Processing technology of aquatic products

A treatment process and aquatic product technology, applied in bivalves processing, shrimp/lobster processing, etc., can solve problems such as easy hair loss, difficult removal, and slag drop, so as to improve the washing quality, improve the washing efficiency, and strengthen the cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

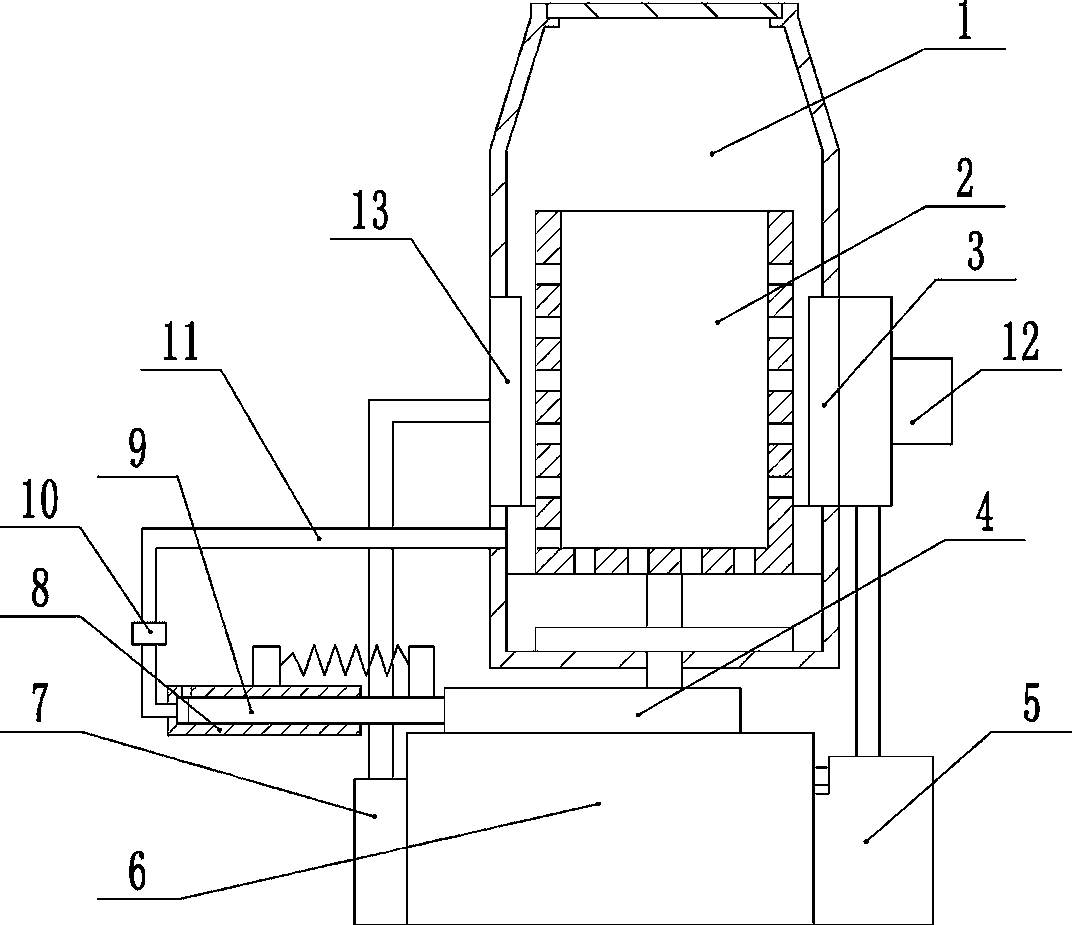

Embodiment 1

[0028] Embodiment 1 Basic Reference figure 1 Shown: The aquatic product treatment process requires the use of an aquatic product cleaning device, including a cleaning cylinder 1 and a drum 2. The cleaning cylinder 1 is covered with a cylinder cover, the bottom of the cleaning cylinder 1 is welded with a hollow ring seat, and the cylinder 2 is connected by rotation. On the ring seat, the bottom of the drum 2 is connected with the ring seat, and the ring seat is connected with an air intake pipe 11. There are several uniformly distributed water holes on the drum 2. The drum 2 is coaxially connected with a cam 4, and the cam 4 is offset by a Piston rod 9, piston rod 9 is slidably connected in piston barrel 8, and air intake pipe 11 is communicated with piston barrel 8, and one-way air intake valve 10 is installed on air intake pipe 11, and has air supply hole on the piston barrel 8, and piston rod 9 and A spring is welded between the outer walls of the piston cylinder 8, an axial...

