Patents

Literature

282results about How to "Control rotation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

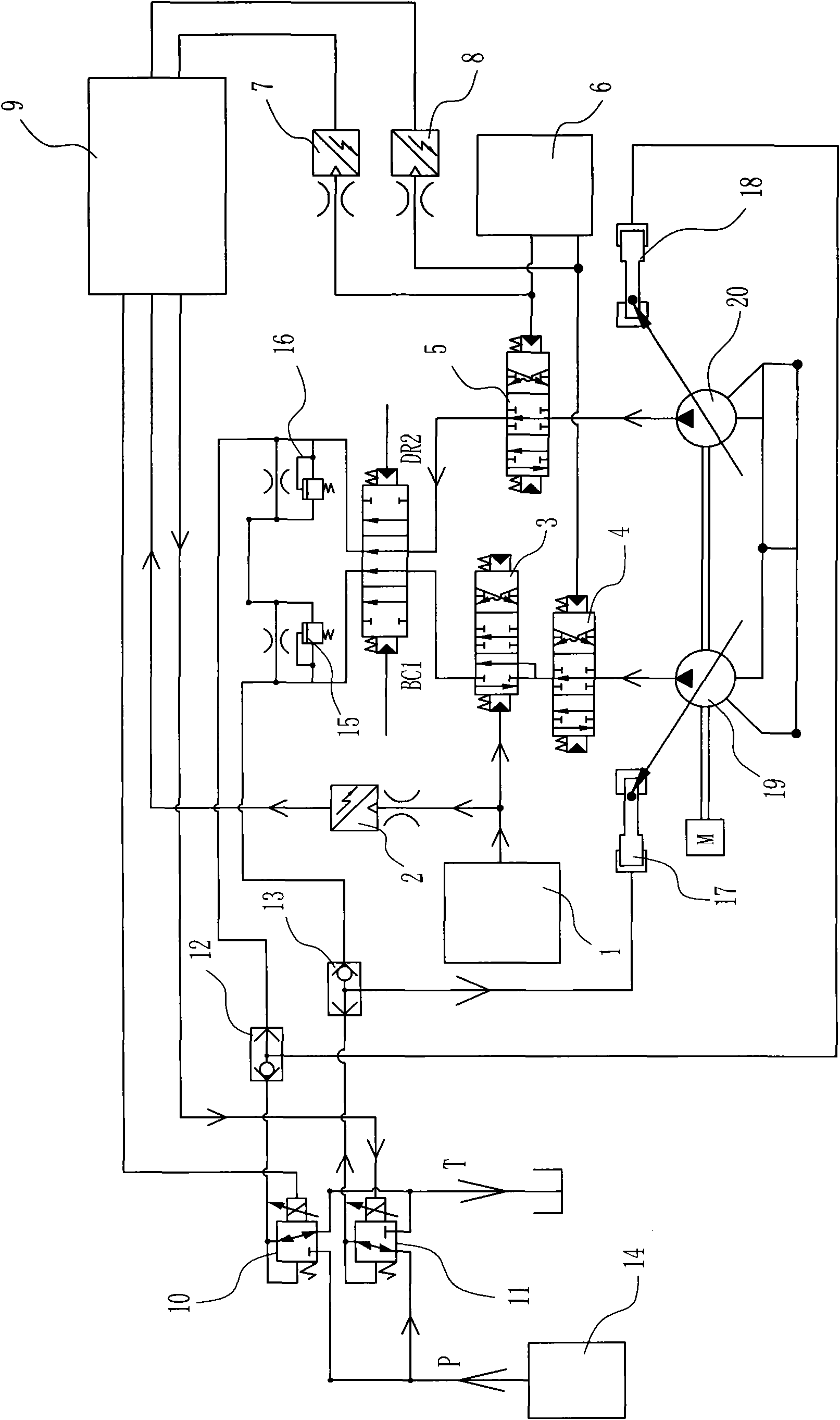

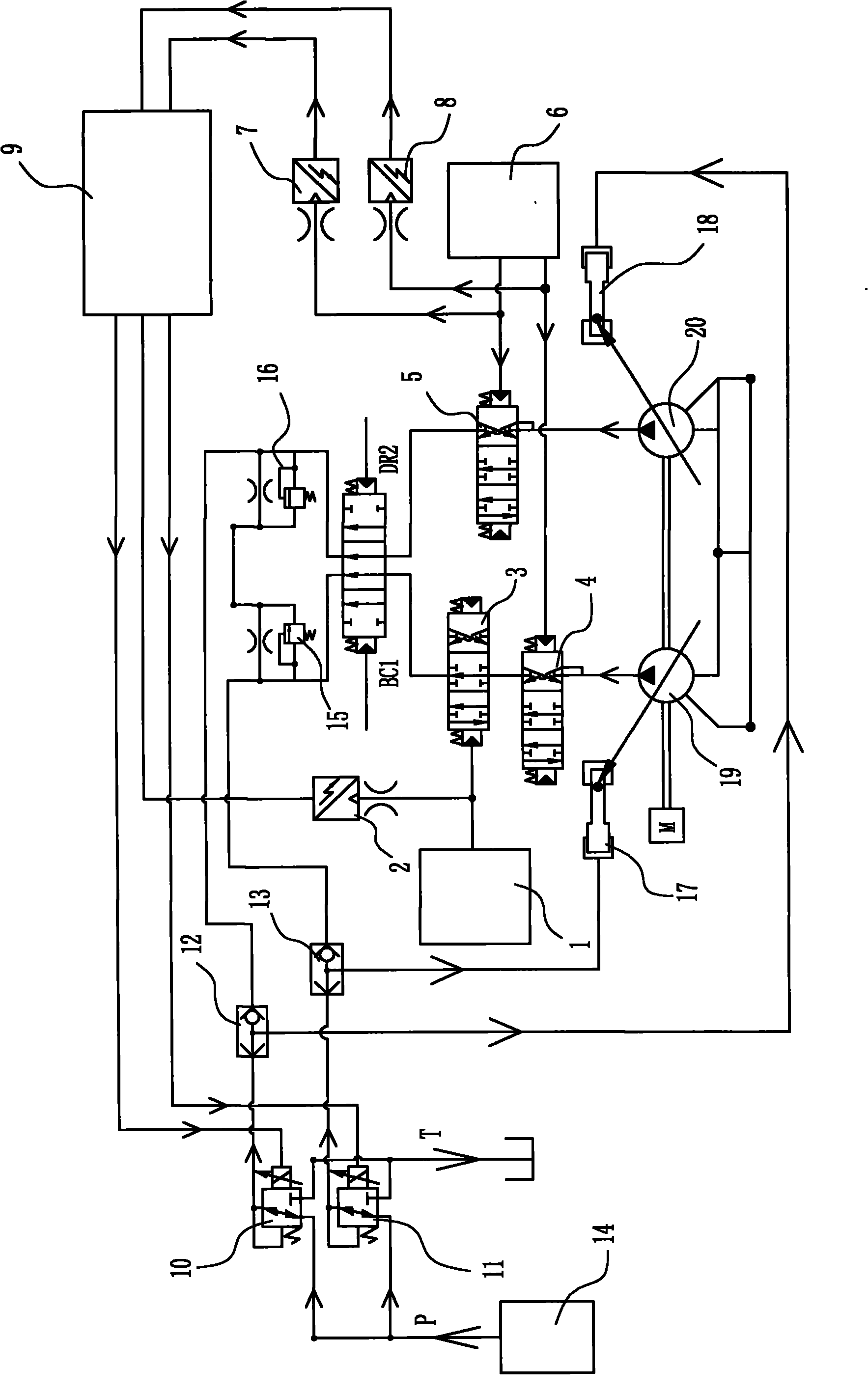

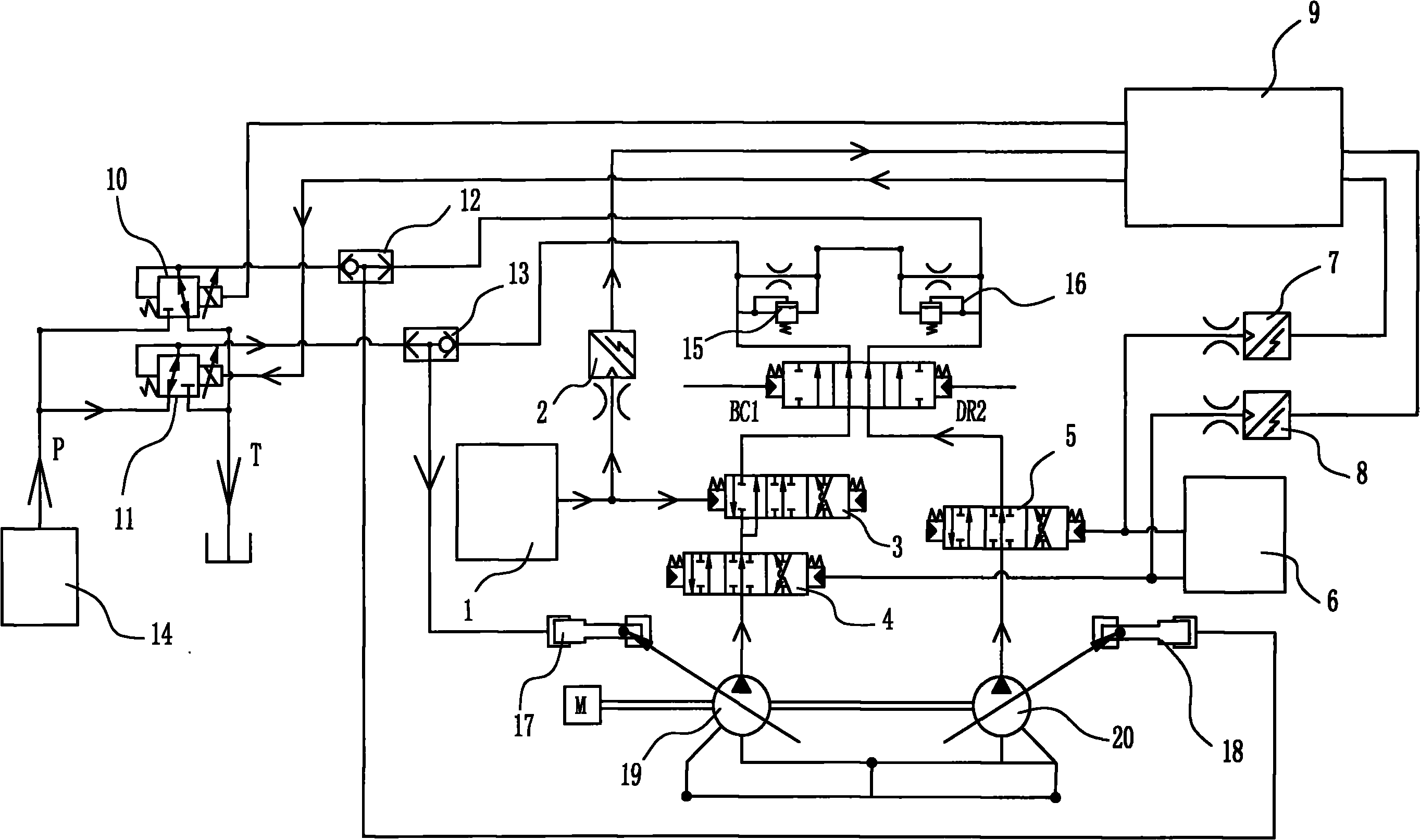

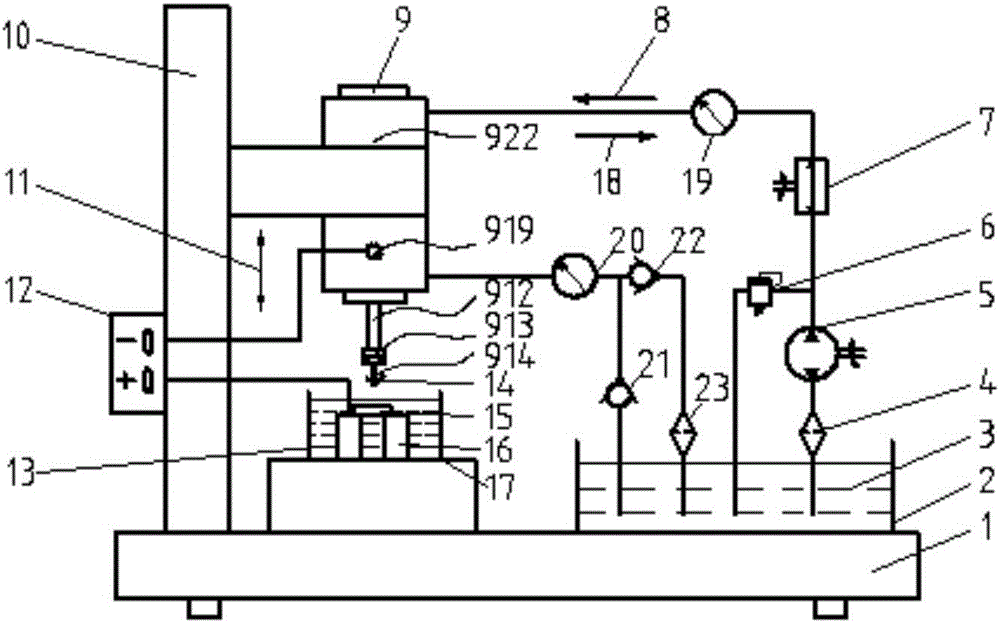

Hydraulic excavator flow rate control method and control loop

InactiveCN102011416AAvoid damageImprove work efficiencyServomotorsSoil-shifting machines/dredgersNegative feedbackElectric control

The invention discloses a hydraulic excavator flow rate control loop which comprises a hydraulic and electric control loop. The hydraulic excavator flow rate control loop is characterized by comprising two electromagnetic proportional valves and two or-gate type three-way shuttle valve, wherein the electric control ends of the proportional valves are respectively connected with the controller, the input end is connected with a pilot pressure pump of an excavator, the output end is connected with a input opening P1of one three-way shuttle valve, input openings P2 of the two three-way shuttle valves are respectively connected with a front negative feedback valve core and a back negative feedback valve of the excavator, and output openings A of the three-way shuttle valves are respectively connected with a front negative feedback regulator and a back negative feedback regulator. A method comprises the following steps of: receiving sensor signals by a controller; sending electromagnetic proportional valve electric control signals; opening proportional valve and shuttle valve paths; controlling the corresponding negative feedback regulators through the pressure of the proportional valves; and finally controlling the delivery capacity of the pump. The method realizes the limitation on the system delivery capacity through controlling the delivery capacity of the pump by using the electromagnetic proportional valves, so the flow rate maintains the normal state when a rotating or walking device works singly, and the damage to a motor caused by high flow rate is avoided.

