High-strength low-alloy hot-dip aluminized and galvanized steel strip and production method thereof

A high-strength, low-alloy, production method technology, applied in the direction of hot-dip plating process, metal material coating process, coating, etc., can solve the problems of high strength and low yield strength, and achieve low production cost and excellent manufacturing process. Simple, uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

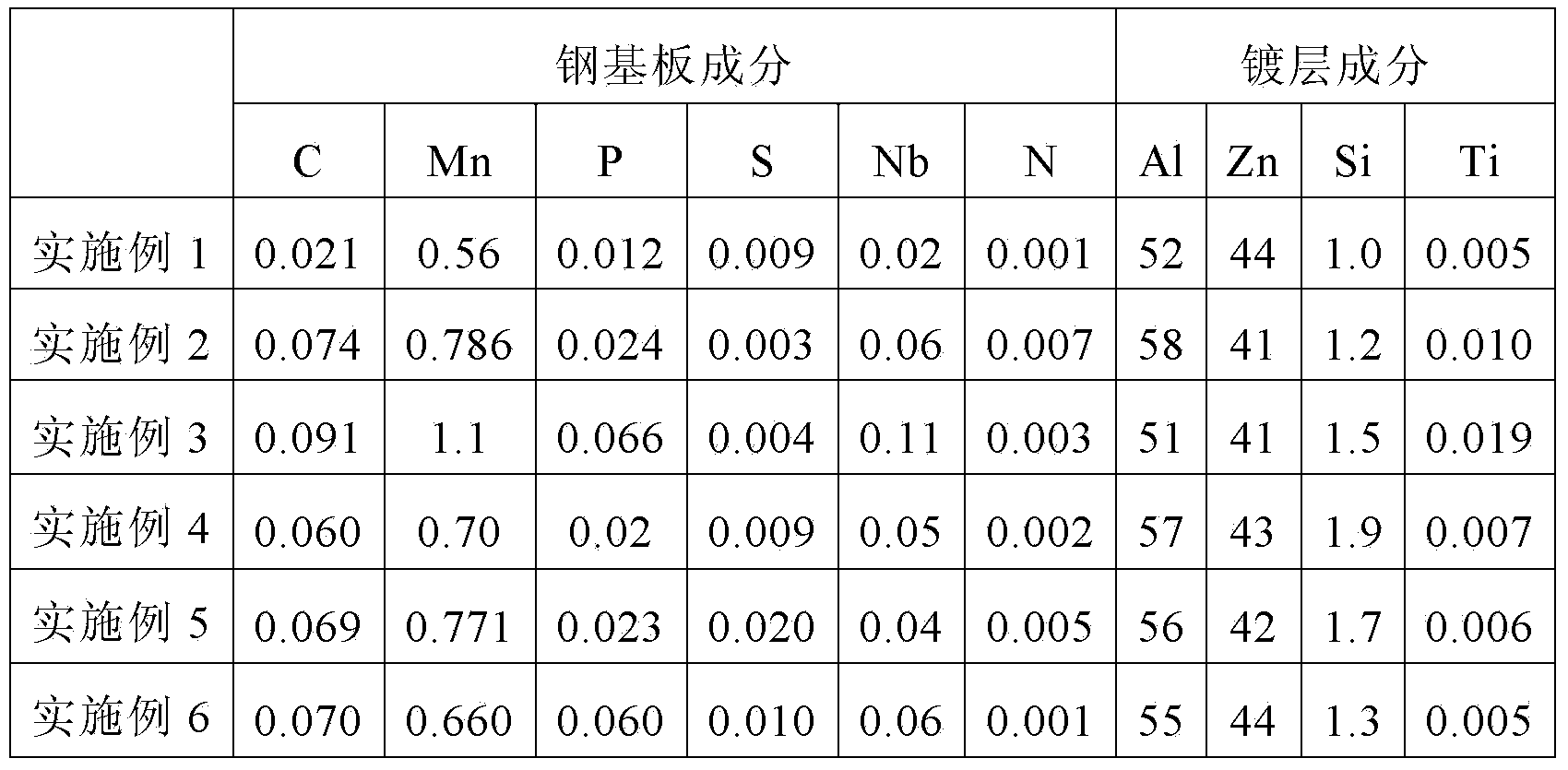

[0048] According to the chemical composition shown in Table 1, after smelting and casting, the billet is obtained, and then hot rolling is carried out in the hot rolling heating furnace, and the hot rolling final rolling and hot rolling coil are carried out on the hot rolling line, and then cold rolling The hot rolling and cold rolling process conditions are shown in Table 2.

[0049] Before entering the continuous annealing furnace, the above-mentioned substrate strip steel is sent to the cleaning device to remove grease, iron powder and dust on the surface of the strip steel. Then the cleaned strip is squeezed by a squeeze roller and dried by hot air. The cleaned strip enters the continuous annealing furnace for annealing treatment. The annealing treatment includes four processes of preheating, heating, soaking and cooling, and the composition of the protective gas in the furnace is: 30% hydrogen and 70% nitrogen. The process conditions of annealing treatment are shown in ...

Embodiment 2

[0054] The embodiment is the same as that in Example 1, wherein the protective gas composition in the continuous annealing furnace is: 25% hydrogen and 75% nitrogen. During hot dipping, the temperature of the solution in the zinc pot is 600°C, the immersion time of the steel substrate in the zinc pot is 5 seconds, and the coating thickness reaches the set value through the air knife control system. After the steel strip is hot-dip galvanized in a zinc pot, it enters the air cooling system of the cooling tower for cooling at a cooling rate of 45°C / s.

Embodiment 3

[0056] The implementation mode is the same as that in Example 1, wherein the protective gas composition in the furnace is: 35% hydrogen and 65% nitrogen. During hot dipping, the temperature of the solution in the zinc pot is 570°C, the immersion time of the steel substrate in the zinc pot is 6 seconds, and the coating thickness reaches the set value through the air knife control system. After the steel strip is hot-dip galvanized, it enters the air cooling system of the cooling tower for cooling, and the cooling rate is 45°C / s.

[0057] Table 1 Unit: weight percentage

[0058]

[0059] Table 2

[0060]

[0061] table 3

[0062]

[0063]

[0064] Table 4

[0065]

[0066] It can be seen from Table 4 that the yield strength of the high-strength low-alloy hot-dip galvalume steel strip produced by the present invention is 410-570 MPa, the tensile strength is ≥ 470 MPa, and the elongation at break is ≥ 15%. The coating is uniform, dense, and of appropriate thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com