Yarn guiding device with dust removing function

A technology of yarn guide device and function, which is applied in the field of yarn guide device with dust cleaning function, which can solve the problems of easy messy yarn, easy yarn breakage, and inability to adjust yarn tension, etc., so as to achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

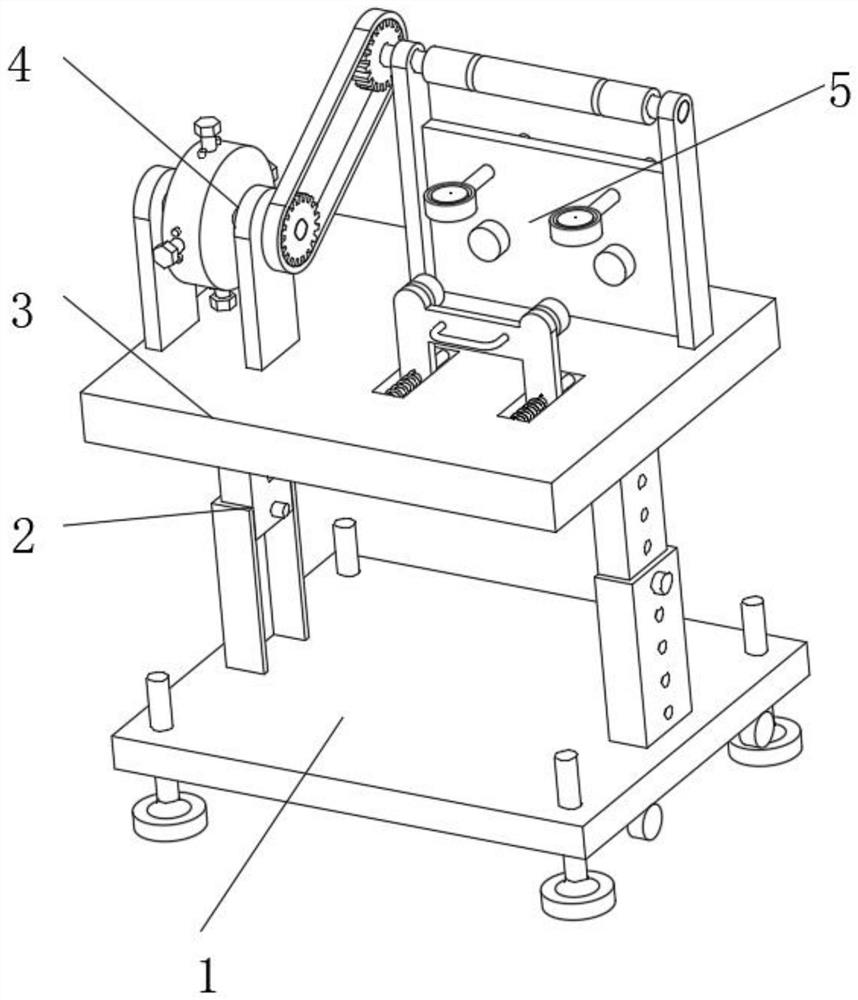

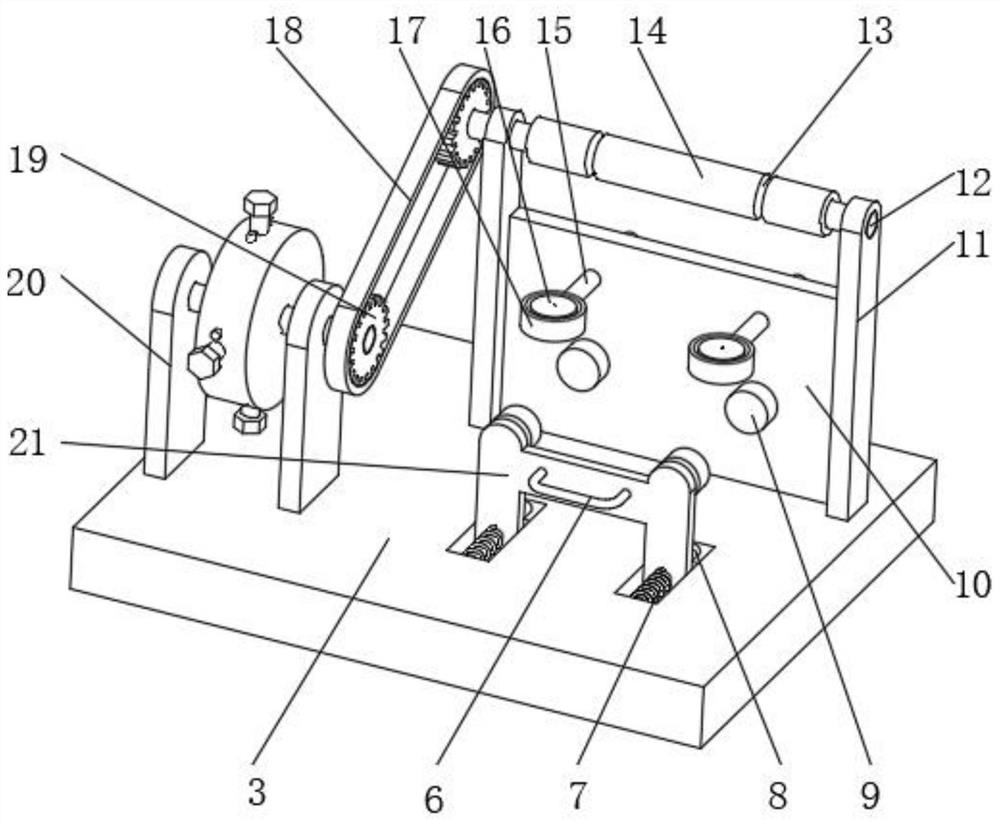

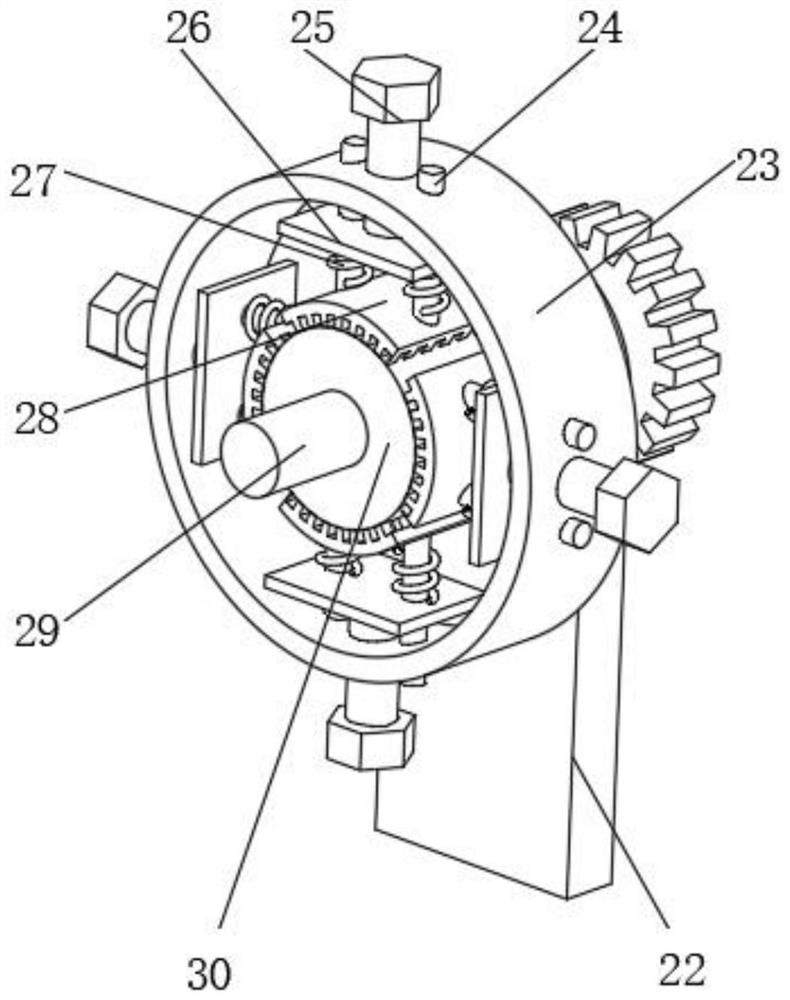

[0034] A yarn guide device with dust removal function, such as Figure 1-4As shown, including a base 1, the top outer wall of the base 1 is connected with a workbench 3 through a lifting mechanism 2, and the top outer wall of the workbench 3 is respectively provided with an adaptive adjustable damping mechanism 4 and a yarn guide mechanism 5. The self-adaptive adjustable damping mechanism 4 includes an outer cover 23, a friction wheel 30 and four groups of friction assemblies. The outer cover 23 is connected with a support plate 3 22 through rotation of a rotating shaft, and the support plate 3 22 is fixed on the top outer wall of the workbench 3 by bolts. Four sets of friction assemblies are arranged in a circular array on the inner wall of the outer cover 23. The friction assemblies include a transition plate 26 and a friction plate 28. The top outer wall of the friction plate 28 is integrally formed with a slide bar 3 24, and the slide bar 3 24 slides Connected on the inner...

Embodiment 2

[0037] A yarn guide device with dust removal function, such as figure 1 , 2 As shown, in order to solve the yarn guiding problem; this embodiment makes the following improvements on the basis of Embodiment 1: the yarn guiding mechanism 5 includes a clamping assembly and a yarn