Owner:SANY HEAVY MACHINERY

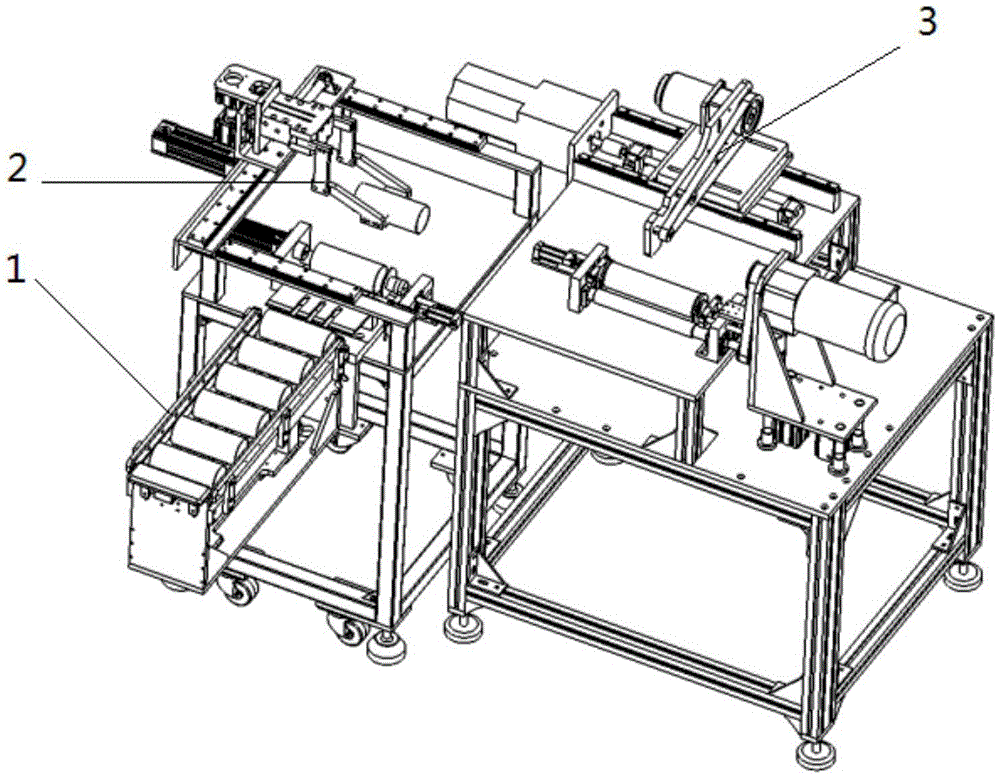

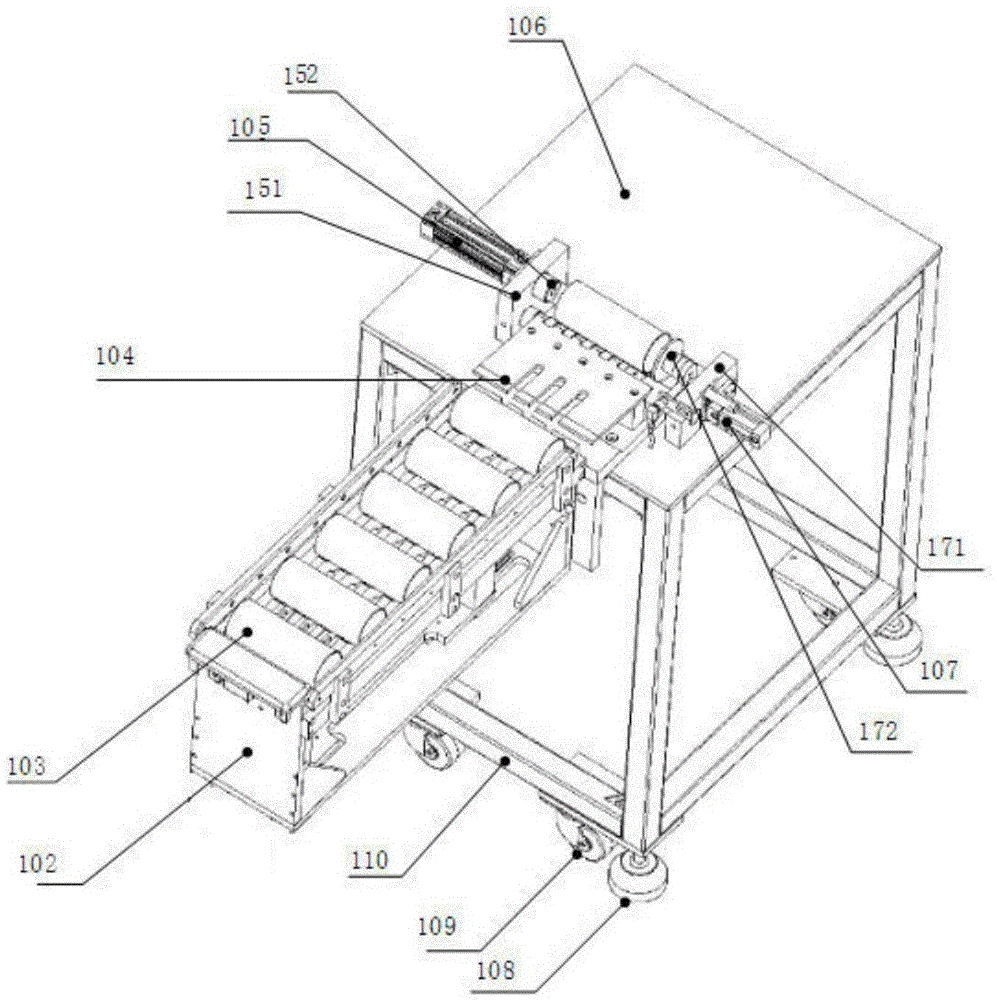

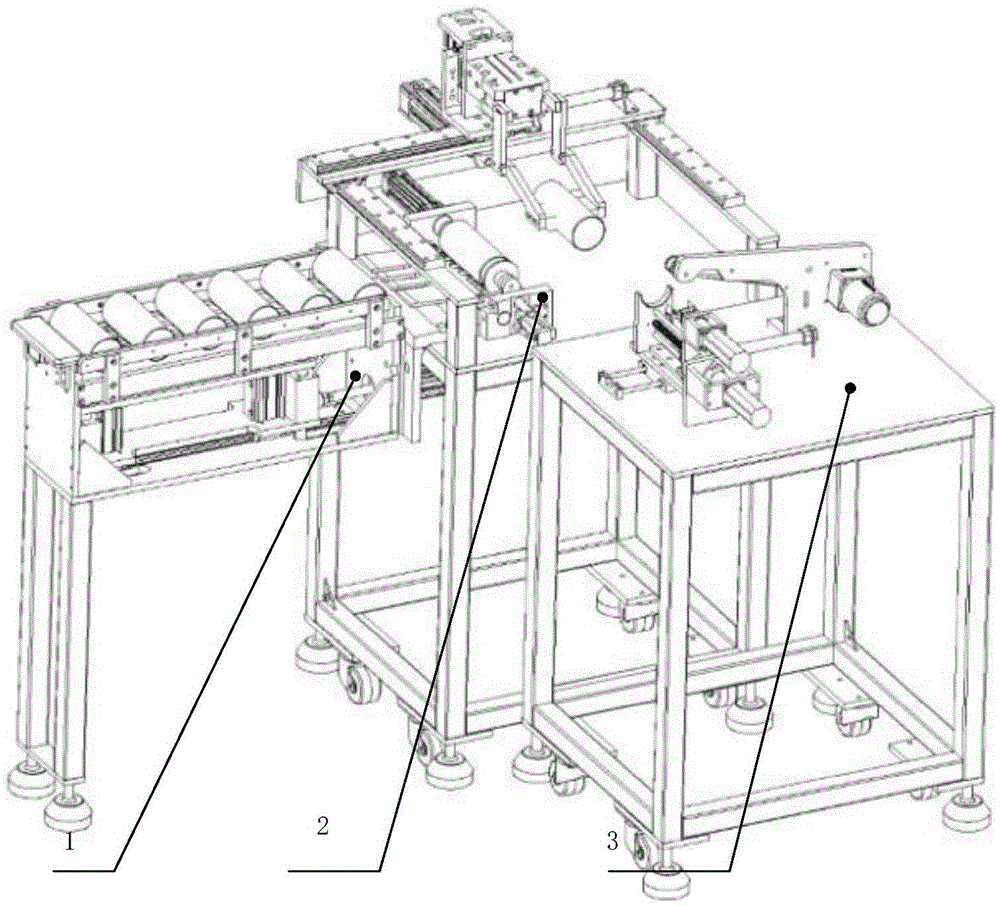

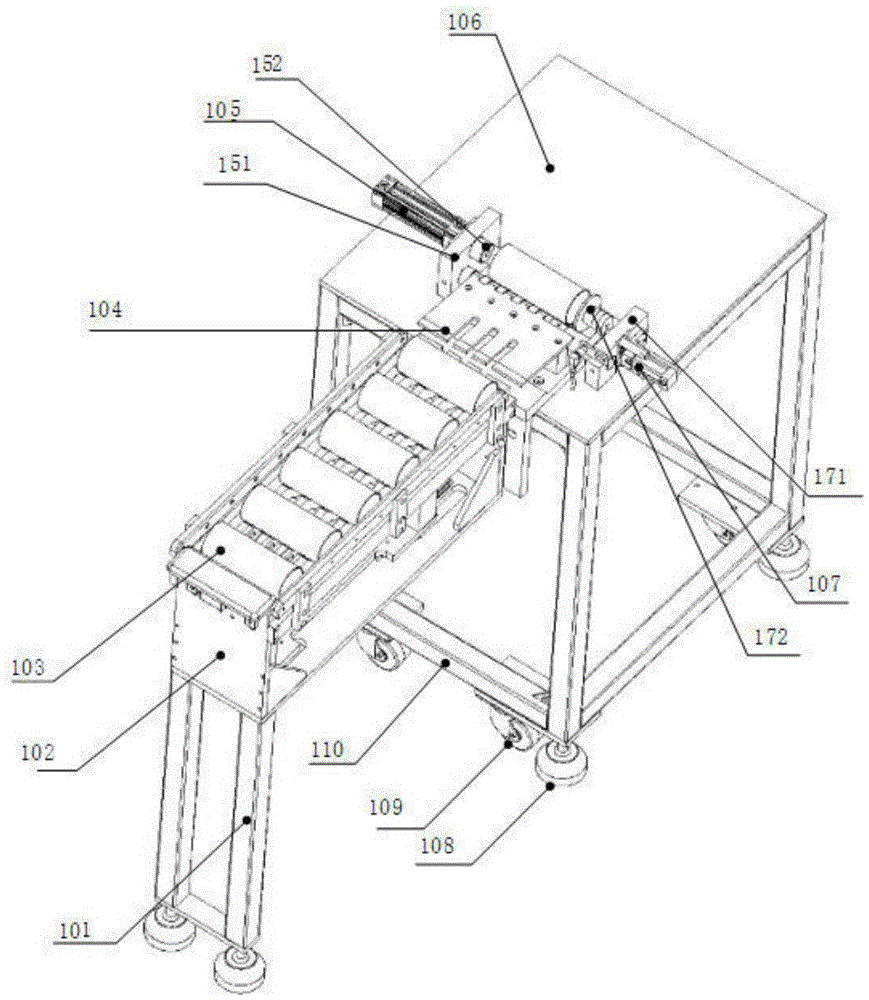

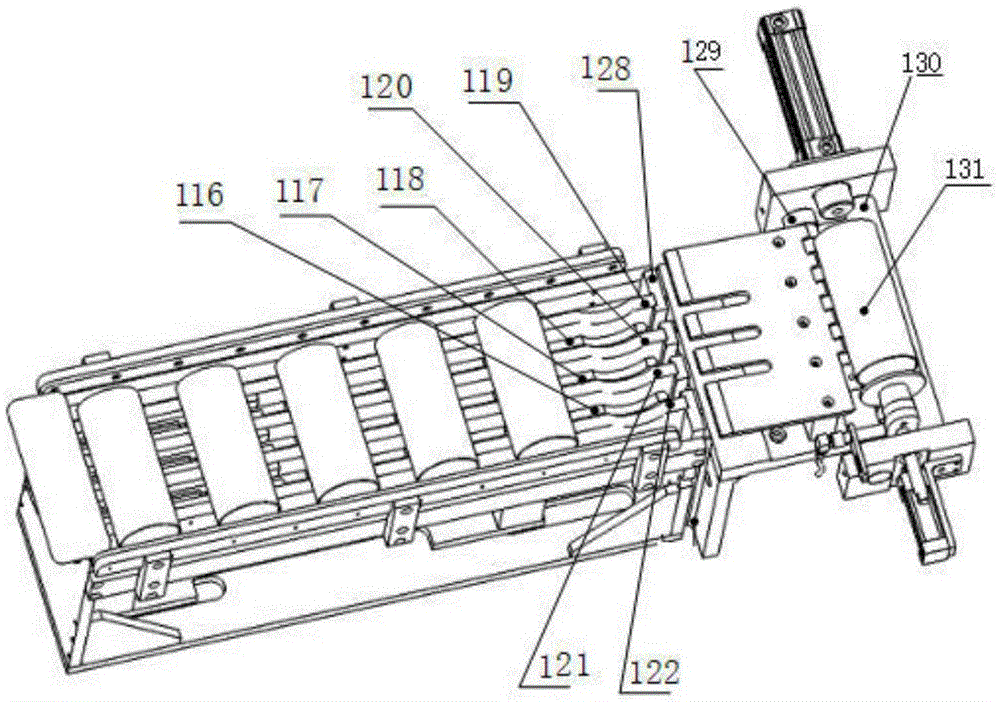

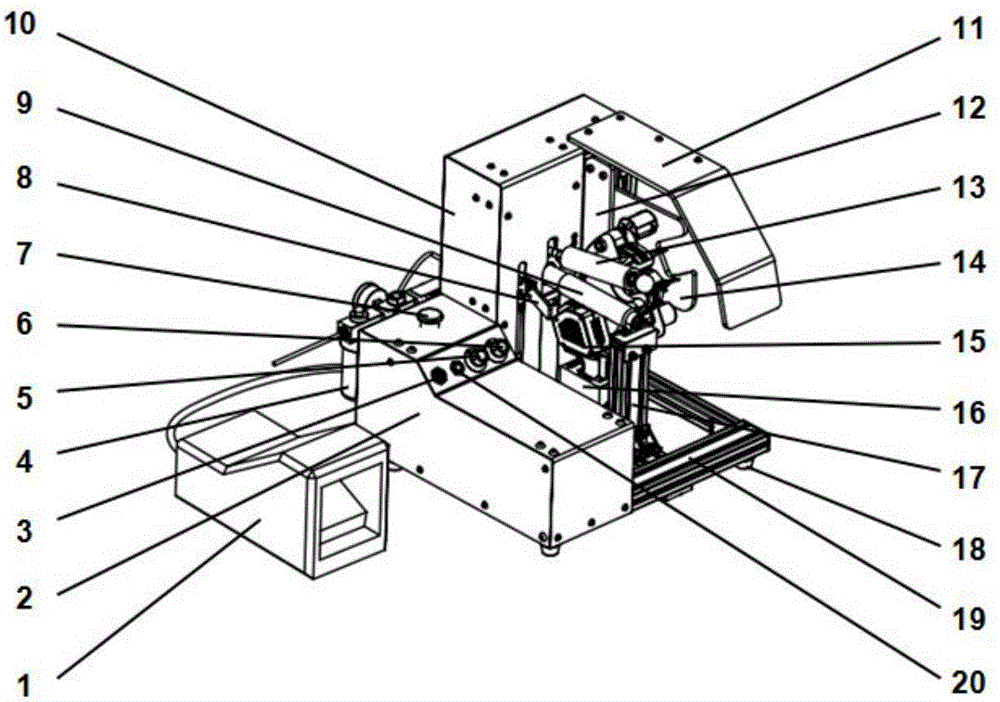

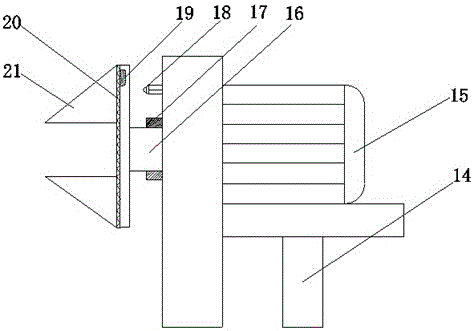

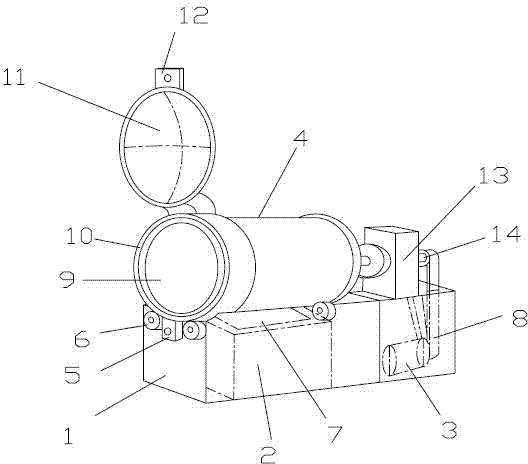

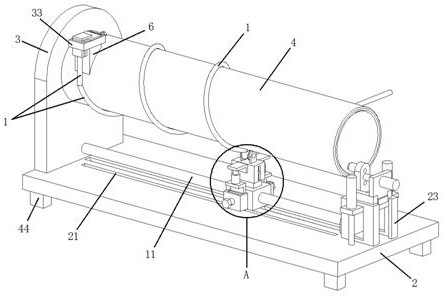

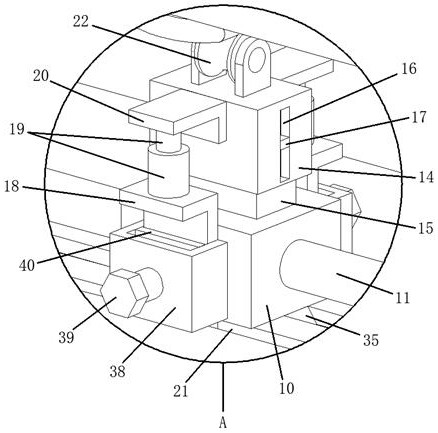

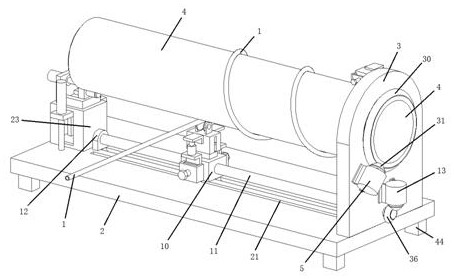

Automatic polishing system for cylindrical workpiece

ActiveCN105619213ARealize automatic deliveryIncrease the level of automationGrinding drivesBelt grinding machinesDrive wheelElectric machinery

The invention provides an automatic polishing system for a cylindrical workpiece. The automatic polishing system comprises a feeding mechanism, a feed mechanism and an outer circle polishing mechanism. The feeding mechanism comprises a feeding rack, a conveying table unit and a pressing unit, and the conveying table unit and the pressing unit are mounted on the feeding rack. The feed mechanism is mounted on a support face plate of the feeding mechanism and comprises a feed rack and a motion control unit mounted on the feed rack. The outer circle polishing mechanism comprises a polishing rack, a motion unit and a polishing unit, and the motion unit and the polishing unit are mounted on the polishing rack. The polishing unit comprises linear guide rails, a sliding base, a stepping motor support, a driving wheel, a lead screw, a servo motor, a sanding belt, a tensioning wheel, a driven wheel and a stepping motor. The automatic polishing system can completely replace manual operation, work efficiency is remarkably improved, manpower cost is reduced, and the automation level of an enterprise is improved; and all polishing parameters are precisely controlled, and the more stable and better polishing quality can be achieved.

Owner:LYNCWELL INNOVATION INTELLIGENT SYST ZHEJIANG CO LTD

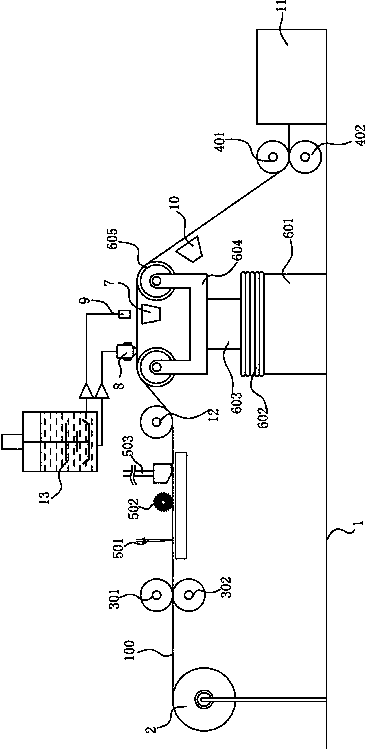

Graphene coating aluminum foil coating machine

ActiveCN105944920AUniform coatingClose contactLiquid surface applicatorsCoatingsGraphene coatingEngineering

The invention relates to a graphene coating aluminum foil coating machine. The machine comprises a base, and an aluminum foil coil, a front tension mechanism, a dust removing mechanism, a transmission mechanism, a vibration mechanism, a coating mechanism, a heating mechanism, a spraying mechanism, a drying mechanism, a back tension mechanism and a storage device arranged on the base; the dust removing mechanism, the transmission mechanism, the coating mechanism and the spraying mechanism are arranged rightly above the section of aluminum foil basal plate in a walking direction of the aluminum foil basal plate; the vibration mechanism and the heating mechanism are arranged below the section of aluminum foil basal plate; the vibration mechanism is perpendicular and corresponding to the coating mechanism and the spraying mechanism; and the heating mechanism is perpendicular and corresponding to the spraying mechanism. The machine is uniform in obtained product coatings, tight in contact with aluminum foil substrates, stable in performance, high in continuity of whole coating process and high in machining efficiency.

Owner:FOSHAN SINO SCI NANO TECH MATERIAL CO LTD

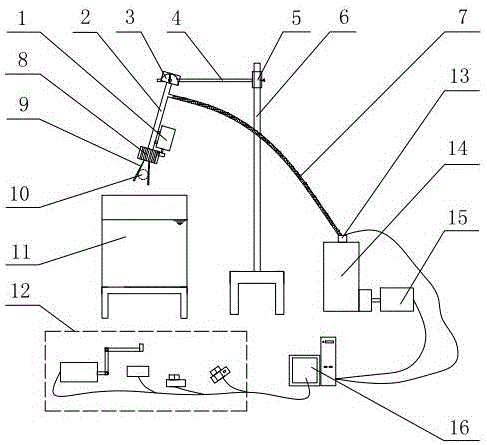

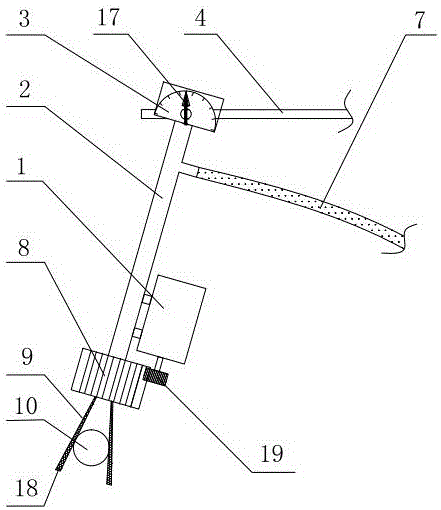

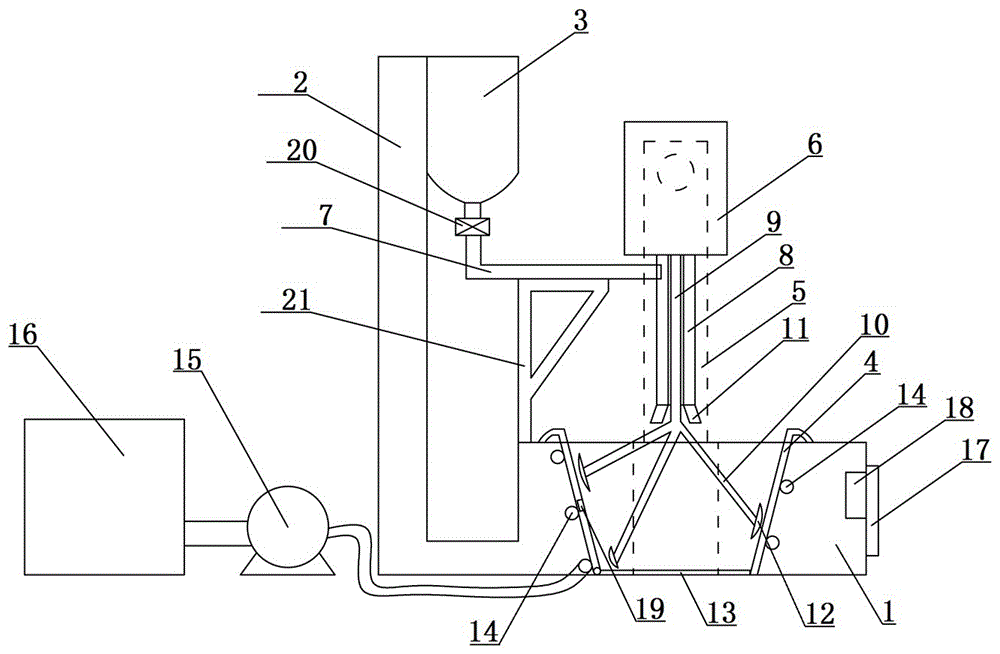

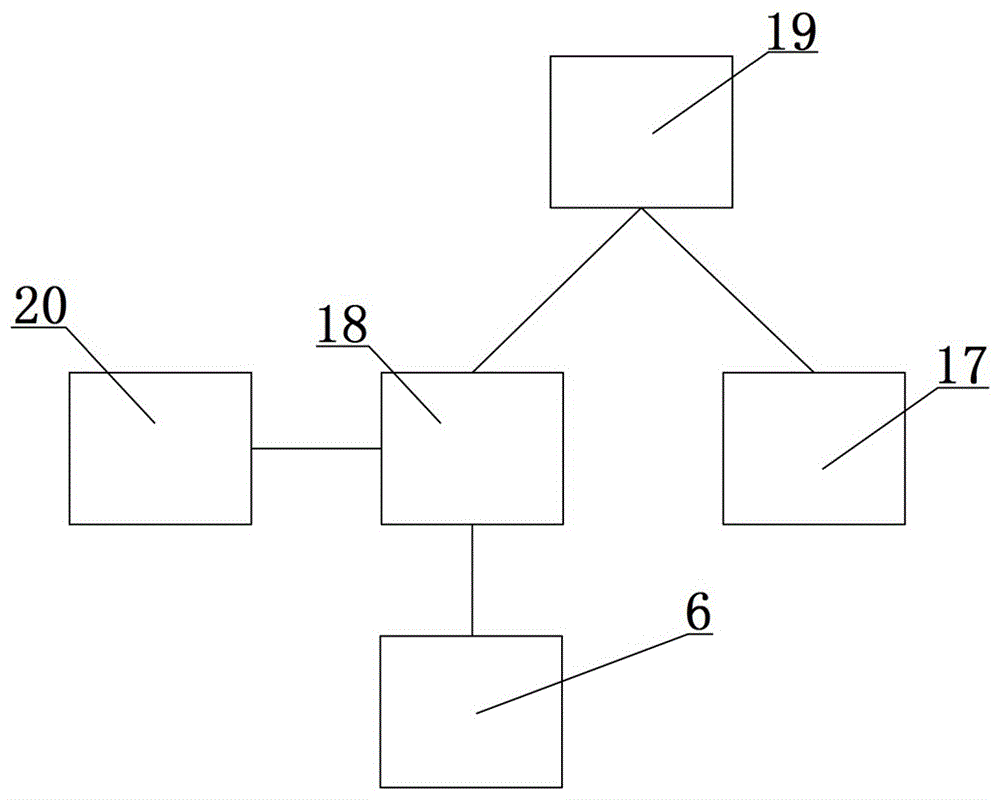

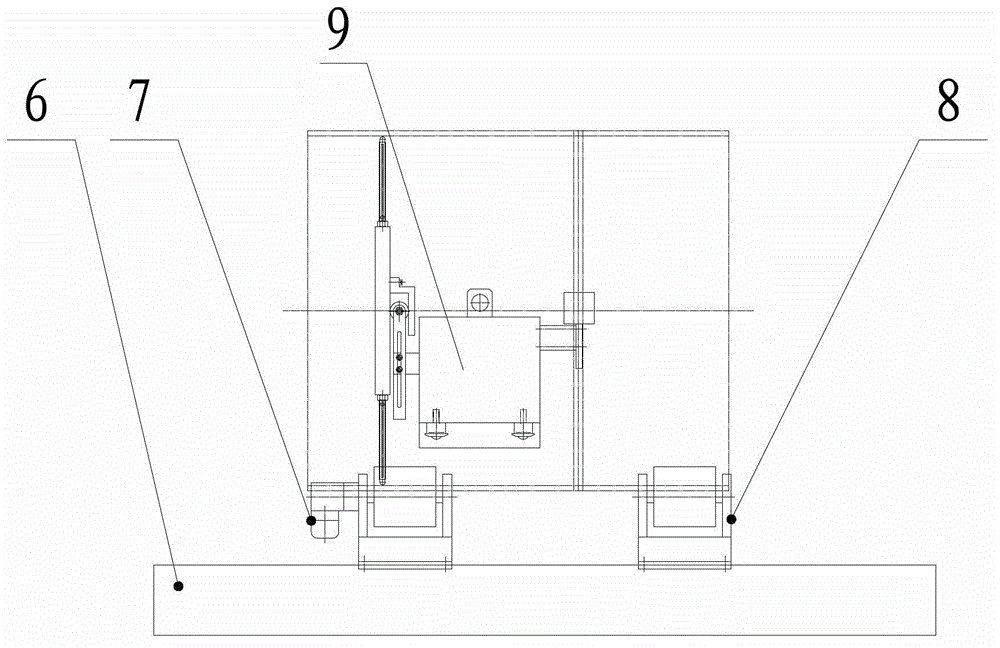

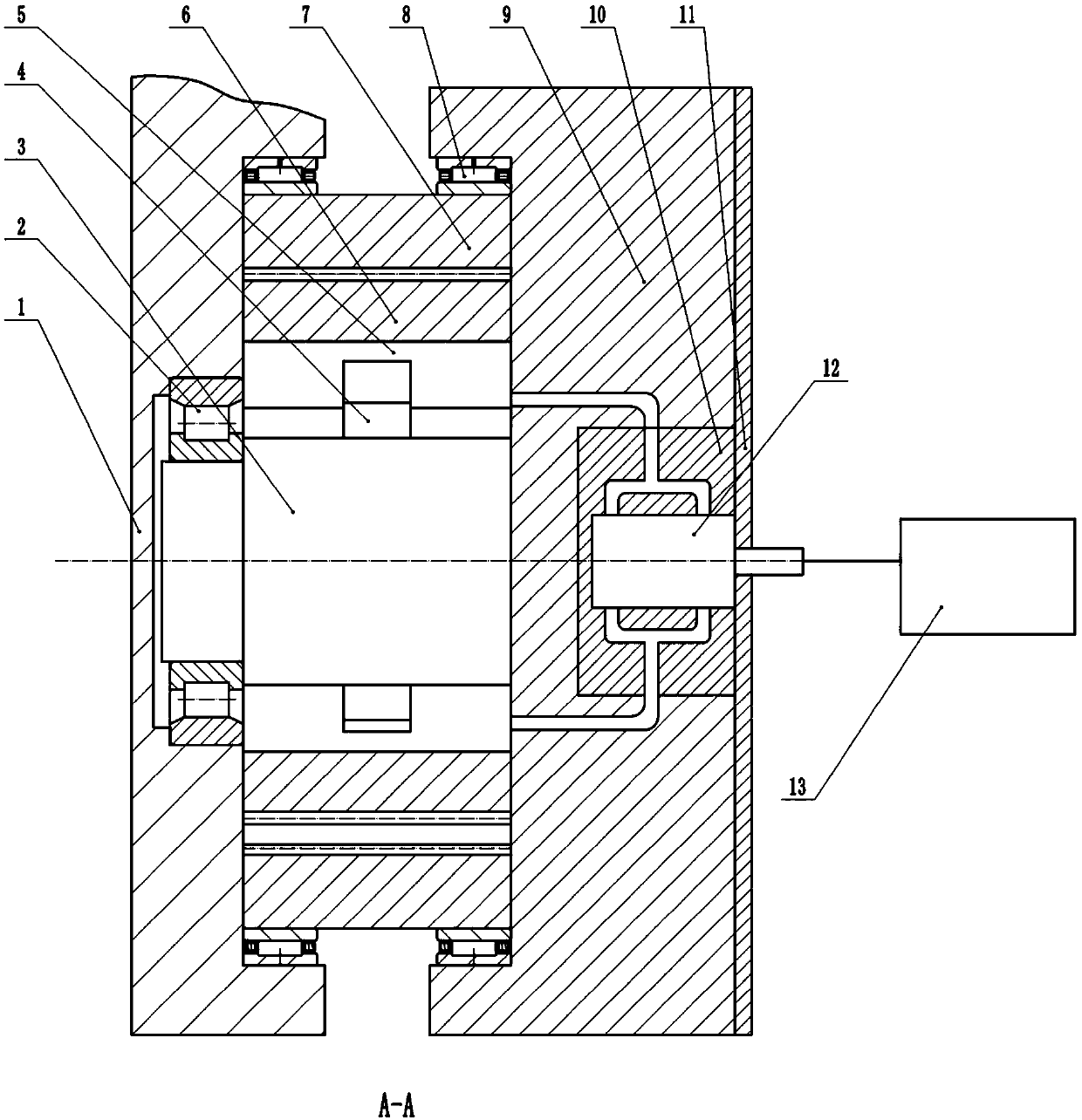

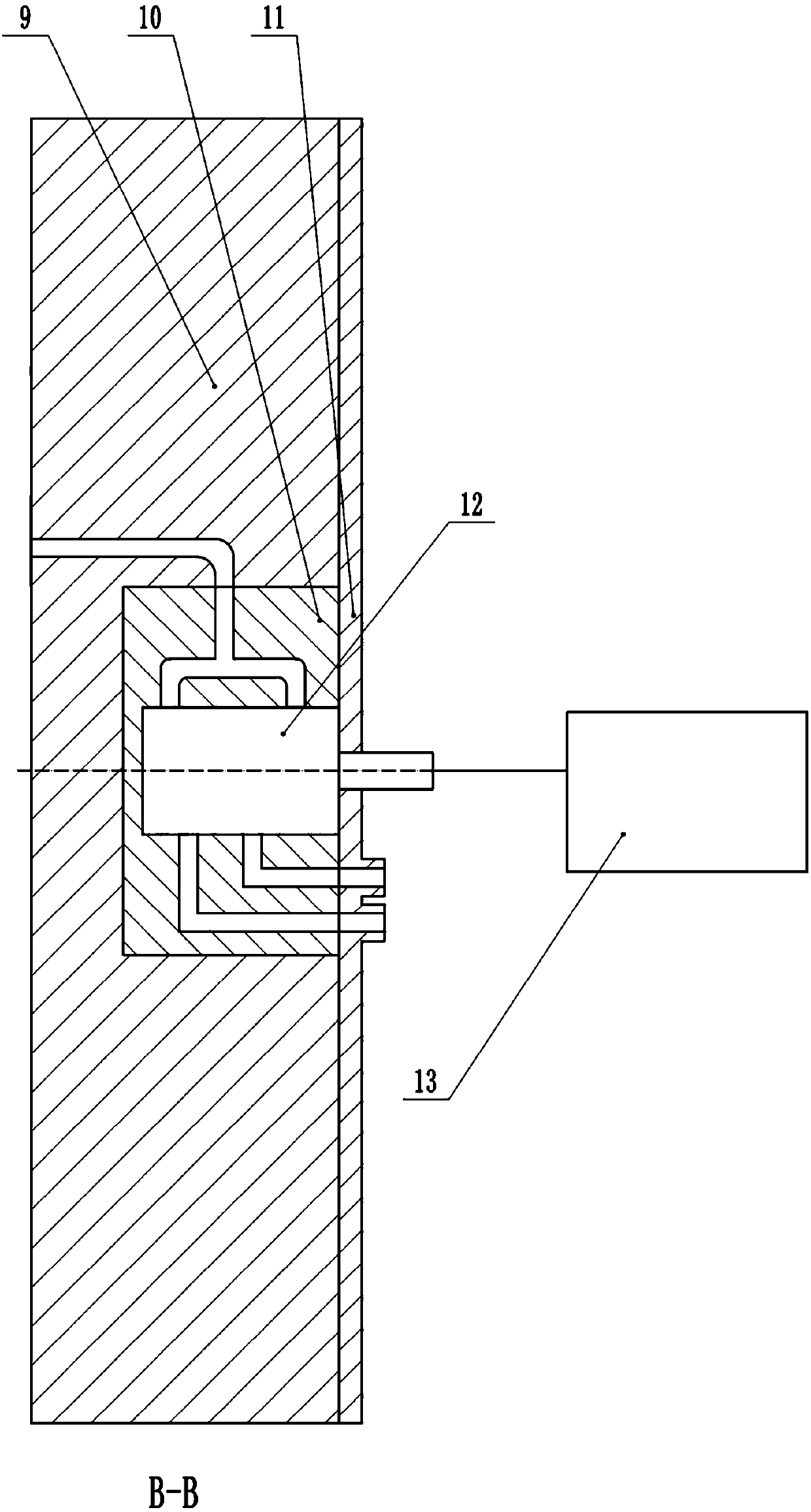

Device for stable, high-speed and variable-angle water entry experiment of rotating body

ActiveCN106353066AHigh water entry speedReduce frictionHydrodynamic testingWater tanksPositive pressure

The invention belongs to the model facility of hydraulics experiment, and specifically relates to a device for stable, high-speed and variable-angle water entry experiment of rotating body, comprising a transparent water tank, a data acquisition system which the connection is controlled by the industrial personal computer as well as a release device of water entry objects arranged above the transparent water tank, the release device of water entry objects comprises an entry angle protractor and a gas guide rod under flexible connection with a horizontal bracing piece, the bottom sleeve connection of the gas guide rod is arranged with the rotary gear and rotating head motor under coordination with the rotary gear, the motor operation drivers the rotation of the water entry objects. The gas guide rod is under sealed connection with a gas supply device via the high-pressure windpipe, the gas supply device comprises a high-pressure gas cylinder with the electro-magnetic switch valve and a air compressor connecting to the high-pressure gas cylinder, negative or positive pressure is formed in the high-pressure gas cylinder by controlling the operation of the air compressor, so as to control absorption and high-speed release of the water entry objects. The device for stable, high-speed and variable-angle water entry experiment of rotating body can stably release different forms of water entry objects under high-speed rotation at high speed, and can accurately control the object entry angle.

