Paper cutting machine

A paper cutter and paper cutting technology, which is applied in metal processing and other directions, can solve the problems affecting paper cutting work, paper jams, and paper cutting machines cannot complete the paper push work, etc., to ensure paper cutting accuracy and improve production speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

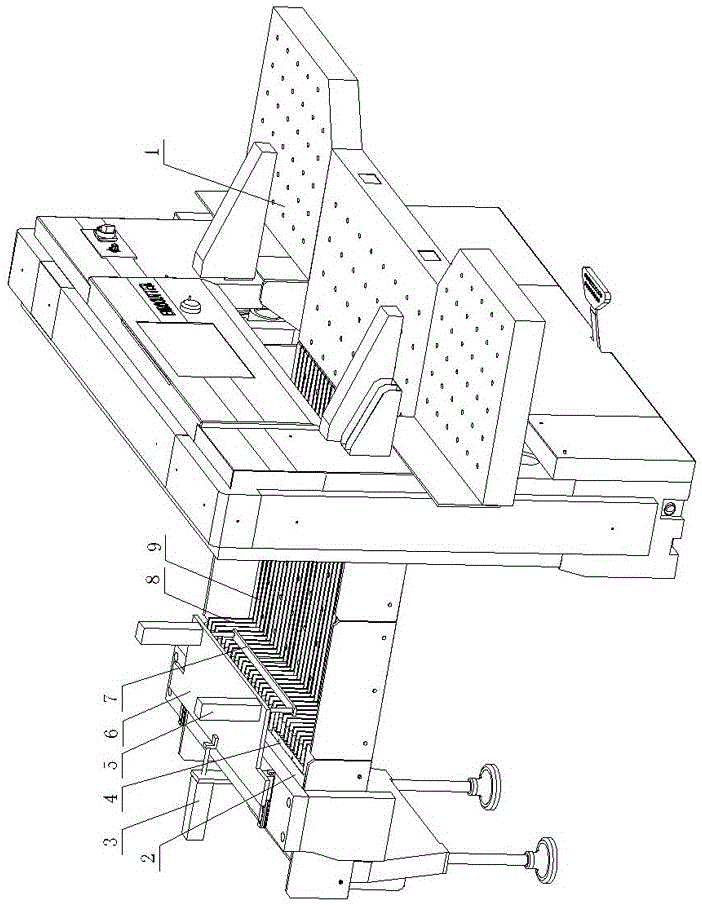

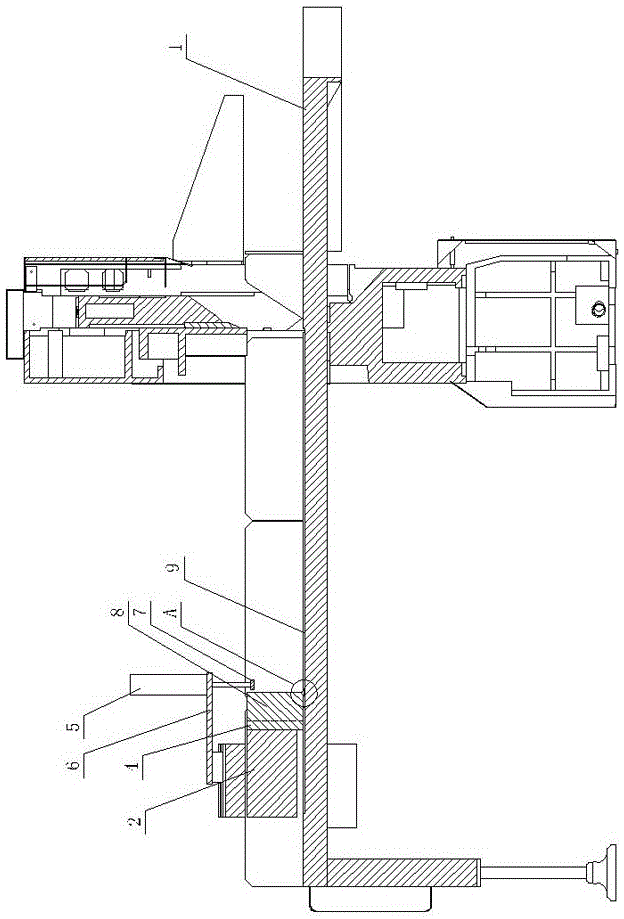

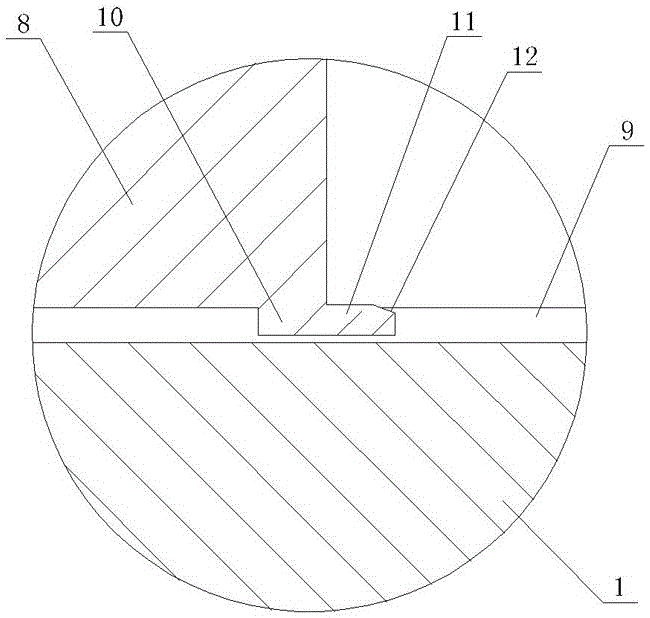

[0013] As shown in the figure, a paper cutter of the present invention includes a paper cutting platform 1 and a paper pushing frame 2 that is movable back and forth on the platform surface of the second half of the paper cutting platform. The front end of the paper pushing frame 2 is fixedly installed to push paper Block 4, the paper pushing surface of the paper pushing block 4 is provided with grid teeth 8, and the platform surface of the rear half paper cutting platform is horizontally arranged with a plurality of narrow strip-shaped shallow grooves 9 in the front and rear directions, and the narrow strip-shaped shallow grooves 9 are connected with the grid. Corresponding to the teeth 8, the bottom of the grid teeth 8 has a downwardly extending flashing plate 10 inserted into the narrow strip-shaped shallow groove 9, the flashing plate 10 has a front extension 11, and the top surface of the front extension 11 has a high height On the platform surface of the paper cutting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com