Cutting bed and belt conveying method thereof

A technology for conveyor belts and cutting machines, which is applied in the field of cutting machines and cutting machines. It can solve the problems of affecting the service life of conveyor belts and clamping devices, low transmission accuracy, and large deformation of conveyor belts. It achieves a simple and reasonable structure and mobile The effect of small resistance, accurate and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

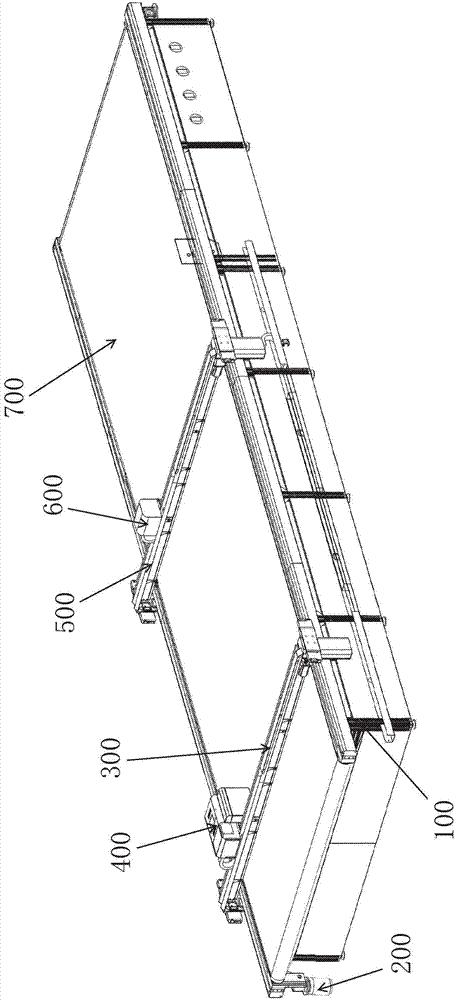

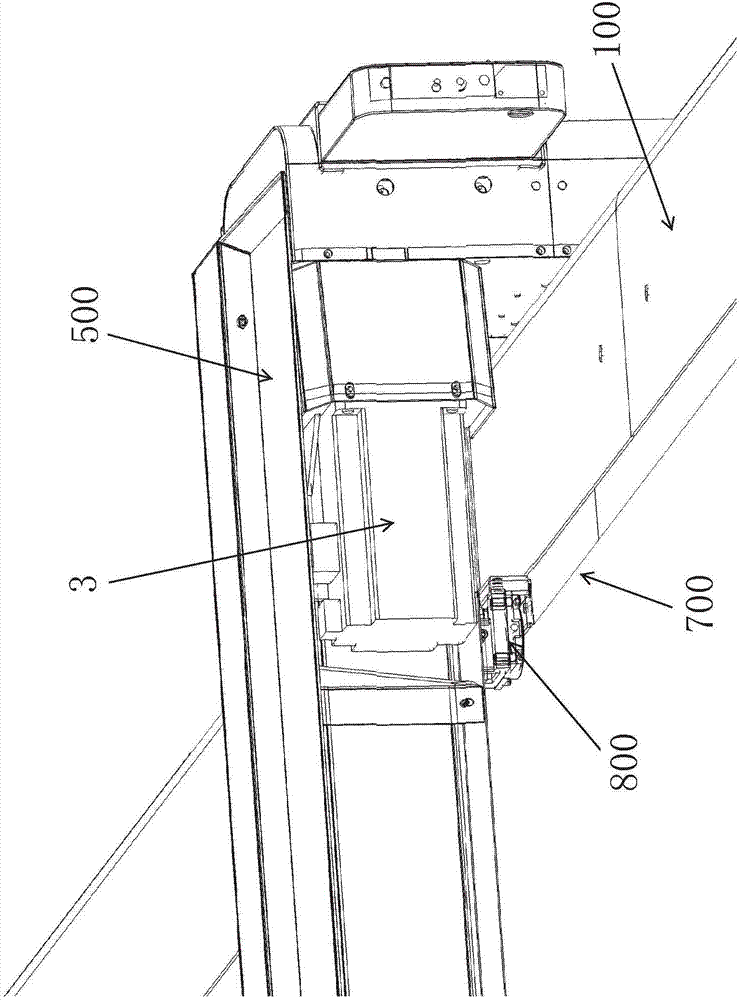

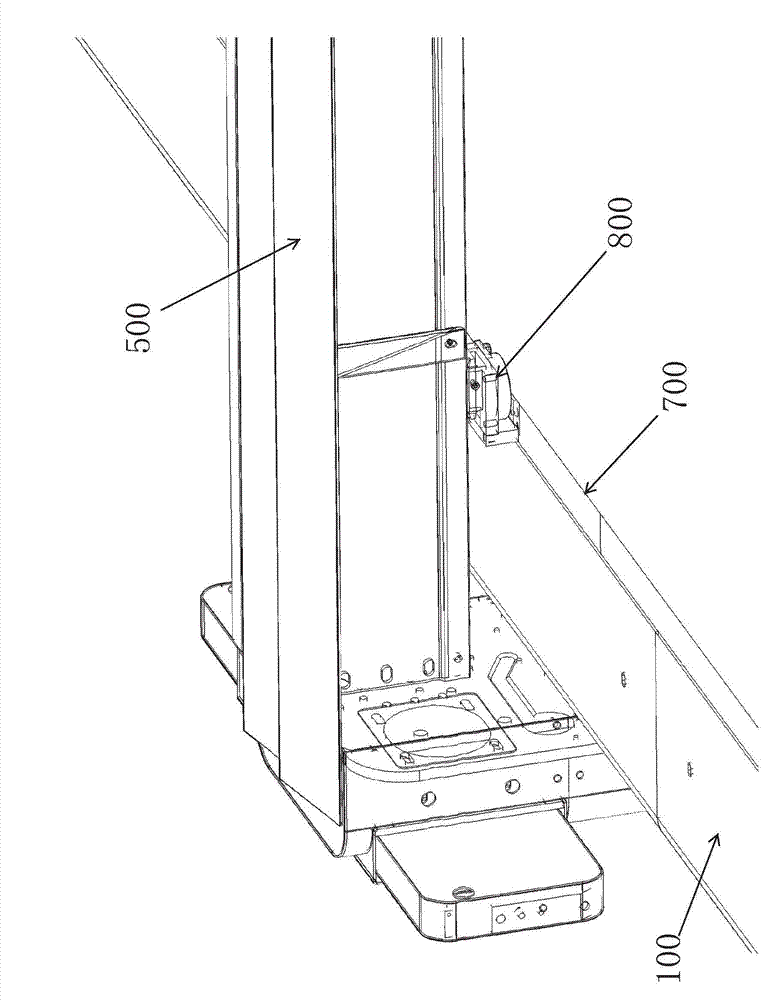

[0028] Such as figure 1 The shown cutting bed includes a frame 100 and a conveyor belt 700, on the frame 100, guide rails 11 are installed on the left and right sides of the conveyor belt 700, and the first crossbeam 300 and the second crossbeam 500 straddle the two sides respectively. On the side guide rail 11 and move back and forth along the guide rail 11, the scanning operation head 400 capable of moving left and right is installed on the first beam 300, and the cutting operation head 600 capable of moving left and right is installed on the second beam 500, as figure 2 , image 3 As shown, the clamping device 800 capable of clamping the left and right sides of the conveyor belt 700 is installed on the first beam 300 or the second beam 500 . Such as Figure 4 As shown, the conveyor belt 700 is wrapped around a driving roller 201 and a driven roller 205, the driving roller 201 and the driven roller 205 are installed at the front and rear ends of the frame 100 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com