Unwinding device for raincoat production

A technology of unwinding device and raincoat, applied in the field of garment production, can solve the problems of low efficiency and labor consumption, and achieve the effects of accurate material unwinding, improving production efficiency and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

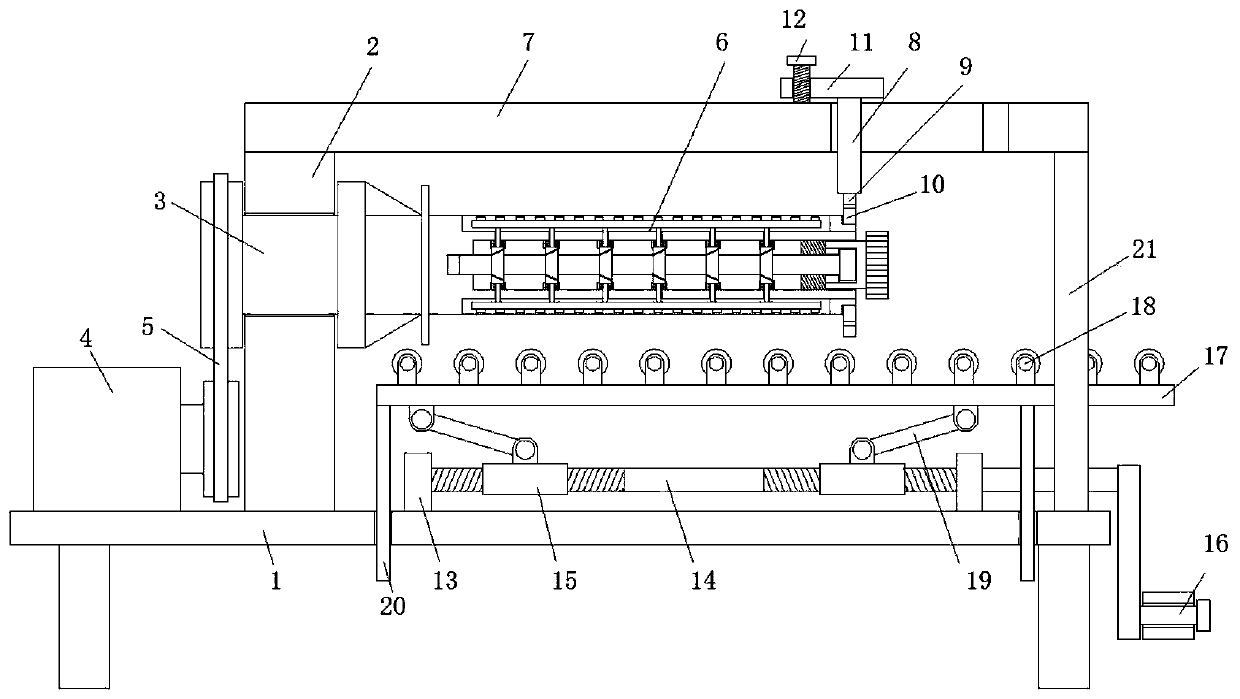

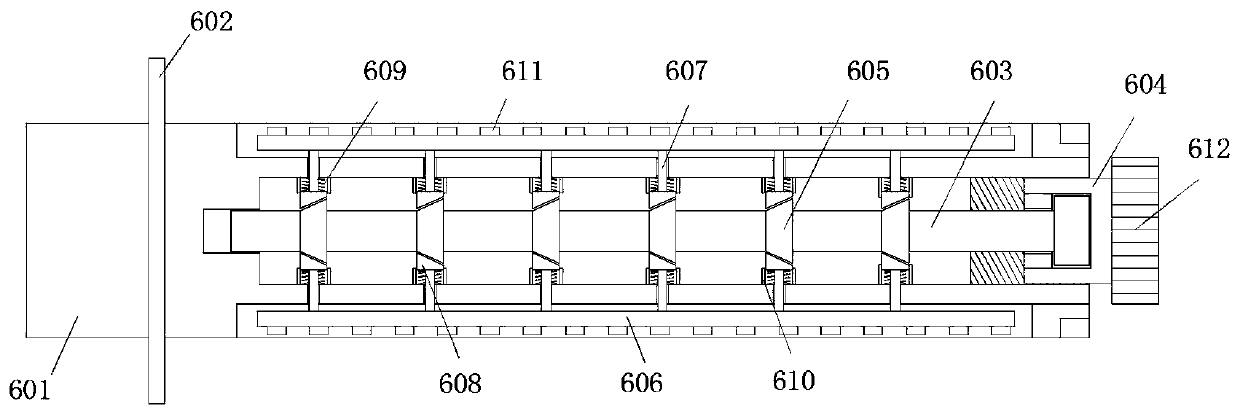

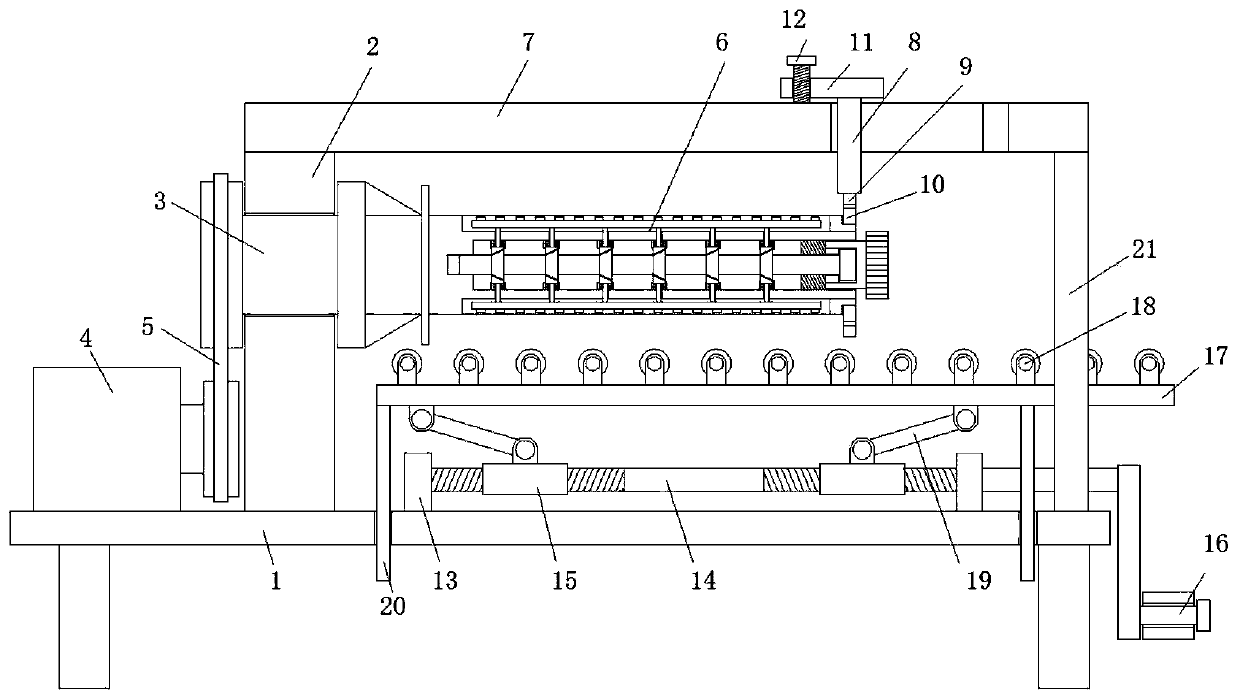

[0021] refer to Figure 1-2 , an unwinding device for raincoat production, comprising a workbench 1, a turntable 2 and a servo motor 4 are arranged on one side of the top of the workbench 1, an I-shaped turntable 3 is connected to the turntable 2 through bearing rotation, and the servomotor 4 output shaft and the I-shaped rotating disk 3 are transmission-connected with a transmission chain 5, and one side of the I-shaped rotating disk 3 is fixedly connected with a carrying shaft 6, and the carrying rotating shaft 6 includes a main shaft 601, and one end of the main shaft 601 is connected to the I-shaped rotating disk 3. One side of the rotating disk 3 is fixedly welded and the outer wall is fixedly welded to limit the side ring 2 602, and the other end of the main shaft 601 is provided with a side cavity, and an inner shaft 603 is arranged in the side cavity, and the side cavity is close to the inner wall of one side of the I-shaped rotating disk 3 A chute is provided, and one...

Embodiment 2

[0024] Such as Figure 1-2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the auxiliary charging mechanism includes a vertical plate 13. There are two vertical plates 13 and they are all fixedly connected to the top side of the workbench 1. Between the two vertical plates 13 Rotationally connected with a two-way threaded rod 14, the outer threaded sleeve of the rod body of the two-way threaded rod 14 is provided with a threaded barrel 15, one end of the two-way threaded rod 14 is connected with a rocker 16, and a bottom supporting plate 17 is arranged vertically below the bearing rotating shaft 6. The supporting plate 17 is provided with several supporting rollers 18 arranged in parallel, and a rotating supporting column 19 is rotatably connected between the bottom of the supporting plate 17 and the threaded cylinder 15 .

[0025] In this embodiment, the setting of the auxiliary loading mechanism makes it more labor-saving when people push the clo...

Embodiment 3

[0027] Such as Figure 1-2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bottom side of the bottom supporting plate 17 is provided with a vertical sliding rod 20, and the workbench 1 is provided with a vertical through hole, and the bottom ends of the vertical sliding rods 20 are respectively slidably connected. in the vertical through hole.

[0028] In this embodiment, when the height of the bottom support plate 17 is adjusted by the crank handle 16, the stability of the bottom support plate 17 is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com