Owner:ZHEJIANG UNIV

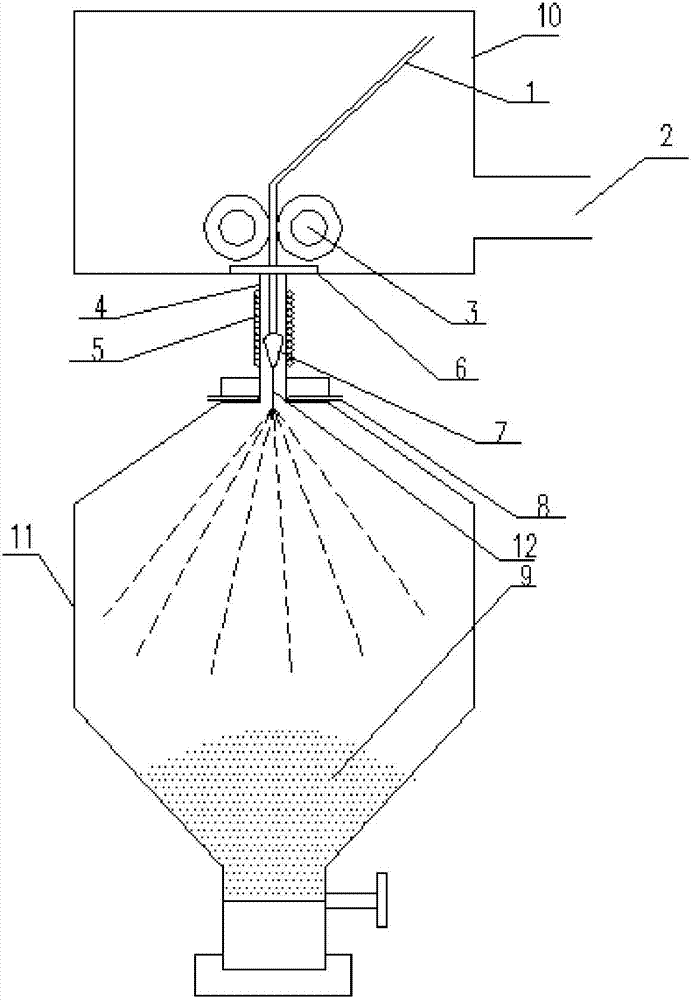

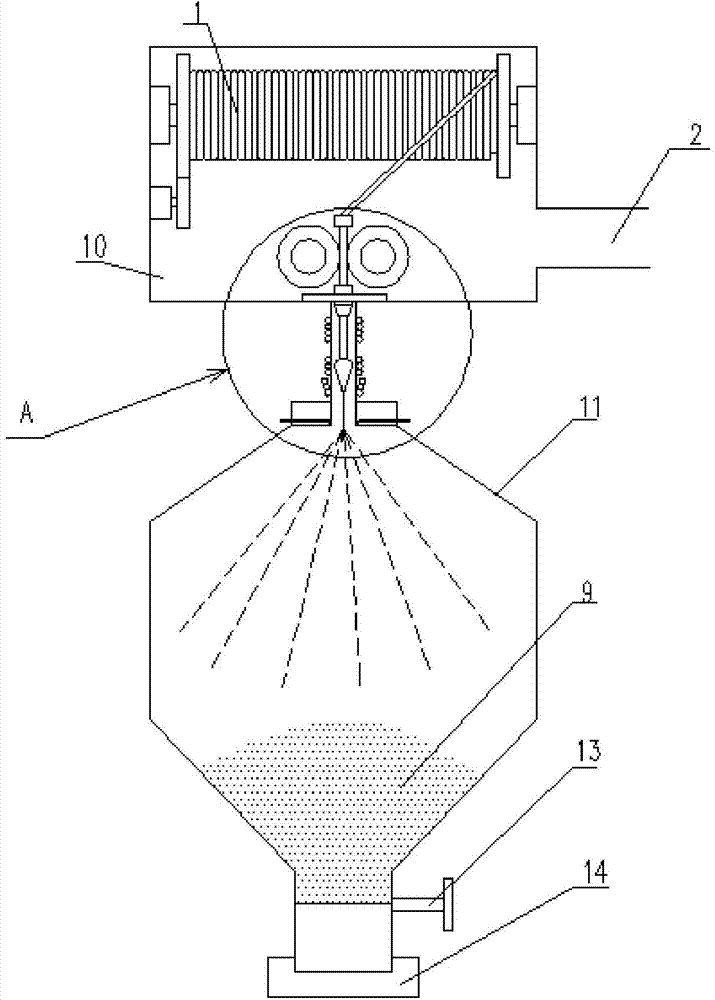

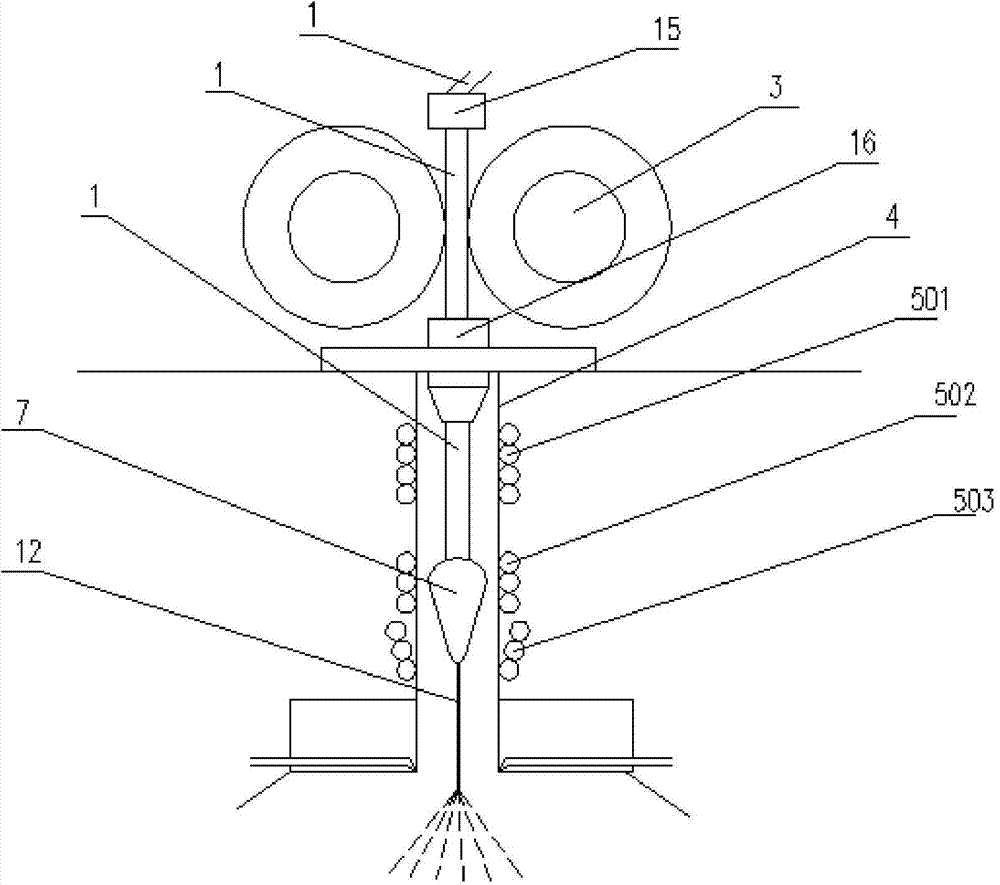

Method and device for metal powder preparation based on controllable magnetic levitation melting technology

The invention provides a method and device for metal powder preparation based on a controllable magnetic levitation melting technology. The method includes the following steps: one end of a metal wire passes through an electromagnetic field at a constant speed; the metal wire is warmed and melted in the electromagnetic field and forms metal droplets continuously; the metal droplets drop into a gas atomization area continuously; and the metal droplets are impacted, scattered and cooled by high-pressure and high-speed inert gas in the gas atomization area to form the metal powder. The device includes a vacuum cavity, a pair of rollers arranged in the vacuum cavity and a quartz glass tube with two open ends. The axial directions of the two rolls are parallel, the rotation directions of the two rollers are opposite, and a gap between rotation surfaces of the two rollers is matched with the diameter of the metal wire. One end of the quartz glass tube is connected with an outlet of the metal wire, and the other end of the quartz glass tube is connected with a gas atomization nozzle and a powder collector successively. A coil is wound around the quartz glass tube. The method and device for metal powder preparation based on the controllable magnetic levitation melting technology can stably control the flow rate of melting metal liquid and can satisfy industrial production requirements.

Owner:CHINA JIUYUAN HI TECH EQUIP

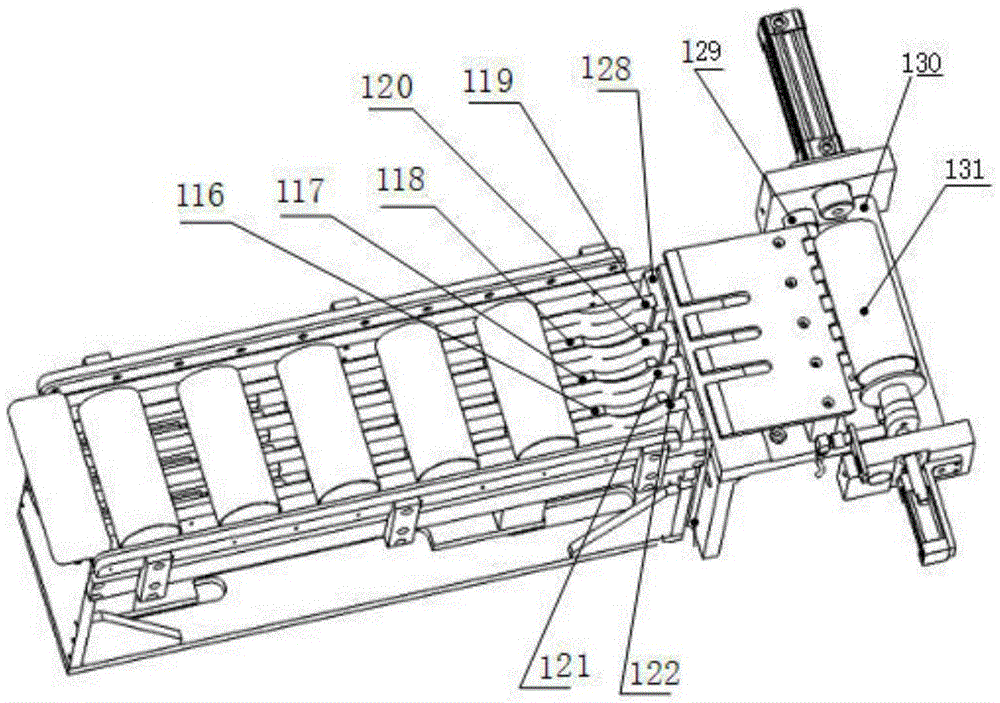

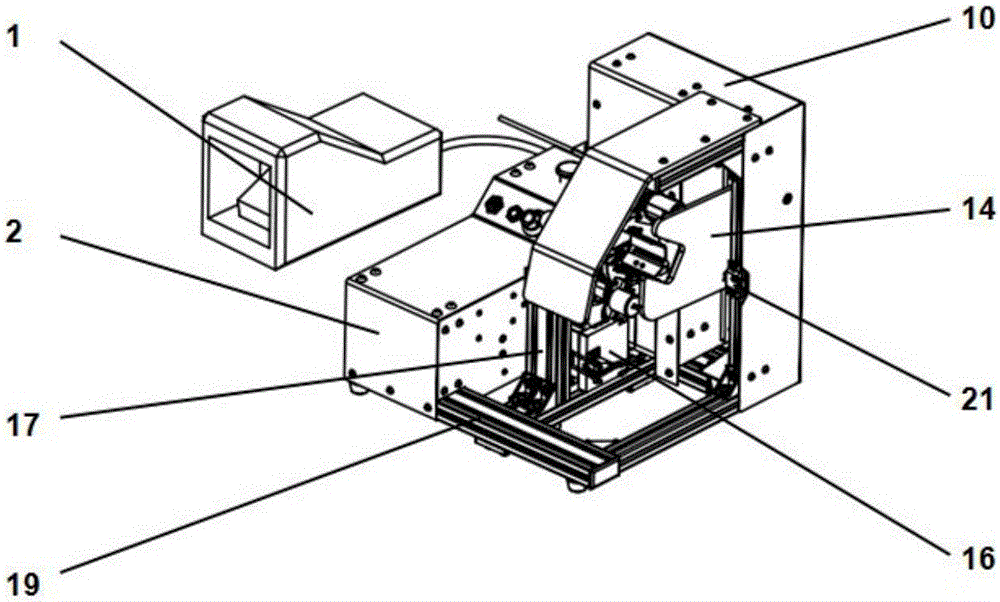

Automatic polishing system for stainless-steel cups

InactiveCN105619212ARealize automatic deliveryRealize automatic clampingGrinding drivesBelt grinding machinesEngineeringMotion control

The invention provides an automatic polishing system for stainless-steel cups, which comprises a conveying mechanism, a feeding mechanism and an external polishing mechanism, wherein the conveying mechanism comprises a conveying frame, a conveying table unit and a pressing unit; the conveying table unit and the pressing unit are mounted on the conveying frame; the feeding mechanism is mounted on a bracket faceplate of the conveying mechanism and comprises a feeding frame and a motion control unit mounted on the feeding frame; the external polishing mechanism comprises a polishing frame, an abrasive belt control unit and a part motion control unit; and the abrasive belt control unit and the part motion control unit are mounted on the polishing frame. The automatic polishing system for the stainless-steel cups can completely replace manual operation, remarkably improves the working efficiency, lowers the labor cost and increases the automation level of enterprises. Meanwhile, the automatic polishing system for the stainless-steel cups realize accurate control of polishing parameters and can achieve more stable and favorable polishing quality.

Owner:望江县雷创科技有限公司

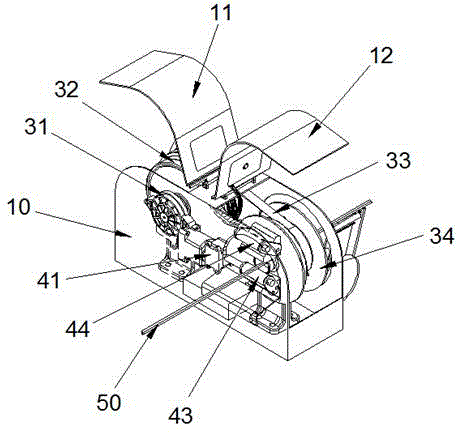

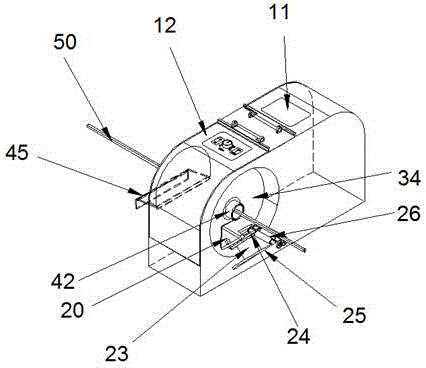

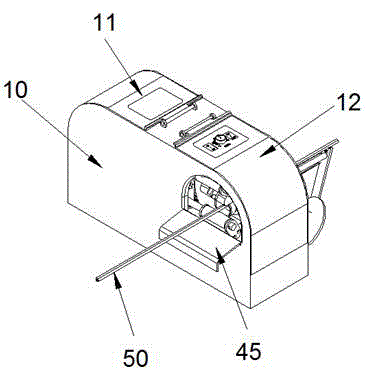

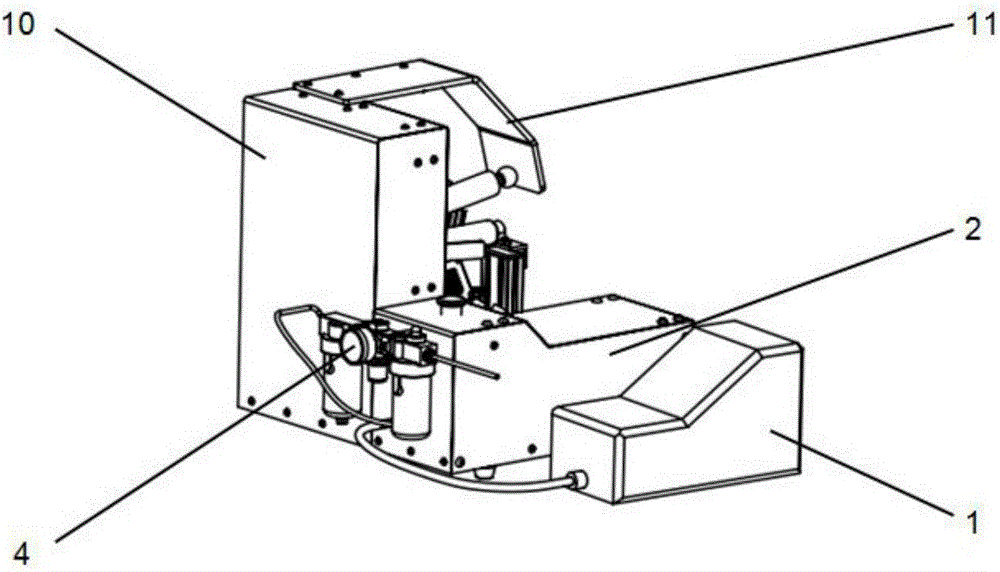

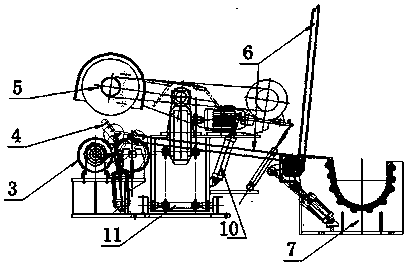

Wire harness adhesive tape winding machine

The invention discloses a wire harness adhesive tape winding machine. The wire harness adhesive tape winding machine comprises the components of a body, an adhesive tape winding mechanism which is arranged on the body, an adhesive tape winding driving mechanism which drives the adhesive tape winding mechanism to operate, and a wire harness traction mechanism. The adhesive tape winding mechanism comprises an adhesive tape rack base, an adhesive tape shaft, an adhesive tape guiding bracket and a roller pair. The adhesive tape winding driving mechanism comprises a first motor and a belt conveying device. The wire harness traction mechanism comprises a second motor, a wire gland, a dynamic pressure bobbin and a static pressure bobbin. The wire harness is fed between the static pressure bobbin and the dynamic pressure bobbin and is output in the wire gland. The wire harness adhesive tape winding machine is suitable for performing wire harness packaging through diversified adhesive tapes and effectively prevents wire harness scratch. Furthermore a suitable wire gland is correspondingly changed according to the outer diameter of the packaged wire harness. The wire harness adhesive tape winding machine has advantages of effectively controlling movement range of the wire harness, reducing vibration, realizing adjustable and controllable winding process, replacing traditional semi-automatic winding operation, reducing labor intensity, improving production efficiency and obtaining high economic benefit.

Owner:SHANGHAI MENSA AUTO PARTS MFG

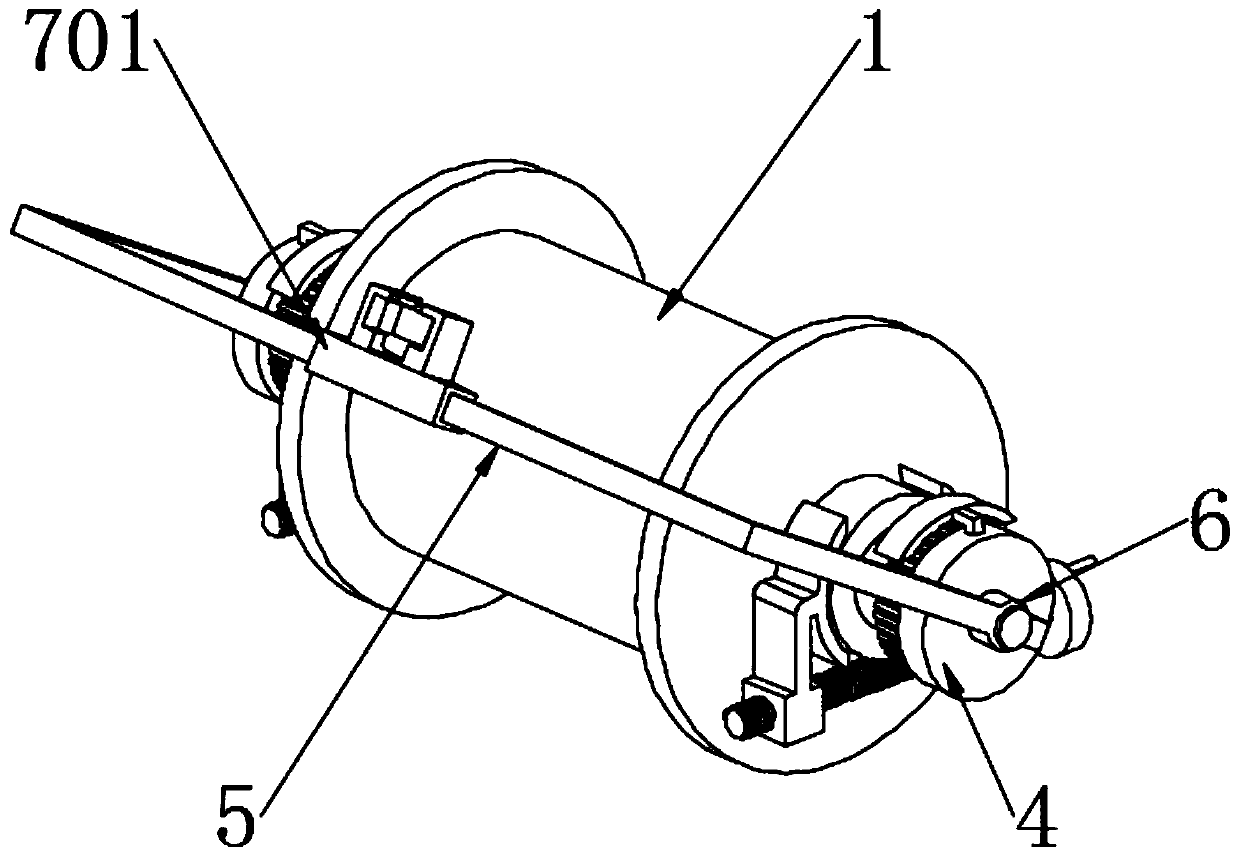

Mechanical damping passive pay-off unit

ActiveCN110642092AScientific and reasonable structureEasy to useFilament handlingGear wheelThreaded rod

The invention discloses a mechanical damping passive pay-off unit. The mechanical damping passive pay-off unit comprises a pay-off wheel and a center shaft, wherein the center shaft is located in thecenter of the pay-off wheel and penetrates through the pay-off wheel. Damping mechanisms are arranged on the two sides of the center shaft respectively. The mechanical damping passive pay-off unit isscientific and reasonable in structure, and safe and convenient to use; because of the damping mechanisms, friction is generated through contact between each damping fin and the corresponding rotary plate, the pay-off speed of the pay-off wheel can be controlled, and the pay-off wheel can carry out pay-off work stably; because of connecting rods, lead screws, threaded rods and nuts, the separationdistance between each threaded rod and the corresponding nut is adjusted by turning the corresponding lead screw to adjust the gluing force between the corresponding damping fin and the correspondingrotary plate, then friction is changed to achieve the effect of having control over the rotating speed of the pay-off wheel, pay-off is smooth and steady, and the tension of cables is kept as well; and because adjusting gears are driven by rotary shafts to rotate, then racks are driven to move upwards or downwards to enable each positioning toothed plate and the corresponding gear to be separatedor be in engagement connection, the gears can rotate freely when each positioning toothed plate and the corresponding gear are separated, and when each positioning toothed plate and the correspondinggear are separated, the gears are locked, the pay-off wheel is locked as well, and the mechanical damping passive pay-off unit is more convenient to use.

Owner:NANJING INST OF RAILWAY TECH

fall protection system

InactiveCN102281923AControl rotation speedReduce rotation speedLiquid resistance brakesSafety beltsFall protectionRotation velocity

A fall protection system comprising a line wound onto a rotatable pulley having a centrifugal clutch which activates a gearbox which in turn drives an input shaft of a hydraulic actuator whereby the hydraulic actuator controls the rate of rotation of the pulley, and a secondary brake which slows the rotational speed of the pulley should it exceed a predetermined speed, whereby in use, the line isattached to a user to restrain a fall and then the system facilitates unwinding of the line at a controlled speed to effect descent.

