Remote controller automatic detection production line

A technology of automatic detection and remote control, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of inability to online automatic detection, low detection efficiency of remote control, etc., to avoid the influence of human subjective judgment, improve detection quality, and improve The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific examples, so as to help to understand the content of the present invention.

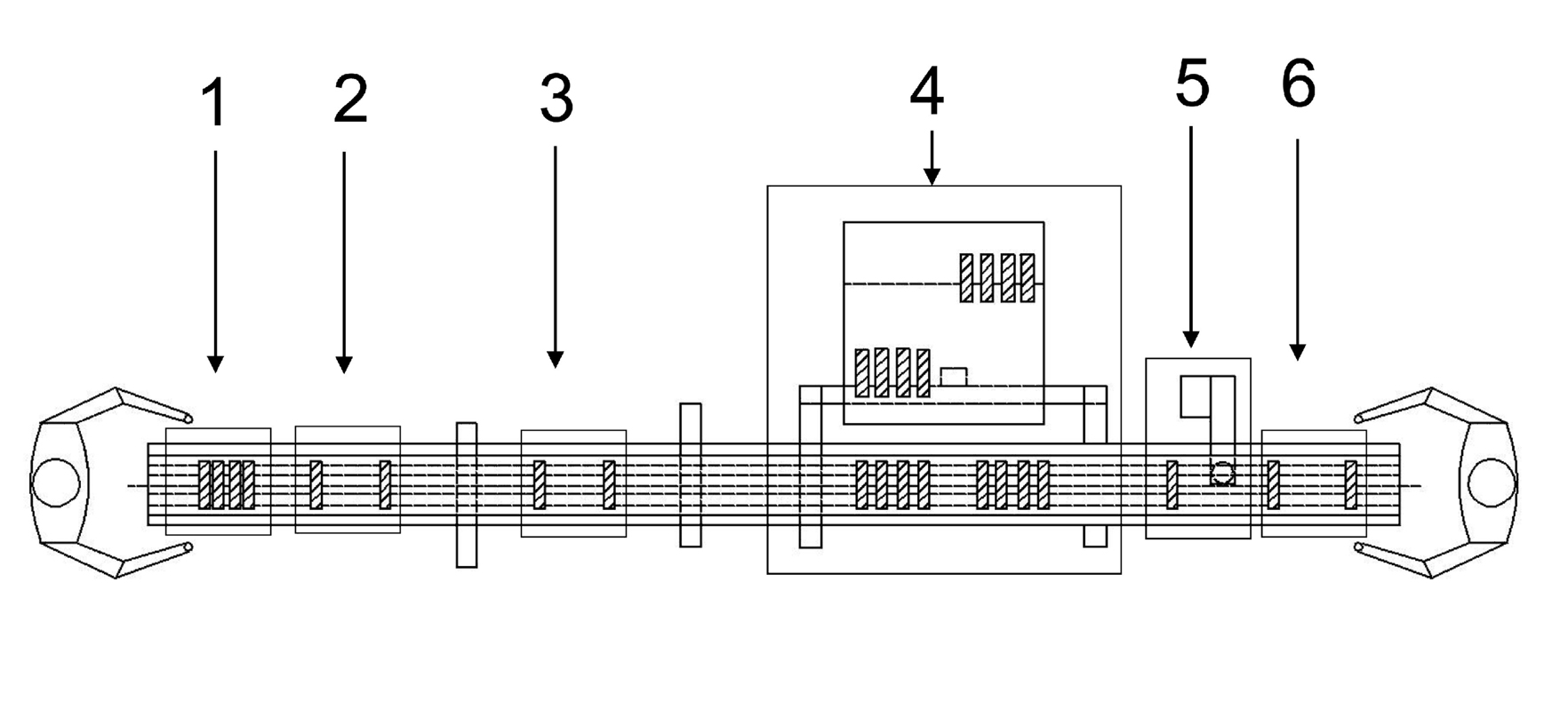

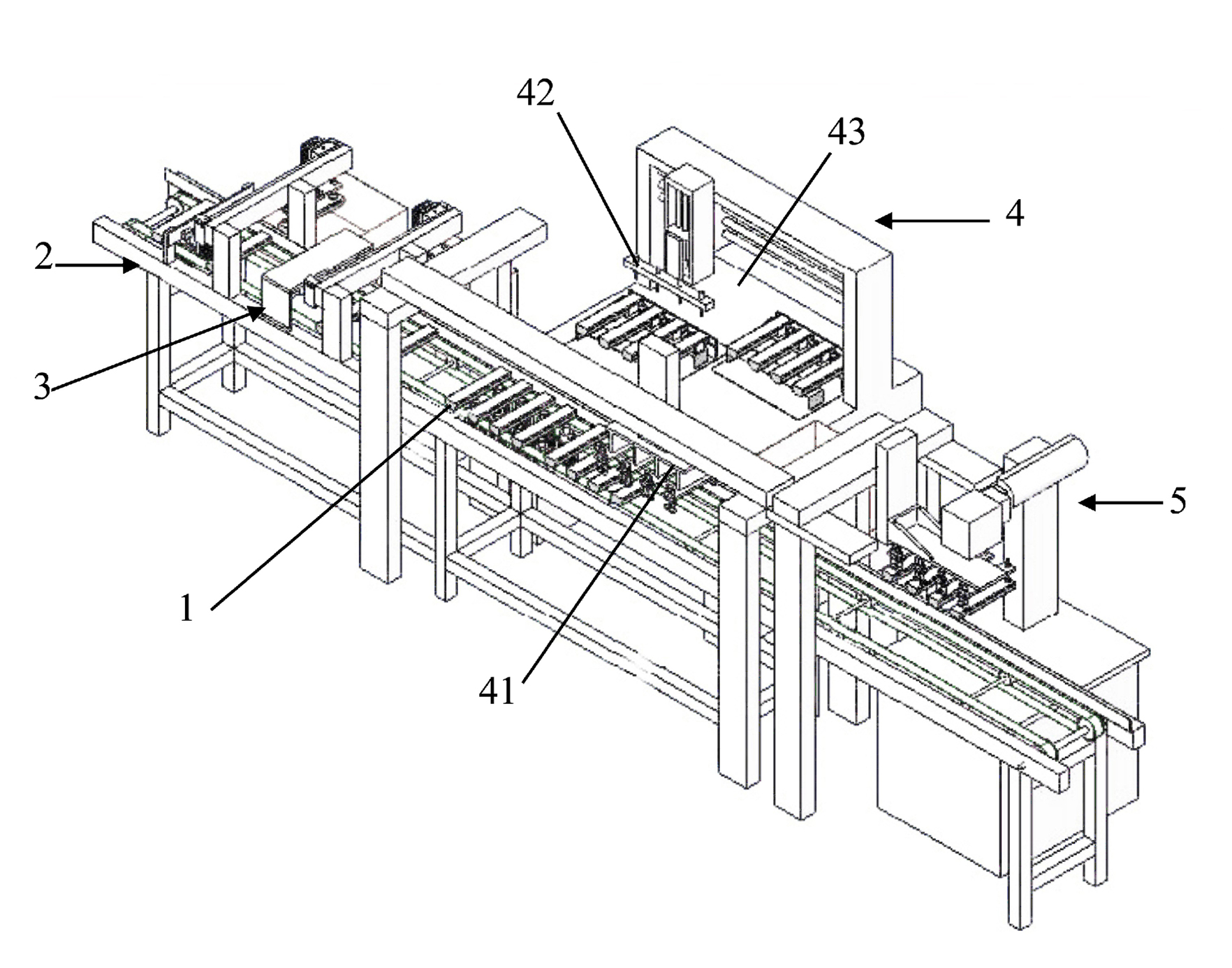

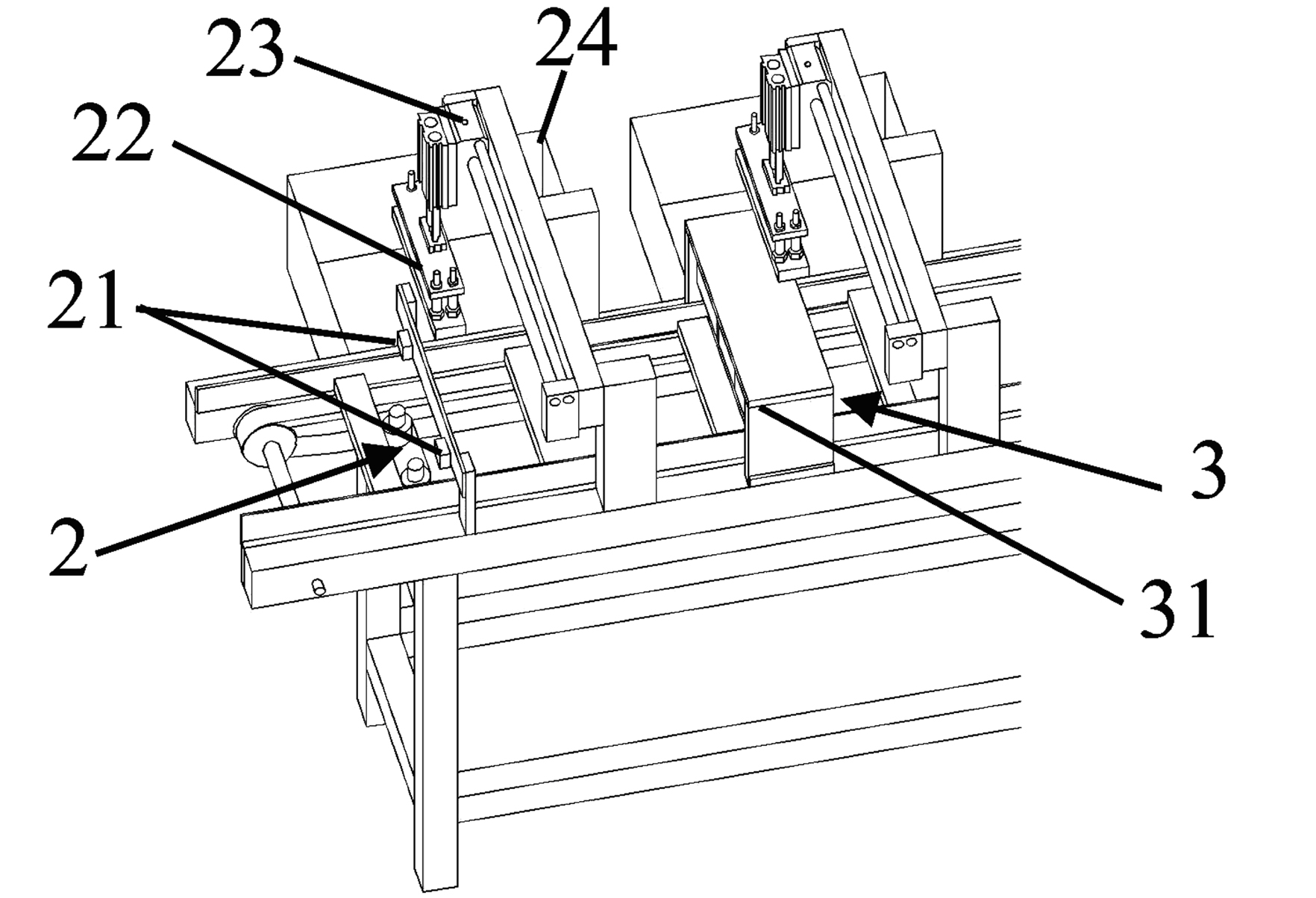

[0018] like figure 1 and figure 2 As shown, it is a preferred embodiment of the present invention, including a conveyor belt for transporting the remote controller 1 through each station, and the order of arrangement of the stations from front to back according to the conveying direction of the conveyor belt is thickness detection station 2, appearance Inspection station 3, function inspection station 4, laser marking station 5 for marking qualified products, and finally finished product packaging station 6. The advantage of this arrangement is that the function inspection of the remote control requires the inspection of each button. To operate and detect whether the product function is normal by detecting the signal of the remote control, so the detection is relatively complicated, the operation is relatively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com