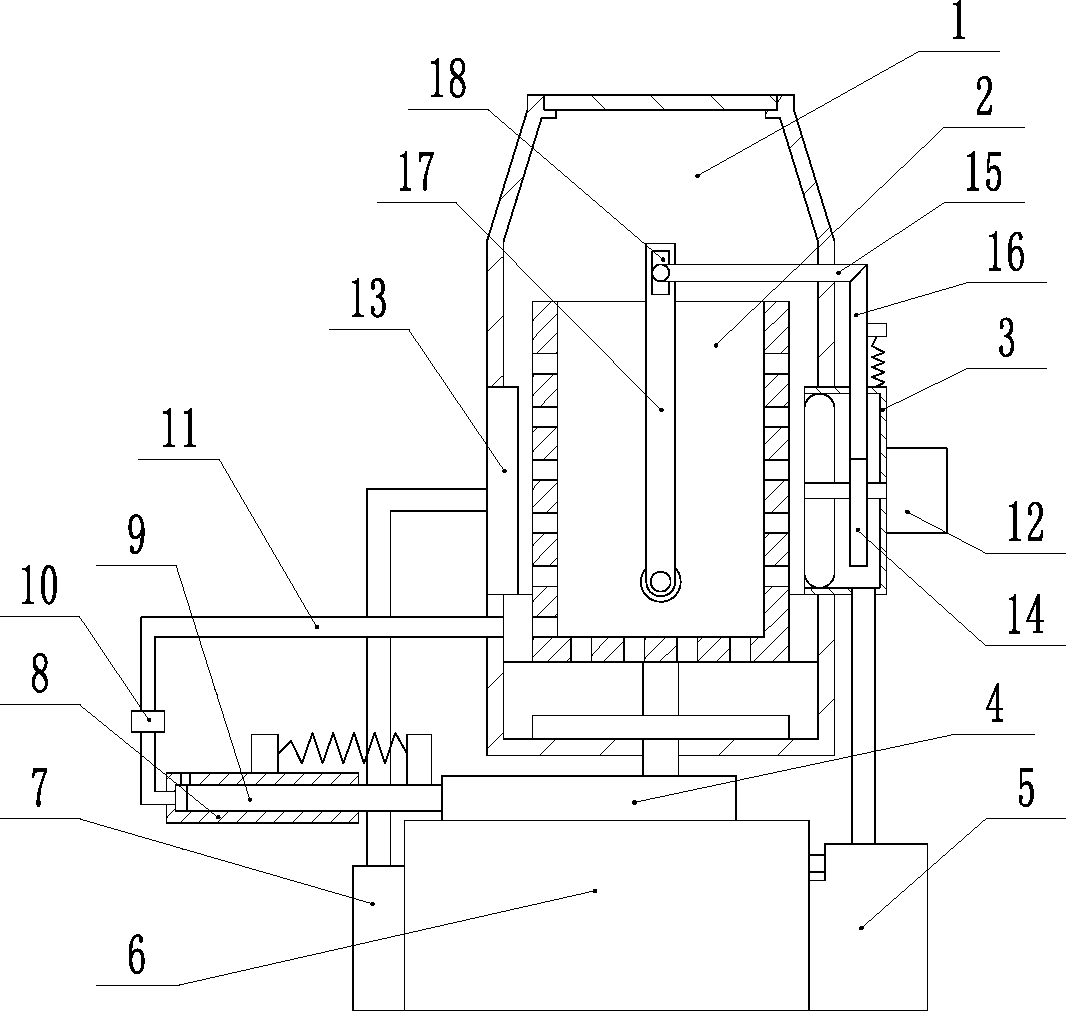

Embodiment 2

[0033] Example 2 Basic Reference figure 2 As shown, the difference from Embodiment 1 is that the output shaft of the motor 12 is also connected with a second cam 14 with a flat key, and the second cam 14 is opposed to a first wedge bar 16, and the first wedge bar 16 is slidably connected to the frame , a tension spring is welded between the first wedge bar 16 and the negative pressure cover, the first wedge bar 16 has a second wedge bar 15, the second wedge bar 15 is slidably connected in the cleaning cylinder 1, and the inner bottom of the drum 2 is hinged with a pendulum Bar 17, fork 17 and cylinder 2 are hinged and welded with torsion spring, fork 17 tops have chute 18, are hinged with roller on the left end of second wedge bar 15, and roller is slidably connected in chute 18.

[0034] When the output shaft of the motor 12 rotates, the output shaft drives the second cam 14 to rotate, and the second cam 14 cooperates with the extension spring to drive the first wedge bar 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com