Owner:FALLSAFE TECH PTY LTD

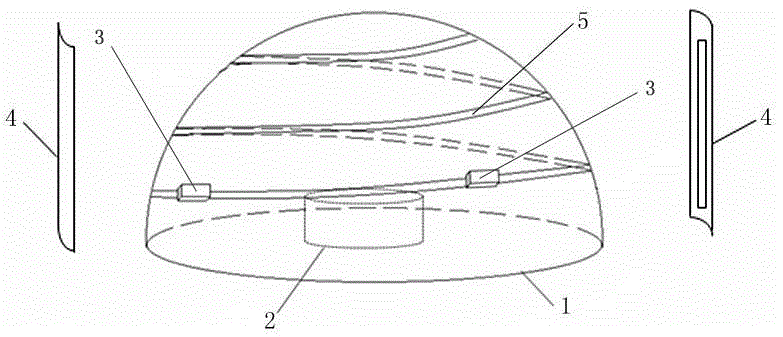

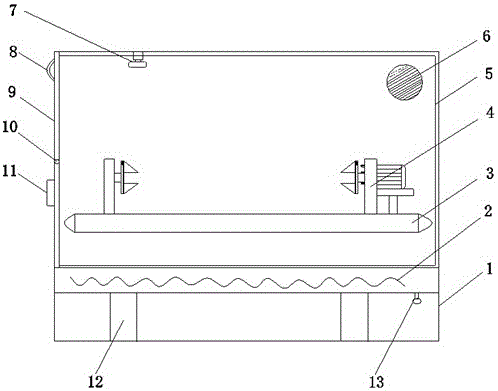

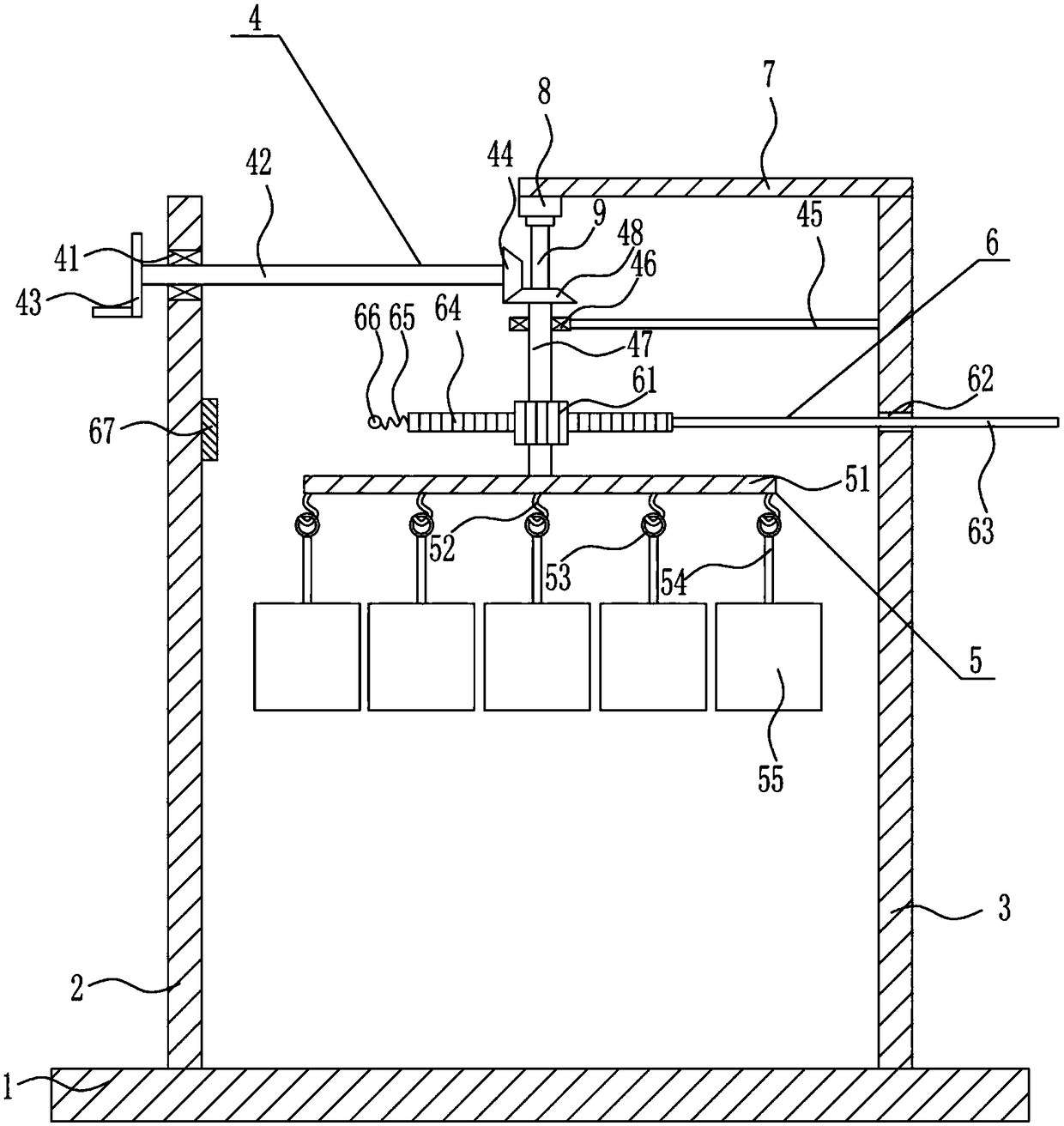

Hemispherical image acquiring box body of 3D printer

ActiveCN105415686ARealize all-roundRealize automatic collectionAdditive manufacturing apparatusStands/trestles3d printerComputer science

The invention aims to provide a hemispherical image acquiring box body of a 3D printer. The hemispherical image acquiring box body comprises a box body, an arranging platform, an image acquiring device and a light source, wherein the box body is a hollow hemisphere; the arranging platform is arranged inside the box body and positioned at the center of the hollow hemisphere; helical guide rails are arranged from top to bottom on the inner wall of the box body; the image acquiring device is mounted on the guide rails and can slide along the guide rails. The hemispherical image acquiring box body of the 3D printer can be used for shooting an object in all directions and is capable of preventing influences caused by human factors and improving the printing quality.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

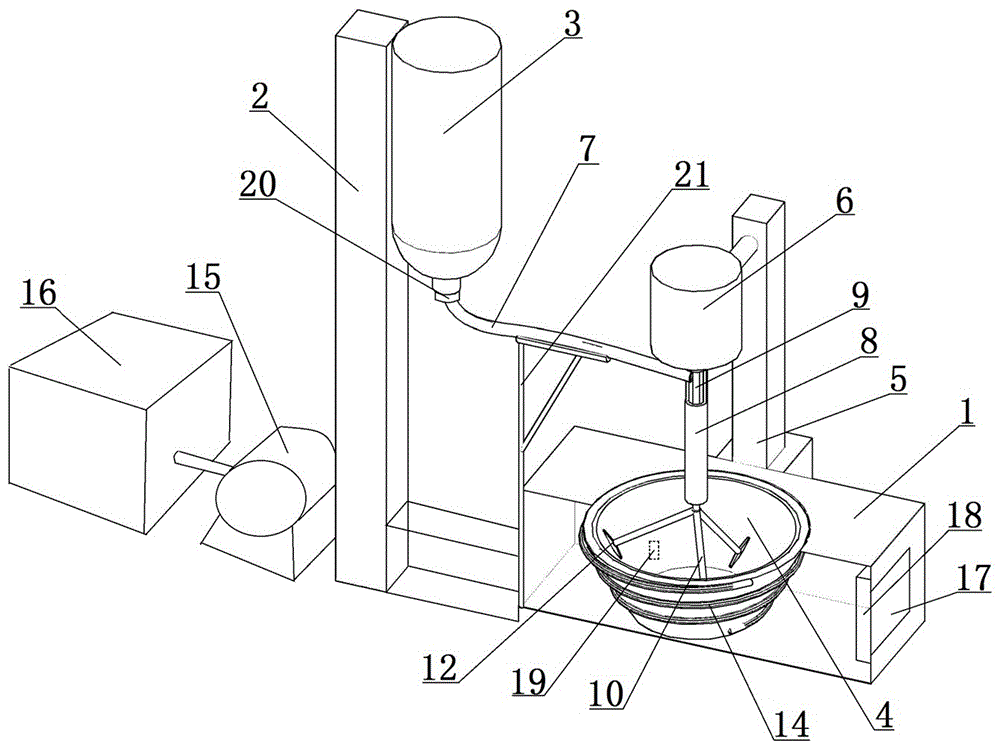

Production device of liquid nitrogen ice cream and making technology thereof

The invention discloses a production device of liquid nitrogen ice cream and a making technology thereof. The production device comprises a pedestal and a support which are fixedly connected. The top of the support is movably connected to a liquid nitrogen tank. A stirring container is arranged inside the pedestal. One side of the pedestal is provided with a motor bracket, the top of which is fixedly connected to a motor. A stirring device is fixedly connected on the motor. The liquid nitrogen tank is connected to the stirring device through a conduit. The invention has the following advantages: the ice cream production device is full-automatic; through cooperation of a PLC control module and a solenoid valve and the motor, addition amount of nitrogen and rotational speed of the motor can be accurately controlled, nitrogen and ice cream are mixed more uniformly, scattering of shaped ice cream due to too high rotational speed of the motor is avoided, ice cream and additives are mixed more fully, mouthfeel of ice cream is greatly improved, and the produced ice cream is externally crispy and internally soft and has unique mouthfeel; and due to addition of nitrogen during the stirring process, preservation performance of ice cream is better.

Owner:甘肃祁牧乳业有限责任公司

Tipping paper placing device

The invention belongs to the technical field of cigarettes and particularly relates to a tipping paper placing device. The tipping paper placing device comprises a box body, a paper disc shaft, a brake arm and a swing arm, wherein the paper disc shaft is arranged on the box body, the rotating speed of the paper disc shaft can be controlled by the brake arm and the swing arm, one end of the brake arm is arranged on the box body, the other end of the brake arm is connected with one end of the swing arm capable of driving the brake arm to rotate, and the middle of the brake arm is attached to the surface of the paper disc shaft; the swing arm is arranged on the box body, the two ends of the swing arm can swing up and down, and the other end of the swing arm is connected with tipping paper in a sleeving way. According to the tipping paper placing device, the swing arm and the brake arm are additionally arranged, the tension of the tipping paper can be automatically adjusted, the rotating speed of the paper disc shaft can be controlled, and the phenomenon that the tipping paper skips and deviates due to the inconsistent length of the tipping paper in the paper placing process is solved. The tipping paper placing device has the advantages of reasonability in design, simplicity in structure, convenience in use, easiness in realization, reduction in defective rate and improvement in work efficiency.

Owner:HUBEI CHINA TOBACCO IND

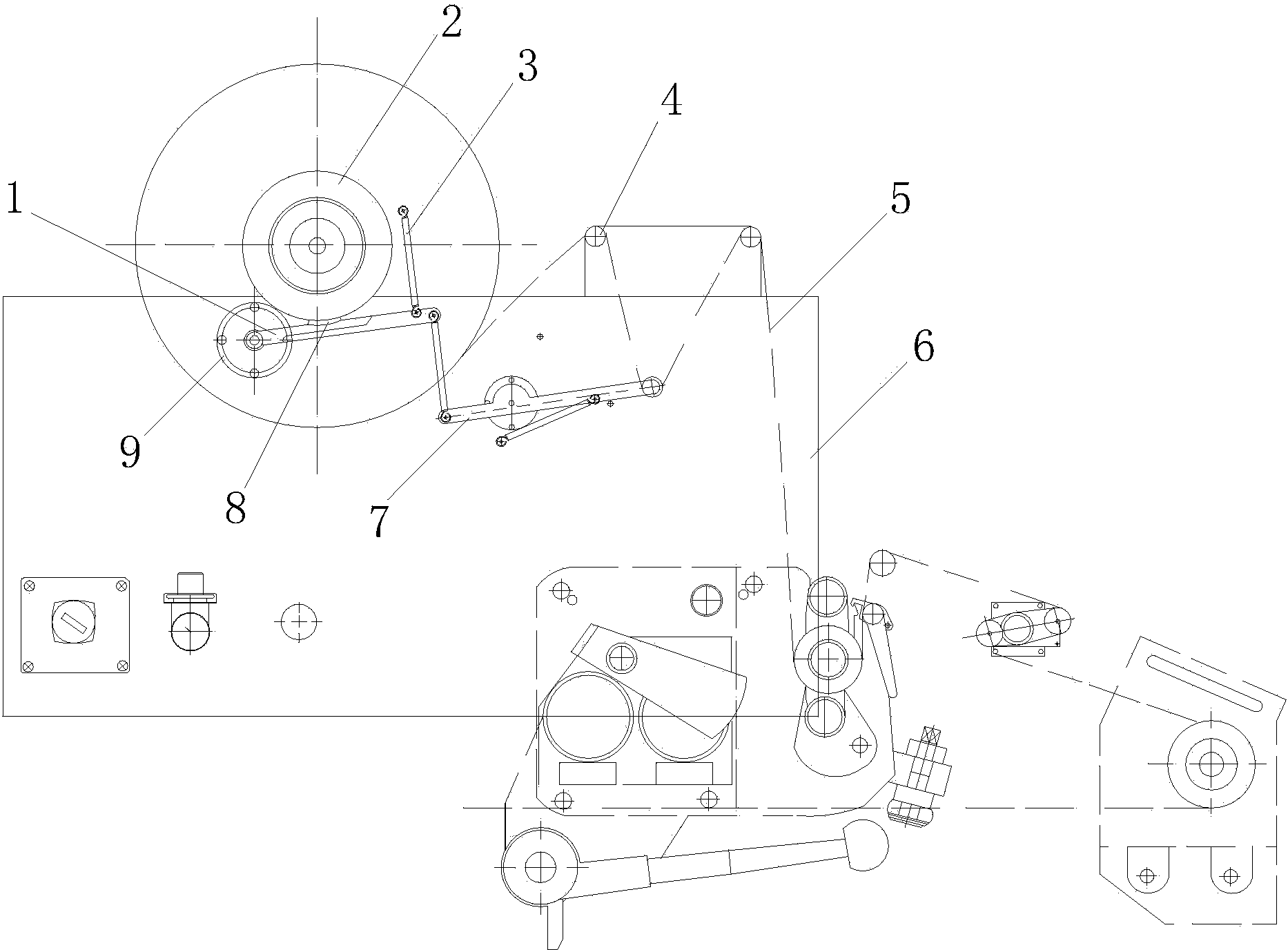

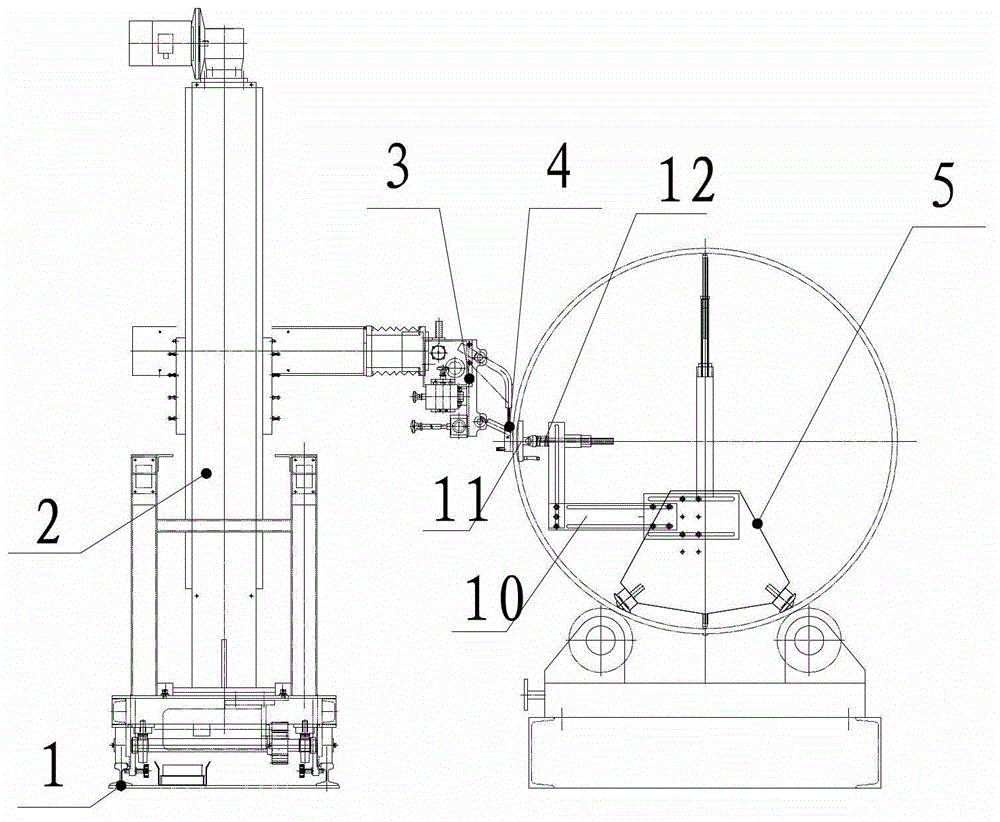

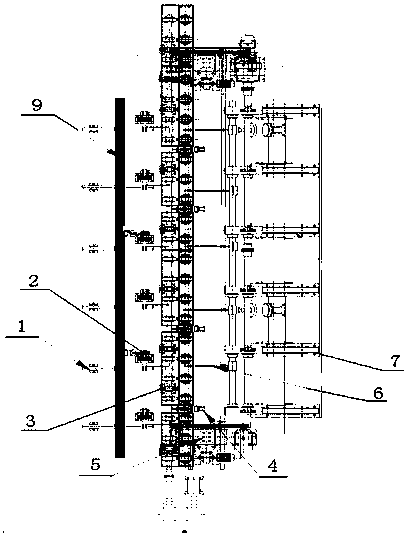

Circumferential seam single-pass electro-gas welding machine

ActiveCN102941393AWelding arc length is constantMeet molding timeElectrode supporting devicesMoulding deviceManufacturing engineering

The invention discloses a circumferential seam single-pass electro-gas welding machine which is mainly composed of a walking track, a cantilever welding machine, an electro-gas welding head, a front side water-cooling slide block, a back-side forming device, a roller frame base, a driving roller frame and a driven roller frame. The cantilever welding machine is installed on the walking track; the electro-gas welding head and the front side water-cooling slide block are integrated to be installed on the cantilever welding machine; the driving roller frame and the driven roller frame are installed on the roller frame base; a barrel to be welded is placed on the roller frame; and the back-side forming device is installed in the barrel during welding. The circumferential seam single-pass electro-gas welding machine has the advantages that the problem of low efficiencies brought by a layer upon layer stacking welding process is solved so that efficiencies are improved; and simultaneously, welding qualities are high, welding control is accurate, and technological blank of the electro-gas welding machine is filled.

Owner:NANJING AUTO ELECTRIC

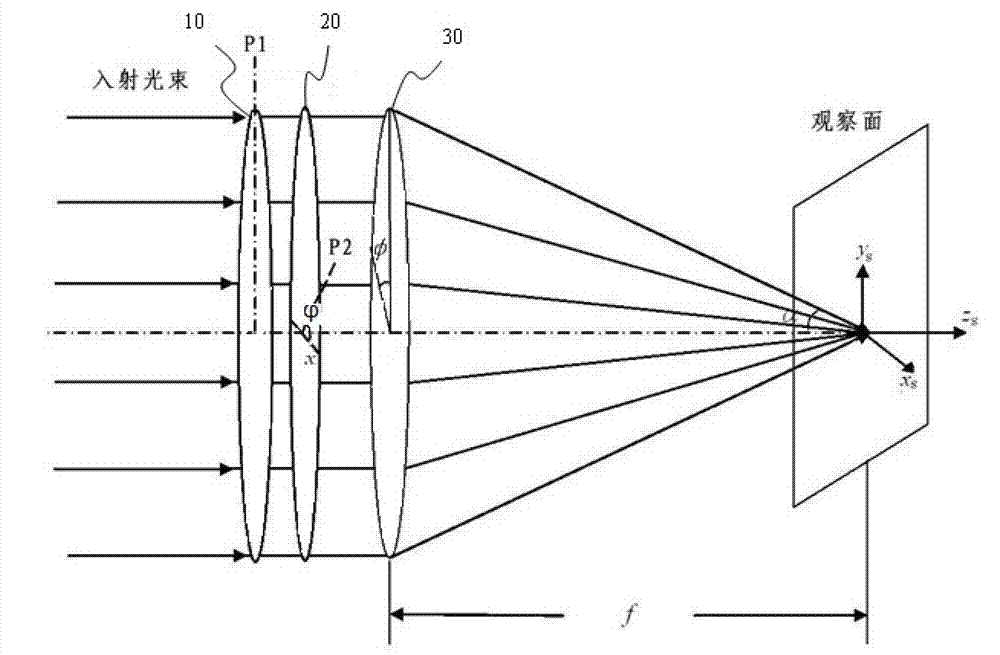

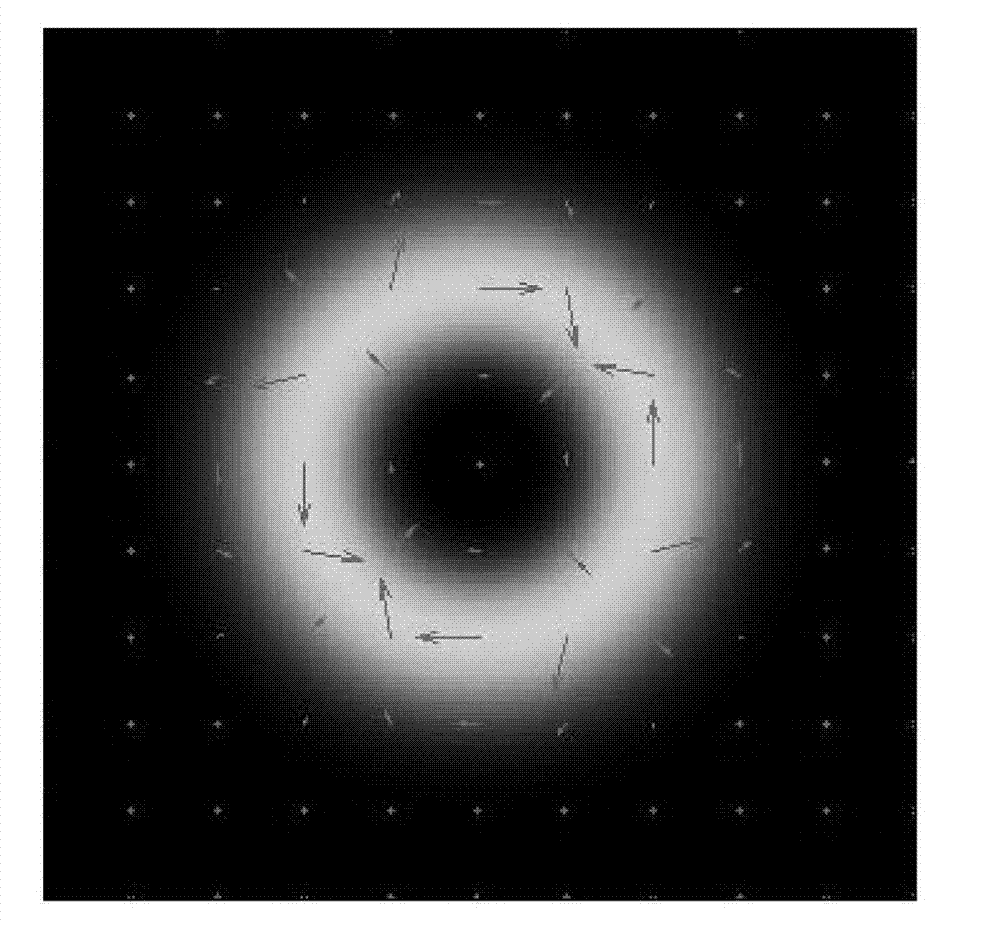

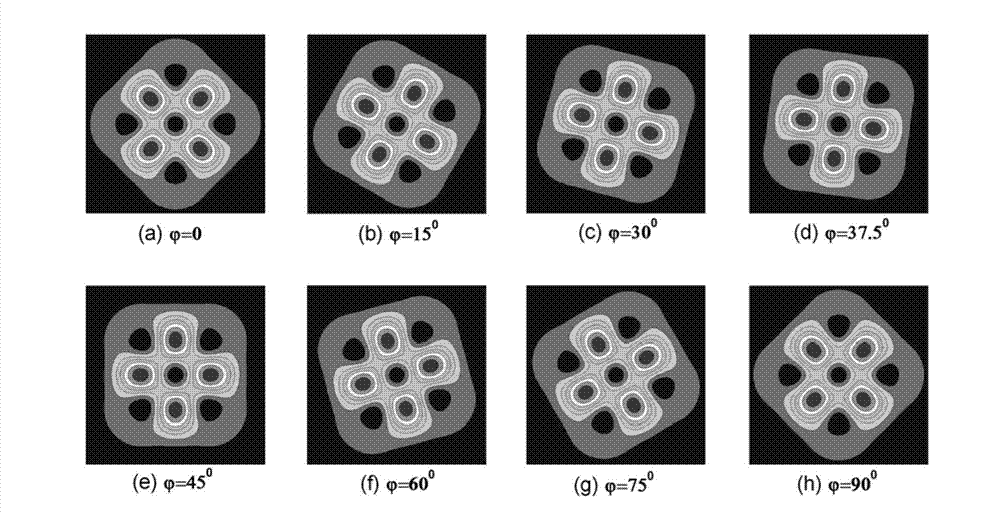

Method and device for generating tightly-focused light spots of column polarized vector beam

InactiveCN102967928AControl rotation speedSimple structureMicroscopesHigh numerical apertureLight spot

The invention discloses a method and device for generating a tightly-focused light spot array of a column polarized vector beam which can be rotated freely. Based on the generation of a column polarized vector beam in the prior art, the polarized direction of the column polarized vector beam is rotated in a way that the beam passes through two half wave plates. Finally, the beam is tightly focused through a microscope objective with a high numerical aperture to obtain array-type focused light spots. Through rotating the second half wave plate, the rotation speed of the focused light spot array is easily controlled. The method provided by the invention is easy to realize, the device provided by the invention has the advantages of simple structure, adjustment easiness and low manufacturing cost. Moreover, the device has good stability and does not need other special optical elements.

Owner:SUZHOU UNIV

Combined type glue coating machine and use method thereof

ActiveCN105845281AErgonomicControl the speed of horizontal movementManufacturing wire harnessesAgricultural engineeringUltimate tensile strength

The invention discloses a combined type glue coating machine and a use method thereof. The combined type glue coating machine comprises a footswitch, a first control box, an air source FRL, a lower roller, a second control box, a safety protection cover, an upper roller, a supporting frame, a glue coating machine body, a glue coating machine clamp, a supporting rod with a bearing, a base and a supporting frame fixing lock, wherein the safety protection cover is fixedly connected with the top surface of the second control box, and is used for covering the upper roller, the lower roller and the supporting frame. The combined type glue coating machine and the use method thereof can reduce labor intensity of workers and improve the glue coating efficiency and glue coating quality.

