Graphene coating aluminum foil coating machine

A technology of graphene and coating machine, which is applied in the direction of coating, liquid coating device on the surface, spraying device, etc., which can solve the problems of not being able to produce high-quality nano-graphene coated aluminum foil, so as to ensure reliable quality Sex, stable rotation speed, close contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

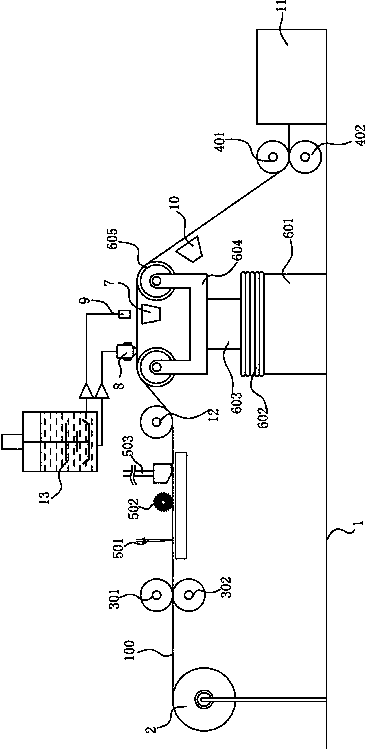

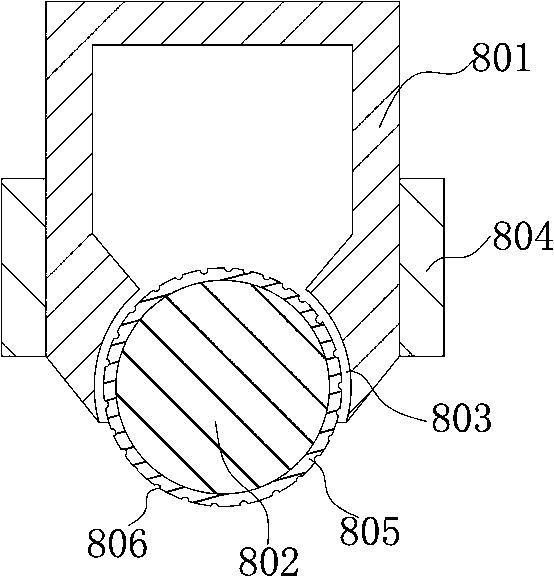

[0030] like figure 1 A graphene-coated aluminum foil coating machine shown includes a base 1, an aluminum foil roll 2 arranged on the base 1, a front tensioning mechanism, a dust removal mechanism, a transmission mechanism 12, a vibration mechanism, and a coating mechanism 8 , heating mechanism 7, spraying mechanism 9, drying mechanism 10, rear tensioning mechanism and storage device 11, the dust removal mechanism, transmission mechanism, vibration mechanism, coating mechanism, spraying mechanism and drying mechanism are arranged on the front tensioning mechanism Between the aluminum foil substrate 100 and the rear tensioning mechanism, the free end of the aluminum foil substrate 100 of the aluminum foil roll passes through the front tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com