Automatic welding device for inflating spring

A technology of automatic welding and spring compression, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of surfacing or missing welding, labor intensity of workers, affecting welding quality, etc., and achieve good welding quality and long service life. , the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

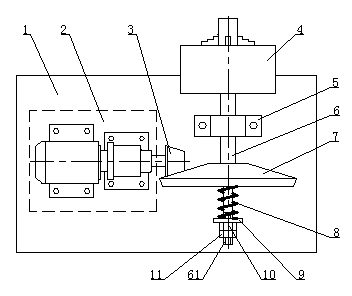

[0007] see figure 1 , the present invention includes a frame 1, a motor reducer 2, a small friction wheel 3, a clamping disc 4, a bearing seat 5, a transmission shaft 6, a large friction wheel 7, a compression spring 8, a pressure plate 9, a pressure adjustment nut 10 and a locking Nut 11, the lower end of the transmission shaft 6 is provided with an external thread 61, the motor reducer 2 and the bearing seat 5 are installed on the frame 1, the clamping disc 4 is installed on the upper end of the transmission shaft 6, and the transmission The bottom of the shaft 6 is sequentially equipped with a large friction wheel 7, a compression spring 8, a pressing plate 9, a pressure adjusting nut 10 and a lock nut 11 from top to bottom. The axis of the small friction wheel 3 is perpendicular to the axis of the large friction wheel 7 . The clamping disc 4 adopts a three-jaw chuck.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com