guiding assembly, and the clamping assembly includes four thimbles 9, fixed plate 10 and clamping plate 21, the fixed plate 10 is fixed on the top outer wall of the workbench 3 by bolts, wherein two thimbles 9 are rotatably connected to the outer wall of the fixed plate 10, and the other two thimbles 9 pass through The rotating shaft is rotatably connected to the inner wall of the clamping plate 21, the inner wall of the workbench 3 is provided with a chute, the inner wall of the chute is fixed with a slide bar 8 by bolts, and the clamping plate 21 is slidably connected to the outer wall of the slide bar 8, And the outer wall of the slide bar one 8 is covered with a spring one 7, the outer wall of the c...

Embodiment 3

[0040] A yarn guide device with dust removal function, such as figure 1 , 5 As shown, in order to solve the yarn guiding problem; this embodiment makes the following improvements on the basis of Embodiment 2: the lifting mechanism 2 includes a lifting column 34 and a fixed column 38, and the two lifting columns 34 are fixed to the workbench by bolts 3 on the bottom outer wall, the two fixed columns 38 are fixed on the top outer wall of the base 1 by bolts, the lifting column 34 is slidably connected to one side of the fixed column 38, and the lifting column 34 and the inner wall of the fixed column 38 Open the uniform adjustment hole 1 35 and the adjustment hole 2 37 respectively, one of the adjustment holes 35 and the inner wall of the adjustment hole 2 37 cooperate with the same elastic pin 36, and the bottom outer wall of the base 1 is provided with ten thousand To the wheel 31, the inner walls of the four corners of the base 1 are all threadedly connected with a lifting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com