Owner:杭州鼎巅科技有限公司

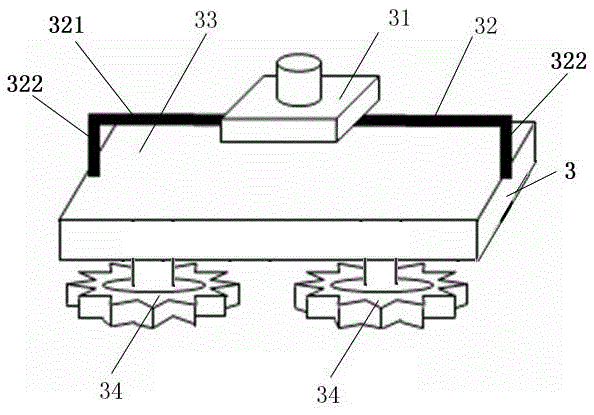

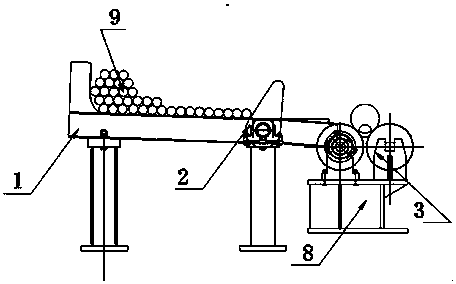

Automatic bar surface spiral grinding device

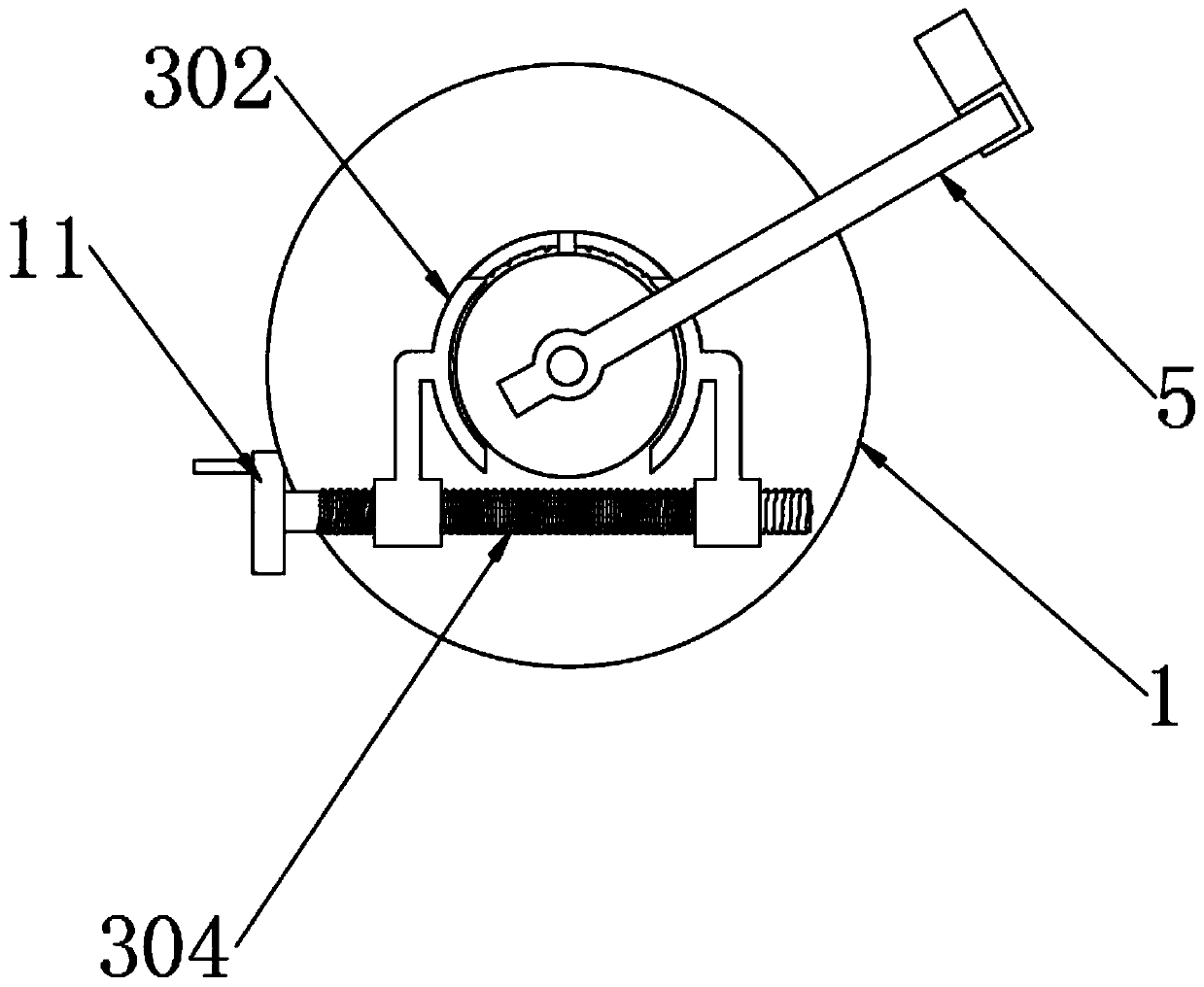

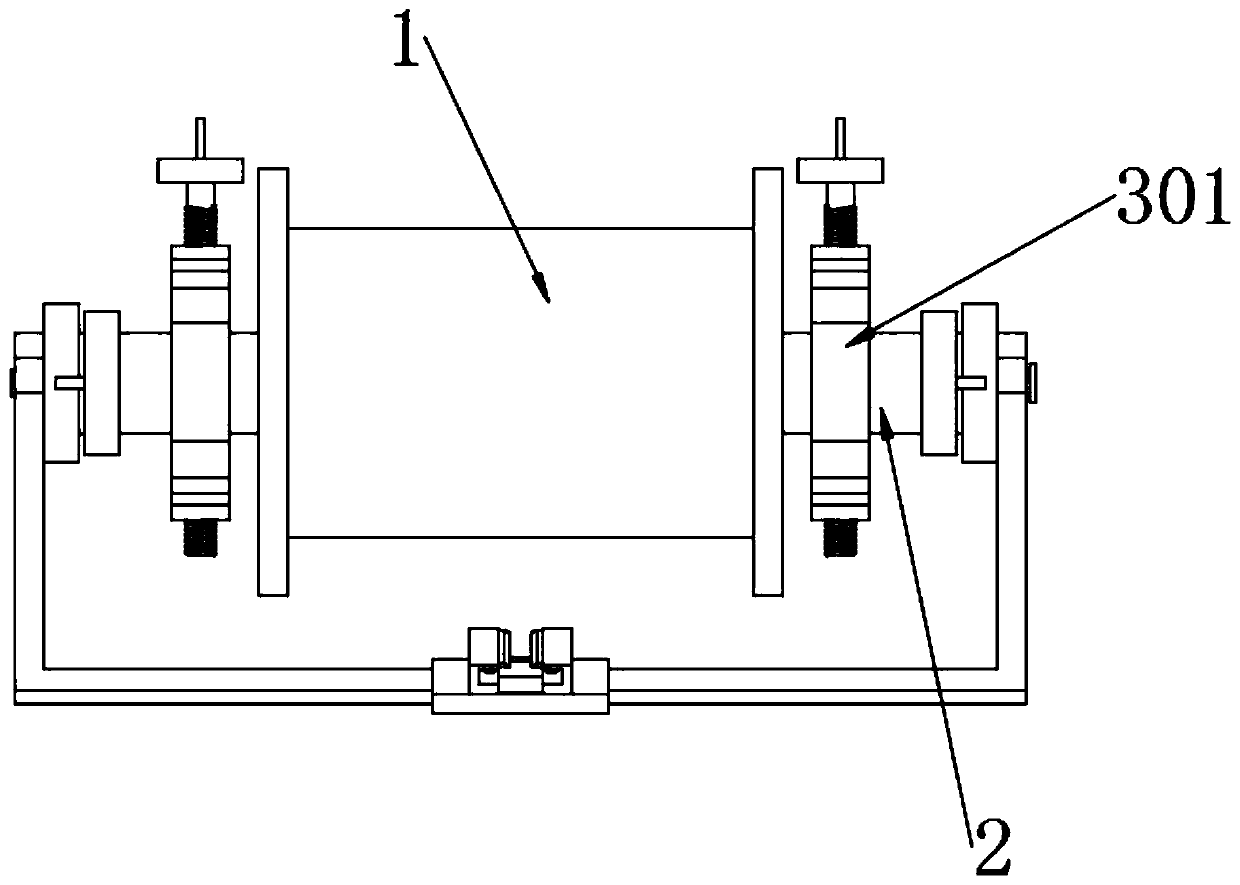

PendingCN108262655AControl rotation speedImprove grinding efficiencyRevolution surface grinding machinesEngineeringUltimate tensile strength

The invention relates to an automatic bar surface spiral grinding device, and belongs to the technical field of metallurgical industry special steel enterprise bar surface coping equipment. Accordingto the technical scheme, a feeding rack (1), a baffle (2), a coupled wheel roller bed (3), a grinding head (5), a transition plate (6) and a collection tank (7) are included; the feeding rack (1) is arranged on one side of the coupled wheel roller bed (3), and the collection tank (7) is arranged on the other side of the coupled wheel roller bed (3); the feeding rack (1) is obliquely arranged towards one side of the coupled wheel roller bed (3); the feeding rack (1) is provided with the baffle (2), the transition plate (6) is arranged between the coupled wheel roller bed (3) and the collectiontank (7), the transition plate (6) and the collection tank (7) are rotationally connected, and the grinding head (5) is arranged above the coupled wheel roller bed (3). The automatic bar surface spiral grinding device has the beneficial effects that the surfaces of bars different in specification and screw pitch can be automatically ground, the bar grinding efficiency and appearance quality are improved, and the labor intensity of workers is relieved.

Owner:SHIJIAZHUANG IRON & STEEL

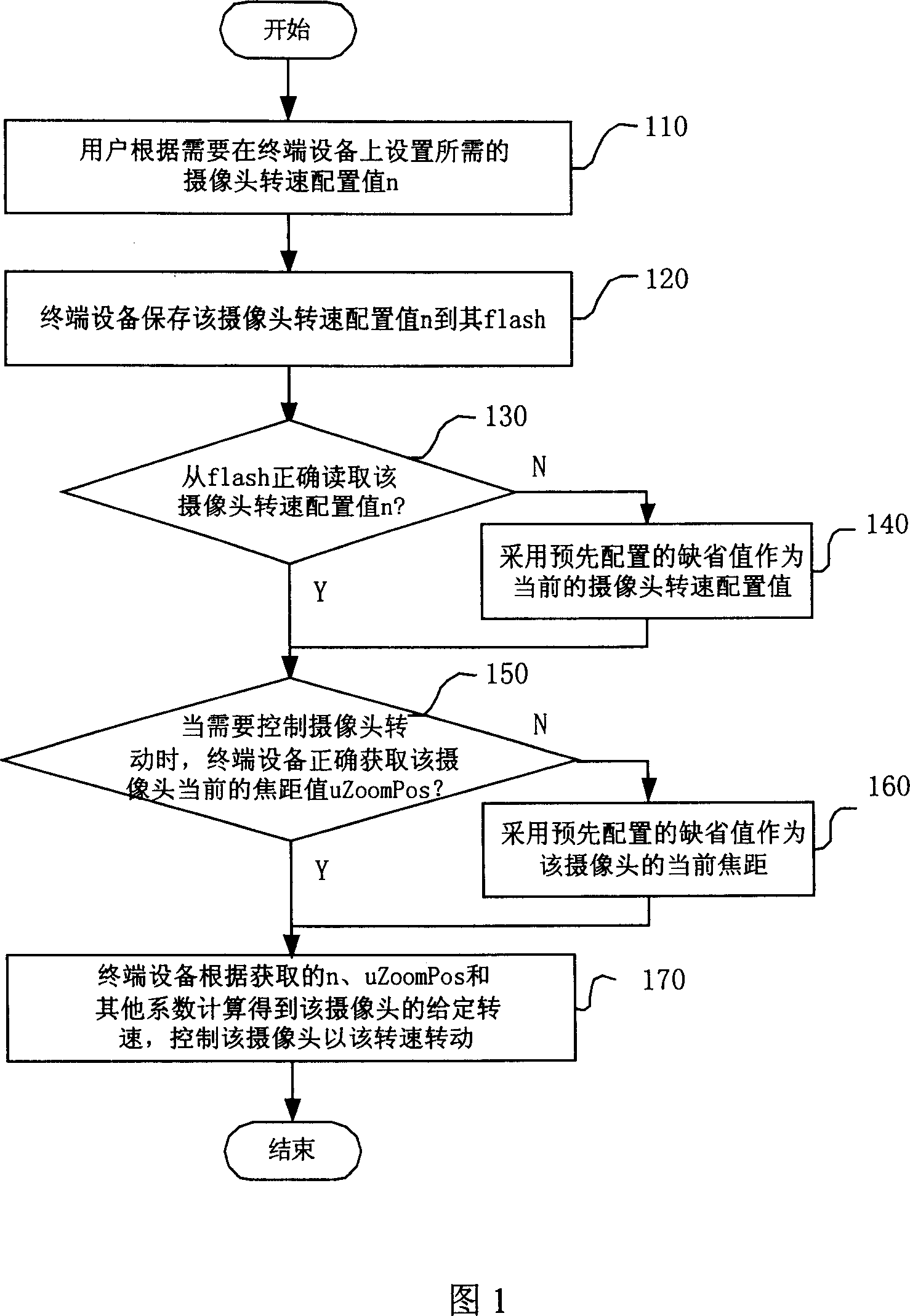

Method for flexible control of rotary speed of cam through terminal device

ActiveCN1972383AControl rotation speedRotate at a constant speedTelevision system detailsTelevision conference systemsCommunication interfaceTerminal equipment

This invention relates to one method to control cameral head rotation speed by terminal device, which comprises the following steps: user sets needed cameral head align value and stores the set by needs; the said terminal device is started to get the align value; in rotating of cameral head, the terminal device gets the cameral head rotation speed according to the cameral head speed and informs the speed to the cameral head through said communication interface to control cameral head rotation speed.

Owner:ZTE CORP

Bamboo-wood floor drying device

InactiveCN105841463AAvoid getting lostControl rotation speedDrying solid materials with heatDrying machines with progressive movementsAutomatic controlMechanical engineering

The invention discloses a bamboo and wood floor drying device, which comprises a working shell and a rotating device. A heating device is installed under the working shell, the heating device is connected with the working shell through a base, and a heating device is installed above the working shell. There is a working main board, an exhaust fan is arranged on the upper right of the working housing, a temperature sensor is installed on the upper side of the working housing, and a gate is installed on the left side of the working main board, and the gate is connected to the working housing. A roller is installed in the middle of the gate, and a control device is installed in the lower part of the gate. The rotating device is installed above the working main board, and the rotating device includes a motor bracket, a motor, a rotating shaft, a braking device, an adjusting device, and a sawtooth. Draw-in slot and movable clip, a motor is installed above the motor bracket, the motor is connected to a rotating shaft, and a brake device is installed on the rotating shaft. The present invention adopts automatic control, shortens the drying and heating process, and saves energy consumption.

Owner:苏清安

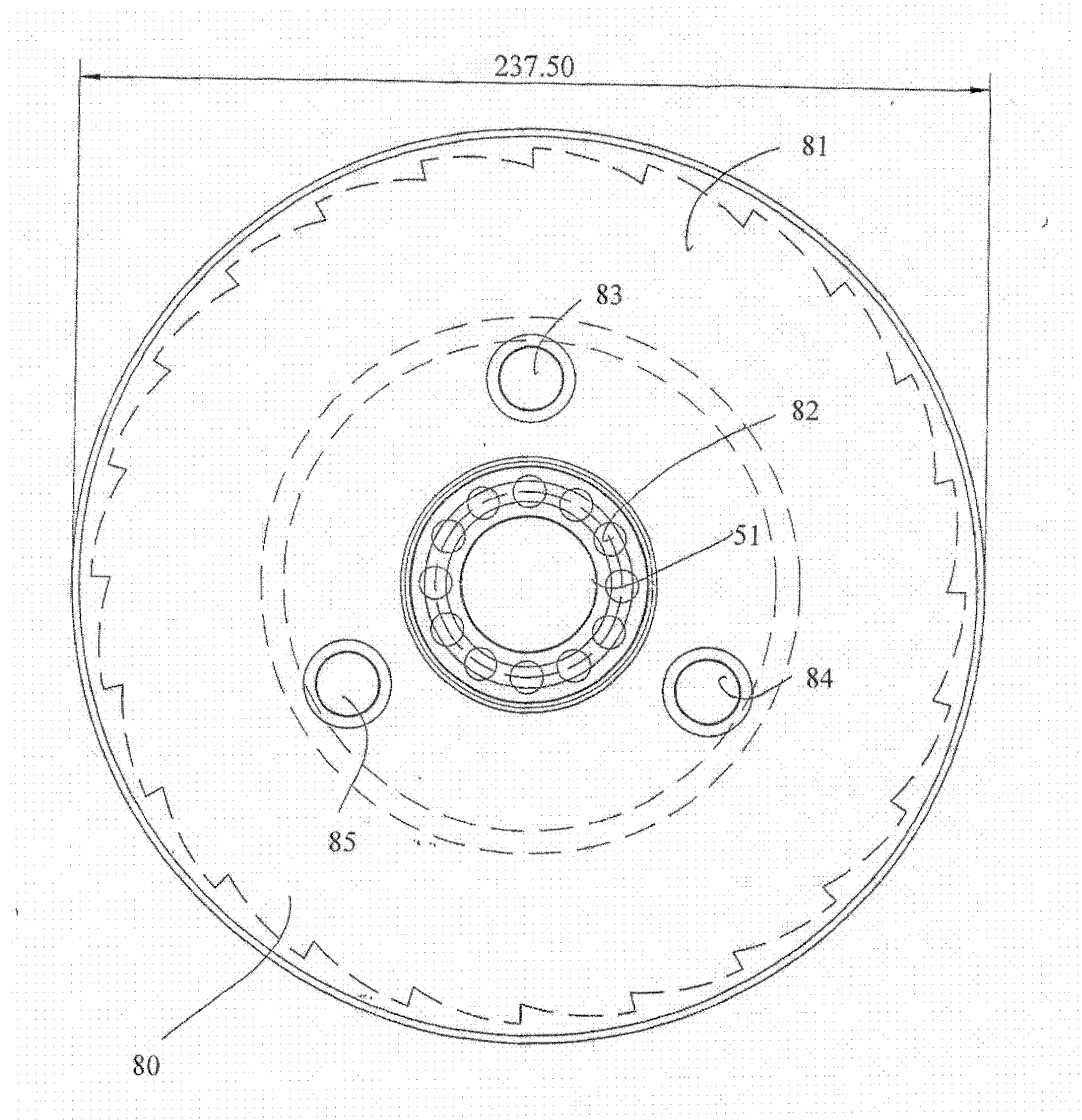

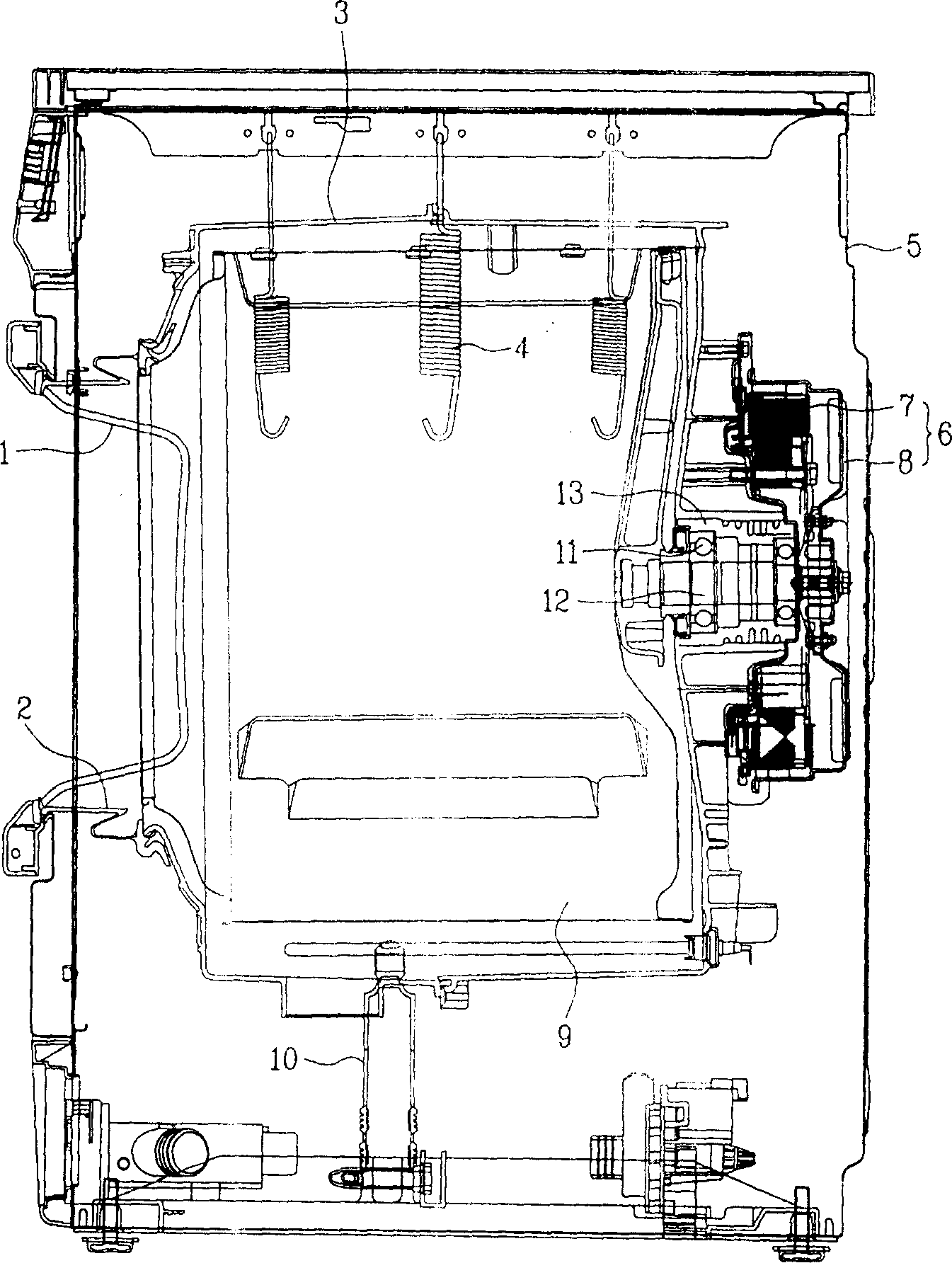

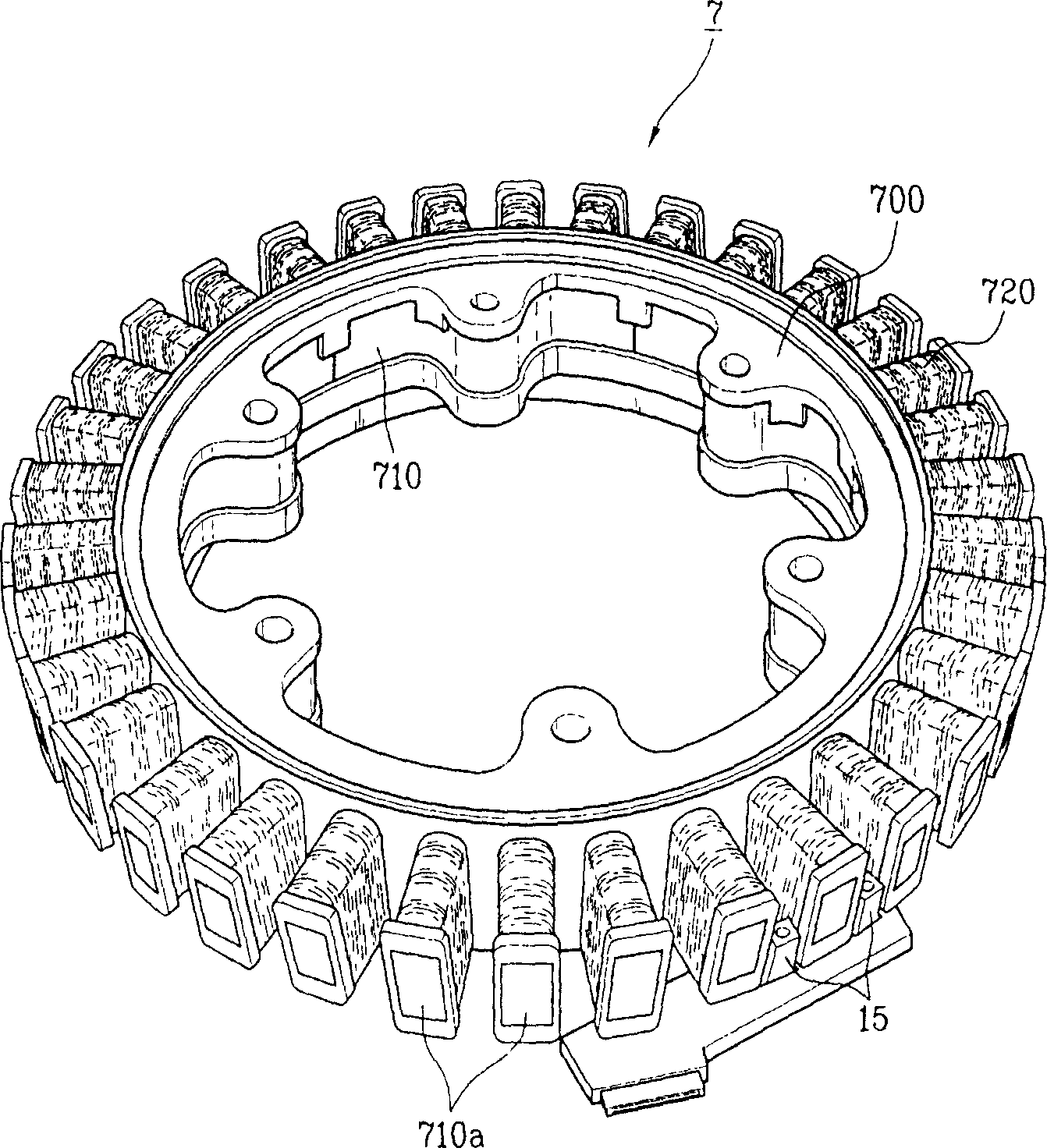

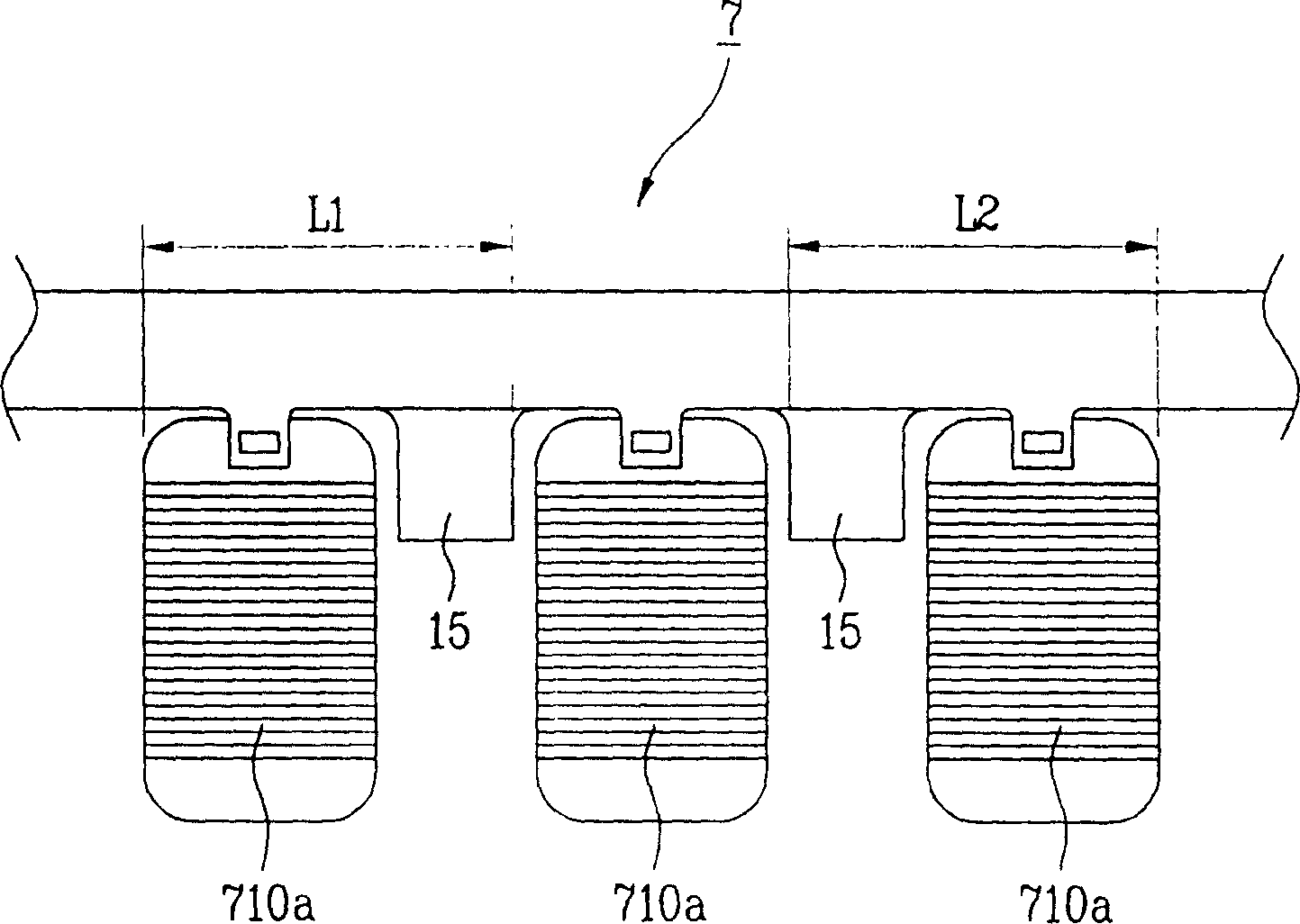

Hull sensor position deviation guarantee method for motor direct driving washing machine using brushless DC motor

InactiveCN1684354AGuaranteed accurate potentialControl rotation speedElectronic commutatorsMicrocomputerElectric machine

This invention discloses a method for ensuring the position deviation of a Hall sensor of a motor direct-drive washing machine applying a brush less DC motor characterizing that a microcomputer acknowledges the counter-electromotive force generated from rotating the rotor by man and the signal sensed by the Hall sensor to compute the potential sensed angle of the sensor and compute the difference between the sensed angle and the potential sensed angle of the Hall sensor on the primary stand and position, the above mentioned compute value of the sensed angle is considered to be stored as the initially acknowledged value.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

