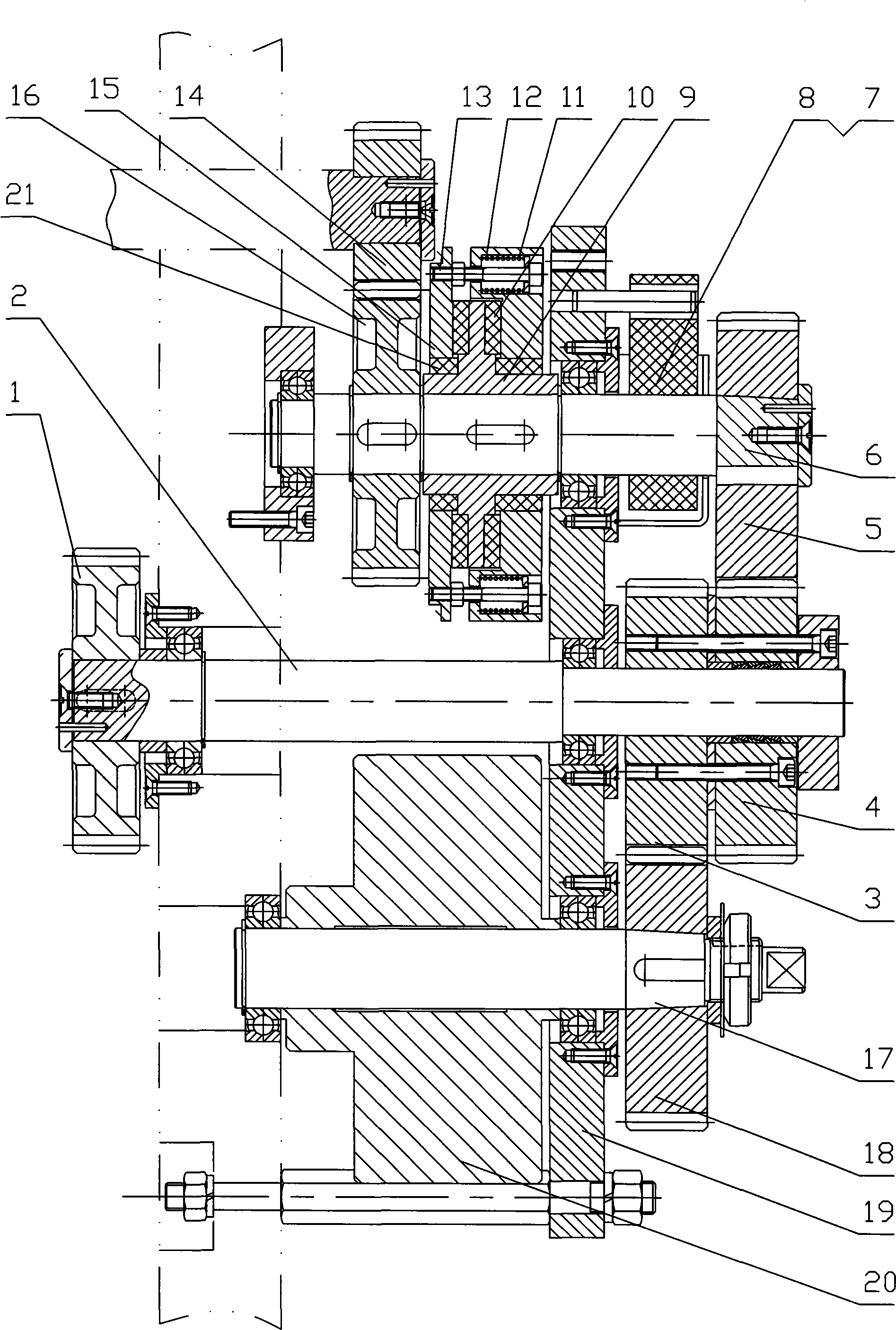

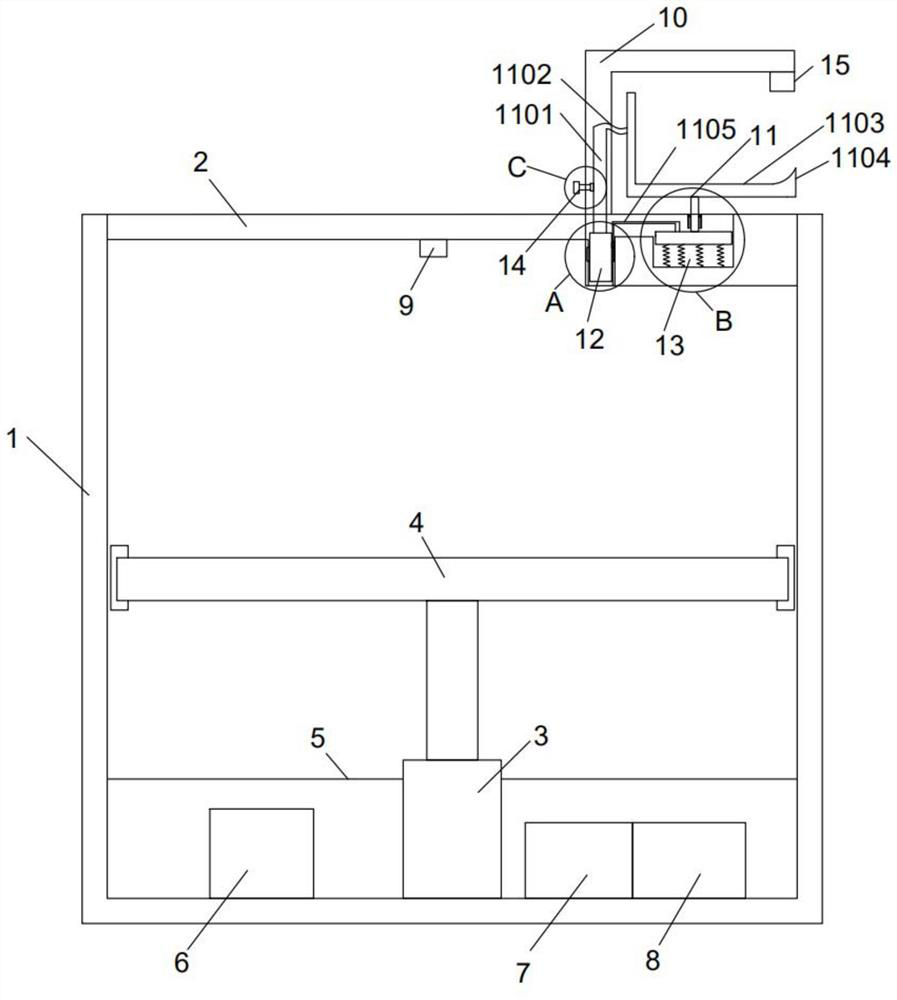

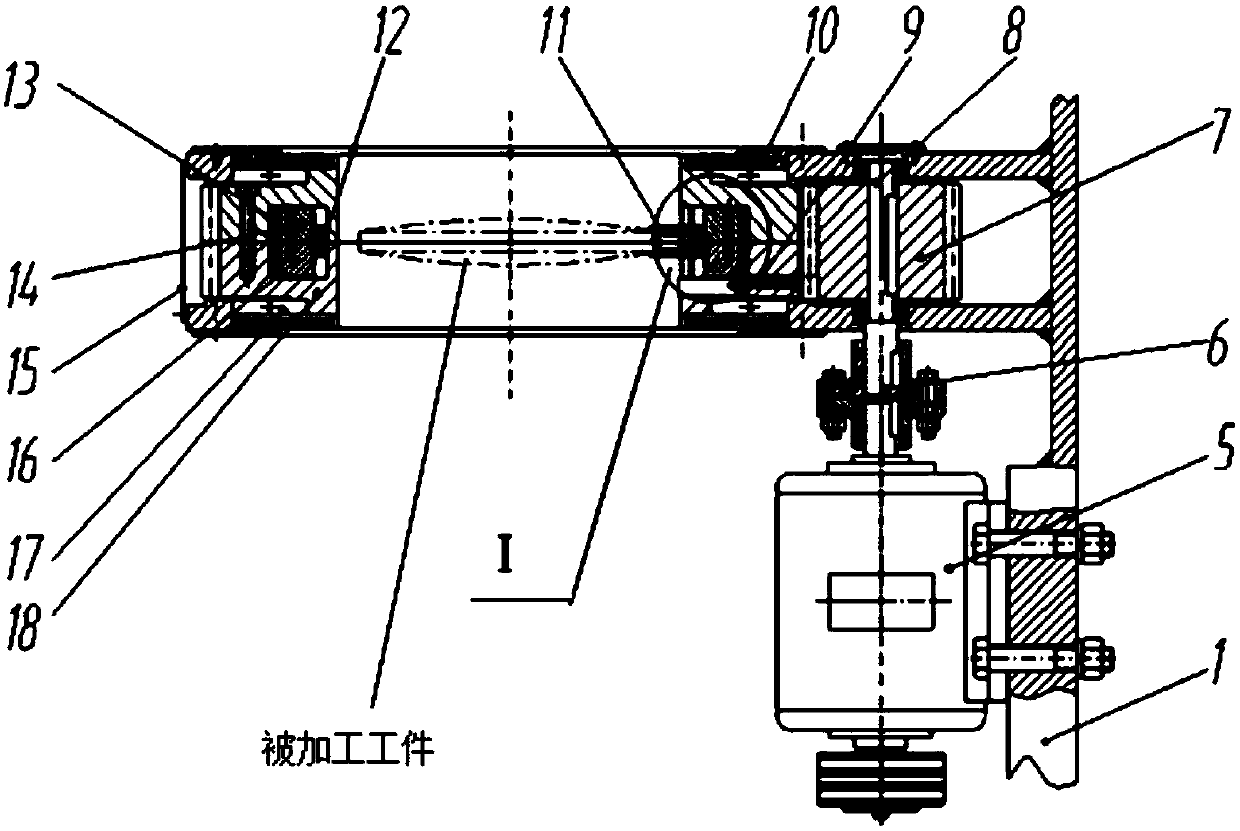

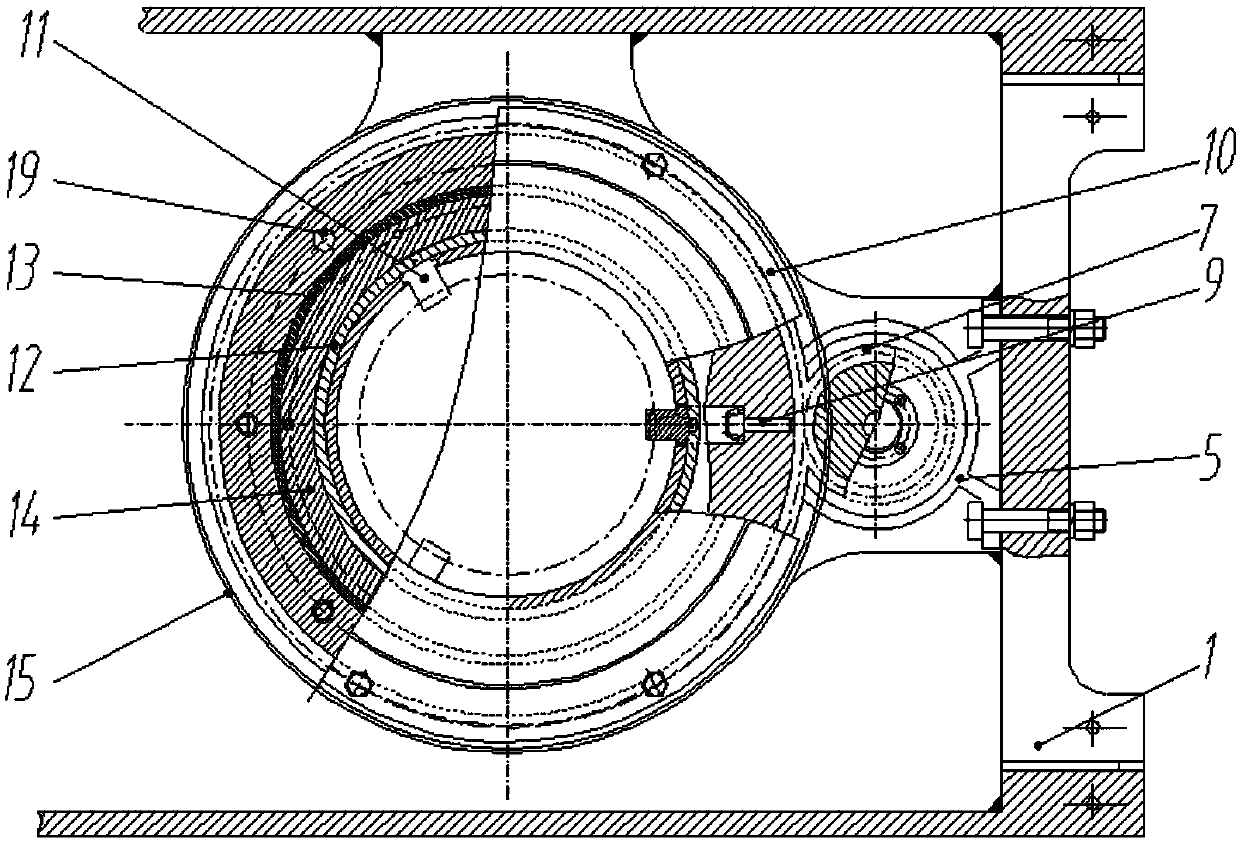

Automatic welding device for inflating spring

InactiveCN104339093ARealize automatic rotationChange speedWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftReducer

The invention discloses an automatic welding device for an inflating spring. The automatic welding device is characterized by comprising a rack (1), a motor reducer (2), a small friction wheel (3), a material clamping plate (4), a bearing pedestal (5), a driving shaft (6), a large friction wheel (7), a compression spring (8), a pressing plate (9), a pressure adjusting nut (10) and a locking nut (11), wherein external threads (61) are arranged at the lower end of the driving shaft (6); the motor reducer (2) and the bearing pedestal (5) are mounted on the rack (1); the material clamping plate (4) is mounted at the upper end of the driving shaft (6); the large friction wheel (7), the compression spring (8), the pressing plate (9), the pressure adjusting nut (10) and the locking nut (11) are sequentially mounted at the lower part of the driving shaft (6) from top to bottom. The automatic welding device disclosed by the invention has the advantages of adjustable rotating speed, stable operation, time conservation, labor conservation, good welding quality and long service life.

Owner:HUANGSHI ZHIYUN ELECTROMECHANICAL TECH INST

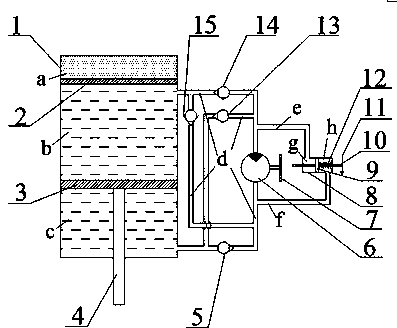

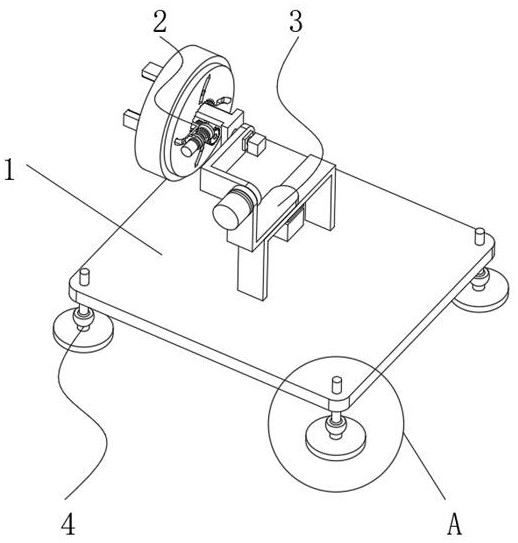

Calibration device of fiber-optic gyroscope inclinometer

The invention discloses a calibration device of a fiber-optic gyroscope inclinometer, relates to the technical field of fiber-optic gyroscope inclinometers, and aims to solve the problem of coaxiality during fixing. The device specifically comprises a base, wherein the top of the base is connected with a clamping assembly through a rotating assembly, the clamping assembly comprises a main body and a clamping ring, four sliding grooves in a 90-degree circular array are formed in the inner wall of the main body, clamping jaws are slidably connected to the inner walls of the sliding grooves, arc-shaped pads are fixed to the outer walls of the clamping jaws through bolts, the clamping ring is rotationally connected with the main body, a limiting sliding column penetrating through the main body is fixed to the outer wall of the other side of the clamping jaw through a bolt, an arc-shaped groove matched with the limiting sliding column is formed in the inner wall of the clamping ring, teeth are arranged on the inner wall of the clamping ring and engaged with a planet wheel, and the planet wheel is fixedly connected with a worm wheel through a transmission shaft. According to the invention, the contact ratio of the axis of the clamped fiber-optic gyroscope inclinometer and the axis of the main body is relatively high, so that the accuracy of subsequent calibration is ensured.

Owner:刘铭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com