Method for achieving steel structure pre-assembling through computer simulation

A realization method and steel structure technology, applied in calculation, software simulation/interpretation/simulation, 3D modeling, etc., can solve problems such as marking errors, low efficiency, production backlog, etc., and achieve the effect of improving detection efficiency and production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

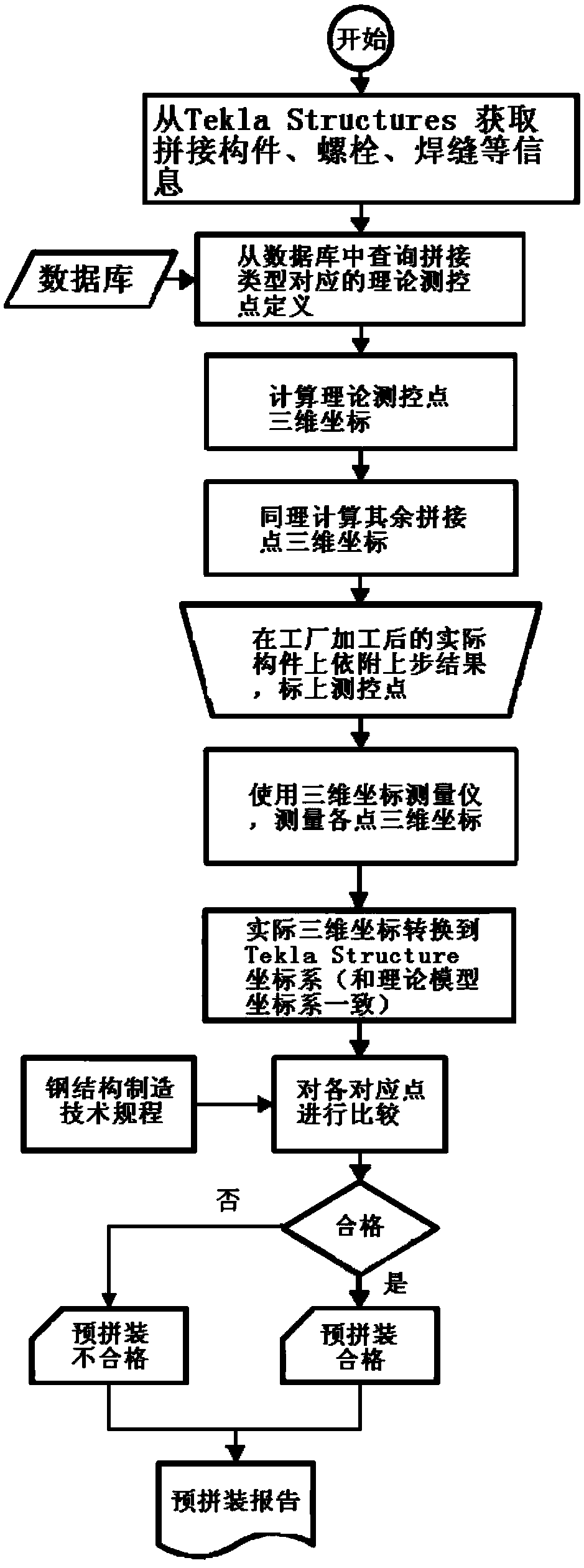

[0024] like Figure 1-4 As shown, by taking the pre-assembly detection of the beam-column rigidly connected beam as an example, the computer simulation method for pre-assembly of steel structures based on intelligent generation of measurement and control points in the present invention is illustrated, which specifically includes the following steps:

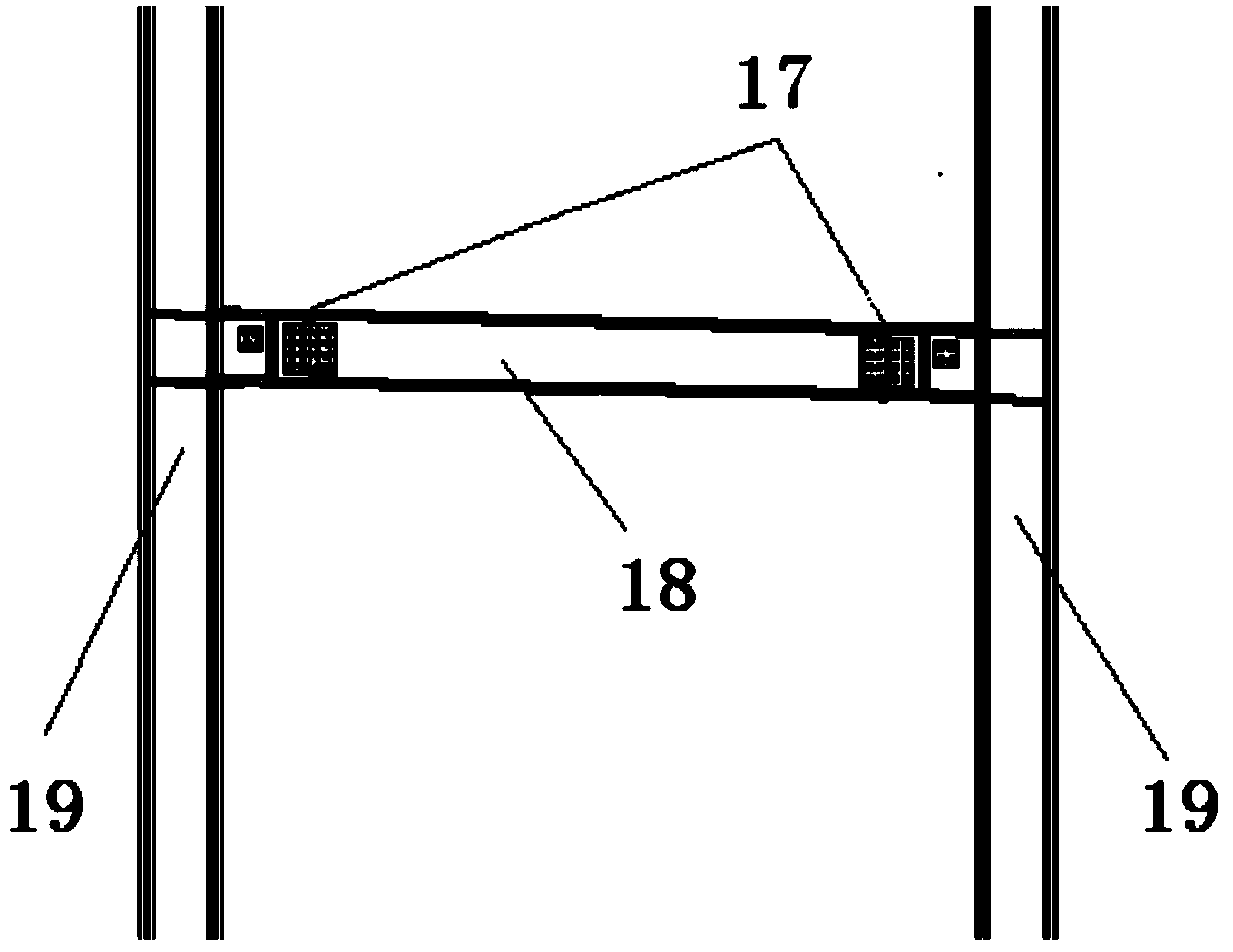

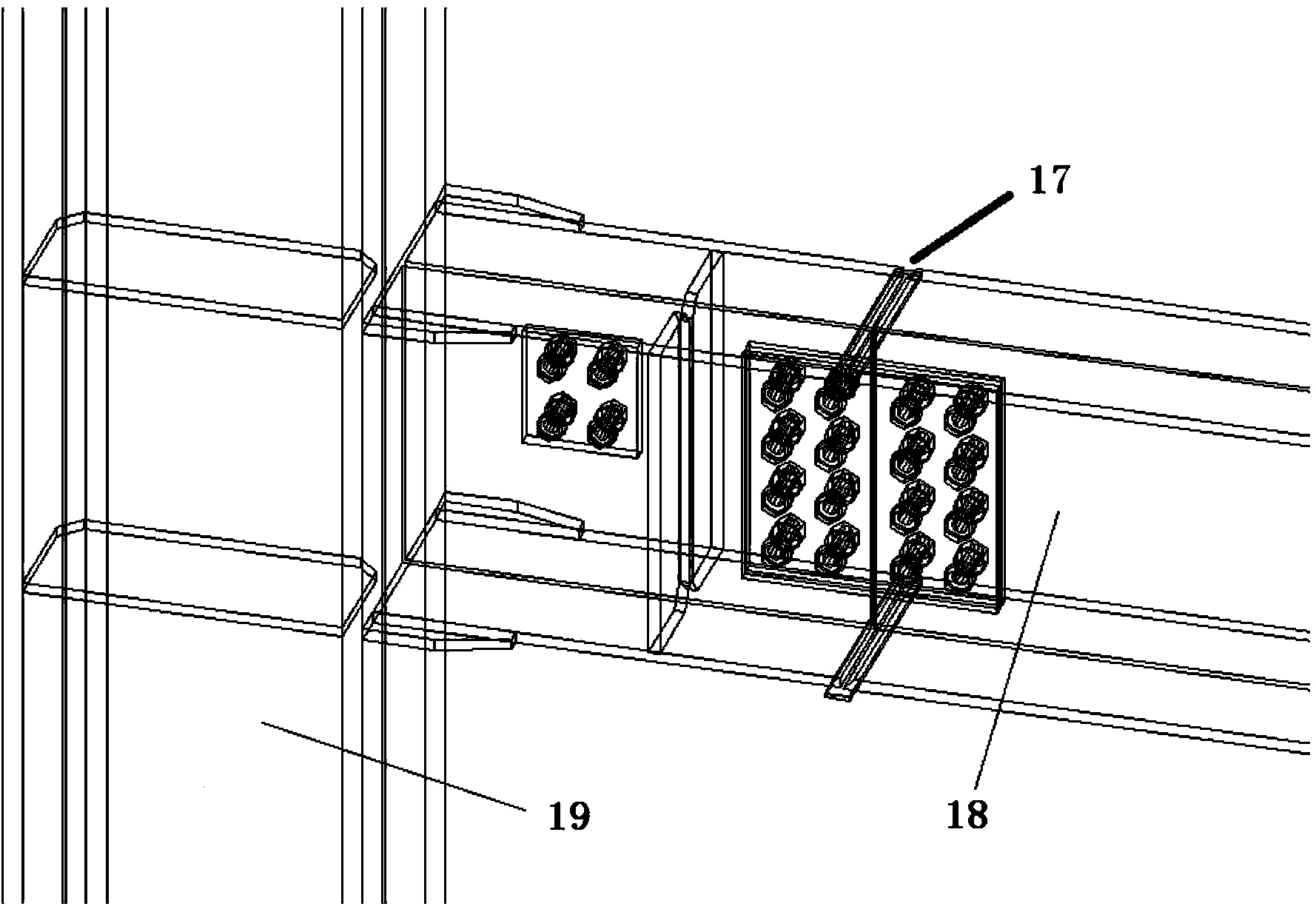

[0025] (1) Design the 3D model in the 3D steel structure detailing software Tekla Structures: the two ends of the beam are rigidly spliced with the column, the column 19 and the beam 18 are both H-shaped sections, the web is connected by high-strength bolts, and the upper and lower flanges are made of Groove weld with partial penetration, see 17 for this splicing point Figure 2-3 ;

[0026] (2) The intelligent generation software of the measurement and control points detects that the assembled section on the left side of the beam is an H-shaped section of the beam;

[0027] (3) According to the characteristics of the H-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com