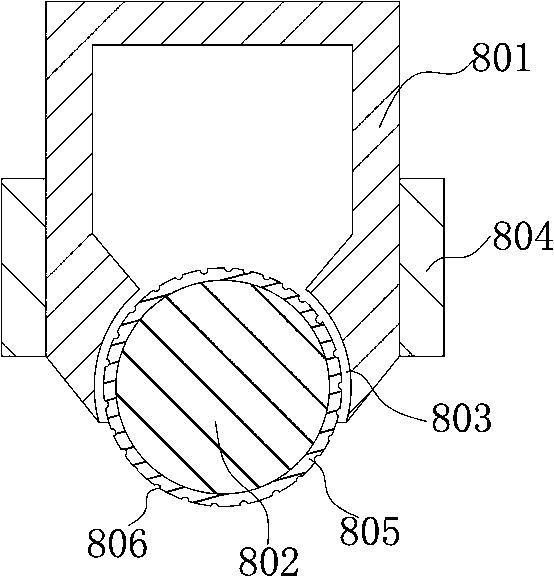

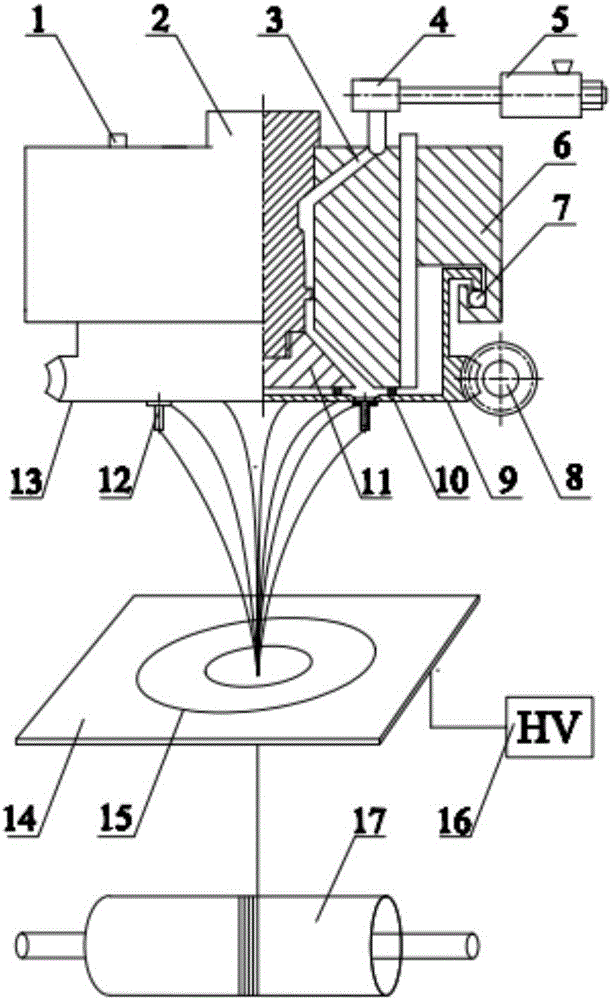

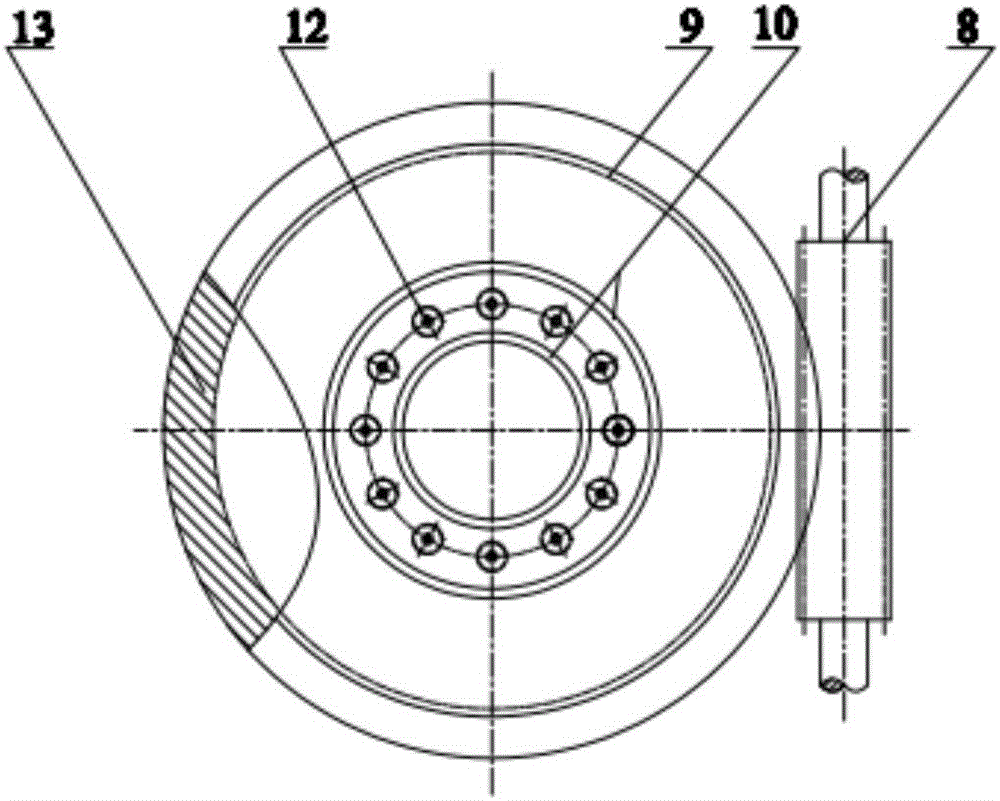

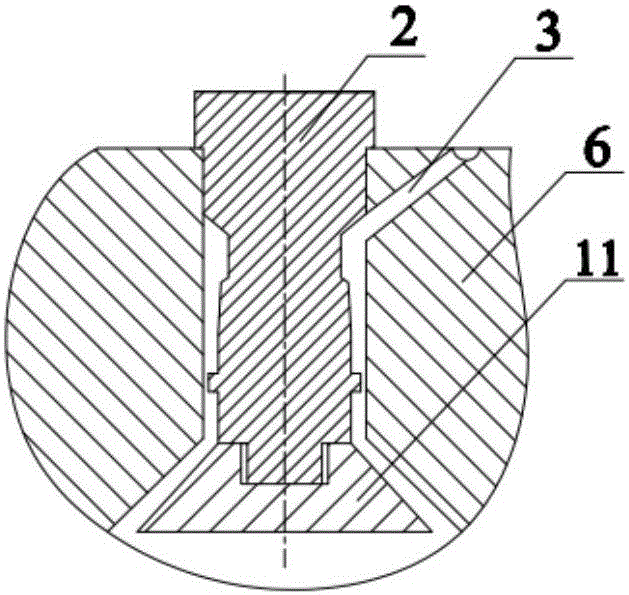

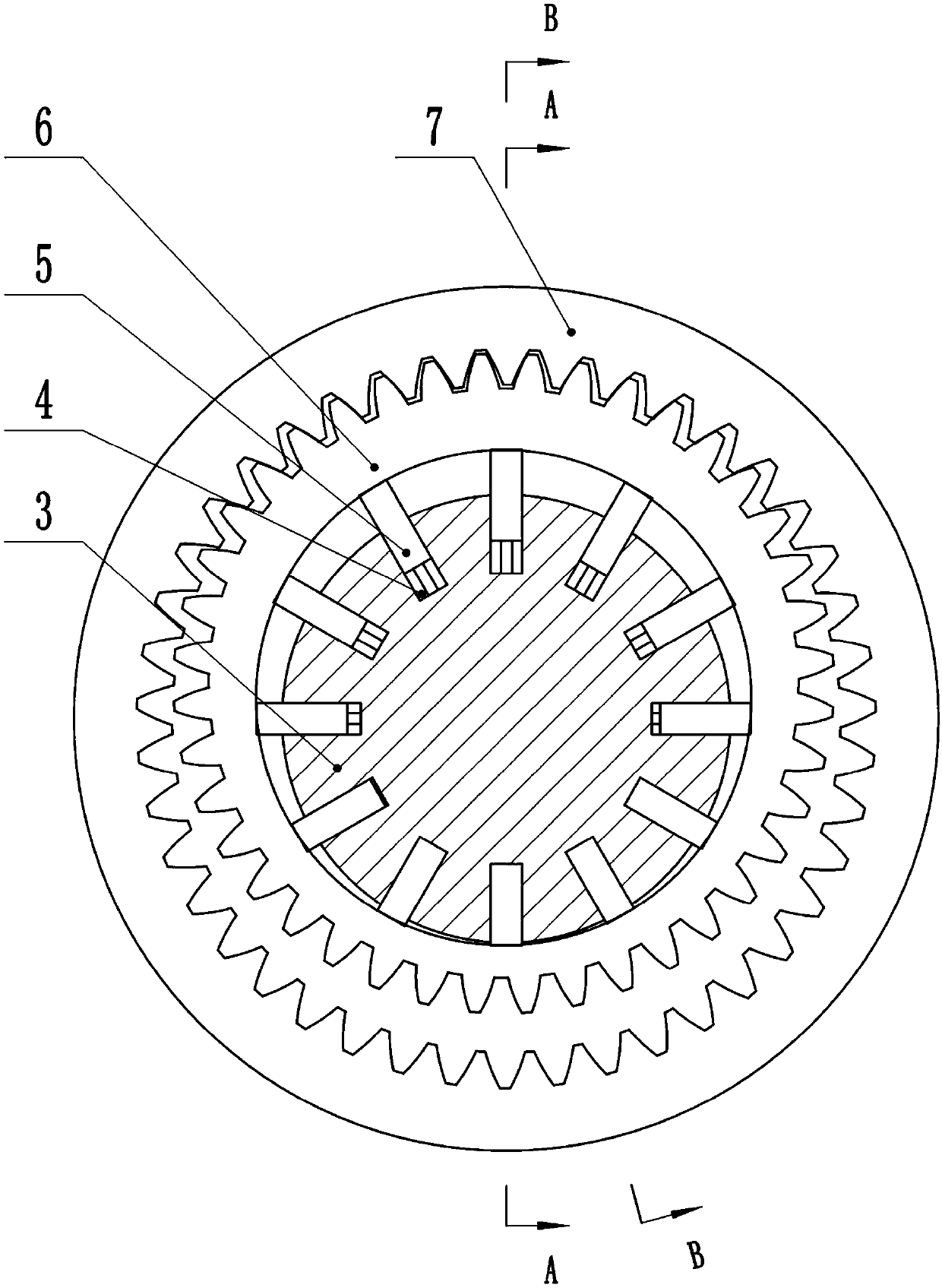

Melt electrospinning nanometer twisted yarn preparing device and method achieving multi-needle rotary twisting

ActiveCN106283219AImprove mechanical propertiesControllable twistFilament/thread formingYarnEngineering

The invention relates to a melt electrospinning nanometer twisted yarn preparing device and method achieving multi-needle rotary twisting, and belongs to the field of electrostatic spinning. The device mainly comprises a heating rod, a center shaft, a flowing channel, a corner handpiece, an extruding machine, a spreader plate, a rolling ball, a worm rod, a thin-walled container, a copper ring, a conical flow guider, multiple single-needle spray heads, a worm wheel, an acrylic board with a hole, an electrode plate, a high-voltage electrostatic generator, a receiving roller and the like. According to the device and method, the conical flow guider is in threaded connection with the center shaft and is arranged to be coaxial with the thin-walled container; the copper ring is arranged between the upper portions of needle heads and the flowing channel to serve as a sealing device; the single-needle spray heads are annularly arranged, so that the spinning efficiency is improved, and the spinning yield is increased; the single-needle spray heads are in threaded connection with a bottom plate of the thin-walled container, and therefore replacing and cleaning are convenient; by replacing the single-needle spray heads with needle head plugs, the fiber number can be controlled; a worm wheel and worm rod transmission device drives the single-needle spray heads to rotate, the twisting degree and the fiber number are controllable, the fiber diameter is uniform, the applicability of nanometer twisted yarn can be improved, and therefore the requirements in different fields are met.

Owner:BEIJING UNIV OF CHEM TECH

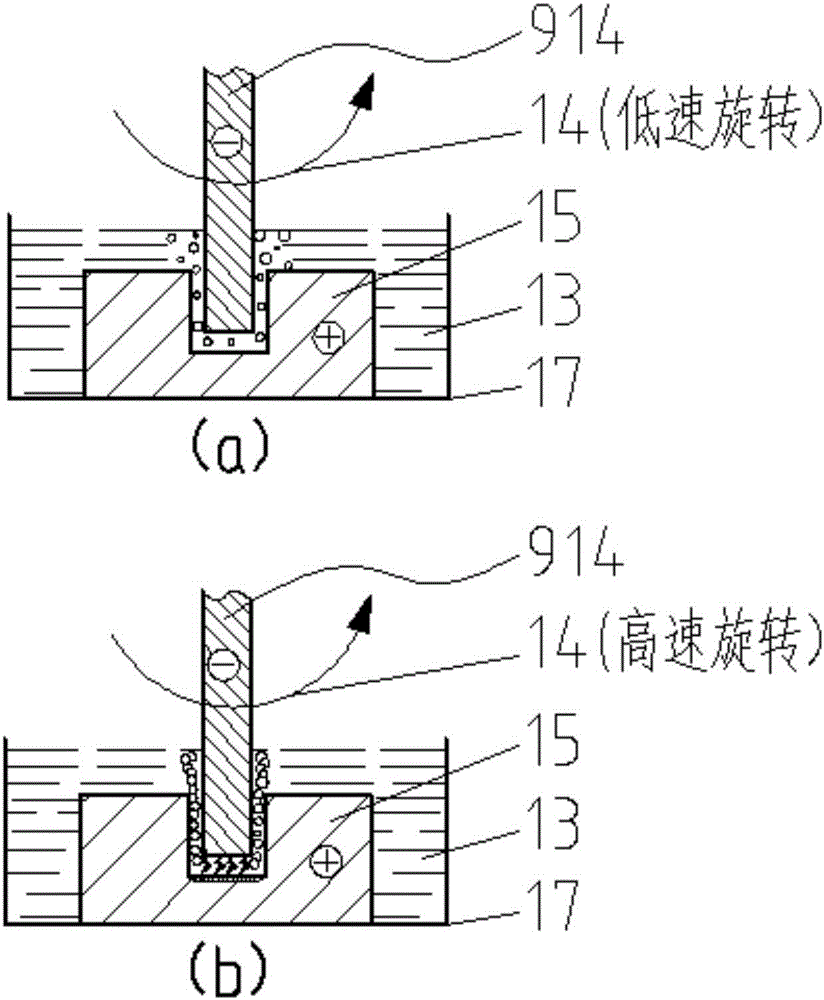

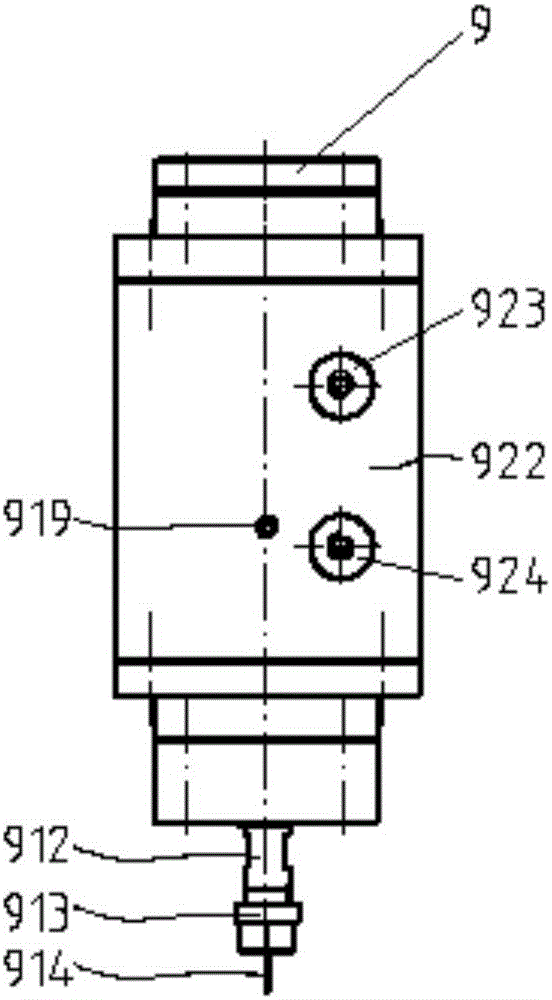

Electromachining method with controllable tool electrode rotating speed for micro-holes and speed adjustment system

ActiveCN106392216AImprove processing qualityAvoid Difficult Chip EvacuationElectrochemical responseElectricity

The invention provides an electromachining method with controllable tool electrode rotating speed for micro-holes and a speed adjustment system, and belongs to the technical field of non-traditional machining. According to the electromachining method, neutral salt solution with the extremely low concentration serves as electrolyte, corresponding voltages are applied to two poles of the electrolyte, the gas film covering status of the surface of a tool electrode is adjusted through control over the tool electrode rotating speed, and if the tool electrode rotating speed is high, discharging reaction occurs when the gas film covering status meets the generation condition of the discharging reaction; if the tool electrode rotating speed is low, electrochemical reaction occurs; and controllable compounding of electrochemical machining and discharging machining is achieved through control over the tool electrode rotating speed. According to the electromachining method with the controllable tool electrode rotating speed for the micro-holes and the speed adjustment system, good surface machining quality and machining consistency can be achieved.

Owner:ANHUI UNIV OF SCI & TECH

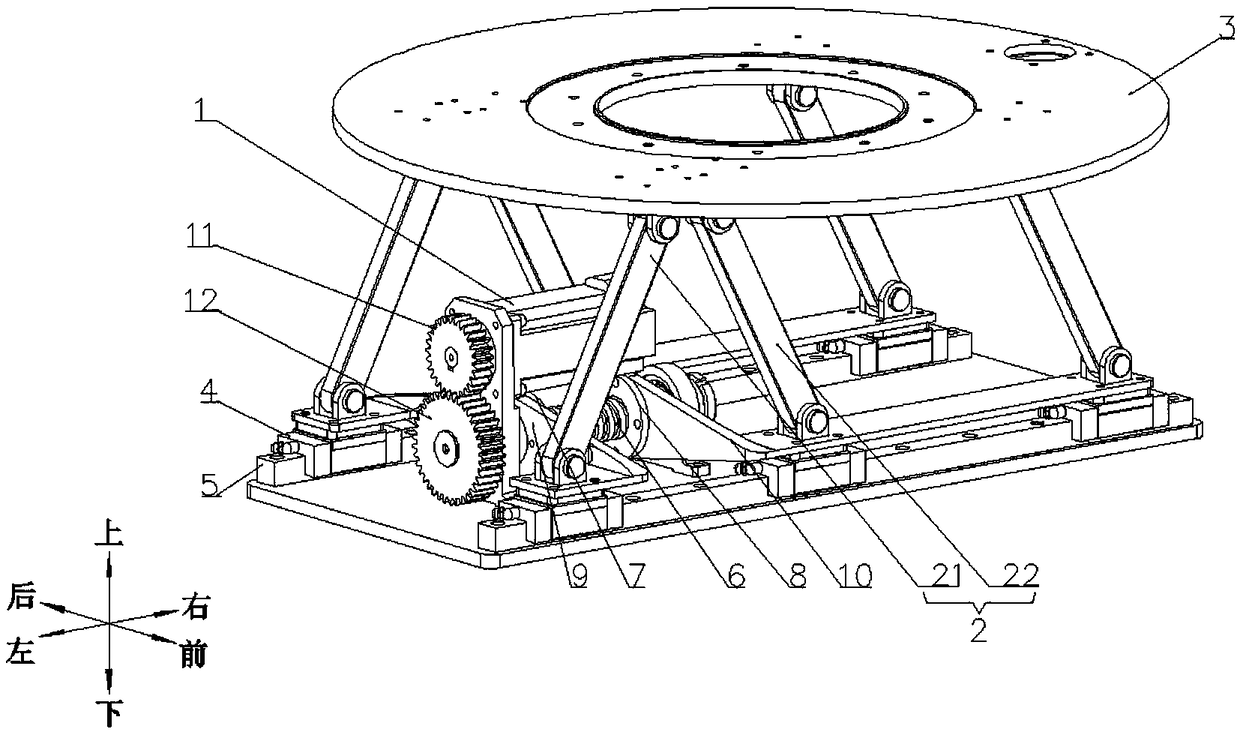

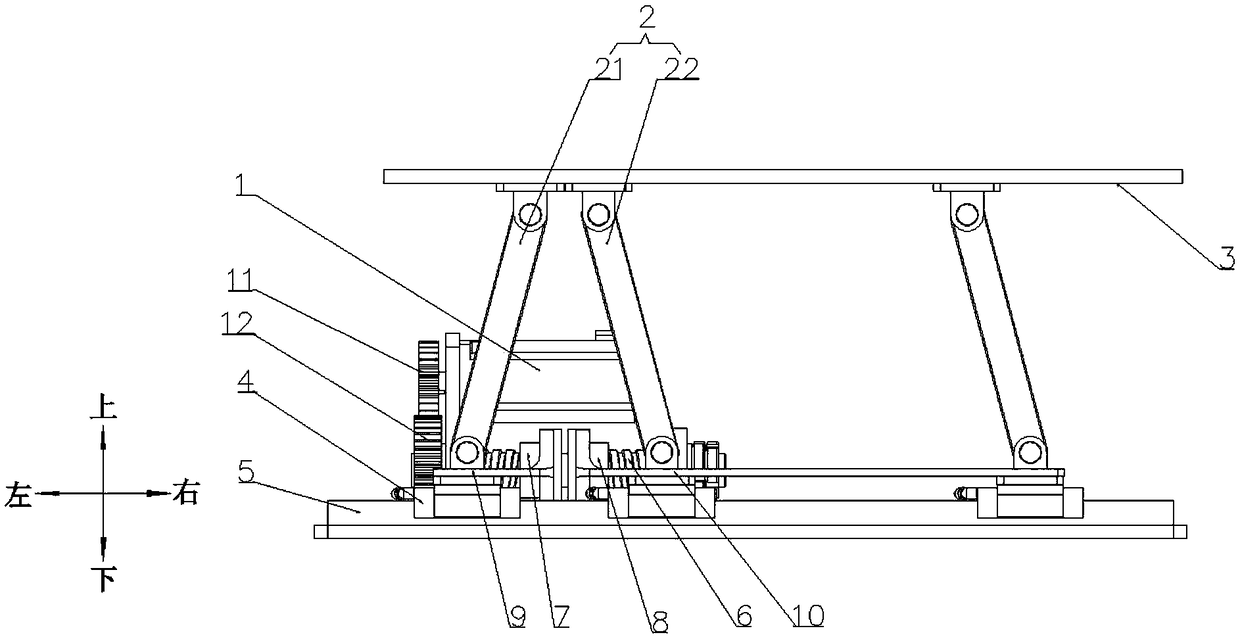

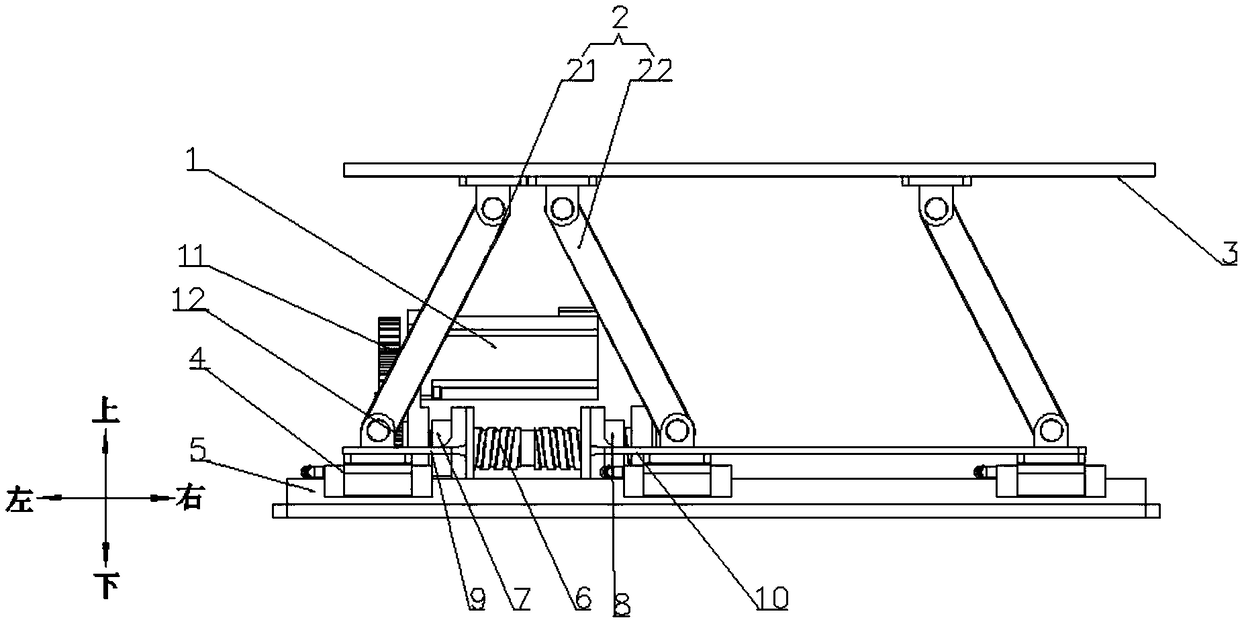

Connection rod type AGV lifting device

The invention relates to a connection rod type AGV lifting device. The connection rod type AGV lifting device comprises a power output device, a transmission mechanism, connection rods and a top plate; the power output device is in transmission connection with the transmission mechanism; the connection rods comprise at least one first connection rod and at least one second connection rod; the transmission mechanism is hinged to the lower end of each connection rod; the upper end of each connection rod is hinged to the top plate; the lower end of each connection rod moves in the horizontal direction under driving by the transmission mechanism; the lower end of each first connection rod is opposite to the lower end of each second connection rod in movement direction; and the top plate is driven by the connection rods to move in the vertical direction. An AGV provided with the lifting device can be applied to more occasions; and the connection rod type lifting device is stable and simplein structure, steady in transmission, convenient to install and low in manufacturing cost, and the connection rods are connected in a hinged manner so that transmission is more steady.

Owner:广东飞库科技有限公司

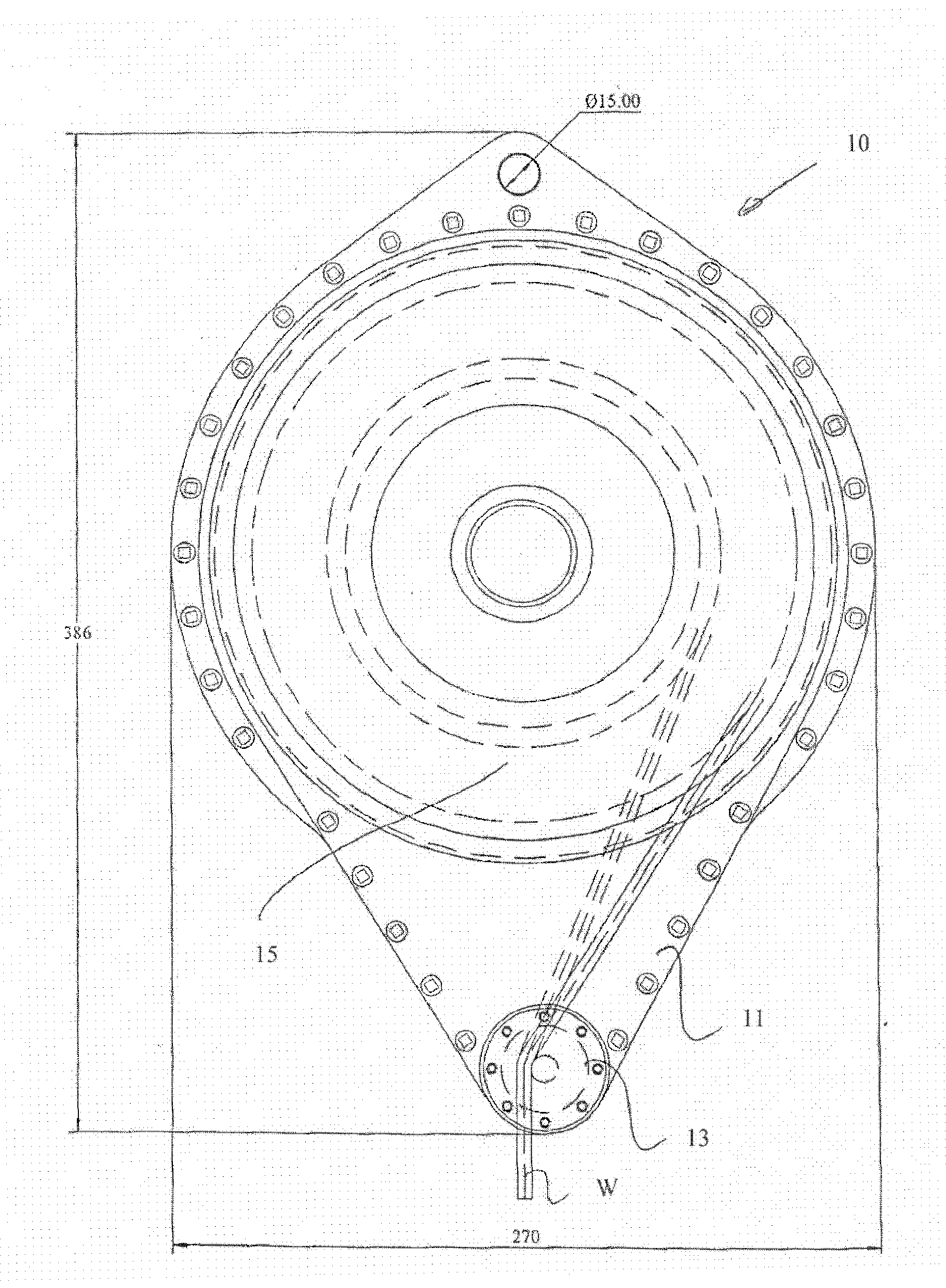

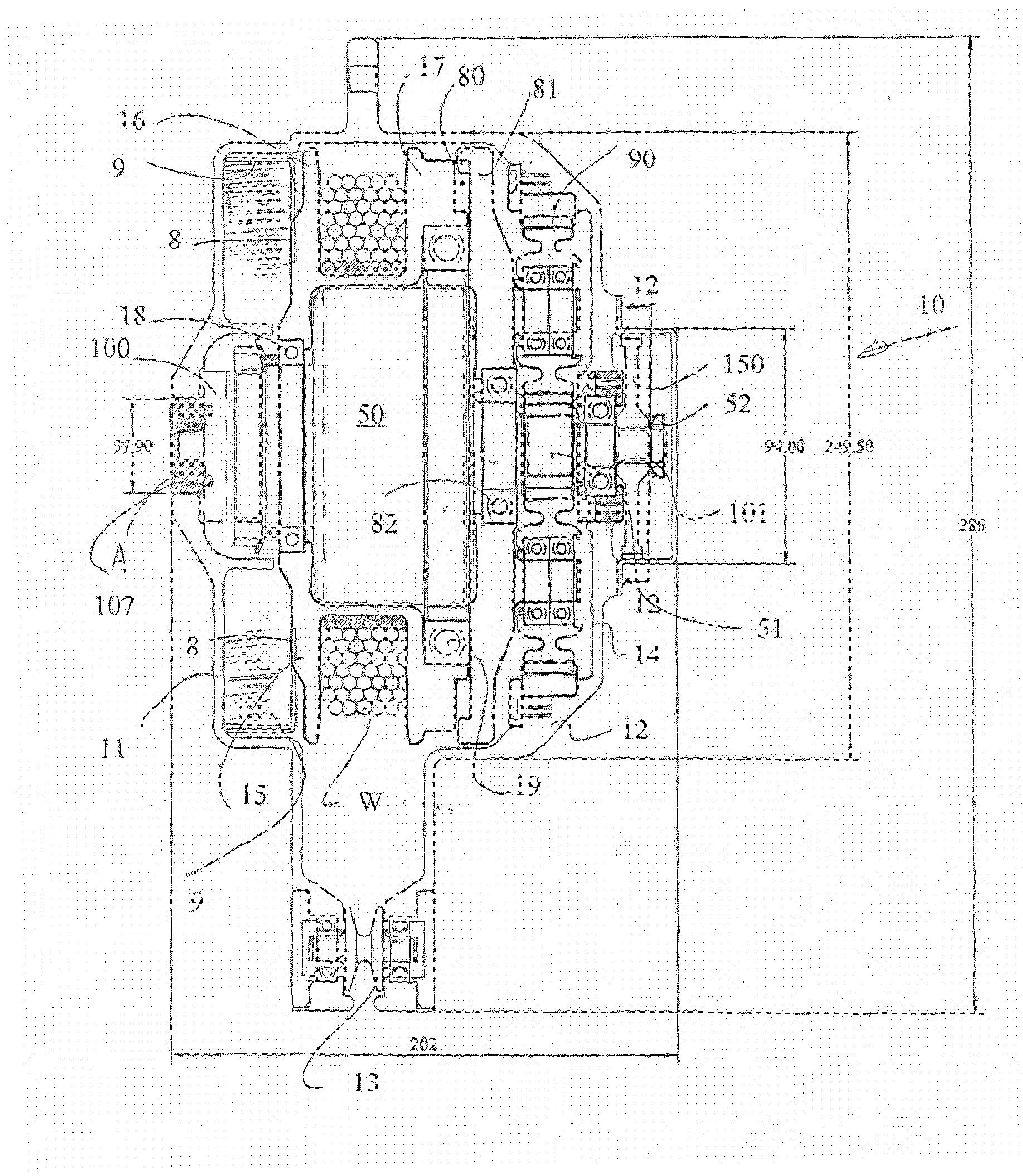

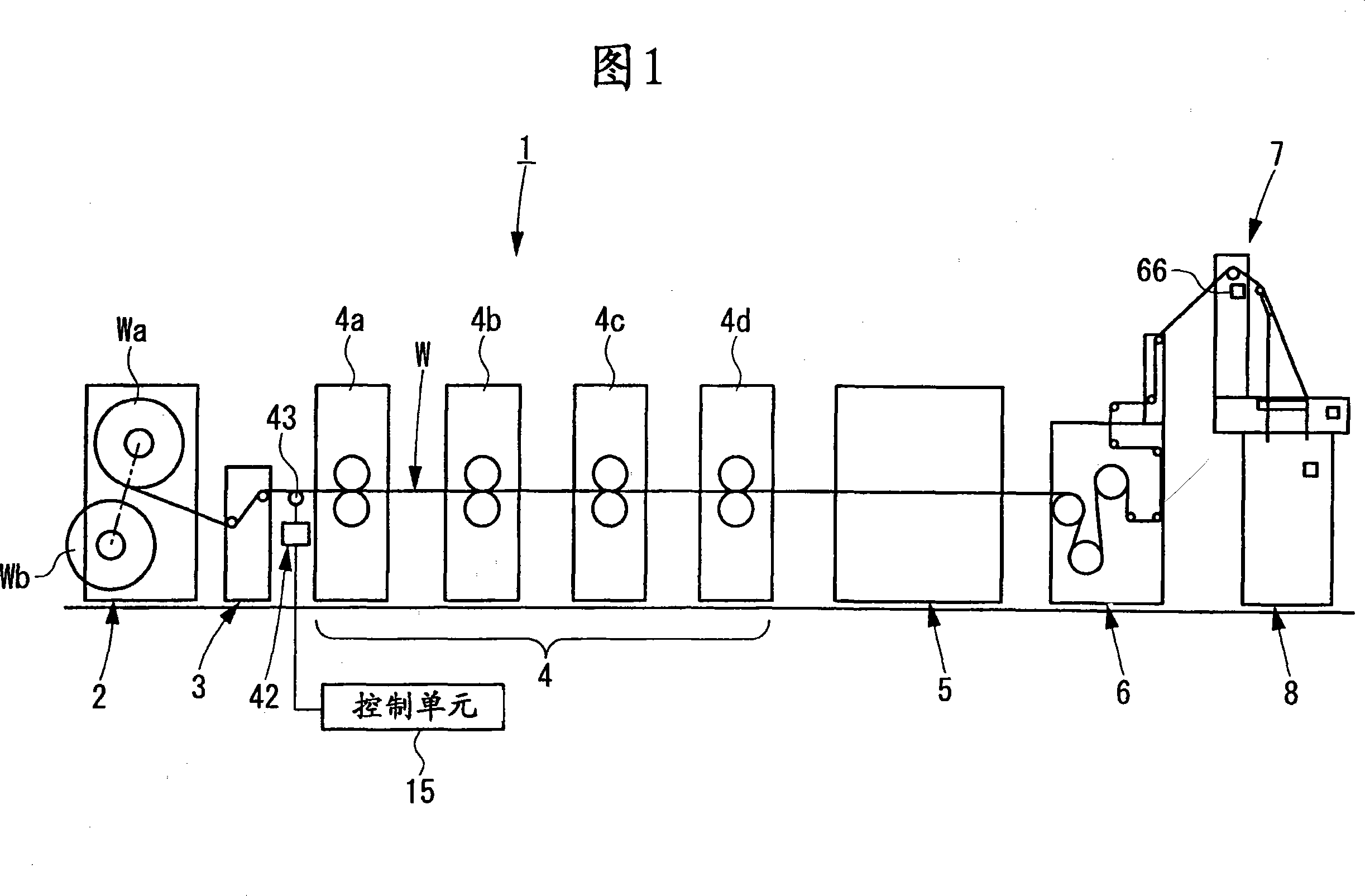

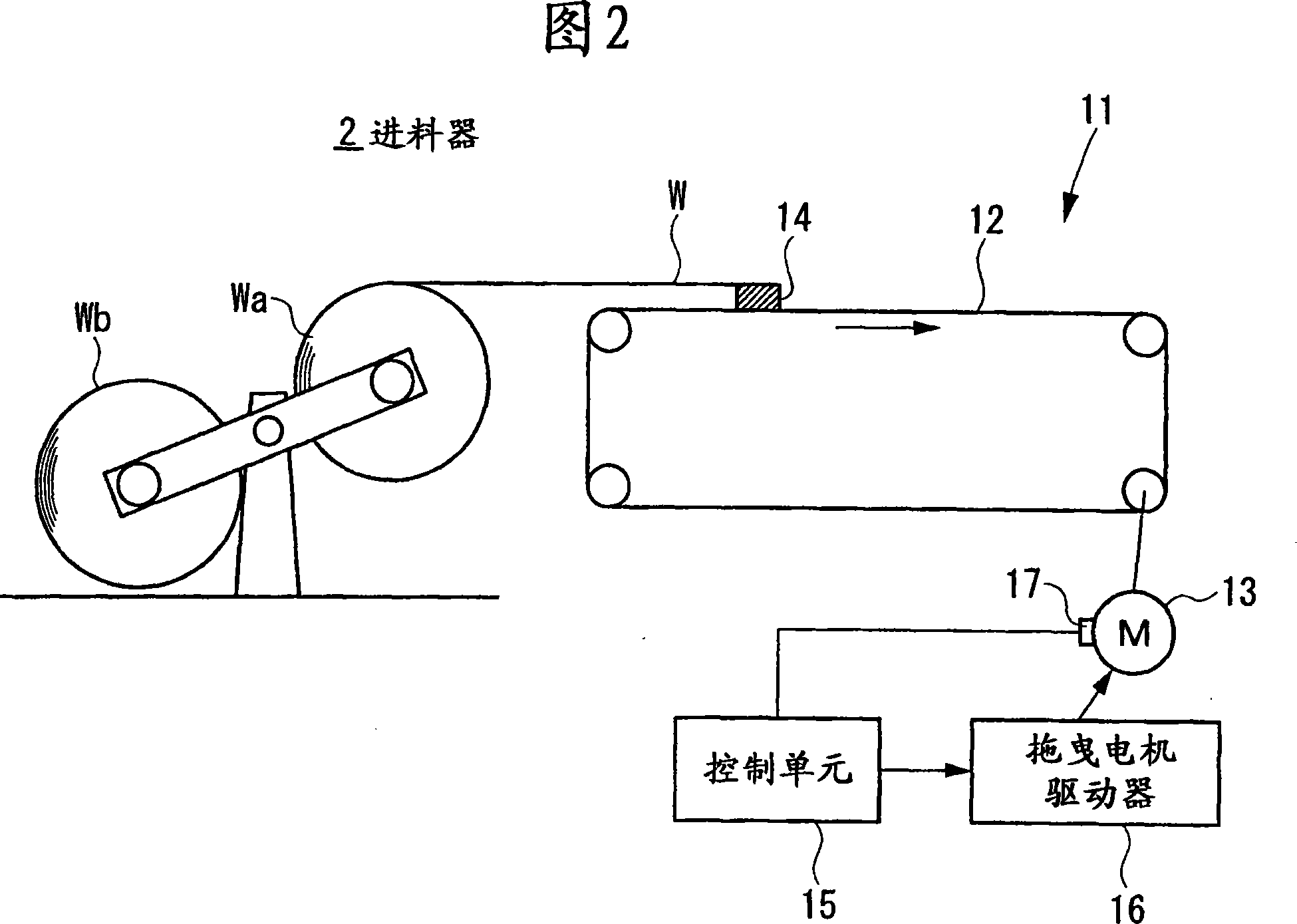

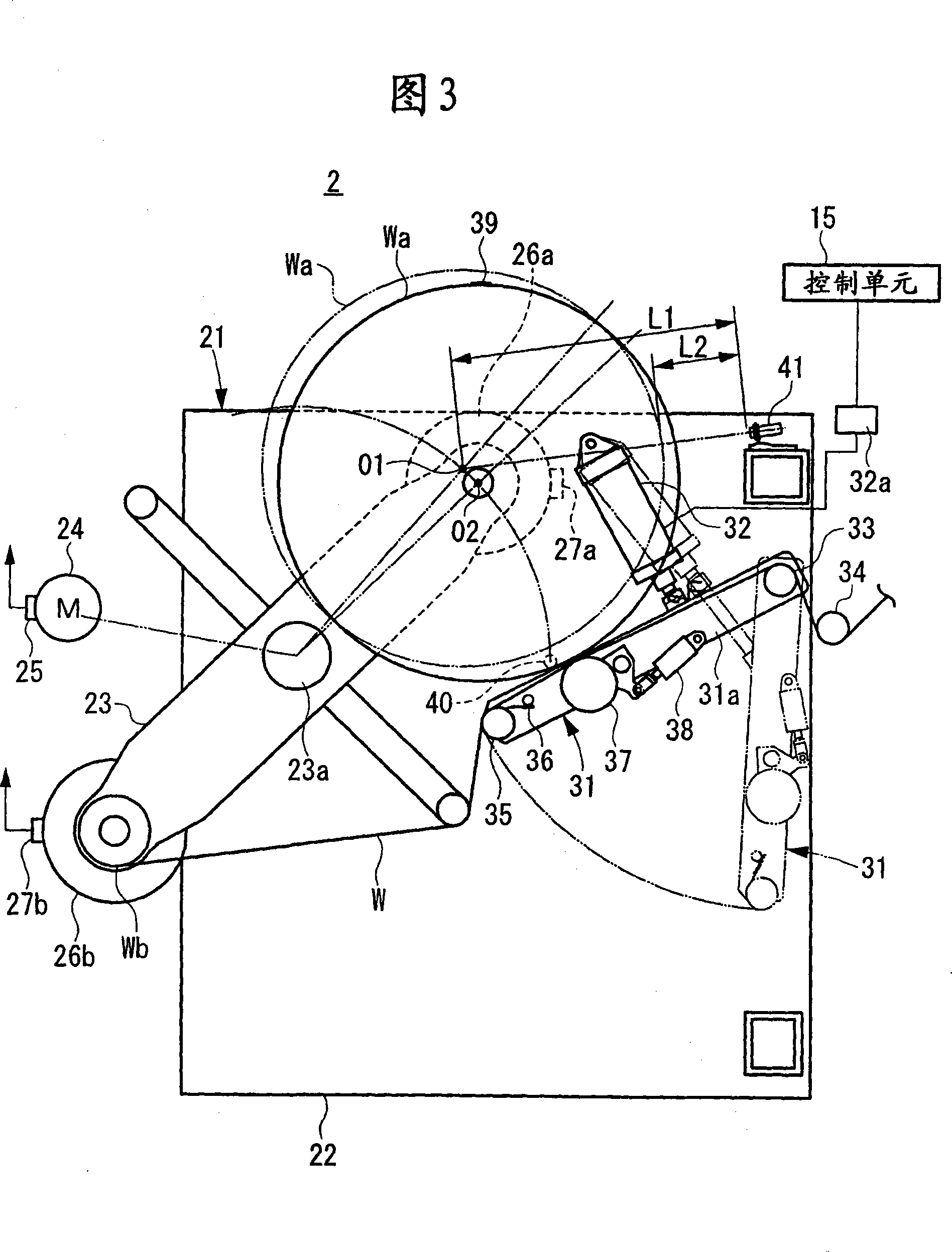

Strip threading method and strip threading device

InactiveCN101134538AControl rotation speedAvoid tearingFunction indicatorsRotary pressesPrinting pressMechanical engineering

Web (W) is in the form of two web rolls (Wa, Wb), and each of which is obtained by wounding the web (W) in a roll. The web (W) of a selected one of the two web rolls (Wa, Wb) is configured to be threaded into a transport route of a printing press by causing a holder (14) to hold a forward edge portion of the web (W), and by thus moving the holder (14) by drive of a motor while causing the web (W) to be rotated and unwound by a corresponding one of motors (26a, 26b). While threading the web (W) into the transport route, a speed at which the selected one of the web rolls (26a, 26b) is rotated or a speed at which the web (W) is towed is configured to be controlled depending on a value representing tension applied to the web (W).

Owner:KOMORI CORP

Drum-type herbal medicine roaster

InactiveCN104706529AEvenly heatedControl rotation speedPharmaceutical product form changeEngineeringHeating furnace

The invention discloses a drum-type herbal medicine roaster which comprises a base, a heating device, a driving device and a herbal medicine roasting drum, wherein the heating device is located in the base, the driving device is located behind the base, the herbal medicine roasting drum is located above the base and the driving device, the base is provided with a fixed seat and guide wheels, the fixed seat is located above the front end of the base, the number of the guide wheels is more than one, the guide wheels are located on both sides of the base, the heating device is provided with a heating furnace, the driving device is connected with a belt, the belt is connected with the herbal medicine roasting drum, the front part of the herbal medicine roasting drum is provided with a drum body, the drum body is provided with a fixed ring and a sealing cover, the fixed ring is matched with the sealing cover, the tail part of the herbal medicine roasting drum is provided with a reduction gearbox, and a belt pulley is carried on the reduction gearbox. The drum-type herbal medicine roaster has the advantages of simple structure, uniform herbal medicine roasting, and high-efficiency production.

Owner:SUZHOU SHENLINTANG TRADITIONAL CHINESE MEDICINE INST

Bending device for heat exchanger machining and bending method of heat exchanger

ActiveCN112718982AWith auto-rotate functionThe auto-rotate function facilitatesHeat exchange apparatusHydraulic cylinderElectric machine

The invention relates to the technical field of heat exchangers, in particular to a bending device for heat exchanger machining. The bending device for heat exchanger machining comprises a heat exchange tube, a bottom plate is arranged on one side of the heat exchange tube, a fixed seat is fixedly arranged on one side of the bottom plate, a through hole is formed in one side of the fixed seat, a rotating cylinder is rotatably connected to the inner side of the through hole, an electromotor is fixedly arranged on one side of the fixed seat, a first transmission device is arranged between the electromotor and the rotating cylinder, a clamp seat is fixedly arranged on the outer side of the rotating cylinder, a fixed clamping seat is fixedly arranged on one side of the clamp seat, and a detachable clamping seat is arranged on one side of the fixed clamping seat. According to the bending device for heat exchanger machining, the rotating cylinder, the electromotor, the clamp seat, the fixed clamping seat, the detachable clamping seat, a sliding block, a threaded rod, a stepping motor, a lifting box, a connecting block, an ejecting hydraulic cylinder, an L-shaped connecting frame, an ejecting groove wheel and an L-shaped adjusting frame are arranged, the bending device has the functions of automatic bending, automatic screw pitch adjusting, convenient disassembly and assembly, convenient material taking, universality and the like.

Owner:浙江大升电子开发有限公司

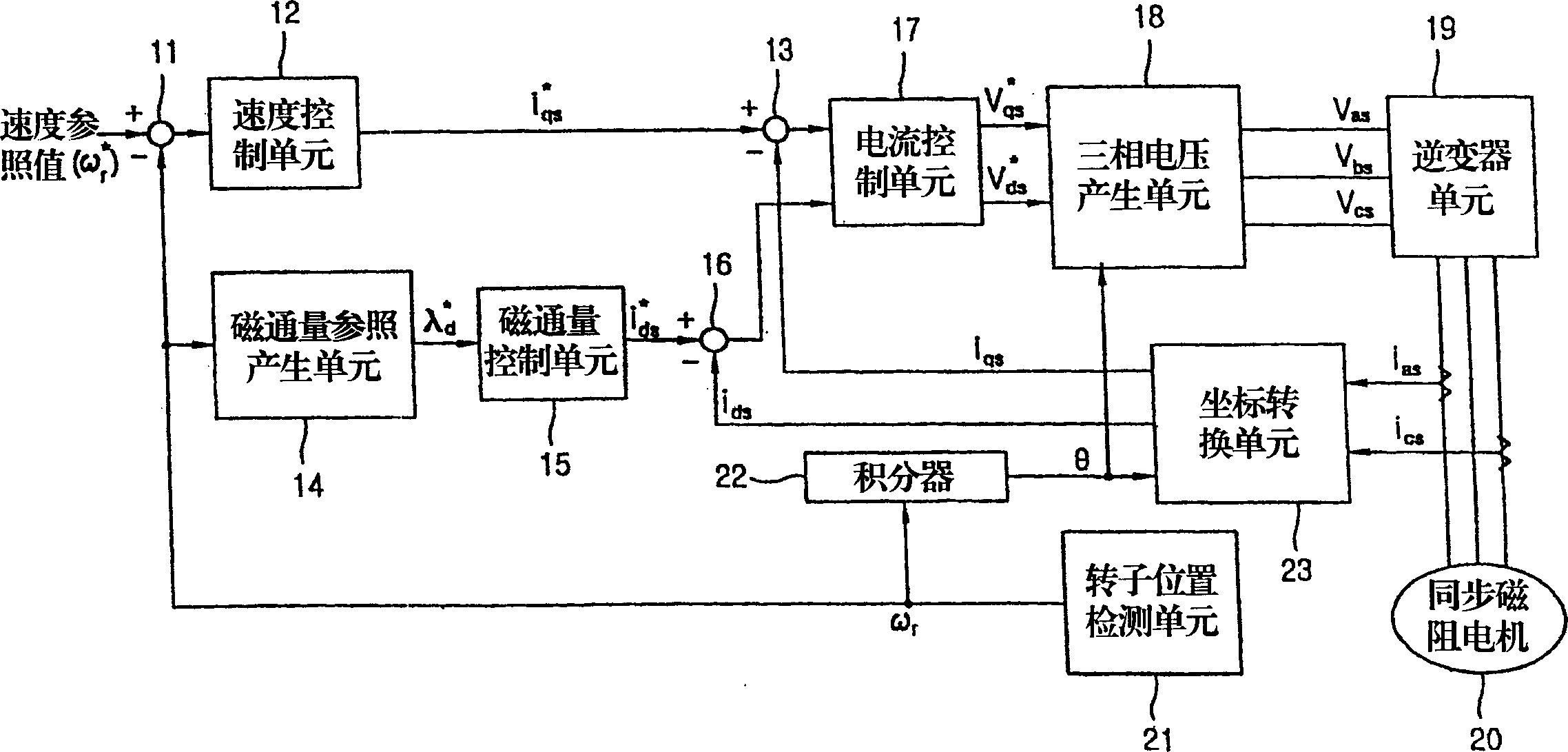

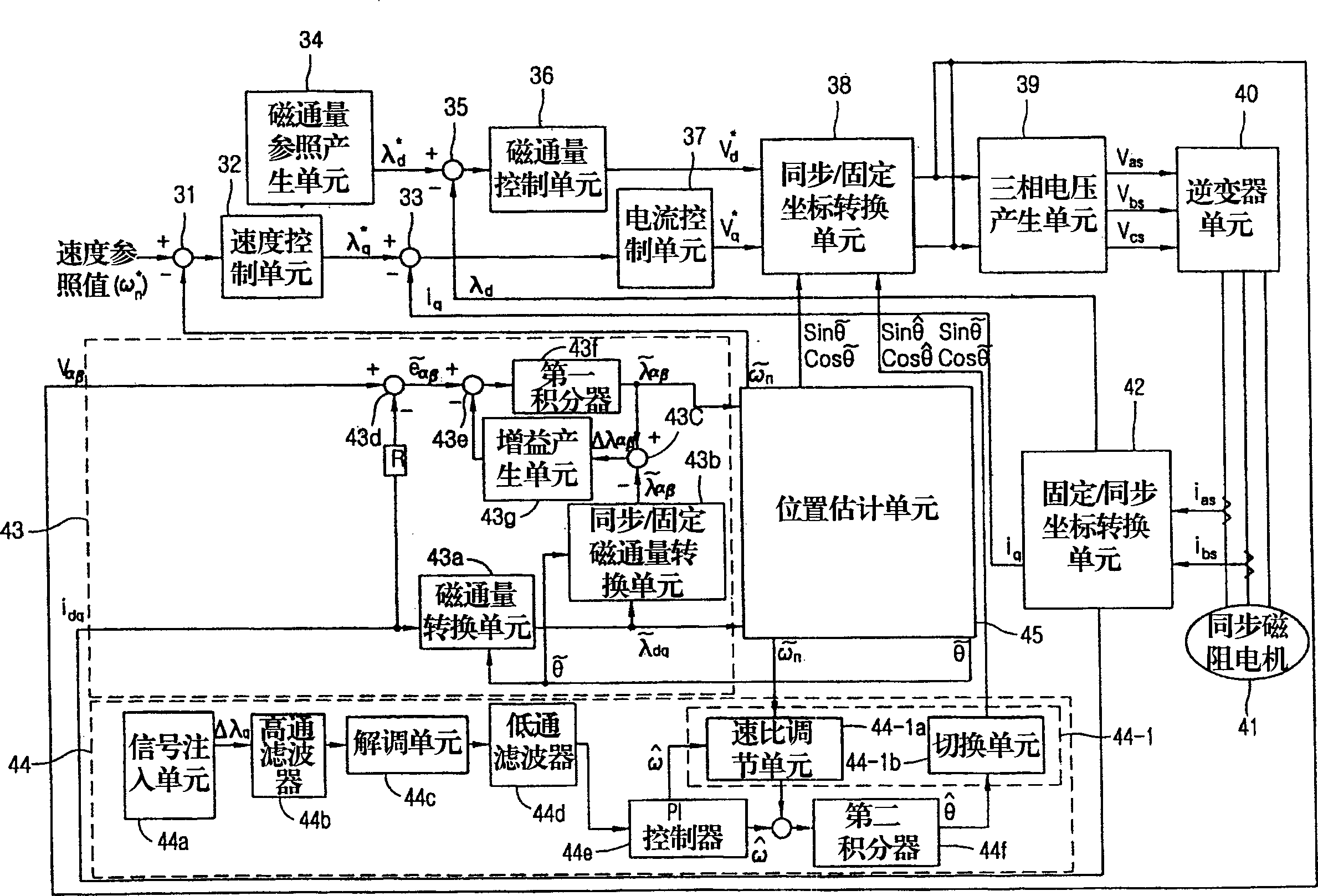

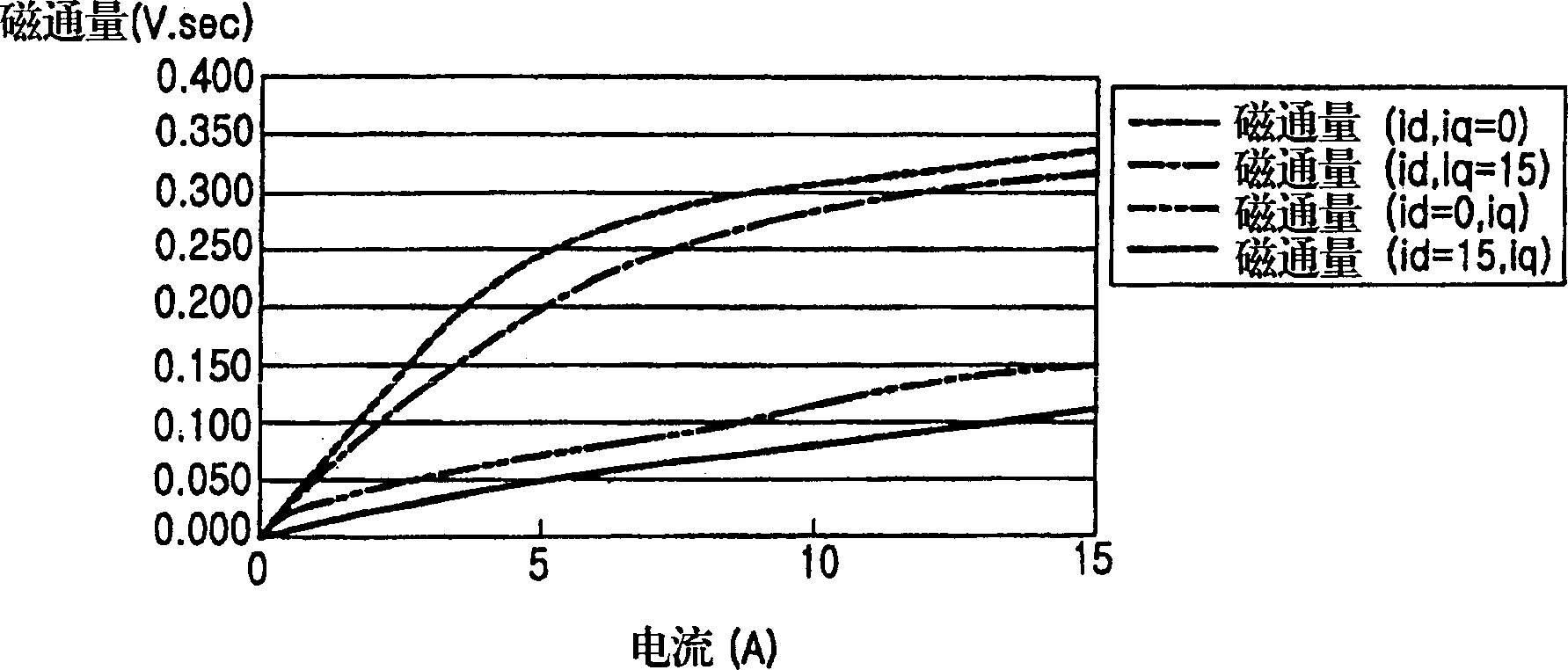

Equipment and method for controlling rotating speed of synchronous magnetic motor

InactiveCN1396704AControl rotation speedVector control systemsSingle motor speed/torque controlTransient stateLow speed

The invention provides an apparatus for controlling a rotation speed of a synchronous reluctance motor, comprising a first comparator, a speed control unit, a second comparator, a magnetic flux reference generation unit, a third comparator, a magnetic flux control unit, a current control unit, a synchronization / fixed coordinate conversion unit, a three phase voltage generation unit, an inverter unit, a synchronous reluctance motor, a magnetic flux observer, a position estimation unit, a low speed control unit and a transient state stabilization unit. The invention also provides a method for controlling the rotation speed of the synchronous reluctance motor.

Owner:LG ELECTRONICS INC

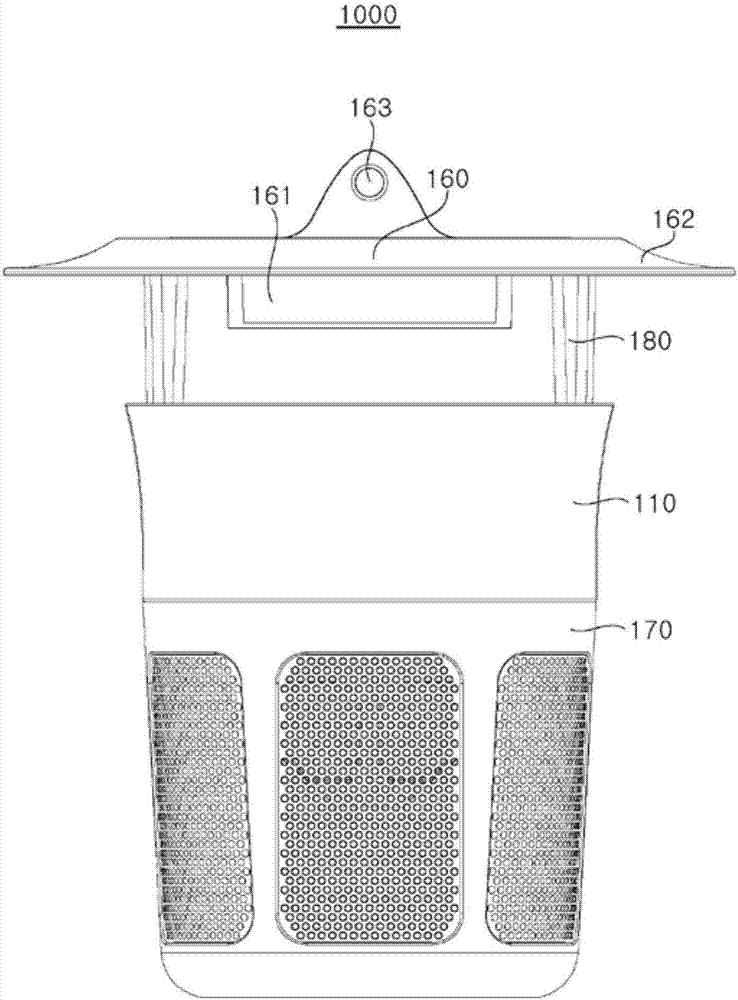

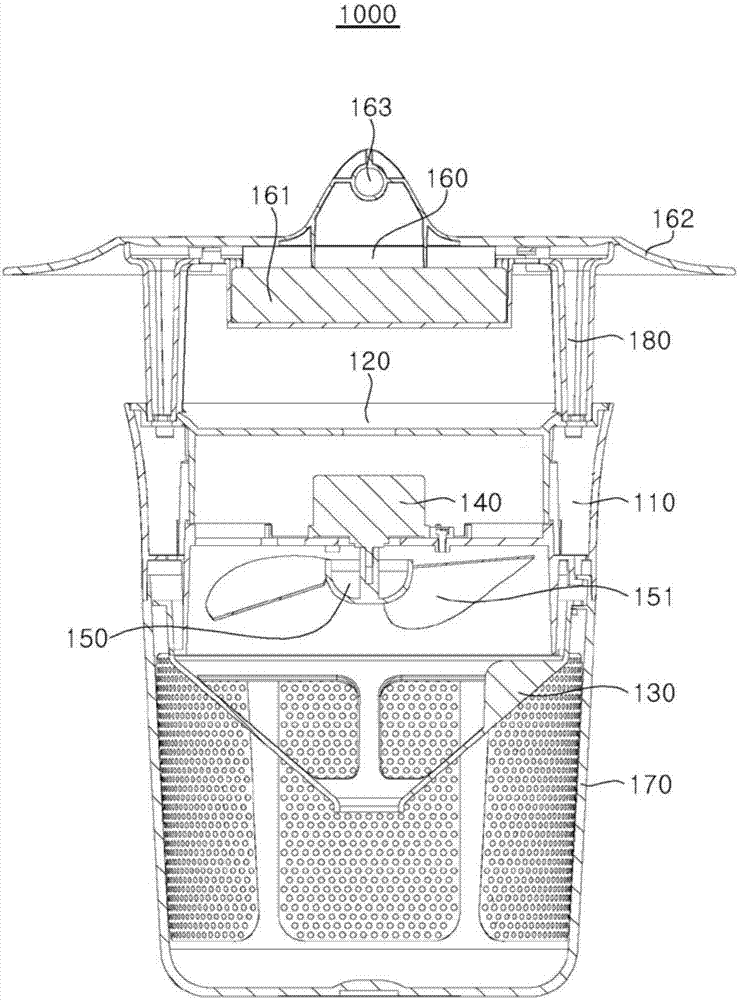

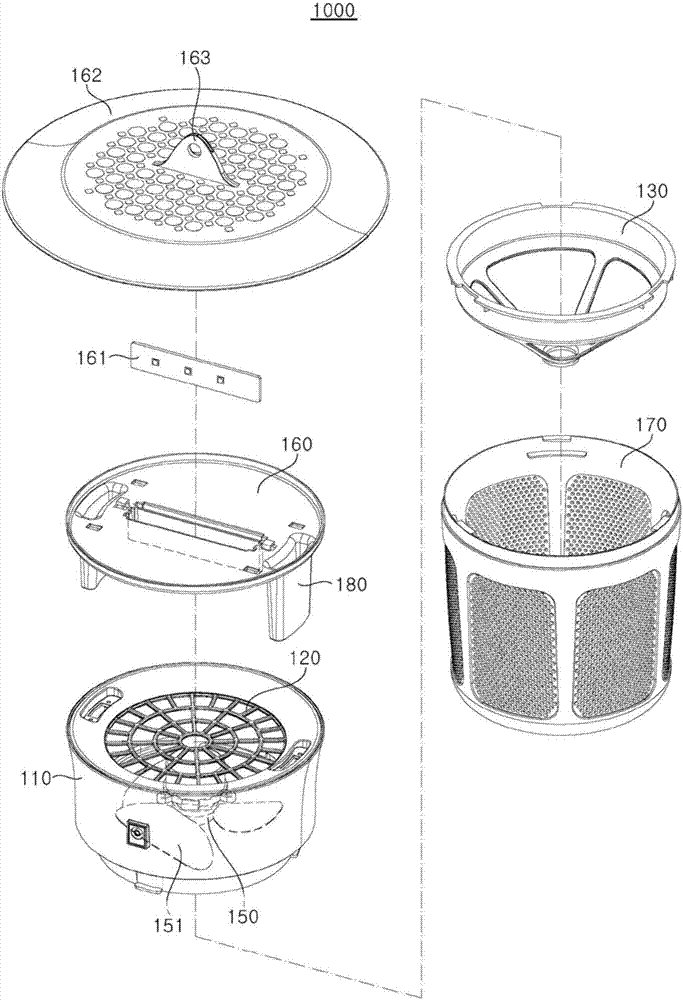

Insect trap

ActiveCN107182968AIncreased durabilitySuppress noiseElectrical apparatusElectroluminescent light sourcesUltravioletInsect trap

The utility model relates to an insect trap, include: a main bod. Insect passing part, set up in in the main part for make the insect pass through, air collection dirt portion, set up in the lower part of main part, inhale the fan, be located insect passing part with between the air collection dirt portion, the UVLED installation department, set up in insect passing part's upper portion to be provided with UV LED module, seizure portion, set up in the lower part of air collection dirt portion for catch the insect, wherein, the insect passing part include: a plurality of insect clearing holes can make insect optionally pass through. The utility model relates to a insect trap not only utilizes the ultraviolet ray to lure the insect, the temperature condition liked for the control insect moreover and produce heat or produce carbon dioxide to can further improve and lure the effect.

Owner:SEOUL VIOSYS CO LTD

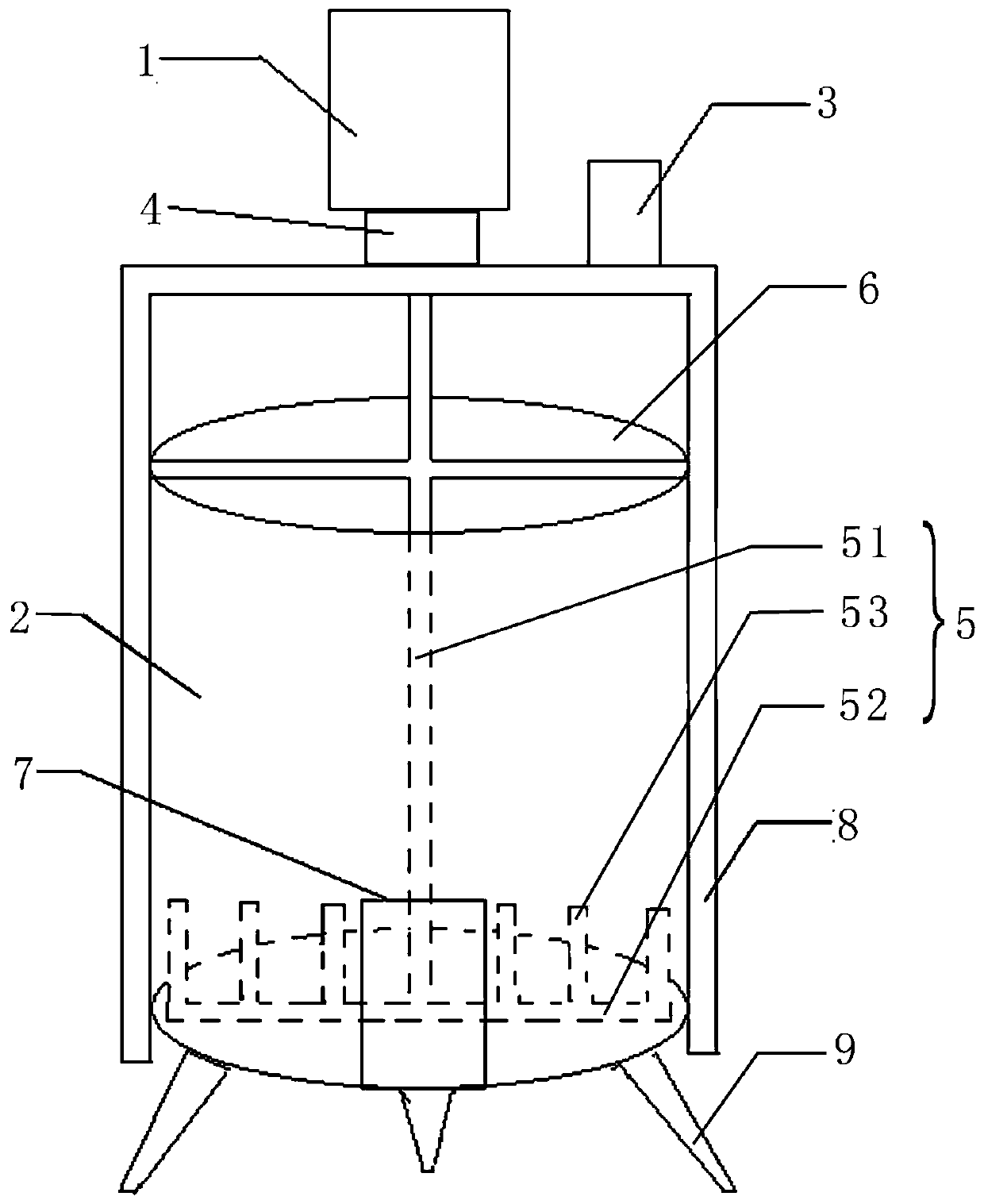

Sulfuric acid delinting machine

PendingCN110366897AControl rotation speedAvoid fastSeed and root treatmentTransportation and packagingGear driveEngineering

The invention discloses a sulfuric acid delinting machine. The sulfuric acid delinting machine comprises an electric motor and a container for containing materials. The electric motor, namely a motorrotating forwardly and backwardly, is connected with a control device through a wire, and the control device is connected with a turning switch and a power switch through wires. An output shaft gear of the electric motor is meshed with a reduction gear, and the reduction gear drives a stirring rod to rotate. The electric motor and the reduction gear are mounted at the top of the container, and thestirring rod extends into the container. The container is provided with an inlet for feeding and an outlet for discharging. The simple, economical and durable sulfuric acid delinting machine is simple and convenient to operate, and can stir the materials alternately in the forward and backward directions to achieve uniform stirring; the reduction gear can effectively control the rotation speed ofthe stirring rod, ultrahigh speed is avoided, and the seed breaking rate is reduced; the sulfuric acid delinting machine is convenient to wash, and has a wide applicable treatment range and a low manufacturing cost.

Owner:SHIHEZI UNIVERSITY

Stepping blade type robot joint

ActiveCN109591046AIncrease the area of actionHigh movement precisionProgramme-controlled manipulatorJointsNeedle roller bearingOil distribution

The invention discloses a stepping blade type robot joint. The stepping blade type robot joint comprises a left end cover, a rolling bearing, a central spindle, child blades, mother blades, an inner meshing gear pair, a needle bearing, a side plate, an oil distribution disc, a right end cover, a rotary oil distribution valve and a stepping motor; the inner meshing gear pair comprises an outer gearcapable of doing planar motion and an inner gear fixed to a central shaft; the central spindle is arranged in the outer gear, can not rotate and is provided with blade grooves and opening grooves; the right end cover is provided with oil ports of an oil supply way and an oil return way, and oil is supplied to oil cavities sequentially through the rotary oil distribution valve; the rotary oil distribution valve is driven by the stepping motor to rotate; and the oil ways sequentially supply oil to the oil cavities, an outer gear small gear is pushed to do planar motion, an inner gear large gearis driven to rotate, and power output is achieved. The stepping blade type robot joint has the advantages of being high in precision, large in output power density and compact in structure.

Owner:ZHEJIANG UNIV

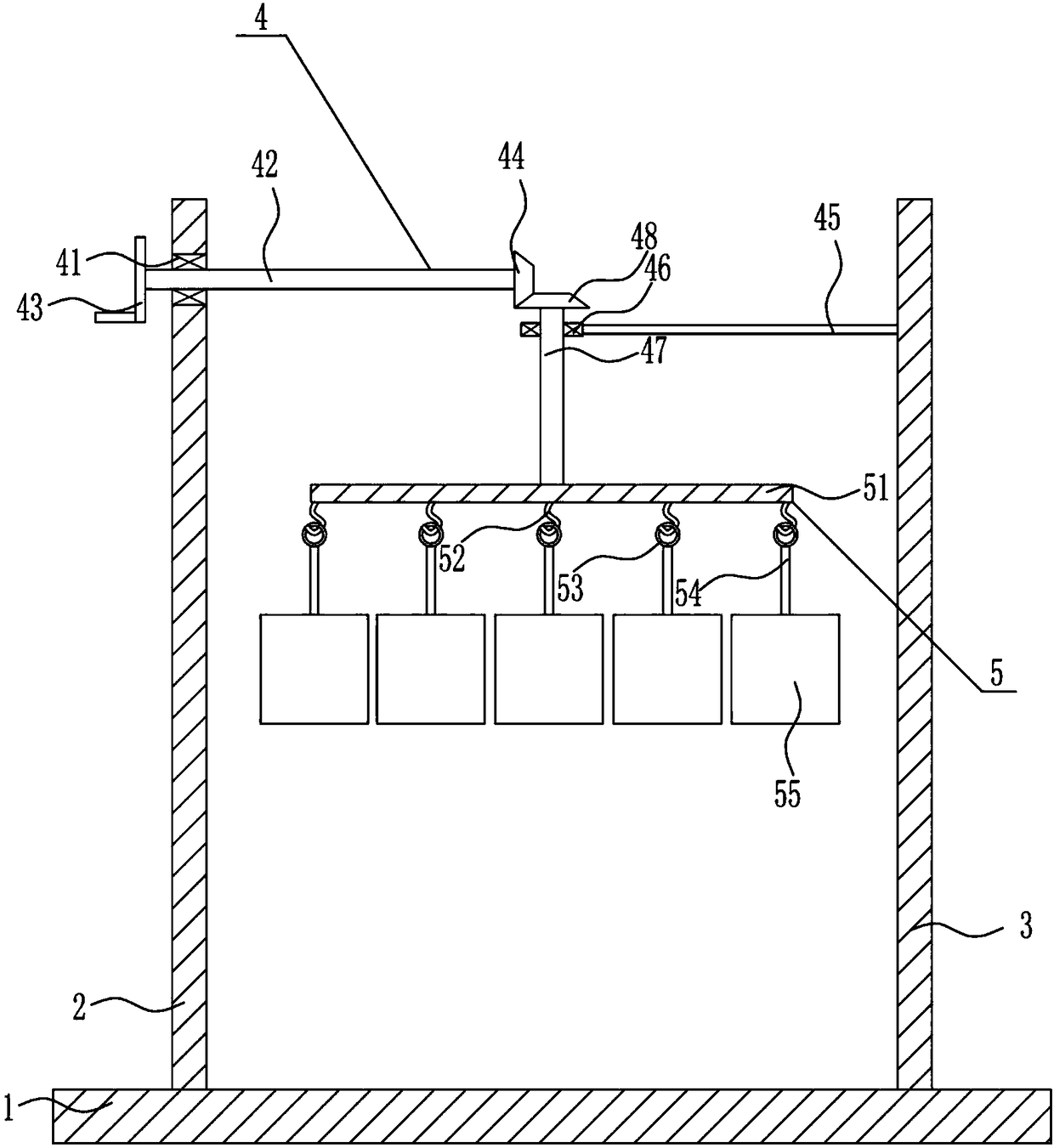

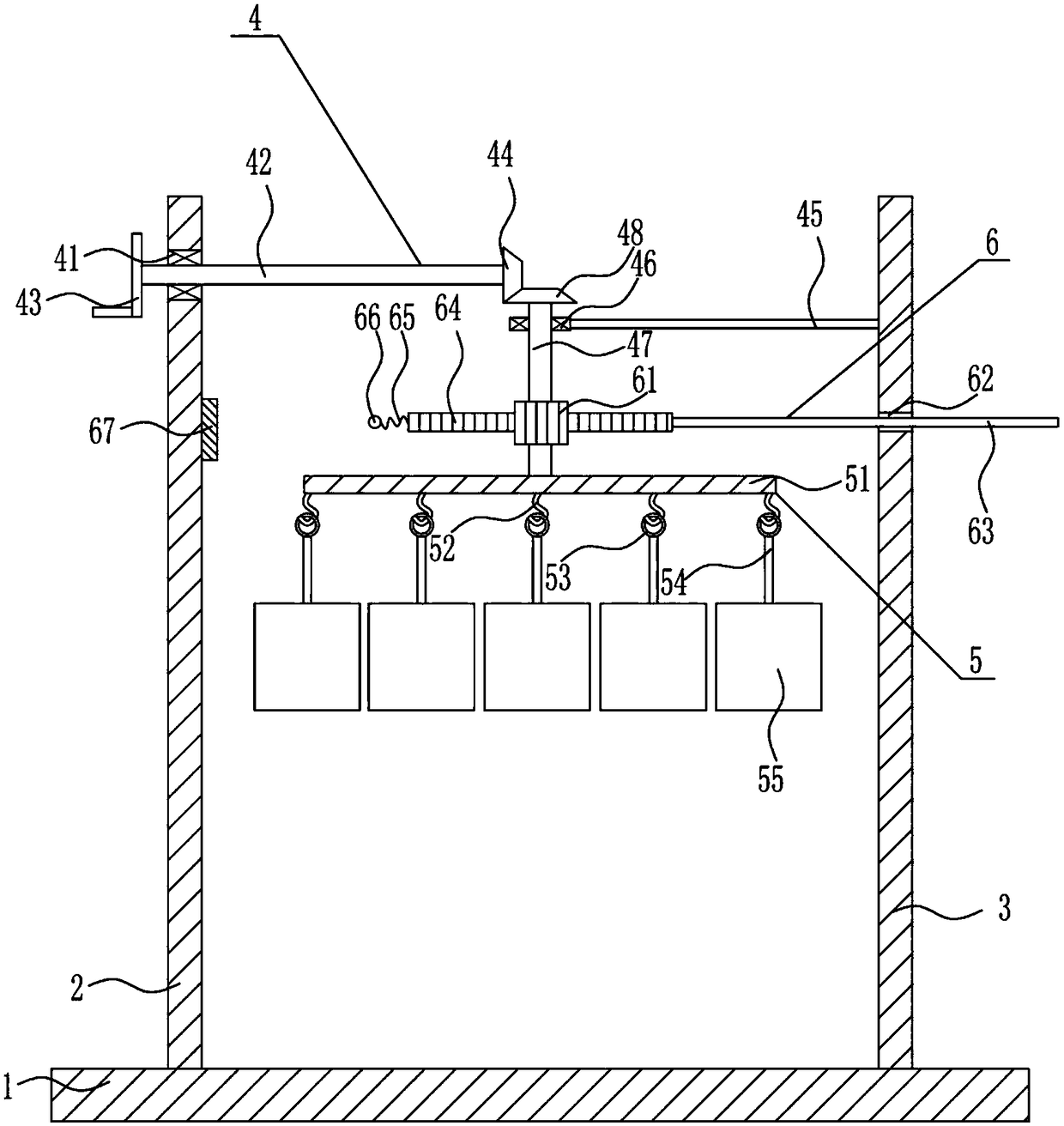

Interesting word memory device for primary education

ActiveCN108198463AControl rotation speedSufficient memoryTeaching apparatusMechanical appliancesComputer scienceAtmosphere

The invention relates to a word memory device, and particularly relates to an interesting word memory device for primary education. The technical purpose is to provide the interesting word memory device which is used for primary education and is capable of building up an active classroom atmosphere and attracting students' attention, so that the students have high enthusiasm. In order to achieve the above technical purpose, the interesting word memory device includes a bottom plate and the like. A left side plate is arranged on the left side of the top of the bottom plate, and a right side plate is arranged on the right side of the top of the bottom plate, a driving mechanism is arranged on the upper portion between the left side plate and the right side plate, and a display mechanism is connected to the bottom of the driving mechanism. According to the interesting word memory device, the display mechanism is driven to rotate by controlling the operation of the driving mechanism, so that the time for the students to memorize words is controlled, the interest in learning of the students is improved, the effects of building up the active classroom atmosphere and attracting the students' attention are achieved, and the enthusiasm of the students is high.

Owner:广东马上信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com